-

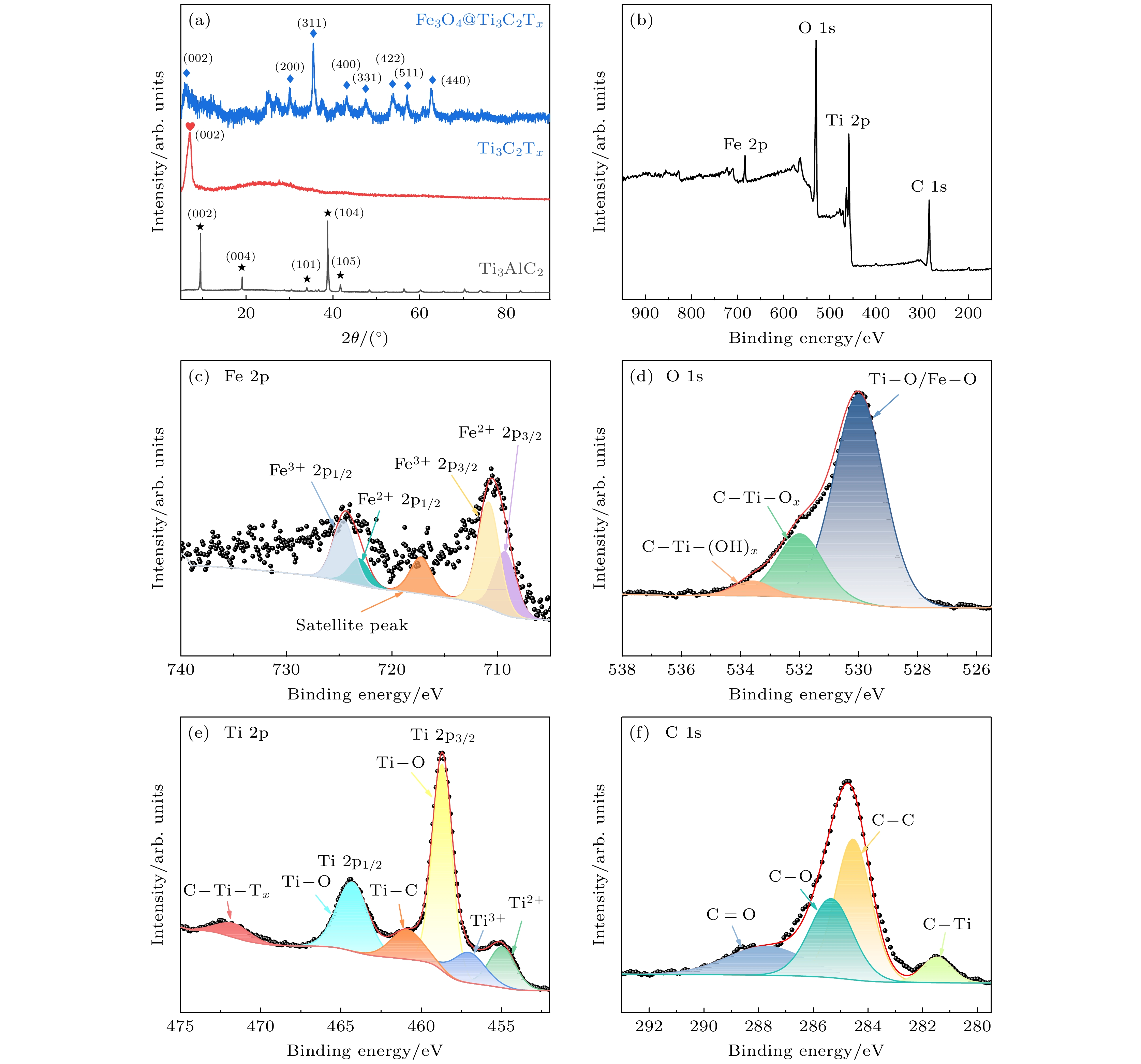

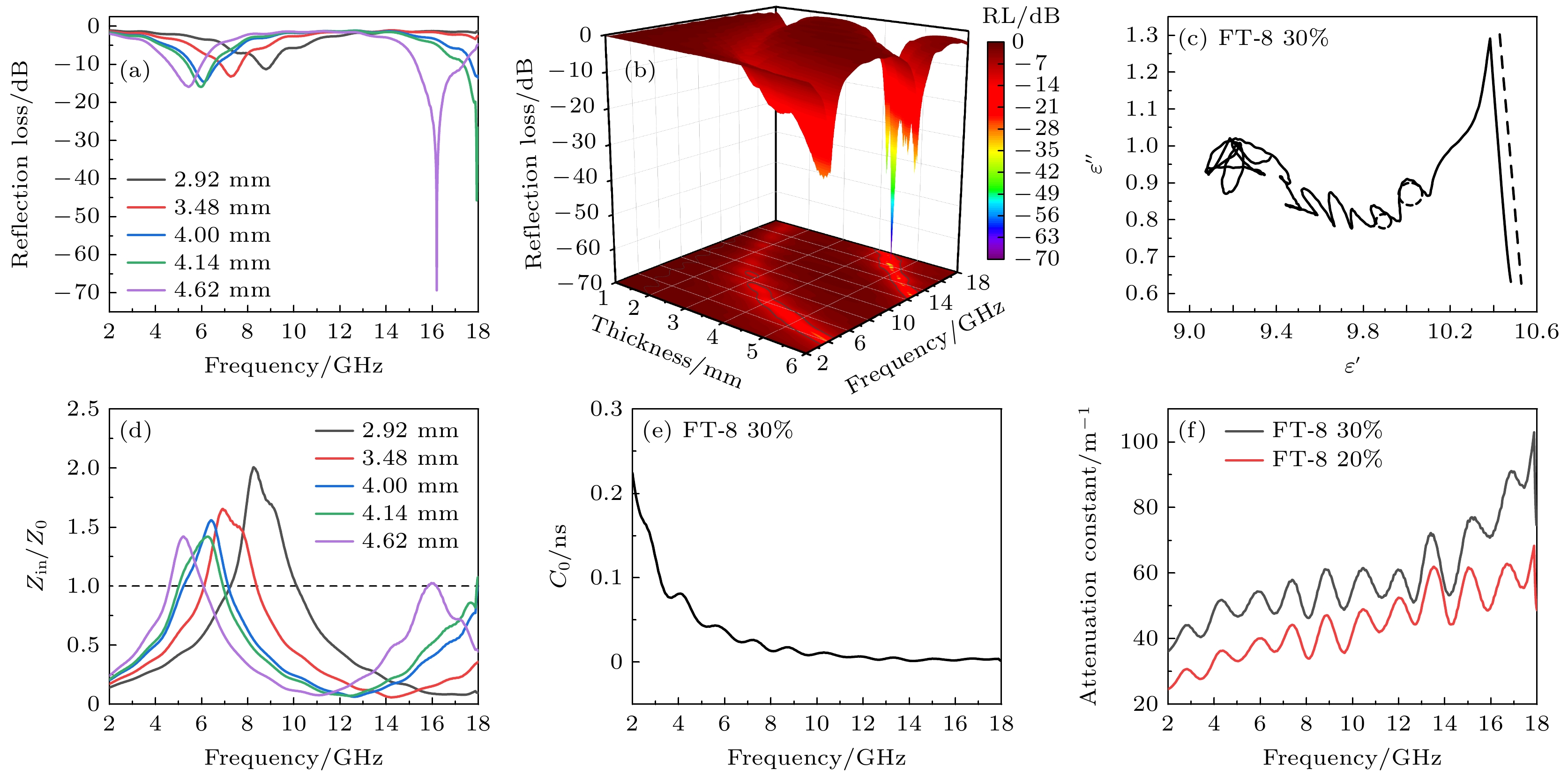

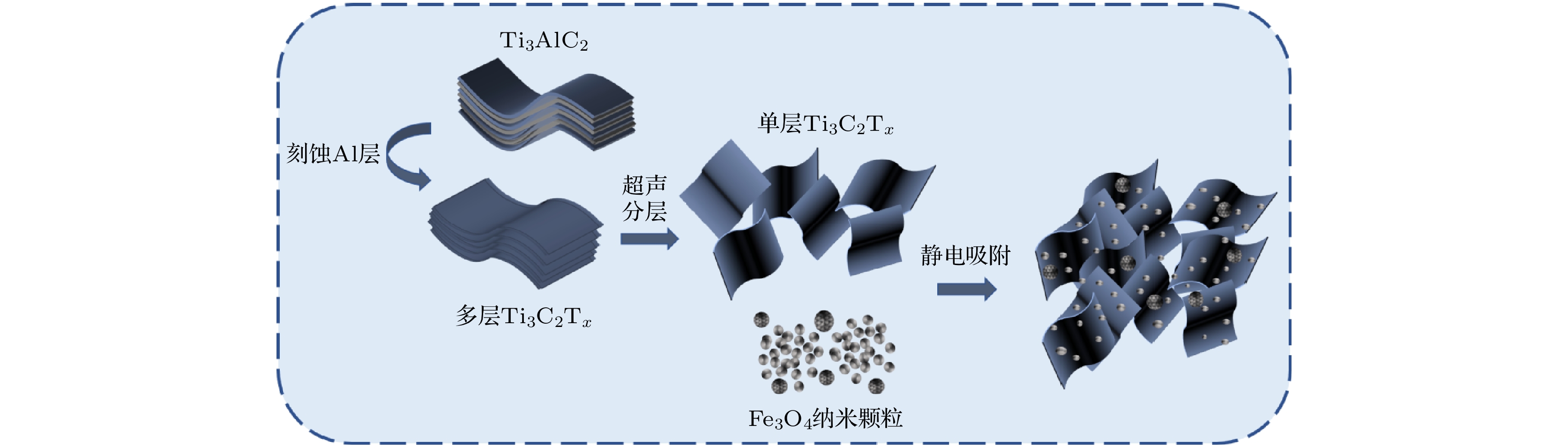

二维碳/氮化物MXene近年来受到了越来越多的关注, 其优异的导电性和表面丰富的官能团可对电磁波吸收有着积极的作用. 然而作为仅有介电损耗的非磁性材料, MXene存在着阻抗不匹配等问题, 极大地限制了实际应用. 因此, 将磁性材料与MXene结合成为了目前微波吸收领域的研究热点, 而降低MXene堆叠现象与调控磁性材料所占比例成为实现良好微波吸收性能的关键因素. 本文通过简单的静电吸附作用将水热法制备的Fe3O4纳米微球锚定在大尺寸单层二维Ti3C2Tx表面, 并在该Fe3O4@Ti3C2Tx复合结构中实现了–69.31 dB的最小反射损耗值(频率为16.19 GHz), 且此时的双峰吸收带宽可达到3.39 GHz. 另外, 雷达截面(RCS)模拟计算表明, 该样品也具有优异的RCS值, 表现出对雷达波优异的衰减能力. 本研究对二维材料和磁性材料在微波吸收领域的性能改善与实际应用提供了新的思路.With the rapid development of electronic equipment, electromagnetic interference and electromagnetic radiation pollution have become serious problems, because excessive electromagnetic interference will not only affect normal operation of electronic equipment but also do great harm to human health. In general, an ideal material for microwave absorption with the characteristics of high reflection loss (RL) intensity, wide effective absorption band (EAB), thin thickness, and lightweight could effectively consume electromagnetic wave (EMW) energy. Therefore, it is crucial to search for such an ideal microwave absorption material to deal with the electromagnetic radiation pollution. Two-dimensional (2D) carbon/nitride MXene has received more and more attention in recent years, because excellent electrical conductivity and rich surface-functional groups in MXene show positive effects on electromagnetic wave absorption. However, as a non-magnetic material with only dielectric loss, MXene exhibits obvious impedance mismatch, which greatly limits its practical applications. Combining MXene with magnetic materials becomes a hotspot for the exploration of ideal microwave absorption materials. As a typical ferrite, Fe3O4 shows excellent soft magnetic properties such as high saturation magnetization, high chemical stability, and simple preparation. In this paper, the 2D Fe3O4@Ti3C2Tx composite is successfully prepared by hydrothermal method and simple electrostatic adsorption process. The Fe3O4 nanoparticles are uniformly anchored on the surface of large-sized monolayer Ti3C2Tx, which effectively reduces the stacking of MXene. By regulating the proportion of magnetic materials, the microwave absorption performance of 2D Fe3O4@Ti3C2Tx composite is investigated. With the content of Fe3O4 nanoparticles in the 2D Fe3O4@Ti3C2Tx composite increasing from 4 mg to 8 mg, the microwave absorption performance is enhanced obviously. This is caused by the abundant Fe3O4/Ti3C2Tx interface, scattering channels, point defect, charge density difference in 2D Fe3O4@Ti3C2Tx composite, and the optimized impedance matching. The minimum reflection loss (RLmin) of 2D Fe3O4@Ti3C2Tx composite reaches –69.31 dB at a frequency of 16.19 GHz, and the effective absorption band (EAB) achieves 3.39 GHz. With the content of Fe3O4 nanoparticles further increasing to 10 mg, the microwave absorption performance shows a decreasing trend. Excessive Fe3O4 nanoparticles in the 2D Fe3O4@Ti3C2Tx composite lead to the decrease of electrical conductivity and thus the impedance dis-matching and dielectric loss decreasing, which leads the microwave absorption performance to decrease. Radar scattering cross section (RCS) is a physical quantity that evaluates the intensity of the scattered echo energy in the intercepted electromagnetic wave energy. The results of the RCS simulation can be applied to real objects which have been widely utilized in radar wave stealth. Its multi-angle simulation results can be used as an important basis for evaluating the stealth capability of microwave-absorbing material. The RCS simulations show that the average RCS value of 2D Fe3O4@Ti3C2Tx composite is over –47.92 dBm2 at an incidence angle of 25°, demonstrating its excellent radar wave absorption performance. This study provides new ideas for improving and practically using two-dimensional and magnetic materials in the microwave absorption field and gives a new path to the subsequent development of microwave-absorbing composites.

-

Keywords:

- microwave absorption /

- MXene /

- Fe3O4 /

- composite structure

[1] Liu W, Wang D H, Li K X, Wei X H 2022 ACS Appl. Nano Mater. 5 18488

Google Scholar

Google Scholar

[2] Yue Y, Wang Y X, Xu X D, Wang C J 2023 J. Alloys Compd. 945 169342

Google Scholar

Google Scholar

[3] Wang J Q, Wu Z, Xing Y Q, Li B J, Huang P, Liu L 2023 Small 19 2207051

Google Scholar

Google Scholar

[4] Wu S J, Liu H, Wang Q H, Yin X Y, Hou L X 2023 J. Alloys Compd. 945 169372

Google Scholar

Google Scholar

[5] Xu Y X, Huang Y F, Zhao J, Han X H, Chai C P, Ma H L 2023 J. Alloys Compd. 960 170829

Google Scholar

Google Scholar

[6] Cai Z, Ma Y F, Zhao K, Yun M C, Wang X Y, Tong Z M, Wang M, Suhr J, Xiao L T, Jia S T, Chen X Y 2023 Chem. Eng. J. 462 142042

Google Scholar

Google Scholar

[7] Wang Y, Gao X, Wu X M, Zhang W Z, Luo C Y, Liu P B 2019 Chem. Eng. J. 375 121942

Google Scholar

Google Scholar

[8] Qiang R, Du Y C, Zhao H T, Wang Y, Tian C H, Li Z G, Han X J, Xu P 2015 J. Mater. Chem. A 3 13426

Google Scholar

Google Scholar

[9] Liu Z Y, Tian H L, Xu R X, Men W W, Su T, Qu Y G, Zhao W, Liu D 2023 Carbon 205 138

Google Scholar

Google Scholar

[10] Zeng X J, Zhao C, Yin Y C, Nie T L, Xie N H, Yu R H, Stucky G D 2022 Carbon 193 26

Google Scholar

Google Scholar

[11] Zhang Z W, Cai Z H, Zhang Y, Peng Y L, Wang Z Y, Xia L, Ma S P, Yin Z Z, Wang R F, Cao Y S, Li Z, Huang Y 2021 Carbon 174 484

Google Scholar

Google Scholar

[12] Che R C, Zhi C Y, Liang C Y, Zhou X G 2006 Appl. Phys. Lett. 88 033105

Google Scholar

Google Scholar

[13] Fan X X, Zhang Z Y, Wang S J, Zhang J, Xiong S S 2023 Appl. Surf. Sci. 625 157116

Google Scholar

Google Scholar

[14] Xiu Z L, Li X G, Zhang M Z, Huang B, Ma J Y, Yu J X, Meng X G 2022 J. Alloys Compd. 921 166068

Google Scholar

Google Scholar

[15] Wang S J, Zhang Z Y, Fan X X, Li Y, Zhang J, Xue L L, Xiong S S 2023 J. Alloys Compd. 960 170724

Google Scholar

Google Scholar

[16] Hua T X, Guo H, Qin J, Wu Q X, Li L Y, Qian B 2022 RSC Adv. 12 24980

Google Scholar

Google Scholar

[17] Song S W, Zhang A T, Chen L, Jia Q, Zhou C L, Liu J Q, Wang X X 2021 Carbon 176 279

Google Scholar

Google Scholar

[18] Li X, Xu D M, Zhou D, Pang S Z, Du C, Darwish M A, Zhou T, Sun S K 2023 Carbon 208 374

Google Scholar

Google Scholar

[19] Wang X L, Han N, Zhang Y, Shi G M, Zhang Y J, Li D 2022 J. Mater. Sci. Mater. Electron. 33 21091

Google Scholar

Google Scholar

[20] Guo R, Fan Y C, Wang L J, Jiang W 2020 Carbon 169 214

Google Scholar

Google Scholar

[21] Zhou X J, Li S C, Zhang M L, Yuan X Y, Wen J W, Xi H, Wu H J, Ma X H 2023 Carbon 204 538

Google Scholar

Google Scholar

[22] Wang Y, Dou Q, Jiang W, Su K, You J, Yin S, Wang T, Yang J, Li Q 2022 ACS Appl. Nano Mater. 5 9209

Google Scholar

Google Scholar

[23] Du Q R, Men Q Q, Li R S, Cheng Y W, Zhao B, Che R C 2022 Small 18 2203609

Google Scholar

Google Scholar

[24] Li M M, Xu Q Y, Jiang W, Farooq A, Qi Y R, Liu L F 2023 Fibers Polym. 24 771

Google Scholar

Google Scholar

[25] He J, Shan D Y, Yan S Q, Luo H, Cao C, Peng Y H 2019 J. Magn. Magn. Mater. 492 165639

Google Scholar

Google Scholar

[26] Lei B Y, Hou Y L, Meng W J, Wang Y Q, Yang X X, Ren M X, Zhao D L 2022 Carbon 196 280

Google Scholar

Google Scholar

[27] Liu M, Zhao B, Pei K, Qian Y T, Yang C D, Liu Y H, Cao H, Zhang J C, Che R C 2023 Small 19 2300363

Google Scholar

Google Scholar

[28] Zhang R X, Wang L, Xu C Y, Liang C Y, Liu X H, Zhang X F, Che R C 2022 Nano Res. 15 6743

Google Scholar

Google Scholar

[29] Wang C, Chen N K, Yang T Y, Cheng Q Z, Wu D a, Xiao Y Y, He S L, Song N N 2023 J. Magn. Magn. Mater. 565 170267

Google Scholar

Google Scholar

[30] Shu X F, Zhou J, Lian W, Jiang Y, Wang Y Q, Shu R W, Liu Y, Han J J, Zhuang Y 2021 J. Alloys Compd. 854 157087

Google Scholar

Google Scholar

[31] Chen N K, Wang C, Xiao Y Y, Han R, Wu Q, Song N N 2023 J. Alloys Compd. 947 169554

Google Scholar

Google Scholar

[32] Song N N, Gu S Z, Wu Q, Li C L, Zhou J, Zhang P P, Wang W, Yue M 2018 J. Magn. Magn. Mater. 451 793

Google Scholar

Google Scholar

[33] Song N N, Yang H T, Liu H L, Ren X, Ding H F, Zhang X Q, Cheng Z H 2013 Sci. Rep. 3 3161

Google Scholar

Google Scholar

[34] Wu Y H, Tan S J, Liu P Y, Zhang Y, Li P, Ji G B 2023 J. Mater. Sci. Technol. 151 10

Google Scholar

Google Scholar

[35] Liu Y L, Tian C H, Wang F Y, Hu B, Xu P, Han X J, Du Y C 2023 Chem. Eng. J. 461 141867

Google Scholar

Google Scholar

[36] Zhang S, Huang Y, Wang J M, Han X P, Zhang G Z, Sun X 2023 Carbon 209 118006

Google Scholar

Google Scholar

[37] Wang L H, Su S L, Wang Y D 2022 ACS Appl. Nano Mater. 5 17565

Google Scholar

Google Scholar

[38] Xiao Y Y, Zhang B X, Liao P, Qiu Z H, Song N N, Xu H J 2023 New J. Chem. 47 2575

Google Scholar

Google Scholar

[39] Liu Q H, Cao Q, Bi H, Liang C Y, Yuan K P, She W, Yang Y J, Che R C 2016 Adv. Mater. 28 486

Google Scholar

Google Scholar

[40] Yuan M Y, Zhao B, Yang C D, Pei K, Wang L Y, Zhang R X, You W B, Liu X H, Zhang X F, Che R C 2022 Adv. Funct. Mater. 32 2203161

Google Scholar

Google Scholar

[41] Chen Z H, Zhang Z N, Zhang H Q, Hu D, Ye Z B, Zhang Y, Yu Y, Nie B H, Xi H X, Duan C X 2022 Rare Metals 41 3100

Google Scholar

Google Scholar

[42] Yamashita T, Hayes P 2008 Appl. Surf. Sci. 254 2441

Google Scholar

Google Scholar

[43] Deng B W, Liu Z C, Pan F, Xiang Z, Zhang X, Lu W 2021 J. Mater. Chem. A 9 3500

Google Scholar

Google Scholar

[44] Lv Y H, Ye X Y, Chen S, Ma L, Zhang L, Liang W K, Wu Y P, Wang Q T 2023 Appl. Surf. Sci. 622 156935

Google Scholar

Google Scholar

[45] Zha L L, Zhang X H, Wu J H, Liu J J, Lan J F, Yang Y, Wu B 2023 Ceram. Int. 49 20672

Google Scholar

Google Scholar

[46] Yan H Y, Guo Y, Bai X Z, Qi J W, Zhao X Y, Lu H P, Deng L J 2023 Appl. Surf. Sci. 633 157602

Google Scholar

Google Scholar

[47] Che R C, Peng L M, Duan X F, Chen Q, Liang X L 2004 Adv. Mater. 16 401

Google Scholar

Google Scholar

[48] Olmedo L, Hourquebie P, Jousse F 1993 Adv. Mater. 5 373

Google Scholar

Google Scholar

[49] Liu D W, Du Y C, Li Z N, Wang Y H, Xu P, Zhao H H, Wang F Y, Li C L, Han X J 2018 J. Mater. Chem. C 6 9615

Google Scholar

Google Scholar

[50] Wang C, Han X J, Ping X, Wang J Y, Du Y C, Wang X H, Qin W, Zhang T 2010 J. Phys. Chem. C 114 3196

Google Scholar

Google Scholar

[51] Ding J, Cheng L G 2021 J. Alloys Compd. 881 160574

Google Scholar

Google Scholar

[52] Liu W, Duan P T, Ding Y, Zhang B W, Su H L, Zhang X B, Wang J Z, Zou Z Q 2022 Dalton Trans. 51 6597

Google Scholar

Google Scholar

[53] Zhu X J, Dong Y Y, Pan F, Xiang Z, Liu Z C, Deng B W, Zhang X, Shi Z, Lu W 2021 Compos. Commun. 25 100731

Google Scholar

Google Scholar

[54] Liu J K, Jia Z R, Zhou W H, Liu X H, Zhang C H, Xu B H, Wu G L 2022 Chem. Eng. J. 429 132253

Google Scholar

Google Scholar

[55] Dai B S, Qi T, Song M J, Geng M Q, Dai Y X, Qi Y 2022 Nanoscale 14 10456

Google Scholar

Google Scholar

-

图 2 (a)单层二维Ti3C2Tx的SEM图; (b) Fe3O4纳米颗粒的SEM图; (c), (d)二维Fe3O4@Ti3C2Tx复合材料的SEM图; (e)二维Fe3O4@Ti3C2Tx复合材料的TEM图, 插图为Fe3O4纳米颗粒的HRTEM图; (f), (g) Fe3O4纳米颗粒和Fe3O4纳米微球的粒径分布图; (h)元素映射图

Fig. 2. SEM image of (a) single layer Ti3C2Tx, (b) Fe3O4 nanoparticles, and (c), (d) 2D Fe3O4@Ti3C2Tx composites; (e) TEM image of 2D Fe3O4@Ti3C2Tx composites, inset shows HRTEM image of Fe3O4 nanoparticle; (f), (g) particle size distributions of Fe3O4 nanoparticles and Fe3O4 nanomicrospheres; (h) elemental mapping.

图 4 FT-4, FT-6, FT-8, FT-10样品的相对复介电常数和相对复磁导率 (a), (b)复介电常数的实部和虚部; (c)介电损耗角正切; (d), (e)复数磁导率的实部和虚部; (f)磁损耗角正切

Fig. 4. (a), (b) Real and imaginary parts of the permittivity, (c) dielectric loss tangent of FT-4, FT-6, FT-8, and FT-10 samples; (d), (e) real and imaginary parts of the complex permeability, (f) magnetic loss tangent of FT-4, FT-6, FT-8, and FT-10 samples.

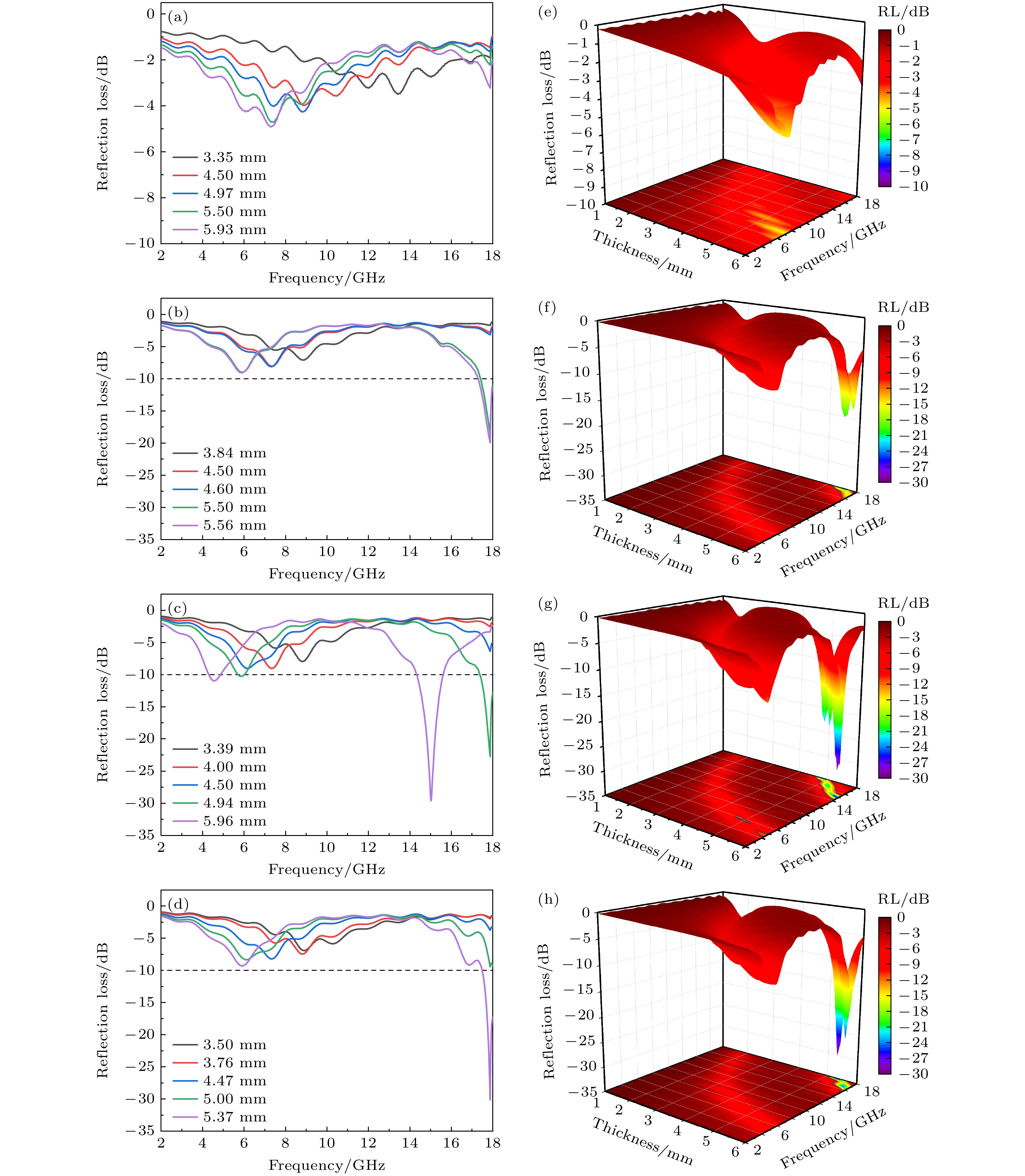

图 6 填充质量分数为20%的(a) FT-4, (b) FT-6, (c) FT-8, (d) FT-10样品的2D反射损耗图; 填充质量分数为20%的(e) FT-4, (f) FT-6, (g) FT-8, (h) FT-10样品的3D反射损耗图

Fig. 6. 2D reflection loss images of (a) FT-4, (b) FT-6, (c) FT-8, and (d) FT-10 samples with 20% filling; 3D reflection loss images of (e) FT-4, (f) FT-6, (g) FT-8, and (h) FT-10 samples with 20% filling.

-

[1] Liu W, Wang D H, Li K X, Wei X H 2022 ACS Appl. Nano Mater. 5 18488

Google Scholar

Google Scholar

[2] Yue Y, Wang Y X, Xu X D, Wang C J 2023 J. Alloys Compd. 945 169342

Google Scholar

Google Scholar

[3] Wang J Q, Wu Z, Xing Y Q, Li B J, Huang P, Liu L 2023 Small 19 2207051

Google Scholar

Google Scholar

[4] Wu S J, Liu H, Wang Q H, Yin X Y, Hou L X 2023 J. Alloys Compd. 945 169372

Google Scholar

Google Scholar

[5] Xu Y X, Huang Y F, Zhao J, Han X H, Chai C P, Ma H L 2023 J. Alloys Compd. 960 170829

Google Scholar

Google Scholar

[6] Cai Z, Ma Y F, Zhao K, Yun M C, Wang X Y, Tong Z M, Wang M, Suhr J, Xiao L T, Jia S T, Chen X Y 2023 Chem. Eng. J. 462 142042

Google Scholar

Google Scholar

[7] Wang Y, Gao X, Wu X M, Zhang W Z, Luo C Y, Liu P B 2019 Chem. Eng. J. 375 121942

Google Scholar

Google Scholar

[8] Qiang R, Du Y C, Zhao H T, Wang Y, Tian C H, Li Z G, Han X J, Xu P 2015 J. Mater. Chem. A 3 13426

Google Scholar

Google Scholar

[9] Liu Z Y, Tian H L, Xu R X, Men W W, Su T, Qu Y G, Zhao W, Liu D 2023 Carbon 205 138

Google Scholar

Google Scholar

[10] Zeng X J, Zhao C, Yin Y C, Nie T L, Xie N H, Yu R H, Stucky G D 2022 Carbon 193 26

Google Scholar

Google Scholar

[11] Zhang Z W, Cai Z H, Zhang Y, Peng Y L, Wang Z Y, Xia L, Ma S P, Yin Z Z, Wang R F, Cao Y S, Li Z, Huang Y 2021 Carbon 174 484

Google Scholar

Google Scholar

[12] Che R C, Zhi C Y, Liang C Y, Zhou X G 2006 Appl. Phys. Lett. 88 033105

Google Scholar

Google Scholar

[13] Fan X X, Zhang Z Y, Wang S J, Zhang J, Xiong S S 2023 Appl. Surf. Sci. 625 157116

Google Scholar

Google Scholar

[14] Xiu Z L, Li X G, Zhang M Z, Huang B, Ma J Y, Yu J X, Meng X G 2022 J. Alloys Compd. 921 166068

Google Scholar

Google Scholar

[15] Wang S J, Zhang Z Y, Fan X X, Li Y, Zhang J, Xue L L, Xiong S S 2023 J. Alloys Compd. 960 170724

Google Scholar

Google Scholar

[16] Hua T X, Guo H, Qin J, Wu Q X, Li L Y, Qian B 2022 RSC Adv. 12 24980

Google Scholar

Google Scholar

[17] Song S W, Zhang A T, Chen L, Jia Q, Zhou C L, Liu J Q, Wang X X 2021 Carbon 176 279

Google Scholar

Google Scholar

[18] Li X, Xu D M, Zhou D, Pang S Z, Du C, Darwish M A, Zhou T, Sun S K 2023 Carbon 208 374

Google Scholar

Google Scholar

[19] Wang X L, Han N, Zhang Y, Shi G M, Zhang Y J, Li D 2022 J. Mater. Sci. Mater. Electron. 33 21091

Google Scholar

Google Scholar

[20] Guo R, Fan Y C, Wang L J, Jiang W 2020 Carbon 169 214

Google Scholar

Google Scholar

[21] Zhou X J, Li S C, Zhang M L, Yuan X Y, Wen J W, Xi H, Wu H J, Ma X H 2023 Carbon 204 538

Google Scholar

Google Scholar

[22] Wang Y, Dou Q, Jiang W, Su K, You J, Yin S, Wang T, Yang J, Li Q 2022 ACS Appl. Nano Mater. 5 9209

Google Scholar

Google Scholar

[23] Du Q R, Men Q Q, Li R S, Cheng Y W, Zhao B, Che R C 2022 Small 18 2203609

Google Scholar

Google Scholar

[24] Li M M, Xu Q Y, Jiang W, Farooq A, Qi Y R, Liu L F 2023 Fibers Polym. 24 771

Google Scholar

Google Scholar

[25] He J, Shan D Y, Yan S Q, Luo H, Cao C, Peng Y H 2019 J. Magn. Magn. Mater. 492 165639

Google Scholar

Google Scholar

[26] Lei B Y, Hou Y L, Meng W J, Wang Y Q, Yang X X, Ren M X, Zhao D L 2022 Carbon 196 280

Google Scholar

Google Scholar

[27] Liu M, Zhao B, Pei K, Qian Y T, Yang C D, Liu Y H, Cao H, Zhang J C, Che R C 2023 Small 19 2300363

Google Scholar

Google Scholar

[28] Zhang R X, Wang L, Xu C Y, Liang C Y, Liu X H, Zhang X F, Che R C 2022 Nano Res. 15 6743

Google Scholar

Google Scholar

[29] Wang C, Chen N K, Yang T Y, Cheng Q Z, Wu D a, Xiao Y Y, He S L, Song N N 2023 J. Magn. Magn. Mater. 565 170267

Google Scholar

Google Scholar

[30] Shu X F, Zhou J, Lian W, Jiang Y, Wang Y Q, Shu R W, Liu Y, Han J J, Zhuang Y 2021 J. Alloys Compd. 854 157087

Google Scholar

Google Scholar

[31] Chen N K, Wang C, Xiao Y Y, Han R, Wu Q, Song N N 2023 J. Alloys Compd. 947 169554

Google Scholar

Google Scholar

[32] Song N N, Gu S Z, Wu Q, Li C L, Zhou J, Zhang P P, Wang W, Yue M 2018 J. Magn. Magn. Mater. 451 793

Google Scholar

Google Scholar

[33] Song N N, Yang H T, Liu H L, Ren X, Ding H F, Zhang X Q, Cheng Z H 2013 Sci. Rep. 3 3161

Google Scholar

Google Scholar

[34] Wu Y H, Tan S J, Liu P Y, Zhang Y, Li P, Ji G B 2023 J. Mater. Sci. Technol. 151 10

Google Scholar

Google Scholar

[35] Liu Y L, Tian C H, Wang F Y, Hu B, Xu P, Han X J, Du Y C 2023 Chem. Eng. J. 461 141867

Google Scholar

Google Scholar

[36] Zhang S, Huang Y, Wang J M, Han X P, Zhang G Z, Sun X 2023 Carbon 209 118006

Google Scholar

Google Scholar

[37] Wang L H, Su S L, Wang Y D 2022 ACS Appl. Nano Mater. 5 17565

Google Scholar

Google Scholar

[38] Xiao Y Y, Zhang B X, Liao P, Qiu Z H, Song N N, Xu H J 2023 New J. Chem. 47 2575

Google Scholar

Google Scholar

[39] Liu Q H, Cao Q, Bi H, Liang C Y, Yuan K P, She W, Yang Y J, Che R C 2016 Adv. Mater. 28 486

Google Scholar

Google Scholar

[40] Yuan M Y, Zhao B, Yang C D, Pei K, Wang L Y, Zhang R X, You W B, Liu X H, Zhang X F, Che R C 2022 Adv. Funct. Mater. 32 2203161

Google Scholar

Google Scholar

[41] Chen Z H, Zhang Z N, Zhang H Q, Hu D, Ye Z B, Zhang Y, Yu Y, Nie B H, Xi H X, Duan C X 2022 Rare Metals 41 3100

Google Scholar

Google Scholar

[42] Yamashita T, Hayes P 2008 Appl. Surf. Sci. 254 2441

Google Scholar

Google Scholar

[43] Deng B W, Liu Z C, Pan F, Xiang Z, Zhang X, Lu W 2021 J. Mater. Chem. A 9 3500

Google Scholar

Google Scholar

[44] Lv Y H, Ye X Y, Chen S, Ma L, Zhang L, Liang W K, Wu Y P, Wang Q T 2023 Appl. Surf. Sci. 622 156935

Google Scholar

Google Scholar

[45] Zha L L, Zhang X H, Wu J H, Liu J J, Lan J F, Yang Y, Wu B 2023 Ceram. Int. 49 20672

Google Scholar

Google Scholar

[46] Yan H Y, Guo Y, Bai X Z, Qi J W, Zhao X Y, Lu H P, Deng L J 2023 Appl. Surf. Sci. 633 157602

Google Scholar

Google Scholar

[47] Che R C, Peng L M, Duan X F, Chen Q, Liang X L 2004 Adv. Mater. 16 401

Google Scholar

Google Scholar

[48] Olmedo L, Hourquebie P, Jousse F 1993 Adv. Mater. 5 373

Google Scholar

Google Scholar

[49] Liu D W, Du Y C, Li Z N, Wang Y H, Xu P, Zhao H H, Wang F Y, Li C L, Han X J 2018 J. Mater. Chem. C 6 9615

Google Scholar

Google Scholar

[50] Wang C, Han X J, Ping X, Wang J Y, Du Y C, Wang X H, Qin W, Zhang T 2010 J. Phys. Chem. C 114 3196

Google Scholar

Google Scholar

[51] Ding J, Cheng L G 2021 J. Alloys Compd. 881 160574

Google Scholar

Google Scholar

[52] Liu W, Duan P T, Ding Y, Zhang B W, Su H L, Zhang X B, Wang J Z, Zou Z Q 2022 Dalton Trans. 51 6597

Google Scholar

Google Scholar

[53] Zhu X J, Dong Y Y, Pan F, Xiang Z, Liu Z C, Deng B W, Zhang X, Shi Z, Lu W 2021 Compos. Commun. 25 100731

Google Scholar

Google Scholar

[54] Liu J K, Jia Z R, Zhou W H, Liu X H, Zhang C H, Xu B H, Wu G L 2022 Chem. Eng. J. 429 132253

Google Scholar

Google Scholar

[55] Dai B S, Qi T, Song M J, Geng M Q, Dai Y X, Qi Y 2022 Nanoscale 14 10456

Google Scholar

Google Scholar

计量

- 文章访问数: 5011

- PDF下载量: 163

- 被引次数: 0

下载:

下载: