-

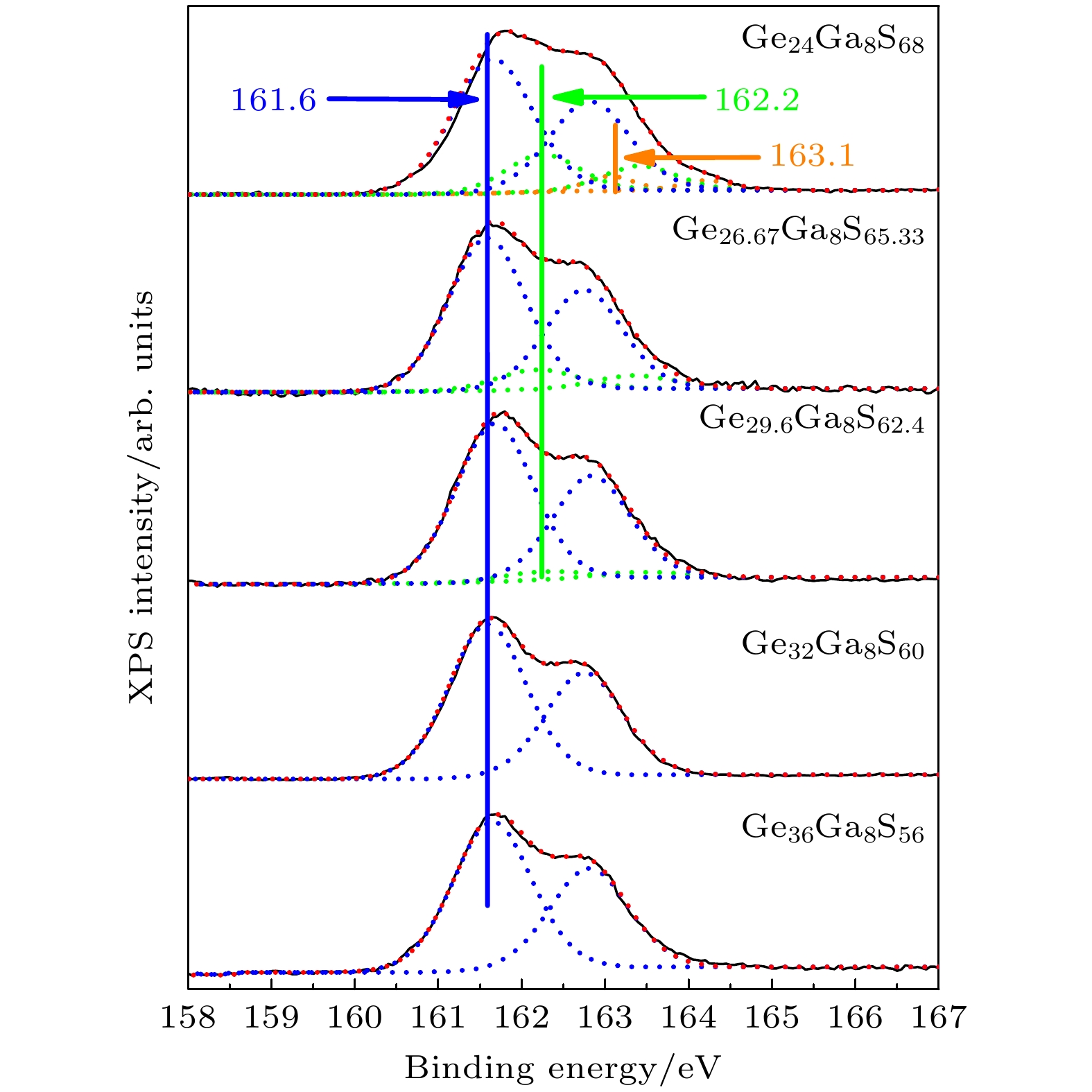

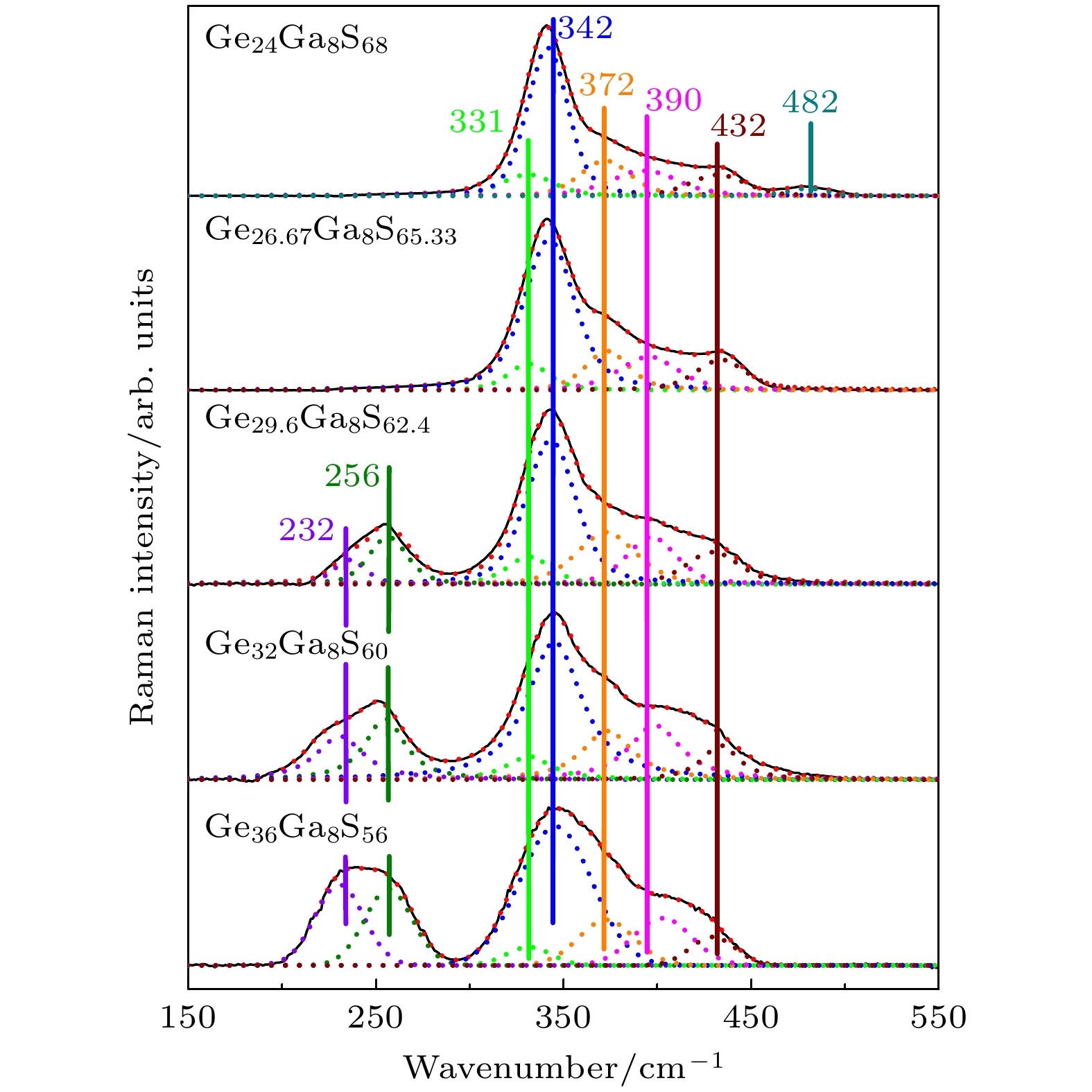

本文在固定Ga原子含量为8%的情况下, 结合高分辨率X射线光电子能谱和拉曼散射光谱对硫系玻璃GexGa8S92–x (x = 24%, 26.67%, 29.6%, 32%和36%)的结构进行了研究. 通过分析玻璃结构中各单元结构的演变情况, 发现玻璃内部网络结构主要为S原子桥接GeS4和GaS4四面体结构. 随着Ge含量的逐渐增大, S链状或环状结构单元迅速减少, 并消失于Ge26.67Ga8S65.33玻璃组分中; 而类乙烷结构S3Ge-GeS3中的Ge—Ge同极键和S3Ge/Ga-Ga/GeS3结构中的M—M (Ge—Ge, Ga—Ga或Ge—Ga)同极键同时出现于Ge29.6Ga8S62.4玻璃中, 并且其结构数量随着Ge含量的增大而逐渐增加. 由此可以判定, 首先, 在硫系玻璃GexGa8S92–x结构中Ge和Ga原子均主要以4配位的形式出现, 而S原子则主要以2配位的形式出现. 其次, M—M键的存在导致纳米相分离, 玻璃网络结构的有序化程度降低.In this paper, the structures of chalcogenide glasses GexGa8S92–x (x = 24%, 26.67%, 29.6%, 32% and 36%) at a fixed Ga atomic content of 8% are studied by high-resolution X-ray photoelectron spectroscopy and Raman scattering spectra. In order to quantify the evolutions of the different structural units in GexGa8S92–x glasses, the number of double peaks in the Ge 3d, Ga 3d and S 2p spectra are determined by iterative fitting method, the binding energy and the full width at half maximum of each peak, and the relative ratio of the integral area of each decomposed peak to that of the whole area of the X-ray photoelectron spectroscopy are thus achieved. On the other hand, the Raman scattering spectra of GexGa8S92–x glass are decomposed into multiple Gaussians based on the structural units. We use the iterative method to simulate the position of peak center, full width at half maximum, and height of each Raman peak. By analyzing the evolution of each unit structure in the glasses, it is found that the network structure of glass network is mainly formed by S atom bridging the tetrahedral structure of GeS4 and GaS4. The S chains or rings structural units are formed in Ge24Ga8S68 glass, indicating that S atoms are in excess in the chemical composition of the glass, so there are enough S atoms around Ge and Ga atoms, forming heteropolar Ge—S and Ga—S bonds. With the gradual increase of Ge content, S chains or rings structure units rapidly disappear in Ge26.67Ga8S65.33 glass. The Ge—Ge homopolar bonds in the ethane-like structure S3Ge—GeS3 and the M—M (Ge—Ge, Ga—Ga or Ge—Ga) homopolar bonds in the S3Ge/Ga—Ga/GeS3 structure simultaneous appear in the Ge29.6Ga8S62.4 glass, and the number of structures increases gradually with the increase of Ge content. This is mainly due to the insufficient number of S atoms in the Ge-Ga-S glass. Once S atoms are lacking, the excess Ge and Ga atoms can only combine with themselves to form the homopolar bond M—M. It can be concluded below. Firstly, Ge and Ga atoms appear mainly in the form of 4-coordination, while S atoms occur mainly in the form of 2-coordination in the chalcogenide glasses of GexGa8S92–x. Secondly, the existence of M—M bond leads the nanophase to separate, and the ordering degree of glass network structure to decrease .

[1] Wang R P 2014 Amorphous Chalcogenides: Advances and Applications (Singapore: Pan Stanford Publisher) pp178–193

[2] Tanaka K, Shimakawa K 2011 Amorphous Chalcogenide Semiconductors and Related Materials (New York: Springer International Publishing) pp115–135

[3] 许思维, 杨晓宁, 杨大鑫, 王训四, 沈祥 2021 70 167101

Google Scholar

Google Scholar

Xu S W, Yang X N, Yang D X, Wang X S, Shen X 2021 Acta Phys. Sin. 70 167101

Google Scholar

Google Scholar

[4] Choi D Y, Madden S, Rode A, Wang R P, Luther-Davies B 2007 Appl. Phys. Lett. 91 011115

Google Scholar

Google Scholar

[5] Kim Y, Saienga J, Martin S W 2006 J. Phys. Chem. B 110 16318

Google Scholar

Google Scholar

[6] 张兴迪, 吴越豪, 杨正胜, 戴世勋, 张培晴, 张巍, 徐铁锋, 张勤远 2016 65 144205

Google Scholar

Google Scholar

Zhang X D, Wu Y H, Yang Z S, Dai S X, Zhang P Q, Zhang W, Xu T F, Zhang Q Y 2016 Acta Phys. Sin. 65 144205

Google Scholar

Google Scholar

[7] 汪俊, 冯赞, 吴国林, 汪金晶, 焦凯, 王弦歌, 刘佳, 梁晓林, 徐铁松, 钟明辉, 肖晶, 赵浙明, 刘自军, 刘永兴, 王训四 2020 发光学报 41 1343

Google Scholar

Google Scholar

Wang J, Feng Z, Wu G L, Wang J J, Jiao K, Wang X G, Liu J, Liang X L, Xu T S, Zhong M H, Xiao J, Zhao Z M, Liu Z J, Liu Y X, Wang X S 2020 Chin. J. Lumin. 41 1343

Google Scholar

Google Scholar

[8] 戴世勋, 彭波, 乐放达, 王训四, 沈祥, 徐铁峰, 聂秋华 2010 59 3547

Google Scholar

Google Scholar

Dai S X, Peng B, Le F D, Wang X S, Shen X, Xu T F, Nie Q H 2010 Acta Phys. Sin. 59 3547

Google Scholar

Google Scholar

[9] 任晶, 卢小送, 王鹏飞 2019 光子学报 48 1148007

Google Scholar

Google Scholar

Ren J, Lu X S, Wang P F 2019 Acta Photonica Sin. 48 1148007

Google Scholar

Google Scholar

[10] Yang Z, Wang R P, Chen Y M, Li Q L, Shen X, Xu T F 2020 Opt. Mater. 100 109677

Google Scholar

Google Scholar

[11] Ren J, Wagner T, Bartos M, Frumar M, Oswald J, Kincl M, Frumarova B, Chen G R 2011 J. Appl. Phys. 109 033105

Google Scholar

Google Scholar

[12] Golovchak R, Shpotyuk O, Kozyukhin S, Shpotyuk M, Kovalskiy A, Jain H 2011 J. Non-Cryst. Solids 357 1797

Google Scholar

Google Scholar

[13] Zhu E W, Liu Y X, Sun X, Yin G L, Jiao Q, Dai S X, Lin C G 2019 J. Non-Cryst. Solids 1 100015

Google Scholar

Google Scholar

[14] Bureau B, Troles J, Floch M L, Guenot P, Smektala F, Lucas J 2003 J. Non-Cryst. Solids 319 145

Google Scholar

Google Scholar

[15] Nazabal V, Charpentier F, Adam J L, Nemec P, Lhermite H, Anne M L B, Charrier J, Guin J P, Moréac A 2011 Int. J. Appl. Ceram. Technol. 8 990

Google Scholar

Google Scholar

[16] Pethes I, Chahal R, Nazabal V, Prestipino C, Trapananti A, Michalik S, Jóvári P 2016 J. Phys. Chem. B 120 9204

Google Scholar

Google Scholar

[17] Golovchak R, Kovalskiy A, Miller A C, Jain H, Shpotyuk O 2007 Phys. Rev. B 76 125208

Google Scholar

Google Scholar

[18] Golovchak R, Shpotyuk O, Kozyukhin S, Kovalskiy A, Miller A C, Jain H 2009 J. Appl. Phys. 105 103704

Google Scholar

Google Scholar

[19] Kondrat O, Holomb R, Csik A, Takats V, Veres M, Mitsa V 2017 Nanoscale Res. Lett. 12 149

Google Scholar

Google Scholar

[20] Xu S W, Wang R P, Luther-Davies B, Kovalskiy A, Miller A C, Jain H 2014 J. Appl. Phys. 115 083518

Google Scholar

Google Scholar

[21] 许思维, 王丽, 沈祥 2015 64 223302

Google Scholar

Google Scholar

Xu S W, Wang L, Shen X 2015 Acta Phys. Sin. 64 223302

Google Scholar

Google Scholar

[22] Golovchak R, Calvez L, Petracovschi E, Bureau B, Savitskii D, Jain H 2013 Mater. Chem. Phys. 138 909

Google Scholar

Google Scholar

[23] Kotsalas I P, Papadimitriou D, Raptis C, Vlcek M, Frumar M 1998 J. Non-Cryst. Solids 226 85

Google Scholar

Google Scholar

[24] Wang K K, Wang W F, Lin C G, Shen X, Dai S X, Chen F F 2022 Ceram. Int. 48 11209

Google Scholar

Google Scholar

[25] Li Z B, Lin C G, Nie Q H, Dai S X 2013 J. Am. Ceram. Soc. 96 125

Google Scholar

Google Scholar

[26] Velmuzhov A P, Sukhanov M V, Tyurina E A, Plekhovich A D, Fadeeva D A, Ketkova L A, Churbanov M F, Shiryaev V S 2021 J. Non-Cryst. Solids 554 120615

Google Scholar

Google Scholar

[27] Li Z B, Lin C G, Nie Q H, Dai S X 2013 Appl. Phys. A 112 939

Google Scholar

Google Scholar

[28] Zhang W, Fu J, Shen X, Chen Y, Dai S X, Chen F, Li J, Xu T F 2013 J. Non-Cryst. Solids 377 191

Google Scholar

Google Scholar

[29] Rana A, Singh B P, Sharma R 2019 J. Non-Cryst. Solids 523 119597

Google Scholar

Google Scholar

[30] Niu L, Chen Y M, Shen X, Xu T F 2020 Chin. Phys. B 29 087803

Google Scholar

Google Scholar

[31] Wang X F, Gu S X, Yu J G, Zhao X J, Tao H Z 2004 J. Solid State Commun. 130 459

Google Scholar

Google Scholar

[32] Hannon A C, Aitken B G 1999 J. Non-Cryst. Solids 256–257 73

Google Scholar

Google Scholar

[33] Masselin P, Coq D L, Cuisset A, Bychkov E 2012 Opt. Mater. Express 2 1768

Google Scholar

Google Scholar

[34] Pauling L 1960 The Nature of the Chemical Bond (Ithaca: Cornell University Press) pp113–121

[35] Xu Q, Yang X Y, Zhang M J, Wang R P 2019 Mater. Res. Express 6 085212

Google Scholar

Google Scholar

[36] Golovchak R, Nazabal V, Bureau B, Oelgoetz J, Kovalskiy A, Jain H 2018 J. Non-Cryst. Solids 499 237

Google Scholar

Google Scholar

[37] Srivastava C P, Van De Vondel D F, Van Der Kelen G P 1977 Inorg. Chim. Acta 23 L29

Google Scholar

Google Scholar

[38] Pethes I, Nazabal V, Chahal R, Bureau B, Kaban I, Belin S, Jovari P 2016 J. Alloys Compd. 673 149

Google Scholar

Google Scholar

[39] Sun Y H, Zhang Z, Yang Z, Niu L, Wu J, Wei T X, Yan K L, Sheng Y, Wang X S, Wang R P 2021 Opt. Mater. Express 11 2413

Google Scholar

Google Scholar

-

表 1 拉曼散射光谱分峰拟合中各个结构单元的相对比例

Table 1. Relative ratio of the different structural units derived from the decomposed Raman scattering spectra.

S3Ge/Ga-Ga/GeS3

/%S3Ge-GeS3

/%Ge/GaS4

(v2)/%GeS4 (CS)

/%GeS4 (ES)

/%GaS4 (F2)

/%S3Ge-S-

GeS3

/%Sn chains

/%Ge24Ga8S68 0 0 9.43 50.76 12.79 15.31 8.89 2.82 Ge26.67Ga8S65.33 0 0 8.27 54.69 12.84 14.73 9.47 0 Ge29.6Ga8S62.4 4.98 8.52 7.48 47.36 12.22 11.21 8.23 0 Ge32Ga8S60 9.09 11.81 6.04 45.27 10.13 10.61 7.05 0 Ge36Ga8S56 15.89 13.31 4.62 43.71 8.31 9.01 5.15 0 表 2 GexGa8S92–x 玻璃的Ge 3d, Ga 3d 和S 2p 的XPS的拟合参数

Table 2. The fitting parameters for the decomposed Ge 3d, Ga 3d and S 2p spectra of GexGa8S92–x glasses.

Structural unit S-S-S S-S-Ge/Ga Ge/Ga -S-

Ge/GaGeS4 Ge-Ge/Ga-related

structureGaS4 Ga-Ge/Ga-

related

structureGe24Ga8S68 BE/eV 163.13 162.26 161.66 30.51 — 19.87 19.56 FWHM/eV 1.11 1.03 1.13 1.17 0.98 0.98 Content/% 4.98 19.17 75.85 100 72.25 27.75 Ge26.67Ga8S65.33 BE/eV — 162.13 161.58 30.44 — 19.86 19.58 FWHM/eV 1.12 1.08 1.13 1.02 1.18 Content/% 11.97 88.03 100 61.94 38.06 Ge29.6Ga8S62.4 BE/eV — 162.25 161.69 30.56 29.61 19.88 19.56 FWHM/eV 1.17 1.09 1.11 1.11 1.05 1.06 Content/% 5.54 94.46 85.41 14.59 53.41 46.59 Ge32Ga8S60 BE/eV — — 161.58 30.58 29.81 19.89 19.51 FWHM/eV 1.09 1.08 0.99 0.89 0.86 Content/% 100 80.98 19.02 44.05 55.95 Ge36Ga8S56 BE/eV — — 161.66 30.49 29.72 19.83 19.49 FWHM/eV 1.16 1.07 1.11 0.87 0.89 Content/% 100 73.26 26.74 39.53 60.47 -

[1] Wang R P 2014 Amorphous Chalcogenides: Advances and Applications (Singapore: Pan Stanford Publisher) pp178–193

[2] Tanaka K, Shimakawa K 2011 Amorphous Chalcogenide Semiconductors and Related Materials (New York: Springer International Publishing) pp115–135

[3] 许思维, 杨晓宁, 杨大鑫, 王训四, 沈祥 2021 70 167101

Google Scholar

Google Scholar

Xu S W, Yang X N, Yang D X, Wang X S, Shen X 2021 Acta Phys. Sin. 70 167101

Google Scholar

Google Scholar

[4] Choi D Y, Madden S, Rode A, Wang R P, Luther-Davies B 2007 Appl. Phys. Lett. 91 011115

Google Scholar

Google Scholar

[5] Kim Y, Saienga J, Martin S W 2006 J. Phys. Chem. B 110 16318

Google Scholar

Google Scholar

[6] 张兴迪, 吴越豪, 杨正胜, 戴世勋, 张培晴, 张巍, 徐铁锋, 张勤远 2016 65 144205

Google Scholar

Google Scholar

Zhang X D, Wu Y H, Yang Z S, Dai S X, Zhang P Q, Zhang W, Xu T F, Zhang Q Y 2016 Acta Phys. Sin. 65 144205

Google Scholar

Google Scholar

[7] 汪俊, 冯赞, 吴国林, 汪金晶, 焦凯, 王弦歌, 刘佳, 梁晓林, 徐铁松, 钟明辉, 肖晶, 赵浙明, 刘自军, 刘永兴, 王训四 2020 发光学报 41 1343

Google Scholar

Google Scholar

Wang J, Feng Z, Wu G L, Wang J J, Jiao K, Wang X G, Liu J, Liang X L, Xu T S, Zhong M H, Xiao J, Zhao Z M, Liu Z J, Liu Y X, Wang X S 2020 Chin. J. Lumin. 41 1343

Google Scholar

Google Scholar

[8] 戴世勋, 彭波, 乐放达, 王训四, 沈祥, 徐铁峰, 聂秋华 2010 59 3547

Google Scholar

Google Scholar

Dai S X, Peng B, Le F D, Wang X S, Shen X, Xu T F, Nie Q H 2010 Acta Phys. Sin. 59 3547

Google Scholar

Google Scholar

[9] 任晶, 卢小送, 王鹏飞 2019 光子学报 48 1148007

Google Scholar

Google Scholar

Ren J, Lu X S, Wang P F 2019 Acta Photonica Sin. 48 1148007

Google Scholar

Google Scholar

[10] Yang Z, Wang R P, Chen Y M, Li Q L, Shen X, Xu T F 2020 Opt. Mater. 100 109677

Google Scholar

Google Scholar

[11] Ren J, Wagner T, Bartos M, Frumar M, Oswald J, Kincl M, Frumarova B, Chen G R 2011 J. Appl. Phys. 109 033105

Google Scholar

Google Scholar

[12] Golovchak R, Shpotyuk O, Kozyukhin S, Shpotyuk M, Kovalskiy A, Jain H 2011 J. Non-Cryst. Solids 357 1797

Google Scholar

Google Scholar

[13] Zhu E W, Liu Y X, Sun X, Yin G L, Jiao Q, Dai S X, Lin C G 2019 J. Non-Cryst. Solids 1 100015

Google Scholar

Google Scholar

[14] Bureau B, Troles J, Floch M L, Guenot P, Smektala F, Lucas J 2003 J. Non-Cryst. Solids 319 145

Google Scholar

Google Scholar

[15] Nazabal V, Charpentier F, Adam J L, Nemec P, Lhermite H, Anne M L B, Charrier J, Guin J P, Moréac A 2011 Int. J. Appl. Ceram. Technol. 8 990

Google Scholar

Google Scholar

[16] Pethes I, Chahal R, Nazabal V, Prestipino C, Trapananti A, Michalik S, Jóvári P 2016 J. Phys. Chem. B 120 9204

Google Scholar

Google Scholar

[17] Golovchak R, Kovalskiy A, Miller A C, Jain H, Shpotyuk O 2007 Phys. Rev. B 76 125208

Google Scholar

Google Scholar

[18] Golovchak R, Shpotyuk O, Kozyukhin S, Kovalskiy A, Miller A C, Jain H 2009 J. Appl. Phys. 105 103704

Google Scholar

Google Scholar

[19] Kondrat O, Holomb R, Csik A, Takats V, Veres M, Mitsa V 2017 Nanoscale Res. Lett. 12 149

Google Scholar

Google Scholar

[20] Xu S W, Wang R P, Luther-Davies B, Kovalskiy A, Miller A C, Jain H 2014 J. Appl. Phys. 115 083518

Google Scholar

Google Scholar

[21] 许思维, 王丽, 沈祥 2015 64 223302

Google Scholar

Google Scholar

Xu S W, Wang L, Shen X 2015 Acta Phys. Sin. 64 223302

Google Scholar

Google Scholar

[22] Golovchak R, Calvez L, Petracovschi E, Bureau B, Savitskii D, Jain H 2013 Mater. Chem. Phys. 138 909

Google Scholar

Google Scholar

[23] Kotsalas I P, Papadimitriou D, Raptis C, Vlcek M, Frumar M 1998 J. Non-Cryst. Solids 226 85

Google Scholar

Google Scholar

[24] Wang K K, Wang W F, Lin C G, Shen X, Dai S X, Chen F F 2022 Ceram. Int. 48 11209

Google Scholar

Google Scholar

[25] Li Z B, Lin C G, Nie Q H, Dai S X 2013 J. Am. Ceram. Soc. 96 125

Google Scholar

Google Scholar

[26] Velmuzhov A P, Sukhanov M V, Tyurina E A, Plekhovich A D, Fadeeva D A, Ketkova L A, Churbanov M F, Shiryaev V S 2021 J. Non-Cryst. Solids 554 120615

Google Scholar

Google Scholar

[27] Li Z B, Lin C G, Nie Q H, Dai S X 2013 Appl. Phys. A 112 939

Google Scholar

Google Scholar

[28] Zhang W, Fu J, Shen X, Chen Y, Dai S X, Chen F, Li J, Xu T F 2013 J. Non-Cryst. Solids 377 191

Google Scholar

Google Scholar

[29] Rana A, Singh B P, Sharma R 2019 J. Non-Cryst. Solids 523 119597

Google Scholar

Google Scholar

[30] Niu L, Chen Y M, Shen X, Xu T F 2020 Chin. Phys. B 29 087803

Google Scholar

Google Scholar

[31] Wang X F, Gu S X, Yu J G, Zhao X J, Tao H Z 2004 J. Solid State Commun. 130 459

Google Scholar

Google Scholar

[32] Hannon A C, Aitken B G 1999 J. Non-Cryst. Solids 256–257 73

Google Scholar

Google Scholar

[33] Masselin P, Coq D L, Cuisset A, Bychkov E 2012 Opt. Mater. Express 2 1768

Google Scholar

Google Scholar

[34] Pauling L 1960 The Nature of the Chemical Bond (Ithaca: Cornell University Press) pp113–121

[35] Xu Q, Yang X Y, Zhang M J, Wang R P 2019 Mater. Res. Express 6 085212

Google Scholar

Google Scholar

[36] Golovchak R, Nazabal V, Bureau B, Oelgoetz J, Kovalskiy A, Jain H 2018 J. Non-Cryst. Solids 499 237

Google Scholar

Google Scholar

[37] Srivastava C P, Van De Vondel D F, Van Der Kelen G P 1977 Inorg. Chim. Acta 23 L29

Google Scholar

Google Scholar

[38] Pethes I, Nazabal V, Chahal R, Bureau B, Kaban I, Belin S, Jovari P 2016 J. Alloys Compd. 673 149

Google Scholar

Google Scholar

[39] Sun Y H, Zhang Z, Yang Z, Niu L, Wu J, Wei T X, Yan K L, Sheng Y, Wang X S, Wang R P 2021 Opt. Mater. Express 11 2413

Google Scholar

Google Scholar

计量

- 文章访问数: 6283

- PDF下载量: 75

- 被引次数: 0

下载:

下载: