-

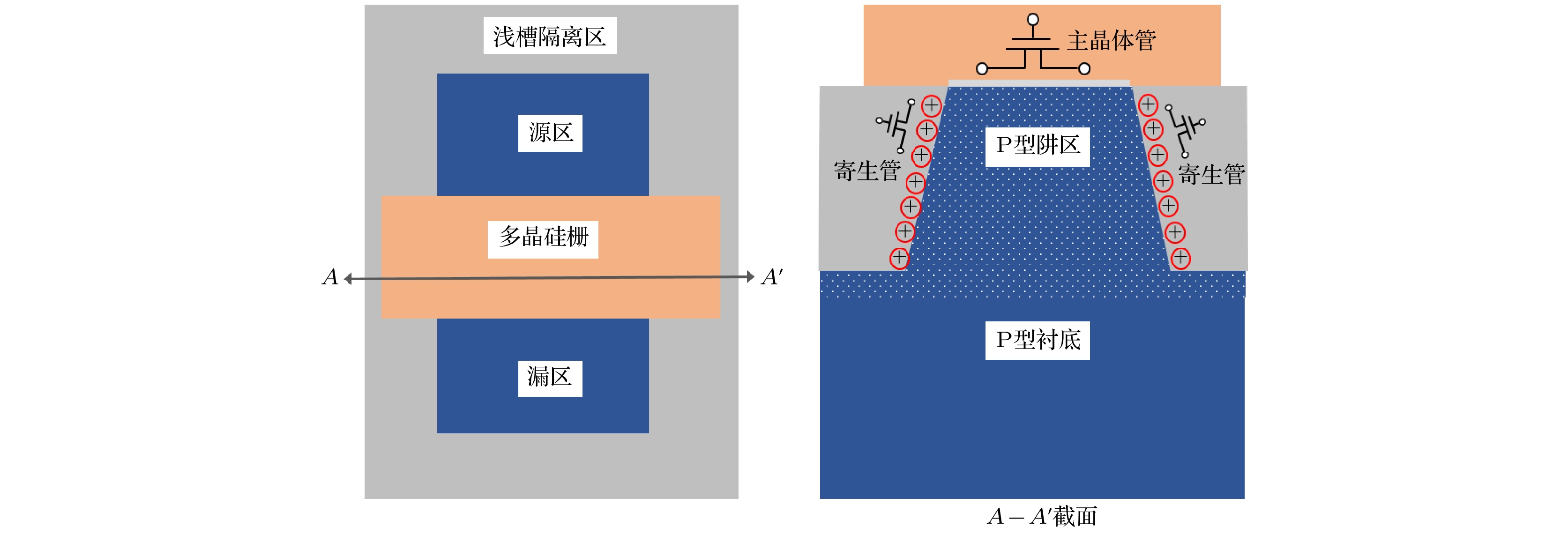

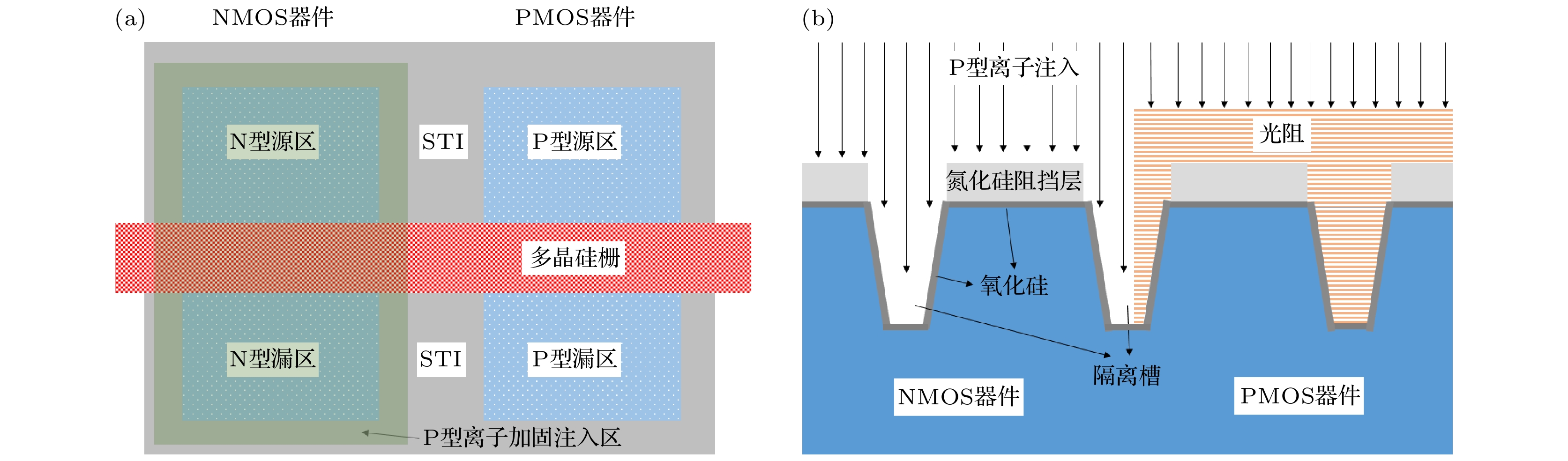

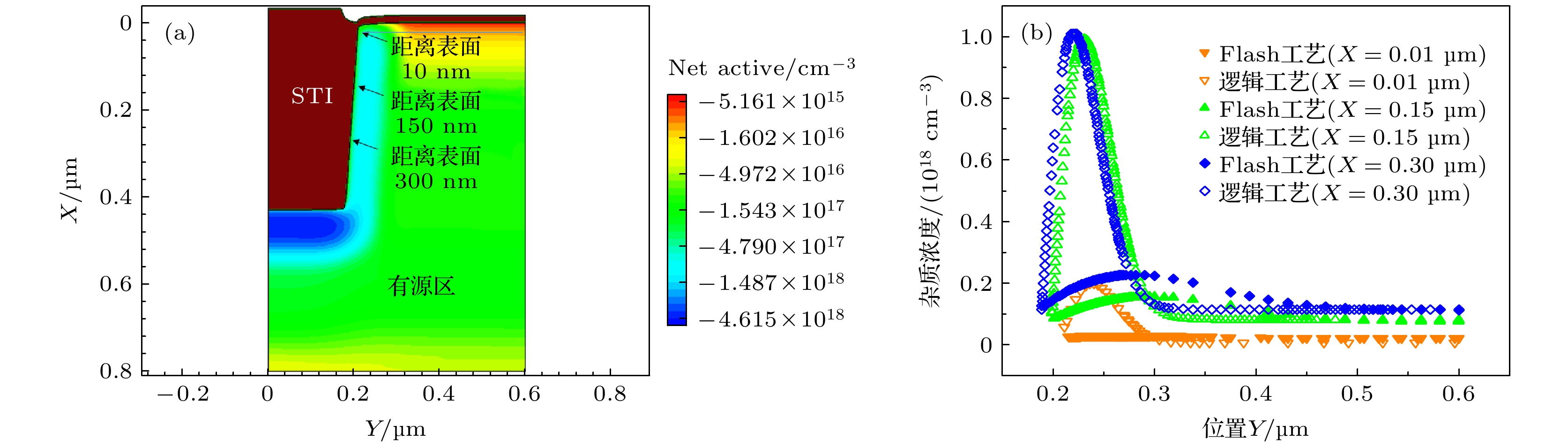

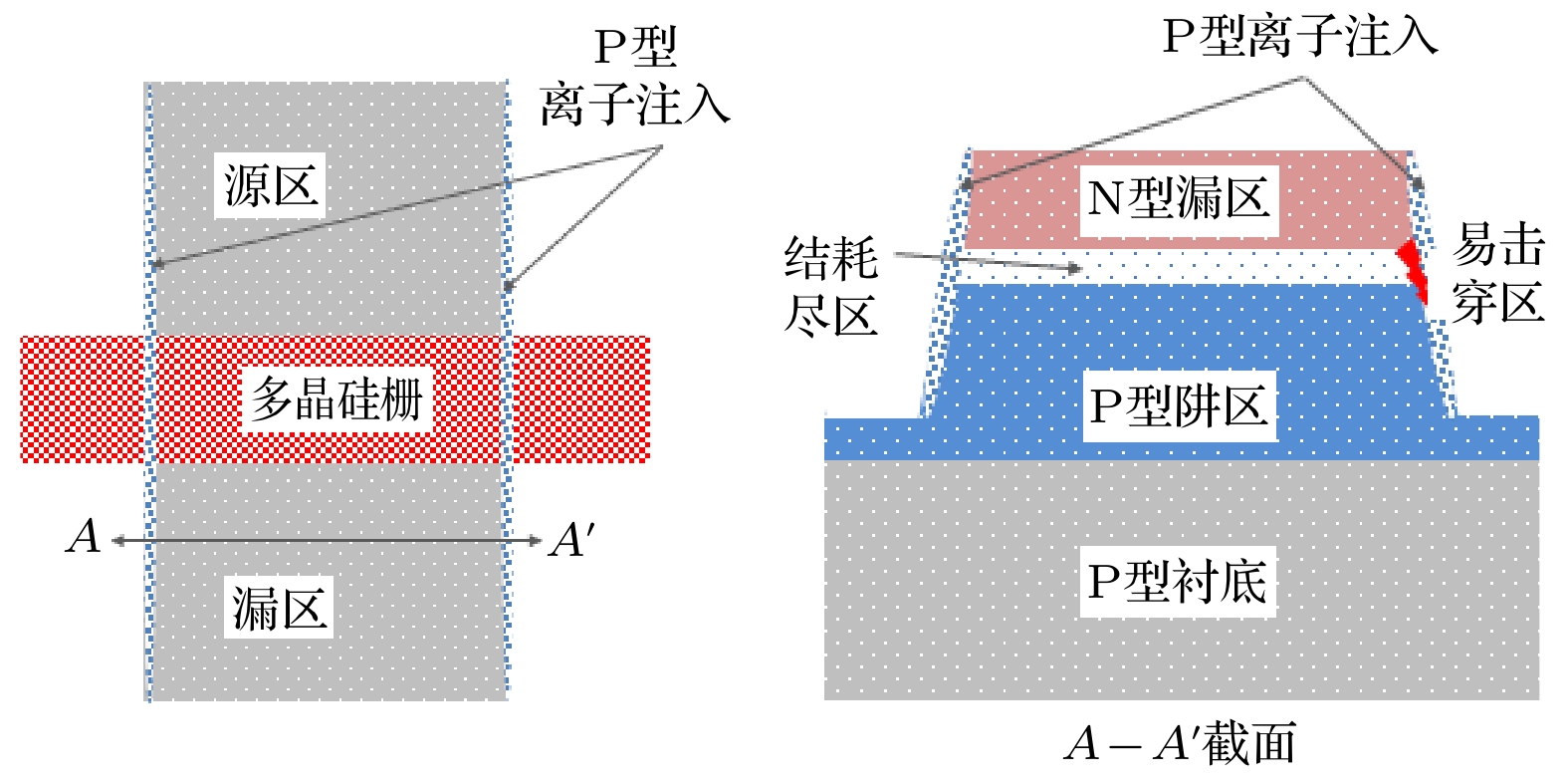

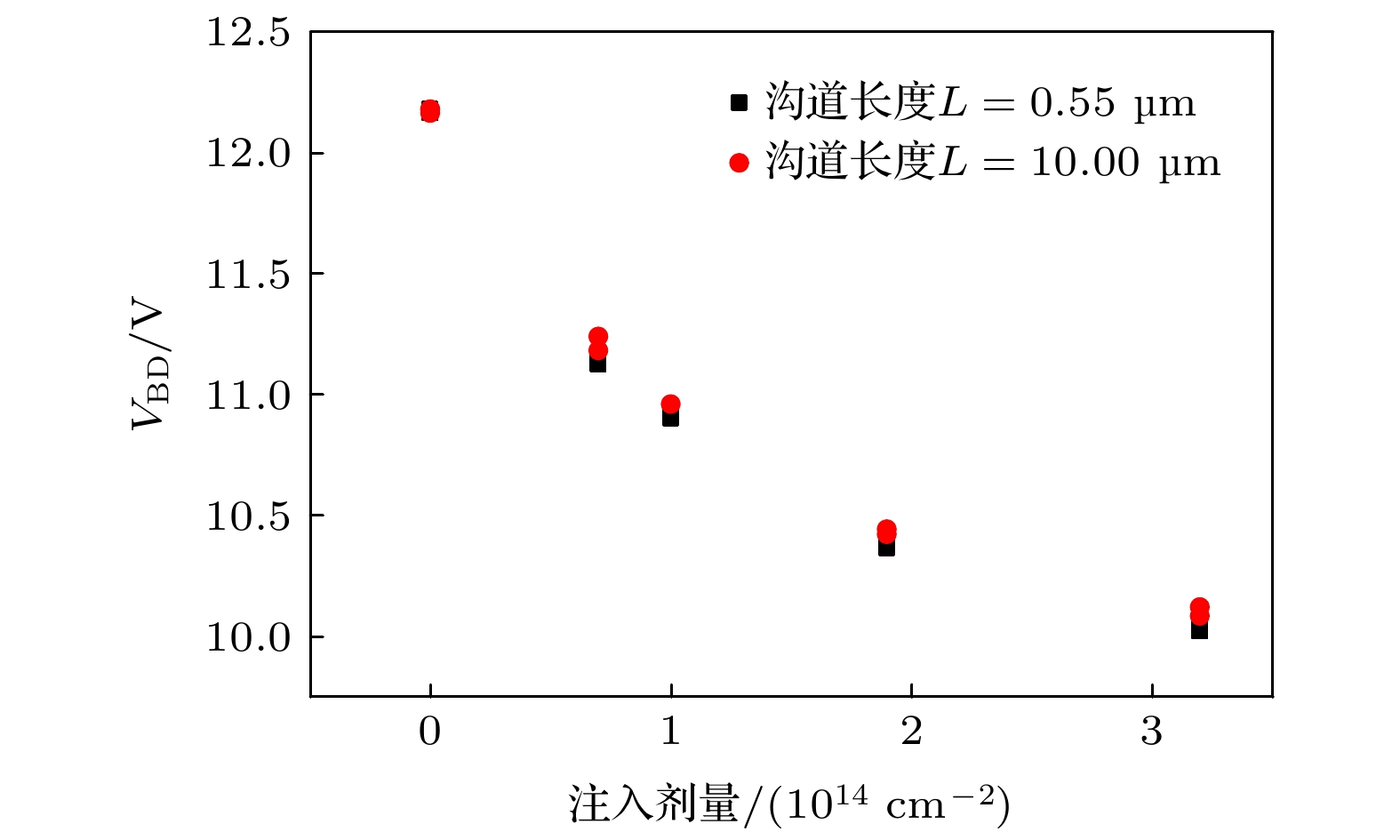

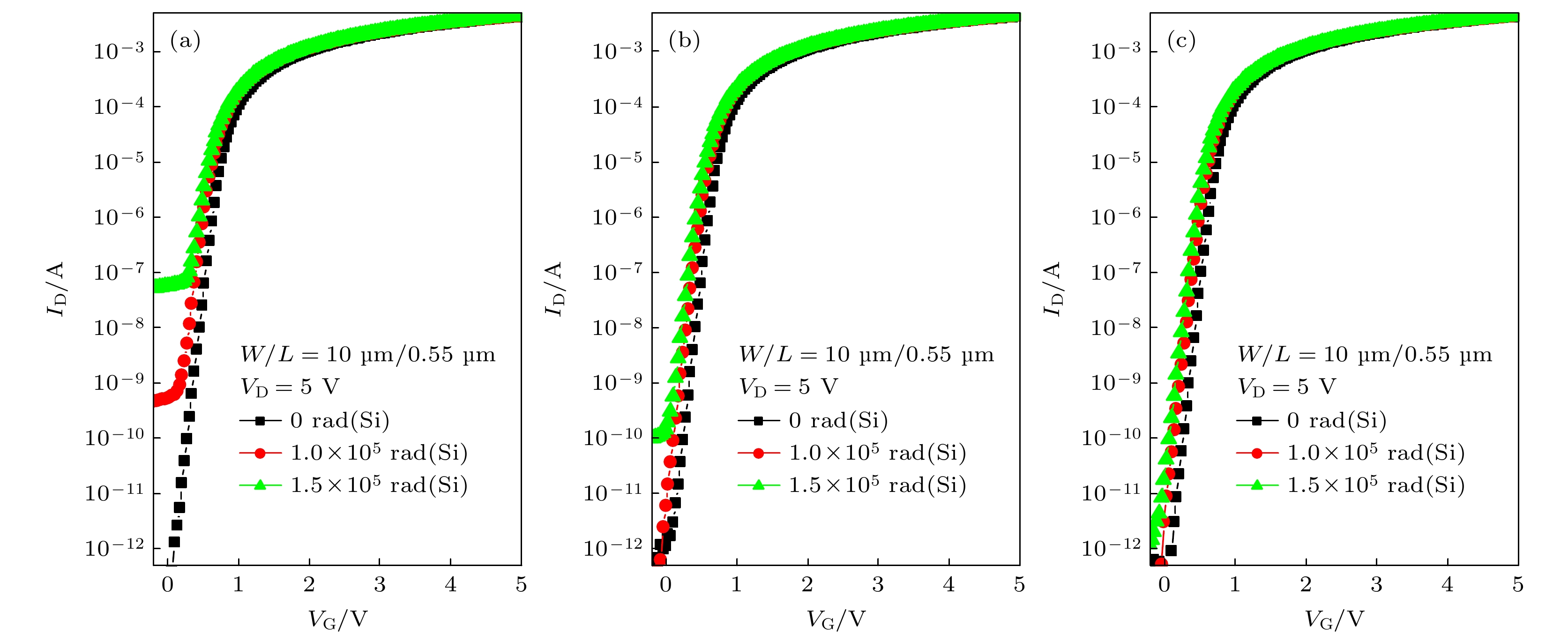

抗辐射嵌入式闪存工艺在航空航天领域应用广泛, 其中高压NMOS器件对总剂量辐射效应最敏感, 对该器件进行加固是提高芯片抗辐射能力的关键之一. 本文采用浅槽隔离(STI)场区离子注入工艺对180 nm嵌入式闪存工艺中的高压NMOS器件进行加固, 实验结果表明该加固器件存在两个主要问题: 1)浅槽刻蚀后进行离子注入, 后续热工艺较多, 存在显著的杂质再分布效应, 导致STI侧壁离子浓度降低, 经过1×105 rad (1 rad = 10–2 Gy)(Si)辐照后, 器件因漏电流增大而无法关断; 2)加固离子注入降低了漏区PN结击穿电压, 不能满足实际应用需求. 为解决上述问题, 本文提出了一种新型部分沟道离子注入加固方案. 该方案调整加固离子注入工艺至热预算较多的栅氧工艺之后, 减弱了离子再分布效应. 另外, 仅在STI边缘的沟道中部进行离子注入, 不影响漏击穿电压. 采用本方案对高压NMOS器件进行总剂量工艺加固, 不改变器件的条形栅设计, 对器件电学参数影响较小, 与通用工艺兼容性好. 测试结果表明, 器件经过1.5×105 rad (Si)总剂量辐照后, 关态漏电流保持在10–12 A左右, 这比传统的STI场区离子注入加固方案降低了5个数量级.Radiation-hardened embedded flash technology is widely used in aerospace field. The high voltage nMOSFET is the key device to be hardened as it is the most sensitive device to total ionizing dose (TID) effect. In this study, the shallow tench isolation (STI) sidewall implantation method is used to harden 5 V nMOSFET for 180 nm eFlash process. Through the study of the TID response of the device, two problems emerge in this hardening technology. Firstly, the hardening ions are implanted after STI trench etching, the doping profile is influenced by the following thermal process, resulting in lower doping concentration at STI edge. The device fails to work due to high leakage current after 1×105 rad (1 rad = 10–2 Gy) (Si) radiation. Secondly, the hardening ions that are implanted in drain region reduce the breakdown voltage of PN junction on the drain side. Device cannot satisfy the actual requirement in the circuit. To solve these problems, we propose a new device hardening method called partial channel ion implantation. Comparing with previous method, in order to reduce the doping redistribution effect, we adjust the hardening ion implantation to an extent after the oxidation of gate oxide. Moreover, an extra mask is introduced to determine the hardening implantation region to avoid ion implantation on the drain side of the device. Therefore, the drain breakdown voltage will not be influenced by hardening implantation. By using this new hardening technology for high voltage NMOS, the device can maintain the typical design of strip-type gate. The hardening method is compatible with general process technology and does not influence the electrical parameters of the device obviously. The results show that with the partial channel ion implantation method, the drain leakage of the device is kept at a pico-ampere level after 1.5×105 rad (Si) radiation. That is five orders of magnitude lower than that obtained by using previous STI implantation hardening technology.

-

Keywords:

- total ionizing dose effect /

- radiation hardening by process /

- high voltage MOSFET /

- embedded flash

[1] Barnaby H J, McLain M L, Sanchez Esqueda I, Chen X J 2009 IEEE Trans. Circuits Syst. Ⅰ 56 1870

Google Scholar

Google Scholar

[2] 卓青青, 刘红侠, 杨兆年, 蔡慧民, 郝跃 2012 61 220702

Google Scholar

Google Scholar

Zhuo Q Q, Liu H X, Yang Z N, Cai H M, Hao Y 2012 Acta Phys. Sin. 61 220702

Google Scholar

Google Scholar

[3] Zheng M Q, Liu Y, Duan C, Luo M T 2014 12 th IEEE International Conference on Solid-State and Integrated Circuit Technology Guilin, China, October 28–31, 2014 p1

[4] Liu Z L, Hu Z Y, Zhang Z X, Shao H, Chen M, Bi D W, Ning B X, Zou S C 2011 Microelectron. Reliab. 51 1148

Google Scholar

Google Scholar

[5] Hu Z Y, Liu Z L, Shao H, Zhang Z X, Ning B X, Chen M, Bi D W, Zou S C 2011 Microelectron. Reliab. 51 1295

Google Scholar

Google Scholar

[6] Liu Z L, Hu Z Y, Zhang Z X, Shao H, Chen M, Bi D W, Ning B X, Wang R, Zou S C 2010 Nucl. Instrum. Methods Phys. Res. Sect. B 268 3498

Google Scholar

Google Scholar

[7] 刘一宁, 杨亚鹏, 陈法国, 张建岗, 郭荣, 梁润成 2021 核技术 44 030502

Google Scholar

Google Scholar

Liu Y N, Yang Y P, Chen F G, Zhang J G, Guo R, Liang R C 2021 Nucl. Tech. 44 030502

Google Scholar

Google Scholar

[8] Schwank J R, Shaneyfelt M R, Fleetwood D M, Felix J A, Dodd P E, Paillet P, VÉronique F C 2008 IEEE Trans. Nucl. Sci. 55 1833

Google Scholar

Google Scholar

[9] Dodd P E, Shaneyfelt M R, Schwank J R, Felix 2010 IEEE Trans. Nucl. Sci. 57 1747

Google Scholar

Google Scholar

[10] 王信, 陆妩, 吴雪, 马武英, 崔江维, 刘默寒, 姜柯 2014 22 226101

Google Scholar

Google Scholar

Wang X, Lu W, Wu X, Ma W Y, Cui J W, Liu M H, Jiang K 2014 Acta Phys. Sin. 22 226101

Google Scholar

Google Scholar

[11] 郑齐文, 崔江维, 王汉宁, 周航, 余德昭, 魏莹, 苏丹丹 2016 65 076102

Google Scholar

Google Scholar

Zheng Q W, Cui J W, Wang H N, Zhou H, Yu D Z, Wei Y, Su D D 2016 Acta Phys. Sin. 65 076102

Google Scholar

Google Scholar

[12] Giovanni B, Valentino L, Alberto S, Stefano G 2013 Proceedings of the European Conference on Radiation and its Effects on Components and Systems Oxford, UK, September 23–27, 2013 p1

[13] 范雪, 李威, 李平, 张斌, 谢小东, 王刚, 胡滨, 翟亚红 2012 61 016106

Google Scholar

Google Scholar

Fan X, Li W, Li P, Zhang B, Xie X D, Wang G, Hu B, Zhai Y H 2012 Acta Phys. Sin. 61 016106

Google Scholar

Google Scholar

[14] Clark L T, Mohr K C, Holbert K E 2007 IEEE International Reliability Physics Symposium Proceedings Phoenix, USA, April 15–19, 2007 p582

[15] Lee M S, Lee H C 2013 IEEE Trans. Nucl. Sci. 60 3084

Google Scholar

Google Scholar

[16] Malik M, Prakash N R, Kumar A, Jatana H S 2022 Silicon 14 3891

Google Scholar

Google Scholar

[17] 董艺, 沈鸣杰, 刘岐 2018 航天器环境工程 35 468

Google Scholar

Google Scholar

Dong Y, Shen M J, Liu Q 2018 Spacecr. Environ. Eng. 35 468

Google Scholar

Google Scholar

[18] Chang J S, Chong K S, Shu W, Lin T, Jiang J, Lwin N K Z, Kang Y 2014 IEEE 57th International Midwest Symposium on Circuits and Systems College Station, USA, August 3–6, 2014 p821

[19] Vaz P I, Both T H, Vidor F F, Brum R M, Wirth G I 2018 J. Electron. Test. 34 735

Google Scholar

Google Scholar

[20] Song L, Hu Z Y, Zhang M Y, Liu X N, Dai L H, Zhang Z X, Zou S C 2017 Microelectron. Reliab. 74 1

Google Scholar

Google Scholar

[21] Peng C, Hu Z Y, En Y F, Chen Y Q, Lei Z F, Zhang Z G, Zhang Z X, Li B 2018 IEEE Trans. Nucl. Sci. 65 877

Google Scholar

Google Scholar

[22] 谢儒彬, 吴建伟, 陈海波, 李艳艳, 洪根深 2016 太赫兹科学与电子信息学报 14 805

Google Scholar

Google Scholar

Xie R B, Wu J W, Chen H B, Li Y Y, Hong G S 2016 J. Terahertz Sci. Electron. Inf. Technol. 14 805

Google Scholar

Google Scholar

[23] 王思浩, 鲁庆, 王文华, 安霞, 黄如 2010 59 1970

Google Scholar

Google Scholar

Wang S H, Lu Q, Wang W H, An X, Huang R 2010 Acta Phys. Sin. 59 1970

Google Scholar

Google Scholar

-

图 9 采用部分沟道离子注入器件总剂量效应 (a)加固注入剂量2×1013 cm–2; (b)加固注入剂5×1013 cm–2 ; (c)加固注入剂量8×1013 cm–2

Fig. 9. TID effect of the devices with partial channel hardened implantation: (a) Hardening implantation dose 2×1013 cm–2 ; (b) hardening implantation dose 5×1013 cm–2 ; (c) hardening implantation dose 8×1013 cm–2.

表 1 STI场区离子注入实验分片方案

Table 1. Split condition of ion implantation for experiment

样品 STI场区离子加固注入 能量/keV 剂量/cm–2 #1 120 0 #2 120 5×1013 #3 120 8×1013 表 2 两种注入加固方案测试结果对比

Table 2. Comparison of two total ionizing dose hardening methodology.

测试条件和参数 STI场区加固技术 部分沟道离子注入技术 #1 #2 #3 #4 #5 #6 辐照前 VT/V 0.72 0.75 0.78 0.74 0.76 0.79 IDsat/(μA·μm–1) 428 421 431 426 433 430 Ioff /(pA·μm–1) 9.7 9.5 1.4 2.0 1.1 2.2 BVD/V 12.2 11.4 11.1 12.1 12.2 12.1 1×105 rad(Si)辐照后 VT/V NA NA 0.35 0.67 0.65 0.69 IDsat/(μA·μm–1) 448 436 445 444 449 441 Ioff /(pA·μm–1) 1.9×107 2.5×107 5.0×106 5.3×102 5.9 3.0 辐照后

参数变化ΔVT/% — — –55.1 –9.5 –14.5 –12.7 ΔIDsat/% 4.7 3.6 3.2 4.2 3.7 2.6 ΔIoff/% 1.4×108 2.6×108 3.6×108 2.6×105 4.2×102 36 -

[1] Barnaby H J, McLain M L, Sanchez Esqueda I, Chen X J 2009 IEEE Trans. Circuits Syst. Ⅰ 56 1870

Google Scholar

Google Scholar

[2] 卓青青, 刘红侠, 杨兆年, 蔡慧民, 郝跃 2012 61 220702

Google Scholar

Google Scholar

Zhuo Q Q, Liu H X, Yang Z N, Cai H M, Hao Y 2012 Acta Phys. Sin. 61 220702

Google Scholar

Google Scholar

[3] Zheng M Q, Liu Y, Duan C, Luo M T 2014 12 th IEEE International Conference on Solid-State and Integrated Circuit Technology Guilin, China, October 28–31, 2014 p1

[4] Liu Z L, Hu Z Y, Zhang Z X, Shao H, Chen M, Bi D W, Ning B X, Zou S C 2011 Microelectron. Reliab. 51 1148

Google Scholar

Google Scholar

[5] Hu Z Y, Liu Z L, Shao H, Zhang Z X, Ning B X, Chen M, Bi D W, Zou S C 2011 Microelectron. Reliab. 51 1295

Google Scholar

Google Scholar

[6] Liu Z L, Hu Z Y, Zhang Z X, Shao H, Chen M, Bi D W, Ning B X, Wang R, Zou S C 2010 Nucl. Instrum. Methods Phys. Res. Sect. B 268 3498

Google Scholar

Google Scholar

[7] 刘一宁, 杨亚鹏, 陈法国, 张建岗, 郭荣, 梁润成 2021 核技术 44 030502

Google Scholar

Google Scholar

Liu Y N, Yang Y P, Chen F G, Zhang J G, Guo R, Liang R C 2021 Nucl. Tech. 44 030502

Google Scholar

Google Scholar

[8] Schwank J R, Shaneyfelt M R, Fleetwood D M, Felix J A, Dodd P E, Paillet P, VÉronique F C 2008 IEEE Trans. Nucl. Sci. 55 1833

Google Scholar

Google Scholar

[9] Dodd P E, Shaneyfelt M R, Schwank J R, Felix 2010 IEEE Trans. Nucl. Sci. 57 1747

Google Scholar

Google Scholar

[10] 王信, 陆妩, 吴雪, 马武英, 崔江维, 刘默寒, 姜柯 2014 22 226101

Google Scholar

Google Scholar

Wang X, Lu W, Wu X, Ma W Y, Cui J W, Liu M H, Jiang K 2014 Acta Phys. Sin. 22 226101

Google Scholar

Google Scholar

[11] 郑齐文, 崔江维, 王汉宁, 周航, 余德昭, 魏莹, 苏丹丹 2016 65 076102

Google Scholar

Google Scholar

Zheng Q W, Cui J W, Wang H N, Zhou H, Yu D Z, Wei Y, Su D D 2016 Acta Phys. Sin. 65 076102

Google Scholar

Google Scholar

[12] Giovanni B, Valentino L, Alberto S, Stefano G 2013 Proceedings of the European Conference on Radiation and its Effects on Components and Systems Oxford, UK, September 23–27, 2013 p1

[13] 范雪, 李威, 李平, 张斌, 谢小东, 王刚, 胡滨, 翟亚红 2012 61 016106

Google Scholar

Google Scholar

Fan X, Li W, Li P, Zhang B, Xie X D, Wang G, Hu B, Zhai Y H 2012 Acta Phys. Sin. 61 016106

Google Scholar

Google Scholar

[14] Clark L T, Mohr K C, Holbert K E 2007 IEEE International Reliability Physics Symposium Proceedings Phoenix, USA, April 15–19, 2007 p582

[15] Lee M S, Lee H C 2013 IEEE Trans. Nucl. Sci. 60 3084

Google Scholar

Google Scholar

[16] Malik M, Prakash N R, Kumar A, Jatana H S 2022 Silicon 14 3891

Google Scholar

Google Scholar

[17] 董艺, 沈鸣杰, 刘岐 2018 航天器环境工程 35 468

Google Scholar

Google Scholar

Dong Y, Shen M J, Liu Q 2018 Spacecr. Environ. Eng. 35 468

Google Scholar

Google Scholar

[18] Chang J S, Chong K S, Shu W, Lin T, Jiang J, Lwin N K Z, Kang Y 2014 IEEE 57th International Midwest Symposium on Circuits and Systems College Station, USA, August 3–6, 2014 p821

[19] Vaz P I, Both T H, Vidor F F, Brum R M, Wirth G I 2018 J. Electron. Test. 34 735

Google Scholar

Google Scholar

[20] Song L, Hu Z Y, Zhang M Y, Liu X N, Dai L H, Zhang Z X, Zou S C 2017 Microelectron. Reliab. 74 1

Google Scholar

Google Scholar

[21] Peng C, Hu Z Y, En Y F, Chen Y Q, Lei Z F, Zhang Z G, Zhang Z X, Li B 2018 IEEE Trans. Nucl. Sci. 65 877

Google Scholar

Google Scholar

[22] 谢儒彬, 吴建伟, 陈海波, 李艳艳, 洪根深 2016 太赫兹科学与电子信息学报 14 805

Google Scholar

Google Scholar

Xie R B, Wu J W, Chen H B, Li Y Y, Hong G S 2016 J. Terahertz Sci. Electron. Inf. Technol. 14 805

Google Scholar

Google Scholar

[23] 王思浩, 鲁庆, 王文华, 安霞, 黄如 2010 59 1970

Google Scholar

Google Scholar

Wang S H, Lu Q, Wang W H, An X, Huang R 2010 Acta Phys. Sin. 59 1970

Google Scholar

Google Scholar

计量

- 文章访问数: 6424

- PDF下载量: 75

- 被引次数: 0

下载:

下载: