-

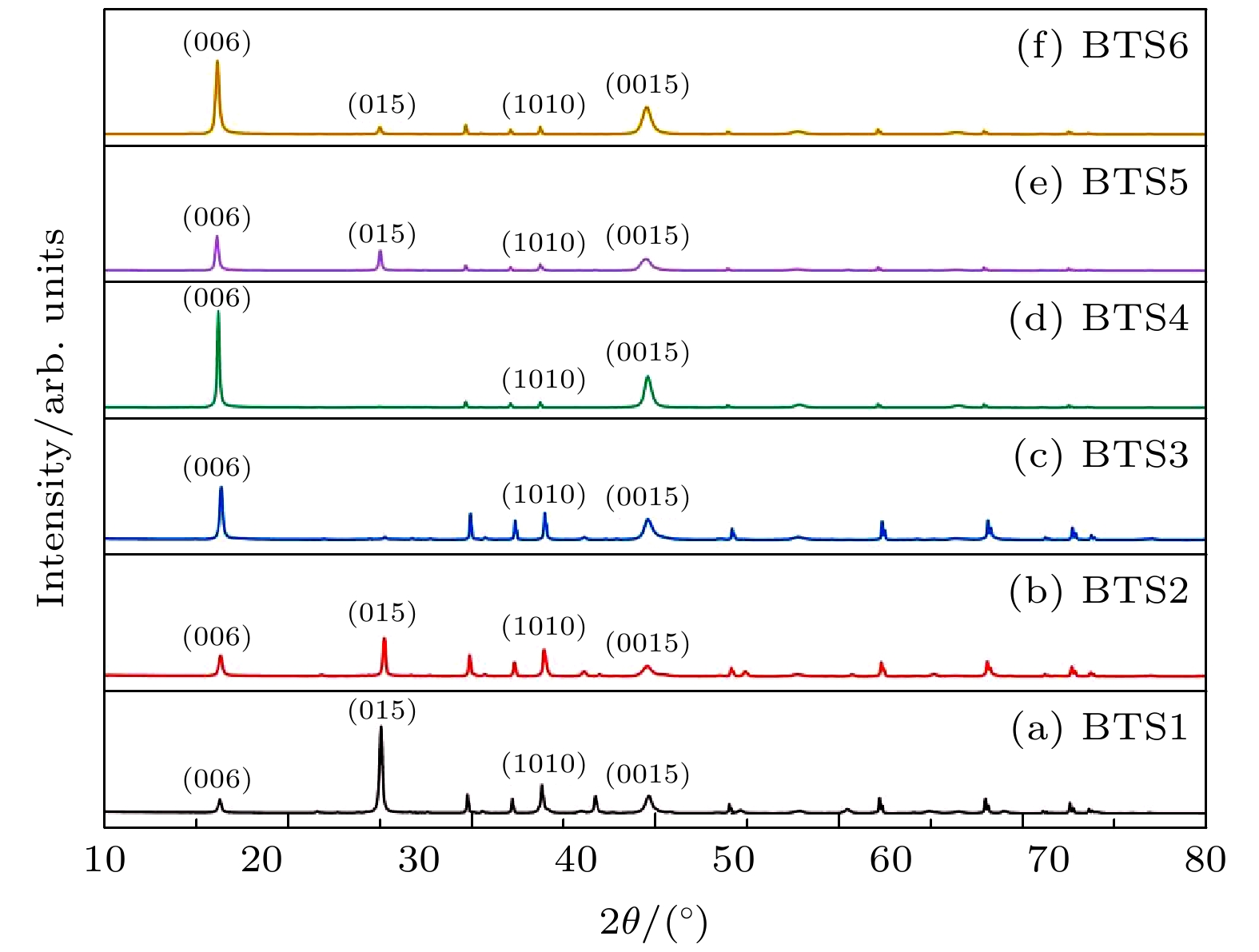

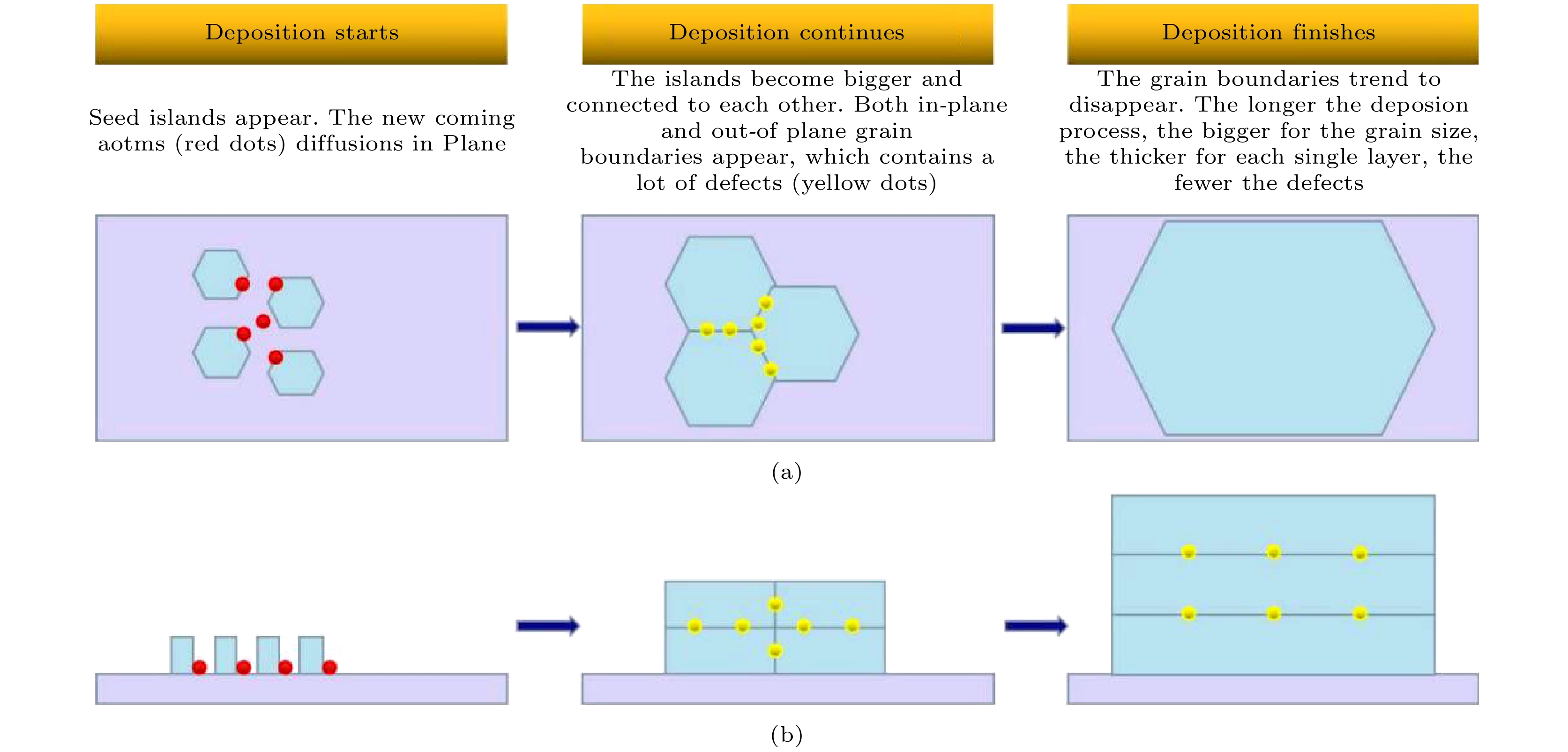

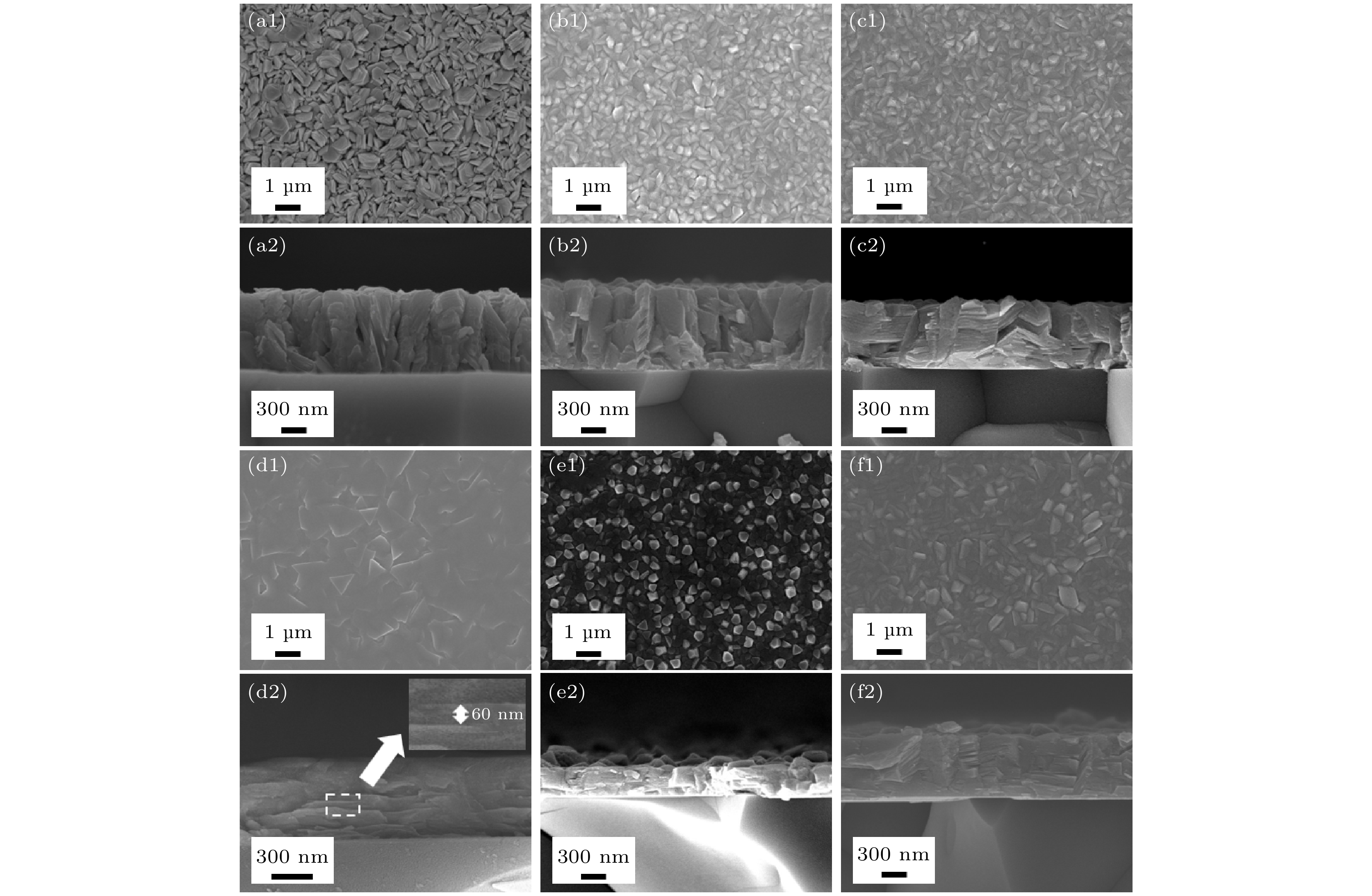

碲化铋基材料一直被认为是室温下性能最优异的热电材料之一, 也是商用热电器件首选的块体材料. 然而面对柔性或高密度设备等应用需求时, 薄膜热电材料比块体材料更具优势. 因此, 提升薄膜材料热电性能及可控制备技术至关重要. 与碲化铋基块体材料和P型碲化铋基薄膜相比, N型碲化铋基薄膜的性能相对偏低. 本工作利用磁控溅射法制备了一系列N型碲化铋薄膜, 研究衬底温度和工作压强对薄膜生长模式的影响规律, 从而通过溅射参数精确调控薄膜的形貌、结构和生长取向, 在合适的衬底温度和工作压强的共同作用下, 制备出(00l)方向层状生长的高质量致密薄膜. 由于层状结构薄膜具有超高的面内载流子迁移率, 该薄膜实现了大于105 S/m的超高电导率. 由于兼具高电导率与高Seebeck系数, 该层状薄膜试样在室温下的功率因子高达42.5 μW/(cm·K2), 克服了N型碲化铋基薄膜材料难以匹配P型碲化铋基薄膜材料的困难.

-

关键词:

- Bi2Te3–xSex薄膜 /

- 磁控溅射 /

- 热电 /

- 功率因子

Bi2Te3-based alloys have been long regarded as the materials chosen for room temperature thermoelectric (TE) applications. With superior TE performances, Bi2Te3-based bulk materials have been commercially used to fabricate TE devices already. However, bulk materials are less suitable for the requirements for applications of flexible or thin film TE devices, and therefore the thin film materials with advanced TE properties are highly demanded. Comparing with bulk materials and P-type Bi2Te3-based thin films, the TE properties of N-type Bi2Te3-based thin films have been relatively poor so far and need further improving for practical applications. In this study, a series of N-type Bi2Te3–xSex thin films is prepared via magnetron sputtering method, and their structures can be precisely controlled by adjusting the sputtering conditions. Preferential layered growth of the Bi2Te3–xSex thin films along the (00l) direction is achieved by adjusting the substrate temperature and working pressure. Superior electrical conductivity over 105 S/m is achieved by virtue of high in-plane mobility. combining the advanced Seebeck coefficient of Bi2Te3-based material with superior electrical conductivity of highly oriented Bi2Te3–xSex thin film, a high power factor (PF) of the optimal Bi2Te3–xSex thin film can be enhanced to 42.5 μW/(cm·K2) at room temperature, which is comparable to that of P-type Bi2Te3-based thin film and bulk material. -

Keywords:

- Bi2Te3–xSex thin film /

- magnetron sputtering /

- thermoelectric /

- power factor

[1] Li P, Cai L, Zhai P, Tang X, Zhang Q, Niino M 2010 J. Electron. Mater. 39 1522

Google Scholar

Google Scholar

[2] Suter C, Jovanovic Z R, Steinfeld A 2012 Appl. Energ. 99 379

Google Scholar

Google Scholar

[3] Yu Y, Zhu W, Wang Y, Zhu P, Peng K, Deng Y 2020Appl. Energ. 275 115404

[4] ChenY, Tan X, Peng S, Xin C, Delahoy A E, Chin K K, Zhang C 2018 J. Electron. Mater. 47 1201

Google Scholar

Google Scholar

[5] Zhou X, Zou J, Chen Z 2020 Chem. Rev. 120 7399

Google Scholar

Google Scholar

[6] Qin H, Liu Y, Zhang Z, Wang Y, Cao J, Cai W, Zhang Q, Sui J 2018 Mater. Today. Phys. 6 31

Google Scholar

Google Scholar

[7] Wei H, Tang J, Xi D 2020 J. Alloy. Compd. 817 153284

Google Scholar

Google Scholar

[8] Liu W, Zhang Q, Lan Y, Chen S, Yan X, Zhang Q, Wang H, Wang D, Chen G, Ren Z 2011 Adv. Energy. Mater. 1 577

Google Scholar

Google Scholar

[9] Wei H, Tang J, Wang H, Xu D 2020 J. Mater. Chem. A 8 24524

Google Scholar

Google Scholar

[10] Zhu W, Deng Y, Cao L 2017 Nano Energy 34 463

Google Scholar

Google Scholar

[11] Vineis C J, Shakouri A, Majumdar A, Kanatzidis M G 2010 Adv. Mater. 22 3970

Google Scholar

Google Scholar

[12] Zhang Z, Wang Y, Deng Y, Xu Y 2011 Solid. State. Commun. 151 1520

Google Scholar

Google Scholar

[13] Takashiri M, Tanaka S, Miyazaki K 2010 Thin Solid Films 519 619

Google Scholar

Google Scholar

[14] Parashchuk T, Kostyuk O, Nykyruy L, Dashevsky Z 2020 Mater. Chem. Phys. 253 123427

Google Scholar

Google Scholar

[15] Bassi A Li, Bailini A, Casari C S, Donati F, Mantegazza A, Passoni M, Russo V, Bottani C E 2009 J. Appl. Phys. 105 123407

[16] Peranio N, Winkler M, Aabdin Z, Konig J, Bottner H, Eibl O 2012 Phys. Status Solidi A 209 289

Google Scholar

Google Scholar

[17] Zhu W, Deng Y, Wang Y, Luo B, Cao L 2014 Thin Solid Films 556 270

Google Scholar

Google Scholar

[18] Mu X, Zhou H, He D, Zhao W, Wei P, Zhu W, Nie X, Liu H, Zhang Q 2017 Nano Energy 33 55

Google Scholar

Google Scholar

[19] Deng Y, Zhang Z, Wang Y, Xu Y 2012 J. Nanopart Res. 14 775

Google Scholar

Google Scholar

[20] Duan X, Jiang Y 2010 Appl. Surf. Sci. 256 7365

Google Scholar

Google Scholar

[21] Duan X, Jiang Y 2011 Thin Solid Films 519 3007

Google Scholar

Google Scholar

[22] Bourgault D, Garampon C Giroud, Caillault N, Carbone L, Aymami J A 2008 Thin Solid Films 516 8579

Google Scholar

Google Scholar

[23] Bottnrt H, Chen G, Venkatasubramanian R 2006 MRS Bulletin 31 211

Google Scholar

Google Scholar

[24] Lewis B, Campell D S 1967J. Vac. Sci. Technol. 4 209

[25] Zhang Z, Lagally M 1997 Science 276 377

Google Scholar

Google Scholar

-

表 1 不同试样的制备参数

Table 1. Sputtering parameters of all the samples.

试样 Bi2Te3–xSex

直流靶功

率/WTe射频靶

功率/W气压/Pa 温度/℃ 时间/h BTS1 12 25 3 350 2 BTS2 12 25 1 450 2 BTS3 12 25 2 450 2 BTS4 12 25 3 450 2 BTS5 12 25 3 450 1 BTS6 12 25 3 450 3 表 2 霍尔效应测试

Table 2. Hall measurements of all the samples.

试样 载流子浓度/(1019 cm–3) 载流子迁移率/(cm2·V–1·s–1) 电导率

/(104 S·m–1)BTS1 11.7 17.1 3.2 BTS2 12.7 30.6 6.2 BTS3 10.0 59.8 9.6 BTS4 8.3 84.2 11.2 BTS5 7.2 45.2 5.2 BTS6 9.1 63.9 9.3 表 3 元素原子比

Table 3. Atomic ratio by EDS measurements.

试样 Bi/% Te/% Se/% BTS1 36.5 60.2 3.3 BTS2 41.7 53.6 4.7 BTS3 41.6 53.9 4.5 BTS4 41.3 54.3 4.4 BTS5 41.4 54.8 3.8 BTS6 41.8 53.5 4.7 -

[1] Li P, Cai L, Zhai P, Tang X, Zhang Q, Niino M 2010 J. Electron. Mater. 39 1522

Google Scholar

Google Scholar

[2] Suter C, Jovanovic Z R, Steinfeld A 2012 Appl. Energ. 99 379

Google Scholar

Google Scholar

[3] Yu Y, Zhu W, Wang Y, Zhu P, Peng K, Deng Y 2020Appl. Energ. 275 115404

[4] ChenY, Tan X, Peng S, Xin C, Delahoy A E, Chin K K, Zhang C 2018 J. Electron. Mater. 47 1201

Google Scholar

Google Scholar

[5] Zhou X, Zou J, Chen Z 2020 Chem. Rev. 120 7399

Google Scholar

Google Scholar

[6] Qin H, Liu Y, Zhang Z, Wang Y, Cao J, Cai W, Zhang Q, Sui J 2018 Mater. Today. Phys. 6 31

Google Scholar

Google Scholar

[7] Wei H, Tang J, Xi D 2020 J. Alloy. Compd. 817 153284

Google Scholar

Google Scholar

[8] Liu W, Zhang Q, Lan Y, Chen S, Yan X, Zhang Q, Wang H, Wang D, Chen G, Ren Z 2011 Adv. Energy. Mater. 1 577

Google Scholar

Google Scholar

[9] Wei H, Tang J, Wang H, Xu D 2020 J. Mater. Chem. A 8 24524

Google Scholar

Google Scholar

[10] Zhu W, Deng Y, Cao L 2017 Nano Energy 34 463

Google Scholar

Google Scholar

[11] Vineis C J, Shakouri A, Majumdar A, Kanatzidis M G 2010 Adv. Mater. 22 3970

Google Scholar

Google Scholar

[12] Zhang Z, Wang Y, Deng Y, Xu Y 2011 Solid. State. Commun. 151 1520

Google Scholar

Google Scholar

[13] Takashiri M, Tanaka S, Miyazaki K 2010 Thin Solid Films 519 619

Google Scholar

Google Scholar

[14] Parashchuk T, Kostyuk O, Nykyruy L, Dashevsky Z 2020 Mater. Chem. Phys. 253 123427

Google Scholar

Google Scholar

[15] Bassi A Li, Bailini A, Casari C S, Donati F, Mantegazza A, Passoni M, Russo V, Bottani C E 2009 J. Appl. Phys. 105 123407

[16] Peranio N, Winkler M, Aabdin Z, Konig J, Bottner H, Eibl O 2012 Phys. Status Solidi A 209 289

Google Scholar

Google Scholar

[17] Zhu W, Deng Y, Wang Y, Luo B, Cao L 2014 Thin Solid Films 556 270

Google Scholar

Google Scholar

[18] Mu X, Zhou H, He D, Zhao W, Wei P, Zhu W, Nie X, Liu H, Zhang Q 2017 Nano Energy 33 55

Google Scholar

Google Scholar

[19] Deng Y, Zhang Z, Wang Y, Xu Y 2012 J. Nanopart Res. 14 775

Google Scholar

Google Scholar

[20] Duan X, Jiang Y 2010 Appl. Surf. Sci. 256 7365

Google Scholar

Google Scholar

[21] Duan X, Jiang Y 2011 Thin Solid Films 519 3007

Google Scholar

Google Scholar

[22] Bourgault D, Garampon C Giroud, Caillault N, Carbone L, Aymami J A 2008 Thin Solid Films 516 8579

Google Scholar

Google Scholar

[23] Bottnrt H, Chen G, Venkatasubramanian R 2006 MRS Bulletin 31 211

Google Scholar

Google Scholar

[24] Lewis B, Campell D S 1967J. Vac. Sci. Technol. 4 209

[25] Zhang Z, Lagally M 1997 Science 276 377

Google Scholar

Google Scholar

计量

- 文章访问数: 9286

- PDF下载量: 411

- 被引次数: 0

下载:

下载: