-

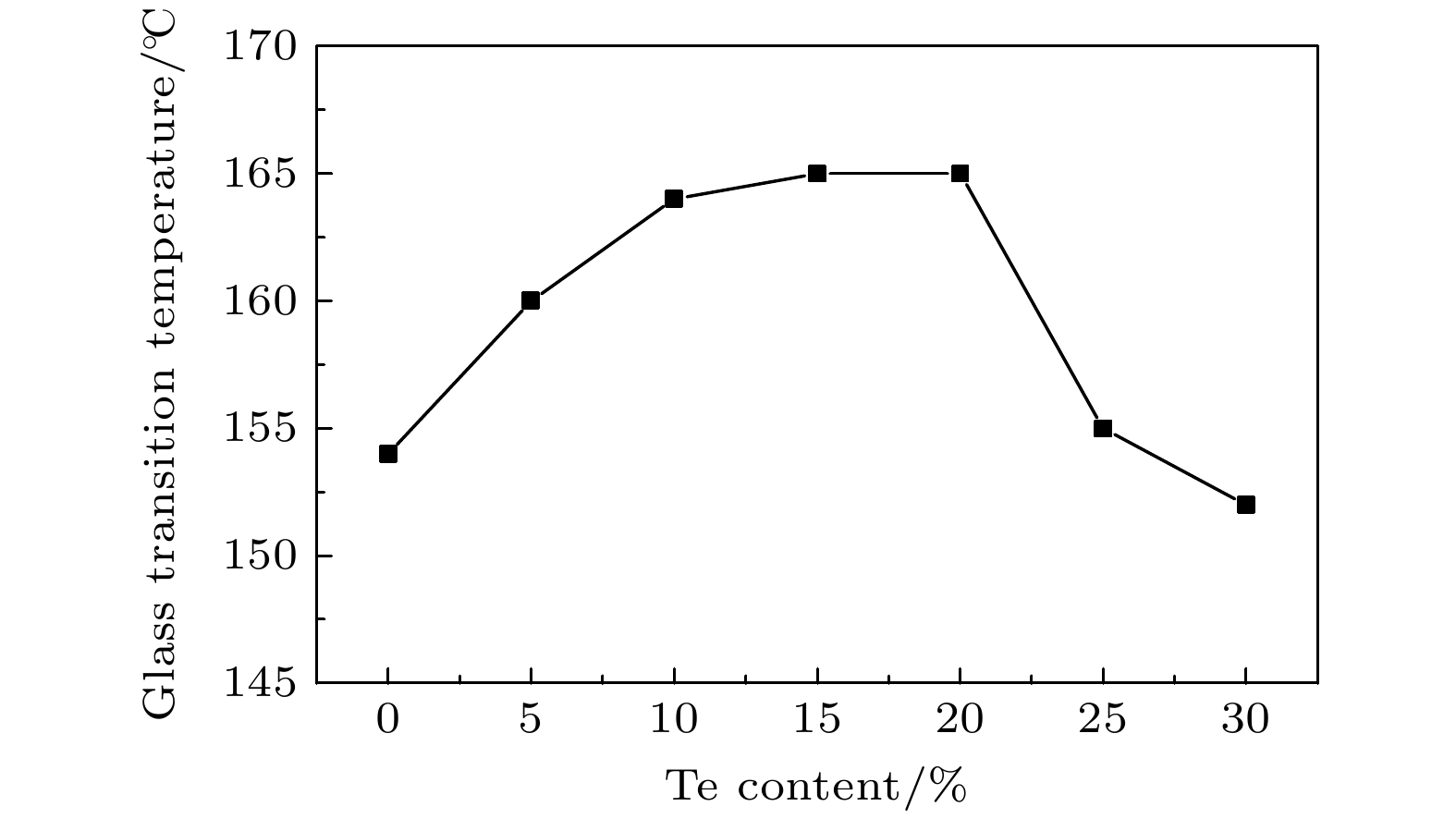

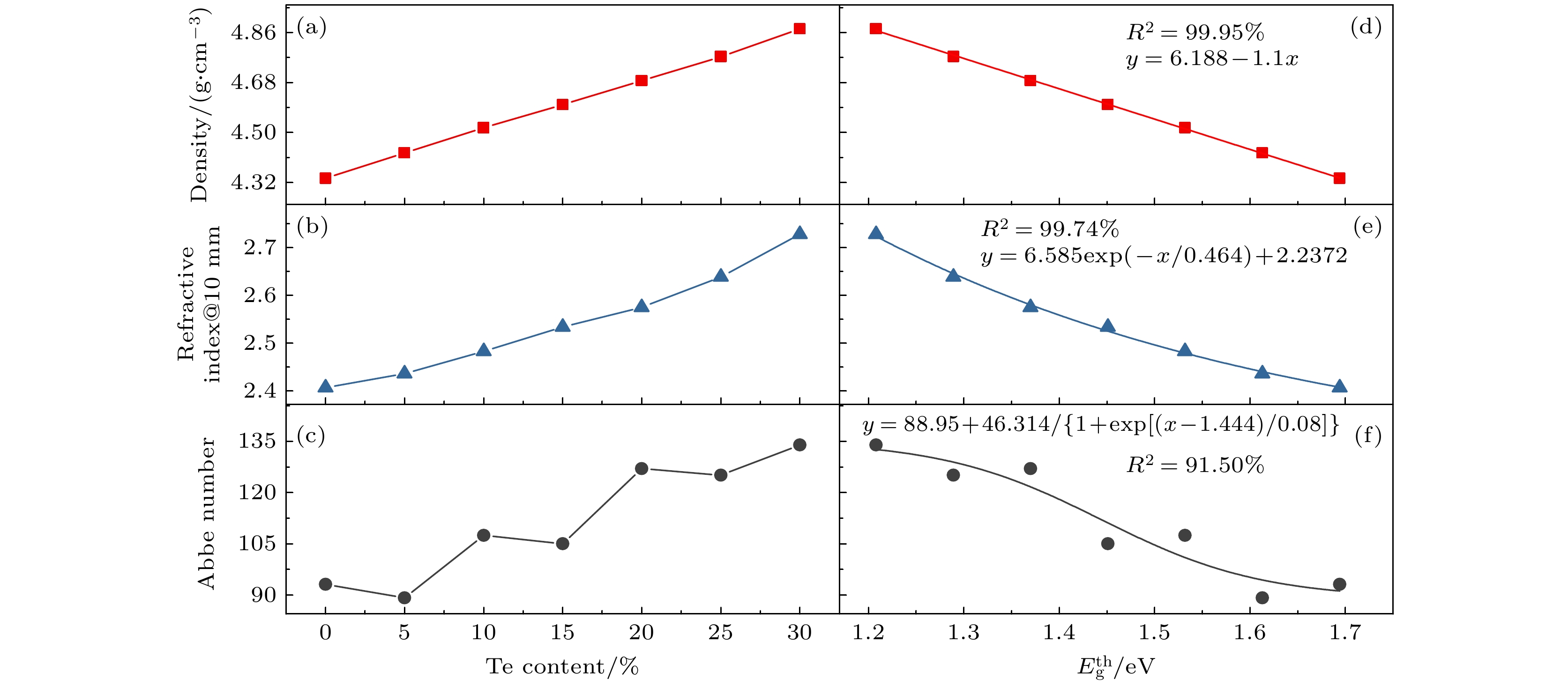

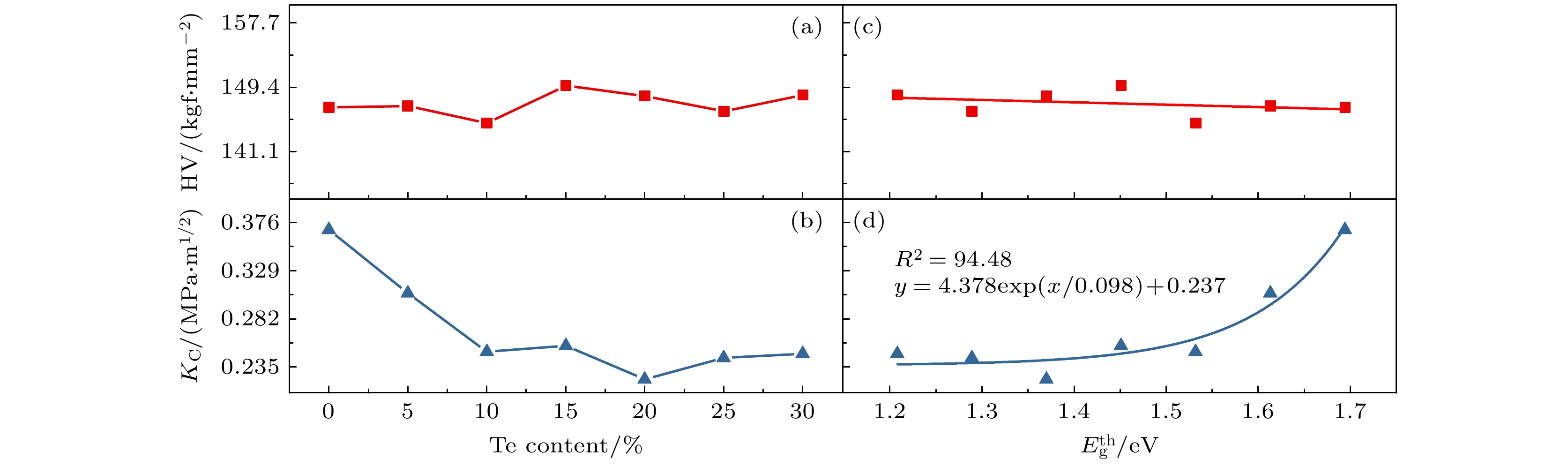

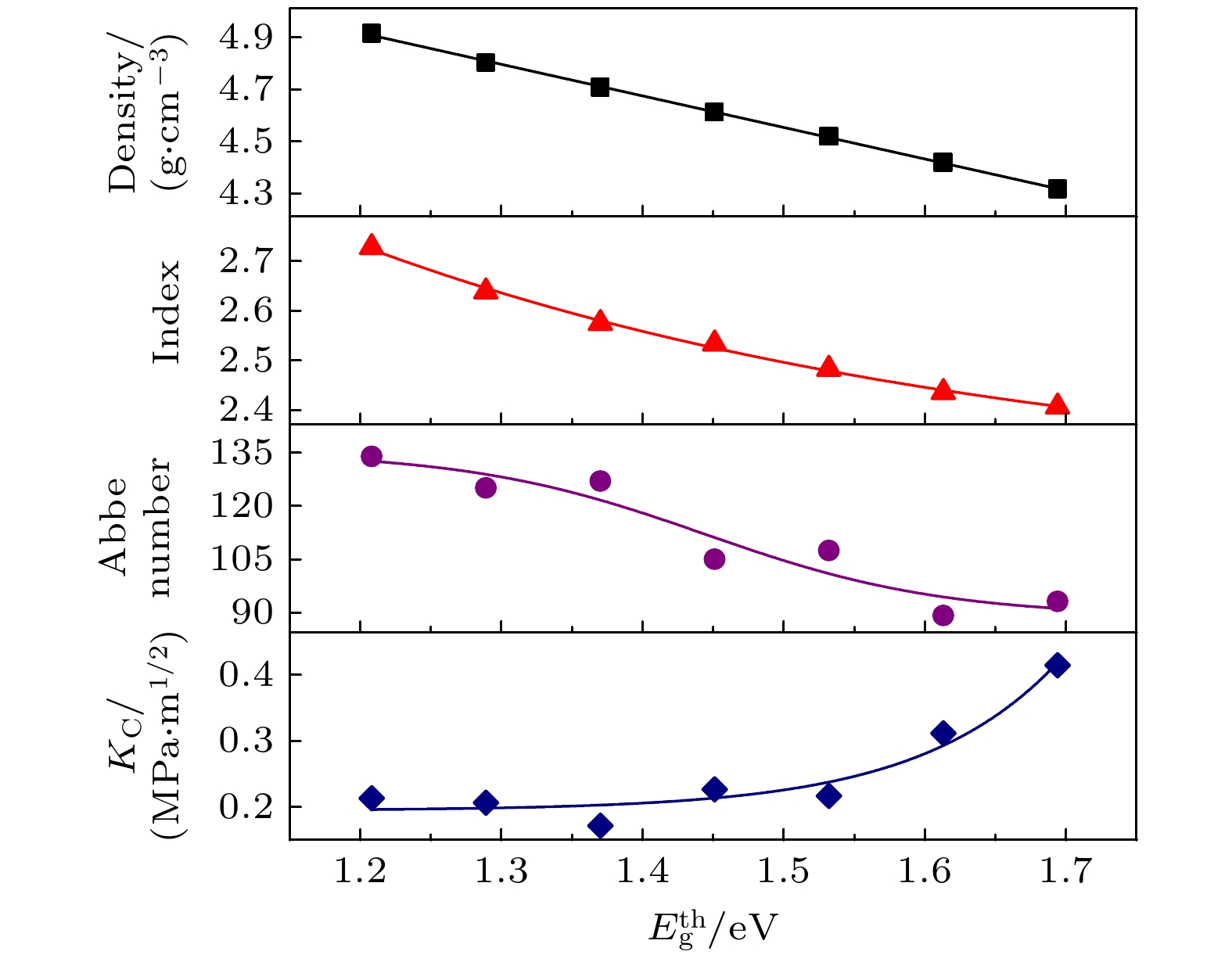

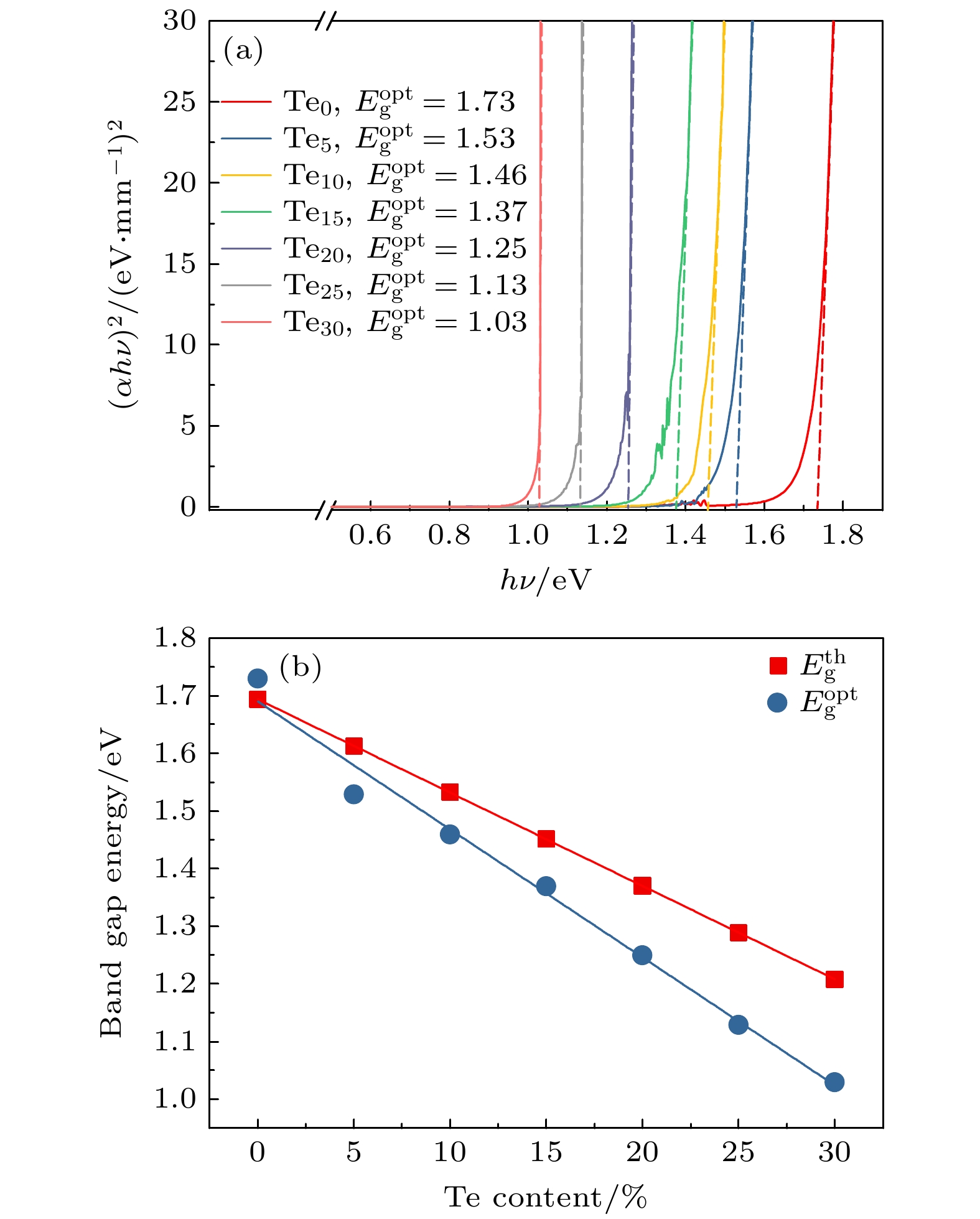

开发特殊性能红外材料是目前提升红外光学系统性能的关键, 硫系玻璃作为组分-性能可调的红外材料无疑成为了热门选项. Se基与Te基玻璃涵盖中波、长波红外窗口, 是最典型的红外器件应用材料之一, 通过对Ge20Se80–xTex玻璃体系的结构与性能分析, 阐述了Te含量对该玻璃体系结构与性能演变的规律. 随着Te含量的增大, 玻璃转变温度(Tg)受网络结构及平均键能的影响先升高后降低, 密度与折射率近似线性的梯度增高, 阿贝数逐渐增大, 而维氏硬度几乎不随Te含量的变化而变化, 断裂韧性随Te含量的增大而降低. 针对平均配位数无法评价两种及以上同族元素组成的玻璃体系问题, 成功建立了理论带隙-玻璃性能评价体系, 并对Ge20Se80–xTex玻璃体系的密度、折射率、阿贝数、断裂韧性等参数与理论带隙建立了函数关系, 该体系可用于快速评估玻璃组分与性能.Infrared imaging systems are being updated towards greater performance as well as lighter and smaller devices. Developing infrared materials with special properties is a critical for enhancing the performance of optical systems as well as miniaturizing devices. Chalcogenide glass becomes a popular option for advanced IR materials due to its component-property tunability. Se—based glasses such as Ge33As12Se55, Ge10As40Se50, and As40Se60, which completely cover the mid- and long-wave infrared windows, are the most typical materials used in infrared equipment. However, these classical materials can no longer meet the requirements of high-performance imaging systems, and adding more elements such as Te, Ga, Sb, and Ag to enhance the performance is a reliable way to solve this problem. By analysing the structure and properties of the Ge20Se80–xTex glass system, the law of its structure and properties evolving with Te content is illustrated. The obtained typical results are shown below. With the increase of Te content, the glass transition temperature (Tg) increases and then decreases, which is caused by the network structure and the average bond energy; the density and refractive index increase in an approximately linear gradient; the Abbe number gradually increases, while the Vickers hardness hardly changes with Te content; the fracture toughness decreases with the Te content increasing. Aiming at the problem that the average coordination number is unable to evaluate the glass systems composed of two or more elements from the same main group, a theoretical bandgap-glass property evaluation system is successfully established. The functional relationships among parameters such as density, refractive index, Abbe number, and fracture toughness, and theoretical band gap are established for Ge20Se80–xTex glass system as shown in the summary figure, which can be used to rapidly evaluate the glass components and properties.

-

Keywords:

- infrared materials /

- chalcogenide glasses /

- theoretical bandgap /

- glass property

[1] Adam J L, Zhang X H 2014 Chalcogenide Glasses (Sawston Cambridge: Woodhead Publishing) pxvii

[2] Maurugeon S, Boussard-Pledel C, Troles J, Faber A J, Lucas P, Zhang X H, Lucas J, Bureau B 2010 J. Lightwave Technol. 28 3358

[3] Calvez L, Ma H L, Lucas J, Zhang X H 2007 Adv. Mater. 19 129

Google Scholar

Google Scholar

[4] Mi H T, Yang A P, Huang Z X, Tian K Z, Li Y B, Ma C, Liu Z J, Shen X, Yang Z Y 2023 Acta Phys. Sin. 72 047101 [米浩婷, 杨安平, 黄梓轩, 田康振, 李跃兵, 马成, 刘自军, 沈祥, 杨志勇 2023 72 047101]

Google Scholar

Google Scholar

Mi H T, Yang A P, Huang Z X, Tian K Z, Li Y B, Ma C, Liu Z J, Shen X, Yang Z Y 2023 Acta Phys. Sin. 72 047101

Google Scholar

Google Scholar

[5] Wang Y W, Qi S S, Yang Z Y, Wang R P, Yang A P, Lucas P 2017 J. Non-Cryst. Solids 459 88

Google Scholar

Google Scholar

[6] Carlie N A 2015 Int. J. Appl. Glass Sci. 6 364

Google Scholar

Google Scholar

[7] Lonergan J, Lonergan C, McCloy J, Richardson K A 2019 J. Non-Cryst. Solids 510 192

Google Scholar

Google Scholar

[8] Yang G, Gueguen Y, Sangleboeuf J-C, Rouxel T, Boussard-Plédel C, Troles J, Lucas P, Bureau B 2013 J. Non-Cryst. Solids 377 54

Google Scholar

Google Scholar

[9] Wang T, Wei W H, Shen X, Wang R P, Davies B L, Jackson I 2013 J. Phys. D: Appl. Phys. 46 165302

Google Scholar

Google Scholar

[10] Wang R P, Wang T, Choi D Y, Madden S, Luther-Davies B 2011 AIP Conf. Proc. 1393 34

[11] Xu S W, Liang T, Zhu X Y 2023 Chalcogenide Lett. 20 55

Google Scholar

Google Scholar

[12] Xu S W, Wang X S, Shen X 2024 Acta Phys. Sin. 73 057102 [许思维, 王训四, 沈祥 2024 73 057102]

Google Scholar

Google Scholar

Xu S W, Wang X S, Shen X 2024 Acta Phys. Sin. 73 057102

Google Scholar

Google Scholar

[13] Phillips J C 1979 J. Non-Cryst. Solids 34 153

Google Scholar

Google Scholar

[14] Xia F, Baccaro S, Wang H, Hua W, Zeng H D, Zhang X H, Chen G R 2008 J. Non-Cryst. Solids 354 1365

Google Scholar

Google Scholar

[15] Opletal G, Wang R P, Russo S P 2013 Phys. Chem. Chem. Phys. 15 4582

Google Scholar

Google Scholar

[16] Tichý L, Tichá H 1995 J. Non-Cryst. Solids 189 141

Google Scholar

Google Scholar

[17] Xia F, Baccaro S, Zhao D, Falconieri M, Chen G 2005 Nucl. Instrum. Methods Phys. Res. B 234 525

Google Scholar

Google Scholar

[18] Sharma E, Sharma R, Sharma V, Sharma P 2018 AIP Conf. Proc. 2050 020008

[19] Zha C, Wang R, Smith A, Prasad A, Jarvis R A, Luther-Davies B 2007 J. Mater. Sci-Mater. El. 18 389

Google Scholar

Google Scholar

[20] Arsova D 1996 J. Phys. Chem. Solids 57 1279

Google Scholar

Google Scholar

[21] Fouad S S 1999 Vacuum 52 505

Google Scholar

Google Scholar

[22] Cheng C, Wang X S, Xu T F, Sun L H, Pan Z H, Liu S, Zhu Q D, Liao F X, Nie Q H, Dai S X, Shen X H, Zhang X H, Chen W 2016 Infrared Phys. Techn. 76 698

Google Scholar

Google Scholar

[23] Abd El-Rahman A A, Eid A, Sanad M, El-Ocker R 1998 J. Phys. Chem. Solids 59 825

Google Scholar

Google Scholar

[24] Sharma P, Katyal S C 2008 J. Non-Cryst. Solids 354 3836

Google Scholar

Google Scholar

[25] Gonçalves C, Mereau R, Nazabal V, Boussard-Pledel C, Roiland C, Furet E, Deschamps M, Bureau B, Dussauze M 2021 J. Solid State Chem. 297 122062

Google Scholar

Google Scholar

[26] Hassanien A S, Sharma I, Akl A A 2020 J. Non-Cryst. Solids 531 119853

Google Scholar

Google Scholar

[27] Knotek P, Kutalek P, Cernoskova E, Vlcek M, Tichy L 2020 RSC Adv. 10 42744

Google Scholar

Google Scholar

-

图 1 (a) Ge20Se80–xTex系列玻璃直接带隙对应的(αhν)2和hν之间的关系, 以及每种玻璃的光学带隙值; (b) 理论带隙、光学带隙与Te含量的变化关系

Fig. 1. (a) The relationship between (αhν)2 and hν corresponding to the direct band gap of Ge20Se80–xTex series glasses, and the optical band gap value of each glass; (b) the relationship between the theoretical bandgap, the optical bandgap and the Te content.

图 4 Ge20Se80–xTex系列玻璃的密度(a)、折射率@10 μm (b)、以及8—12 μm窗口的阿贝数 (c)与Te含量的变化关系; Ge20Se80–xTex系列玻璃的密度(d)、折射率@10 μm(e)、以及8—12 μm窗口的阿贝数(f)与理论带隙$ E_{\text{g}}^{{\text{th}}} $的变化关系及其拟合曲线

Fig. 4. Variation of density (a), refractive index @10 μm (b), and Abbe number (c) for the 8–12 μm window versus Te content for Ge20Se80–xTex series glasses; variation of density (d), refractive index @10 μm (e), and Abbe number (f) for the 8–12 μm window versus the theoretical bandgap $ E_{\text{g}}^{{\text{th}}} $and their fitting curves for the Ge20Se80–xTex series glasses.

图 5 Ge20Se80–xTex系列玻璃的维氏硬度(a)、断裂韧性(b)与Te含量的变化关系; Ge20Se80–xTex系列玻璃的维氏硬度(d)、断裂韧性(e)与理论带隙$ E_{\text{g}}^{{\text{th}}} $的变化关系及其拟合曲线

Fig. 5. Variation of Vickers hardness (a) and fracture toughness (b) versus Te content for the Ge20Se80–xTex series of glasses; variation of Vickers hardness (d) and fracture toughness (e) versus the theoretical bandgap $ E_{\text{g}}^{{\text{th}}} $, and their fitted curves for the Ge20Se80–xTex series of glasses.

表 1 Ge, Se, Te元素的基本特性参数

Table 1. The basic characteristic parameters of Ge, Se, and Te elements.

元素 配位数 密度/(g·cm–3) 摩尔质量/(g·mol–1) 摩尔体积/(cm3·mol–1) 电负性Pauling scale 带隙/eV 键能/(kcal·mol–1) Ge 4 5.33 72.63 13.63 2.01 0.67 37.78 Se 2 4.81 78.97 16.42 2.55 1.95 44.04 Te 2 6.22 127.6 20.50 2.10 0.33 33.00 表 2 Ge20Se80–xTex的玻璃可能出现的共价键及其键能

Table 2. Possible bond types and bond energies for Ge20Se80–xTex glass.

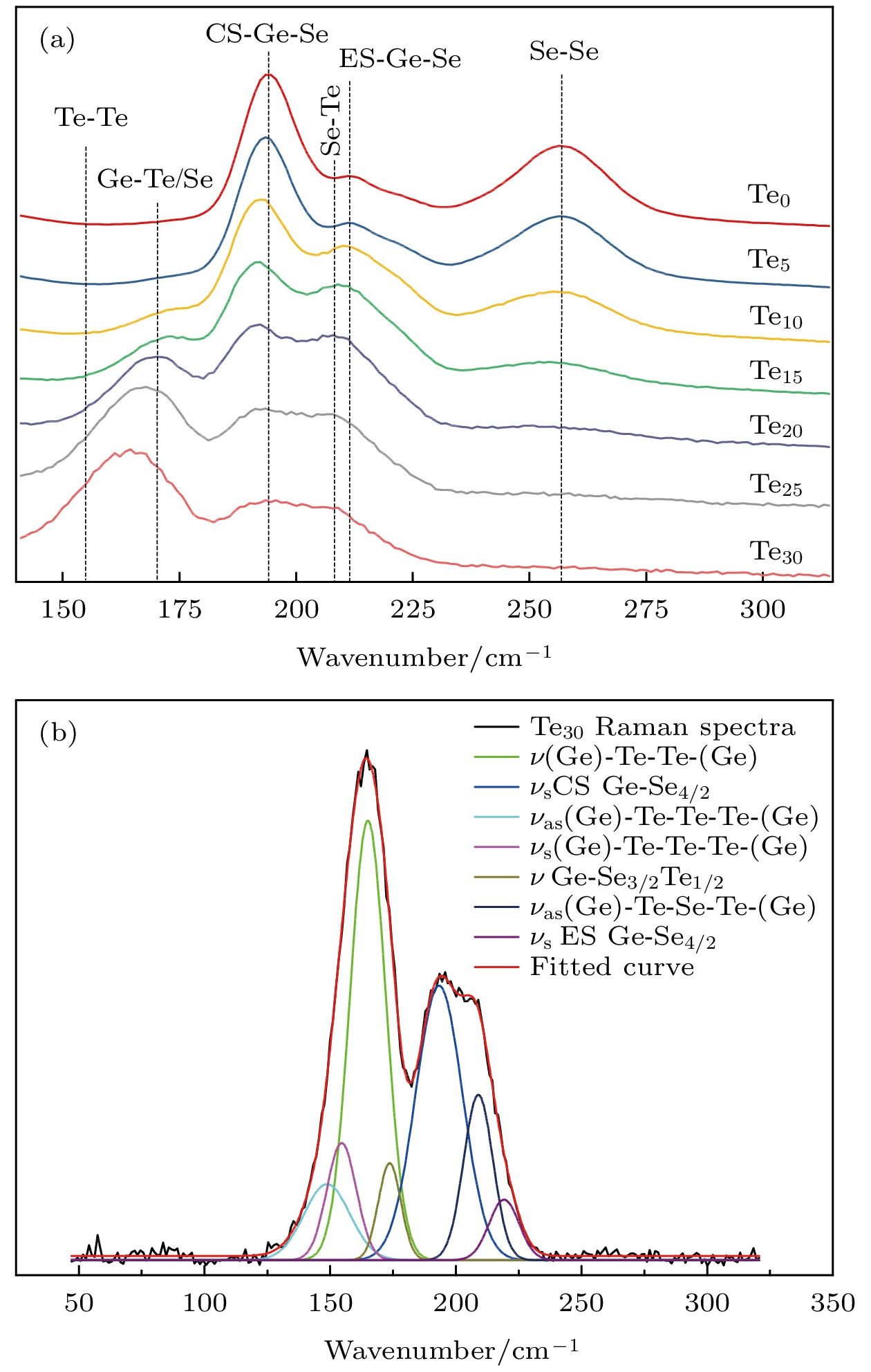

成键类型 Ge—Se Se—Te Se—Se Ge—Te Te—Te 键能/(kcal·mol–1) 49.54 44.20 44.04 35.55 33.00 表 3 Ge20Se80–xTex系列玻璃可能出现的振动模式及其频率位置

Table 3. Possible vibration modes and frequency positions of Ge20Se80–xTex series glasses.

Wavenumber/cm–1 Vibrational mode 145 ν (Te)—Te–Te—(Te) 151 νas (Ge)—Te—Te—Te—(Ge) 154 νs (Ge)—Te—Te—Te—(Ge) 157 ν (Ge)—Te—Te—(Te) 164 ν (Ge)—Te—Te—(Ge) 145 ν Ge—Se1/2Te3/2 160 ν Ge—Se2/2Te2/2 170 ν Ge—Se3/2Te1/2 194 νs Corner-Sharing Ge—Se4/2 211 νs Edge-sharing Ge—Se4/2 299 νas Ge—Se4/2 208 νas (Ge)—Te—Se—Te—(Ge) 210 ν (Se)-Se—Te—(Ge) 211 νs (Ge)—Te—Se—Te—(Ge) 212 νas (Ge)-Se—Te—Se—(Ge) 219 νs (Te)—Te—Se—(Ge) 222 νs (Ge)-Se—Te—Se—(Ge) 245 ν -(Se—Se)n- long chain 252 νas Se—Se—Se 263 ν (Se)-Se—Se—(Ge) 270 ν Se—Se -

[1] Adam J L, Zhang X H 2014 Chalcogenide Glasses (Sawston Cambridge: Woodhead Publishing) pxvii

[2] Maurugeon S, Boussard-Pledel C, Troles J, Faber A J, Lucas P, Zhang X H, Lucas J, Bureau B 2010 J. Lightwave Technol. 28 3358

[3] Calvez L, Ma H L, Lucas J, Zhang X H 2007 Adv. Mater. 19 129

Google Scholar

Google Scholar

[4] Mi H T, Yang A P, Huang Z X, Tian K Z, Li Y B, Ma C, Liu Z J, Shen X, Yang Z Y 2023 Acta Phys. Sin. 72 047101 [米浩婷, 杨安平, 黄梓轩, 田康振, 李跃兵, 马成, 刘自军, 沈祥, 杨志勇 2023 72 047101]

Google Scholar

Google Scholar

Mi H T, Yang A P, Huang Z X, Tian K Z, Li Y B, Ma C, Liu Z J, Shen X, Yang Z Y 2023 Acta Phys. Sin. 72 047101

Google Scholar

Google Scholar

[5] Wang Y W, Qi S S, Yang Z Y, Wang R P, Yang A P, Lucas P 2017 J. Non-Cryst. Solids 459 88

Google Scholar

Google Scholar

[6] Carlie N A 2015 Int. J. Appl. Glass Sci. 6 364

Google Scholar

Google Scholar

[7] Lonergan J, Lonergan C, McCloy J, Richardson K A 2019 J. Non-Cryst. Solids 510 192

Google Scholar

Google Scholar

[8] Yang G, Gueguen Y, Sangleboeuf J-C, Rouxel T, Boussard-Plédel C, Troles J, Lucas P, Bureau B 2013 J. Non-Cryst. Solids 377 54

Google Scholar

Google Scholar

[9] Wang T, Wei W H, Shen X, Wang R P, Davies B L, Jackson I 2013 J. Phys. D: Appl. Phys. 46 165302

Google Scholar

Google Scholar

[10] Wang R P, Wang T, Choi D Y, Madden S, Luther-Davies B 2011 AIP Conf. Proc. 1393 34

[11] Xu S W, Liang T, Zhu X Y 2023 Chalcogenide Lett. 20 55

Google Scholar

Google Scholar

[12] Xu S W, Wang X S, Shen X 2024 Acta Phys. Sin. 73 057102 [许思维, 王训四, 沈祥 2024 73 057102]

Google Scholar

Google Scholar

Xu S W, Wang X S, Shen X 2024 Acta Phys. Sin. 73 057102

Google Scholar

Google Scholar

[13] Phillips J C 1979 J. Non-Cryst. Solids 34 153

Google Scholar

Google Scholar

[14] Xia F, Baccaro S, Wang H, Hua W, Zeng H D, Zhang X H, Chen G R 2008 J. Non-Cryst. Solids 354 1365

Google Scholar

Google Scholar

[15] Opletal G, Wang R P, Russo S P 2013 Phys. Chem. Chem. Phys. 15 4582

Google Scholar

Google Scholar

[16] Tichý L, Tichá H 1995 J. Non-Cryst. Solids 189 141

Google Scholar

Google Scholar

[17] Xia F, Baccaro S, Zhao D, Falconieri M, Chen G 2005 Nucl. Instrum. Methods Phys. Res. B 234 525

Google Scholar

Google Scholar

[18] Sharma E, Sharma R, Sharma V, Sharma P 2018 AIP Conf. Proc. 2050 020008

[19] Zha C, Wang R, Smith A, Prasad A, Jarvis R A, Luther-Davies B 2007 J. Mater. Sci-Mater. El. 18 389

Google Scholar

Google Scholar

[20] Arsova D 1996 J. Phys. Chem. Solids 57 1279

Google Scholar

Google Scholar

[21] Fouad S S 1999 Vacuum 52 505

Google Scholar

Google Scholar

[22] Cheng C, Wang X S, Xu T F, Sun L H, Pan Z H, Liu S, Zhu Q D, Liao F X, Nie Q H, Dai S X, Shen X H, Zhang X H, Chen W 2016 Infrared Phys. Techn. 76 698

Google Scholar

Google Scholar

[23] Abd El-Rahman A A, Eid A, Sanad M, El-Ocker R 1998 J. Phys. Chem. Solids 59 825

Google Scholar

Google Scholar

[24] Sharma P, Katyal S C 2008 J. Non-Cryst. Solids 354 3836

Google Scholar

Google Scholar

[25] Gonçalves C, Mereau R, Nazabal V, Boussard-Pledel C, Roiland C, Furet E, Deschamps M, Bureau B, Dussauze M 2021 J. Solid State Chem. 297 122062

Google Scholar

Google Scholar

[26] Hassanien A S, Sharma I, Akl A A 2020 J. Non-Cryst. Solids 531 119853

Google Scholar

Google Scholar

[27] Knotek P, Kutalek P, Cernoskova E, Vlcek M, Tichy L 2020 RSC Adv. 10 42744

Google Scholar

Google Scholar

计量

- 文章访问数: 788

- PDF下载量: 30

- 被引次数: 0

下载:

下载: