-

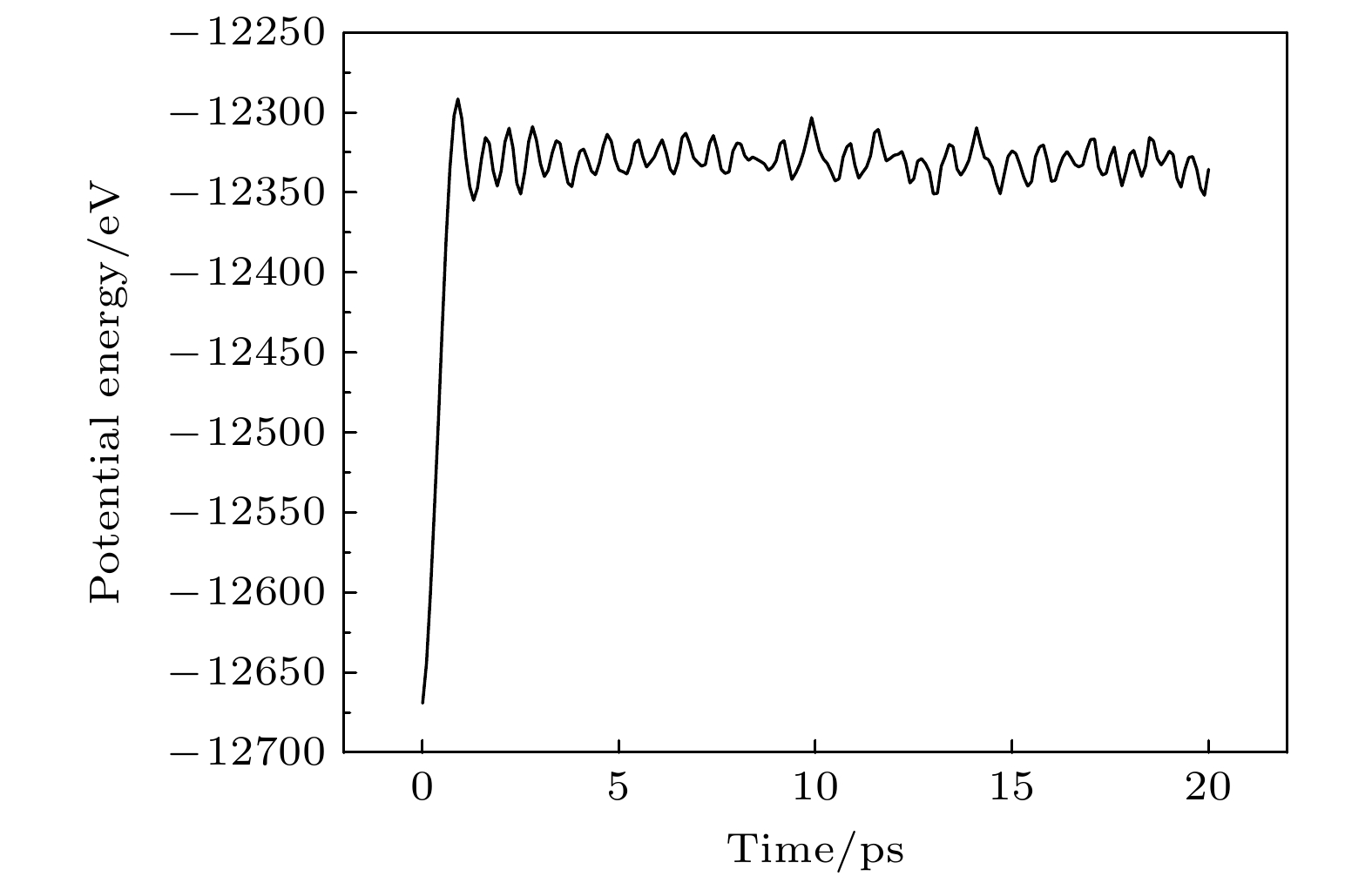

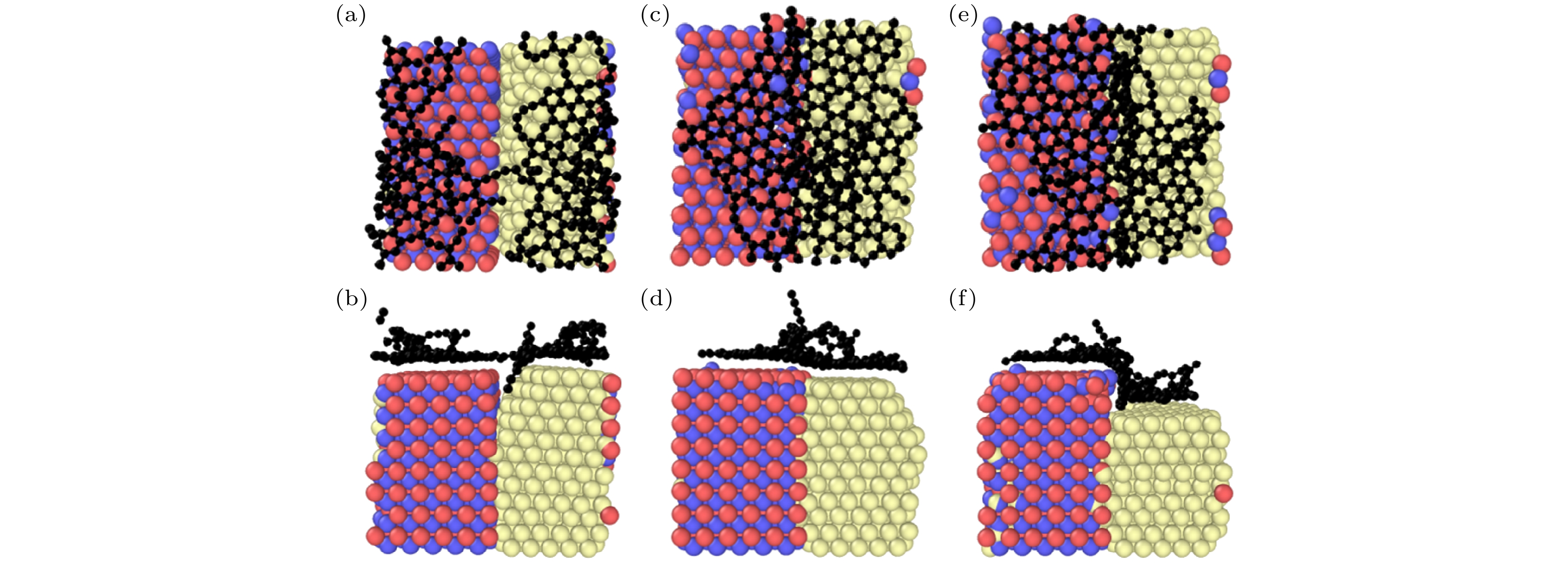

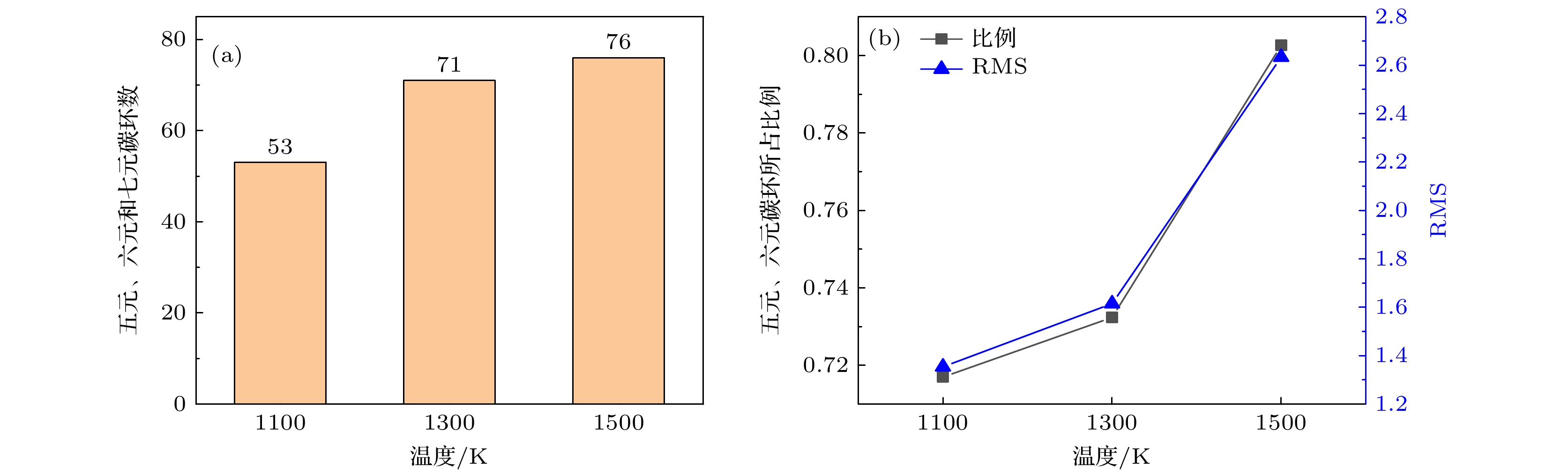

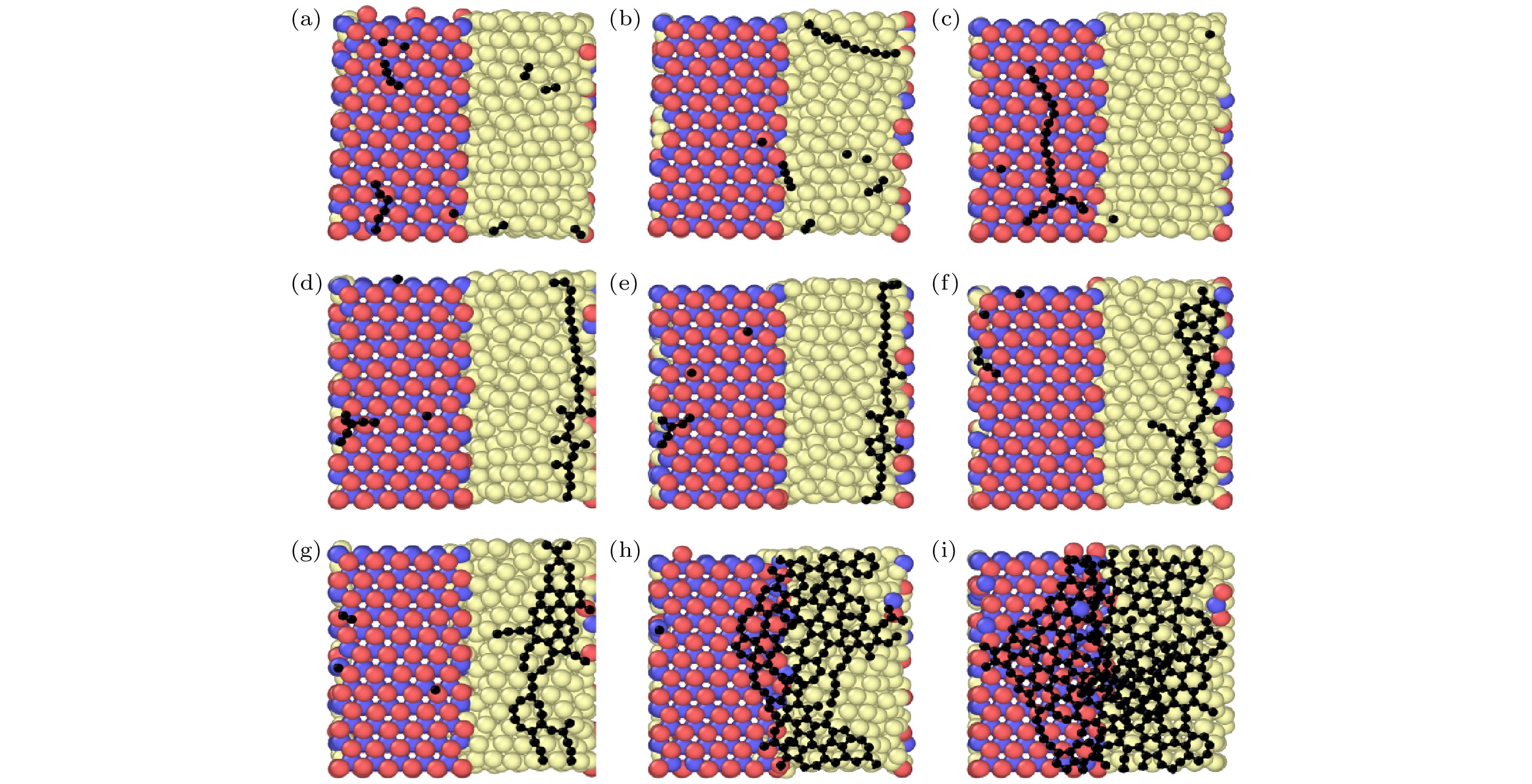

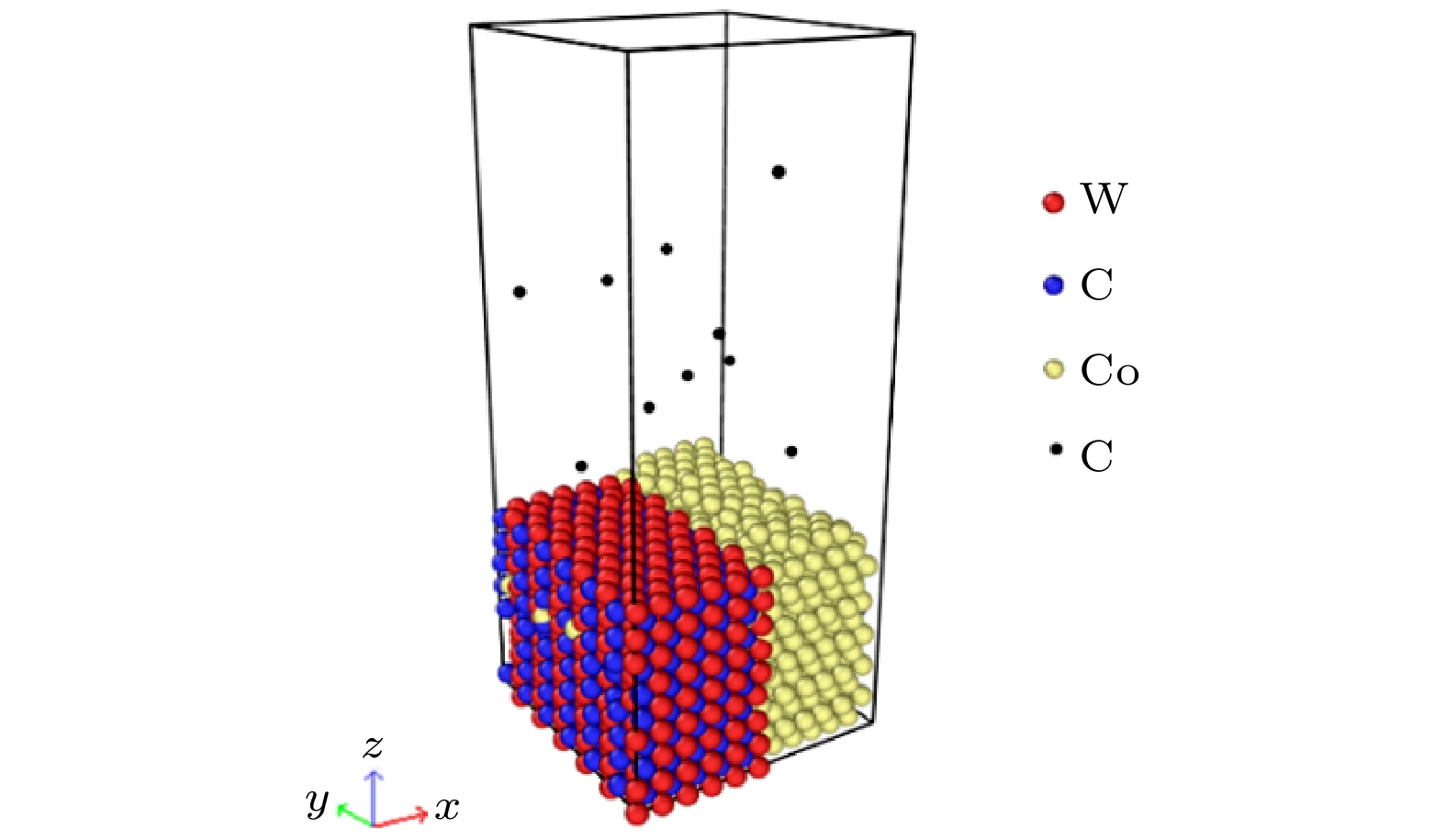

对碳原子在硬质合金(WC-Co)表面的自组装及石墨烯生长过程进行了分子动力学模拟. 揭示石墨烯生长中的碳原子沉积、不同长度碳链形成, 以及碳链向多边形转变和石墨烯缺陷愈合及自修复过程. 研究温度和碳沉积速率对高质量石墨烯生长的影响. 模拟结果发现, 低温生长的石墨烯缺陷较多, 质量较低; 高温有助于石墨烯生长, 但是高温会对基底造成损伤, 使生长的石墨烯表面平整度降低. 较高的沉积速率, 获得较高的石墨烯形核率, 分布较为均匀, 但是存在较多的缺陷, 而低的沉积速率有助于碳原子的迁移, 导致碳原子出现团聚, 降低石墨烯质量. 因此, 选择合适的沉积温度和沉积速率有助于生长高质量石墨烯. 仿真优化参数即沉积温度为1300 K, 沉积速率为10 ps/C时, 生长的石墨烯表面平整度较高(RMS = 1.615), 且保持着数目较多的基本单元(N = 71), 质量较好.In this paper, molecular dynamics is used to simulate the self-assembly of carbon atoms and the growth of graphene on the surface of cemented carbide, which has some advantages, such as reducing manufacturing costs, shortening the experimental cycle, and optimizing the preparation parameters of graphene. A proper potential function is designed to simulate the formation of graphene on the WC (

$10 \bar{1} 0$ ) surface and Co (0001) surface by a single carbon atom. The growth process of graphene, such as the deposition of carbon atoms, the formation of carbon chains with different lengths, the transformation about carbon chains into polygons, and the basic units and natural defects of graphene are investigated in detail. Three processes of self-repair of graphene defects, including carbon chain rotation, splitting and embedding, are described respectively. The effects of temperature and carbon deposition rate on the growth of high-quality graphene are also studied. The simulation results show that at low temperature, the mobility of carbon atoms is low and grown graphene contains a lot of defects, and the coverage of the substrate is low, which leads to low quality graphene to be prepared. High temperature promotes the migration of carbon atoms and helps to grow high quality graphene. However, high temperature can cause damage to the substrate and reduce the flatness of the growing graphene. At a higher deposition rate, the nucleation rate of graphene is higher and the distribution is more uniform. However, due to the different ability of each graphene nucleus to absorb carbon atoms, there are many macrocyclic defects in the graphene. The low deposition rate has a longer annealing time, which excessively stimulates the migration of carbon atoms. It leads to the aggregation of carbon atoms and reduce the quality of graphene. The proper deposition rate can ensure the nucleation density of graphene, and at the same time, it has enough time to form six membered rings and repair defects, which is conducive to the formation of the high quality graphene. Therefore, it is significantly important to design the appropriate deposition temperature and deposition rate for the growth of high-quality graphene. After optimizing the simulation parameters, high-quality graphene is successfully grown at 1300 K deposition temperature and 10 ps/C deposition rate.-

Keywords:

- molecular dynamics /

- graphene /

- cemented carbide /

- deposition rate

[1] Barfmal M, Montazeri A 2017 Ceram. Int. 43 17167

Google Scholar

Google Scholar

[2] 林奎鑫, 李多生, 叶寅, 江五贵, 叶志国, Qin Qinghua, 邹伟 2018 67 246802

Google Scholar

Google Scholar

Lin K X, Li D S, Ye Y, Jiang W G, Ye Z G, Qin Q H, Zou W 2018 Acta Phys. Sin. 67 246802

Google Scholar

Google Scholar

[3] Novoselov K S, Geim A K, Morozov S V, Jiang D, Zhang Y, Dubonos S V, Grigorieva I V, Firsov A A 2004 Science 306 666

Google Scholar

Google Scholar

[4] Kumar N, Salehiyan R, Chauke V, Joseph Botlhoko O, Setshedi K, Scriba M, Masukume M, Sinha Ray S 2021 FlatChem 27 100224

Google Scholar

Google Scholar

[5] Manawi Y M, Ihsanullah, Samara A, Al-Ansari T, Atieh M A 2018 Materials 11 822

Google Scholar

Google Scholar

[6] Shi Q, Tokarska K, Ta H Q, Yang X, Liu Y, Ullah S, Liu L, Trzebicka B, Bachmatiuk A, Sun J, Fu L, Liu Z, Rümmeli M H 2020 Adv. Mater. Interfaces 7 1902024

Google Scholar

Google Scholar

[7] Dong Y, Guo S, Mao H, Xu C, Xie Y, Deng J, Wang L, Du Z, Xiong F, Sun J 2019 ACS Appl. Electron. Mater. 2 238

Google Scholar

Google Scholar

[8] Kim S, Shin S, Kim T, Du H, Song M, Lee C W, Kim K, Cho S, Seo D H, Seo S 2016 Carbon 98 352

Google Scholar

Google Scholar

[9] Sein H, Ahmed W, Rego C A, Jones A N, Amar M, Jackson M, Polini R 2003 J. Phys. Condens. Matter. 15 S2961

Google Scholar

Google Scholar

[10] Tian Q, Huang N, Yang B, Zhuang H, Wang C, Zhai Z, Li J, Jia X, Liu L, Jiang X 2017 J. Mater. Sci. Technol. 33 1097

Google Scholar

Google Scholar

[11] Kim J S, Park Y M, Bae M K, Kim C W, Kim D W, Shin D C, Kim T G 2018 Mod. Phys. Lett. B 32 1850236

Google Scholar

Google Scholar

[12] Liu K, Ren E, Ma J, Cao Y, Du J, Ming W, Li X, Li B 2020 J. Mater. Sci. 55 4251

Google Scholar

Google Scholar

[13] 李锦锦, 李多生, 洪跃, 邹伟, 何俊杰 2017 66 217101

Google Scholar

Google Scholar

Li J J, Li D S, Hong Y, Zou W, He J J 2017 Acta Phys. Sin. 66 217101

Google Scholar

Google Scholar

[14] 王泽, 李国禄, 王海斗, 徐滨士, 康嘉杰 2014 材料导报 28 91

Google Scholar

Google Scholar

Wang Z, Li G L, Wang H D, Xu B S, Kang J J 2014 Mater. Rev. 28 91

Google Scholar

Google Scholar

[15] 颜超, 段军红, 何兴道 2010 59 8807

Google Scholar

Google Scholar

Yan C, Duan J H, He X D 2010 Acta Phys. Sin. 59 8807

Google Scholar

Google Scholar

[16] Rong Y, Zhang L, He H 2021 Thin Solid Films 732 138778

Google Scholar

Google Scholar

[17] Kametani N, Nakamura M, Yashiro K, Takaki T 2022 Comput. Mater. Sci. 209 111420

Google Scholar

Google Scholar

[18] Nasim M, Vo T Q, Mustafi L, Kim B H, Lee C S, Chu W S, Chun D M 2019 Comput. Mater. Sci. 169 109091

Google Scholar

Google Scholar

[19] Shibuta Y, Elliott J A 2009 Chem. Phys. Lett. 472 200

Google Scholar

Google Scholar

[20] Xu Z, Yan T, Liu G, Qiao G, Ding F 2016 Nanoscale 8 921

Google Scholar

Google Scholar

[21] 白清顺, 窦昱昊, 何欣, 张爱民, 郭永博 2020 69 226102

Google Scholar

Google Scholar

Bai Q S, Dou Y H, He X, Zhang A M, Guo Y B 2020 Acta Phys. Sin. 69 226102

Google Scholar

Google Scholar

[22] Edin E, Blomqvist A, Lattemann M, Luo W, Ahuja R 2019 Int. J. Refract. Met. Hard Mater. 85 105054

Google Scholar

Google Scholar

[23] Juslin N, Erhart P, Träskelin P, Nord J, Henriksson K O E, Nordlund K, Salonen E, Albe K 2005 J. Appl. Phys. 98 123520

Google Scholar

Google Scholar

[24] Petisme M V G, Gren M A, Wahnström G 2015 Int. J. Refract. Met. Hard Mater. 49 75

Google Scholar

Google Scholar

[25] Feng Q, Song X Y, Xie H X, Wang H B, Liu X M, Yin F X 2017 Mater. Design. 120 193

Google Scholar

Google Scholar

[26] Daw M S, Baskes M I 1984 Phys. Rev. B 29 6443

Google Scholar

Google Scholar

[27] Stuart S J, Tutein A B, Harrison J A 2000 J. Chem. Phys. 112 6472

Google Scholar

Google Scholar

[28] Morse P M 1929 Phys. Rev. 34 57

Google Scholar

Google Scholar

[29] 冯艳, 段海明 2011 原子与分子 28 251

Google Scholar

Google Scholar

Feng Y, Duan H M 2011 J. At. Mol. Phys. 28 251

Google Scholar

Google Scholar

[30] Jones J E 1924 Proc. R. Soc. London, Ser. A 106 463

Google Scholar

Google Scholar

[31] Pun G P P, Mishin Y 2012 Phys. Rev. B 86 134116

Google Scholar

Google Scholar

[32] Brenner D W, Shenderova O A, Harrison J A, Stuart S J, Ni B, Sinnott S B 2002 J. Phys. Condens. Matter. 14 783

Google Scholar

Google Scholar

[33] Cao Q, Chen Y, Shao W, Ma X, Zheng C, Cui Z, Liu Y, Yu B 2020 J. Mol. Liq. 319 114218

Google Scholar

Google Scholar

[34] Li N, Zhen Z, Zhang R, Mu R, Xu Z, He L 2022 Vacuum 196 110750

Google Scholar

Google Scholar

[35] Yan H, Yang H, Lin S, He J, Zhang M, Li H 2021 Thin Solid Films 736 138921

Google Scholar

Google Scholar

[36] Batzill M 2012 Surf. Sci. Rep. 67 83

Google Scholar

Google Scholar

[37] Yu X, Zhang Z, Liu F, Pei J X, Tian X Y 2019 J. Alloys Compd. 806 1309

Google Scholar

Google Scholar

[38] Zhang L, Zhu Y C, Teng W R, Xia T, Rong Y, Li N, Ma H Z 2017 Comput. Mater. Sci. 130 10

Google Scholar

Google Scholar

-

图 4 不同温度下, 生长石墨烯的质量 (a) 不同温度下, 石墨烯中五元、六元和七元碳环数; (b) 黑色折线表示不同温度下, 五元和六元碳环所占的比例; 蓝色折线表示不同温度下, 石墨烯的RMS值

Fig. 4. Quality of growing graphene at different temperatures: (a) The number of five, six, and seven-membered carbon rings in graphene at different temperatures; (b) the black broken line represents the proportions of five and six-membered carbon rings at different temperatures; the blue broken line represents the RMS values of graphene at different temperatures.

图 5 不同CDR下, 生长石墨烯的正视图、侧视图以及三维形貌图 (a), (b), (c), (d) CDR为2, 5, 10, 20 ps/C时的正视图; (e), (f), (g), (h) CDR为2, 5, 10, 20 ps/C时的侧视图; (i), (j), (k), (l) CDR为2, 5, 10, 20 ps/C时的三维形貌图

Fig. 5. Front view, side view and topography of growing graphene under different CDRs: (a), (b), (c), (d) The front views at CDRs of 2, 5, 10, 20 ps/C; (e), (f), (g), (h) the side views at CDRs of 2, 5, 10, 20 ps/C; (i), (j), (k), (l) three-dimensional topography at CDRs of 2, 5, 10, 20 ps/C.

图 7 在不同时间, 在硬质合金表面生长石墨烯的正视图 (a) 0.229 ns; (b) 0.250 ns; (c) 0.264 ns; (d) 0.405 ns; (e) 0.411 ns; (f) 0.587 ns; (g) 0.676 ns; (h) 1.649 ns; (i) 3.070 ns

Fig. 7. Front views of graphene growth on cemented carbide at different times: (a) 0.229 ns; (b) 0.250 ns; (c) 0.264 ns; (d) 0.405 ns; (e) 0.411 ns; (f) 0.587 ns; (g) 0.676 ns; (h) 1.649 ns; (i) 3.070 ns.

表 1 WC的ABOP使用的拟合参数, W-C 系统的参数取自文献[23]

Table 1. Fit parameters used by the ABOP of WC, the parameters for the W-C system are taken from Ref. [23].

W-W W-C C-C D0/eV 5.41861 6.64 6.0 r0/Å 2.34095 1.90547 1.39 β/Å–1 1.38528 1.80370 2.1 S 1.92708 2.96149 1.22 γ 1.88227$ \times {10}^{-3} $ 7.2855$ \times {10}^{-2} $ 2.0813$ \times {10}^{-4} $ α/Å–1 0.45876 0.0 0.0 c 2.14969 1.10304 330 d 0.17126 0.33018 3.5 h –0.27780 0.75107 1.0 R/Å 3.5 2.8 1.85 D/Å 0.3 0.2 0.15 -

[1] Barfmal M, Montazeri A 2017 Ceram. Int. 43 17167

Google Scholar

Google Scholar

[2] 林奎鑫, 李多生, 叶寅, 江五贵, 叶志国, Qin Qinghua, 邹伟 2018 67 246802

Google Scholar

Google Scholar

Lin K X, Li D S, Ye Y, Jiang W G, Ye Z G, Qin Q H, Zou W 2018 Acta Phys. Sin. 67 246802

Google Scholar

Google Scholar

[3] Novoselov K S, Geim A K, Morozov S V, Jiang D, Zhang Y, Dubonos S V, Grigorieva I V, Firsov A A 2004 Science 306 666

Google Scholar

Google Scholar

[4] Kumar N, Salehiyan R, Chauke V, Joseph Botlhoko O, Setshedi K, Scriba M, Masukume M, Sinha Ray S 2021 FlatChem 27 100224

Google Scholar

Google Scholar

[5] Manawi Y M, Ihsanullah, Samara A, Al-Ansari T, Atieh M A 2018 Materials 11 822

Google Scholar

Google Scholar

[6] Shi Q, Tokarska K, Ta H Q, Yang X, Liu Y, Ullah S, Liu L, Trzebicka B, Bachmatiuk A, Sun J, Fu L, Liu Z, Rümmeli M H 2020 Adv. Mater. Interfaces 7 1902024

Google Scholar

Google Scholar

[7] Dong Y, Guo S, Mao H, Xu C, Xie Y, Deng J, Wang L, Du Z, Xiong F, Sun J 2019 ACS Appl. Electron. Mater. 2 238

Google Scholar

Google Scholar

[8] Kim S, Shin S, Kim T, Du H, Song M, Lee C W, Kim K, Cho S, Seo D H, Seo S 2016 Carbon 98 352

Google Scholar

Google Scholar

[9] Sein H, Ahmed W, Rego C A, Jones A N, Amar M, Jackson M, Polini R 2003 J. Phys. Condens. Matter. 15 S2961

Google Scholar

Google Scholar

[10] Tian Q, Huang N, Yang B, Zhuang H, Wang C, Zhai Z, Li J, Jia X, Liu L, Jiang X 2017 J. Mater. Sci. Technol. 33 1097

Google Scholar

Google Scholar

[11] Kim J S, Park Y M, Bae M K, Kim C W, Kim D W, Shin D C, Kim T G 2018 Mod. Phys. Lett. B 32 1850236

Google Scholar

Google Scholar

[12] Liu K, Ren E, Ma J, Cao Y, Du J, Ming W, Li X, Li B 2020 J. Mater. Sci. 55 4251

Google Scholar

Google Scholar

[13] 李锦锦, 李多生, 洪跃, 邹伟, 何俊杰 2017 66 217101

Google Scholar

Google Scholar

Li J J, Li D S, Hong Y, Zou W, He J J 2017 Acta Phys. Sin. 66 217101

Google Scholar

Google Scholar

[14] 王泽, 李国禄, 王海斗, 徐滨士, 康嘉杰 2014 材料导报 28 91

Google Scholar

Google Scholar

Wang Z, Li G L, Wang H D, Xu B S, Kang J J 2014 Mater. Rev. 28 91

Google Scholar

Google Scholar

[15] 颜超, 段军红, 何兴道 2010 59 8807

Google Scholar

Google Scholar

Yan C, Duan J H, He X D 2010 Acta Phys. Sin. 59 8807

Google Scholar

Google Scholar

[16] Rong Y, Zhang L, He H 2021 Thin Solid Films 732 138778

Google Scholar

Google Scholar

[17] Kametani N, Nakamura M, Yashiro K, Takaki T 2022 Comput. Mater. Sci. 209 111420

Google Scholar

Google Scholar

[18] Nasim M, Vo T Q, Mustafi L, Kim B H, Lee C S, Chu W S, Chun D M 2019 Comput. Mater. Sci. 169 109091

Google Scholar

Google Scholar

[19] Shibuta Y, Elliott J A 2009 Chem. Phys. Lett. 472 200

Google Scholar

Google Scholar

[20] Xu Z, Yan T, Liu G, Qiao G, Ding F 2016 Nanoscale 8 921

Google Scholar

Google Scholar

[21] 白清顺, 窦昱昊, 何欣, 张爱民, 郭永博 2020 69 226102

Google Scholar

Google Scholar

Bai Q S, Dou Y H, He X, Zhang A M, Guo Y B 2020 Acta Phys. Sin. 69 226102

Google Scholar

Google Scholar

[22] Edin E, Blomqvist A, Lattemann M, Luo W, Ahuja R 2019 Int. J. Refract. Met. Hard Mater. 85 105054

Google Scholar

Google Scholar

[23] Juslin N, Erhart P, Träskelin P, Nord J, Henriksson K O E, Nordlund K, Salonen E, Albe K 2005 J. Appl. Phys. 98 123520

Google Scholar

Google Scholar

[24] Petisme M V G, Gren M A, Wahnström G 2015 Int. J. Refract. Met. Hard Mater. 49 75

Google Scholar

Google Scholar

[25] Feng Q, Song X Y, Xie H X, Wang H B, Liu X M, Yin F X 2017 Mater. Design. 120 193

Google Scholar

Google Scholar

[26] Daw M S, Baskes M I 1984 Phys. Rev. B 29 6443

Google Scholar

Google Scholar

[27] Stuart S J, Tutein A B, Harrison J A 2000 J. Chem. Phys. 112 6472

Google Scholar

Google Scholar

[28] Morse P M 1929 Phys. Rev. 34 57

Google Scholar

Google Scholar

[29] 冯艳, 段海明 2011 原子与分子 28 251

Google Scholar

Google Scholar

Feng Y, Duan H M 2011 J. At. Mol. Phys. 28 251

Google Scholar

Google Scholar

[30] Jones J E 1924 Proc. R. Soc. London, Ser. A 106 463

Google Scholar

Google Scholar

[31] Pun G P P, Mishin Y 2012 Phys. Rev. B 86 134116

Google Scholar

Google Scholar

[32] Brenner D W, Shenderova O A, Harrison J A, Stuart S J, Ni B, Sinnott S B 2002 J. Phys. Condens. Matter. 14 783

Google Scholar

Google Scholar

[33] Cao Q, Chen Y, Shao W, Ma X, Zheng C, Cui Z, Liu Y, Yu B 2020 J. Mol. Liq. 319 114218

Google Scholar

Google Scholar

[34] Li N, Zhen Z, Zhang R, Mu R, Xu Z, He L 2022 Vacuum 196 110750

Google Scholar

Google Scholar

[35] Yan H, Yang H, Lin S, He J, Zhang M, Li H 2021 Thin Solid Films 736 138921

Google Scholar

Google Scholar

[36] Batzill M 2012 Surf. Sci. Rep. 67 83

Google Scholar

Google Scholar

[37] Yu X, Zhang Z, Liu F, Pei J X, Tian X Y 2019 J. Alloys Compd. 806 1309

Google Scholar

Google Scholar

[38] Zhang L, Zhu Y C, Teng W R, Xia T, Rong Y, Li N, Ma H Z 2017 Comput. Mater. Sci. 130 10

Google Scholar

Google Scholar

计量

- 文章访问数: 7699

- PDF下载量: 108

- 被引次数: 0

下载:

下载: