-

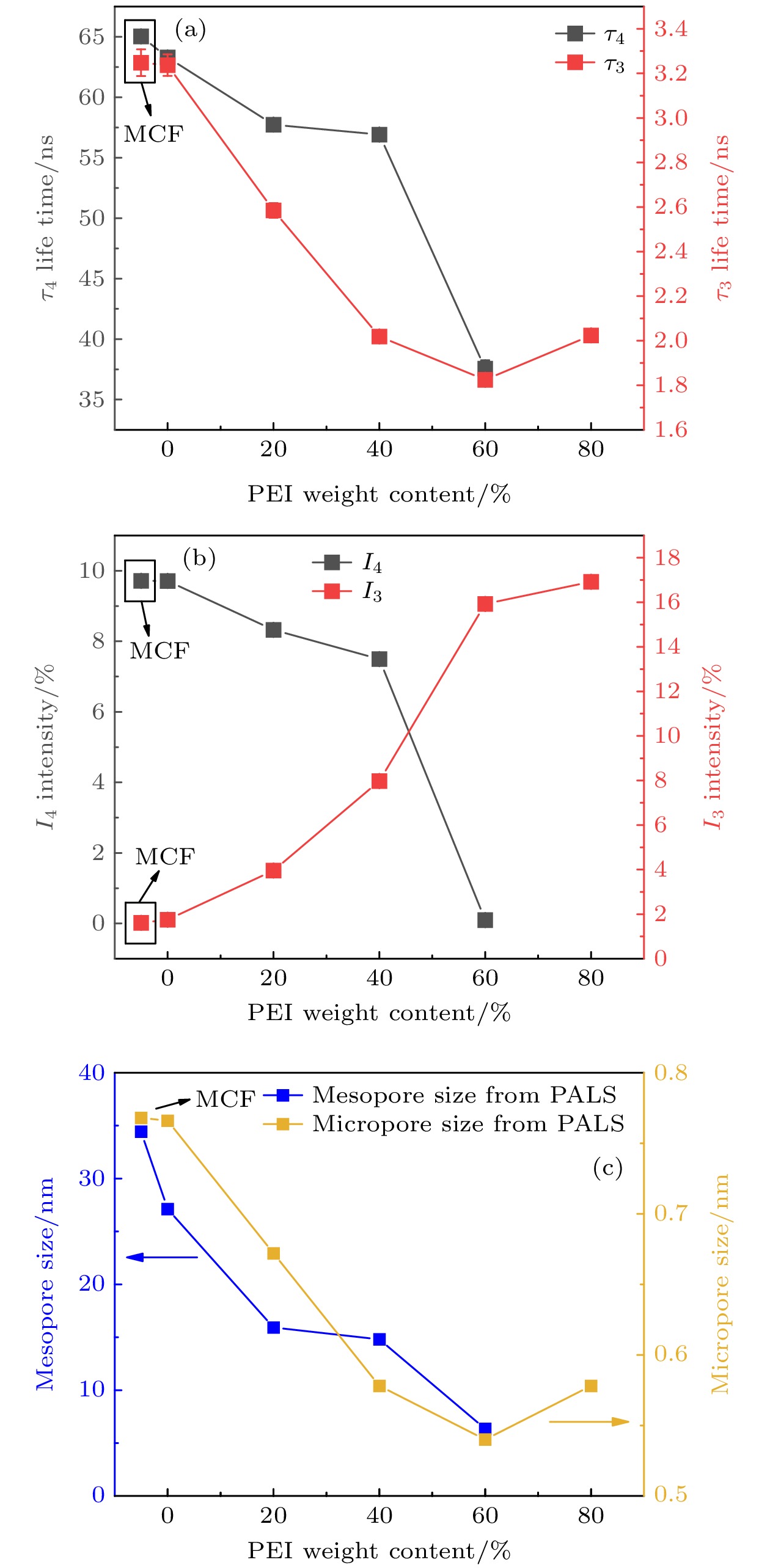

A novel mesoporous silica foam (MCF) with a specific surface area of 712.5 m2/g and a pore volume of 2.44 cm3/g is synthesized by using triblock copolymer poly (ethylene oxide, polypropylene oxide and ethylene oxide, P123) as template and TEOS (C8H20O4Si) as silicon source. The effect of polyethylenimide (PEI) modified MCF on nanoscale pore structure is studied by positron annihilation lifetime spectroscopy (PALS) and conventional characterization methods, such as N2 adsorption desorption, transmission electron microscopy, thermogravimetric analysis and Fourier transform infrared spectroscopy. The results show that the synthesized MCF has an obvious disordered mesoporous structure, and a continuous porous network with window connection between the pores is formed. Meanwhile, it can be seen directly that PEI is successfully introduced into MCF pore channels. In order to evaluate the pore size and its distribution more comprehensively, the mechanism of positron annihilation which is highly sensitive to nanometer scale open volumes in PEI loaded MCF is studied. It is found that there are two long life components τ3 and τ4, indicating the micropores and mesopores co-existing in the sample. Furthermore, the introduction of PEI molecules results in a significant decrease in τ3 and τ4, and the lifetime values are then corrected by using the positron annihilation rate formula in pure gas to calculate the pore size. The results show that the pore size gradually decreases with the filling of the organic molecule PEI. This provides a new insight into the mechanism of regulating the pore structure of MCF by polyethyleneimine modification, as well as the characterization of pore structure in organic-modified mesoporous molecular sieves.

[1] Song C F, Liu Q L, Ji N, Deng S, Zhao J, Li Y, Song Y J, Li H L 2018 Renewable Sustainable Energy Rev. 82 215

Google Scholar

Google Scholar

[2] Xu X C, Song C S, Andresen J M, Miller B G, Scaroni A W 2002 Energy Fuels 16 1463

Google Scholar

Google Scholar

[3] Ma X L, Wang X X, Song C S 2009 J. Am. Chem. Soc. 131 5777

Google Scholar

Google Scholar

[4] Zhao D Y, Feng J L, Huo Q S, Melosh N, Fredrickson G H, Chmelka B F, Stucky G D 1998 Science 279 548

Google Scholar

Google Scholar

[5] Xiong H F, Zhang Y H, Wang S G, Liew K Y, Li J L 2008 J. Phys. Chem. A 112 9706

Google Scholar

Google Scholar

[6] Liu H, Wang G X, Liu J, Qiao S Z, Ahn H 2011 J. Mater. Chem. A 21 3046

Google Scholar

Google Scholar

[7] Zhang Z Y, Zuo F, Feng P Y 2010 J. Mater. Chem. A 20 2206

Google Scholar

Google Scholar

[8] Lu B W, Kawamoto K 2013 J. Environ. Chem. Eng. 1 300

Google Scholar

Google Scholar

[9] Belmabkhout Y, Serna-Guerrero R, Sayari A 2010 Ind. Eng. Chem. Res. 49 359

Google Scholar

Google Scholar

[10] Kim S, Ida J, Guliants V V, Lin Y S 2005 J. Phys. Chem. B 109 6287

Google Scholar

Google Scholar

[11] Wang L, Ma L, Wang A, Liu Q, Zhang T 2007 Chin. J. Catal. 28 805

Google Scholar

Google Scholar

[12] Zheng F, Tran D N, Busche B J, Fryxell G E, Addleman R S, Zemanian T S, Aardahl C L 2005 Ind. Eng. Chem. Res 44 3099

Google Scholar

Google Scholar

[13] Zelenak V, Halamova D, Gaberova L, Bloch E, Llewellyn P 2008 Microporous Mesoporous Mater. 116 358

Google Scholar

Google Scholar

[14] Mosquera M J, Pozo J, Esquivias L, Rivas T, Silva B 2002 J. Non-Cryst. Solids 311 185

Google Scholar

Google Scholar

[15] Brandt W, Paulin R 1968 Phys. Rev. Lett. 21 193

[16] Zaleski R 2015 Nukleonika 60 795

Google Scholar

Google Scholar

[17] Schmidt-Winkel P, Lukens W W, Yang P, Margolese D I, Lettow J S, Ying J Y, Stucky G D 2000 Chem. Mater. 12 686

Google Scholar

Google Scholar

[18] Schmidt-Winkel P, Lukens W W, Zhao D, Yang P, Chmelka B F, Stucky G D 1999 J. Am. Chem. Soc. 121 254

Google Scholar

Google Scholar

[19] Song T, Zhang P, Zhang C, Gong L L, Cao X Z, Wang B Y, Yu R S, Zhou W 2022 Microporous Mesoporous Mater. 334 111761

Google Scholar

Google Scholar

[20] Chen Q j, Fan F C, Long D H, Liu X J, Lian X Y, Qiao W M, Ling L C 2010 Ind. Eng. Chem. Res. 49 11408

Google Scholar

Google Scholar

[21] Ouyang J, Zheng C H, Gu W, Zhang Y, Yang H M, Suib S L 2018 Chem. Eng. J. 337 342

Google Scholar

Google Scholar

[22] Klinthong W, Huang C H, Tan C S 2016 Ind. Eng. Chem. Res. 55 6481

Google Scholar

Google Scholar

[23] Ghoul M, Bacquet M, Crini G, Morcellet M 2003 J. Appl. Polym. Sci. 90 799

Google Scholar

Google Scholar

[24] Saito H, Hyodo T 2003 Phys. Rev. Lett. 90 193401

Google Scholar

Google Scholar

[25] Wiertel M, Surowiec Z, Budzyński M, Gac W 2013 Nukleonika 58 245

[26] 尹昊, 宋通, 彭雄刚, 张鹏, 于润升, 陈喆, 曹兴忠, 王宝义 2023 72 114101

Google Scholar

Google Scholar

Yin H, Song T, Peng X G, Zhang P, Yu R S, Chen Z, Cao X Z, Wang B Y 2023 Acta Phys. Sin. 72 114101

Google Scholar

Google Scholar

[27] Dull T L, Frieze W E, Gidley D W, Sun J N, Yee A F 2001 J. Phys. Chem. B 105 4657

Google Scholar

Google Scholar

-

图 1 (a) PEI改性前后MCF的N2吸附-脱附等温线; (b) 由吸附曲线得到的孔尺寸; (c) 由脱附曲线得到的窗口尺寸; (d) P/P0 = 0.99时, 采用BET方程和单点吸附法计算比表面积和孔体积

Figure 1. (a) N2 adsorption-desorption isotherms of MCF before and after PEI modification; (b) cell size from adsorption curve; (c) window dimensions obtained from desorption curves; (d) specific surface area and pore volume calculated by BET equation and single point adsorption measurement at P/P0 = 0.99.

-

[1] Song C F, Liu Q L, Ji N, Deng S, Zhao J, Li Y, Song Y J, Li H L 2018 Renewable Sustainable Energy Rev. 82 215

Google Scholar

Google Scholar

[2] Xu X C, Song C S, Andresen J M, Miller B G, Scaroni A W 2002 Energy Fuels 16 1463

Google Scholar

Google Scholar

[3] Ma X L, Wang X X, Song C S 2009 J. Am. Chem. Soc. 131 5777

Google Scholar

Google Scholar

[4] Zhao D Y, Feng J L, Huo Q S, Melosh N, Fredrickson G H, Chmelka B F, Stucky G D 1998 Science 279 548

Google Scholar

Google Scholar

[5] Xiong H F, Zhang Y H, Wang S G, Liew K Y, Li J L 2008 J. Phys. Chem. A 112 9706

Google Scholar

Google Scholar

[6] Liu H, Wang G X, Liu J, Qiao S Z, Ahn H 2011 J. Mater. Chem. A 21 3046

Google Scholar

Google Scholar

[7] Zhang Z Y, Zuo F, Feng P Y 2010 J. Mater. Chem. A 20 2206

Google Scholar

Google Scholar

[8] Lu B W, Kawamoto K 2013 J. Environ. Chem. Eng. 1 300

Google Scholar

Google Scholar

[9] Belmabkhout Y, Serna-Guerrero R, Sayari A 2010 Ind. Eng. Chem. Res. 49 359

Google Scholar

Google Scholar

[10] Kim S, Ida J, Guliants V V, Lin Y S 2005 J. Phys. Chem. B 109 6287

Google Scholar

Google Scholar

[11] Wang L, Ma L, Wang A, Liu Q, Zhang T 2007 Chin. J. Catal. 28 805

Google Scholar

Google Scholar

[12] Zheng F, Tran D N, Busche B J, Fryxell G E, Addleman R S, Zemanian T S, Aardahl C L 2005 Ind. Eng. Chem. Res 44 3099

Google Scholar

Google Scholar

[13] Zelenak V, Halamova D, Gaberova L, Bloch E, Llewellyn P 2008 Microporous Mesoporous Mater. 116 358

Google Scholar

Google Scholar

[14] Mosquera M J, Pozo J, Esquivias L, Rivas T, Silva B 2002 J. Non-Cryst. Solids 311 185

Google Scholar

Google Scholar

[15] Brandt W, Paulin R 1968 Phys. Rev. Lett. 21 193

[16] Zaleski R 2015 Nukleonika 60 795

Google Scholar

Google Scholar

[17] Schmidt-Winkel P, Lukens W W, Yang P, Margolese D I, Lettow J S, Ying J Y, Stucky G D 2000 Chem. Mater. 12 686

Google Scholar

Google Scholar

[18] Schmidt-Winkel P, Lukens W W, Zhao D, Yang P, Chmelka B F, Stucky G D 1999 J. Am. Chem. Soc. 121 254

Google Scholar

Google Scholar

[19] Song T, Zhang P, Zhang C, Gong L L, Cao X Z, Wang B Y, Yu R S, Zhou W 2022 Microporous Mesoporous Mater. 334 111761

Google Scholar

Google Scholar

[20] Chen Q j, Fan F C, Long D H, Liu X J, Lian X Y, Qiao W M, Ling L C 2010 Ind. Eng. Chem. Res. 49 11408

Google Scholar

Google Scholar

[21] Ouyang J, Zheng C H, Gu W, Zhang Y, Yang H M, Suib S L 2018 Chem. Eng. J. 337 342

Google Scholar

Google Scholar

[22] Klinthong W, Huang C H, Tan C S 2016 Ind. Eng. Chem. Res. 55 6481

Google Scholar

Google Scholar

[23] Ghoul M, Bacquet M, Crini G, Morcellet M 2003 J. Appl. Polym. Sci. 90 799

Google Scholar

Google Scholar

[24] Saito H, Hyodo T 2003 Phys. Rev. Lett. 90 193401

Google Scholar

Google Scholar

[25] Wiertel M, Surowiec Z, Budzyński M, Gac W 2013 Nukleonika 58 245

[26] 尹昊, 宋通, 彭雄刚, 张鹏, 于润升, 陈喆, 曹兴忠, 王宝义 2023 72 114101

Google Scholar

Google Scholar

Yin H, Song T, Peng X G, Zhang P, Yu R S, Chen Z, Cao X Z, Wang B Y 2023 Acta Phys. Sin. 72 114101

Google Scholar

Google Scholar

[27] Dull T L, Frieze W E, Gidley D W, Sun J N, Yee A F 2001 J. Phys. Chem. B 105 4657

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 4604

- PDF Downloads: 80

- Cited By: 0

DownLoad:

DownLoad: