-

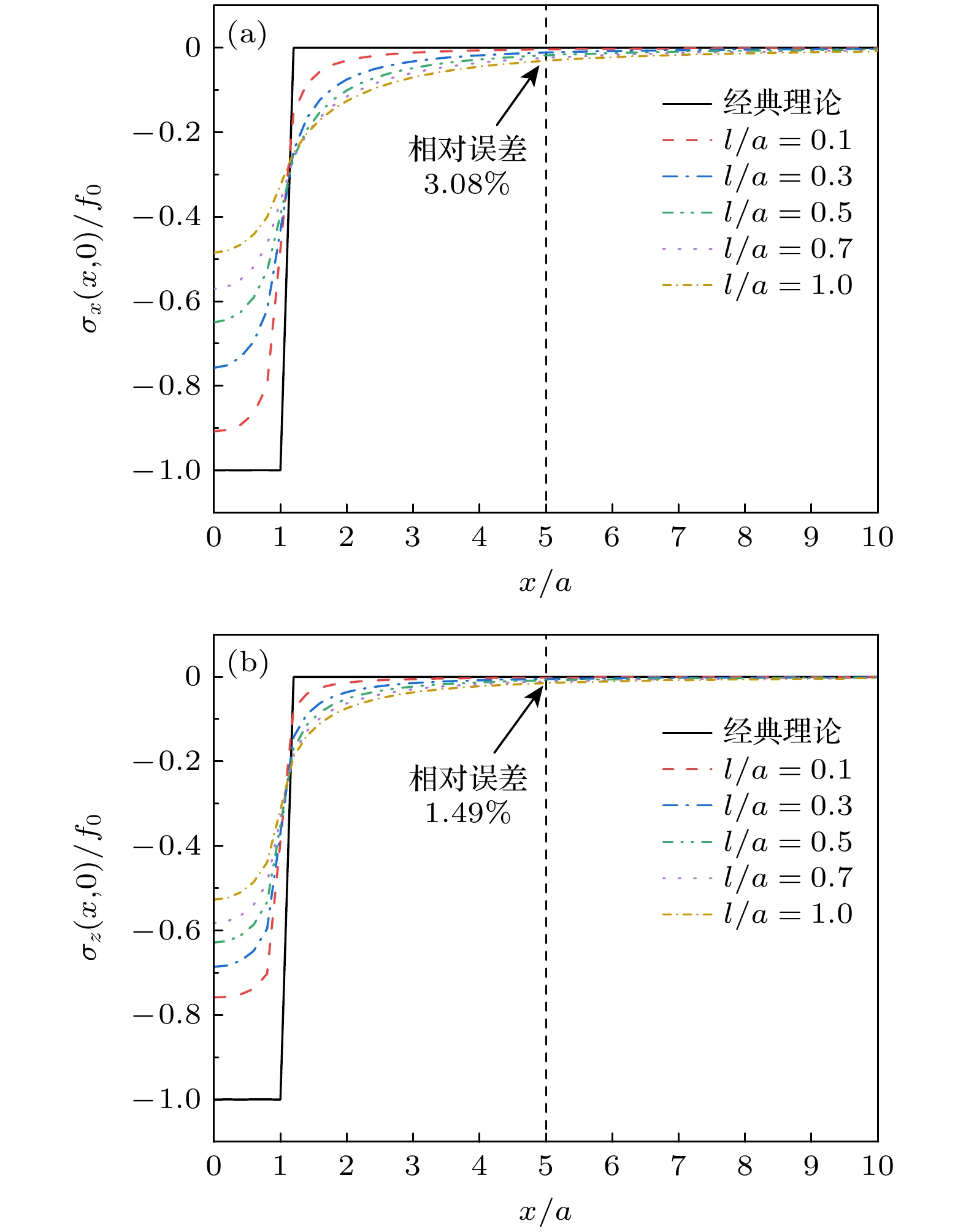

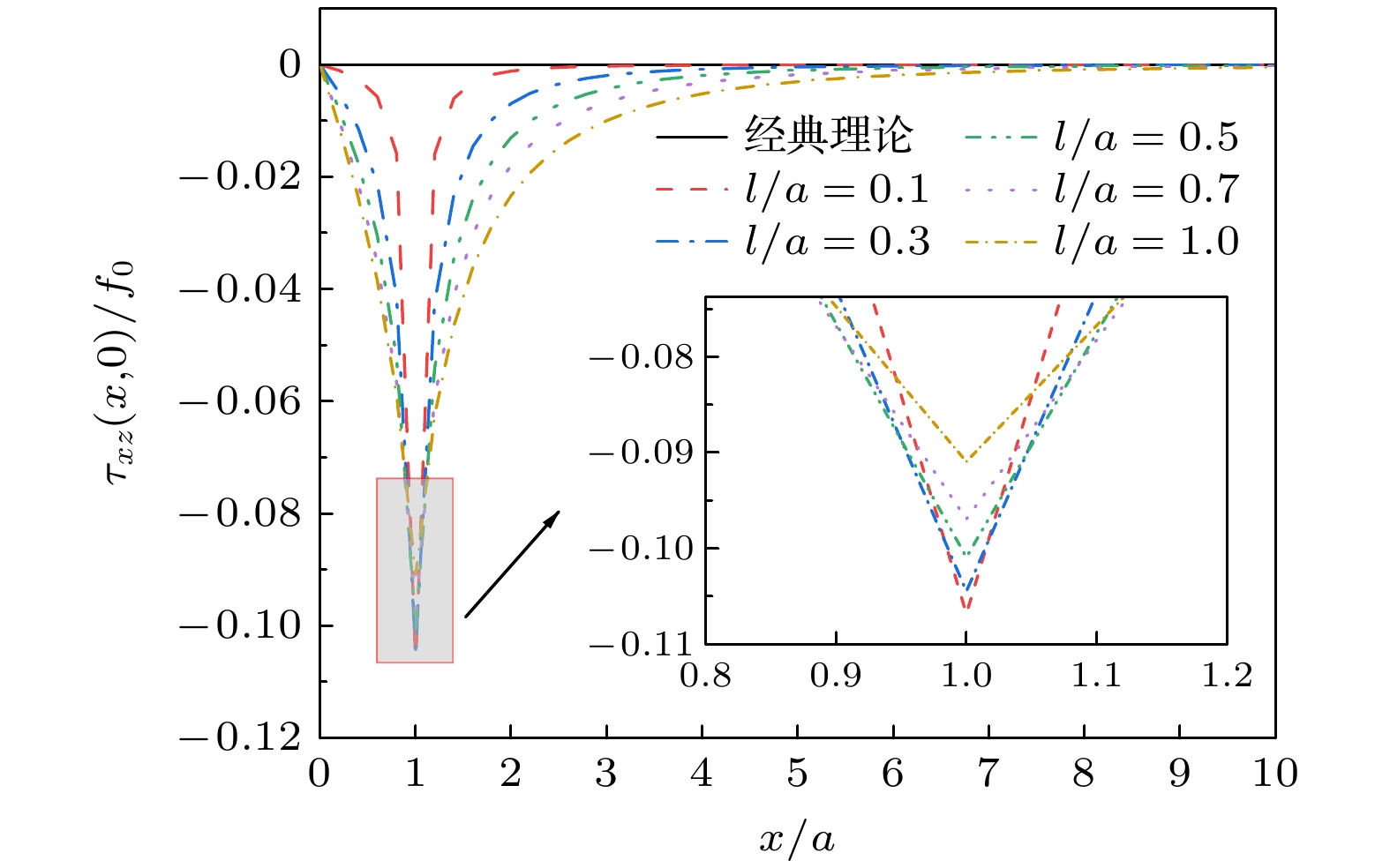

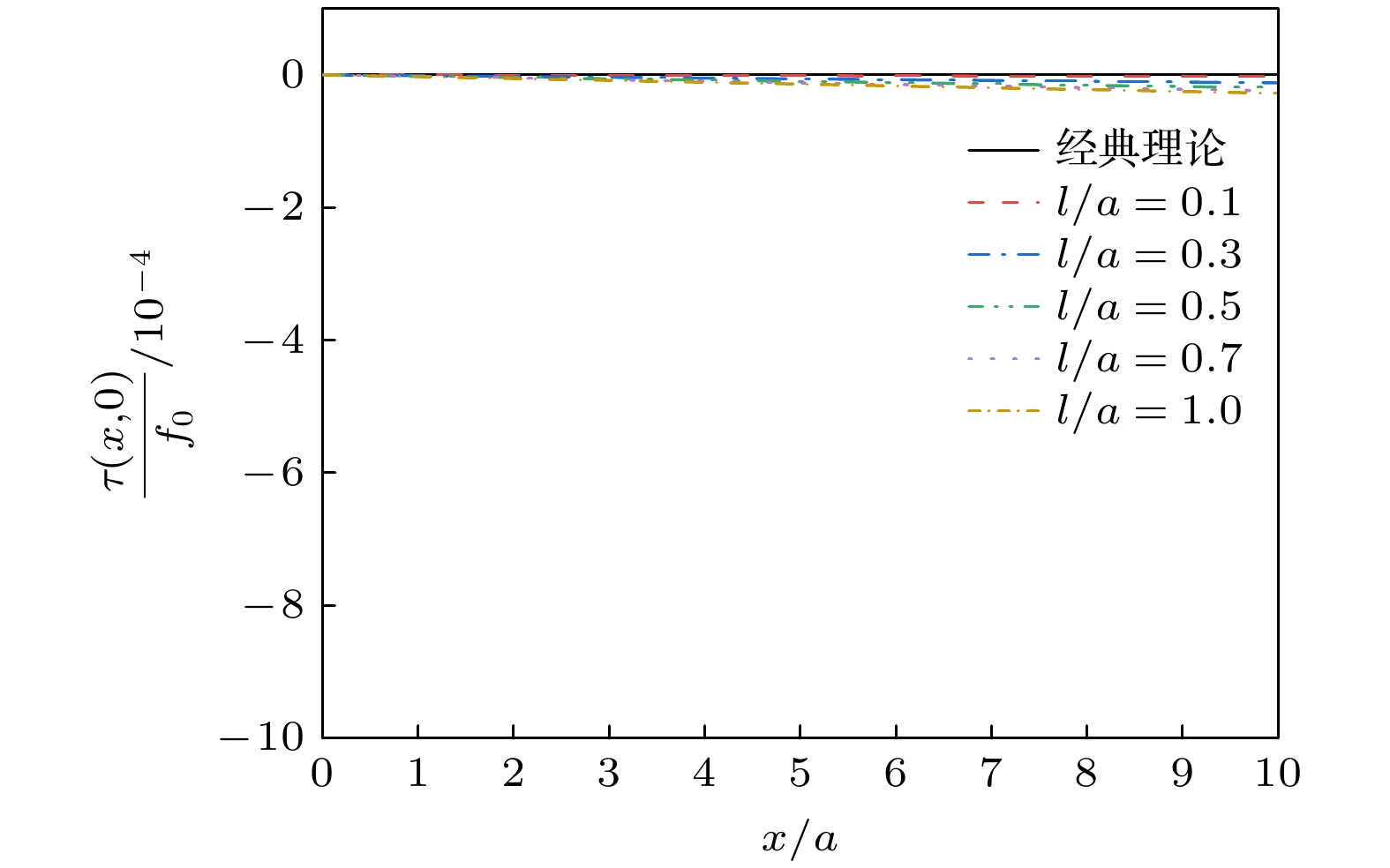

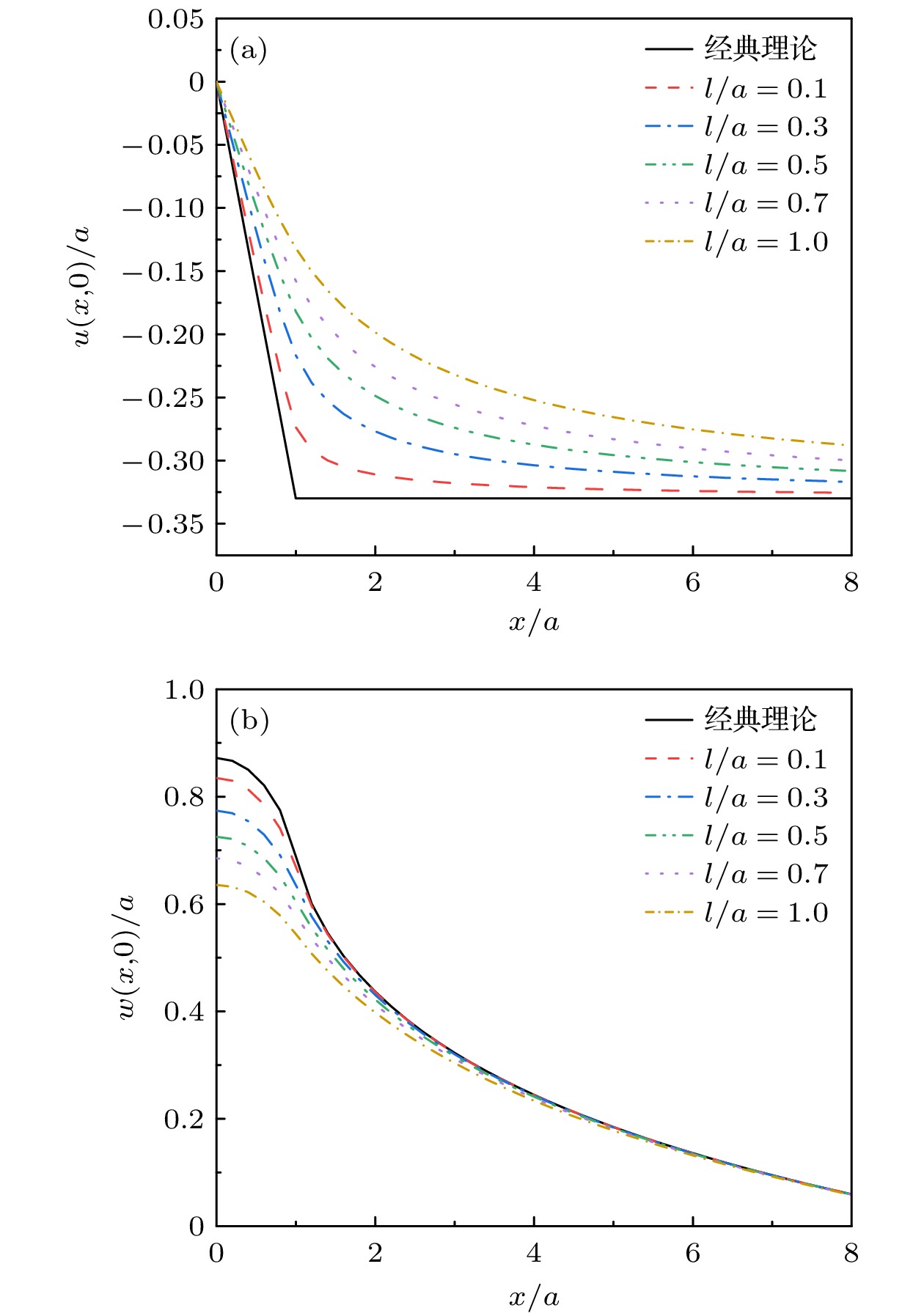

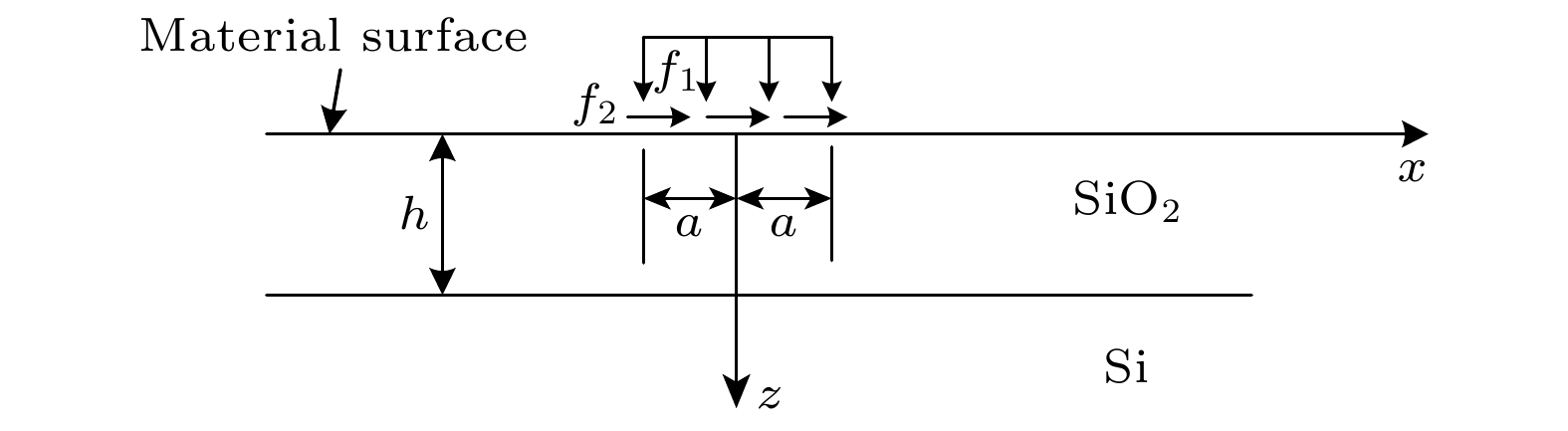

随着微纳声学器件的快速发展, 其核心声学结构已进入纳米尺度范畴, 表面效应对薄膜材料性能的影响日益凸显, 经典弹性理论面临挑战. 本文基于表面弹性理论, 引入表面能密度研究纳米尺度下的表面效应, 采用傅里叶积分变换法推导出纳米尺度SiO2/Si异质结构薄膜表面牵引力下应力场与位移场的解析表达式. 结果显示, 若以表面应力分布与经典理论相差3%作为判断标准, 在激励区域宽度2a的5倍范围内, 材料的微观特性彰显主导地位. 随着激励区域不断减小, 在激励区域内及边界附近表面应力分布较经典理论更加集中, 剪切应力于边界处有极大值, 材料表面刚度与抗变形能力增加, 横向与纵向位移较经典理论减小. 纳米尺度异质结构存在显著表面效应, 导致应力和位移分布明显偏离弹性理论, 经典弹性假设在相应纳米尺度范围不再适用. 以上结果表明, 在纳米尺度固体表面中, 超高频纳米波长声波传播将明显受到尺度效应影响, 经典弹性波理论在纳米尺度存在失效现象, 这对纳米声学理论研究具有参考价值.The rapid advancement of micro-nano acoustic devices has led their core acoustic structures to shrink to the nanoscale level. The influence of surface effects on the mechanical properties of thin-film materials on a nanoscale becomes increasingly prominent, and the classical elasticity theory struggles to accurately describe their mechanical behavior on this scale. In this paper, a mechanical model of nano-SiO2/Si heterostructured thin films that considers surface effects is developed using surface elasticity theory. This model incorporates the key parameter of surface energy density. In this paper, a mechanical model of heterostructured nano-SiO2/Si films is developed using the surface elasticity theory, incorporating surface effects through the introduction of surface energy density as a key parameter. Using the Fourier integral transform method, analytical expressions for stress and displacement fields under surface traction are systematically derived, revealing the influence of surface effects on the mechanical behavior of materials on a nanoscale by comparing the analytical solution with that from the classical theory. The results show that when the surface stress distribution deviates by 3% from that predicted by the classical theory, the microscopic properties of the material become significant, and the surface effect cannot be ignored in a range of five times the width of the excitation region 2a. As the size of the excitation region decreases, the surface effect is significantly increases and the stress distribution within the excitation region and near the boundary becomes more concentrated than the counterparts in the classical theory. The shear stress is no longer zero, and an extreme value is observed at the boundary, which is significantly different from that predicted by the classical theory of elasticity. The transverse and longitudinal displacements are reduced compared with those from the classical theory, and the surface stiffness and deformation resistance of the material are greatly enhanced. Significant surface effects occur on nano-heterostructure thin films, leading to large deviations in stress and displacement distributions from the results of elasticity theory. Therefore, the classical elasticity assumptions are no longer applicable in the corresponding nanoscale range. The results demonstrate that the propagation of ultrahigh-frequency nano- length acoustic waves in nanoscale solid film surfaces is significantly affected by the scale effect. The failure of the classical elastic wave theory on a nanoscale is of great value for the study of nanoscale acoustic theory. Furthermore, these findings provide a theoretical basis for the subsequent development of more precise models of interfacial effects and a more detailed investigation of the influence of the film-substrate modulus ratio.

-

Keywords:

- surface elasticity theory /

- nanoscale /

- surface effects /

- failure phenomenon

[1] Hui X P 2024 Acta Mech. Solida Sin. 37 371

Google Scholar

Google Scholar

[2] Farajpour A, Ghayesh H M, Farokhi H 2018 Int. J. Eng. Sci. 133 231

Google Scholar

Google Scholar

[3] Peddieson J, Buchanan R G, McNitt P R 2003 Int. J. Eng. Sci. 41 305

Google Scholar

Google Scholar

[4] Eringen A C 1999 Theory of Micropolar Elasticity (New York: Springer

[5] Toupin R A 1964 Arch. Ration. Mech. Anal. 17 85

Google Scholar

Google Scholar

[6] Gibbs J W 1879 Trans. Conn. Acad. 2 300

Google Scholar

Google Scholar

[7] Gurtin M E, Murdoch A I 1975 Arch. Ration. Mech. Anal. 59 389-390

Google Scholar

Google Scholar

[8] Miller R E, Shenoy V B 2000 Nanotechnology 11 139

Google Scholar

Google Scholar

[9] He J, Lilley C M 2008 Nano Lett. 8 1798

Google Scholar

Google Scholar

[10] Tong L H, Lin F, Xiang Y, Shen H S, Lim C W 2021 Compos. Struct. 265 113708

Google Scholar

Google Scholar

[11] Zhang S Y, Tang X Y, Ruan H H, Zhu L L 2019 Appl. Phys. A 125 1

Google Scholar

Google Scholar

[12] Chen S H, Yao Y 2014 Appl. Mech. 81 121002

Google Scholar

Google Scholar

[13] Zhang Y Y, Wang Y X, Zhang X, Shen H M, She G L 2021 Steel Compos. Struct. 38 293

Google Scholar

Google Scholar

[14] Wang L Y, Wu H M, Ou Z Y 2024 Math. Mech. Solids 29 401

Google Scholar

Google Scholar

[15] George V, Mohammadreza Y 2017 Crystals 7 321

Google Scholar

Google Scholar

[16] Saffari S, Hashemian M, Toghraie D 2017 Physica B 520 97

Google Scholar

Google Scholar

[17] Chen D Q, Sun D L, Li X F 2017 Compos. Struct. 173 116

Google Scholar

Google Scholar

[18] 叶高杰, 殷澄, 黎思瑜, 俞强, 王贤平, 吴坚 2023 72 104201

Google Scholar

Google Scholar

Ye G J, Yin C, Li S Y, Wang X P, Wu J 2023 Acta Phys. Sin. 72 104201

Google Scholar

Google Scholar

[19] 尚帅朋, 陆勇俊, 王峰会 2022 71 033101

Google Scholar

Google Scholar

Shang S P, Lu Y J, Wang F H 2022 Acta Phys. Sin. 71 033101

Google Scholar

Google Scholar

[20] Tian X G, Tao L Q, Liu B, Zhou C J, Ren T L 2016 IEEE Electron Device Lett. 37 1063

Google Scholar

Google Scholar

[21] Shen B, Huang Z W, Ji Z, Lin Q, Chen S L, Cui D J, Zhang Z N 2019 Surf. Coat. Technol. 380 125061

Google Scholar

Google Scholar

[22] Selvadurai A P S 2000 Partial Differential Equations in Mechanics (Berlin: Springer

[23] Ouyang G, Wang C X, Yang G W 2009 Chem. Rev. 109 4221

Google Scholar

Google Scholar

[24] Zhang C, Yao Y, Chen S H 2014 Comput. Mater. Sci. 82 372

Google Scholar

Google Scholar

[25] Yao Y, Chen S H 2016 Acta Mech. 227 1799

Google Scholar

Google Scholar

[26] Gao X, Hao F, Fang D N, Huang Z P 2013 Int. J. Solids Struct. 50 2620

Google Scholar

Google Scholar

[27] Wang L Y 2020 Int. J. Mech. Mater. Des. 16 633

Google Scholar

Google Scholar

-

表 1 纳米薄膜特性相关参数表

Table 1. Table of parameters related to nanofilm properties.

-

[1] Hui X P 2024 Acta Mech. Solida Sin. 37 371

Google Scholar

Google Scholar

[2] Farajpour A, Ghayesh H M, Farokhi H 2018 Int. J. Eng. Sci. 133 231

Google Scholar

Google Scholar

[3] Peddieson J, Buchanan R G, McNitt P R 2003 Int. J. Eng. Sci. 41 305

Google Scholar

Google Scholar

[4] Eringen A C 1999 Theory of Micropolar Elasticity (New York: Springer

[5] Toupin R A 1964 Arch. Ration. Mech. Anal. 17 85

Google Scholar

Google Scholar

[6] Gibbs J W 1879 Trans. Conn. Acad. 2 300

Google Scholar

Google Scholar

[7] Gurtin M E, Murdoch A I 1975 Arch. Ration. Mech. Anal. 59 389-390

Google Scholar

Google Scholar

[8] Miller R E, Shenoy V B 2000 Nanotechnology 11 139

Google Scholar

Google Scholar

[9] He J, Lilley C M 2008 Nano Lett. 8 1798

Google Scholar

Google Scholar

[10] Tong L H, Lin F, Xiang Y, Shen H S, Lim C W 2021 Compos. Struct. 265 113708

Google Scholar

Google Scholar

[11] Zhang S Y, Tang X Y, Ruan H H, Zhu L L 2019 Appl. Phys. A 125 1

Google Scholar

Google Scholar

[12] Chen S H, Yao Y 2014 Appl. Mech. 81 121002

Google Scholar

Google Scholar

[13] Zhang Y Y, Wang Y X, Zhang X, Shen H M, She G L 2021 Steel Compos. Struct. 38 293

Google Scholar

Google Scholar

[14] Wang L Y, Wu H M, Ou Z Y 2024 Math. Mech. Solids 29 401

Google Scholar

Google Scholar

[15] George V, Mohammadreza Y 2017 Crystals 7 321

Google Scholar

Google Scholar

[16] Saffari S, Hashemian M, Toghraie D 2017 Physica B 520 97

Google Scholar

Google Scholar

[17] Chen D Q, Sun D L, Li X F 2017 Compos. Struct. 173 116

Google Scholar

Google Scholar

[18] 叶高杰, 殷澄, 黎思瑜, 俞强, 王贤平, 吴坚 2023 72 104201

Google Scholar

Google Scholar

Ye G J, Yin C, Li S Y, Wang X P, Wu J 2023 Acta Phys. Sin. 72 104201

Google Scholar

Google Scholar

[19] 尚帅朋, 陆勇俊, 王峰会 2022 71 033101

Google Scholar

Google Scholar

Shang S P, Lu Y J, Wang F H 2022 Acta Phys. Sin. 71 033101

Google Scholar

Google Scholar

[20] Tian X G, Tao L Q, Liu B, Zhou C J, Ren T L 2016 IEEE Electron Device Lett. 37 1063

Google Scholar

Google Scholar

[21] Shen B, Huang Z W, Ji Z, Lin Q, Chen S L, Cui D J, Zhang Z N 2019 Surf. Coat. Technol. 380 125061

Google Scholar

Google Scholar

[22] Selvadurai A P S 2000 Partial Differential Equations in Mechanics (Berlin: Springer

[23] Ouyang G, Wang C X, Yang G W 2009 Chem. Rev. 109 4221

Google Scholar

Google Scholar

[24] Zhang C, Yao Y, Chen S H 2014 Comput. Mater. Sci. 82 372

Google Scholar

Google Scholar

[25] Yao Y, Chen S H 2016 Acta Mech. 227 1799

Google Scholar

Google Scholar

[26] Gao X, Hao F, Fang D N, Huang Z P 2013 Int. J. Solids Struct. 50 2620

Google Scholar

Google Scholar

[27] Wang L Y 2020 Int. J. Mech. Mater. Des. 16 633

Google Scholar

Google Scholar

计量

- 文章访问数: 467

- PDF下载量: 5

- 被引次数: 0

下载:

下载: