-

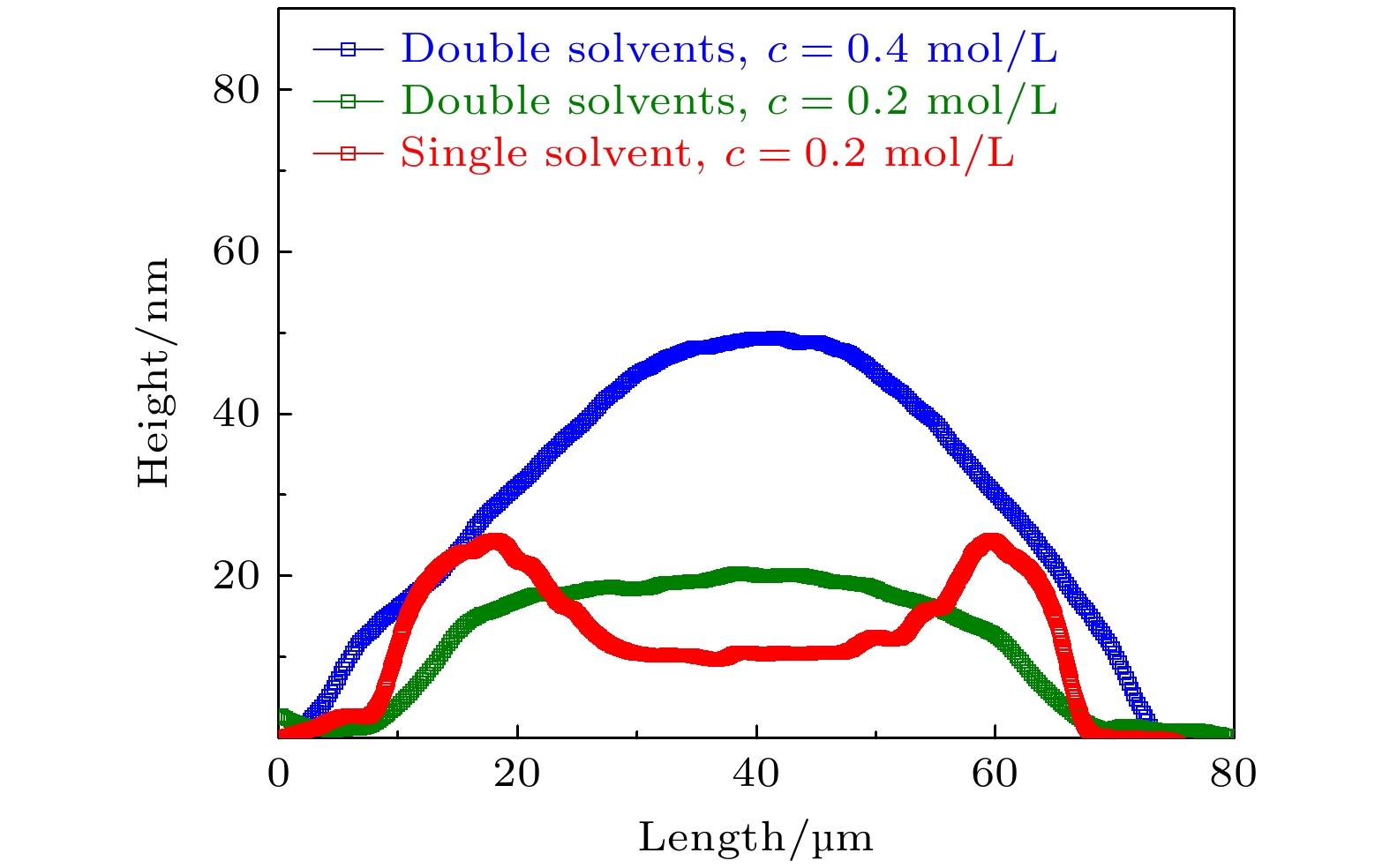

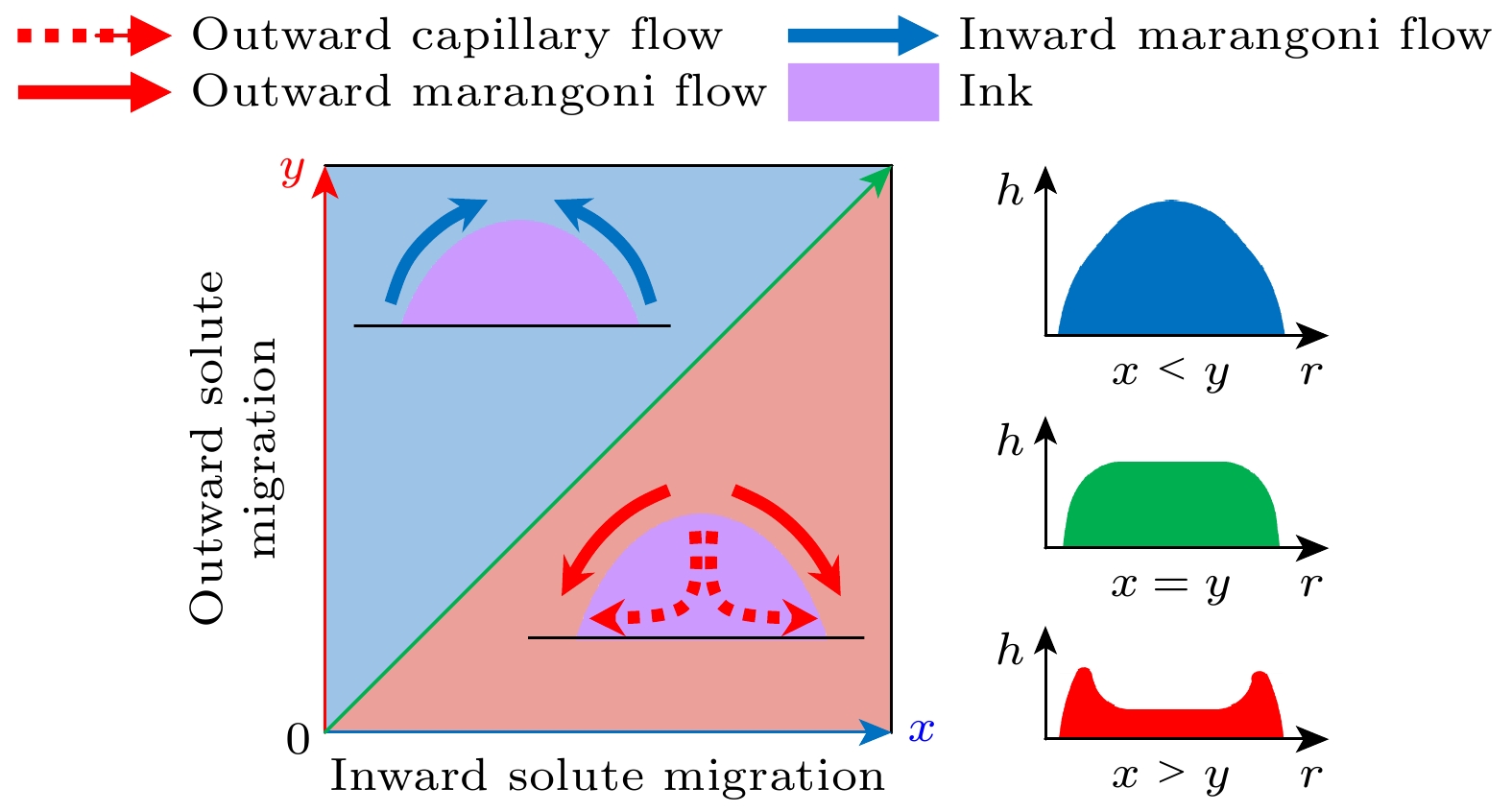

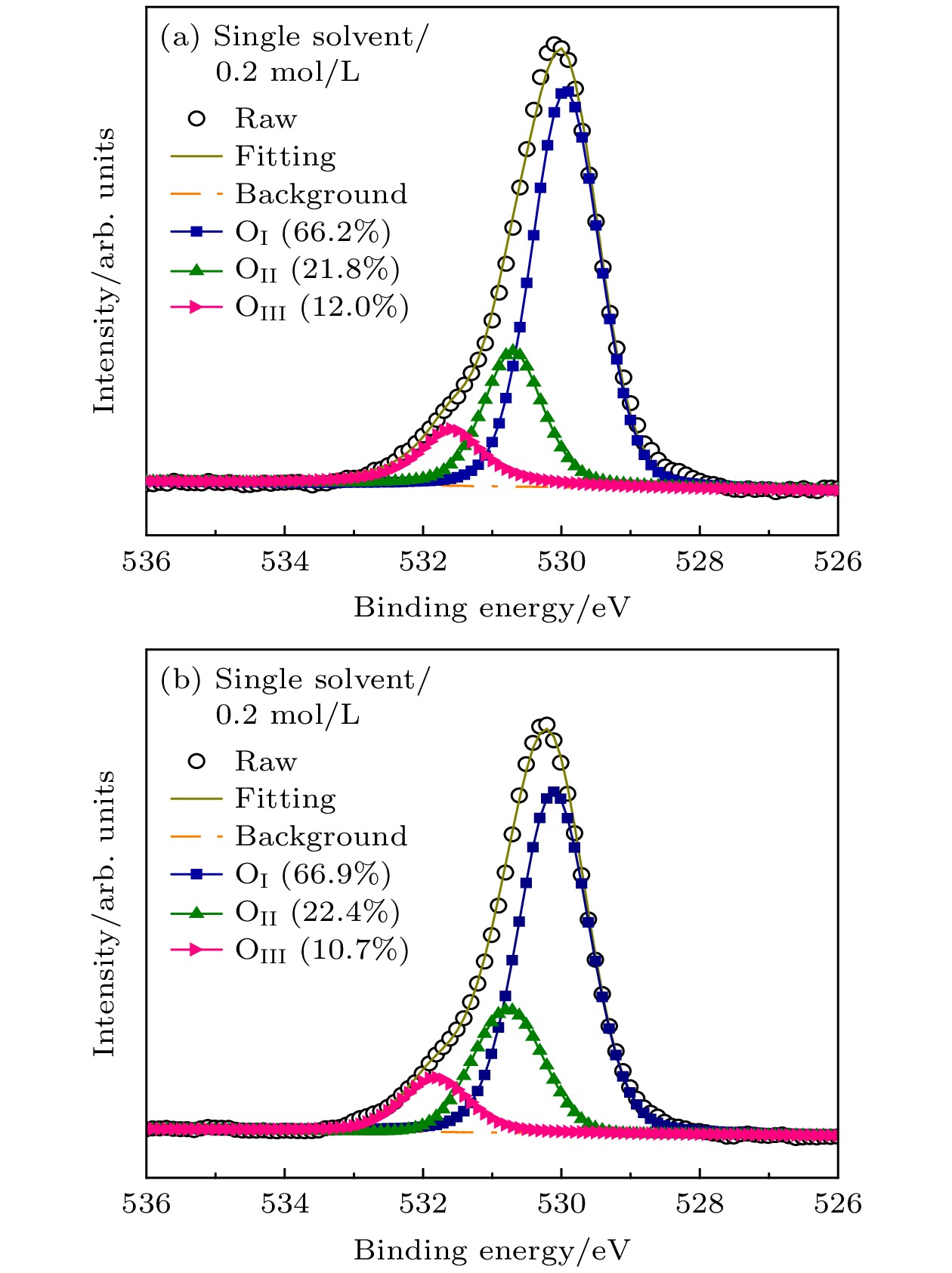

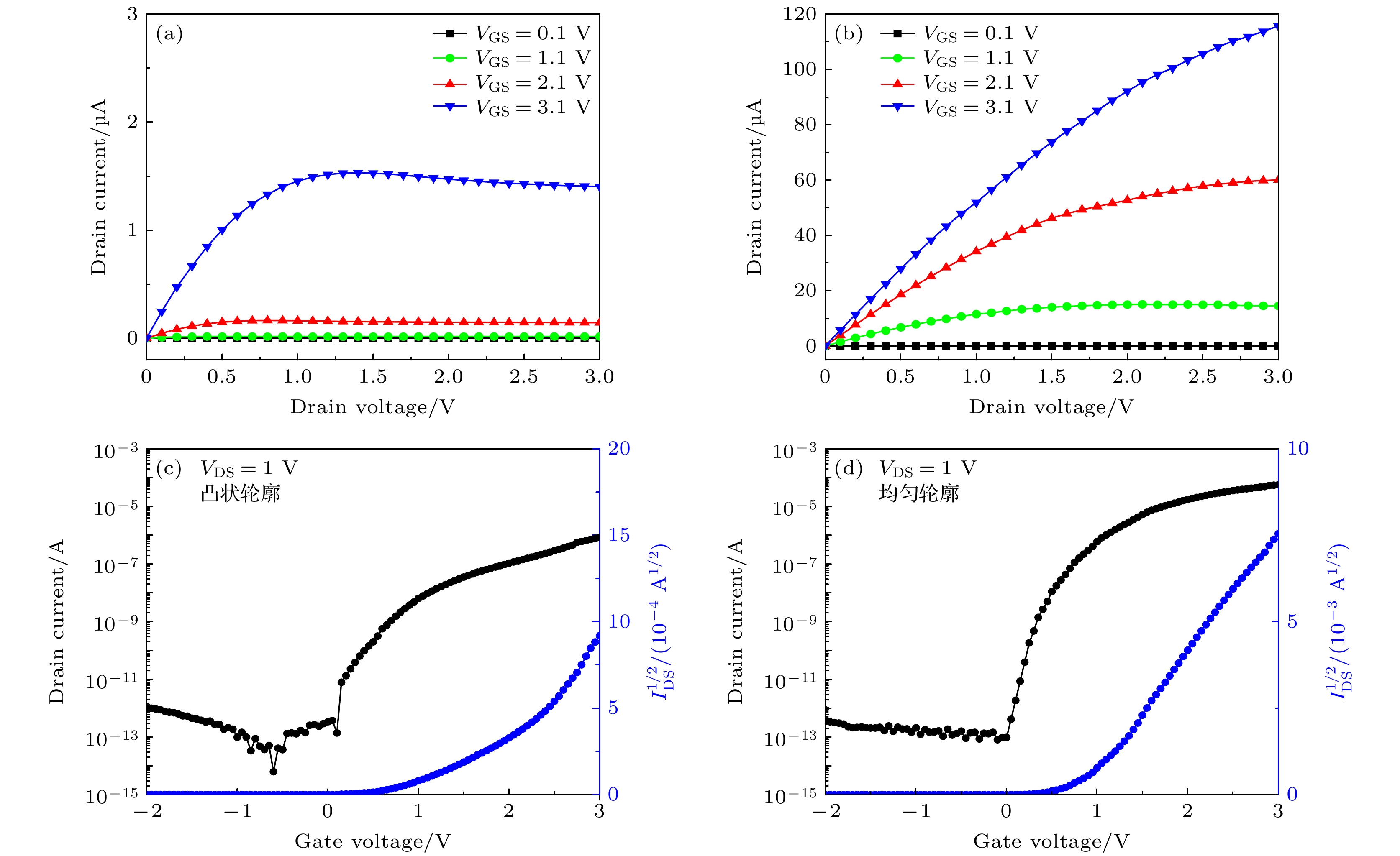

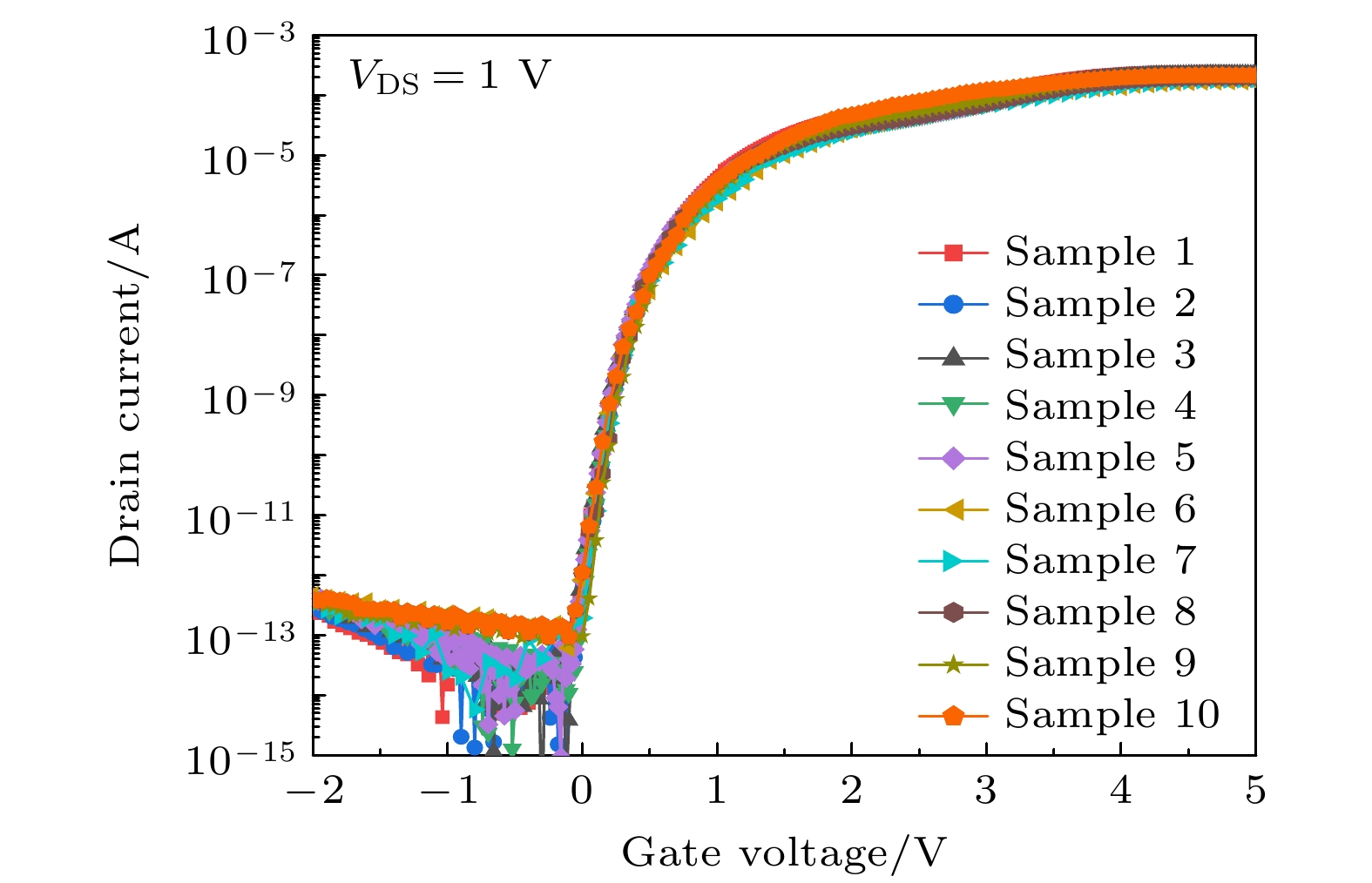

采用喷墨打印工艺制备了铟锌锡氧化物(indium-zinc-tin-oxide, IZTO)半导体薄膜, 并应用于底栅顶接触结构薄膜晶体管(thin-film transistor, TFT). 研究了墨水的溶剂成分以及溶质浓度对打印薄膜图案轮廓的影响. 结果表明二元溶剂IZTO墨水中乙二醇溶剂可有效平衡溶质向内的马兰戈尼回流与向外的毛细管流, 避免了单一溶剂墨水下溶质流动不平衡造成IZTO薄膜的咖啡环状沉积轮廓图案, 获得均匀平坦的薄膜图案轮廓和良好接触特性, 接触电阻为820 Ω, 优化后IZTO TFT器件的饱和迁移率达到16.6 cm2/(V·s), 阈值电压为0.84 V, 开关比高达3.74×109, 亚阈值摆幅为0.24 V/dec. 通过打印薄膜凝胶化模型解释了IZTO墨水溶剂成分、溶质浓度与最终薄膜形貌的关系.Metal oxide thin film transistor has been widely used in flat panel display industry because of its low leakage current, high mobility and large area uniformity. Besides, with the development of printed display technology, inkjet printing process can fabricate the customizable patterns on diverse substrates with no need of vacuum or lithography to be used, thus significantly reducing cost and receiving more and more attention. In this paper, we use inkjet printing technology to prepare a bottom gate bottom contact thin film transistor (TFT) by using indium-zinc-tin-oxide (IZTO) semiconductor. The surface morphology of the printed IZTO film is modified by adjusting the solvent composition and solute concentration of the printing precursor ink. The experimental result show that the use of binary solvents can effectively overcome the coffee ring shape caused by the accumulation of solute edge in the volatilization process of a single solvent, ultimately presenting a uniform and flat contour surface. Further increase in solute concentration is in favor of formation of convex surface topology. The reason for the formation of the flat surface of the oxide film is the balance between the inward Marangoni reflux of the solute and the outward capillary flow during volatilization. In addition, IZTO thin film transistor printed with binary solvents exhibits excellent electrical properties. The ratio of width/length = 50/30 exhibits a high on-off ratio of 1.21×109, a high saturation field-effect mobility is 16.6 cm2/(V·s), a low threshold voltage is 0.84 V, and subthreshold swing is 0.24 V/dec. The uniform and flat active layer thin film pattern can form good contact with the source leakage electrode, and the contact resistances of TFT devices with different width-to-length ratios are less than 1000 Ω, which can reach the basic conditions of high mobility thin film transistors prepared by inkjet printing. Therefore, using solvent mixture provides a universal and simple way to print oxide films with required surface topology, and present a visible path for inkjet printing of high-mobility thin film transistors.

[1] 荆斌, 徐萌, 彭聪, 陈龙龙, 张建华, 李喜峰 2022 71 138502

Google Scholar

Google Scholar

Jing B, Xu M, Peng C, Chen L L, Zhang J H, Li X F 2022 Acta Phys. Sin. 71 138502

Google Scholar

Google Scholar

[2] Chu S, Hollberg L, Bjorkholm J E, Bolot S, Fuchs P, Knobelspies S, Temel O, Sevilla G T, Gilshtein E, Andres C, Shorubalko I, Liu Y, Troester G, Tiwari A A N, Romanyuk Y E 2019 Adv. Electron. Mater. 5 1800843

Google Scholar

Google Scholar

[3] Song O, Rhee D, Kim J, Jeon Y, Mazánek V, Söll A, Kwon Y A, Cho J H, Kim Y H, Kang J, Sofer Z 2022 npj 2D Mater. Appl. 6 64

Google Scholar

Google Scholar

[4] Liang K, Li D W, Ren H H, Zhao M M, Wang H, Ding M F, Xu G W, Zhao X L, Long S B, Zhu S Y, Sheng P, Li W B, Lin X, Zhu B W 2021 Nano-Micro Lett. 13 164

Google Scholar

Google Scholar

[5] Kwon J, Baek S, Lee Y, Tokito S, Jung S 2021 Langmuir 37 10692

Google Scholar

Google Scholar

[6] Deegan R D, Bakajin O, Dupont T F, Huber G, Nagel S R, Witten T A 1997 Nature 389 827

Google Scholar

Google Scholar

[7] 兰林峰, 陈宝中, 彭俊彪, 曹镛 2021 高分子材料科学与工程 37 150

Google Scholar

Google Scholar

Lan L F, Chen B Z, Peng J B, Cao Y 2021 Polym. Mater. Sci. Eng. 37 150

Google Scholar

Google Scholar

[8] Li Y Z, Lan L F, Gao P, He P H, Dai X, Cao H, Liang L, Peng J B 2019 IEEE Electron Device Lett. 40 228

Google Scholar

Google Scholar

[9] Ryu S O, Ha C H, Jun H Y, Ryu S O 2020 J. Electron. Mater. 49 2003

Google Scholar

Google Scholar

[10] Gillan L, Li S, Lahtinen J, Chang C H, Alastalo A, Leppäniemi J 2021 Adv. Mater. Interfaces 8 2100728

Google Scholar

Google Scholar

[11] Matavz A, Ursic U, Mocivnik J, Richter D, Humar M, Copar S, Malic B, Bobnar V 2022 J. Colloid Interface Sci. 608 1718

Google Scholar

Google Scholar

[12] Sun D W, Chen C H, Zhang J, Wu X M, Chen H P, Guo T L 2018 Appl. Phys. Lett. 112 012102

Google Scholar

Google Scholar

[13] Zhu Z N, Zhang J H, Zhou Z W, Ning H L, Cai W, Wei J L, Zhou S X, Yao R H, Lu X B, Peng J B A 2019 ACS Appl. Mater. Interfaces 11 5193

Google Scholar

Google Scholar

[14] Zhu Z N, Ning H L, Cai W, Wei J L, Zhou S X, Yao R H, Lu X B, Zhang J H, Zhou Z W, Peng J B A 2018 Langmuir 34 6413

Google Scholar

Google Scholar

[15] Still T, Yunker P J, Yodh A G 2012 Langmuir 28 4984

Google Scholar

Google Scholar

[16] Hu H L, Zhu J G, Chen M S, Guo T L, Li F S 2018 Appl. Surf. Sci. 441 295

Google Scholar

Google Scholar

[17] Zhong X, Duan F 2016 Eur. Phys. J. B 39 18

Google Scholar

Google Scholar

[18] Oh G, Jeong W, Jung N, Kang S H, Weon B M 2022 Phys. Rev. Appl. 17 024010

Google Scholar

Google Scholar

[19] Kim D, Jeong S, Park B K, Moon J 2006 Appl. Phys. Lett. 89 264101

Google Scholar

Google Scholar

[20] Kim M G, Kim H S, Ha Y G, He J Q, Kanatzidis M G, Facchetti A, Marks T J 2010 J. Am. Chem. Soc. 132 10352

Google Scholar

Google Scholar

[21] 朱乐永, 高娅娜, 李喜峰, 张建华 2015 64 168501

Google Scholar

Google Scholar

Zhu L Y, Gao Y N, Zhang J H, Li X F 2015 Acta Phys. Sin. 64 168501

Google Scholar

Google Scholar

[22] Choi S, Kim K T, Park S K, Kim Y H 2019 Materials 12 852

Google Scholar

Google Scholar

[23] Friederich A, Binder J R, Bauer W 2013 J. Am. Ceram. Soc. 96 2093

Google Scholar

Google Scholar

[24] Ishizuka H, Fukai J 2018 Exp. Fluids 59 4

Google Scholar

Google Scholar

[25] Li Y Z, He P H, Chen S T, Lan L F, Dai X Q, Peng J B 2019 ACS Appl. Mater. Interfaces 11 28052

Google Scholar

Google Scholar

[26] Park J, Moon J 2006 Langmuir 22 3506

Google Scholar

Google Scholar

[27] Huang H, Hu H L, Zhu J G, Guo T L 2017 J. Electron. Mater. 46 4497

Google Scholar

Google Scholar

[28] 陶洪, 罗浩德, 宁洪龙, 姚日晖, 蔡炜, 郑喜凤, 汪洋, 王铂, 曹慧, 彭俊彪 2021 液晶与显示 36 663

Google Scholar

Google Scholar

Tao H, Luo H D, Ning H L, Yao R H, Cai W, Zheng X F, Wang Y, Wang B, Cao H, Peng, J B 2021 Chin. J. Liq. Cryst. Disp. 36 663

Google Scholar

Google Scholar

[29] Chen S T, Li Y Z, Lin Y L, He P H, Long T, Deng C H, Chen Z, Chen G S, Tao H, Lan L F, Peng J B 2020 Coatings 10 425

Google Scholar

Google Scholar

[30] Fan C L, Hsin T C, Yu X W, Lin Z C 2024 Mater. Sci. Semicond. Process. 172 1396

Google Scholar

Google Scholar

[31] Weber C, Oberberg M, Weber D, Bock C, Pham D V, Kunze U 2014 Adv. Mater. Interfaces 1 1400137

Google Scholar

Google Scholar

[32] 林奕龙, 陈思婷, 吴永波, 兰林锋, 彭俊彪 2021 液晶与显示 36 1239

Google Scholar

Google Scholar

Lin Y L, Chen S T, Wu Y B, Lan L F, Peng J B A 2021 Chin. J. Liq. Cryst. Disp. 36 1239

Google Scholar

Google Scholar

-

表 1 不同浓度、溶剂下对应的IZTO墨水的物理参数

Table 1. Structural parameters of IZTO ink of different concentration and solvents.

IZTO墨水样品 ρ/(g·cm–3) η/cP γ/(mN·m–1) Z c = 0.2 mol/L,

2-MOE1.04 4.05 34.4 6.59 c = 0.2 mol/L,

2-MOE+EG1.07 6.90 38.1 4.14 c = 0.4 mol/L,

2-MOE+EG1.10 8.44 39.1 3.48 表 2 喷墨打印法制备TFT器件的性能对比

Table 2. Performance comparison of TFT devices prepared by inkjet printing method.

表 3 喷墨打印IZTO TFT的电性能参数平均值

Table 3. Average electrical performance parameters of inkjet printed IZTO TFT.

μ/(cm2·V–1·s–1) VTH/V S.S/(mV·dec–1) Average value 11 ± 2 0.6 ± 0.15 90 ± 15 表 4 不同沟道宽长比的IZTO为有源层TFT器件性能对比

Table 4. Structural parameters of IZTO TFT devices with different aspect ratios.

W/L μsat/

(cm2·V–1·s–1)VTH/

VS.S/(V·dec–1) Ion/Ioff 50/30 16.6 0.84 0.24 1.21×109 50/20 14.9 0.73 0.15 2.79×109 50/10 11.5 0.57 0.10 3.74×109 -

[1] 荆斌, 徐萌, 彭聪, 陈龙龙, 张建华, 李喜峰 2022 71 138502

Google Scholar

Google Scholar

Jing B, Xu M, Peng C, Chen L L, Zhang J H, Li X F 2022 Acta Phys. Sin. 71 138502

Google Scholar

Google Scholar

[2] Chu S, Hollberg L, Bjorkholm J E, Bolot S, Fuchs P, Knobelspies S, Temel O, Sevilla G T, Gilshtein E, Andres C, Shorubalko I, Liu Y, Troester G, Tiwari A A N, Romanyuk Y E 2019 Adv. Electron. Mater. 5 1800843

Google Scholar

Google Scholar

[3] Song O, Rhee D, Kim J, Jeon Y, Mazánek V, Söll A, Kwon Y A, Cho J H, Kim Y H, Kang J, Sofer Z 2022 npj 2D Mater. Appl. 6 64

Google Scholar

Google Scholar

[4] Liang K, Li D W, Ren H H, Zhao M M, Wang H, Ding M F, Xu G W, Zhao X L, Long S B, Zhu S Y, Sheng P, Li W B, Lin X, Zhu B W 2021 Nano-Micro Lett. 13 164

Google Scholar

Google Scholar

[5] Kwon J, Baek S, Lee Y, Tokito S, Jung S 2021 Langmuir 37 10692

Google Scholar

Google Scholar

[6] Deegan R D, Bakajin O, Dupont T F, Huber G, Nagel S R, Witten T A 1997 Nature 389 827

Google Scholar

Google Scholar

[7] 兰林峰, 陈宝中, 彭俊彪, 曹镛 2021 高分子材料科学与工程 37 150

Google Scholar

Google Scholar

Lan L F, Chen B Z, Peng J B, Cao Y 2021 Polym. Mater. Sci. Eng. 37 150

Google Scholar

Google Scholar

[8] Li Y Z, Lan L F, Gao P, He P H, Dai X, Cao H, Liang L, Peng J B 2019 IEEE Electron Device Lett. 40 228

Google Scholar

Google Scholar

[9] Ryu S O, Ha C H, Jun H Y, Ryu S O 2020 J. Electron. Mater. 49 2003

Google Scholar

Google Scholar

[10] Gillan L, Li S, Lahtinen J, Chang C H, Alastalo A, Leppäniemi J 2021 Adv. Mater. Interfaces 8 2100728

Google Scholar

Google Scholar

[11] Matavz A, Ursic U, Mocivnik J, Richter D, Humar M, Copar S, Malic B, Bobnar V 2022 J. Colloid Interface Sci. 608 1718

Google Scholar

Google Scholar

[12] Sun D W, Chen C H, Zhang J, Wu X M, Chen H P, Guo T L 2018 Appl. Phys. Lett. 112 012102

Google Scholar

Google Scholar

[13] Zhu Z N, Zhang J H, Zhou Z W, Ning H L, Cai W, Wei J L, Zhou S X, Yao R H, Lu X B, Peng J B A 2019 ACS Appl. Mater. Interfaces 11 5193

Google Scholar

Google Scholar

[14] Zhu Z N, Ning H L, Cai W, Wei J L, Zhou S X, Yao R H, Lu X B, Zhang J H, Zhou Z W, Peng J B A 2018 Langmuir 34 6413

Google Scholar

Google Scholar

[15] Still T, Yunker P J, Yodh A G 2012 Langmuir 28 4984

Google Scholar

Google Scholar

[16] Hu H L, Zhu J G, Chen M S, Guo T L, Li F S 2018 Appl. Surf. Sci. 441 295

Google Scholar

Google Scholar

[17] Zhong X, Duan F 2016 Eur. Phys. J. B 39 18

Google Scholar

Google Scholar

[18] Oh G, Jeong W, Jung N, Kang S H, Weon B M 2022 Phys. Rev. Appl. 17 024010

Google Scholar

Google Scholar

[19] Kim D, Jeong S, Park B K, Moon J 2006 Appl. Phys. Lett. 89 264101

Google Scholar

Google Scholar

[20] Kim M G, Kim H S, Ha Y G, He J Q, Kanatzidis M G, Facchetti A, Marks T J 2010 J. Am. Chem. Soc. 132 10352

Google Scholar

Google Scholar

[21] 朱乐永, 高娅娜, 李喜峰, 张建华 2015 64 168501

Google Scholar

Google Scholar

Zhu L Y, Gao Y N, Zhang J H, Li X F 2015 Acta Phys. Sin. 64 168501

Google Scholar

Google Scholar

[22] Choi S, Kim K T, Park S K, Kim Y H 2019 Materials 12 852

Google Scholar

Google Scholar

[23] Friederich A, Binder J R, Bauer W 2013 J. Am. Ceram. Soc. 96 2093

Google Scholar

Google Scholar

[24] Ishizuka H, Fukai J 2018 Exp. Fluids 59 4

Google Scholar

Google Scholar

[25] Li Y Z, He P H, Chen S T, Lan L F, Dai X Q, Peng J B 2019 ACS Appl. Mater. Interfaces 11 28052

Google Scholar

Google Scholar

[26] Park J, Moon J 2006 Langmuir 22 3506

Google Scholar

Google Scholar

[27] Huang H, Hu H L, Zhu J G, Guo T L 2017 J. Electron. Mater. 46 4497

Google Scholar

Google Scholar

[28] 陶洪, 罗浩德, 宁洪龙, 姚日晖, 蔡炜, 郑喜凤, 汪洋, 王铂, 曹慧, 彭俊彪 2021 液晶与显示 36 663

Google Scholar

Google Scholar

Tao H, Luo H D, Ning H L, Yao R H, Cai W, Zheng X F, Wang Y, Wang B, Cao H, Peng, J B 2021 Chin. J. Liq. Cryst. Disp. 36 663

Google Scholar

Google Scholar

[29] Chen S T, Li Y Z, Lin Y L, He P H, Long T, Deng C H, Chen Z, Chen G S, Tao H, Lan L F, Peng J B 2020 Coatings 10 425

Google Scholar

Google Scholar

[30] Fan C L, Hsin T C, Yu X W, Lin Z C 2024 Mater. Sci. Semicond. Process. 172 1396

Google Scholar

Google Scholar

[31] Weber C, Oberberg M, Weber D, Bock C, Pham D V, Kunze U 2014 Adv. Mater. Interfaces 1 1400137

Google Scholar

Google Scholar

[32] 林奕龙, 陈思婷, 吴永波, 兰林锋, 彭俊彪 2021 液晶与显示 36 1239

Google Scholar

Google Scholar

Lin Y L, Chen S T, Wu Y B, Lan L F, Peng J B A 2021 Chin. J. Liq. Cryst. Disp. 36 1239

Google Scholar

Google Scholar

计量

- 文章访问数: 3653

- PDF下载量: 123

- 被引次数: 0

下载:

下载: