-

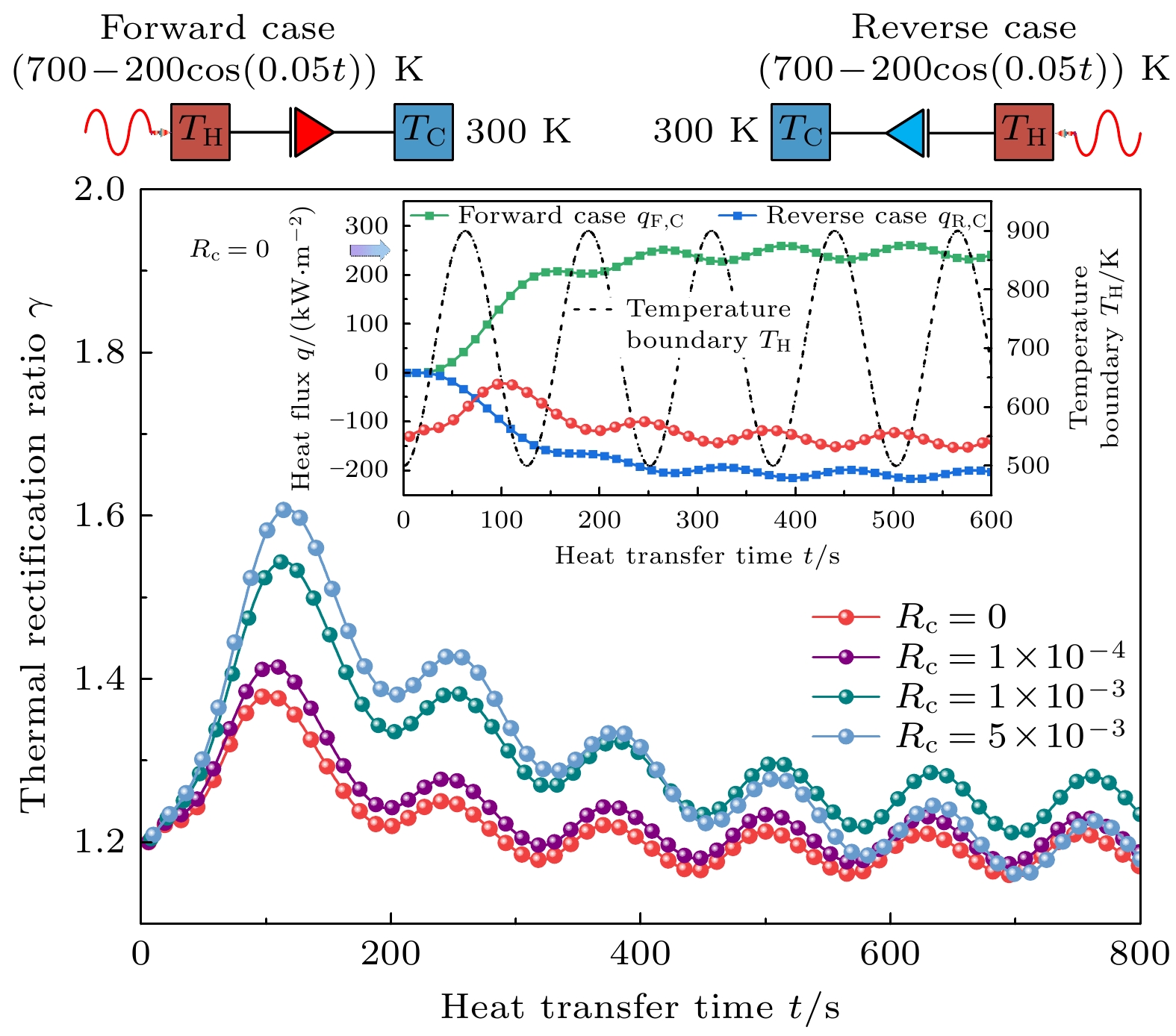

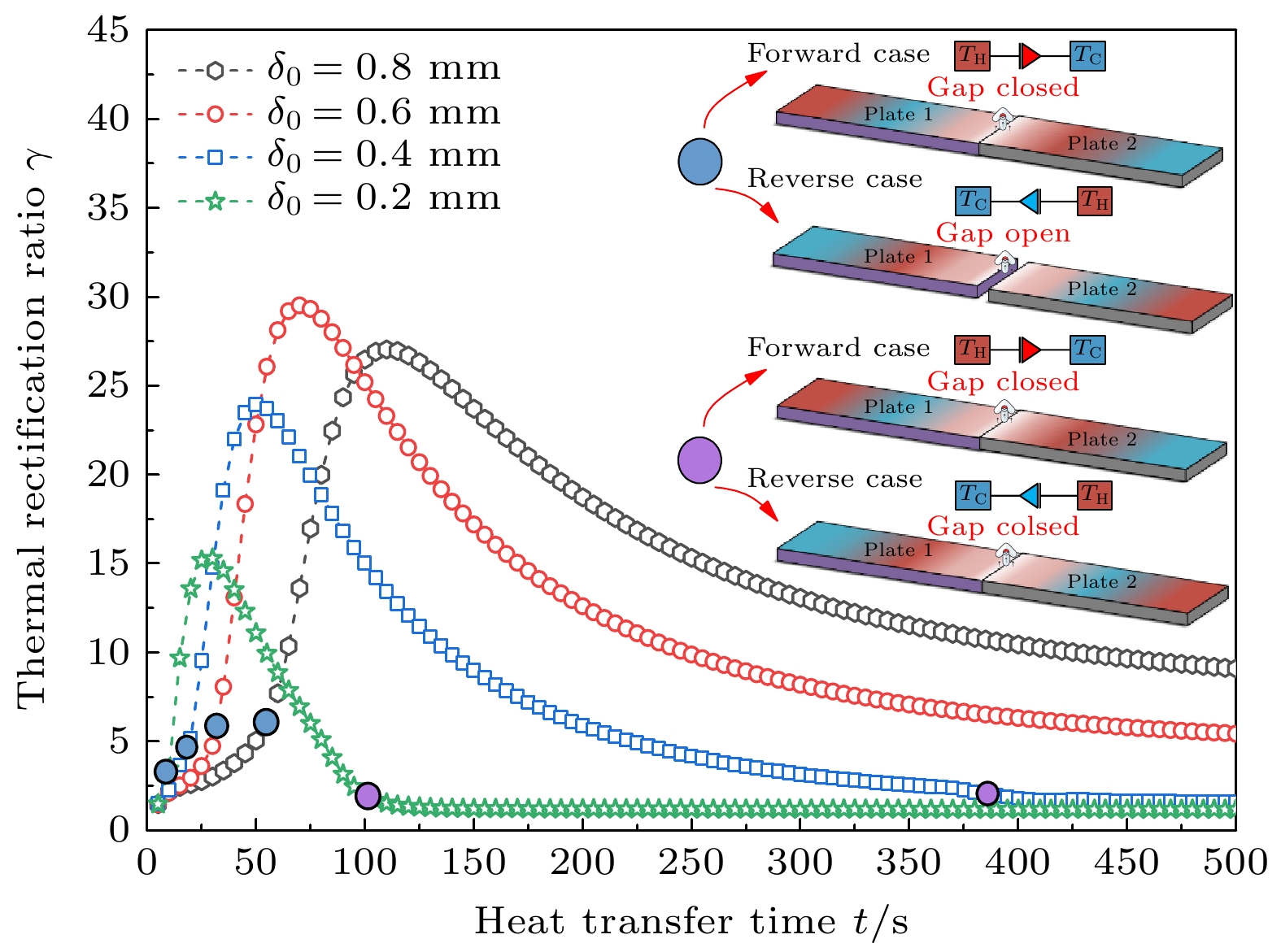

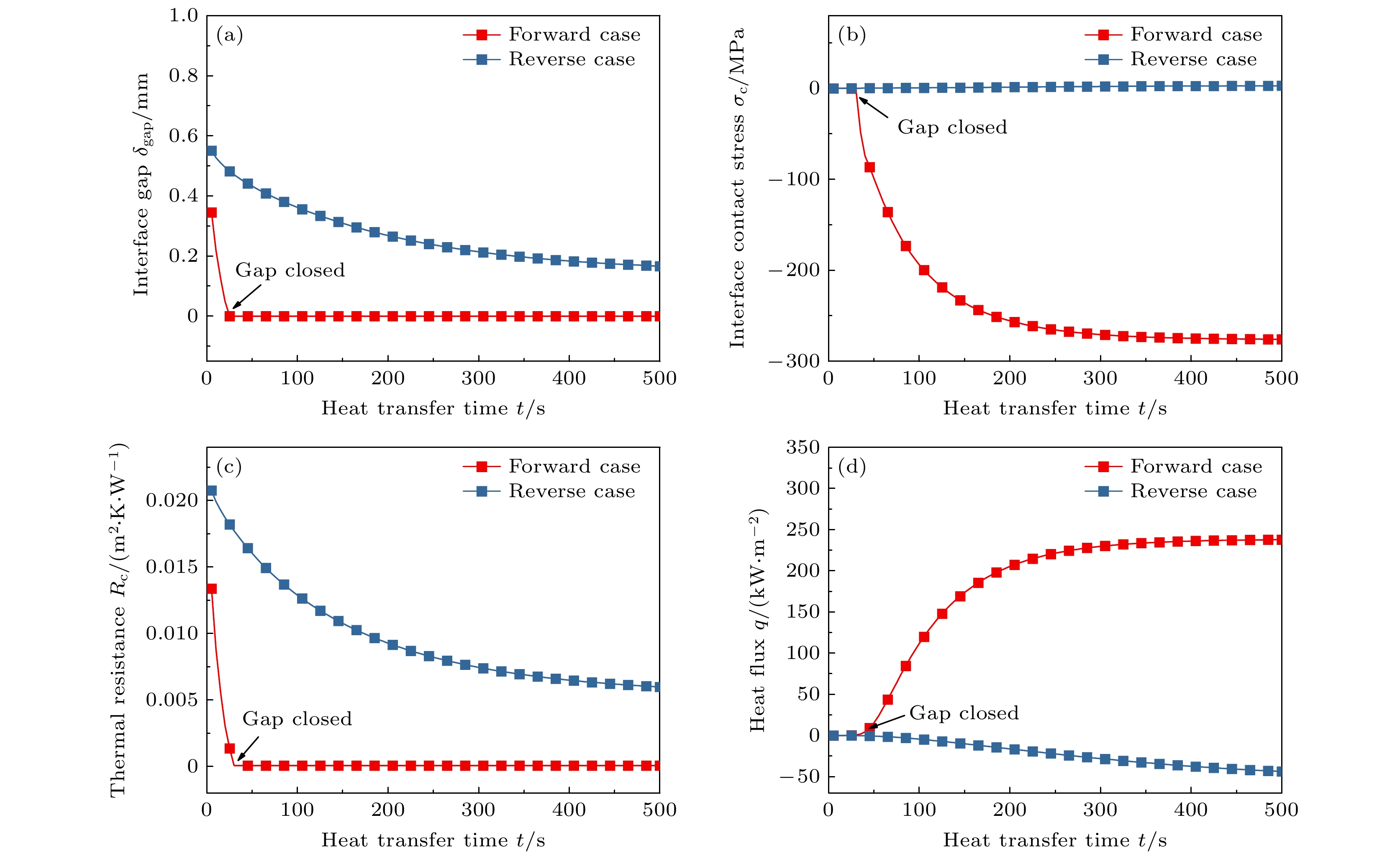

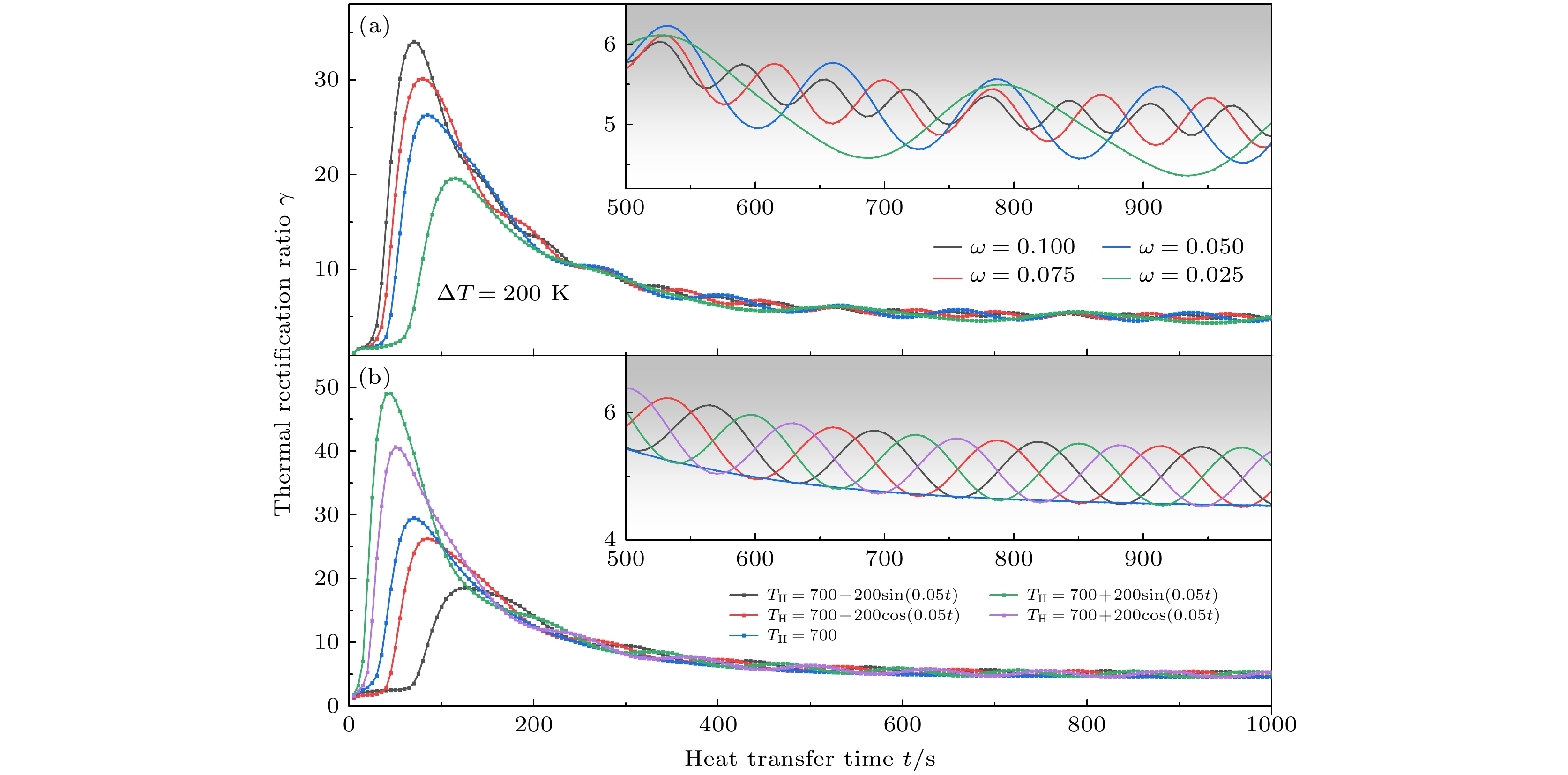

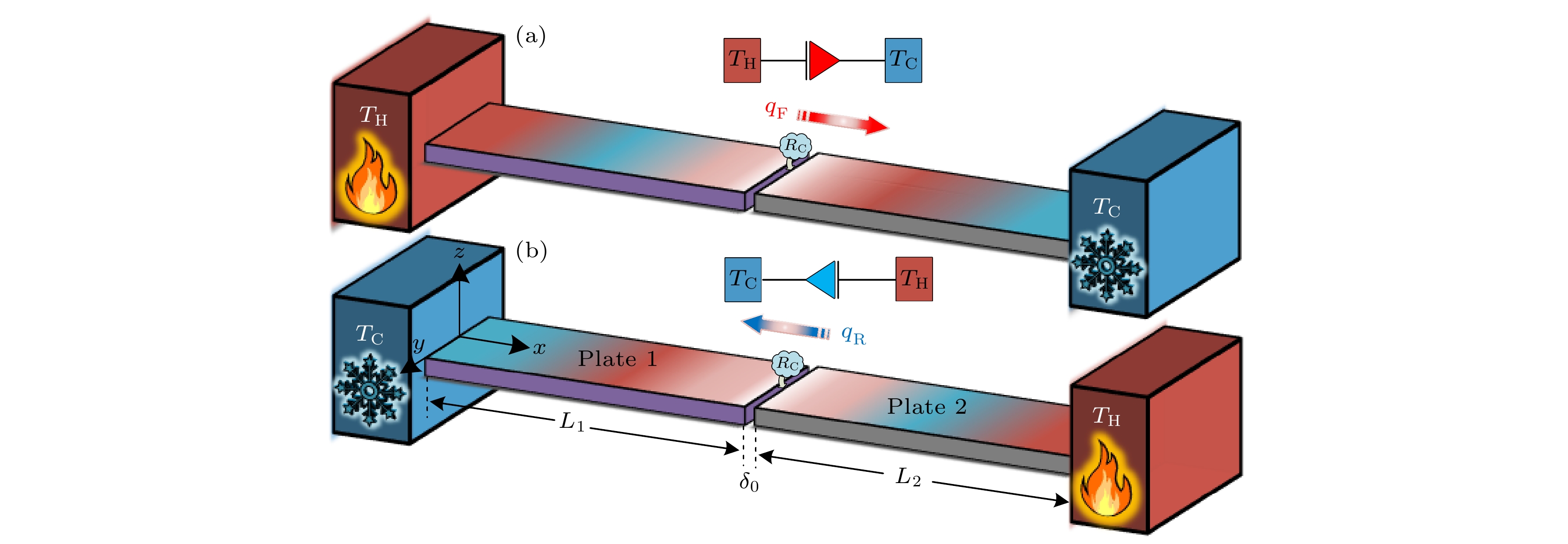

Like an electric diode, thermal diode transmits heat in a specific direction, and thermal rectification is also a fundamental phenomenon for active heat flow control. However, in practical applications, thermal rectification needs to be operated under transient conditions. In this study, transient thermal rectification ratio of a one-dimensional heterostructure is numerically investigated by using the finite element method. The effects of interface thermal resistance, interface initial gap, periodic boundary condition and geometric and material parameters on the transient thermal resistance ratio are obtained. Research indicates that the interface thermal resistance can enhance the thermal rectification effect of the system, and the introduction of the initial interface gap improves the transient thermal rectification ratio by an order of magnitude. The ability to engineer the thermal diffusivity of materials allows us to control the heat flux and improve transient thermal rectification ratio. Since interface thermal resistance can enlarge the difference in heat transfer capability between forward case and reverse case, it is reasonable to suggest that adjusting the interface thermal resistance may also enhance the thermal rectification effect, but excessive interface thermal resistance will reduce it. Under the periodic temperature boundary conditions, the larger the temperature difference in boundary fluctuation, the larger the fluctuation amplitude of the transient thermal rectification ratio is. The fluctuation frequency of thermal rectification changes with the periodic boundary frequency, which also affects the amplitude of the fluctuation. Furthermore, by adjusting the initial interface gap, the gap is closed during heat transfer and the interface thermal resistance is reduced in the forward case, while the interface gap is kept open in the reverse case, thereby improving the overall thermal rectification ratio by an order of magnitude. For different transient stages, the equivalent thermal conductivity can be changed by adjusting the material and geometrical properties to improve the thermal rectification ratio.Therefore, the proposed numerical approach and results can guide the optimal design of the transient thermal rectifier.

-

Keywords:

- transient thermal rectification ratio /

- composite structure /

- interface thermal resistance /

- periodic boundary condition

[1] Starr C 1936 Physics 7 15

Google Scholar

Google Scholar

[2] Wong M Y, Tso C Y, Ho T C, Lee H H 2021 Int. J. Heat Mass Transfer 164 120607

Google Scholar

Google Scholar

[3] Yang N, Xu X F, Zhang G, Li B W 2012 AIP Adv. 2 041410

Google Scholar

Google Scholar

[4] Li B W, Wang L, Casati G L 2004 Phys. Rev. Lett. 93 184301

Google Scholar

Google Scholar

[5] Zhu J, Hippalgaonkar K, Shen S, et al. 2014 Nano Lett. 14 4867

Google Scholar

Google Scholar

[6] Paolucci F, Marchegiani G, Strambini E, Giazotto F 2018 Phys. Rev. Appl. 10 024003

Google Scholar

Google Scholar

[7] Wang J, Shao C R, Li H Y, Xia G D 2022 Int. J. Heat Mass Transfer 188 122627

Google Scholar

Google Scholar

[8] Sarkar S, Nefzaoui E, Basset P, Bourouina T 2021 J. Quant. Spectrosc. Radiat. Transfer 266 107573

Google Scholar

Google Scholar

[9] Leon-Gil J A, Martinez-Flores J J, Alvarez-Quintana J 2018 J. Mater. Sci. 54 3211

Google Scholar

Google Scholar

[10] Go D B, Sen M 2010 J. Heat Transfer 132 124502

Google Scholar

Google Scholar

[11] Peyrard M 2006 Europhys. Lett. 76 49

Google Scholar

Google Scholar

[12] Dames C 2009 J. Heat Transfer 131 061301

Google Scholar

Google Scholar

[13] Kobayashi W, Teraoka Y, Terasaki I 2009 Appl. Phys. Lett. 95 171905

Google Scholar

Google Scholar

[14] Yang Y, Chen H Y, Wang H, Li N B, Zhang L F 2018 Phys. Rev. E 98 042131

Google Scholar

Google Scholar

[15] Majdi T, Pal S, Puri I K 2017 Int. J. Therm. Sci. 117 260

Google Scholar

Google Scholar

[16] Shih T M, Gao Z J, Guo Z Q, Merlitz H, Pagni P J, Chen Z 2015 Sci. Rep. 5 12677

Google Scholar

Google Scholar

[17] 邵春瑞, 李海洋, 王军, 夏国栋 2021 70 236501

Google Scholar

Google Scholar

Shao C R, Li H Y, Wang J, Xia G D 2021 Acta Phys. Sin. 70 236501

Google Scholar

Google Scholar

[18] Sawaki D, Kobayashi W, Moritomo Y, Terasaki I 2011 Appl. Phys. Lett. 98 081915

Google Scholar

Google Scholar

[19] Tian H, Xie D, Yang Y, Ren T L, Zhang G, Wang Y F, Zhou C J, Peng P G, Wang L G, Liu L T 2012 Sci. Rep. 2 523

Google Scholar

Google Scholar

[20] Sadat H, Le Dez V 2016 Mech. Res. Commun. 76 48

Google Scholar

Google Scholar

[21] Carlomagno I, Cimmelli V A, Jou D 2020 Mech. Res. Commun. 103 103472

Google Scholar

Google Scholar

[22] 赵建宁, 刘冬欢, 魏东, 尚新春 2020 69 056501

Google Scholar

Google Scholar

Zhao J N, Liu D H, Wei D, Shang X C 2020 Acta Phys. Sin. 69 056501

Google Scholar

Google Scholar

[23] 朱玉鑫, 王珏, 罗爽, 王军, 夏国栋 2016 中国科学:技术科学 46 175

Google Scholar

Google Scholar

Zhu Y X, Wang J, Luo S, Wang J, Xia G D 2016 Sci. China Ser. E 46 175

Google Scholar

Google Scholar

[24] Chumak K, Martynyak R 2012 Int. J. Heat Mass Transfer 55 5603

Google Scholar

Google Scholar

[25] Sayer R A 2016 Heat Transfer Res. 47 733

Google Scholar

Google Scholar

[26] Carlomagno I, Cimmelli V A, Jou D 2021 J. Therm. Stresses 44 919

Google Scholar

Google Scholar

[27] Carlomagno I, Cimmelli V A, Jou D 2020 Phys. Lett. A 384 126905

Google Scholar

Google Scholar

[28] Zhao J N, Wei D, Gao A Q, Dong H L, Bao Y B, Jiang Y M, Liu D H 2020 Appl. Therm. Eng. 176 115410

Google Scholar

Google Scholar

[29] Zhao J N, Wei D, Dong Y Y, Zhang D, Liu D H 2022 Int. J. Heat Mass Transfer 194 123024

Google Scholar

Google Scholar

[30] 单小东, 王沫然 2014 工程热 35 1401

Google Scholar

Google Scholar

Shan X D, Wang M R 2014 J. Eng. Thermophys. 35 1401

Google Scholar

Google Scholar

[31] 温家乐, 徐志成, 古宇, 郑冬琴, 钟伟荣 2015 64 216501

Google Scholar

Google Scholar

Wen J L, Xu Z C, Gu Y, Zheng D Q, Zhong W R 2015 Acta Phys. Sin. 64 216501

Google Scholar

Google Scholar

[32] 李威, 冯妍卉, 唐晶晶, 张欣欣 2013 62 076106

Google Scholar

Google Scholar

Li W, Feng Y H, Tang J J, Zhang X X 2013 Acta Phys. Sin. 62 076106

Google Scholar

Google Scholar

[33] 鞠生宏, 梁新刚 2013 62 026101

Google Scholar

Google Scholar

Ju S H, Liang X G 2013 Acta Phys. Sin. 62 026101

Google Scholar

Google Scholar

[34] Herrera F A, Luo T F, Go D B 2017 J. Heat Transfer 139 091301

Google Scholar

Google Scholar

[35] Klinar K, Rojo M M, Kutnjak Z, Kitanovski A 2020 J. Appl. Phys. 127 234101

Google Scholar

Google Scholar

[36] Ordonez-Miranda J, Guo Y Y, Alvarado-Gil J J, Volz S, Nomura M 2021 Phys. Rev. Appl. 16 L041002

Google Scholar

Google Scholar

[37] Zhang G, Cottrill A L, Koman V B, Liu A T, Mahajan S G, Piephoff D E, Strano M S 2020 Appl. Energy 280 115881

Google Scholar

Google Scholar

[38] Shimokusu T J, Zhu Q, Rivera N, Wehmeyer G 2022 Int. J. Heat Mass Transfer 182 122035

Google Scholar

Google Scholar

[39] Barber J R, Zhang R 1988 Int. J. Mech. Sci. 30 691

Google Scholar

Google Scholar

[40] Touloukian Y S, Powell R W, Ho C Y, Klemens P G 1970 Thermophysical Properties of Mmatter-the Tprc Data Series (United States: Purdue University)

-

-

[1] Starr C 1936 Physics 7 15

Google Scholar

Google Scholar

[2] Wong M Y, Tso C Y, Ho T C, Lee H H 2021 Int. J. Heat Mass Transfer 164 120607

Google Scholar

Google Scholar

[3] Yang N, Xu X F, Zhang G, Li B W 2012 AIP Adv. 2 041410

Google Scholar

Google Scholar

[4] Li B W, Wang L, Casati G L 2004 Phys. Rev. Lett. 93 184301

Google Scholar

Google Scholar

[5] Zhu J, Hippalgaonkar K, Shen S, et al. 2014 Nano Lett. 14 4867

Google Scholar

Google Scholar

[6] Paolucci F, Marchegiani G, Strambini E, Giazotto F 2018 Phys. Rev. Appl. 10 024003

Google Scholar

Google Scholar

[7] Wang J, Shao C R, Li H Y, Xia G D 2022 Int. J. Heat Mass Transfer 188 122627

Google Scholar

Google Scholar

[8] Sarkar S, Nefzaoui E, Basset P, Bourouina T 2021 J. Quant. Spectrosc. Radiat. Transfer 266 107573

Google Scholar

Google Scholar

[9] Leon-Gil J A, Martinez-Flores J J, Alvarez-Quintana J 2018 J. Mater. Sci. 54 3211

Google Scholar

Google Scholar

[10] Go D B, Sen M 2010 J. Heat Transfer 132 124502

Google Scholar

Google Scholar

[11] Peyrard M 2006 Europhys. Lett. 76 49

Google Scholar

Google Scholar

[12] Dames C 2009 J. Heat Transfer 131 061301

Google Scholar

Google Scholar

[13] Kobayashi W, Teraoka Y, Terasaki I 2009 Appl. Phys. Lett. 95 171905

Google Scholar

Google Scholar

[14] Yang Y, Chen H Y, Wang H, Li N B, Zhang L F 2018 Phys. Rev. E 98 042131

Google Scholar

Google Scholar

[15] Majdi T, Pal S, Puri I K 2017 Int. J. Therm. Sci. 117 260

Google Scholar

Google Scholar

[16] Shih T M, Gao Z J, Guo Z Q, Merlitz H, Pagni P J, Chen Z 2015 Sci. Rep. 5 12677

Google Scholar

Google Scholar

[17] 邵春瑞, 李海洋, 王军, 夏国栋 2021 70 236501

Google Scholar

Google Scholar

Shao C R, Li H Y, Wang J, Xia G D 2021 Acta Phys. Sin. 70 236501

Google Scholar

Google Scholar

[18] Sawaki D, Kobayashi W, Moritomo Y, Terasaki I 2011 Appl. Phys. Lett. 98 081915

Google Scholar

Google Scholar

[19] Tian H, Xie D, Yang Y, Ren T L, Zhang G, Wang Y F, Zhou C J, Peng P G, Wang L G, Liu L T 2012 Sci. Rep. 2 523

Google Scholar

Google Scholar

[20] Sadat H, Le Dez V 2016 Mech. Res. Commun. 76 48

Google Scholar

Google Scholar

[21] Carlomagno I, Cimmelli V A, Jou D 2020 Mech. Res. Commun. 103 103472

Google Scholar

Google Scholar

[22] 赵建宁, 刘冬欢, 魏东, 尚新春 2020 69 056501

Google Scholar

Google Scholar

Zhao J N, Liu D H, Wei D, Shang X C 2020 Acta Phys. Sin. 69 056501

Google Scholar

Google Scholar

[23] 朱玉鑫, 王珏, 罗爽, 王军, 夏国栋 2016 中国科学:技术科学 46 175

Google Scholar

Google Scholar

Zhu Y X, Wang J, Luo S, Wang J, Xia G D 2016 Sci. China Ser. E 46 175

Google Scholar

Google Scholar

[24] Chumak K, Martynyak R 2012 Int. J. Heat Mass Transfer 55 5603

Google Scholar

Google Scholar

[25] Sayer R A 2016 Heat Transfer Res. 47 733

Google Scholar

Google Scholar

[26] Carlomagno I, Cimmelli V A, Jou D 2021 J. Therm. Stresses 44 919

Google Scholar

Google Scholar

[27] Carlomagno I, Cimmelli V A, Jou D 2020 Phys. Lett. A 384 126905

Google Scholar

Google Scholar

[28] Zhao J N, Wei D, Gao A Q, Dong H L, Bao Y B, Jiang Y M, Liu D H 2020 Appl. Therm. Eng. 176 115410

Google Scholar

Google Scholar

[29] Zhao J N, Wei D, Dong Y Y, Zhang D, Liu D H 2022 Int. J. Heat Mass Transfer 194 123024

Google Scholar

Google Scholar

[30] 单小东, 王沫然 2014 工程热 35 1401

Google Scholar

Google Scholar

Shan X D, Wang M R 2014 J. Eng. Thermophys. 35 1401

Google Scholar

Google Scholar

[31] 温家乐, 徐志成, 古宇, 郑冬琴, 钟伟荣 2015 64 216501

Google Scholar

Google Scholar

Wen J L, Xu Z C, Gu Y, Zheng D Q, Zhong W R 2015 Acta Phys. Sin. 64 216501

Google Scholar

Google Scholar

[32] 李威, 冯妍卉, 唐晶晶, 张欣欣 2013 62 076106

Google Scholar

Google Scholar

Li W, Feng Y H, Tang J J, Zhang X X 2013 Acta Phys. Sin. 62 076106

Google Scholar

Google Scholar

[33] 鞠生宏, 梁新刚 2013 62 026101

Google Scholar

Google Scholar

Ju S H, Liang X G 2013 Acta Phys. Sin. 62 026101

Google Scholar

Google Scholar

[34] Herrera F A, Luo T F, Go D B 2017 J. Heat Transfer 139 091301

Google Scholar

Google Scholar

[35] Klinar K, Rojo M M, Kutnjak Z, Kitanovski A 2020 J. Appl. Phys. 127 234101

Google Scholar

Google Scholar

[36] Ordonez-Miranda J, Guo Y Y, Alvarado-Gil J J, Volz S, Nomura M 2021 Phys. Rev. Appl. 16 L041002

Google Scholar

Google Scholar

[37] Zhang G, Cottrill A L, Koman V B, Liu A T, Mahajan S G, Piephoff D E, Strano M S 2020 Appl. Energy 280 115881

Google Scholar

Google Scholar

[38] Shimokusu T J, Zhu Q, Rivera N, Wehmeyer G 2022 Int. J. Heat Mass Transfer 182 122035

Google Scholar

Google Scholar

[39] Barber J R, Zhang R 1988 Int. J. Mech. Sci. 30 691

Google Scholar

Google Scholar

[40] Touloukian Y S, Powell R W, Ho C Y, Klemens P G 1970 Thermophysical Properties of Mmatter-the Tprc Data Series (United States: Purdue University)

计量

- 文章访问数: 5587

- PDF下载量: 109

- 被引次数: 0

下载:

下载: