-

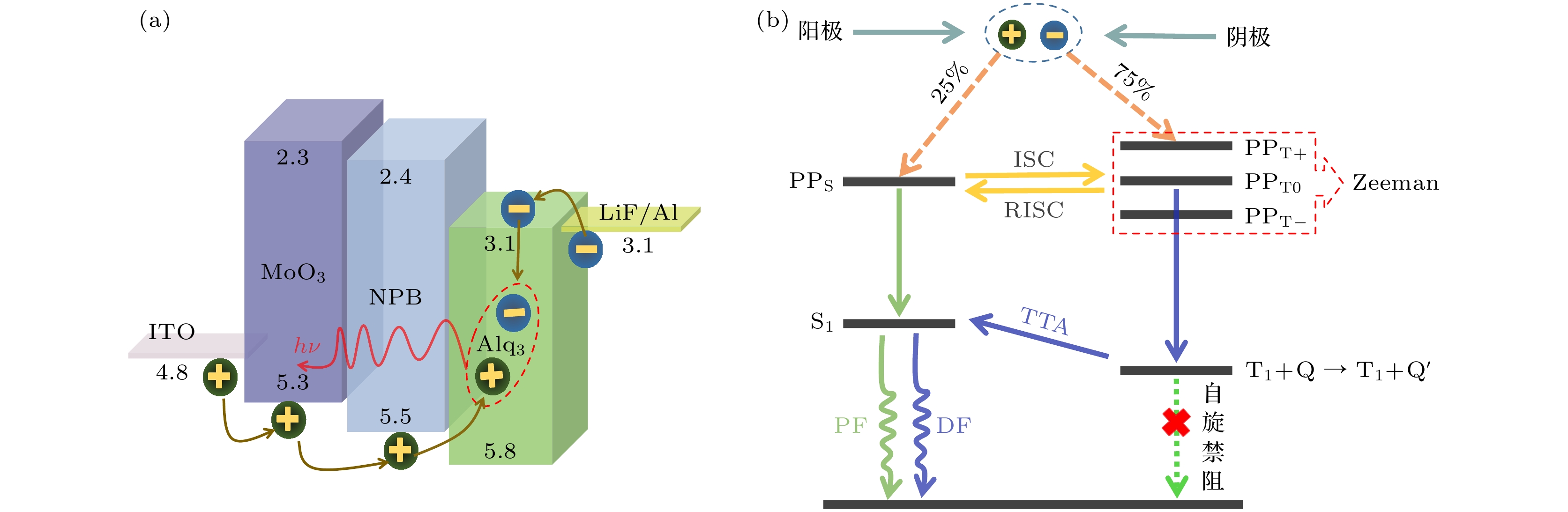

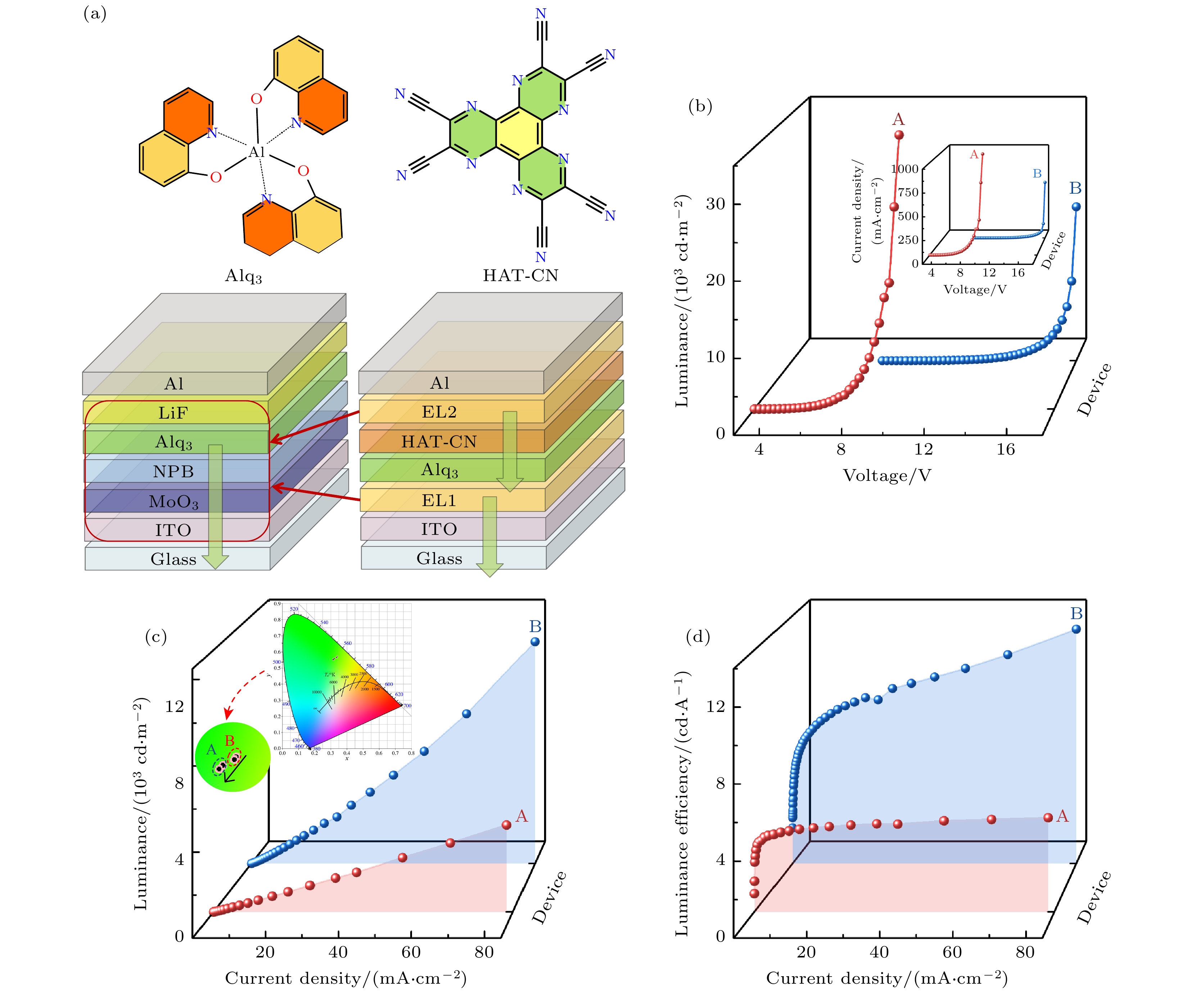

叠层有机电致发光器件(organic electroluminescent device, OLED)因寿命长和电流效率高等优点引起广泛关注. 本文利用Alq3/HAT-CN作为中间连接层制备了双发光单元叠层OLED, 对其光电性能和激子调控机制探究. 结果表明, 在80 mA/cm2电流密度下, 叠层OLED的亮度(11189.86 cd/m2)和效率(13.85 cd/A)达到了单发光单元OLED (亮度和效率分别为4007.14 cd/m2和5.00 cd/A)的2.7倍. 在室温下, 磁场诱导极化子对发生系间窜越(intersystem crossing, ISC), 增加三重态激子(triplet exciton, T1)浓度, 促进电荷散射, 使磁电致发光(magneto-electroluminescence, MEL)低磁场快速增加和高磁场缓慢上升. 当固定电流, Alq3/HAT-CN器件中未复合的电荷较少, 导致T1与电荷湮灭(triplet-charge annihilation, TQA)减弱, 致使MEL上升幅度最小. 随电流增大, T1浓度升高使TQA增强而ISC减弱. 降低温度, 电荷减弱, T1浓度增大, 使T1湮灭(triplet-triplet annihilation, TTA)增强. 因此, 通过改变注入电流和温度可调控T1的浓度, 进而影响ISC, TQA和TTA的强弱, 导致直接发光的单重态激子数量的增加, 最终引起叠层OLED发光效率的提高. 总之, 本工作有助于深入理解小分子叠层OLED发光机制, 对探明其光电性能提高的机理具有重要意义.

-

关键词:

- 叠层有机电致发光器件 /

- 中间连接层 /

- 系间窜越 /

- 三重态与电荷湮灭

Tandem organic electroluminescent devices (OLEDs) have attracted widespread attention due to their long lifetime and high current efficiency. In this study, a double-emitting unit tandem OLED is fabricated by using Alq3/HAT-CN as an interconnect layer. Its photovoltaic properties and exciton regulation mechanism are investigated. The results show that the luminance (11189.86 cd/m2) and efficiency (13.85 cd/A) of the tandem OLED reaches 2.7 times that of the single electroluminescent (EL) unit OLED (luminance and efficiency of 4007.14 cd/m2 and 5.00 cd/A, respectively) at a current density of 80 mA/cm2. This proves that the Alq3/HAT-CN is an efficient interconnect layer. At room temperature, the polaron pair undergoes intersystem crossing (ISC) due to hyperfine interaction (HFI) when a magnetic field is applied to the device. This increases the concentration of the triplet excitons (T1), thus promoting the charge scattering. The result is a rapid increase in the low magnetic field and a slow increase in the high magnetic field of the MEL. When the injection current strength is constant, there is less uncompounded charge in the Alq3/HAT-CN device than in other connected layer devices. Triplet-charge annihilation (TQA) is weak, resulting in a relative increase in the value of T1, which is not involved in the TQA. This suppresses the ISC and leads to a minimal increase in the MEL. As the current strength increases, the T1 value increases, causing TQA to increase and ISC to decrease. Since the TQA is related to charge and T1 value, lowering the temperature reduces the carrier mobility in the device, resulting in the relative decreasing of charge concentration and the weakening of TQA. Lowering the temperature reduces the quenching of thermal phonons and increases the T1 value while extending its lifetime, resulting in the enhancement of triplet-triplet annihilation (TTA). At low temperatures, the high magnetic field shape of the MEL changes from slowly increasing to rapidly decreasing. Therefore, the T1 value can be regulated by varying the current strength and temperature, which further affects the strength of ISC, TQA and TTA, and the luminescence and efficiency of the device can be effectively improved by reducing TQA and ISC. This work is of great significance in understanding the luminescence mechanism of small molecule tandem devices and studying the mechanism for improving their photovoltaic properties.-

Keywords:

- tandem organic electroluminescent device /

- interconnect layer /

- intersystem crossing /

- triplet-charge annihilation

[1] Liu Y C, Li C S, Ren Z J, Yan S Y, Bryce M R 2018 Nat. Rev. Mater. 3 1

Google Scholar

Google Scholar

[2] Chen Q S, Jia W Y, Chen L X, Yuan D, Zou Y, Xiong Z H 2016 Sci. Rep. 6 25331

Google Scholar

Google Scholar

[3] Chen L X, Jia W Y, Lan Z J, Tang X T, Zhu F R, Xiong Z H 2018 Org. Electron. 55 165

Google Scholar

Google Scholar

[4] Reineke S, Thomschke M, Lüssem B, Leo K 2013 Rev. Mod. Phys. 85 1245

Google Scholar

Google Scholar

[5] Lee S, Lee J H, Lee J H, Kim J J 2012 Adv. Funct. Mater. 22 855

Google Scholar

Google Scholar

[6] Chiba T, Pu Y J, Miyazaki R, Nakayama K I, Sasabe H, Kido J 2011 Org. Electron. 12 710

Google Scholar

Google Scholar

[7] Yuan J K, Liu W, Yao J W, Sun Q, Dai Y F, Chen J S, Yang D Z, Qiao X F, Ma D G 2020 Org. Electron. 83 105745

Google Scholar

Google Scholar

[8] Matsumoto T, Nakada T, Endo J, Koichi M, Kawamura N, Yokoi A, Kido J 2003 SID Symp. Dig. Tech. Pap. 34 979

Google Scholar

Google Scholar

[9] Sun H D, Guo Q X, Yang D Z, Chen Y H, Chen J S, Ma D G 2015 ACS Photonics 2 271

Google Scholar

Google Scholar

[10] Liu Y, Wu X M, Xiao Z H, Gao J, Zhang Y, Rui H S, Lin X, Zhang N, Hua Y L, Yin S G 2017 Appl. Surf. Sci. 413 302

Google Scholar

Google Scholar

[11] Guo Q X, Dai Y F, Sun Q, Qiao X F, Chen J S, Zhu T Z, Ma D G 2018 Adv. Electron. Mater. 4 1800177

Google Scholar

Google Scholar

[12] Wang J, Wang Y, Qin Y, Li R Q, An J X, Chen Y H, Lai W Y, Zhang X W, Huang W 2021 J. Mater. Chem. C 9 8570

Google Scholar

Google Scholar

[13] Xu Y C, Niu Y X, Gong C L, Shi W, Yang X Y, Wei B, Wong W Y 2022 Adv. Opt. Mater. 10 2200984

Google Scholar

Google Scholar

[14] Wei H X, Zhang R, Huang G Y, Lv C K, Tang J X 2022 J. Mater. Chem. C 10 5994

Google Scholar

Google Scholar

[15] Kalinowski J, Cocchi M, Virgili D, Marco P D, Fattori V 2003 Chem. Phys. Lett. 380 710

Google Scholar

Google Scholar

[16] Tang X T, Pan R H, Zhao X, Jia W Y, Wang Y, Ma C H, Tu L Y, Xiong Z H 2020 Adv. Funct. Mater. 30 2005765

Google Scholar

Google Scholar

[17] Tang X T, Hu Y Q, Jia W Y, Pan R H, Deng J Q, Deng J Q, He Z H, Xiong Z H 2018 ACS Appl. Mater. Inter. 10 1948

Google Scholar

Google Scholar

[18] Xiang J, Chen Y B, Yuan D, Jia W Y, Zhang Q M, Xiong Z H 2016 Appl. Phys. Lett. 109 103301

Google Scholar

Google Scholar

[19] Thompson N, Hontz E, Congreve D N, Bahlke M E, Reineke S, Voorhis T V, Baldo M A 2014 Adv. Mater. 26 1366

Google Scholar

Google Scholar

[20] Wang Y, Ning Y R, Wu F J, Chen J, Chen X L, Xiong Z H 2022 Adv. Funct. Mater. 32 2202882

Google Scholar

Google Scholar

[21] Zhang T T, Holford D F, Gu H, Kreouzis T, Zhang S J, Gillin W P 2016 Appl. Phys. Lett. 108 023303

Google Scholar

Google Scholar

[22] Van Reenen S, Kersten S P, Wouters S H W, et al. 2013 Phys. Rev. B 88 125203

Google Scholar

Google Scholar

[23] Chang Q, Lü Z Y, Yin Y H, Xiao J, Wang J L 2022 Displays 75 102306

Google Scholar

Google Scholar

[24] 陈秋松, 袁德, 贾伟尧, 陈历相, 邹越, 向杰, 陈颖冰, 张巧明, 熊祖洪 2015 64 177801

Google Scholar

Google Scholar

Chen Q S, Yuan D, Jia W Y, Chen L X, Zou Y, Xiang J, Chen Y B, Zhang Q M, Xiong Z H 2015 Acta Phys. Sin. 64 177801

Google Scholar

Google Scholar

[25] Keawin T, Prachumrak N, Namuangruk S, et al. 2015 RSC Adv. 5 73481

Google Scholar

Google Scholar

[26] 王春梅, 雷衍连, 张巧明, 焦威, 游胤涛, 熊祖洪 2013 中国科学: 物理学 力学 天文学 43 732

Google Scholar

Google Scholar

Wang C M, Lei Y L, Zhang Q M, Jiao W, You Y T, Xiong Z H 2013 Sci. Sin-Phys. Mech. Astron. 43 732

Google Scholar

Google Scholar

[27] Can M, Havare A K, Aydın H, Yagmurcukardes N, Demic S, Icli S, Okur S 2014 Appl. Surf. Sci. 314 1082

Google Scholar

Google Scholar

[28] Talik N A, Yeoh K H, Ng C Y B, Tan C Y, Yap B K 2016 J. Lumin. 169 61

Google Scholar

Google Scholar

[29] Yuan P S, Guo X M, Qiao X F, Yan D H, Ma D G 2019 Adv. Opt. Mater. 7 1801648

Google Scholar

Google Scholar

[30] Engmann S, Bittle E G, Richter L J, Hallani R K, Anthony J E, Gundlach D J 2021 J. Mater. Chem. C 9 10052

Google Scholar

Google Scholar

[31] 宁亚茹, 赵茜, 汤仙童, 陈敬, 吴凤娇, 贾伟尧, 陈晓莉, 熊祖洪 2022 71 087201

Google Scholar

Google Scholar

Ning Y R, Zhao X, Tang X T, Chen J, Wu F J, Jia W Y, Chen X L, Xiong Z H 2022 Acta Phys. Sin. 71 087201

Google Scholar

Google Scholar

[32] Zhao X, Tang X T, Zhu H Q, Ma C H, Wang Y, Ye S N, Tu L Y, Xiong Z H 2021 ACS Appl. Electron. Mater. 3 3034

Google Scholar

Google Scholar

[33] 邓金秋, 汤仙童, 潘睿亨, 胡叶倩, 朱洪强, 熊祖洪, 陈晓莉 2018 科学通报 63 2974

Google Scholar

Google Scholar

Deng J Q, Tang X T, Pan R H, Hu Y Q, Zhu H Q, Xiong Z H, Chen X L 2018 Chin. Sci. Bull. 63 2974

Google Scholar

Google Scholar

[34] Jou J H, Lin W J, Shih S H, Wang Y S, Sahoo S, Singh M, Tsai Y C, Wen S W 2023 Electronics 12 2099

Google Scholar

Google Scholar

[35] Chen P, Peng Q M, Yao L, Gao Na, Li F 2013 Appl. Phys. Lett. 102 063301

[36] Peng Q M, Li A W, Fan Y X, Chen P, Li F 2014 J. Mater. Chem. C 2 6264

Google Scholar

Google Scholar

[37] Liu H, Jia W Y, Zhang Y, Zhang Q M, Lei Y L, Lu C L, Ling Y Z, Xiong Z H 2014 Synth. Met. 198 6

Google Scholar

Google Scholar

[38] Desai P, Shakya P, Kreouzis T, Gilin W P, Morley N A, Gibbs M R J 2007 Phys. Rev. B 75 094423

Google Scholar

Google Scholar

[39] Sheng Y, Nguyen T D, Veeraraghavan G, Mermer Ö, Wohlgenannt M, Qiu S, Scherf U 2006 Phys. Rev. B 74 045213

Google Scholar

Google Scholar

[40] Baniya S, Pang Z Y, Sun D L, Zhai Y X, Kwon O, Choi H, Choi B, Lee S, Vardeny Z V 2016 Adv. Funct. Mater. 26 6930

Google Scholar

Google Scholar

[41] Janssen P, Cox M, Wouters S H W, Kemerink M, Wienk M M, Koopmans B 2013 Nat. Commun. 4 2286

Google Scholar

Google Scholar

[42] Kim C Y, Lee C, Kim H J, Hwang J, Godumala M, Jeong J E, Woo H Y, Cho M J, Park S, Choi D H 2020 J. Mater. Chem. C 8 6780

Google Scholar

Google Scholar

[43] Liu F L, Kelley M R, Crooker S A, Nie W Y, Mohite A D, Ruden P P, Smith D L 2014 Phys. Rev. B 90 235314

Google Scholar

Google Scholar

[44] Yuan P S, Qiao X F, Yan D H, Ma D G 2018 J. Mater. Chem. C 6 5721

Google Scholar

Google Scholar

[45] Shao M, Yan L, Li M X, Ilia L, Hu B 2013 J. Mater. Chem. C 1 1330

Google Scholar

Google Scholar

-

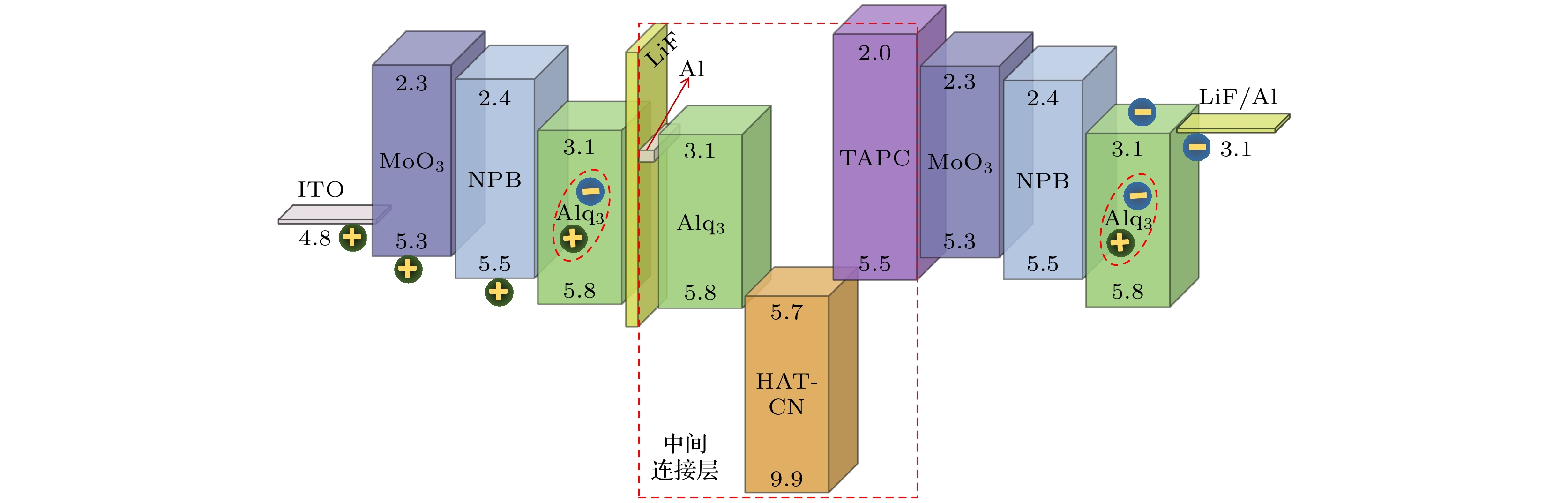

图 1 器件A和器件B的结构及其电流密度-亮度-发光效率特性 (a) 器件结构图以及Alq3, HAT-CN的分子结构; (b) 电压-亮度曲线, 插图为电压-电流密度曲线; (c) 电流密度-亮度曲线以及在亮度为1000 cd/m2和15000 cd/m2的色坐标插图; (d) 电流密度-发光效率曲线

Fig. 1. Structural diagram of device A and device B and their current density-luminance-luminance efficiency curves: (a) Structural diagrams and molecular structures of Alq3 and HAT-CN; (b) voltage-luminance curves, insets shows the voltage-current density curves; (c) current density-luminance curves and color coordinate insets at luminance of 1000 cd/m2 and 15000 cd/m2; (d) current density-luminance efficiency curves.

图 3 不同连接层的叠层OLED器件C—H (无连接层, HAT-CN, Alq3/HAT-CN, Al/Alq3/HAT-CN和Alq3 /HAT-CN/TAPC)的光电性能 (a) 电压-电流密度曲线; (b) 电压-亮度曲线; (c) 电流密度-亮度曲线; (d) 电流密度-发光效率曲线; (e) 归一化EL光谱图; (f) 器件C—H电压-电流密度双对数曲线图(黑色为拟合曲线)

Fig. 3. Optoelectronic properties of tandem OLED devices C—H (without interconnect layer, HAT-CN, Alq3/HAT-CN, Al/Alq3/HAT-CN and Alq3/HAT-CN/TAPC) with different interconnect layers: (a) Voltage-current density curves; (b) voltage-luminance curves; (c) current density-luminance curves; (d) current density-luminance efficiency curves; (e) normalized EL spectra; (f) the double logarithmic curves of voltage-current density of device C—H (black for fitting curve).

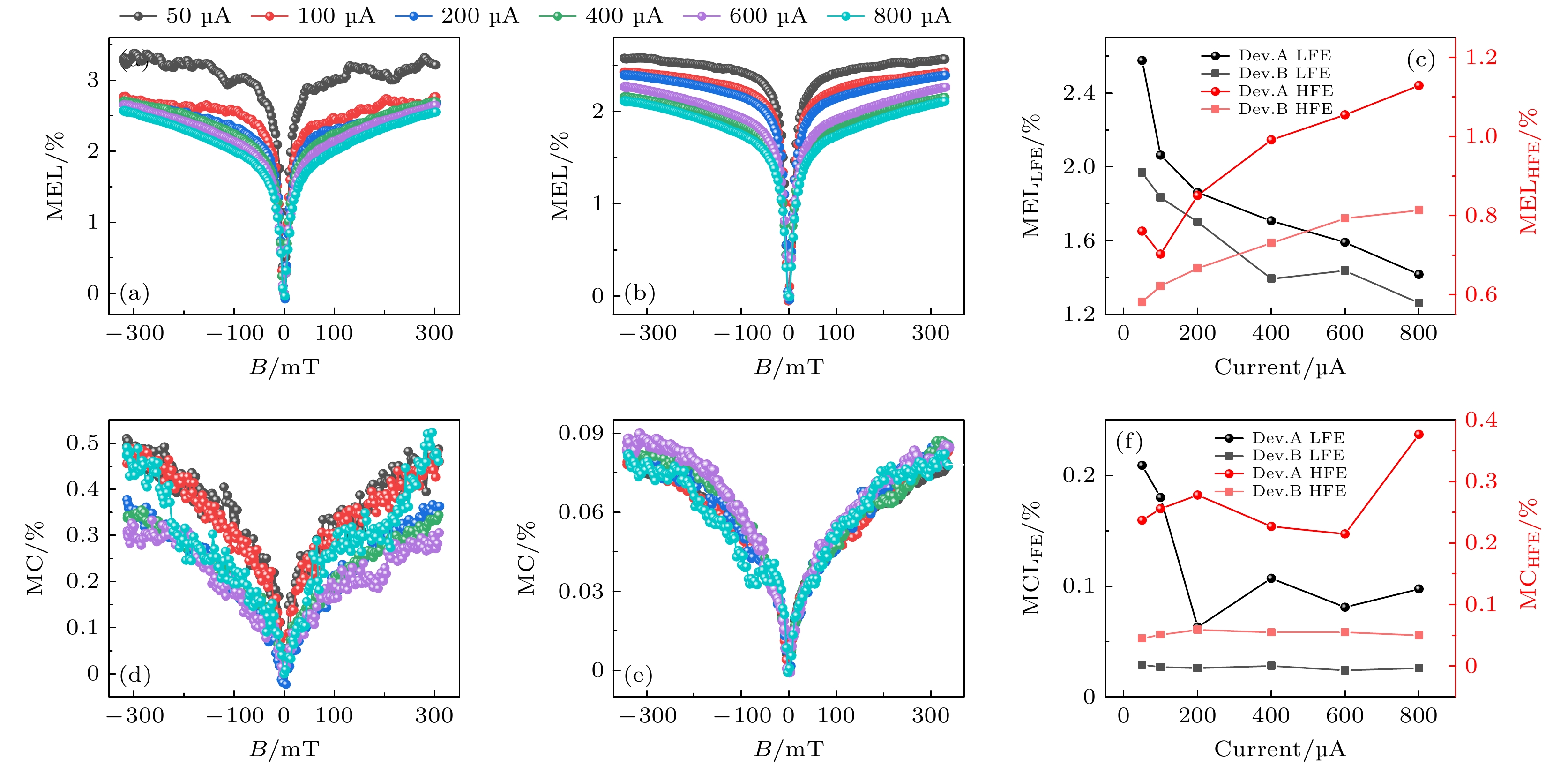

图 4 单发光单元器件A和叠层OLED器件B在不同电流下的MEL, MC曲线 (a) 器件A的MEL; (b) 器件B的MEL; (c) MEL的低场和高场效应; (d) 器件A的MC; (e) 器件B的MC; (f) MC的低场和高场效应

Fig. 4. The MEL, MC curves of single EL unit device A and tandem OLED device B at different current: (a) MEL curves of device A; (b) MEL curves of device B; (c) MELLFE and MELHFE; (d) MC curves of device A; (e) MC curves of device B; (f) MCLFE and MCHFE.

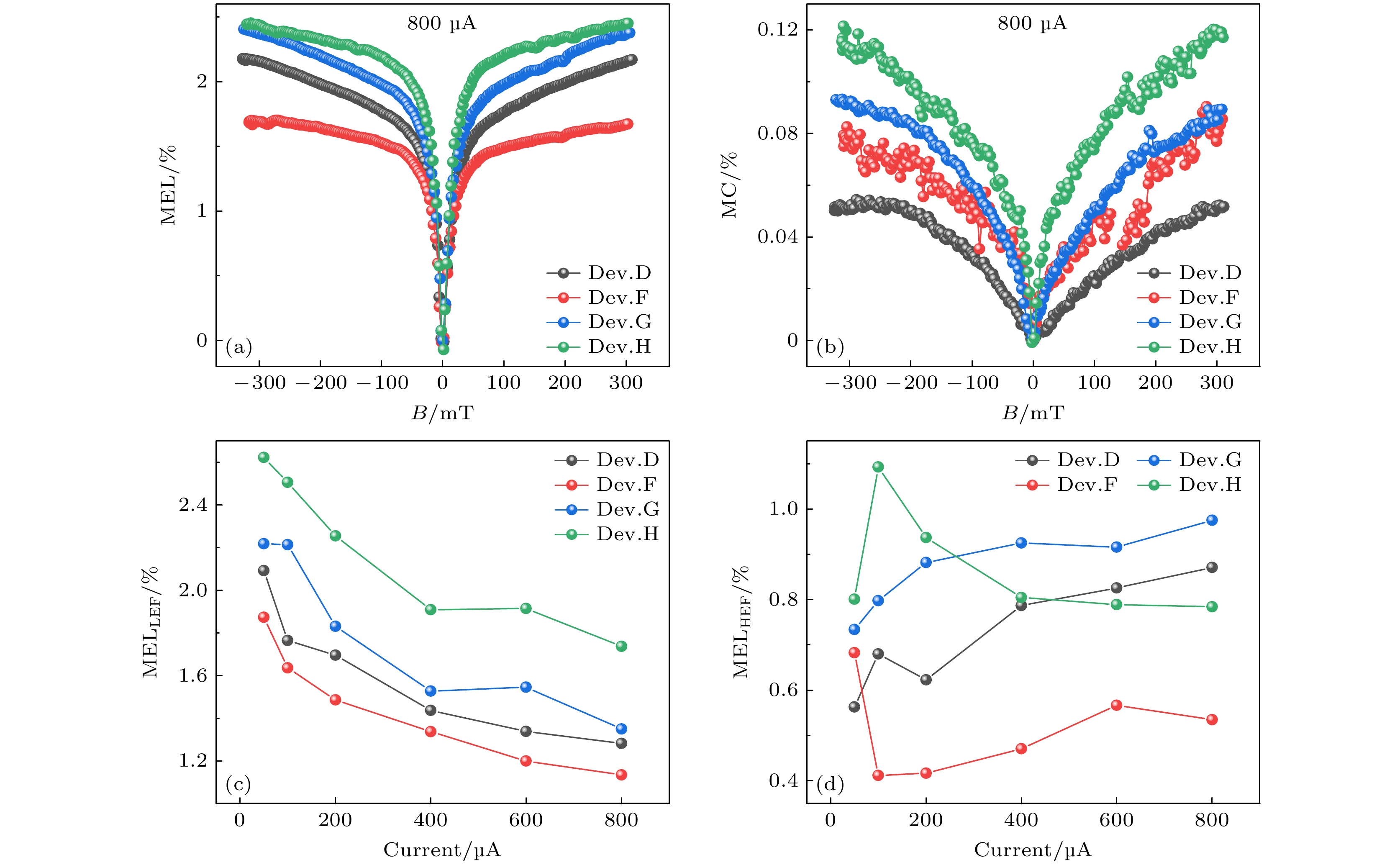

图 5 室温下不同连接层叠层OLED器件D, F—H(Alq3, Alq3/HAT-CN, Al/Alq3/HAT-CN和Alq3/HAT-CN/TAPC)的MEL和MC曲线, 以及MEL的低场效应和高场效应随电流的变化 (a) MEL曲线; (b) MC曲线; (c) 随电流变化的MEL低场效应; (d) 随电流变化的MEL高场效应

Fig. 5. The MEL and MC curves of different interconnect layer tandem OLED devices D, F–H (Alq3, Alq3/HAT-CN, Al/Alq3/HAT-CN and Alq3/HAT-CN/TAPC) at room temperature, and the variation of MELLFE and MELHFE with current: (a) MEL curves; (b) MC curves; (c) MELLFE of the current variation; (d) MELHFE of the current variation.

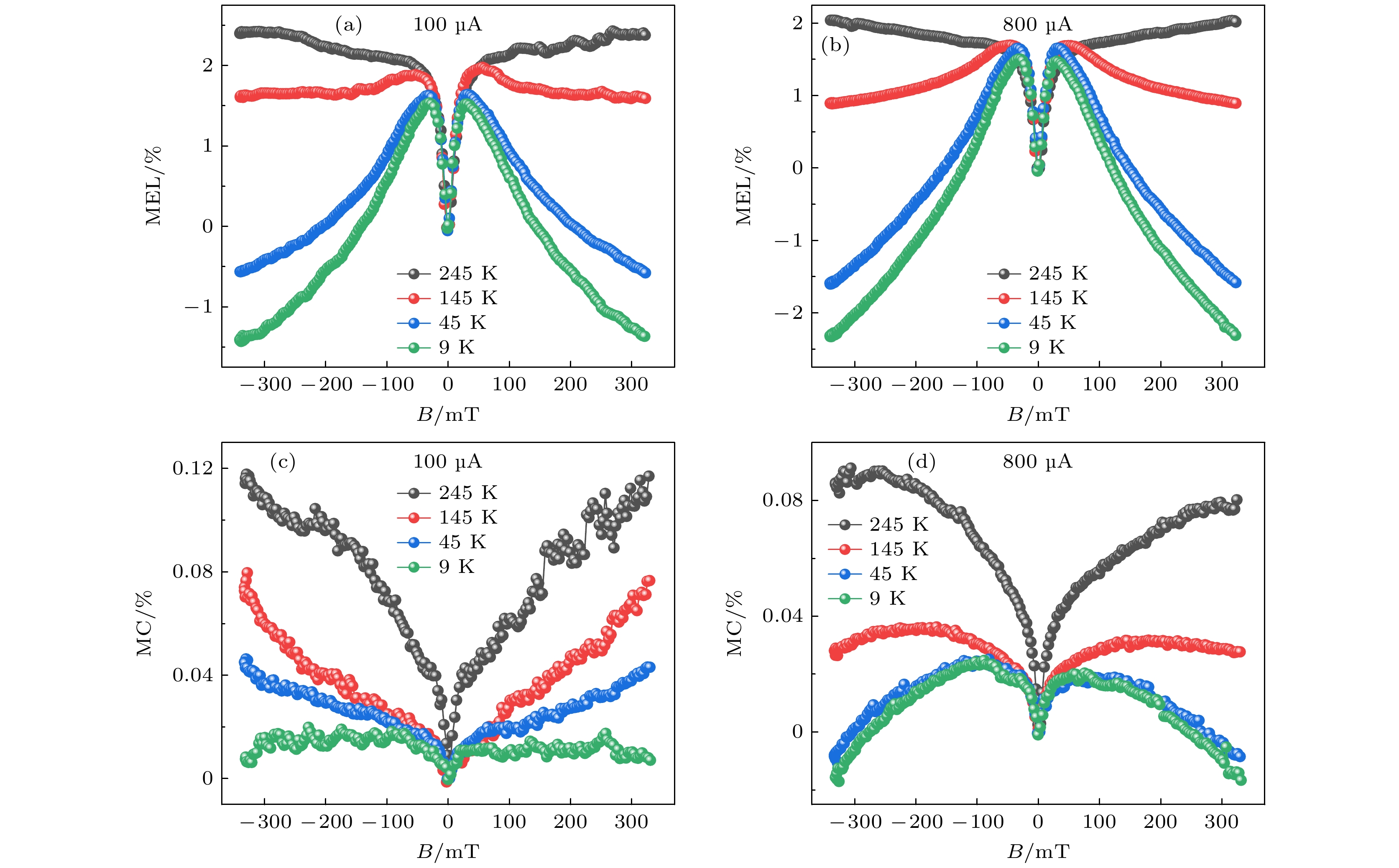

图 6 在一定电流下随温度变化的Alq3/HATCN连接层叠层OLED的MEL和MC曲线 (a) 100 μA的MEL; (b) 800 μA的MEL; (c) 100 μA的MC; (d) 800 μA的MC

Fig. 6. The MEL and MC curves of Alq3/HATCN interconnect layer tandem OLED that vary with temperature under a certain current: (a) MEL curves of 100 μA; (b) MEL curves of 800 μA; (c) MC curves of 100 μA; (d) MC curves of 800 μA.

表 1 单发光单元器件A和连接层为Alq3/HAT-CN叠层器件B, 以及不同连接层的叠层器件C—H的光电性能

Table 1. Photovoltaic performance of single EL unit device A, tandem device B with Alq3/HAT-CN as the interconnect layers, and tandem devices C—H with different interconnect layers.

Device Voltageon/V Voltage/V Luminance/(cd·m–2) Luminance efficiency/(cd·A–1) J80 Max J80 Max J80 A 4.09 7.96 36640 4007.14 5.53 5.00 B 7.65 17.45 21710 10410.00 13.28 12.92 C 4.05 11.73 15200 3353.27 5.29 4.19 D 9.38 18.39 12080 5494.57 9.00 6.84 E 5.43 17.94 9181 3072.57 4.23 3.84 F 7.89 15.32 26420 11189.86 15.35 13.85 G 8.25 18.20 14530 6039.05 8.79 7.54 H 6.76 12.54 13630 6340.97 8.22 7.91 注: J表示电流密度, J80数据列代表电流密度为80 mA·cm–2时, 相应参量的取值; Max数据列表示相应参量的最大值. -

[1] Liu Y C, Li C S, Ren Z J, Yan S Y, Bryce M R 2018 Nat. Rev. Mater. 3 1

Google Scholar

Google Scholar

[2] Chen Q S, Jia W Y, Chen L X, Yuan D, Zou Y, Xiong Z H 2016 Sci. Rep. 6 25331

Google Scholar

Google Scholar

[3] Chen L X, Jia W Y, Lan Z J, Tang X T, Zhu F R, Xiong Z H 2018 Org. Electron. 55 165

Google Scholar

Google Scholar

[4] Reineke S, Thomschke M, Lüssem B, Leo K 2013 Rev. Mod. Phys. 85 1245

Google Scholar

Google Scholar

[5] Lee S, Lee J H, Lee J H, Kim J J 2012 Adv. Funct. Mater. 22 855

Google Scholar

Google Scholar

[6] Chiba T, Pu Y J, Miyazaki R, Nakayama K I, Sasabe H, Kido J 2011 Org. Electron. 12 710

Google Scholar

Google Scholar

[7] Yuan J K, Liu W, Yao J W, Sun Q, Dai Y F, Chen J S, Yang D Z, Qiao X F, Ma D G 2020 Org. Electron. 83 105745

Google Scholar

Google Scholar

[8] Matsumoto T, Nakada T, Endo J, Koichi M, Kawamura N, Yokoi A, Kido J 2003 SID Symp. Dig. Tech. Pap. 34 979

Google Scholar

Google Scholar

[9] Sun H D, Guo Q X, Yang D Z, Chen Y H, Chen J S, Ma D G 2015 ACS Photonics 2 271

Google Scholar

Google Scholar

[10] Liu Y, Wu X M, Xiao Z H, Gao J, Zhang Y, Rui H S, Lin X, Zhang N, Hua Y L, Yin S G 2017 Appl. Surf. Sci. 413 302

Google Scholar

Google Scholar

[11] Guo Q X, Dai Y F, Sun Q, Qiao X F, Chen J S, Zhu T Z, Ma D G 2018 Adv. Electron. Mater. 4 1800177

Google Scholar

Google Scholar

[12] Wang J, Wang Y, Qin Y, Li R Q, An J X, Chen Y H, Lai W Y, Zhang X W, Huang W 2021 J. Mater. Chem. C 9 8570

Google Scholar

Google Scholar

[13] Xu Y C, Niu Y X, Gong C L, Shi W, Yang X Y, Wei B, Wong W Y 2022 Adv. Opt. Mater. 10 2200984

Google Scholar

Google Scholar

[14] Wei H X, Zhang R, Huang G Y, Lv C K, Tang J X 2022 J. Mater. Chem. C 10 5994

Google Scholar

Google Scholar

[15] Kalinowski J, Cocchi M, Virgili D, Marco P D, Fattori V 2003 Chem. Phys. Lett. 380 710

Google Scholar

Google Scholar

[16] Tang X T, Pan R H, Zhao X, Jia W Y, Wang Y, Ma C H, Tu L Y, Xiong Z H 2020 Adv. Funct. Mater. 30 2005765

Google Scholar

Google Scholar

[17] Tang X T, Hu Y Q, Jia W Y, Pan R H, Deng J Q, Deng J Q, He Z H, Xiong Z H 2018 ACS Appl. Mater. Inter. 10 1948

Google Scholar

Google Scholar

[18] Xiang J, Chen Y B, Yuan D, Jia W Y, Zhang Q M, Xiong Z H 2016 Appl. Phys. Lett. 109 103301

Google Scholar

Google Scholar

[19] Thompson N, Hontz E, Congreve D N, Bahlke M E, Reineke S, Voorhis T V, Baldo M A 2014 Adv. Mater. 26 1366

Google Scholar

Google Scholar

[20] Wang Y, Ning Y R, Wu F J, Chen J, Chen X L, Xiong Z H 2022 Adv. Funct. Mater. 32 2202882

Google Scholar

Google Scholar

[21] Zhang T T, Holford D F, Gu H, Kreouzis T, Zhang S J, Gillin W P 2016 Appl. Phys. Lett. 108 023303

Google Scholar

Google Scholar

[22] Van Reenen S, Kersten S P, Wouters S H W, et al. 2013 Phys. Rev. B 88 125203

Google Scholar

Google Scholar

[23] Chang Q, Lü Z Y, Yin Y H, Xiao J, Wang J L 2022 Displays 75 102306

Google Scholar

Google Scholar

[24] 陈秋松, 袁德, 贾伟尧, 陈历相, 邹越, 向杰, 陈颖冰, 张巧明, 熊祖洪 2015 64 177801

Google Scholar

Google Scholar

Chen Q S, Yuan D, Jia W Y, Chen L X, Zou Y, Xiang J, Chen Y B, Zhang Q M, Xiong Z H 2015 Acta Phys. Sin. 64 177801

Google Scholar

Google Scholar

[25] Keawin T, Prachumrak N, Namuangruk S, et al. 2015 RSC Adv. 5 73481

Google Scholar

Google Scholar

[26] 王春梅, 雷衍连, 张巧明, 焦威, 游胤涛, 熊祖洪 2013 中国科学: 物理学 力学 天文学 43 732

Google Scholar

Google Scholar

Wang C M, Lei Y L, Zhang Q M, Jiao W, You Y T, Xiong Z H 2013 Sci. Sin-Phys. Mech. Astron. 43 732

Google Scholar

Google Scholar

[27] Can M, Havare A K, Aydın H, Yagmurcukardes N, Demic S, Icli S, Okur S 2014 Appl. Surf. Sci. 314 1082

Google Scholar

Google Scholar

[28] Talik N A, Yeoh K H, Ng C Y B, Tan C Y, Yap B K 2016 J. Lumin. 169 61

Google Scholar

Google Scholar

[29] Yuan P S, Guo X M, Qiao X F, Yan D H, Ma D G 2019 Adv. Opt. Mater. 7 1801648

Google Scholar

Google Scholar

[30] Engmann S, Bittle E G, Richter L J, Hallani R K, Anthony J E, Gundlach D J 2021 J. Mater. Chem. C 9 10052

Google Scholar

Google Scholar

[31] 宁亚茹, 赵茜, 汤仙童, 陈敬, 吴凤娇, 贾伟尧, 陈晓莉, 熊祖洪 2022 71 087201

Google Scholar

Google Scholar

Ning Y R, Zhao X, Tang X T, Chen J, Wu F J, Jia W Y, Chen X L, Xiong Z H 2022 Acta Phys. Sin. 71 087201

Google Scholar

Google Scholar

[32] Zhao X, Tang X T, Zhu H Q, Ma C H, Wang Y, Ye S N, Tu L Y, Xiong Z H 2021 ACS Appl. Electron. Mater. 3 3034

Google Scholar

Google Scholar

[33] 邓金秋, 汤仙童, 潘睿亨, 胡叶倩, 朱洪强, 熊祖洪, 陈晓莉 2018 科学通报 63 2974

Google Scholar

Google Scholar

Deng J Q, Tang X T, Pan R H, Hu Y Q, Zhu H Q, Xiong Z H, Chen X L 2018 Chin. Sci. Bull. 63 2974

Google Scholar

Google Scholar

[34] Jou J H, Lin W J, Shih S H, Wang Y S, Sahoo S, Singh M, Tsai Y C, Wen S W 2023 Electronics 12 2099

Google Scholar

Google Scholar

[35] Chen P, Peng Q M, Yao L, Gao Na, Li F 2013 Appl. Phys. Lett. 102 063301

[36] Peng Q M, Li A W, Fan Y X, Chen P, Li F 2014 J. Mater. Chem. C 2 6264

Google Scholar

Google Scholar

[37] Liu H, Jia W Y, Zhang Y, Zhang Q M, Lei Y L, Lu C L, Ling Y Z, Xiong Z H 2014 Synth. Met. 198 6

Google Scholar

Google Scholar

[38] Desai P, Shakya P, Kreouzis T, Gilin W P, Morley N A, Gibbs M R J 2007 Phys. Rev. B 75 094423

Google Scholar

Google Scholar

[39] Sheng Y, Nguyen T D, Veeraraghavan G, Mermer Ö, Wohlgenannt M, Qiu S, Scherf U 2006 Phys. Rev. B 74 045213

Google Scholar

Google Scholar

[40] Baniya S, Pang Z Y, Sun D L, Zhai Y X, Kwon O, Choi H, Choi B, Lee S, Vardeny Z V 2016 Adv. Funct. Mater. 26 6930

Google Scholar

Google Scholar

[41] Janssen P, Cox M, Wouters S H W, Kemerink M, Wienk M M, Koopmans B 2013 Nat. Commun. 4 2286

Google Scholar

Google Scholar

[42] Kim C Y, Lee C, Kim H J, Hwang J, Godumala M, Jeong J E, Woo H Y, Cho M J, Park S, Choi D H 2020 J. Mater. Chem. C 8 6780

Google Scholar

Google Scholar

[43] Liu F L, Kelley M R, Crooker S A, Nie W Y, Mohite A D, Ruden P P, Smith D L 2014 Phys. Rev. B 90 235314

Google Scholar

Google Scholar

[44] Yuan P S, Qiao X F, Yan D H, Ma D G 2018 J. Mater. Chem. C 6 5721

Google Scholar

Google Scholar

[45] Shao M, Yan L, Li M X, Ilia L, Hu B 2013 J. Mater. Chem. C 1 1330

Google Scholar

Google Scholar

计量

- 文章访问数: 4717

- PDF下载量: 79

- 被引次数: 0

下载:

下载: