-

Aluminum nitride (AlN) is of paramount importance in developing electronic devices because of excellent stability and thermal transport performance. However, lack of novel materials which can provide colorful physical and chemical properties seriously hinders further digging out application potential. In this work, we perform an evolutionary structural search based on first-principles calculation and verify the dynamic and thermal dynamic stability of porous buckled AlN and X-AlN (X = C, Si, TC) structural system, which constructs by introducing C, Si atoms and triangular carbon (TC) into the porous vacancy of AlN, by calculating phonon spectra and first-principles molecular dynamic simulations. Structural deformation becomes gradually serious with the increase of structural unit size and significantly influences structural, electronic, and thermal transport properties. Firstly, we point out that a flat energy band appears around the Fermi level in C-AlN and Si-AlN because of weak interatomic interaction between C/Si and the neighbor Al atoms. Unoccupied C-/Si-pz and Al-pz do not form

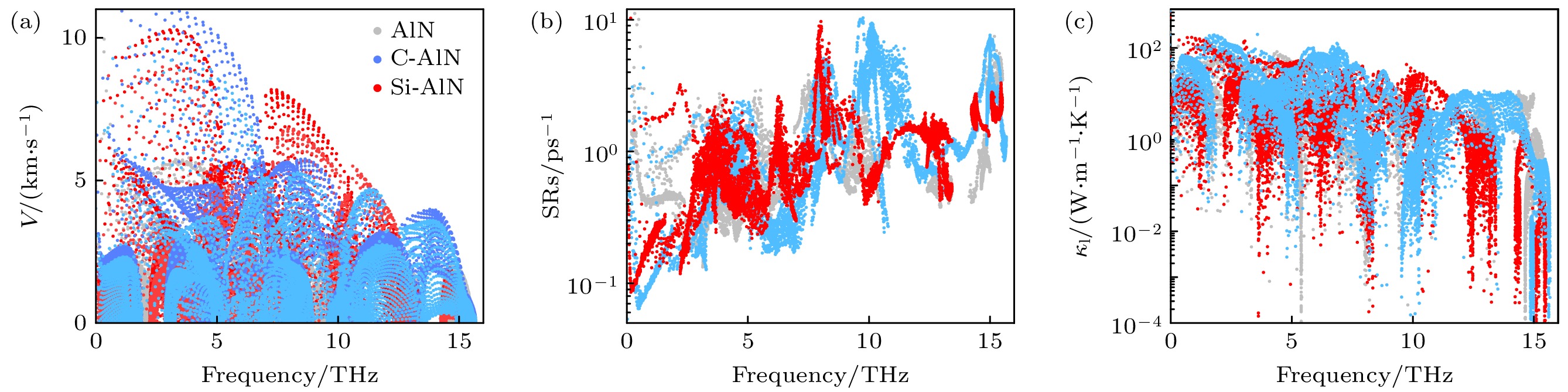

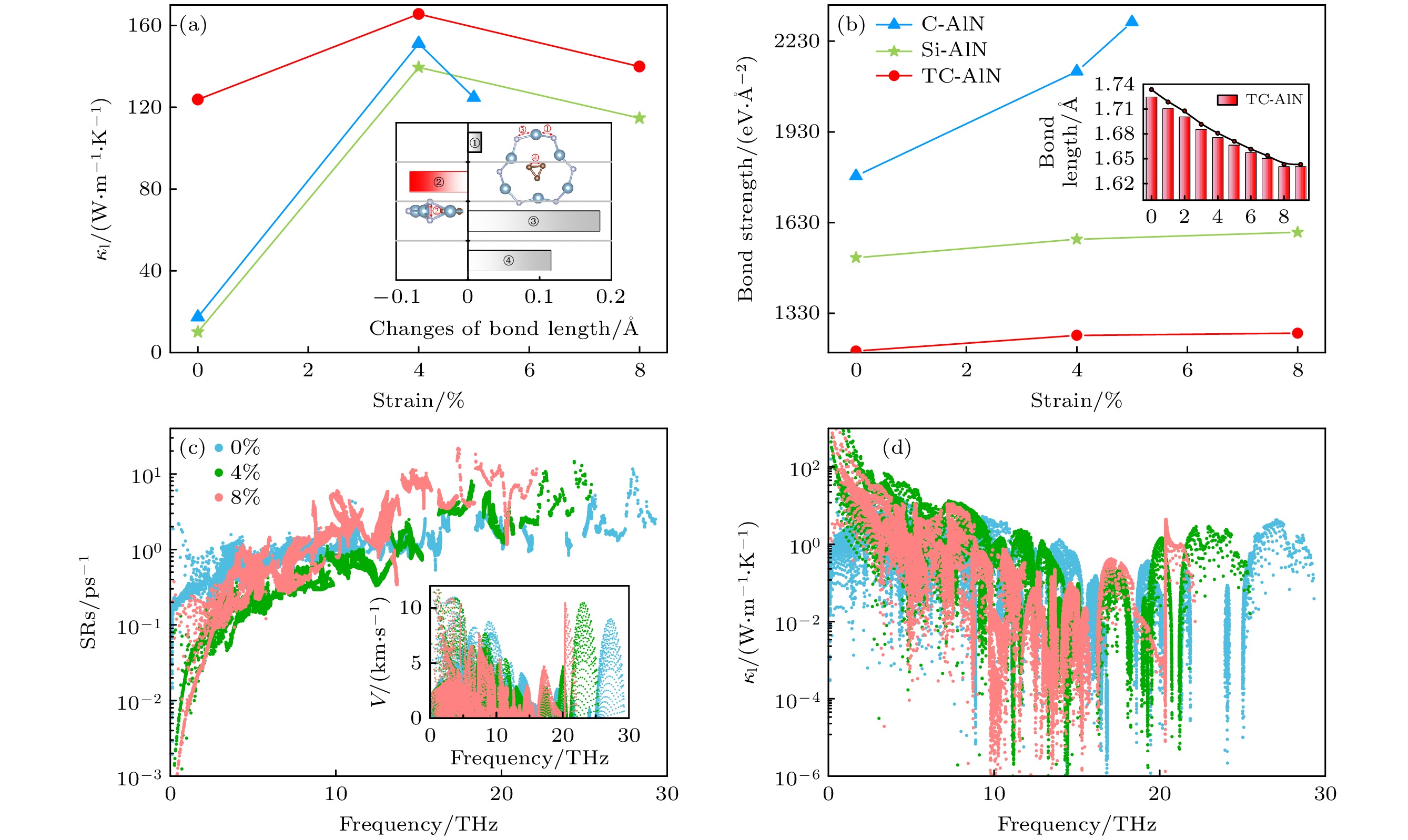

$ {\rm{\pi }} $ bond and only a localized flat band near Fermi level arises, and thus the absorption peaks of structures are enhanced and the red shift occurs. Bonding state of$ {\rm{\pi }} $ bond from hybridized C-pz orbitals in triangular carbon of TC-AlN lowers the energy of conduction band at K point in the first Brillouin zone and the corresponding antibonding state raises the band at Γ, therefore transition from indirect bandgap of AlN to direct bandgap of TC-AlN appears. Secondly, porous buckled AlN shows the lowest thermal conductivity due to asymmetric Al—N bonds around the porous vacancy and vertically stacked N—N bonds. Introduced C and Si atoms both reduce structural anharmonicity, while the former has a relatively small distortion, and so it has a higher thermal conductivity. Triangular carbon in TC-AlN hinders phonon scattering between FA mode and other phonon modes and has the weakest anharmonicity because of the strongest bond strength, and obtains the highest thermal transport performance. Finally, we unveil the physical mechanism of anomalous thermal conductivity in X-AlN system by modulating the biaxial tensile strain. Enhanced vertical N—N bonds dominate thermal transport due to its weaker anharmonicity with a slightly strain, and when tensile strain is above the 4%, soften phonon modes reduce phonon velocity and thus hinders the thermal transport process. Therefore, occurs the anomalous thermal transport behavior, i.e. thermal conductivity first rises and then drops with applied biaxial strain increasing. Our work paves the way for modulating two-dimensional AlN performance and provides a new insight for designing promising novel two-dimensional semiconductors.-

Keywords:

- two-dimensional semiconductor /

- thermal transport /

- electronic structure /

- biaxial stress-strain

[1] Robinson J A 2018 APL Mater. 6 058202

Google Scholar

Google Scholar

[2] Shi L, Xu A, Zhao T 2017 ACS Appl. Mater. Interfaces 9 1987

Google Scholar

Google Scholar

[3] Cai Y, Liu Y, Xie Y, Zou Y, Gao C, Zhao Y, Liu S, Xu H, Shi J, Guo S, Sun C 2020 APL Mater. 8 021107

Google Scholar

Google Scholar

[4] 叶倩, 沈阳, 袁野, 赵祎峰, 段纯刚 2020 69 217710

Google Scholar

Google Scholar

Ye Q, Shen Y, Yuan Y, Zhao Y F, Duan C G 2020 Acta Phys. Sin. 69 217710

Google Scholar

Google Scholar

[5] 陈蓉, 王远帆, 王熠欣, 梁前, 谢泉 2022 71 127301

Google Scholar

Google Scholar

Chen R, Wang Y F, Wang Y X, Liang Q, Xie Q 2022 Acta Phys. Sin. 71 127301

Google Scholar

Google Scholar

[6] Liang H P, Duan Y F 2022 Chin. Phys. B 31 076301

Google Scholar

Google Scholar

[7] Lü F, Liang H P, Duan Y F 2023 J. Phys. Chem. Lett. 14 663

Google Scholar

Google Scholar

[8] Wan X G, Turner A M, Vishwanath A, Savrasov S Y 2011 Phys. Rev. B 83 205101

Google Scholar

Google Scholar

[9] Liang H P, Duan Y F 2021 Nanoscale 13 11994

Google Scholar

Google Scholar

[10] Akal L, Kusuki Y, N Shiba, Takayanagi T, Wei Z X 2021 Phys. Rev. Lett. 126 061604

Google Scholar

Google Scholar

[11] Novoselov K S, Geim A K, Morozov S V, Jiang D, Zhang Y, Dubonos S V, Grigorieva I V, Firsov A 2004 Science 306 666

Google Scholar

Google Scholar

[12] 卢晓波, 张广宇 2015 64 077305

Google Scholar

Google Scholar

Lu X B, Zhang G Y 2015 Acta Phys. Sin. 64 077305

Google Scholar

Google Scholar

[13] Cao Y, Fatemi V, Fang S, Watanabe K, Taniguchi T, Kaxiras E, Jarillo-Herrero P 2018 Nature 556 43

Google Scholar

Google Scholar

[14] Tan X, Xin Z Y, Liu X J, Mu Q G 2013 Adv. Mater. Research 821 841

[15] Shimada K, Sota T, Suzuki K 1998 J. Appl. Phys. 84 4951

Google Scholar

Google Scholar

[16] Zhang H, Yu S, Liu F, Wang Z, Lu M, Hu X, Chen Y, Xu X 2017 Sci. Chin. Phys. Mech. Astron. 60 044311

Google Scholar

Google Scholar

[17] 冯嘉恒, 唐立丹, 刘邦武, 夏洋, 王冰 2013 62 116302

Google Scholar

Google Scholar

Feng J H, Tang L D, Liu B W, Xia Y, Wang B 2013 Acta Phys. Sin. 62 116302

Google Scholar

Google Scholar

[18] 林竹, 郭志友, 毕艳君, 董玉成 2009 58 191707

Google Scholar

Google Scholar

Lin Z, Guo Z Y, Bi Y Z, Dong Y C 2009 Acta phys. Sin. 58 191707

Google Scholar

Google Scholar

[19] 程丽, 王德兴, 张杨, 苏丽萍, 陈淑妍, 王晓峰, 孙鹏, 易重桂 2018 67 047101

Google Scholar

Google Scholar

Cheng L, Wang D X, Zhang Y, Su L P, Chen S Y, Wang X F, Sun P, Yi C G 2018 Acta Phys. Sin. 67 047101

Google Scholar

Google Scholar

[20] 高小奇, 郭志友, 曹东兴, 张宇飞, 孙慧卿, 邓贝 2010 59 3418

Google Scholar

Google Scholar

Gao X Q, Guo Z Y, Cao D X, Zhang Y F, Sun H Q, Deng B 2010 Acta Phys. Sin. 59 3418

Google Scholar

Google Scholar

[21] de Almeida Jr E F, de Brito Mota F, de Castilho C M C, Kakanakova-Georgieva A, Gueorguiev G K 2012 Eur. Phys. J. B 85 48

Google Scholar

Google Scholar

[22] Jia Y P, Shi Z M, Hou W T, Zang H, Jiang K, Chen Y, Zhang S L, Qi Z B, Wu T, Sun X J, Li D B 2020 Npj 2D Mater. Appl. 4 31

Google Scholar

Google Scholar

[23] Gürbüz E, Cahangirov S, Durgun E, Ciraci S 2017 Phys. Rev. B 96 205427

Google Scholar

Google Scholar

[24] Zhou R, Liang H P, Duan Y F, Wei S H 2023 J. Phys. Chem. Lett. 14 737

Google Scholar

Google Scholar

[25] Sheng X L, Yan Q B, Ye F, Zheng Q R, Su G 2011 Phys. Rev. Lett. 106 155703

Google Scholar

Google Scholar

[26] Zhang J, Wang R, Zhu X, Pan A, Han C, Li X, Zhao D, Ma C, Wang Q, Su H, Niu C 2017 Nat. Commun. 8 683

Google Scholar

Google Scholar

[27] Liu W H, Luo J W, Li S, Wang L W 2020 Phys. Rev. B 102 184308

Google Scholar

Google Scholar

[28] Liang H P, Zhong H Z, Huang S, Duan Y F 2021 J. Phys. Chem. Lett. 12 10975

Google Scholar

Google Scholar

[29] Oganov A R, Ma Y, Lyahov A O, Valle M, Gatti C 2010 Rev. Mineral. Geochem. 71 271

Google Scholar

Google Scholar

[30] Oganov A R, Lyahov A O, Valle M 2011 Acc. Chem. Res. 44 227

Google Scholar

Google Scholar

[31] Oganov A R, Class C W 2006 J. Chem. Phys. 124 244704

Google Scholar

Google Scholar

[32] Hohenberg P, Kohn W 1964 Phys. Rev. 136 B864

Google Scholar

Google Scholar

[33] Kohn W, Sham L J 1965 Phys. Rev. 140 A1133

Google Scholar

Google Scholar

[34] Kresse H, Hafner J 1993 Phys. Rev. B 47 558

Google Scholar

Google Scholar

[35] Kresse H, Hafner J 1994 Phys. Rev. B 49 14251

Google Scholar

Google Scholar

[36] Kresse H, Furthmüller J 1996 Phys. Rev. B 54 11169

Google Scholar

Google Scholar

[37] Perdew J P, Burke K, Ernzerhof M 1996 Phys. Rev. Lett. 77 3865

Google Scholar

Google Scholar

[38] Heyd J, Scueria G E, Ernzerhof M 2003 J. Chem. Phys. 118 8207

Google Scholar

Google Scholar

[39] Jia W, Fu J, Cao Z, Wang L, Chi X, Gao W, Wang L W 2013 Comput. Phys. Commun. 251 102

Google Scholar

Google Scholar

[40] Jia W, Cao Z, Wang L, Fu J, Chi X, Gao W, Wang L W 2013 Comput. Phys. Commun. 184 9

Google Scholar

Google Scholar

[41] Atsush T, Isa T 2015 Scr. Mater. 108 1

Google Scholar

Google Scholar

[42] Li W, Carrete J, Katcho N A, Mingo N 2014 Comput. Phys. Commun. 185 1747

Google Scholar

Google Scholar

[43] Homayoun J, Bahram A R, Mahdi F 2018 Solid State Commun. 282 21

Google Scholar

Google Scholar

[44] 程正富, 郑瑞伦 2016 65 104701

Google Scholar

Google Scholar

Cheng Z F, Zheng R L 2016 Acta Phys. Sin. 65 104701

Google Scholar

Google Scholar

[45] Lü F, Liang H P, Duan Y F 2023 Phys. Rev. B 107 045422

Google Scholar

Google Scholar

[46] Koh Y R, Mamun A, Bin Hoque M S, Liu Z Y, Bai T Y, Hussain K, Liao M E, Li R Y, Gaskins J T, Giri A, Tomko J, Braun J L, Gaevski M, Lee E, Yates L, Goorsky M S, Luo T F, Khan A, Graham S, Hopkins P E 2020 ACS Appl. Mater. Interfaces 12 29443

[47] Mortazavi B, Shahrokhi M, Raeisi M, Zhuang X, Pereira L F C, Rabczuk T 2019 Carbon 149 733

Google Scholar

Google Scholar

[48] Lindsay L, Broido D A, Mingo N 2010 Phys. Rev. B 82 115427

Google Scholar

Google Scholar

-

图 4 孔状皱面AlN与X-AlN (X = C, Si, TC)的(a)在300 K下的晶格热导率, (b) 各声子支相对热导贡献, (d) 声子弛豫时间与(e) 声子群速度平方. (c) TC-AlN前九支声子支非谐散射率在第一布里渊区中的分布. 图(a)中的插图为随温度变化的晶格热导率; 图(b)中的插图为TC-AlN声子支的热导贡献

Figure 4. (a) Lattice thermal conductivity at 300 K, (b) relative thermal conductivity contribution of each phonon branch, (d) phonon relaxation time and (e) square of phonon group velocity for porous buckled AlN and X-AlN (X = C, Si, TC). (c) The distribution of anharmonic scattering rates of the first 9 phonon branches of TC-AlN in the first Brillouin zone. The lattice thermal conductivity versus temperature is inserted in panel (a); the thermal conductivity contribution of each phonon branch of TC-AlN is inserted in panel (b).

图 6 在不同应变下X-AlN (X = C, Si, TC)的(a) 300 K下晶格热导率、(b) N—N键键强. TC-AlN的(c)非谐散射率与(d)频率变化的晶格热导. 8%应力下N—N键键长改变量、随应力变化的键长与群速度作为插图分别在图(a), 图(b), 图(c) 中

Figure 6. (a) Lattice thermal conductivity at 300 K and (b) N—N bond strength at different strains for X-AlN (X = C, Si and TC). (c) Anharmonic scattering rates and (d) lattice thermal conductivity distribution versus frequency for TC-AlN. The changes of N—N bond length at 8% strain, bond lengths with variation of strains, and group velocity of TC-AlN as the insets of panels (a), (b), and (c), respectively.

表 1 X-AlN (X = C, Si, TC)的结构参数与电子、结构和热学性质. 其中键角

$ \alpha $ 为孔状空位边缘N—Al—N的角度, 键长为所引入原子X与临近Al成键的键长Table 1. Structural parameters and electronic, structural and thermal properties of X-AlN (X = C, Si, TC). Bond angle

$ \alpha $ locates at the N—Al—N near the porous vacancy, and bond length is the distance between the introduced atoms and the neighbor Al.结构 晶格常数/Å 键角$ \alpha / $(°) 键长/Å 杨氏模量 /(N·m–1) 泊松比 带隙/eV 热导率/(W·m–1·K–1) AlN 5.12 113.90 — 70.57 0.39 4.12/间接 6.86 C-AlN 5.51 122.08 1.94 89.02 0.50 0.65/间接 17.30 Si-AlN 5.89 138.38 2.44 79.28 0.47 1.85/间接 10.08 TC-AlN 6.08 167.63 1.96 90.95 0.41 3.95/直接 123.75 -

[1] Robinson J A 2018 APL Mater. 6 058202

Google Scholar

Google Scholar

[2] Shi L, Xu A, Zhao T 2017 ACS Appl. Mater. Interfaces 9 1987

Google Scholar

Google Scholar

[3] Cai Y, Liu Y, Xie Y, Zou Y, Gao C, Zhao Y, Liu S, Xu H, Shi J, Guo S, Sun C 2020 APL Mater. 8 021107

Google Scholar

Google Scholar

[4] 叶倩, 沈阳, 袁野, 赵祎峰, 段纯刚 2020 69 217710

Google Scholar

Google Scholar

Ye Q, Shen Y, Yuan Y, Zhao Y F, Duan C G 2020 Acta Phys. Sin. 69 217710

Google Scholar

Google Scholar

[5] 陈蓉, 王远帆, 王熠欣, 梁前, 谢泉 2022 71 127301

Google Scholar

Google Scholar

Chen R, Wang Y F, Wang Y X, Liang Q, Xie Q 2022 Acta Phys. Sin. 71 127301

Google Scholar

Google Scholar

[6] Liang H P, Duan Y F 2022 Chin. Phys. B 31 076301

Google Scholar

Google Scholar

[7] Lü F, Liang H P, Duan Y F 2023 J. Phys. Chem. Lett. 14 663

Google Scholar

Google Scholar

[8] Wan X G, Turner A M, Vishwanath A, Savrasov S Y 2011 Phys. Rev. B 83 205101

Google Scholar

Google Scholar

[9] Liang H P, Duan Y F 2021 Nanoscale 13 11994

Google Scholar

Google Scholar

[10] Akal L, Kusuki Y, N Shiba, Takayanagi T, Wei Z X 2021 Phys. Rev. Lett. 126 061604

Google Scholar

Google Scholar

[11] Novoselov K S, Geim A K, Morozov S V, Jiang D, Zhang Y, Dubonos S V, Grigorieva I V, Firsov A 2004 Science 306 666

Google Scholar

Google Scholar

[12] 卢晓波, 张广宇 2015 64 077305

Google Scholar

Google Scholar

Lu X B, Zhang G Y 2015 Acta Phys. Sin. 64 077305

Google Scholar

Google Scholar

[13] Cao Y, Fatemi V, Fang S, Watanabe K, Taniguchi T, Kaxiras E, Jarillo-Herrero P 2018 Nature 556 43

Google Scholar

Google Scholar

[14] Tan X, Xin Z Y, Liu X J, Mu Q G 2013 Adv. Mater. Research 821 841

[15] Shimada K, Sota T, Suzuki K 1998 J. Appl. Phys. 84 4951

Google Scholar

Google Scholar

[16] Zhang H, Yu S, Liu F, Wang Z, Lu M, Hu X, Chen Y, Xu X 2017 Sci. Chin. Phys. Mech. Astron. 60 044311

Google Scholar

Google Scholar

[17] 冯嘉恒, 唐立丹, 刘邦武, 夏洋, 王冰 2013 62 116302

Google Scholar

Google Scholar

Feng J H, Tang L D, Liu B W, Xia Y, Wang B 2013 Acta Phys. Sin. 62 116302

Google Scholar

Google Scholar

[18] 林竹, 郭志友, 毕艳君, 董玉成 2009 58 191707

Google Scholar

Google Scholar

Lin Z, Guo Z Y, Bi Y Z, Dong Y C 2009 Acta phys. Sin. 58 191707

Google Scholar

Google Scholar

[19] 程丽, 王德兴, 张杨, 苏丽萍, 陈淑妍, 王晓峰, 孙鹏, 易重桂 2018 67 047101

Google Scholar

Google Scholar

Cheng L, Wang D X, Zhang Y, Su L P, Chen S Y, Wang X F, Sun P, Yi C G 2018 Acta Phys. Sin. 67 047101

Google Scholar

Google Scholar

[20] 高小奇, 郭志友, 曹东兴, 张宇飞, 孙慧卿, 邓贝 2010 59 3418

Google Scholar

Google Scholar

Gao X Q, Guo Z Y, Cao D X, Zhang Y F, Sun H Q, Deng B 2010 Acta Phys. Sin. 59 3418

Google Scholar

Google Scholar

[21] de Almeida Jr E F, de Brito Mota F, de Castilho C M C, Kakanakova-Georgieva A, Gueorguiev G K 2012 Eur. Phys. J. B 85 48

Google Scholar

Google Scholar

[22] Jia Y P, Shi Z M, Hou W T, Zang H, Jiang K, Chen Y, Zhang S L, Qi Z B, Wu T, Sun X J, Li D B 2020 Npj 2D Mater. Appl. 4 31

Google Scholar

Google Scholar

[23] Gürbüz E, Cahangirov S, Durgun E, Ciraci S 2017 Phys. Rev. B 96 205427

Google Scholar

Google Scholar

[24] Zhou R, Liang H P, Duan Y F, Wei S H 2023 J. Phys. Chem. Lett. 14 737

Google Scholar

Google Scholar

[25] Sheng X L, Yan Q B, Ye F, Zheng Q R, Su G 2011 Phys. Rev. Lett. 106 155703

Google Scholar

Google Scholar

[26] Zhang J, Wang R, Zhu X, Pan A, Han C, Li X, Zhao D, Ma C, Wang Q, Su H, Niu C 2017 Nat. Commun. 8 683

Google Scholar

Google Scholar

[27] Liu W H, Luo J W, Li S, Wang L W 2020 Phys. Rev. B 102 184308

Google Scholar

Google Scholar

[28] Liang H P, Zhong H Z, Huang S, Duan Y F 2021 J. Phys. Chem. Lett. 12 10975

Google Scholar

Google Scholar

[29] Oganov A R, Ma Y, Lyahov A O, Valle M, Gatti C 2010 Rev. Mineral. Geochem. 71 271

Google Scholar

Google Scholar

[30] Oganov A R, Lyahov A O, Valle M 2011 Acc. Chem. Res. 44 227

Google Scholar

Google Scholar

[31] Oganov A R, Class C W 2006 J. Chem. Phys. 124 244704

Google Scholar

Google Scholar

[32] Hohenberg P, Kohn W 1964 Phys. Rev. 136 B864

Google Scholar

Google Scholar

[33] Kohn W, Sham L J 1965 Phys. Rev. 140 A1133

Google Scholar

Google Scholar

[34] Kresse H, Hafner J 1993 Phys. Rev. B 47 558

Google Scholar

Google Scholar

[35] Kresse H, Hafner J 1994 Phys. Rev. B 49 14251

Google Scholar

Google Scholar

[36] Kresse H, Furthmüller J 1996 Phys. Rev. B 54 11169

Google Scholar

Google Scholar

[37] Perdew J P, Burke K, Ernzerhof M 1996 Phys. Rev. Lett. 77 3865

Google Scholar

Google Scholar

[38] Heyd J, Scueria G E, Ernzerhof M 2003 J. Chem. Phys. 118 8207

Google Scholar

Google Scholar

[39] Jia W, Fu J, Cao Z, Wang L, Chi X, Gao W, Wang L W 2013 Comput. Phys. Commun. 251 102

Google Scholar

Google Scholar

[40] Jia W, Cao Z, Wang L, Fu J, Chi X, Gao W, Wang L W 2013 Comput. Phys. Commun. 184 9

Google Scholar

Google Scholar

[41] Atsush T, Isa T 2015 Scr. Mater. 108 1

Google Scholar

Google Scholar

[42] Li W, Carrete J, Katcho N A, Mingo N 2014 Comput. Phys. Commun. 185 1747

Google Scholar

Google Scholar

[43] Homayoun J, Bahram A R, Mahdi F 2018 Solid State Commun. 282 21

Google Scholar

Google Scholar

[44] 程正富, 郑瑞伦 2016 65 104701

Google Scholar

Google Scholar

Cheng Z F, Zheng R L 2016 Acta Phys. Sin. 65 104701

Google Scholar

Google Scholar

[45] Lü F, Liang H P, Duan Y F 2023 Phys. Rev. B 107 045422

Google Scholar

Google Scholar

[46] Koh Y R, Mamun A, Bin Hoque M S, Liu Z Y, Bai T Y, Hussain K, Liao M E, Li R Y, Gaskins J T, Giri A, Tomko J, Braun J L, Gaevski M, Lee E, Yates L, Goorsky M S, Luo T F, Khan A, Graham S, Hopkins P E 2020 ACS Appl. Mater. Interfaces 12 29443

[47] Mortazavi B, Shahrokhi M, Raeisi M, Zhuang X, Pereira L F C, Rabczuk T 2019 Carbon 149 733

Google Scholar

Google Scholar

[48] Lindsay L, Broido D A, Mingo N 2010 Phys. Rev. B 82 115427

Google Scholar

Google Scholar

-

096301-20230116补充材料.pdf

096301-20230116补充材料.pdf

Catalog

Metrics

- Abstract views: 8159

- PDF Downloads: 163

- Cited By: 0

DownLoad:

DownLoad: