-

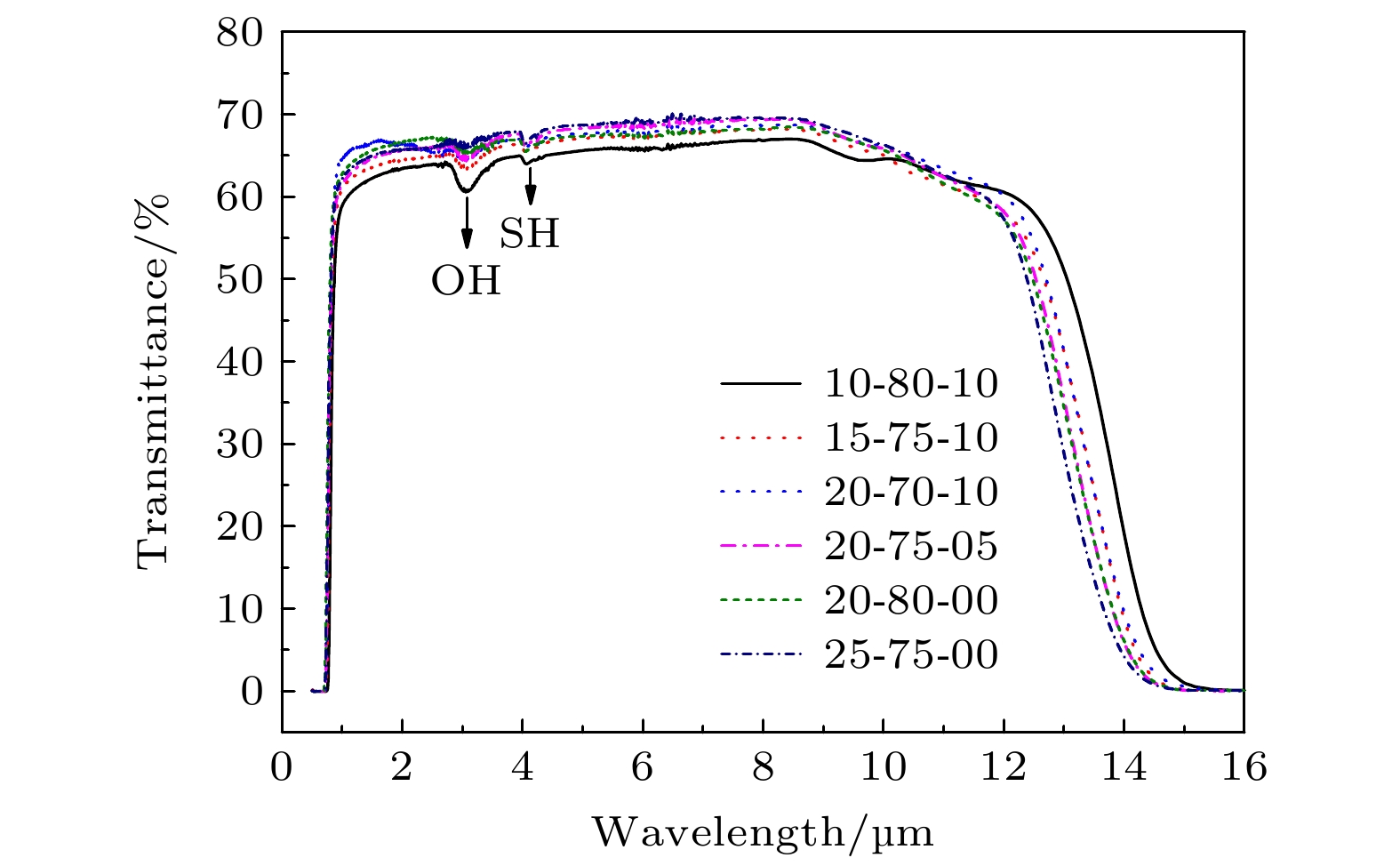

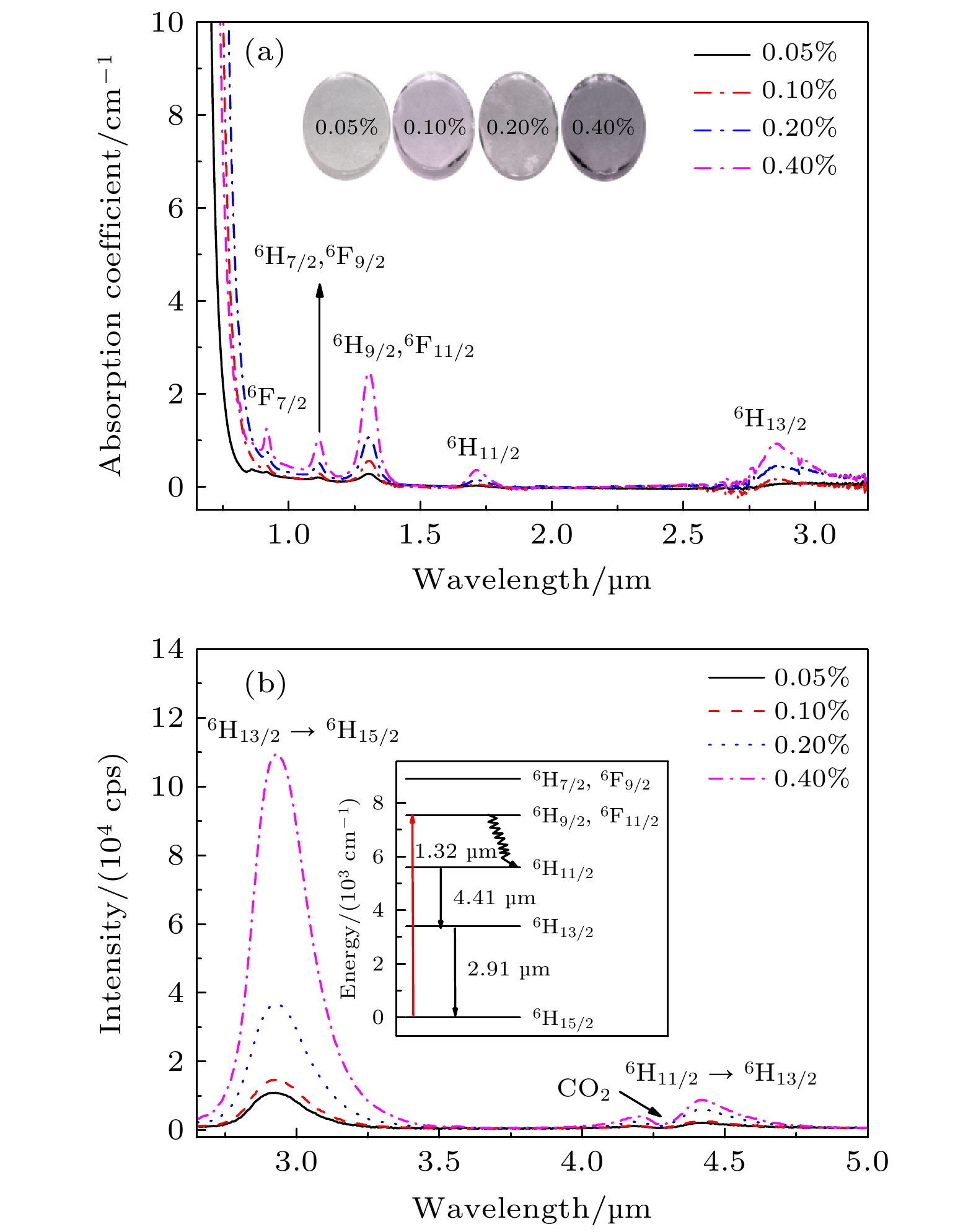

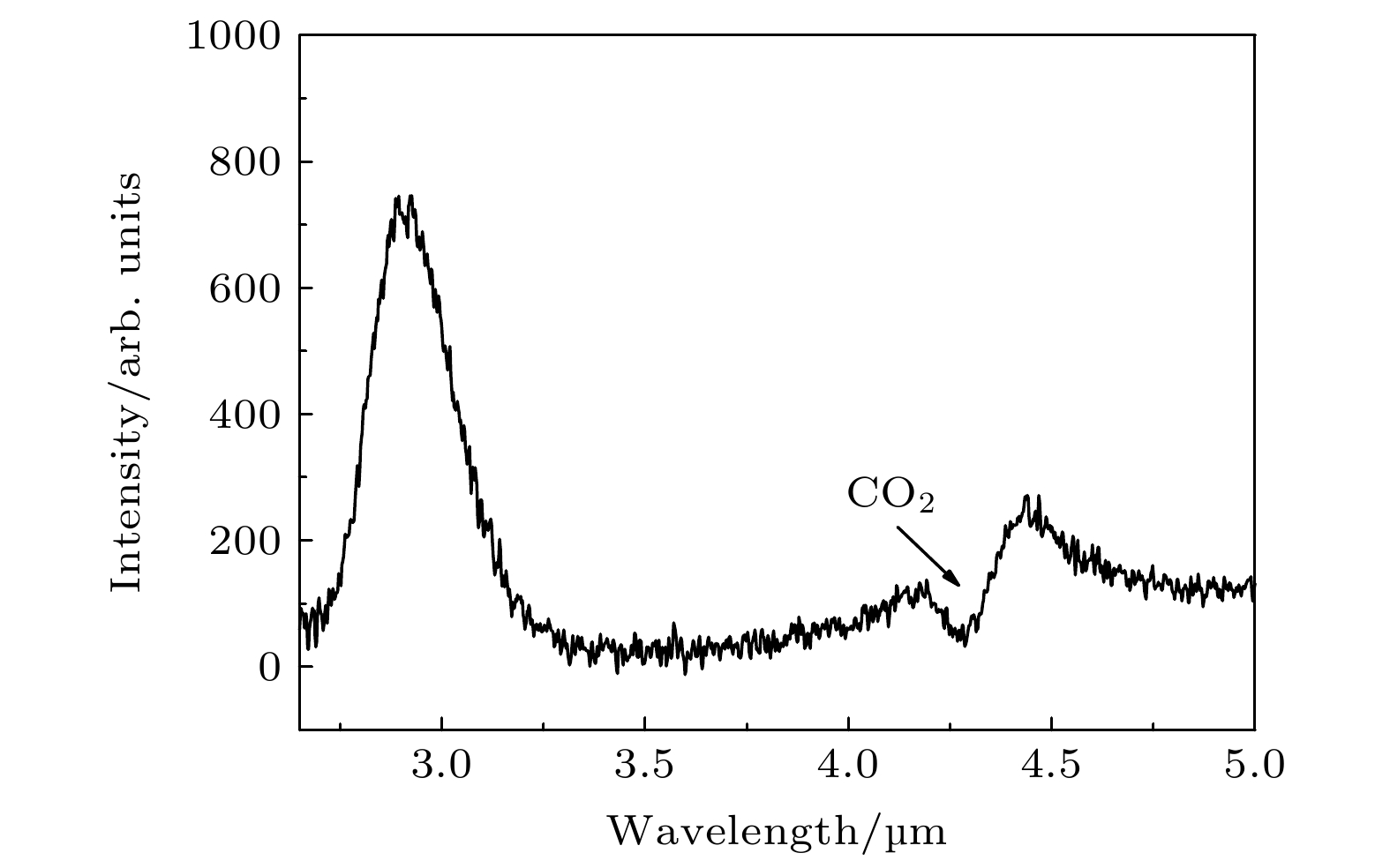

本工作确定了一种新型的Ga2S3-Sb2S3-Ag2S硫系玻璃体系的玻璃形成区, 研究了玻璃的热稳定性和光学性能、稀土离子掺杂玻璃的中红外发光特性以及玻璃的成纤性能, 评估了该玻璃在中红外波段的应用潜力. 实验结果表明, Ga2S3-Sb2S3-Ag2S体系的玻璃形成区为 ~10%—30% Ga2S3, ~60%—80% Sb2S3和~0—15% Ag2S(均为摩尔分数); 该玻璃具有较宽的红外透过范围 (~0.8—13.5 μm)、较高的线性折射率 (~2.564—2.713@10 μm)和较大的三阶非线性折射率 (~9.7×10–14—15.7×10–14 cm2/W @1.55 μm); 使用1.32 µm激光抽运, 稀土离子Dy3+在该玻璃中表现出较强的2.91 μm和4.41 μm中红外发射, 发射量子效率分别达76.6%和70.8%; 拉制的 20Ga2S3-75Sb2S3-5Ag2S: Dy3+(质量分数为0.05%)/20Ga2S3-70Sb2S3-10Ag2S (纤芯/包层)光纤在2—8 μm具有良好的传输性能, 最低损耗为~3.5 dB/m (@5.7 μm). 这些优异的性能使得该玻璃或光纤有望应用于红外热成像、非线性光学、中红外光纤激光器等领域.With the rapid development of infrared technology and the wide applications of infrared optical components, the demand for infrared optical materials has risen significantly. Chalcogenide glass has been considered as one of the most popular infrared optical materials because of its wide infrared transmission range, high refractive index, low phonon energy, good rheological properties, low cost, etc. In this work, a new type of Ga2S3-Sb2S3-Ag2S chalcogenide glass system is reported, and its glass forming domain is determined. The thermal stability and optical property, mid-infrared (MIR) emission of rare earth dopant, and fiber-forming property for the glasses are studied. The potential applications of the glasses in the MIR region are also evaluated. The experimental results show that the Ga2S3-Sb2S3-Ag2S system has a glass forming domain of ~10%–30% Ga2S3, ~60%–80% Sb2S3 and ~0–15% Ag2S (all in molar percentage). These glasses have a wide infrared transmission range of ~0.8–13.5 μm, relatively high linear refractive indices of~2.564–2.713 (at 10 μm), and relatviely large third-order nonlinear refractive indices of ~9.7×10–14–15.7×10–14 cm2/W (at 1.55 μm). These excellent properties make the Ga2S3-Sb2S3-Ag2S glass promising material in the fields of infrared thermal imaging and nonlinear optics. Under the excitation of 1.32 µm laser, the rare earth dopant Dy3+ shows strong 2.91 μm and 4.41 μm MIR emissions in the glass. According to the J-O theory, the three strength parameters (Ω2, Ω4, Ω6) of Dy3+ in 0.05% weight of Dy3+ doped 20Ga2S3-75Sb2S3-5Ag2S glass are 7.38×10–20 cm2, 2.24×10–20 cm2 and 0.75×10–20 cm2, respectively. The quantum efficiencies of the 2.91 μm and 4.41 μm emissions are calculated to be 76.6% and 70.8%, respectively, while the stimulated emission cross sections of those two bands are 1.27×10–20 cm2 and 1.43×10–20 cm2, respectively. The fiber based on 20Ga2S3-75Sb2S3-5Ag2S: 0.05% Dy3+ core glass and 20Ga2S3-70Sb2S3-10Ag2S cladding glass is fabricated by rod tube method. The fiber has good transmission performance in the 2–8 μm wavelength range, and the minimum loss is ~3.5 dB/m at 5.7 μm. The Dy3+ ions show intense 2.93 μm and 4.45 μm MIR emissions in the fibers under 1.32 μm excitation. These results indicate that the Dy3+ doped Ga2S3-Sb2S3-Ag2S glass fiber can be a promising candidate for MIR fiber laser medium.

-

Keywords:

- chalcogenide glasses /

- fiber /

- mid-infrared /

- rare earth doping

[1] Cai D W, Xie Y, Guo X, Wang P, and Tong L M 2021 Photonics 8 497

Google Scholar

Google Scholar

[2] Karami E, Tavoosi M, Ghasemi A, Loghmanestarki M R 2019 Ceram. Int. 45 7956

Google Scholar

Google Scholar

[3] Zhang L F, Guan F, Zhang L, Jiang Y G 2022 Opt. Mater. Express 12 1683

Google Scholar

Google Scholar

[4] Zhu J Q, Zhu H, Xu H L, Weng Z P, Wu H Z 2018 Infrared Phys. Technol. 92 13

Google Scholar

Google Scholar

[5] Shiryaev V S, Churbanov M F 2017 J. Non-Cryst. Solids 475 1

Google Scholar

Google Scholar

[6] Gui Y M, Guan Y N, Zhang X S, Zhang C Q, Xia K L, He L, Shen X, Liu Z J 2022 Opt. Express 30 21491

Google Scholar

Google Scholar

[7] Liu L T, Chen F Y, Cui J, Xiao X S, Xu Y T, Hou C Q, Cui X X, Guo H T 2021 Ceram. Int. 47 6388

Google Scholar

Google Scholar

[8] Lucas P, Yang Z Y, Fah M K, Luo T, Jiang S B, Boussard-Pledel C, Anne M-L, and Bureau B 2013 Opt. Mater. Express 3 1049

Google Scholar

Google Scholar

[9] Zhang X H, Bureau B, Lucas P, Boussard-Pledel C, Lucas J 2008 Chemistry 14 432

Google Scholar

Google Scholar

[10] 田康振, 胡永胜, 任和, 祁思胜, 杨安平, 冯宪, 杨志勇 2021 70 047801

Google Scholar

Google Scholar

Tian K Z, Hu Y S, Ren H, Qi S S, Yang A P, Feng X, Yang Z Y 2021 Acta Phys. Sin. 70 047801

Google Scholar

Google Scholar

[11] Li R, Zhou W J, Zhou C F, Qi Q Y, Li Y W, Yang Y T, Zhang W, Zhang P Q, Dai S X, Xu T F 2022 Ceram. Int. 48 7956

[12] Yang A P, Zhang M J, Li L, Wang Y W, Zhang B, Yang Z Y, Tang D Y 2016 J. Am. Ceram. S℃. 99 12

Google Scholar

Google Scholar

[13] Huang X Y, Jiao Q, Lin C G, Ma H L, Zhang X H, Zhu E W, Liu X Y, Dai S X, Xu T F 2018 Sci. Rep. 8 1699

Google Scholar

Google Scholar

[14] Qiu J H, Yang A P, Zhang M J, Li L, Zhang B, Yang Z Y, Tang D Y 2017 J. Am. Ceram. Soc. 100 5107

Google Scholar

Google Scholar

[15] Yang A P, Qiu J H, Zhang M J, Ren H, Zhai C C, Qi S S, Zhang B, Tang D Y, Yang Z Y 2017 J. Alloys Compd. 695 1237

Google Scholar

Google Scholar

[16] Sun M Y, Yang A P, Zhang X H, Ma H L, Zhang M J, Tian K Z, Feng X, Yang Z Y 2019 J. Am. Ceram. Soc. 102 6600

Google Scholar

Google Scholar

[17] 杨安平, 王雨伟, 张少伟, 李兴隆, 杨志杰, 李耀程, 杨志勇 2019 68 017801

Google Scholar

Google Scholar

Yang A P, Wang Y W, Zhang S W, Li X L, Yang Z J, Li Y C, Yang Z Y 2019 Acta Phys. Sin. 68 017801

Google Scholar

Google Scholar

[18] Yang Y, Yang Z Y, Lucas P, Wang Y W, Yang Z J, Yang A P, Zhang B, Tao H Z 2016 J. Non-Cryst. Solids 440 38

Google Scholar

Google Scholar

[19] Zhang M J, Li L, Li T T, Wang F, Tian K Z, Tao H Z, Feng X, Yang A P, Yang Z Y 2019 Opt. Express 27 29287

Google Scholar

Google Scholar

[20] 张鸣杰, 杨安平, 张斌, 任和, 郭威, 杨艳, 翟诚诚, 王雨伟, 杨志勇, 唐定远 2015 中国激光 42 08060001

Zhang M J, Yang A P, Zhang B, Ren H, Guo W, Yang Y, Zhai C C, Wang Y W, Yang Z Y, Tang D Y 2015 Chin. J. Lasers 42 08060001

[21] Zhang M J, Yang Z Y, Zhao H, Yang A P, Li L, Tao H Z 2017 J. Alloys Compd. 722 166

Google Scholar

Google Scholar

[22] Wang T, Gai X, Wei W H, Wang R P, Yang Z Y, Shen X, Madden S, Luther-Davies B 2014 Opt. Mater. Express 4 1011

Google Scholar

Google Scholar

[23] Boyd R, Masters B 2009 J. Biomed. Opt. 14 029902

Google Scholar

Google Scholar

[24] Yang Z Y, Li B T, He F, Luo L, Chen W 2008 J. Non-Cryst. Solids 354 1198

Google Scholar

Google Scholar

[25] Shiryaev V S, Sukhanov M V, Velmuzhov A P, Karaksina E V, Kotereva T V, Snopatin G E, Denker B I, Galagan B I, Sverchkov S E, Koltashev V V, Plotnichenko V G 2021 J. Non-Cryst. Solids 567 120939

Google Scholar

Google Scholar

[26] Shiryaev V S, Velmuzhov A P, Tang Z Q, Churbanov M F, Seddon A B 2014 Opt. Mater. 37 18

Google Scholar

Google Scholar

[27] 郭威, 张斌, 翟诚诚, 祁思胜, 余懿, 杨安平, 李雷, 杨志勇, 王荣平, 唐定远, 陶光明, Luther-Davies Barry 2016 无机材料学报 31 180

Google Scholar

Google Scholar

Guo W, Zhang B, Zhai C C, Qi S S, Yu Y, Yang A P, Li L, Yang Z Y, Wang R P, Tang D Y, Tao G M, Luther-Davies B 2016 J. Inorg. Mater. 31 180

Google Scholar

Google Scholar

[28] Tichy L, Ticha H 1995 J. Non-Cryst. Solids 189 141

Google Scholar

Google Scholar

[29] Luo Y R 2007 Comprehensive Handbook of Chemical Bond Energies (Boca Raton: CRC Press) p1687

[30] Dean J A 1998 Lange's handbook of chemistry (New York: McGraw-Hill Professional) p1561

[31] Fraenkl M, Frumarova B, Podzemna V, Slang S, Benes L, Vlcek M, Wagner T 2018 J. Non-Cryst. Solids 499 412

Google Scholar

Google Scholar

[32] Ma B C, Jiao Q, Zhang Y T, Sun X, Yin G L, Zhang X H, Ma H L, Liu X Y, Dai S X 2020 Ceram. Int. 46 6544

Google Scholar

Google Scholar

[33] Yang Z Y, Luo L, Chen W 2006 J. Am. Ceram. Soc. 89 2327

[34] 崔茂林 1987 玻璃工艺学(北京: 中国轻工业出版社) 第140—153页

Cui M L 1987 Glass Technology (Beijing: Light Industry Press) pp140–153 (in Chinese)

[35] Dimitrov V, Komatsu T 2010 J. Univ. Chem. Technol. Metall. 45 219

[36] Nakamoto K 2009 Infrared and Raman Spectra of Inorganic and Coordination Compounds (New York: John Wiley) pp419– 427

[37] Gleason B, Richardson K, Sisken L, Smith C 2016 Int. J. Appl. Glass Sci. 7 374

Google Scholar

Google Scholar

[38] Gai X, Choi D-Y, Madden S, Yang Z Y, Wang R P, Luther-Davies B 2012 Opt. Lett. 37 3870

Google Scholar

Google Scholar

[39] Choia Y G, Song J H 2009 J. Non-Cryst. Solids 355 48

[40] Judd B 1962 Phys. Rev. 127 750

Google Scholar

Google Scholar

[41] Ofelt G 1962 J. Chem. Phys. 37 511

Google Scholar

Google Scholar

[42] Chen D Q, Wang Y S, Yu Y L, Ma E, Hu Z J 2005 J. Phys. Condens. Matter 17 6545

Google Scholar

Google Scholar

[43] Yang A P, Sun M Y, Ren H, Lin H X, Feng X, Yang Z Y 2021 J. Lumin. 237 118169

Google Scholar

Google Scholar

[44] Zhang M J, Yang A P, Peng Y F, Zhang B, Ren H, Guo W, Yang Y, Zhai C C, Wang Y W, Yang Z Y, Tang D Y 2015 Mater. Res. Bull. 70 55

Google Scholar

Google Scholar

[45] Schweizer T, Hewak D W, Samson B N, Payne D N 1996 Opt. Lett. 21 1594

Google Scholar

Google Scholar

-

图 3 (a) Dy3+掺杂20Ga2S3-75Sb2S3-5Ag2S玻璃的吸收光谱, 插图是玻璃在940 nm红外相机下的照片; (b) 1.32 μm激光抽运时, Dy3+掺杂20Ga2S3-75Sb2S3-5Ag2S玻璃的2—5 μm发射光谱

Fig. 3. (a) Absorption spectra of Dy3+-doped 20Ga2S3-75Sb2S3-5Ag2S glasses, the inset shows photos of the glasses under a 940 nm infrared camera; (b) 2–5 μm emission spectra of Dy3+-doped 20Ga2S3-75Sb2S3-5Ag2S glasses under 1.32 μm laser excitation

表 1 xGa2S3-ySb2S3-zAg2S玻璃的特征温度

Table 1. Characteristic temperatures of xGa2S3-ySb2S3-zAg2S glasses.

x-y-z Tg (±1℃) Tx (±1℃) ΔT/℃ Series A 20-80-0 240 357 117 20-75-5 235 365 130 20-70-10 232 349 117 20-65-15 228 336 108 Series B 25-75-0 244 369 125 20-75-5 235 365 130 15-75-10 227 342 115 10-75-15 210 319 109 Series C 10-80-10 216 313 97 15-75-10 227 342 115 20-70-10 232 349 117 30-60-10 246 346 100 表 2 xGa2S3-ySb2S3-zAg2S玻璃的物理参数

Table 2. The physical parameters of xGa2S3-ySb2S3-zAg2S glasses.

x-y-z d/(g·cm–3) V/ (cm3·mol–1) λS/nm λ /μm n0 (@10 μm) Series A 20-80-0 4.09 15.60 729 13.71 2.6430 20-75-5 4.16 15.42 745 13.67 2.6380 20-70-10 4.23 15.26 751 13.63 2.6261 20-65-15 4.32 15.03 765 13.54 2.5990 Series B 25-75-0 4.06 15.46 741 13.53 2.6279 20-75-5 4.16 15.42 745 13.67 2.6380 15-75-10 4.26 15.32 760 13.80 2.6650 10-75-15 4.39 15.29 773 13.94 2.6970 Series C 10-80-10 4.30 15.51 785 13.97 2.7130 15-75-10 4.26 15.32 760 13.80 2.6650 20-70-10 4.23 15.26 751 13.63 2.6261 30-60-10 4.15 15.03 750 13.36 2.5641 表 3 xGa2S3-ySb2S3-zAg2S 玻璃在1.55 μm波长的n0和 n2

Table 3. n0 and n2 of xGa2S3-ySb2S3-zAg2S glasses at 1.55 μm.

x-y-z n0 (@1.55 μm) n2/ (10–14 cm2·W–1) 10-80-10 2.7802 15.7 15-75-10 2.7748 14.0 20-80-00 2.7516 12.4 20-75-05 2.7370 11.1 20-70-10 2.7255 10.6 25-75-00 2.6887 9.7 表 4 Dy3+ 在20 Ga2S3-75 Sb2S3-5 Ag2S玻璃中的辐射参数, λ, β, τrad, τmea分别是发射波长、荧光分支比、能级辐射寿命和实测荧光寿命

Table 4. Radiative parameters of Dy3+ in 20 Ga2S3-75 Sb2S3-5 Ag2S glass, λ, β, τrad, τmea are emission wavelength, fluorescence branch ratio, radiative lifetime, and measured lifetime, respectively.

Transition λ/μm n0 β/% τrad/ms τmea/ms η/% σem/(10–20 cm) 6H11/2→6H13/2 4.41 2.70 20 2.74 1.94 70.8 1.43 6H13/2→6H15/2 2.91 2.71 80 4.95 3.79 76.6 1.27 -

[1] Cai D W, Xie Y, Guo X, Wang P, and Tong L M 2021 Photonics 8 497

Google Scholar

Google Scholar

[2] Karami E, Tavoosi M, Ghasemi A, Loghmanestarki M R 2019 Ceram. Int. 45 7956

Google Scholar

Google Scholar

[3] Zhang L F, Guan F, Zhang L, Jiang Y G 2022 Opt. Mater. Express 12 1683

Google Scholar

Google Scholar

[4] Zhu J Q, Zhu H, Xu H L, Weng Z P, Wu H Z 2018 Infrared Phys. Technol. 92 13

Google Scholar

Google Scholar

[5] Shiryaev V S, Churbanov M F 2017 J. Non-Cryst. Solids 475 1

Google Scholar

Google Scholar

[6] Gui Y M, Guan Y N, Zhang X S, Zhang C Q, Xia K L, He L, Shen X, Liu Z J 2022 Opt. Express 30 21491

Google Scholar

Google Scholar

[7] Liu L T, Chen F Y, Cui J, Xiao X S, Xu Y T, Hou C Q, Cui X X, Guo H T 2021 Ceram. Int. 47 6388

Google Scholar

Google Scholar

[8] Lucas P, Yang Z Y, Fah M K, Luo T, Jiang S B, Boussard-Pledel C, Anne M-L, and Bureau B 2013 Opt. Mater. Express 3 1049

Google Scholar

Google Scholar

[9] Zhang X H, Bureau B, Lucas P, Boussard-Pledel C, Lucas J 2008 Chemistry 14 432

Google Scholar

Google Scholar

[10] 田康振, 胡永胜, 任和, 祁思胜, 杨安平, 冯宪, 杨志勇 2021 70 047801

Google Scholar

Google Scholar

Tian K Z, Hu Y S, Ren H, Qi S S, Yang A P, Feng X, Yang Z Y 2021 Acta Phys. Sin. 70 047801

Google Scholar

Google Scholar

[11] Li R, Zhou W J, Zhou C F, Qi Q Y, Li Y W, Yang Y T, Zhang W, Zhang P Q, Dai S X, Xu T F 2022 Ceram. Int. 48 7956

[12] Yang A P, Zhang M J, Li L, Wang Y W, Zhang B, Yang Z Y, Tang D Y 2016 J. Am. Ceram. S℃. 99 12

Google Scholar

Google Scholar

[13] Huang X Y, Jiao Q, Lin C G, Ma H L, Zhang X H, Zhu E W, Liu X Y, Dai S X, Xu T F 2018 Sci. Rep. 8 1699

Google Scholar

Google Scholar

[14] Qiu J H, Yang A P, Zhang M J, Li L, Zhang B, Yang Z Y, Tang D Y 2017 J. Am. Ceram. Soc. 100 5107

Google Scholar

Google Scholar

[15] Yang A P, Qiu J H, Zhang M J, Ren H, Zhai C C, Qi S S, Zhang B, Tang D Y, Yang Z Y 2017 J. Alloys Compd. 695 1237

Google Scholar

Google Scholar

[16] Sun M Y, Yang A P, Zhang X H, Ma H L, Zhang M J, Tian K Z, Feng X, Yang Z Y 2019 J. Am. Ceram. Soc. 102 6600

Google Scholar

Google Scholar

[17] 杨安平, 王雨伟, 张少伟, 李兴隆, 杨志杰, 李耀程, 杨志勇 2019 68 017801

Google Scholar

Google Scholar

Yang A P, Wang Y W, Zhang S W, Li X L, Yang Z J, Li Y C, Yang Z Y 2019 Acta Phys. Sin. 68 017801

Google Scholar

Google Scholar

[18] Yang Y, Yang Z Y, Lucas P, Wang Y W, Yang Z J, Yang A P, Zhang B, Tao H Z 2016 J. Non-Cryst. Solids 440 38

Google Scholar

Google Scholar

[19] Zhang M J, Li L, Li T T, Wang F, Tian K Z, Tao H Z, Feng X, Yang A P, Yang Z Y 2019 Opt. Express 27 29287

Google Scholar

Google Scholar

[20] 张鸣杰, 杨安平, 张斌, 任和, 郭威, 杨艳, 翟诚诚, 王雨伟, 杨志勇, 唐定远 2015 中国激光 42 08060001

Zhang M J, Yang A P, Zhang B, Ren H, Guo W, Yang Y, Zhai C C, Wang Y W, Yang Z Y, Tang D Y 2015 Chin. J. Lasers 42 08060001

[21] Zhang M J, Yang Z Y, Zhao H, Yang A P, Li L, Tao H Z 2017 J. Alloys Compd. 722 166

Google Scholar

Google Scholar

[22] Wang T, Gai X, Wei W H, Wang R P, Yang Z Y, Shen X, Madden S, Luther-Davies B 2014 Opt. Mater. Express 4 1011

Google Scholar

Google Scholar

[23] Boyd R, Masters B 2009 J. Biomed. Opt. 14 029902

Google Scholar

Google Scholar

[24] Yang Z Y, Li B T, He F, Luo L, Chen W 2008 J. Non-Cryst. Solids 354 1198

Google Scholar

Google Scholar

[25] Shiryaev V S, Sukhanov M V, Velmuzhov A P, Karaksina E V, Kotereva T V, Snopatin G E, Denker B I, Galagan B I, Sverchkov S E, Koltashev V V, Plotnichenko V G 2021 J. Non-Cryst. Solids 567 120939

Google Scholar

Google Scholar

[26] Shiryaev V S, Velmuzhov A P, Tang Z Q, Churbanov M F, Seddon A B 2014 Opt. Mater. 37 18

Google Scholar

Google Scholar

[27] 郭威, 张斌, 翟诚诚, 祁思胜, 余懿, 杨安平, 李雷, 杨志勇, 王荣平, 唐定远, 陶光明, Luther-Davies Barry 2016 无机材料学报 31 180

Google Scholar

Google Scholar

Guo W, Zhang B, Zhai C C, Qi S S, Yu Y, Yang A P, Li L, Yang Z Y, Wang R P, Tang D Y, Tao G M, Luther-Davies B 2016 J. Inorg. Mater. 31 180

Google Scholar

Google Scholar

[28] Tichy L, Ticha H 1995 J. Non-Cryst. Solids 189 141

Google Scholar

Google Scholar

[29] Luo Y R 2007 Comprehensive Handbook of Chemical Bond Energies (Boca Raton: CRC Press) p1687

[30] Dean J A 1998 Lange's handbook of chemistry (New York: McGraw-Hill Professional) p1561

[31] Fraenkl M, Frumarova B, Podzemna V, Slang S, Benes L, Vlcek M, Wagner T 2018 J. Non-Cryst. Solids 499 412

Google Scholar

Google Scholar

[32] Ma B C, Jiao Q, Zhang Y T, Sun X, Yin G L, Zhang X H, Ma H L, Liu X Y, Dai S X 2020 Ceram. Int. 46 6544

Google Scholar

Google Scholar

[33] Yang Z Y, Luo L, Chen W 2006 J. Am. Ceram. Soc. 89 2327

[34] 崔茂林 1987 玻璃工艺学(北京: 中国轻工业出版社) 第140—153页

Cui M L 1987 Glass Technology (Beijing: Light Industry Press) pp140–153 (in Chinese)

[35] Dimitrov V, Komatsu T 2010 J. Univ. Chem. Technol. Metall. 45 219

[36] Nakamoto K 2009 Infrared and Raman Spectra of Inorganic and Coordination Compounds (New York: John Wiley) pp419– 427

[37] Gleason B, Richardson K, Sisken L, Smith C 2016 Int. J. Appl. Glass Sci. 7 374

Google Scholar

Google Scholar

[38] Gai X, Choi D-Y, Madden S, Yang Z Y, Wang R P, Luther-Davies B 2012 Opt. Lett. 37 3870

Google Scholar

Google Scholar

[39] Choia Y G, Song J H 2009 J. Non-Cryst. Solids 355 48

[40] Judd B 1962 Phys. Rev. 127 750

Google Scholar

Google Scholar

[41] Ofelt G 1962 J. Chem. Phys. 37 511

Google Scholar

Google Scholar

[42] Chen D Q, Wang Y S, Yu Y L, Ma E, Hu Z J 2005 J. Phys. Condens. Matter 17 6545

Google Scholar

Google Scholar

[43] Yang A P, Sun M Y, Ren H, Lin H X, Feng X, Yang Z Y 2021 J. Lumin. 237 118169

Google Scholar

Google Scholar

[44] Zhang M J, Yang A P, Peng Y F, Zhang B, Ren H, Guo W, Yang Y, Zhai C C, Wang Y W, Yang Z Y, Tang D Y 2015 Mater. Res. Bull. 70 55

Google Scholar

Google Scholar

[45] Schweizer T, Hewak D W, Samson B N, Payne D N 1996 Opt. Lett. 21 1594

Google Scholar

Google Scholar

计量

- 文章访问数: 5508

- PDF下载量: 69

- 被引次数: 0

下载:

下载: