-

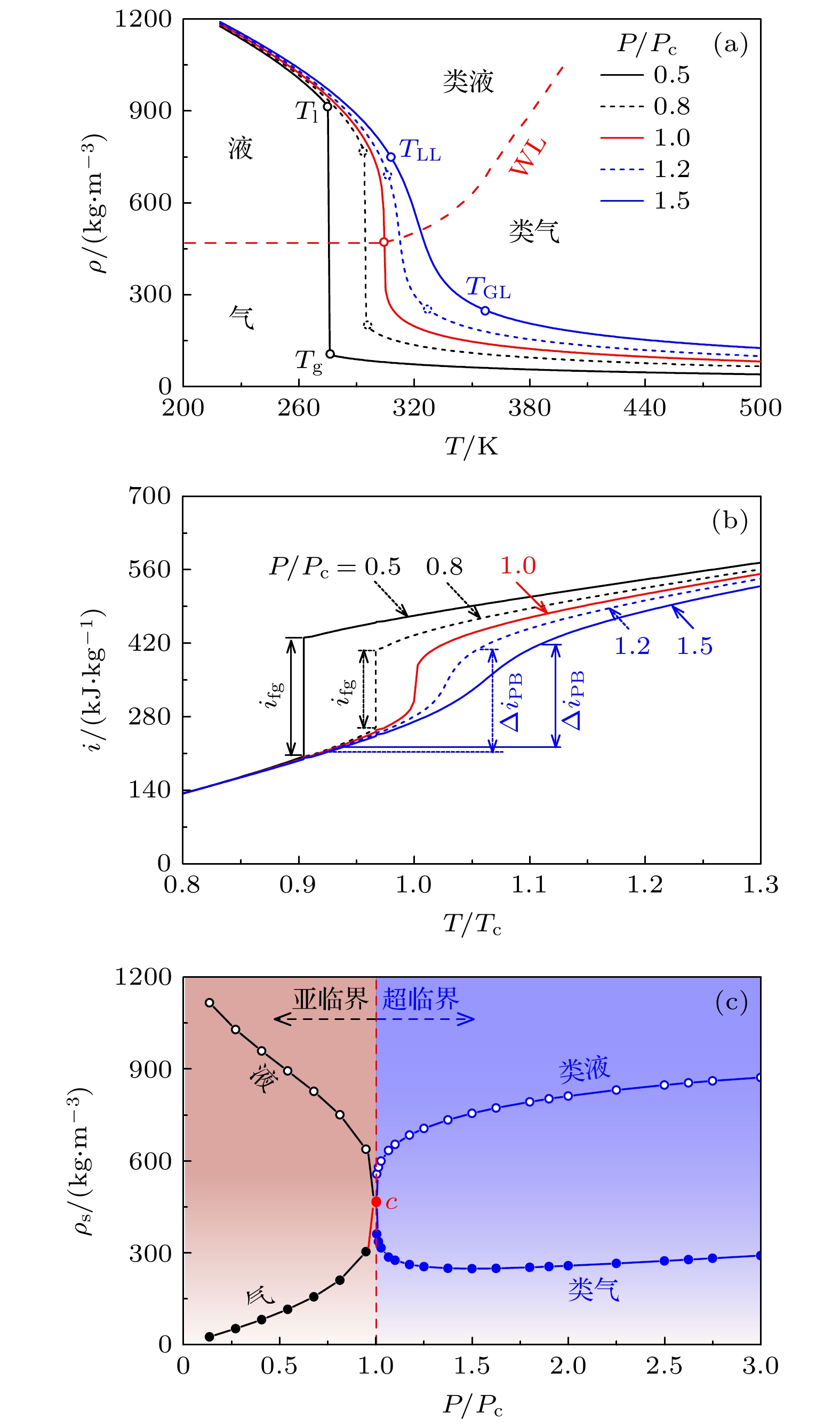

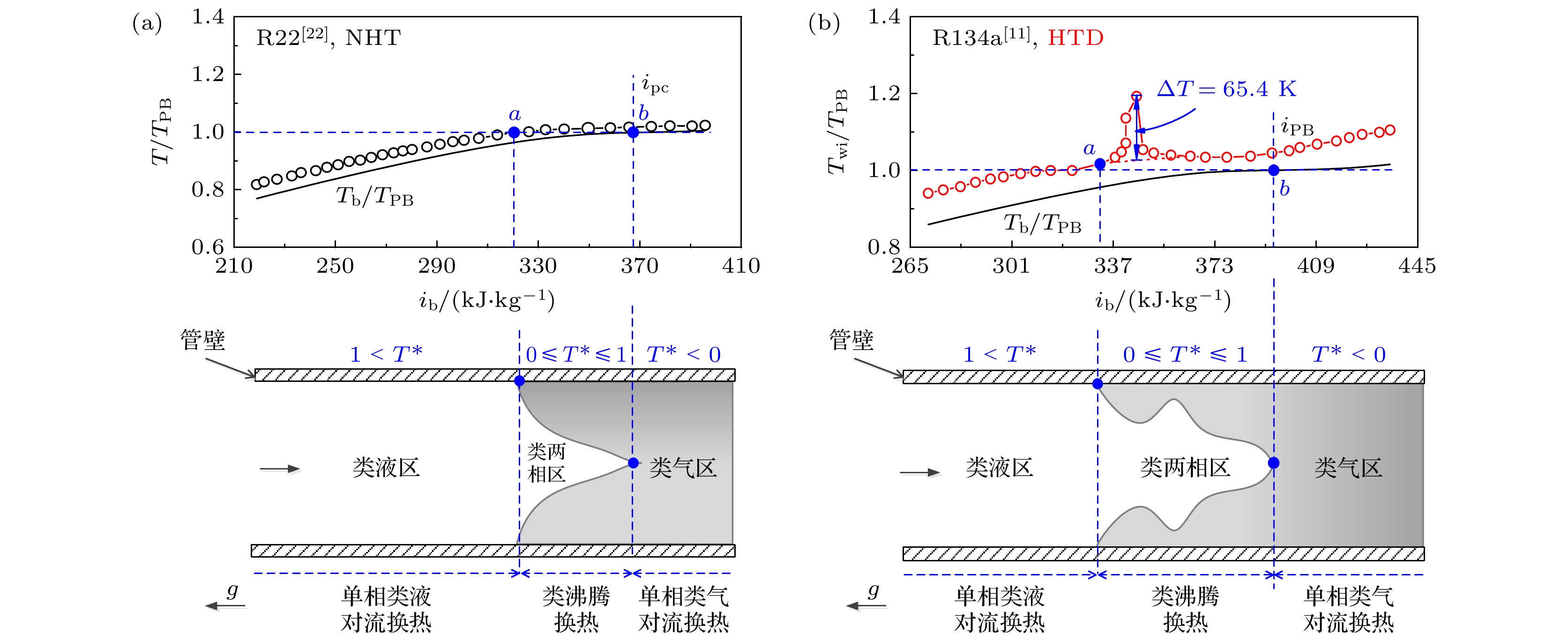

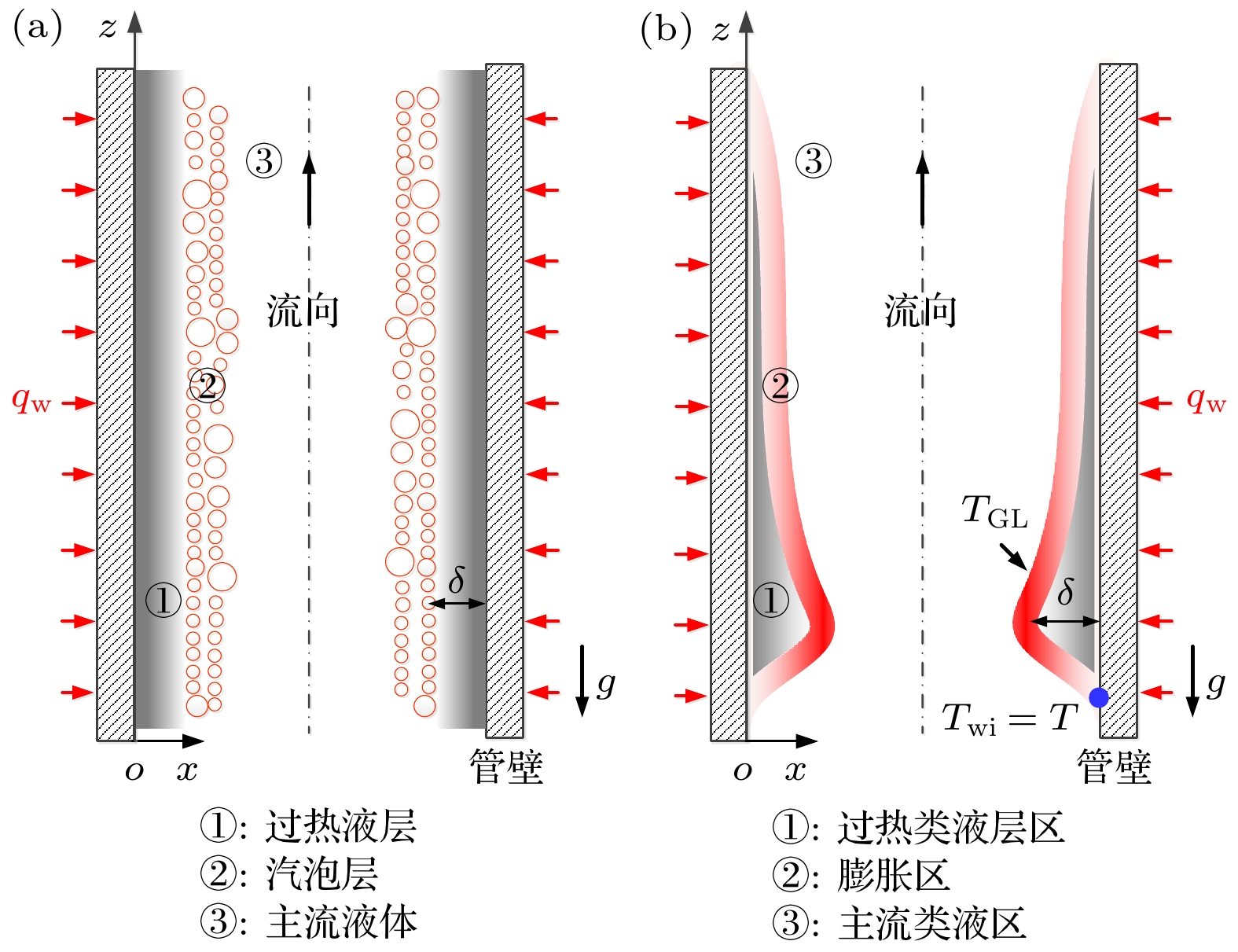

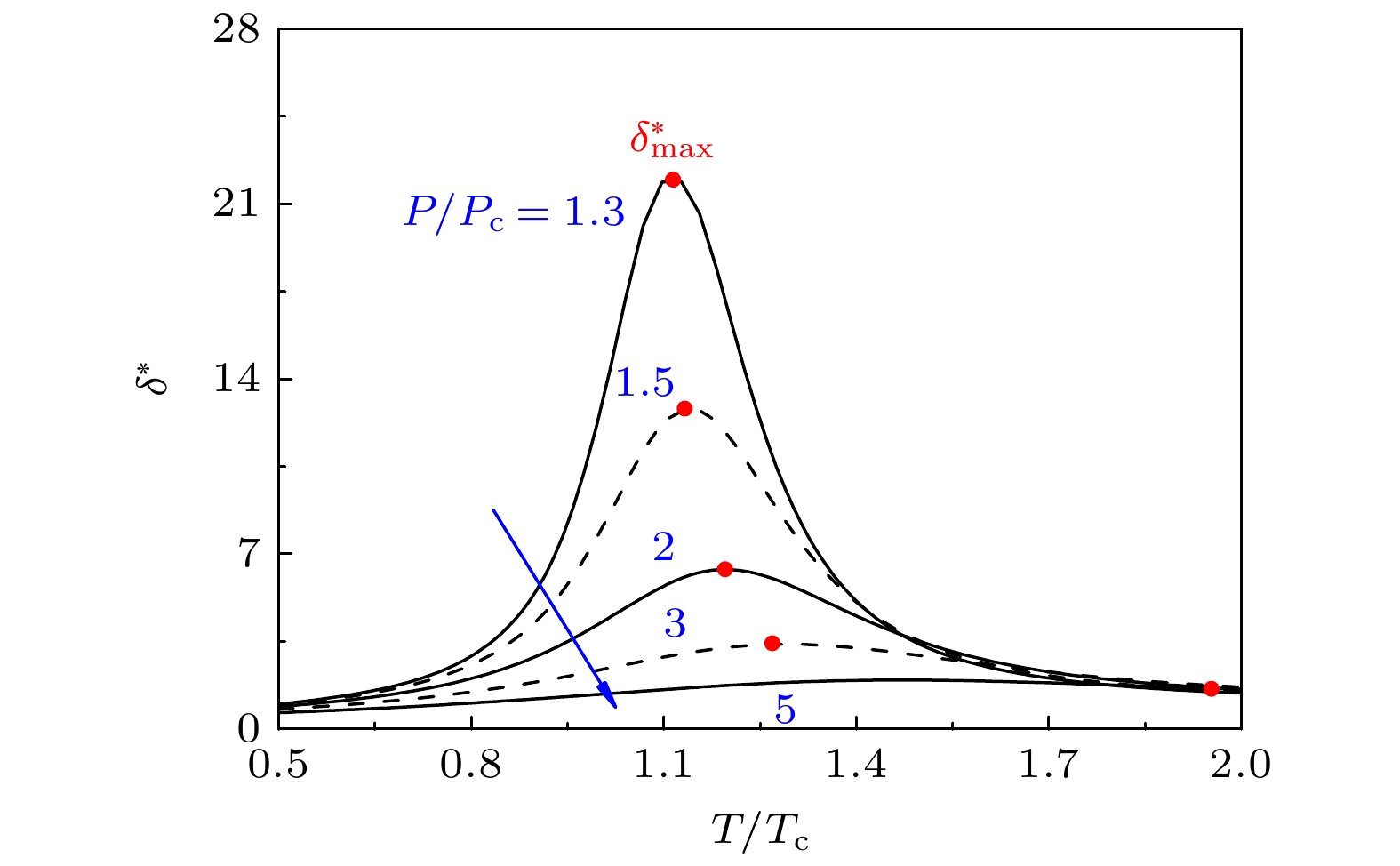

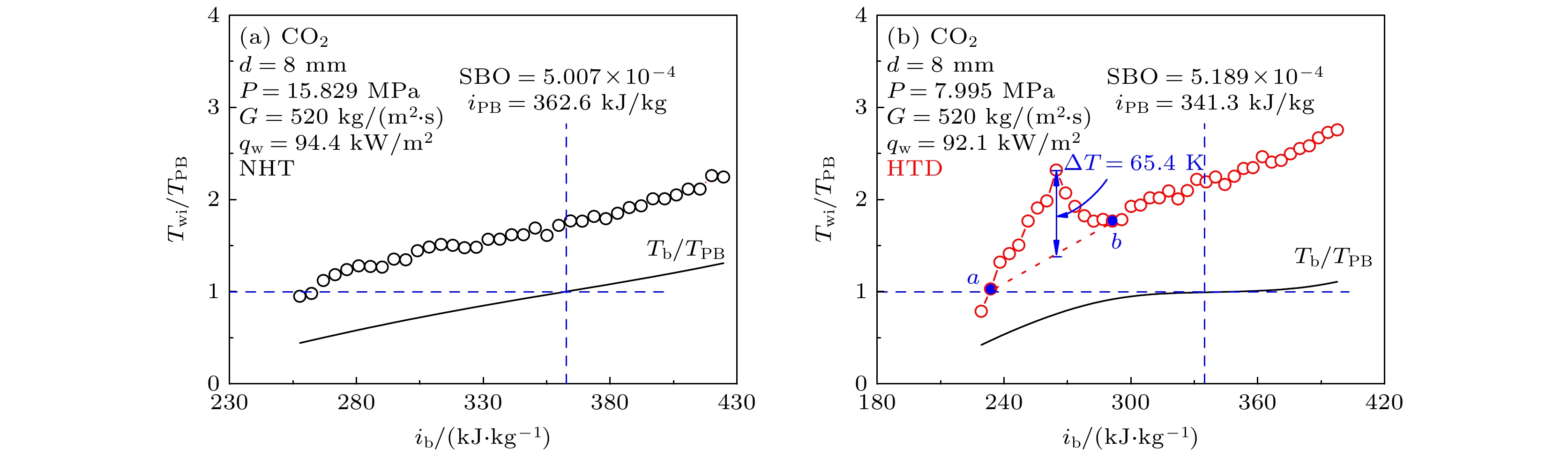

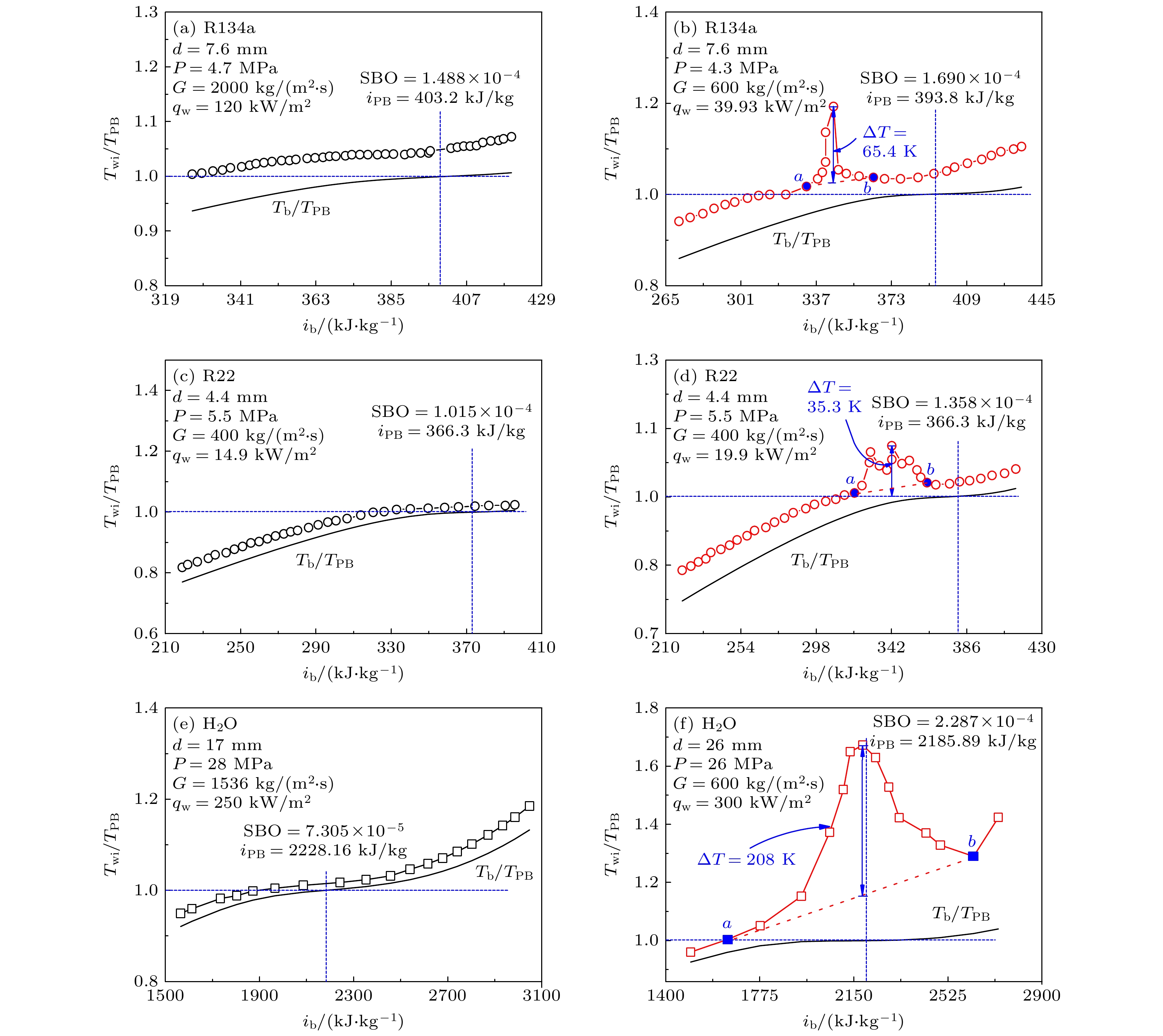

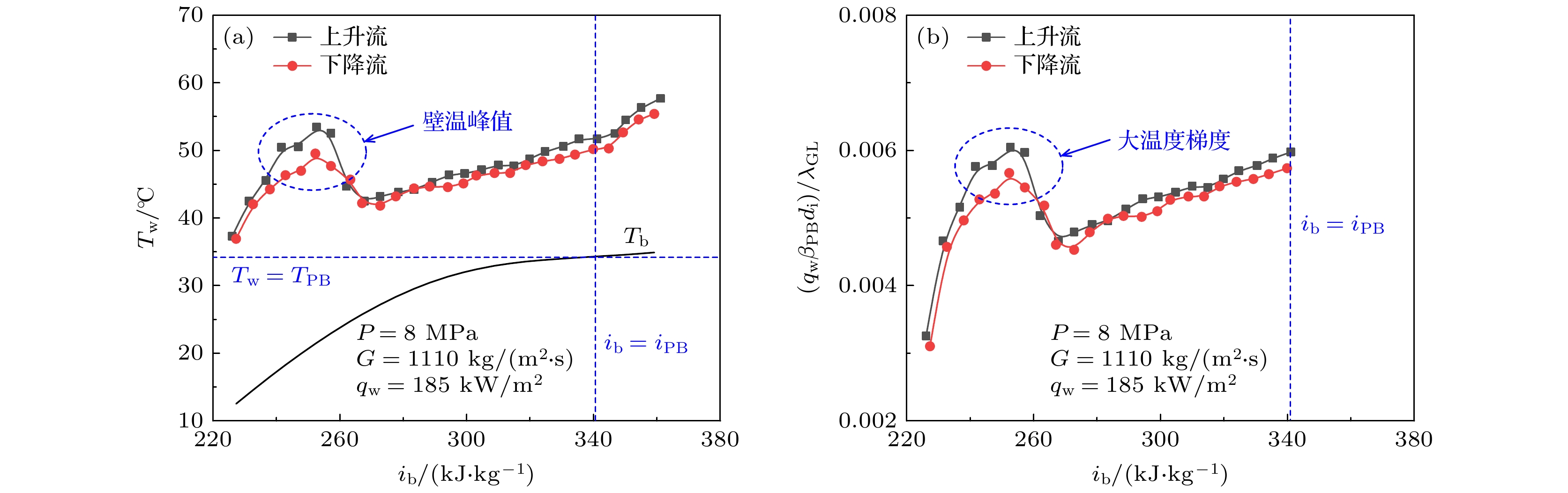

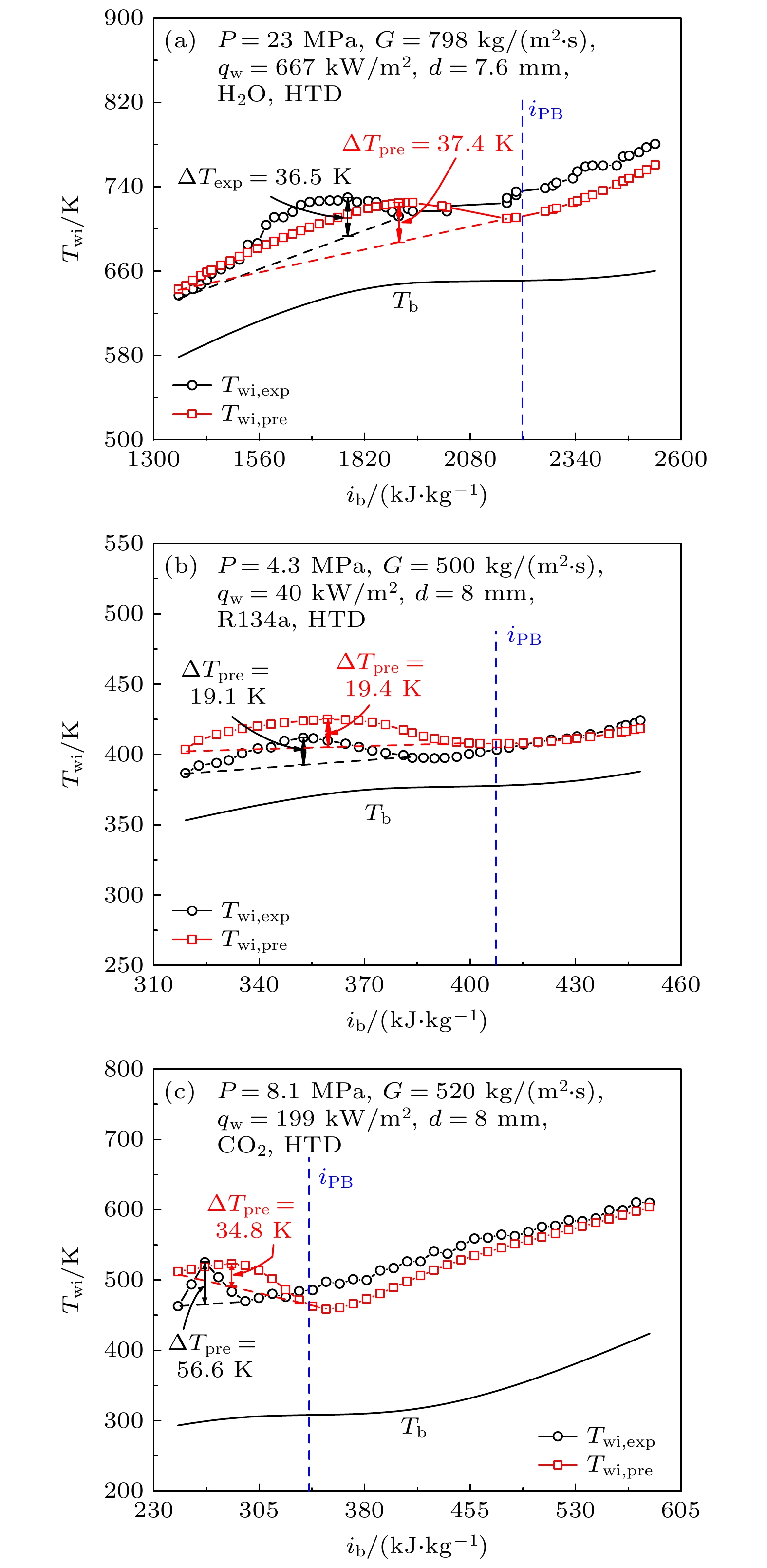

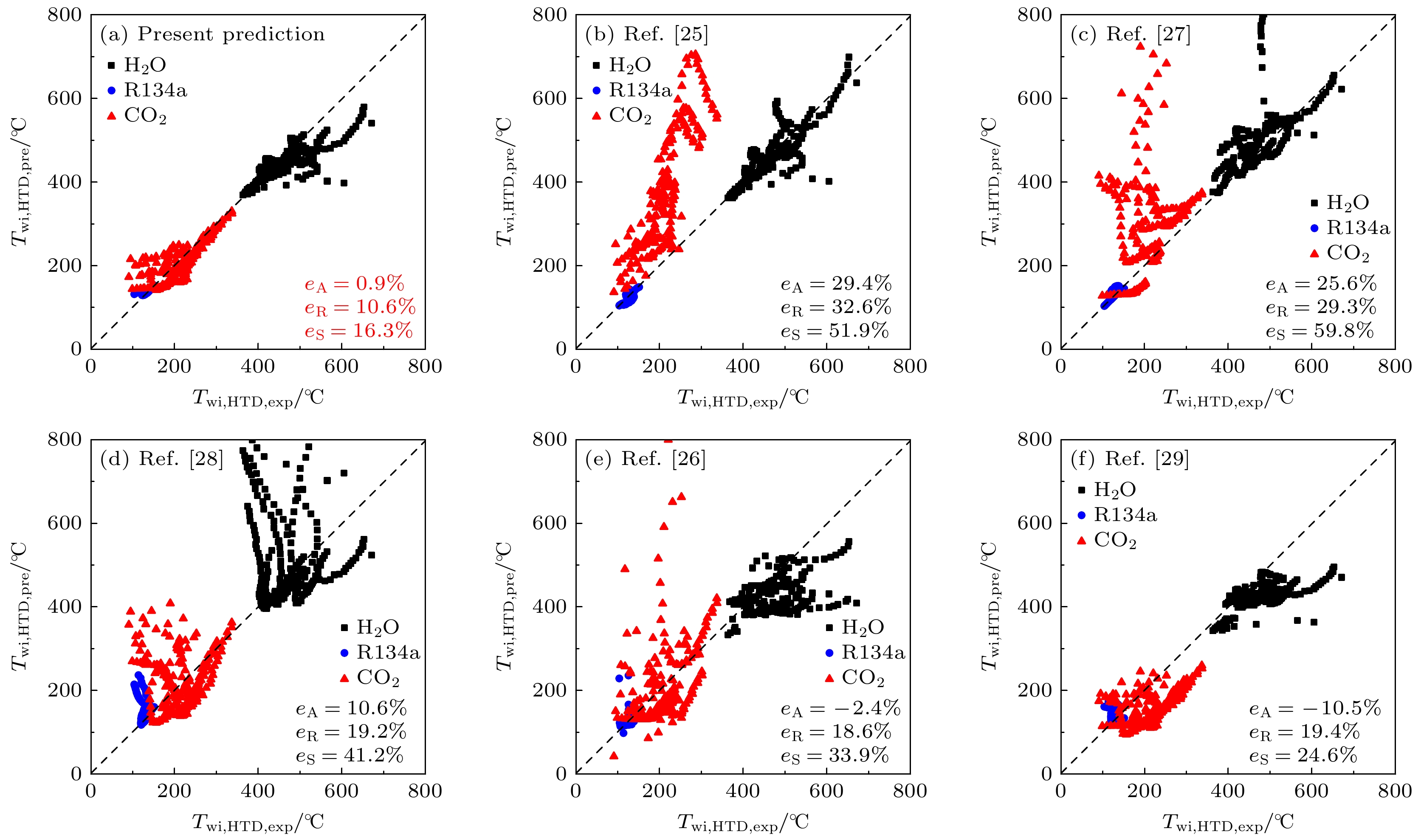

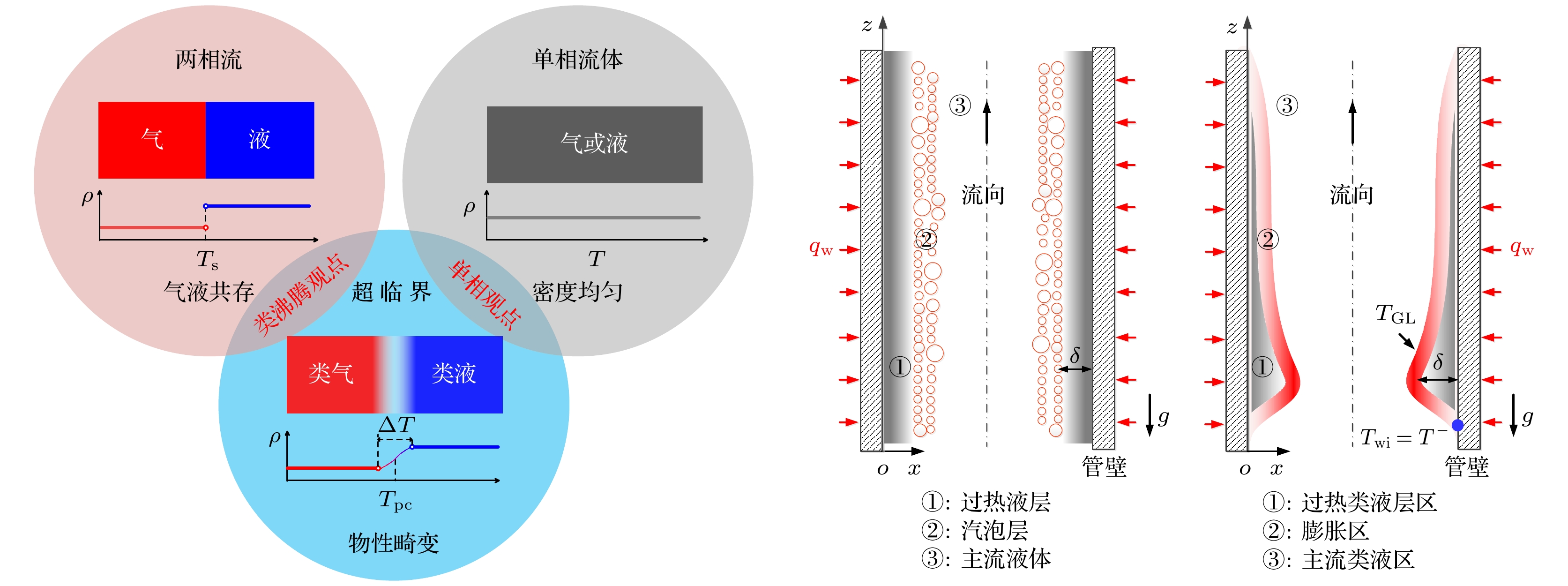

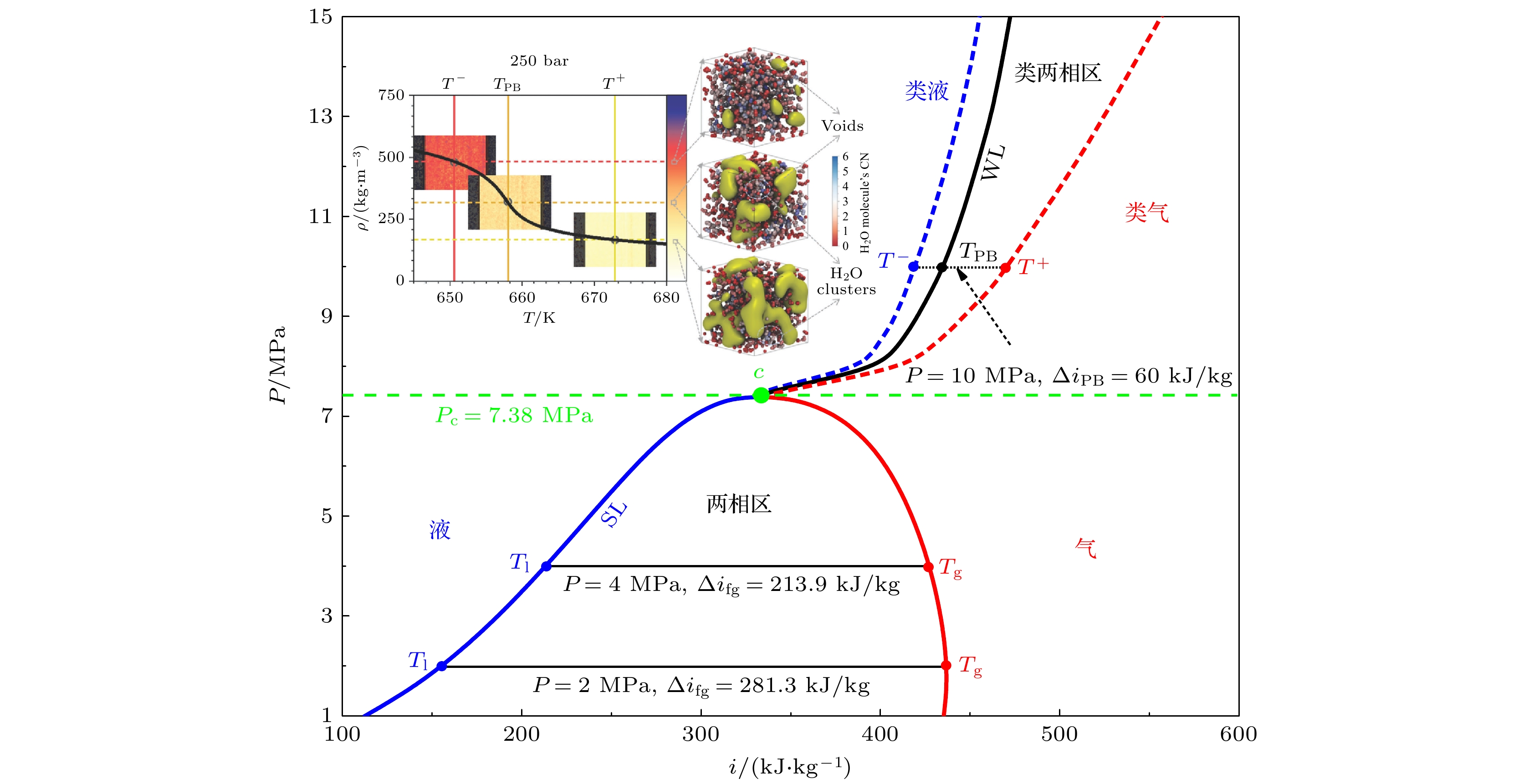

传热恶化是超临界流体(supercutical fluid, SCF)传热研究重要问题之一, 但由于SCF在跨过拟临界点时, 流体存在非平衡过程, 类气和类液之间的转变对传热的影响尚没有统一认识. 本文假设SCF在宏观上存在类似于亚临界流动沸腾现象, 通过类比亚临界沸腾传热, 认为超临界CO2传热恶化原因之一是由于流体膨胀导致热量不能被及时从壁面被带走, 并提出一个类沸腾临界点模型. 结果表明: 类沸腾引起的传热恶化发生在大温度梯度下, 较大的温度梯度使类过热液层覆盖在壁面, 并使类气和类液呈现不同的分布形式, 从而表现出不同的传热特性; 当内壁温高于拟临界温度时, 覆盖在壁面的过热类液焓值超过一定值会发生传热恶化, 提出的理论模型能够较好地解释实验结果, 此外考虑类沸腾的传热关联式, 预测精度大大提高. 本文从理论上建立超临界和亚临界传热之间的联系, 为SCF传热恶化研究提供了新思路, 丰富了超临界压力下的传热理论.Heat transfer deterioration (HTD) is one of the important issues in the study of supercritical fluid (SCF) heat transfer. However, when the SCF crosses the pseudo-critical point, the none-quilibrium process occurs in liquid, so SCF is very complicated. Recently, the existence of SCF pseudo-boiling on a macro scale has sparked controversy. There is still no unified understanding of the mechanism of gas-like and liquid-like transition affecting heat transfer. In this work, it is assumed that SCF has a macroscopic phenomenon similar to subcritical flow boiling. By analogy with subcritical boiling heat transfer, a boiling critical point model is proposed to describe the HTD in supercritical CO2. Our study reveals that the HTD caused by pseudo-boiling only occurs under large temperature gradient, which makes the superheated liquid-like layer cover the wall, and the gas-like and liquid-like may present different distribution forms, thus changing the heat transfer characteristics. When the wall temperature is higher than the pseudo-critical temperature and the enthalpy of the fluid layer covering the wall exceeds a certain value, the HTD may occur. The proposed theoretical model can explain the experimental results well, and the prediction accuracy of heat transfer correlation considering pseudo-boiling is greatly improved. In this work, the connection between supercritical heat transfer and subcritical heat transfer is established theoretically, which provides a new idea for studying the deterioration of SCF heat transfer, thus enriching the theory of supercritical heat transfer.

-

Keywords:

- supercritical fluid /

- expansion /

- pseudo-boiling /

- heat transfer deterioration /

- theoretical model

[1] Jackson J D 2017 Appl. Therm. Eng. 124 1481

Google Scholar

Google Scholar

[2] Huang D, Wu Z, Sunden B, Li W 2016 Appl. Energ. 162 494

Google Scholar

Google Scholar

[3] Xie J Z, Liu D C, Yan H B, Xie G N, Boetcher S K S 2020 Int. J. Heat Mass Tran. 149 119233

Google Scholar

Google Scholar

[4] Cabeza L, Gracia A, Fernández A, Farid M 2017 Appl. Therm. Eng. 125 799

Google Scholar

Google Scholar

[5] Chen W W, Fang X D, Yu X, Su X H 2015 Ann. Nucl. Energy 76 451

Google Scholar

Google Scholar

[6] Cheng X, Liu X J 2018 J. Nucl. Eng. Radiat Sc. 4 011003

Google Scholar

Google Scholar

[7] Maxim F, Contescu C, Boillat P, Niceno B, Karalis K, Testino A, Ludwig C 2019 Nat. Commun. 10 4114

Google Scholar

Google Scholar

[8] Maxim F, Karalis K, Boillat P, Banuti D, Marquez J, Damian B, Niceno P, Ludwig C 2021 Adv. Sci. 8 2002312

Google Scholar

Google Scholar

[9] Liu M Y, Tang J, Liu S H 2022 J. Supercrit. Fluids 183 105554

Google Scholar

Google Scholar

[10] Ackerman J W 1970 J. Heat Tran. 92 490

Google Scholar

Google Scholar

[11] Zhu B G, Xu J L, Wu X M, Xie J, Li M J 2019 J Int. J. Therm. Sci. 136 254

Google Scholar

Google Scholar

[12] Zhang H S, Xu J L, Zhu X J, Xie J, Li M J, Zhu B G 2021 Appl. Therm. Eng. 182 116078

Google Scholar

Google Scholar

[13] Wang Q Y, Ma X J, Xu J L, Li M J, Wang Y 2021 Int. J. Heat Mass Tran. 181 121875

Google Scholar

Google Scholar

[14] Tripathi P, Basu S 2021 Phys. Fluids 33 043304

Google Scholar

Google Scholar

[15] Wang J T, Li Z H, Zhai Y L, Wang H 2023 Int. J. Heat Mass Tran. 201 123571

Google Scholar

Google Scholar

[16] Peeters J 2022 Int. J. Heat Mass Tran. 186 122441

Google Scholar

Google Scholar

[17] Fan Y H, Tang G H, Sheng Q, Li X 2023 Energy 262 125470

Google Scholar

Google Scholar

[18] Banuti D T 2015 J. Supercrit. Fluids 98 12

Google Scholar

Google Scholar

[19] 何孝天, 徐进良, 程怡玮 2023 72 057801

Google Scholar

Google Scholar

He X T, Xu J L, Cheng Y W 2023 Acta Phys. Sin. 72 057801

Google Scholar

Google Scholar

[20] 林瑞泰 1988 沸腾换热 (北京: 科学出版社) 第278页

Lin R T 1988 Boiling Heat Transfer (Beijing: Science Press) p278

[21] Xu J L, Zhang H S, Zhu B G, Xie J 2020 Solar Eng. 195 27

Google Scholar

Google Scholar

[22] 张海松, 徐进良, 朱鑫杰 2021 70 044401

Google Scholar

Google Scholar

Zhang H S, Xu J L, Zhu X J 2021 Acta Phys. Sin. 70 044401

Google Scholar

Google Scholar

[23] Zhang H S, Xu J L, Wang Q Y 2023 Int. J. Therm. Sci. 188 108242

Google Scholar

Google Scholar

[24] Zhu B G, Xu J L, Yan C S, Xie J 2020 Int. J. Heat Mass Tran. 148 119080

Google Scholar

Google Scholar

[25] Cheng X, Zhao M, Feuerstein F, Liu X J 2019 Int. J. Heat Mass Tran. 131 527

Google Scholar

Google Scholar

[26] Gupta S, Mokry S, Pioro I 2011 Proc. ICONE-19 43503 11

Google Scholar

Google Scholar

[27] Mokry S, Pioro I, Farah A, King K, Gupta S, Peiman W, Kirillov P 2011 Nucl. Eng. Des. 241 1126

Google Scholar

Google Scholar

[28] Kim D, Kim M 2010 Nucl. Eng. Des. 240 3336

Google Scholar

Google Scholar

[29] Petukhov B, Kirillov S 1958 Thermal Eng. 4 63

-

表 1 超临界流体传热关联式回顾

Table 1. Review of supercutical fluids heat transfer correlations.

Ref. Correlation Operatings parameters [25] $N{u_{\text{b}}} = 0.023 Re_{\text{b}}^{1.03}Pr_{\text{b}}^{0.5}{F_1}{F_2} \qquad\qquad \qquad \qquad \qquad \qquad \qquad \qquad $ CO2/H2O/R134a ${F_1} = \left\{ {\begin{aligned} &0.98, & &{\text{ for }}{{\textit{π}} _{\text{A}}} < 1.75 \times {{10}^{ - 4}}, \\ &0.85 + 0.056{{\left( {{{10}^4}{{\textit{π}} _{\text{A}}}} \right)}^{1.5}}, & &{\text{ for }}1.75 \times {{10}^{ - 4}} \leqslant {{\textit{π}} _{\text{A}}} < 3.75 \times {{10}^{ - 4}}, \\ &13.1/4.5 + {{\left( {104{{\textit{π}} _{\text{A}}}} \right)}^{1.35}}, & &{\text{ for }}3.75 \times {{10}^{ - 4}} < {{\textit{π}} _{\text{A}}} ,\end{aligned}} \right.$ $ {F_2} = \left\{ {\begin{aligned} & 0.93 Pr_{\text{b}}^{0.265}, & &{\text{ for }}P{r_{\text{b}}} \leqslant 2.5, \\ &1.61 Pr_{\text{b}}^{ - 0.333}, & &{\text{ for }}P{r_{\text{b}}} > 2.5, \end{aligned}} \right. \qquad {{\textit{π}} _{\text{A}}} = \dfrac{{{q_{\text{w}}}{\beta _{\text{b}}}}}{{G{c_{{\text{p}}, {\text{b}}}}}} \qquad\qquad \qquad\qquad $ [26] $N u_{\mathrm{w}}=0.0033 R e_{\mathrm{w}}^{0.94} \overline{Pr}_{\mathrm{w}}^{0.76}\left( {\rho_{\mathrm{w}}}/{\rho_{\mathrm{b}}}\right)^{0.16}\left( {\mu_{\mathrm{w}}}/{\mu_{\mathrm{b}}}\right)^{0.4} $ — [27] $N u_{\mathrm{b}}=0.0061 R e_{\mathrm{b}}^{0.904} P r_{\mathrm{b}, \mathrm{ave}}^{0.684}\left({\rho_{\mathrm{w}}}/{\rho_{\mathrm{b}}}\right)^{0.564}$ H2O

P = 24 MPa; di = 10.0 mm

G = 200—1500 kg/(m2·s)

qw = 0—1250 kW/m2$P{r_{{\mathrm{b, ave}}}} = \dfrac{{{\mu _{\text{b}}}}}{{{\lambda _{{\mathrm{b}}} }}}\dfrac{{{i_{{\mathrm{w}}} } - {i_{{\mathrm{b}}} }}}{{{T_{{\mathrm{w}}} } - {T_{{\mathrm{b}}} }}}$ [28] $ N{u_{\mathrm{b}}} = 0.226 Re_{\mathrm{b}}^{1.174}Pr_{{{\mathrm{b}}} , {\mathrm{ave}}}^{1.057}{\left( {\dfrac{{{\rho _{\mathrm{w}}}}}{{{\rho _{{\mathrm{b}}} }}}} \right)^{0.571}}{\left( {\dfrac{{{{\overline c }_{{{\mathrm{p, b}}}}}}}{{{c_{{{\mathrm{p} , b}}}}}}} \right)^{1.023}}A{c^{0.489}}B{u^{0.0021}} $ CO2

P = 7.46—10.26 MPa

di = 4.5 mm

G = 208–847 kg/(m2·s)

qw = 38—234 kW/m2$Ac = \dfrac{{{q_{{\mathrm{w}}} }{\beta _{{\mathrm{b}}} }}}{{G{c_{{{\mathrm{p}}} , {\mathrm{b}}}}Re_{{\mathrm{b}}} ^{0.625}}}\left( {\dfrac{{{\mu _{{\mathrm{w}}} }}}{{{\mu _{{\mathrm{b}}} }}}} \right){\left( {\dfrac{{{\rho _{{\mathrm{b}}} }}}{{{\rho _{{\mathrm{w}}} }}}} \right)^{0.5}}$, $Gr{=}\dfrac{{{g} {\beta _{{\mathrm{b}}} }d_{\mathrm{i}}^4{q_{{\mathrm{w}}} }}}{{v_{\mathrm{b}}^2{\lambda _{{\mathrm{b}}} }}}$ $ Bu = \dfrac{{Gr}}{{Re_{{\mathrm{b}}} ^{3.425}P{r^{0.8}}}}\left( {\dfrac{{{\mu _{{\mathrm{w}}} }}}{{{\mu _{{\mathrm{b}}} }}}} \right){\left( {\dfrac{{{\rho _{{\mathrm{b}}} }}}{{{\rho _{{\mathrm{w}}} }}}} \right)^{0.5}}$, ${\overline c _{{{\mathrm{p, b}}}}} = \dfrac{{{i_{{\mathrm{w}}} } - {i_{{\mathrm{b}}} }}}{{{T_{{\mathrm{w}}} } - {T_{{\mathrm{b}}} }}}$ [29] $ N u_{\mathrm{b}}=\dfrac{(\xi / 8) R e_{\mathrm{b}} \overline{{Pr}}_{\mathrm{b}}}{1+900 / R e_{\mathrm{b}}+12.7 \sqrt{\xi / 8}\left(\overline{P r}_{\mathrm{b}}^{2 / 3}-1\right)}$ — $\xi=\left[1.82 \log _{10}\left(R e_{\mathrm{b}}\right)-1.64\right]^{-2}\left( {\rho_{\mathrm{w}}}/{\rho_{\mathrm{b}}}\right)^{0.4}\left({\mu_{\mathrm{w}}}/{\mu_{\mathrm{b}}}\right)^{0.2}$ -

[1] Jackson J D 2017 Appl. Therm. Eng. 124 1481

Google Scholar

Google Scholar

[2] Huang D, Wu Z, Sunden B, Li W 2016 Appl. Energ. 162 494

Google Scholar

Google Scholar

[3] Xie J Z, Liu D C, Yan H B, Xie G N, Boetcher S K S 2020 Int. J. Heat Mass Tran. 149 119233

Google Scholar

Google Scholar

[4] Cabeza L, Gracia A, Fernández A, Farid M 2017 Appl. Therm. Eng. 125 799

Google Scholar

Google Scholar

[5] Chen W W, Fang X D, Yu X, Su X H 2015 Ann. Nucl. Energy 76 451

Google Scholar

Google Scholar

[6] Cheng X, Liu X J 2018 J. Nucl. Eng. Radiat Sc. 4 011003

Google Scholar

Google Scholar

[7] Maxim F, Contescu C, Boillat P, Niceno B, Karalis K, Testino A, Ludwig C 2019 Nat. Commun. 10 4114

Google Scholar

Google Scholar

[8] Maxim F, Karalis K, Boillat P, Banuti D, Marquez J, Damian B, Niceno P, Ludwig C 2021 Adv. Sci. 8 2002312

Google Scholar

Google Scholar

[9] Liu M Y, Tang J, Liu S H 2022 J. Supercrit. Fluids 183 105554

Google Scholar

Google Scholar

[10] Ackerman J W 1970 J. Heat Tran. 92 490

Google Scholar

Google Scholar

[11] Zhu B G, Xu J L, Wu X M, Xie J, Li M J 2019 J Int. J. Therm. Sci. 136 254

Google Scholar

Google Scholar

[12] Zhang H S, Xu J L, Zhu X J, Xie J, Li M J, Zhu B G 2021 Appl. Therm. Eng. 182 116078

Google Scholar

Google Scholar

[13] Wang Q Y, Ma X J, Xu J L, Li M J, Wang Y 2021 Int. J. Heat Mass Tran. 181 121875

Google Scholar

Google Scholar

[14] Tripathi P, Basu S 2021 Phys. Fluids 33 043304

Google Scholar

Google Scholar

[15] Wang J T, Li Z H, Zhai Y L, Wang H 2023 Int. J. Heat Mass Tran. 201 123571

Google Scholar

Google Scholar

[16] Peeters J 2022 Int. J. Heat Mass Tran. 186 122441

Google Scholar

Google Scholar

[17] Fan Y H, Tang G H, Sheng Q, Li X 2023 Energy 262 125470

Google Scholar

Google Scholar

[18] Banuti D T 2015 J. Supercrit. Fluids 98 12

Google Scholar

Google Scholar

[19] 何孝天, 徐进良, 程怡玮 2023 72 057801

Google Scholar

Google Scholar

He X T, Xu J L, Cheng Y W 2023 Acta Phys. Sin. 72 057801

Google Scholar

Google Scholar

[20] 林瑞泰 1988 沸腾换热 (北京: 科学出版社) 第278页

Lin R T 1988 Boiling Heat Transfer (Beijing: Science Press) p278

[21] Xu J L, Zhang H S, Zhu B G, Xie J 2020 Solar Eng. 195 27

Google Scholar

Google Scholar

[22] 张海松, 徐进良, 朱鑫杰 2021 70 044401

Google Scholar

Google Scholar

Zhang H S, Xu J L, Zhu X J 2021 Acta Phys. Sin. 70 044401

Google Scholar

Google Scholar

[23] Zhang H S, Xu J L, Wang Q Y 2023 Int. J. Therm. Sci. 188 108242

Google Scholar

Google Scholar

[24] Zhu B G, Xu J L, Yan C S, Xie J 2020 Int. J. Heat Mass Tran. 148 119080

Google Scholar

Google Scholar

[25] Cheng X, Zhao M, Feuerstein F, Liu X J 2019 Int. J. Heat Mass Tran. 131 527

Google Scholar

Google Scholar

[26] Gupta S, Mokry S, Pioro I 2011 Proc. ICONE-19 43503 11

Google Scholar

Google Scholar

[27] Mokry S, Pioro I, Farah A, King K, Gupta S, Peiman W, Kirillov P 2011 Nucl. Eng. Des. 241 1126

Google Scholar

Google Scholar

[28] Kim D, Kim M 2010 Nucl. Eng. Des. 240 3336

Google Scholar

Google Scholar

[29] Petukhov B, Kirillov S 1958 Thermal Eng. 4 63

计量

- 文章访问数: 310

- PDF下载量: 12

- 被引次数: 0

下载:

下载: