-

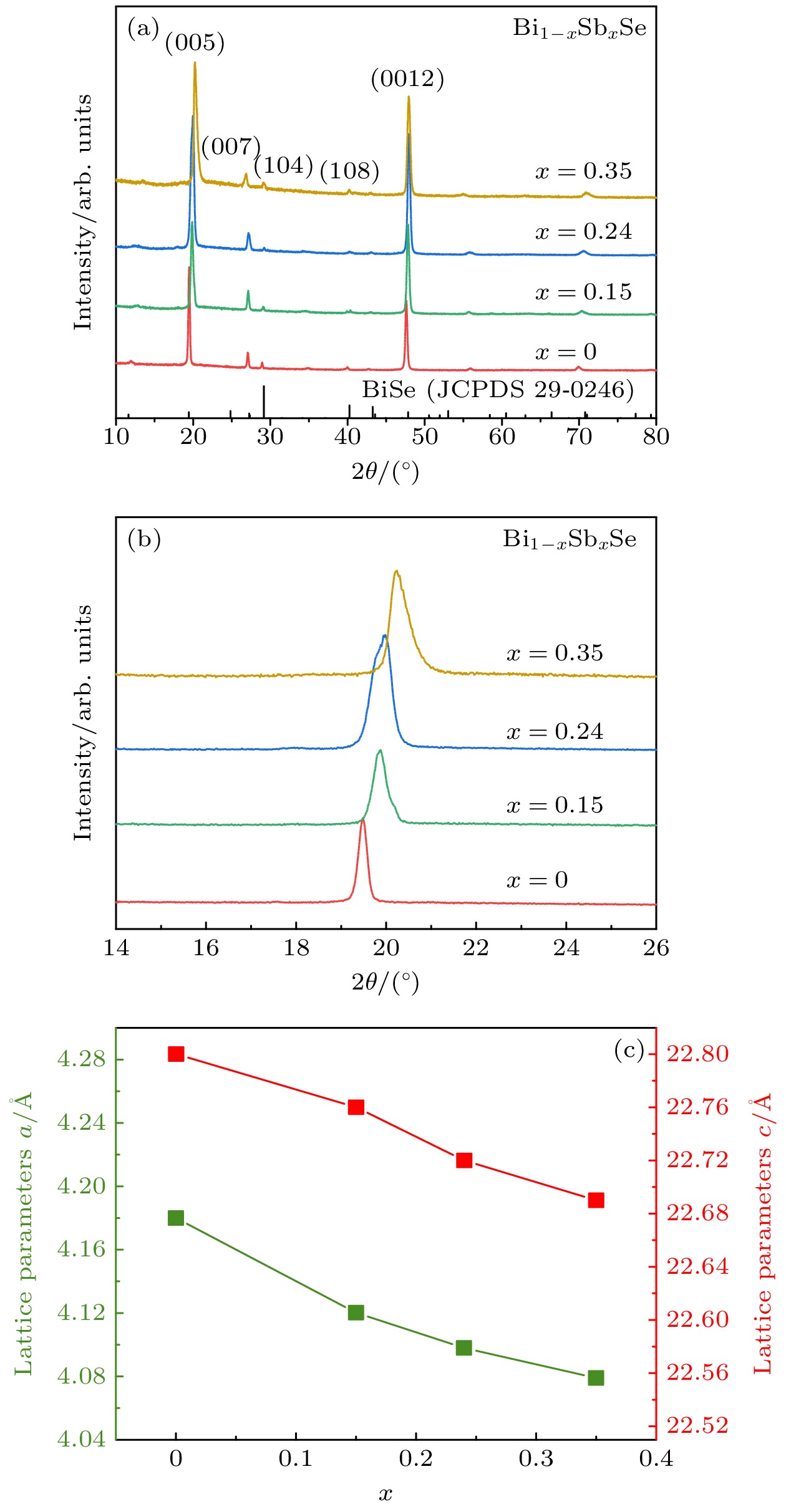

BiSe是近年来发现的具有超低本征晶格热导率材料, 显示出比传统的Bi2Se3更高的热电性能潜力. 本文采用真空热蒸发法制备了具有(00l)取向生长的N型纯相BiSe纳米晶薄膜, 并通过Sb共蒸发, 制备得到不同掺杂浓度的Bi1–xSbxSe热电薄膜. 对薄膜样品物相、形貌、组份、晶格振动、化学价态及电输运性质进行了表征. 结果显示, Sb进入到BiSe晶格中取代了Bi原子的位置, 而Sb原子与Bi原子之间的金属性差异使得掺杂后的样品载流子浓度下降, 塞贝克系数上升. 同时, 随着Sb掺杂浓度的增大, 组成薄膜的纳米晶粒尺寸减小, 薄膜面内形成更加致密的层状结构, 有利于载流子输运,导致样品的载流子迁移率由13.6 cm2/(V·s)显著提升至19.3 cm2/(V·s). 受到Seebeck系数与电导率的综合作用, Bi0.76Sb0.24Se薄膜具有2.18 μW/(cm·K2)的室温功率因子, 相对于未掺杂BiSe薄膜功率因子得到提升. 本工作表明BiSe基薄膜在近室温热电薄膜器件中具有潜在的应用前景.

-

关键词:

- N型 /

- Bi1–xSbxSe /

- 热电纳米晶薄膜 /

- 层状结构 /

- 功率因子

BiSe is found to be a promising near-room-temperature thermoelectric material with higher performance than traditional Bi2Se3 due to its ultra-low intrinsic lattice thermal conductivity. In this work, N-type BiSe nanocrystalline thin films with (00l) preferred orientation are first prepared via vacuum thermal evaporation method, and Bi1–xSbxSe nanocrystalline films with different doping concentrations are obtained by Sb co-evaporation. The phases, morphologies, chemical compositions and valences, lattical vibrations, and electrical properties of these films are characterized. It is found that the Sb dopant successfully enters into the crystal lattice and replaces the Bi site of Bi2Se3 quintuple layers and Bi2 bilayers without selectivity, and the difference of gold properties between Sb atom and Bi atoms leads the carrier concentration to sharply decrease and the Seebeck coefficient in doped BiSe to increase. Meanwhile, the sizes of nanocrystals in the films decrease and the denser layered structure is formed due to the Sb doping, which is conducive to the carrier transport in the samples, and the in-plane carrier mobility of the films effectively increases from 13.6 cm2·V–1·s–1 (BiSe) to 19.3 cm2·V–1·s–1 (Bi0.65Sb0.35Se). The maximum room-temperature power factor of 2.18 μW·cm–1·K–2 is obtained in Bi0.76Sb0.24Se, which is higher than that in undoped BiSe. The results of this work indicate that the BiSe-based thin films have potential applications in room temperature thermoelectric thin film devices. -

Keywords:

- N-type /

- Bi1–xSbxSe /

- thermoelectric nanocrystalline films /

- layered structure /

- power factor

[1] Zhou M, Al-Furjan M S H, Zou J, Liu W 2018 Renew. Sust. Energ. Rev. 82 3582

Google Scholar

Google Scholar

[2] Kraemer D, Jie Q, McEnaney K, Cao F, Liu W, Weinstein L A, Loomis J, Ren Z, Chen G 2016 Nat. Energy 1 16153

Google Scholar

Google Scholar

[3] Hasan M N, Wahid H, Nayan N, Mohamed Ali M S 2020 Int. J. Energy Res. 44 6170

Google Scholar

Google Scholar

[4] Chen A, Madan D, Wright P K, Evans J W 2011 J. Micromech. Microeng. 21 104006

Google Scholar

Google Scholar

[5] Orr B, Akbarzadeh A, Mochizuki M, Singh R 2016 Appl. Therm. Eng. 101 490

Google Scholar

Google Scholar

[6] Lee K H, Kim S W 2017 J. Korean Ceram. Soc. 54 75

Google Scholar

Google Scholar

[7] Samanta M, Pal K, Pal P, Waghmare U V, Biswas K 2018 J. Am. Chem. Soc. 140 5866

Google Scholar

Google Scholar

[8] Lind H, Lidin S, Häussermann U 2005 Phys. Rev. B. 72 184101

Google Scholar

Google Scholar

[9] Ju Z, Hou Y, Bernard A, Taufour V, Yu D, Kauzlarich S M 2019 CS Appl. Electron. 1 1917

[10] Samanta M, Biswas K 2020 Chem. Mater. 32 8819

Google Scholar

Google Scholar

[11] Zhang J, Huang G 2014 Solid State Commun. 197 34

Google Scholar

Google Scholar

[12] Valla T, Ji H, Schoop L, Weber A, Pan Z-H, Sadowski J, Vescovo E, Fedorov A, Caruso A, Gibson Q 2012 Phys. Rev. B. 86 241101

Google Scholar

Google Scholar

[13] Ouyang Y, Zhang Z W, Li D F, Chen J, Zhang G 2019 Ann. Phys. (Berlin) 531 1800437

Google Scholar

Google Scholar

[14] Qiu B, Ruan X L 2009 Phys. Rev. B 80 165203

Google Scholar

Google Scholar

[15] He J, Hu X X, Li D F, Chen J 2022 Nano Res. 15 3804

Google Scholar

Google Scholar

[16] Shen X C, Zhang X, Zhang B, Wang G Y, He J, Zhou X Y 2020 Rare Metals 39 1374

Google Scholar

Google Scholar

[17] He Z M, Lan K L, Chen S Y, Dong Y Z, Lai X F, Liu F S, Jian J K 2022 J. Alloys Compd. 901 163652

Google Scholar

Google Scholar

[18] Shi X L, Zou J, Chen Z G 2020 Chem. Rev. 120 7399

Google Scholar

Google Scholar

[19] 魏江涛, 杨亮亮, 秦源浩, 宋培帅, 张明亮, 杨富华, 王晓东 2021 70 047301

Google Scholar

Google Scholar

Wei J T, Yang L L, Qin Y H, Song P S, Zhang M L, Yang F H, Wang X D 2021 Acta Phys. Sin. 70 047301

Google Scholar

Google Scholar

[20] Venkatasubramanian R, Siivola E, Colpitts T, O'Quinn B 2001 Nature 413 597

Google Scholar

Google Scholar

[21] Li J F, Liu W S, Zhao L D, Zhou M 2010 NPG Asia Mater. 2 152

Google Scholar

Google Scholar

[22] Wu H, Carrete J, Zhang Z, Qu Y, Shen X, Wang Z, Zhao L-D, He J 2014 NPG Asia Mater. 6 e108

Google Scholar

Google Scholar

[23] Dun C, Hewitt C A, Huang H, Xu J, Zhou C, Huang W, Cui Y, Zhou W, Jiang Q, Carroll D L 2015 Nano Energy 18 306

Google Scholar

Google Scholar

[24] 陈赟斐, 魏锋, 王赫, 赵未昀, 邓元 2021 70 207303

Google Scholar

Google Scholar

Chen Y F, Wei F, Wang H, Zhao W Y, Deng Y 2021 Acta Phys. Sin. 70 207303

Google Scholar

Google Scholar

[25] Adam A M, El-Khouly A, Diab A K 2021 J. Alloys Compd. 851 156887

Google Scholar

Google Scholar

[26] Lu M P, Liao C N, Huang J Y, Hsu H C 2015 Inorg. Chem. 54 7438

Google Scholar

Google Scholar

[27] Kim K, Kim G, Kim S I, Lee K H, Lee W 2019 J. Alloys Compd. 772 593

Google Scholar

Google Scholar

[28] Chen C L, Wang H, Chen Y Y, Day T, Snyder G J 2014 J. Mater. Chem. A. 2 11171

Google Scholar

Google Scholar

[29] Han M K, Hoang K, Kong H, Pcionek R, Uher C, Paraskevopoulos K M, Mahanti S D, Kanatzidis M G 2008 Chem. Mater. 20 3512

Google Scholar

Google Scholar

[30] Ibrahim E M M, Hakeem A M A, Adam A M M, Shokr E K 2015 Phys. Scr. 90 045802

Google Scholar

Google Scholar

[31] Bando H, Koizumi K, Oikawa Y, Daikohara K, Kulbachinskii V A, Ozaki H 2000 J. Phys. Condens. Matter 12 5607

Google Scholar

Google Scholar

[32] Jia F, Liu Y Y, Zhang Y F, Shu X, Chen L, Wu L M 2020 J. Am. Chem. Soc. 142 12536

Google Scholar

Google Scholar

[33] Liu X, Chen J, Luo M, Leng M, Xia Z, Zhou Y, Qin S, Xue D J, Lv L, Huang H, Niu D, Tang J 2014 ACS Appl. Mater. Interfaces 6 10687

Google Scholar

Google Scholar

[34] Zhang C, Yin H, Han M, Dai Z, Pang H, Zheng Y, Lan Y Q, Bao J, Zhu J 2014 ACS Nano 8 3761

Google Scholar

Google Scholar

[35] Heremans J P, Jovovic V, Toberer E S, Saramat A, Kurosaki K, Charoenphakdee A, Yamanaka S, Snyder G J 2008 Science 321 554

Google Scholar

Google Scholar

[36] Jia B, Liu S, Li G, Liu S, Zhou Y, Wang Q 2019 Thin Solid Films 672 133

Google Scholar

Google Scholar

-

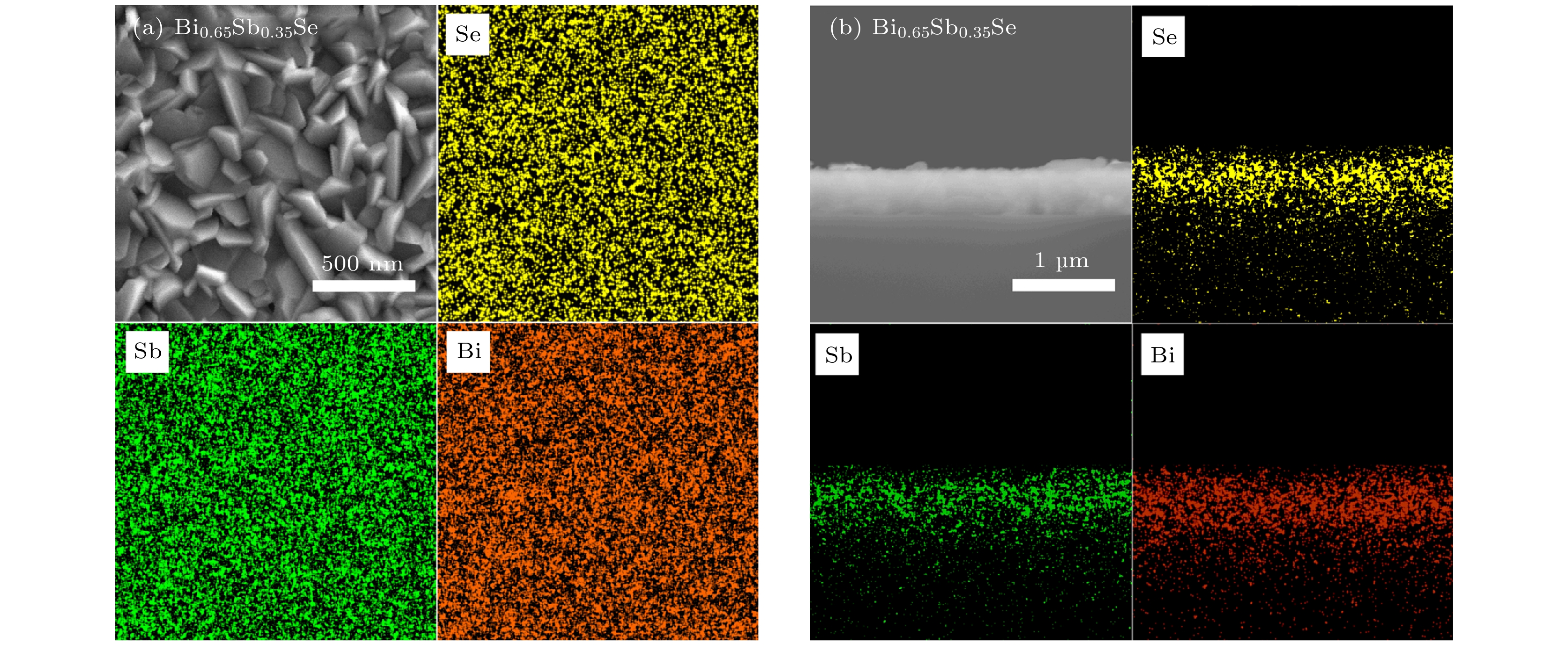

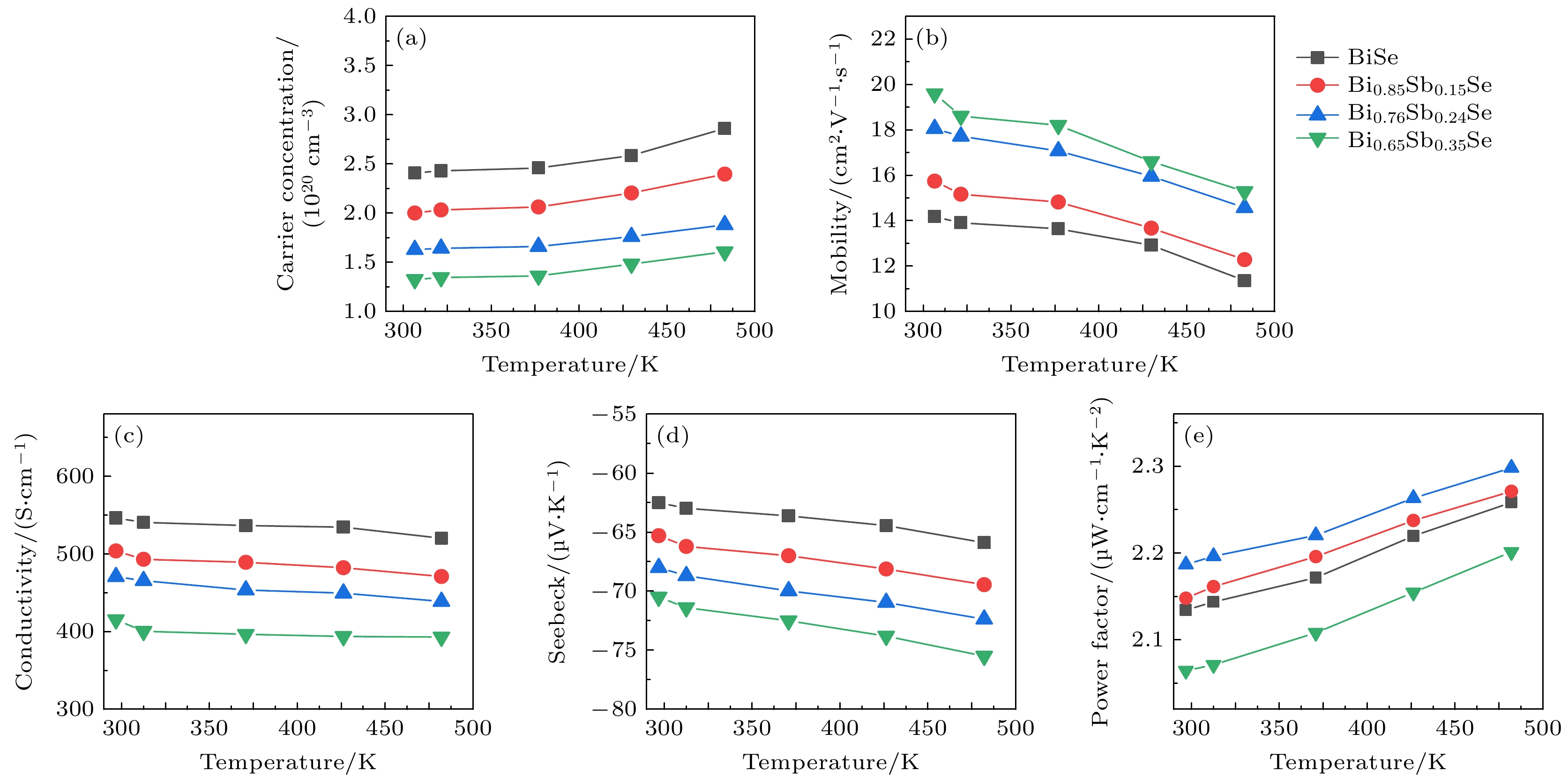

图 6 Bi1–xSbxSe纳米晶薄膜(x = 0, 0.15, 0.24, 0.35)在不同温度下的 (a) 载流子浓度; (b) 迁移率; (c) 面内电导率; (d) 塞贝克系数; (e) 功率因子

Fig. 6. Temperature dependence of (a) carrier concentrations, (b) electron mobilities, (c) the in-plane conductivities, (d) Seebeck coefficients and (e) power factors for Bi1–xSbxSe (x = 0, 0.15, 0.24, 0.35) samples.

表 1 Bi1–xSbxSe纳米薄膜的实验条件

Table 1. Experimental conditions of Bi1–xSbxSe thin films.

样品 (Bi+Bi2Se3)蒸发源温度/℃ Sb蒸发源温度/℃ 源与衬底的距离/cm 衬底温度/

℃蒸镀时间/

minBiSe 500 — 10 475 10 Bi0.85Sb0.15Se 500 300 10 475 10 Bi0.76Sb0.24Se 500 350 10 475 10 Bi0.65Sb0.35Se 500 375 10 475 10 表 2 Bi1–xSbxSe薄膜的元素原子比

Table 2. Atomic ratio of Bi1–xSbxSe thin films.

样品 Bi/% Sb/% Se/% BiSe 49.97 — 50.03 Bi0.85Sb0.15Se 42.37 7.53 50.10 Bi0.76Sb0.24Se 38.01 11.91 50.08 Bi0.65Sb0.35Se 32.49 17.45 50.05 表 3 Bi1–xSbxSe (x = 0, 0.15, 0.24, 0.35)薄膜的拉曼振动峰(cm–1)

Table 3. Raman vibration peaks (cm–1) of Bi1–x SbxSe (x = 0, 0.15, 0.24, 0.35) films.

BiSe Bi0.85Sb0.15Se Bi0.76Sb0.24Se Bi0.65Sb0.35Se $ \rm A^1_{1g} $ 68.1 70.5 70.9 71.4 Eg 93.7 95.4 95.9 96.7 $ \rm E^2_g $ 120.6 121.4 122.1 122.9 $\rm A^2_{1g}$ 155.4 157.9 160.5 161.5 表 4 Bi1–xSbxSe(x = 0, 0.15, 0.24, 0.35)薄膜在室温下的霍尔效应测试结果

Table 4. The electrical transport properties of Bi1–xSbxSe (x = 0, 0.15, 0.24, 0.35) thin films at room temperature.

薄膜样品 载流子浓度

n/(1020 cm–3)载流子迁移率

μ/(cm2·V–1·s–1)电导率

σ/(S·cm–1)BiSe 2.5 13.6 544.2 Bi0.85Sb0.15Se 1.9 16.7 502.3 Bi0.76Sb0.24Se 1.6 18.4 468.8 Bi0.65Sb0.35Se 1.3 19.3 416.8 -

[1] Zhou M, Al-Furjan M S H, Zou J, Liu W 2018 Renew. Sust. Energ. Rev. 82 3582

Google Scholar

Google Scholar

[2] Kraemer D, Jie Q, McEnaney K, Cao F, Liu W, Weinstein L A, Loomis J, Ren Z, Chen G 2016 Nat. Energy 1 16153

Google Scholar

Google Scholar

[3] Hasan M N, Wahid H, Nayan N, Mohamed Ali M S 2020 Int. J. Energy Res. 44 6170

Google Scholar

Google Scholar

[4] Chen A, Madan D, Wright P K, Evans J W 2011 J. Micromech. Microeng. 21 104006

Google Scholar

Google Scholar

[5] Orr B, Akbarzadeh A, Mochizuki M, Singh R 2016 Appl. Therm. Eng. 101 490

Google Scholar

Google Scholar

[6] Lee K H, Kim S W 2017 J. Korean Ceram. Soc. 54 75

Google Scholar

Google Scholar

[7] Samanta M, Pal K, Pal P, Waghmare U V, Biswas K 2018 J. Am. Chem. Soc. 140 5866

Google Scholar

Google Scholar

[8] Lind H, Lidin S, Häussermann U 2005 Phys. Rev. B. 72 184101

Google Scholar

Google Scholar

[9] Ju Z, Hou Y, Bernard A, Taufour V, Yu D, Kauzlarich S M 2019 CS Appl. Electron. 1 1917

[10] Samanta M, Biswas K 2020 Chem. Mater. 32 8819

Google Scholar

Google Scholar

[11] Zhang J, Huang G 2014 Solid State Commun. 197 34

Google Scholar

Google Scholar

[12] Valla T, Ji H, Schoop L, Weber A, Pan Z-H, Sadowski J, Vescovo E, Fedorov A, Caruso A, Gibson Q 2012 Phys. Rev. B. 86 241101

Google Scholar

Google Scholar

[13] Ouyang Y, Zhang Z W, Li D F, Chen J, Zhang G 2019 Ann. Phys. (Berlin) 531 1800437

Google Scholar

Google Scholar

[14] Qiu B, Ruan X L 2009 Phys. Rev. B 80 165203

Google Scholar

Google Scholar

[15] He J, Hu X X, Li D F, Chen J 2022 Nano Res. 15 3804

Google Scholar

Google Scholar

[16] Shen X C, Zhang X, Zhang B, Wang G Y, He J, Zhou X Y 2020 Rare Metals 39 1374

Google Scholar

Google Scholar

[17] He Z M, Lan K L, Chen S Y, Dong Y Z, Lai X F, Liu F S, Jian J K 2022 J. Alloys Compd. 901 163652

Google Scholar

Google Scholar

[18] Shi X L, Zou J, Chen Z G 2020 Chem. Rev. 120 7399

Google Scholar

Google Scholar

[19] 魏江涛, 杨亮亮, 秦源浩, 宋培帅, 张明亮, 杨富华, 王晓东 2021 70 047301

Google Scholar

Google Scholar

Wei J T, Yang L L, Qin Y H, Song P S, Zhang M L, Yang F H, Wang X D 2021 Acta Phys. Sin. 70 047301

Google Scholar

Google Scholar

[20] Venkatasubramanian R, Siivola E, Colpitts T, O'Quinn B 2001 Nature 413 597

Google Scholar

Google Scholar

[21] Li J F, Liu W S, Zhao L D, Zhou M 2010 NPG Asia Mater. 2 152

Google Scholar

Google Scholar

[22] Wu H, Carrete J, Zhang Z, Qu Y, Shen X, Wang Z, Zhao L-D, He J 2014 NPG Asia Mater. 6 e108

Google Scholar

Google Scholar

[23] Dun C, Hewitt C A, Huang H, Xu J, Zhou C, Huang W, Cui Y, Zhou W, Jiang Q, Carroll D L 2015 Nano Energy 18 306

Google Scholar

Google Scholar

[24] 陈赟斐, 魏锋, 王赫, 赵未昀, 邓元 2021 70 207303

Google Scholar

Google Scholar

Chen Y F, Wei F, Wang H, Zhao W Y, Deng Y 2021 Acta Phys. Sin. 70 207303

Google Scholar

Google Scholar

[25] Adam A M, El-Khouly A, Diab A K 2021 J. Alloys Compd. 851 156887

Google Scholar

Google Scholar

[26] Lu M P, Liao C N, Huang J Y, Hsu H C 2015 Inorg. Chem. 54 7438

Google Scholar

Google Scholar

[27] Kim K, Kim G, Kim S I, Lee K H, Lee W 2019 J. Alloys Compd. 772 593

Google Scholar

Google Scholar

[28] Chen C L, Wang H, Chen Y Y, Day T, Snyder G J 2014 J. Mater. Chem. A. 2 11171

Google Scholar

Google Scholar

[29] Han M K, Hoang K, Kong H, Pcionek R, Uher C, Paraskevopoulos K M, Mahanti S D, Kanatzidis M G 2008 Chem. Mater. 20 3512

Google Scholar

Google Scholar

[30] Ibrahim E M M, Hakeem A M A, Adam A M M, Shokr E K 2015 Phys. Scr. 90 045802

Google Scholar

Google Scholar

[31] Bando H, Koizumi K, Oikawa Y, Daikohara K, Kulbachinskii V A, Ozaki H 2000 J. Phys. Condens. Matter 12 5607

Google Scholar

Google Scholar

[32] Jia F, Liu Y Y, Zhang Y F, Shu X, Chen L, Wu L M 2020 J. Am. Chem. Soc. 142 12536

Google Scholar

Google Scholar

[33] Liu X, Chen J, Luo M, Leng M, Xia Z, Zhou Y, Qin S, Xue D J, Lv L, Huang H, Niu D, Tang J 2014 ACS Appl. Mater. Interfaces 6 10687

Google Scholar

Google Scholar

[34] Zhang C, Yin H, Han M, Dai Z, Pang H, Zheng Y, Lan Y Q, Bao J, Zhu J 2014 ACS Nano 8 3761

Google Scholar

Google Scholar

[35] Heremans J P, Jovovic V, Toberer E S, Saramat A, Kurosaki K, Charoenphakdee A, Yamanaka S, Snyder G J 2008 Science 321 554

Google Scholar

Google Scholar

[36] Jia B, Liu S, Li G, Liu S, Zhou Y, Wang Q 2019 Thin Solid Films 672 133

Google Scholar

Google Scholar

计量

- 文章访问数: 7901

- PDF下载量: 205

- 被引次数: 0

下载:

下载: