-

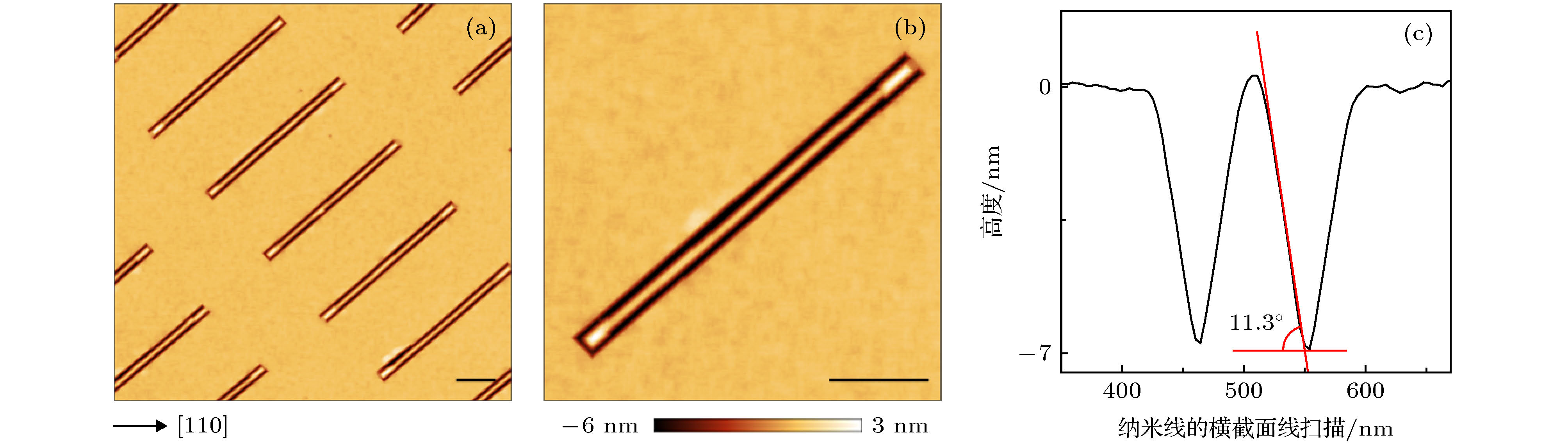

Controllable growth of nanowires is a prerequisite for addressability and scalability of nanowire quantum devices. By combining top-down nanofabrication and bottom-up self-assembly, site-controlled GeSi nanowires with two (105) facets can be grown on Si (001) substrate with pre-patterned trenches. Trenches along the [100] or [010] crystallographic direction with 60 nm in width and 6 nm in height are fabricated on Si substrate by electron beam lithography and reactive ion etching. Subsequently, a 60-nm-thick Si buffer layer is grown at 330–400 ℃ on the patterned substrate to improve the surface quality. The facets at the tip of the trenches transform into (11n) after depositing the Si buffer layer. Self-organized GeSi nanowires form inside the trenches by depositing the 6-nm-thick Si67Ge33 film at 450 ℃ followed by 1 h annealing at 510 ℃. The GeSi nanowires are (105)-faceted with an average height of approximately 7 nm. Furthermore, we systematically study the influence of annealing temperature, Ge concentration and pattern period on the formation of site-controllable GeSi nanowire on a patterned Si (001) substrate. The GeSi nanowires can be formed only inside the trenches within a specific annealing temperature ranging from 500 ℃ to 520 ℃. It is also discovered that GeSi nanowires are very sensitive to Ge concentration, as they cannot form at lower Ge concentration due to a large nucleation energy barrier. In contrast, high Ge concentration will lead to the discontinuity of nanowires caused by higher atomic diffusion barrier. The generated GeSi nanowires in the trenches exhibit similar dimensions at different pattern periods, which indicates that the growth process is thermodynamically determined. Overall, we realize the controllable growth of the GeSi nanowires, while the length of nanowires can reach the millimeter even centimeter scales, replying on the patterned trench length. The above results offer a controllable growth method of the Ge nanowires, which could potentially lead to the scalability of the Ge quantum devices on Si substrates.

-

Keywords:

- molecular beam epitaxy /

- qubit /

- patterned substrate /

- GeSi nanowires

[1] Loss D, diVincenzo D P 1998 Phys. Rev. A 57 120

Google Scholar

Google Scholar

[2] Petta J R, Johnson A C, Taylor J M, Laird E A, Yacoby A, Lukin M D, Marcus C M, Hanson M P, Gossard A C 2005 Science 309 2180

Google Scholar

Google Scholar

[3] Nowack K C, Koppens F H L, Nazarov Y V, Vandersypen L M K 2007 Science 318 1430

Google Scholar

Google Scholar

[4] Elzerman J M, Hanson R, Greidanus J S, Willems van Beveren L H, de Franceschi S, Vandersypen L M K, Tarucha S, Kouwenhoven L P 2003 Phys. Rev. B 67 161308

Google Scholar

Google Scholar

[5] Bluhm H, Foletti S, Neder I, Rudner M, Mahalu D, Umansky V, Yacoby A 2011 Nat. Phys. 7 109

Google Scholar

Google Scholar

[6] Wang J Y, Huang S Y, Huang G Y, Pan D, Zhao J H, Xu H Q 2017 Nano Lett. 17 4158

Google Scholar

Google Scholar

[7] Koppens F, Buizert C, Tielrooij K J, Vink I T, Nowack K C, Meunier T, Kouwenhoven L P, Vandersypen L 2006 Nature 442 766

Google Scholar

Google Scholar

[8] Hanson R, Kouwenhoven L P, Petta J R, Tarucha S, Vandersypen L M K 2007 Rev. Mod. Phys. 79 1217

Google Scholar

Google Scholar

[9] Khaetskii A V, Loss D, Glazman L 2002 Phys. Rev. Lett. 88 186802

Google Scholar

Google Scholar

[10] Zhong Z, Fang Y, Lu W, Lieber C M 2005 Nano Lett. 5 1143

Google Scholar

Google Scholar

[11] Katsaros G, Spathis P, Stoffel M, Fournel F, Mongillo M, Bouchiat V, Lefloch F, Rastelli A, Schmidt O G, de Franceschi S 2010 Nat. Nanotech. 5 458

Google Scholar

Google Scholar

[12] Hu Y J, Churchill H O H, Reilly D J, Xiang J, Lieber C M, Marcus C M 2007 Nat. Nanotech. 2 622

Google Scholar

Google Scholar

[13] Higginbotham A P, Larsen T W, Yao J, Yan H, Lieber C M, Marcus C M, Kuemmeth F 2014 Nano Lett. 14 3582

Google Scholar

Google Scholar

[14] Li S X, Li Y, Gao F, Xu G, Li H O, Cao G, Xiao M, Wang T, Zhang J J, Guo G P 2017 Appl. Phys. Lett. 110 133105

Google Scholar

Google Scholar

[15] Kloeffel C, Trif M, Loss D 2011 Phys. Rev. B 84 195314

Google Scholar

Google Scholar

[16] Maier F, Klinovaja J, Loss D 2014 Phys. Rev. B 90 195421

Google Scholar

Google Scholar

[17] Watzinger H, Kukučka J, Vukušić L, Gao F, Wang T, Schäffler F, Zhang J J, Katsaros G 2018 Nat. Commun. 9 3902

Google Scholar

Google Scholar

[18] de Vries F K, Shen J, Skolasinski R J, Nowak M P, Varjas D, Wang L, Wimmer M, Ridderbos J, Zwanenburg F A, Li A, Koelling S, Verheijen M A, Bakkers E P A M, Kouwenhoven L P 2018 Nano Lett. 18 6483

Google Scholar

Google Scholar

[19] Li W D, Wu W, Williams R S 2012 J. Vac. Sci. Technol. B 30 06F304

Google Scholar

Google Scholar

[20] Wagner R S, Ellis W C 1964 Appl. Phys. Lett. 4 89

Google Scholar

Google Scholar

[21] Lauhon L J, Gudiksen M S, Wang D, Lieber C M 2002 Nature 420 57

Google Scholar

Google Scholar

[22] Zhang J J, Katsaros G, Montalenti F, Scopece D, Rezaev R O, Mickel C, Rellinghaus B, Miglio L, de Franceschi S, Rastelli A, Schmidt O G 2012 Phys. Rev. Lett. 109 085502

Google Scholar

Google Scholar

[23] Li Y, Li S X, Gao F, Li H O, Xu G, Wang K, Liu D, Cao G, Xiao M, Wang T, Zhang J J, Guo G C, Guo G P 2018 Nano Lett. 18 2091

Google Scholar

Google Scholar

[24] Xu G, Li Y, Gao F, Li H O, Liu H, Wang K, Cao G, Xiao M, Wang T, Zhang J J, Guo G C, Guo G P 2019 arXiv: 1905.01586v1

[25] Zhang J J, Stoffel M, Rastelli A, Schmidt O G, Jovanović V, Nanver L K, Bauer G 2007 Appl. Phys. Lett. 91 173115

Google Scholar

Google Scholar

[26] Zhong Z Y, Halilovic A, Fromherz T, Schäffler F, Bauera G 2003 Appl. Phys. Lett. 82 4779

Google Scholar

Google Scholar

[27] Chen G, Springholz G, Jantsch W, Schäffler F 2011 Appl. Phys. Lett. 99 043103

Google Scholar

Google Scholar

[28] Du L, Scopece D, Springholz G, Schäffler F, Chen G 2014 Phys. Rev. B 90 075308

Google Scholar

Google Scholar

[29] Kern W, Puotinen D A 1970 RCA Review 31 187

[30] Eaglesham D J, White A E, Feldman L C, Moriya N, Jacobson D C 1993 Phys. Rev. Lett. 70 1643

Google Scholar

Google Scholar

[31] Gai Z, Yang W S, Sakurai T, Zhao R G 1999 Phys. Rev. B 59 13009

Google Scholar

Google Scholar

[32] Zhong Z, Schwinger W, Schäffler F, Bauer G, Vastola G, Montalenti F, Miglio L 2007 Phys. Rev. Lett. 98 176102

Google Scholar

Google Scholar

[33] Vastola G, Grydlik M, Brehm M, Fromherz T, Bauer G, Boioli F, Miglio L, Montalenti F 2011 Phys. Rev. B. 84 155415

Google Scholar

Google Scholar

[34] Hu H, Gao H J, Liu F 2008 Phys. Rev. Lett. 101 216102

Google Scholar

Google Scholar

[35] Zhang J J, Rastelli A, Schmidt O G, Scopece D, Miglio L, Montalenti F 2013 Appl. Phys. Lett. 103 083109

Google Scholar

Google Scholar

[36] Chen G, Sanduijav B, Matei D, Springholz G, Scopece D, Beck M J, Montalenti F, Miglio L 2012 Phys. Rev. Lett. 108 055503

Google Scholar

Google Scholar

[37] Jesson D E, Chen K M, Pennycook S J, Thundat T, Warmack R J 1996 Phys. Rev. Lett. 77 1330

Google Scholar

Google Scholar

[38] Tersoff J, leGoues F K 1994 Phys. Rev. Lett. 72 3570

Google Scholar

Google Scholar

[39] Shu D J, Liu F, Gong X G 2001 Phys. Rev. B 64 245410

Google Scholar

Google Scholar

[40] Huang L, Liu F, Gong X G 2004 Phys. Rev. B 70 155320

Google Scholar

Google Scholar

-

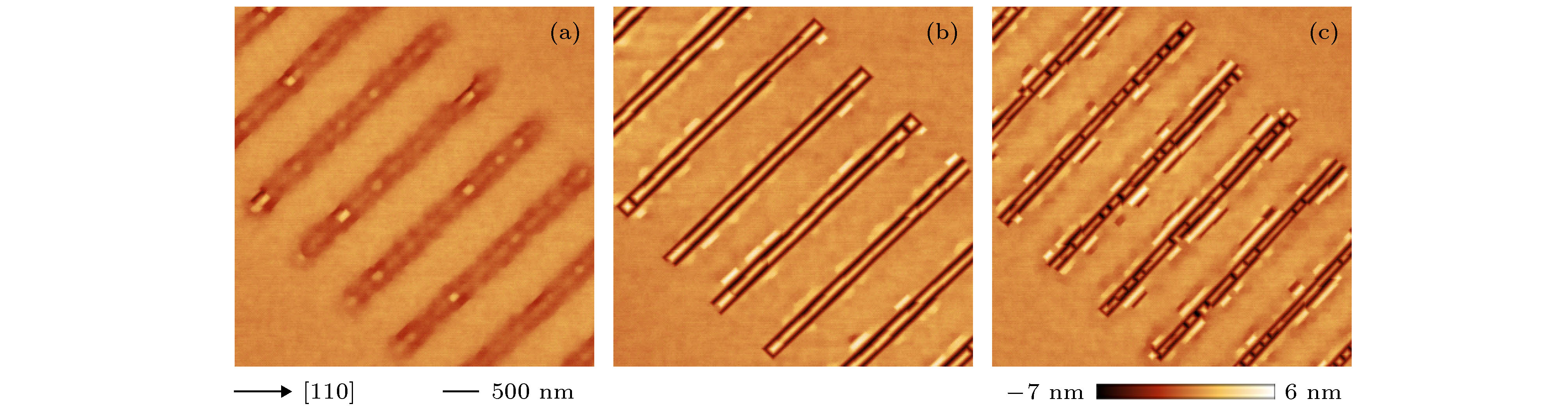

图 3 在硅凹槽结构图形衬底上沉积4 nm的Si67G33薄膜, 然后在不同温度退火后得到的样品表面AFM图 (a) 450 ℃; (b) 500 ℃; (c) 510 ℃; (d) 520 ℃; (e) 530 ℃; (f) 550 ℃

Figure 3. AFM images of the trench-patterned samples with 4 nm Si67Ge33 film after 1 h annealing at different temperatures: (a) 450 ℃; (b) 500 ℃; (c) 510 ℃; (d) 520 ℃; (e) 530 ℃; (f) 550 ℃.

-

[1] Loss D, diVincenzo D P 1998 Phys. Rev. A 57 120

Google Scholar

Google Scholar

[2] Petta J R, Johnson A C, Taylor J M, Laird E A, Yacoby A, Lukin M D, Marcus C M, Hanson M P, Gossard A C 2005 Science 309 2180

Google Scholar

Google Scholar

[3] Nowack K C, Koppens F H L, Nazarov Y V, Vandersypen L M K 2007 Science 318 1430

Google Scholar

Google Scholar

[4] Elzerman J M, Hanson R, Greidanus J S, Willems van Beveren L H, de Franceschi S, Vandersypen L M K, Tarucha S, Kouwenhoven L P 2003 Phys. Rev. B 67 161308

Google Scholar

Google Scholar

[5] Bluhm H, Foletti S, Neder I, Rudner M, Mahalu D, Umansky V, Yacoby A 2011 Nat. Phys. 7 109

Google Scholar

Google Scholar

[6] Wang J Y, Huang S Y, Huang G Y, Pan D, Zhao J H, Xu H Q 2017 Nano Lett. 17 4158

Google Scholar

Google Scholar

[7] Koppens F, Buizert C, Tielrooij K J, Vink I T, Nowack K C, Meunier T, Kouwenhoven L P, Vandersypen L 2006 Nature 442 766

Google Scholar

Google Scholar

[8] Hanson R, Kouwenhoven L P, Petta J R, Tarucha S, Vandersypen L M K 2007 Rev. Mod. Phys. 79 1217

Google Scholar

Google Scholar

[9] Khaetskii A V, Loss D, Glazman L 2002 Phys. Rev. Lett. 88 186802

Google Scholar

Google Scholar

[10] Zhong Z, Fang Y, Lu W, Lieber C M 2005 Nano Lett. 5 1143

Google Scholar

Google Scholar

[11] Katsaros G, Spathis P, Stoffel M, Fournel F, Mongillo M, Bouchiat V, Lefloch F, Rastelli A, Schmidt O G, de Franceschi S 2010 Nat. Nanotech. 5 458

Google Scholar

Google Scholar

[12] Hu Y J, Churchill H O H, Reilly D J, Xiang J, Lieber C M, Marcus C M 2007 Nat. Nanotech. 2 622

Google Scholar

Google Scholar

[13] Higginbotham A P, Larsen T W, Yao J, Yan H, Lieber C M, Marcus C M, Kuemmeth F 2014 Nano Lett. 14 3582

Google Scholar

Google Scholar

[14] Li S X, Li Y, Gao F, Xu G, Li H O, Cao G, Xiao M, Wang T, Zhang J J, Guo G P 2017 Appl. Phys. Lett. 110 133105

Google Scholar

Google Scholar

[15] Kloeffel C, Trif M, Loss D 2011 Phys. Rev. B 84 195314

Google Scholar

Google Scholar

[16] Maier F, Klinovaja J, Loss D 2014 Phys. Rev. B 90 195421

Google Scholar

Google Scholar

[17] Watzinger H, Kukučka J, Vukušić L, Gao F, Wang T, Schäffler F, Zhang J J, Katsaros G 2018 Nat. Commun. 9 3902

Google Scholar

Google Scholar

[18] de Vries F K, Shen J, Skolasinski R J, Nowak M P, Varjas D, Wang L, Wimmer M, Ridderbos J, Zwanenburg F A, Li A, Koelling S, Verheijen M A, Bakkers E P A M, Kouwenhoven L P 2018 Nano Lett. 18 6483

Google Scholar

Google Scholar

[19] Li W D, Wu W, Williams R S 2012 J. Vac. Sci. Technol. B 30 06F304

Google Scholar

Google Scholar

[20] Wagner R S, Ellis W C 1964 Appl. Phys. Lett. 4 89

Google Scholar

Google Scholar

[21] Lauhon L J, Gudiksen M S, Wang D, Lieber C M 2002 Nature 420 57

Google Scholar

Google Scholar

[22] Zhang J J, Katsaros G, Montalenti F, Scopece D, Rezaev R O, Mickel C, Rellinghaus B, Miglio L, de Franceschi S, Rastelli A, Schmidt O G 2012 Phys. Rev. Lett. 109 085502

Google Scholar

Google Scholar

[23] Li Y, Li S X, Gao F, Li H O, Xu G, Wang K, Liu D, Cao G, Xiao M, Wang T, Zhang J J, Guo G C, Guo G P 2018 Nano Lett. 18 2091

Google Scholar

Google Scholar

[24] Xu G, Li Y, Gao F, Li H O, Liu H, Wang K, Cao G, Xiao M, Wang T, Zhang J J, Guo G C, Guo G P 2019 arXiv: 1905.01586v1

[25] Zhang J J, Stoffel M, Rastelli A, Schmidt O G, Jovanović V, Nanver L K, Bauer G 2007 Appl. Phys. Lett. 91 173115

Google Scholar

Google Scholar

[26] Zhong Z Y, Halilovic A, Fromherz T, Schäffler F, Bauera G 2003 Appl. Phys. Lett. 82 4779

Google Scholar

Google Scholar

[27] Chen G, Springholz G, Jantsch W, Schäffler F 2011 Appl. Phys. Lett. 99 043103

Google Scholar

Google Scholar

[28] Du L, Scopece D, Springholz G, Schäffler F, Chen G 2014 Phys. Rev. B 90 075308

Google Scholar

Google Scholar

[29] Kern W, Puotinen D A 1970 RCA Review 31 187

[30] Eaglesham D J, White A E, Feldman L C, Moriya N, Jacobson D C 1993 Phys. Rev. Lett. 70 1643

Google Scholar

Google Scholar

[31] Gai Z, Yang W S, Sakurai T, Zhao R G 1999 Phys. Rev. B 59 13009

Google Scholar

Google Scholar

[32] Zhong Z, Schwinger W, Schäffler F, Bauer G, Vastola G, Montalenti F, Miglio L 2007 Phys. Rev. Lett. 98 176102

Google Scholar

Google Scholar

[33] Vastola G, Grydlik M, Brehm M, Fromherz T, Bauer G, Boioli F, Miglio L, Montalenti F 2011 Phys. Rev. B. 84 155415

Google Scholar

Google Scholar

[34] Hu H, Gao H J, Liu F 2008 Phys. Rev. Lett. 101 216102

Google Scholar

Google Scholar

[35] Zhang J J, Rastelli A, Schmidt O G, Scopece D, Miglio L, Montalenti F 2013 Appl. Phys. Lett. 103 083109

Google Scholar

Google Scholar

[36] Chen G, Sanduijav B, Matei D, Springholz G, Scopece D, Beck M J, Montalenti F, Miglio L 2012 Phys. Rev. Lett. 108 055503

Google Scholar

Google Scholar

[37] Jesson D E, Chen K M, Pennycook S J, Thundat T, Warmack R J 1996 Phys. Rev. Lett. 77 1330

Google Scholar

Google Scholar

[38] Tersoff J, leGoues F K 1994 Phys. Rev. Lett. 72 3570

Google Scholar

Google Scholar

[39] Shu D J, Liu F, Gong X G 2001 Phys. Rev. B 64 245410

Google Scholar

Google Scholar

[40] Huang L, Liu F, Gong X G 2004 Phys. Rev. B 70 155320

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 14330

- PDF Downloads: 169

- Cited By: 0

DownLoad:

DownLoad: