-

本文基于高压研究及超硬材料生产所用的静高压立方大腔体(六面顶)压机的需要, 制备了源于南非叶腊石矿的两种(A和B)叶腊石粉压块, 并与同工艺国产(北京门头沟)黄色叶腊石粉压块进行比较, 以此建立评估叶腊石传压及密封性能的实验方法与物理判据. 采用Bi, Tl, Ba等标压物质原位标定了以上3种叶腊石压腔中心位置及密封边处的压力; 同时, 采用银熔点法分别获得了3种叶腊石作传压密封材料时高温下腔体压力与系统加载的对应关系. 结果表明, 在相同加载油压下南非叶腊石B粉压块和国内叶腊石粉压块中心位置的压力差值不超过0.1 GPa, 在升压和降压过程中叶腊石块中心位置与密封边位置的压力差值也更为相近. 相比于南非叶蜡石A粉压块, B粉压块在高温传压和密封性能上更接近国产叶腊石粉压块.

-

关键词:

- 立方大腔体静高压装置 /

- 高温高压 /

- 叶腊石 /

- 密封性能 /

- 传压效率

Owing to the need for a hydrostatic high-pressure cubic large cavity (hexahedral top) press used in high-pressure research and production of superhard material, two kinds of pyrophyllite powder compacts (A and B) from pyrophyllite mine in South Africa are prepared, and compared with the domestic yellow pyrophyllite powder compacts (Mentougou, Beijing) produced by the same process, to establish experimental methods and physical criteria for evaluating the pressure transmission and sealing performance of pyrophyllite. During the experiment, standard pressure materials such as Bi, Tl, and Ba are used to in-situ calibrate the pressure at the central positions and sealing edges of the pyrophyllite pressure chambers from the three aforementioned compacts under normal pressure conditions. Additionally, the silver melting point method is employed to obtain the corresponding relationship between chamber pressure at high temperature and system loading when using these three types of pyrophyllite as load-transmitting sealing materials. The results show that under the same hydraulic pressure loading, the difference in pressure at the central position between South African pyrophyllite B powder blocks and domestically produced pyrophyllite powder blocks does not exceed 0.1 GPa. Furthermore, in pressurization process and depressurization processe, the differences in pressure between the central position and the sealing edge of the pyrophyllite blocks are notably similar. Compared with South African pyrophyllite A powder blocks, pyrophyllite B powder blocks exhibit a closer resemblance to domestically produced pyrophyllite powder blocks in terms of high-temperature load transmission and sealing performance. Pyrophyllite B powder blocks from South Africa have the potential to serve as a substitute for domestically produced pyrophyllite without changing the existing superhard material synthesis process, making them promising candidates for use as load-transmitting media and sealing materials. These research findings hold significant academic importance in the realms of high-pressure research and superhard material production. They provide valuable insights into the selection of suitable transmission and sealing materials and the optimization of high-pressure experimental conditions. Additionally, this study presents robust method and criteria for experimental procedures and performance assessment.-

Keywords:

- large-volume cubic static high-pressure apparatus /

- high temperature and high pressure /

- pyrophyllite /

- sealing performance /

- pressure transmission efficiency

[1] 王海阔, 贺端威, 许超, 管俊伟, 王文丹, 寇自力, 彭放 2013 高压 27 633

Google Scholar

Google Scholar

Wang H K, He D W, Xu C, Guan J W, Wang W D, Kou Z L, Peng F 2013 Chin. J. High Pressure Phys. 27 633

Google Scholar

Google Scholar

[2] 彭放, 贺端威 2018 高压 32 010105

Google Scholar

Google Scholar

Peng F, He D W 2018 Chin. J. High Pressure Phys. 32 010105

Google Scholar

Google Scholar

[3] 崔祥仁, 方啸虎, 邢英 2021 超硬材料工程 33 39

Cui X R, Fang X H, Xing Y 2021 Superhard Mater. Eng. 33 39

[4] He D W, Zhao Y S, Sheng T D, et al. 2003 Rev. Sci. Instrum. 74 3012

Google Scholar

Google Scholar

[5] Yan X Z, He D W, Xu C, Ren X T, Zhou X L, Liu S Z 2012 High Press. Res. 32 482

Google Scholar

Google Scholar

[6] Fang L M, He D W, Chen C, Ding L, Luo X J 2007 High Press. Res. 27 367

Google Scholar

Google Scholar

[7] Liu X, Chen J L, Tang J J, He Q, Li S C, Peng F, He D W, Zhang L F, Fei Y W 2012 High Press. Res. 32 239

Google Scholar

Google Scholar

[8] Hu Q W, Fang L M, Li Q, et al. 2019 High Press. Res. 39 655

Google Scholar

Google Scholar

[9] 王海阔, 任瑛, 贺端威, 许超 2017 66 090702

Google Scholar

Google Scholar

Wang H K, Ren Y, He D W, Xu C 2017 Acta Phys. Sin. 66 090702

Google Scholar

Google Scholar

[10] Wang H K, He D W 2012 High Press. Res. 32 186

Google Scholar

Google Scholar

[11] Wang Y P, Kou Z L, Zhang J W, Chen S J, Zhang L, Peng B, Zhao M X, Jiang M L, Yin X S, He D W 2020 Rev. Sci. Instrum. 91 035119.

Google Scholar

Google Scholar

[12] Yan X Z, Ren X T, He D W 2016 Rev. Sci. Instrum. 87 125006

Google Scholar

Google Scholar

[13] 李帅锜, 贺端威, 张佳威 2022 物理 51 228

Google Scholar

Google Scholar

Li S Q, He D W, Zhang J W 2022 Physics 51 228

Google Scholar

Google Scholar

[14] 张佳威, 李强, 王俊普, 贺端威 2019 高压 33 020105

Google Scholar

Google Scholar

Zhang J W, Li Q, Wang J P, He D W 2019 Chin. J. High Pressure Phys. 33 020105

Google Scholar

Google Scholar

[15] 王强, 贺端威, 刘进, 刘方明, 丁未, 马迎功, 刘腾, 李媛媛, 吴京军, 张佳威, 寇自力 2017 高压 31 511

Google Scholar

Google Scholar

Wan Q, He D W, Liu J, Liu F M, Ding W, Ma Y G, Liu T, Li Y Y, Wu J J, Zhang J W, Kou Z L 2017 Chin. J. High Pressure Phys. 31 511

Google Scholar

Google Scholar

[16] 王文丹, 贺端威, 王海阔, 王福龙, 董海妮, 陈海花, 李子扬, 张剑, 王善民, 寇自力, 彭放 2010 59 3107

Google Scholar

Google Scholar

Wang W D, He D W, Wang H K, Wang F L, Dong H N, Chen H H, Li Z Y, Zhang J, Wang S M, Kou Z L, Peng F 2010 Acta Phys. Sin. 59 3107

Google Scholar

Google Scholar

[17] 王福龙, 贺端威, 房雷鸣, 陈晓芳, 李拥军, 张伟, 张 剑, 寇自力, 彭放 2008 57 5429

Google Scholar

Google Scholar

Wang F L, He D W, Fang L M, Chen X F, Li Y J, Zhang W, Zhang J, Kou Z L, Peng F 2008 Acta Phys. Sin. 57 5429

Google Scholar

Google Scholar

[18] 何强, 唐俊杰, 王霏, 刘曦 2014 高压 28 145

He Q, Tang J J, Wang F, Liu X 2014 Chin. J. High Pressure Phys. 28 145

[19] 管俊伟, 贺端威, 王海阔, 彭放, 许超, 王文丹, 王凯雪, 贺凯 2012 61 100701

Google Scholar

Google Scholar

Guan J W, He D W, Wang H K, Peng F, Xu C, Wang W D, Wang K X, He K 2012 Acta Phys. Sin. 61 100701

Google Scholar

Google Scholar

[20] 张旺玺, 梁宝岩, 李启泉 2021 超硬材料工程 33 30

Zhang W X, Liang B Y, Li Q Q 2021 Superhard Mater. Eng. 33 30

[21] 王明智 2020 金刚石与磨料磨具工程 40 1

Wang M Z 2020 Diamond Abrasives Eng. 40 1

[22] 谢光灼, 王绍斌, 李波, 吴瑞良, 陈立舫, 徐珊慧 1998 金刚石与磨料磨具工程 3 7

Xie G Z, Wang S B, Li B, Wu R L, Chen L F, Xu S H 1998 Diamond Abrasives Eng. 3 7

[23] 史斌, 刘鑫, 辛蜜蜜, 林元惠, 赵云鹏, 刘钦甫 2017 煤田地质与勘探 45 25

Google Scholar

Google Scholar

Shi B, Liu X, Xin M M, Lin Y H, Zhao Y P, Liu Q F 2017 Coal Geol. Explor. 45 25

Google Scholar

Google Scholar

[24] 许饮豪, 赵美玉 1995 广东工学院学报 12 72

Xu Y H, Zhao M Y 1995 J. Guangdong Univ. Technol. 12 72

[25] Gatta G D, Lotti P, Merlini M, Liermann H P, Lausi A, Valdrè G, Pavese A 2014 Phys. Chem. Miner. 42 309

Google Scholar

Google Scholar

[26] 陈丽英, 刘秀茹, 吴学华, 苏磊, 洪时明 2004 珠宝科技 16 6

Chen L Y, Liu X R, Wu X H, Su L, Hong S M 2004 Jewelry Science and Technology 16 6

[27] 张巍 2017 金属矿山 8 1

Google Scholar

Google Scholar

Zhang W 2017 Met. Mine 8 1

Google Scholar

Google Scholar

[28] 郑日升, 王大伟, 方啸虎 2011 有色金属工程 63 219

Zheng R S, Wang D W, Fang X H 2011 Nonferrous Metals 63 219

[29] 贾攀, 刘乾坤, 张凤莲, 胡来运, 吴定雨, 王飞飞, 丁建 2015 超硬材料工程 27 34

Jia P, Liu Q K, Zhang F L, Hu L Y, Wu D Y, Wang F F, Ding J 2015 Superhard Mater. Eng. 27 34

[30] Wang H K, He D W, Yan X Z, Xu C, Guan J W, Tan N, Wang W D 2011 High Press. Res. 31 581

Google Scholar

Google Scholar

[31] Li R, Xu B J, Zhang Q C, Gu X, Zheng G L, Ma H A, Jia X P 2016 High Press. Res. 36 575

Google Scholar

Google Scholar

[32] 刘乾坤, 赵鹏, 吴定雨, 昝亚男, 武周军, 王卫康 2019 超硬材料工程 31 16

Liu Q K, Zhao P, Wu D Y, Zan Y N, Wu Z J, Wang W K 2019 Superhard Mater. Eng. 31 16

[33] Zhang J W, Liu F M, Wu J J, et al. 2018 Rev. Sci. Instrum. 89 075106

Google Scholar

Google Scholar

[34] 魏存弟, 赵峰, 马鸿文, 李金洪, 杨殿范, 三国彰 2005 吉林大学学报(地球科学版) 35 150

Wei C D, Zhao F, Ma H W, Li J H, Yang D F, San G Z 2005 J. Jilin Univ. , Earth Sci. Ed. 35 150

[35] 徐文炘, 李蘅, 郭陀珠, 郭桦 2003 矿产与地质 17 242

Google Scholar

Google Scholar

Xu W X, Li H, Guo T Z, Guo H 2003 Mineral Resources and Geology 17 242

Google Scholar

Google Scholar

[36] Boren M D, Babb S E, Scott G J 1965 Rev. Sci. Instrum. 36 1456

Google Scholar

Google Scholar

[37] Decker D L, Bassett W A, Merrill L, Hall H T, Barnett J D 1972 J. Phys. Chem. Ref. Data 1 773

Google Scholar

Google Scholar

[38] Cohen L H, Klement W, Kennedy G C 1966 Phys. Rev. 145 519

Google Scholar

Google Scholar

[39] 张振禹, 汪灵 1998 硅酸盐学报 26 618

Zhang Z Y, Wang L 1998 J. Chin. Silic. Soc. 26 618

[40] 徐跃, 陈晓东, 郝兆印 2007 金刚石与磨料磨具工程 6 76

Google Scholar

Google Scholar

Xu Y, Chen X D, Hao Z Y 2007 Diamond Abrasives Eng. 6 76

Google Scholar

Google Scholar

[41] Chen D M, Jiang Z C, Zhang H F 1991 J. Mineral. Petrol. 2 45 [陈大梅, 姜泽春, 张惠芬 1991 矿物岩石 2 45

Chen D M, Jiang Z C, Zhang H F 1991 J. Mineral. Petrol.2 45 [42] Akella J, Kennedy G C 1971 J. Geophys. Res. 76 496

Google Scholar

Google Scholar

-

图 1 叶腊石粉压立方块的光学照片、断面SEM图及XRD衍射谱 (a)黄色叶腊石; (b)南非A; (c) 南非B; (d) 3种叶腊石的XRD检测结果

Fig. 1. Optical photos, cross section SEM and XRD spectrum of pyrophyllite powder pressing block: (a) Yellow pyrophyllite; (b) South Africa pyrophyllite A; (c) South Africa pyrophyllite B; (d) XRD results of three pyrophyllite powder pressing block.

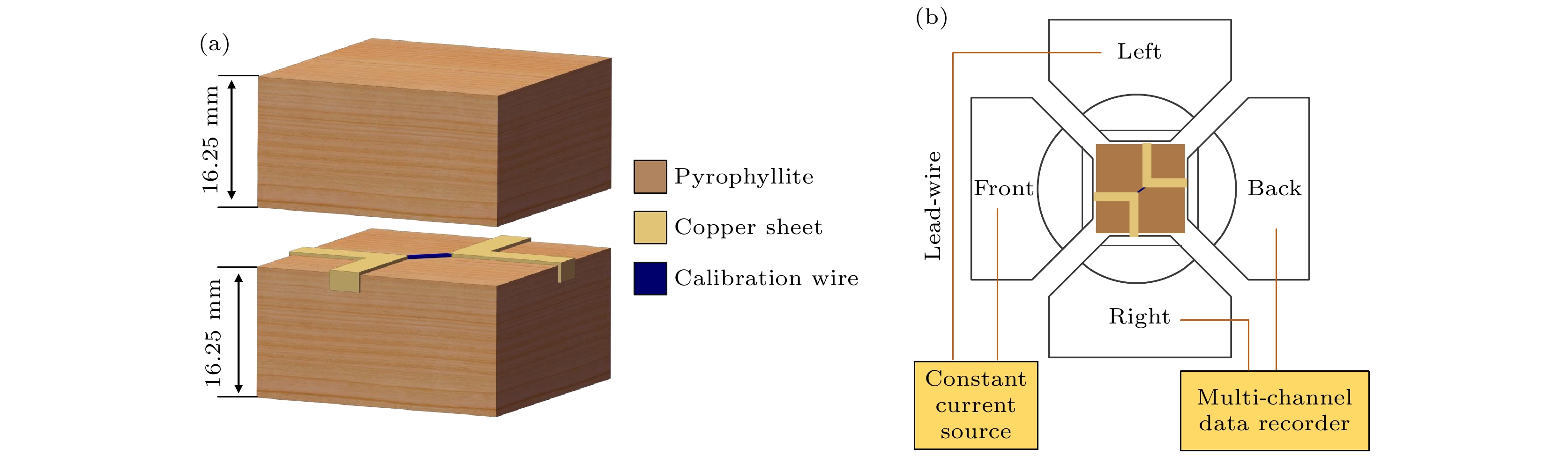

图 3 高温压力标定实验组装示意图及标定结果 (a)实验组装; (b) 50 MPa油压加载下黄色叶腊石作密封材料时的压力标定结果

Fig. 3. Assembly diagram and calibration results of high-temperature pressure calibration experiment: (a) Assembly diagram; (b) pressure calibration results of yellow pyrophyllite as sealing material under 50 MPa oil pressure loading.

-

[1] 王海阔, 贺端威, 许超, 管俊伟, 王文丹, 寇自力, 彭放 2013 高压 27 633

Google Scholar

Google Scholar

Wang H K, He D W, Xu C, Guan J W, Wang W D, Kou Z L, Peng F 2013 Chin. J. High Pressure Phys. 27 633

Google Scholar

Google Scholar

[2] 彭放, 贺端威 2018 高压 32 010105

Google Scholar

Google Scholar

Peng F, He D W 2018 Chin. J. High Pressure Phys. 32 010105

Google Scholar

Google Scholar

[3] 崔祥仁, 方啸虎, 邢英 2021 超硬材料工程 33 39

Cui X R, Fang X H, Xing Y 2021 Superhard Mater. Eng. 33 39

[4] He D W, Zhao Y S, Sheng T D, et al. 2003 Rev. Sci. Instrum. 74 3012

Google Scholar

Google Scholar

[5] Yan X Z, He D W, Xu C, Ren X T, Zhou X L, Liu S Z 2012 High Press. Res. 32 482

Google Scholar

Google Scholar

[6] Fang L M, He D W, Chen C, Ding L, Luo X J 2007 High Press. Res. 27 367

Google Scholar

Google Scholar

[7] Liu X, Chen J L, Tang J J, He Q, Li S C, Peng F, He D W, Zhang L F, Fei Y W 2012 High Press. Res. 32 239

Google Scholar

Google Scholar

[8] Hu Q W, Fang L M, Li Q, et al. 2019 High Press. Res. 39 655

Google Scholar

Google Scholar

[9] 王海阔, 任瑛, 贺端威, 许超 2017 66 090702

Google Scholar

Google Scholar

Wang H K, Ren Y, He D W, Xu C 2017 Acta Phys. Sin. 66 090702

Google Scholar

Google Scholar

[10] Wang H K, He D W 2012 High Press. Res. 32 186

Google Scholar

Google Scholar

[11] Wang Y P, Kou Z L, Zhang J W, Chen S J, Zhang L, Peng B, Zhao M X, Jiang M L, Yin X S, He D W 2020 Rev. Sci. Instrum. 91 035119.

Google Scholar

Google Scholar

[12] Yan X Z, Ren X T, He D W 2016 Rev. Sci. Instrum. 87 125006

Google Scholar

Google Scholar

[13] 李帅锜, 贺端威, 张佳威 2022 物理 51 228

Google Scholar

Google Scholar

Li S Q, He D W, Zhang J W 2022 Physics 51 228

Google Scholar

Google Scholar

[14] 张佳威, 李强, 王俊普, 贺端威 2019 高压 33 020105

Google Scholar

Google Scholar

Zhang J W, Li Q, Wang J P, He D W 2019 Chin. J. High Pressure Phys. 33 020105

Google Scholar

Google Scholar

[15] 王强, 贺端威, 刘进, 刘方明, 丁未, 马迎功, 刘腾, 李媛媛, 吴京军, 张佳威, 寇自力 2017 高压 31 511

Google Scholar

Google Scholar

Wan Q, He D W, Liu J, Liu F M, Ding W, Ma Y G, Liu T, Li Y Y, Wu J J, Zhang J W, Kou Z L 2017 Chin. J. High Pressure Phys. 31 511

Google Scholar

Google Scholar

[16] 王文丹, 贺端威, 王海阔, 王福龙, 董海妮, 陈海花, 李子扬, 张剑, 王善民, 寇自力, 彭放 2010 59 3107

Google Scholar

Google Scholar

Wang W D, He D W, Wang H K, Wang F L, Dong H N, Chen H H, Li Z Y, Zhang J, Wang S M, Kou Z L, Peng F 2010 Acta Phys. Sin. 59 3107

Google Scholar

Google Scholar

[17] 王福龙, 贺端威, 房雷鸣, 陈晓芳, 李拥军, 张伟, 张 剑, 寇自力, 彭放 2008 57 5429

Google Scholar

Google Scholar

Wang F L, He D W, Fang L M, Chen X F, Li Y J, Zhang W, Zhang J, Kou Z L, Peng F 2008 Acta Phys. Sin. 57 5429

Google Scholar

Google Scholar

[18] 何强, 唐俊杰, 王霏, 刘曦 2014 高压 28 145

He Q, Tang J J, Wang F, Liu X 2014 Chin. J. High Pressure Phys. 28 145

[19] 管俊伟, 贺端威, 王海阔, 彭放, 许超, 王文丹, 王凯雪, 贺凯 2012 61 100701

Google Scholar

Google Scholar

Guan J W, He D W, Wang H K, Peng F, Xu C, Wang W D, Wang K X, He K 2012 Acta Phys. Sin. 61 100701

Google Scholar

Google Scholar

[20] 张旺玺, 梁宝岩, 李启泉 2021 超硬材料工程 33 30

Zhang W X, Liang B Y, Li Q Q 2021 Superhard Mater. Eng. 33 30

[21] 王明智 2020 金刚石与磨料磨具工程 40 1

Wang M Z 2020 Diamond Abrasives Eng. 40 1

[22] 谢光灼, 王绍斌, 李波, 吴瑞良, 陈立舫, 徐珊慧 1998 金刚石与磨料磨具工程 3 7

Xie G Z, Wang S B, Li B, Wu R L, Chen L F, Xu S H 1998 Diamond Abrasives Eng. 3 7

[23] 史斌, 刘鑫, 辛蜜蜜, 林元惠, 赵云鹏, 刘钦甫 2017 煤田地质与勘探 45 25

Google Scholar

Google Scholar

Shi B, Liu X, Xin M M, Lin Y H, Zhao Y P, Liu Q F 2017 Coal Geol. Explor. 45 25

Google Scholar

Google Scholar

[24] 许饮豪, 赵美玉 1995 广东工学院学报 12 72

Xu Y H, Zhao M Y 1995 J. Guangdong Univ. Technol. 12 72

[25] Gatta G D, Lotti P, Merlini M, Liermann H P, Lausi A, Valdrè G, Pavese A 2014 Phys. Chem. Miner. 42 309

Google Scholar

Google Scholar

[26] 陈丽英, 刘秀茹, 吴学华, 苏磊, 洪时明 2004 珠宝科技 16 6

Chen L Y, Liu X R, Wu X H, Su L, Hong S M 2004 Jewelry Science and Technology 16 6

[27] 张巍 2017 金属矿山 8 1

Google Scholar

Google Scholar

Zhang W 2017 Met. Mine 8 1

Google Scholar

Google Scholar

[28] 郑日升, 王大伟, 方啸虎 2011 有色金属工程 63 219

Zheng R S, Wang D W, Fang X H 2011 Nonferrous Metals 63 219

[29] 贾攀, 刘乾坤, 张凤莲, 胡来运, 吴定雨, 王飞飞, 丁建 2015 超硬材料工程 27 34

Jia P, Liu Q K, Zhang F L, Hu L Y, Wu D Y, Wang F F, Ding J 2015 Superhard Mater. Eng. 27 34

[30] Wang H K, He D W, Yan X Z, Xu C, Guan J W, Tan N, Wang W D 2011 High Press. Res. 31 581

Google Scholar

Google Scholar

[31] Li R, Xu B J, Zhang Q C, Gu X, Zheng G L, Ma H A, Jia X P 2016 High Press. Res. 36 575

Google Scholar

Google Scholar

[32] 刘乾坤, 赵鹏, 吴定雨, 昝亚男, 武周军, 王卫康 2019 超硬材料工程 31 16

Liu Q K, Zhao P, Wu D Y, Zan Y N, Wu Z J, Wang W K 2019 Superhard Mater. Eng. 31 16

[33] Zhang J W, Liu F M, Wu J J, et al. 2018 Rev. Sci. Instrum. 89 075106

Google Scholar

Google Scholar

[34] 魏存弟, 赵峰, 马鸿文, 李金洪, 杨殿范, 三国彰 2005 吉林大学学报(地球科学版) 35 150

Wei C D, Zhao F, Ma H W, Li J H, Yang D F, San G Z 2005 J. Jilin Univ. , Earth Sci. Ed. 35 150

[35] 徐文炘, 李蘅, 郭陀珠, 郭桦 2003 矿产与地质 17 242

Google Scholar

Google Scholar

Xu W X, Li H, Guo T Z, Guo H 2003 Mineral Resources and Geology 17 242

Google Scholar

Google Scholar

[36] Boren M D, Babb S E, Scott G J 1965 Rev. Sci. Instrum. 36 1456

Google Scholar

Google Scholar

[37] Decker D L, Bassett W A, Merrill L, Hall H T, Barnett J D 1972 J. Phys. Chem. Ref. Data 1 773

Google Scholar

Google Scholar

[38] Cohen L H, Klement W, Kennedy G C 1966 Phys. Rev. 145 519

Google Scholar

Google Scholar

[39] 张振禹, 汪灵 1998 硅酸盐学报 26 618

Zhang Z Y, Wang L 1998 J. Chin. Silic. Soc. 26 618

[40] 徐跃, 陈晓东, 郝兆印 2007 金刚石与磨料磨具工程 6 76

Google Scholar

Google Scholar

Xu Y, Chen X D, Hao Z Y 2007 Diamond Abrasives Eng. 6 76

Google Scholar

Google Scholar

[41] Chen D M, Jiang Z C, Zhang H F 1991 J. Mineral. Petrol. 2 45 [陈大梅, 姜泽春, 张惠芬 1991 矿物岩石 2 45

Chen D M, Jiang Z C, Zhang H F 1991 J. Mineral. Petrol.2 45 [42] Akella J, Kennedy G C 1971 J. Geophys. Res. 76 496

Google Scholar

Google Scholar

计量

- 文章访问数: 4226

- PDF下载量: 225

- 被引次数: 0

下载:

下载: