-

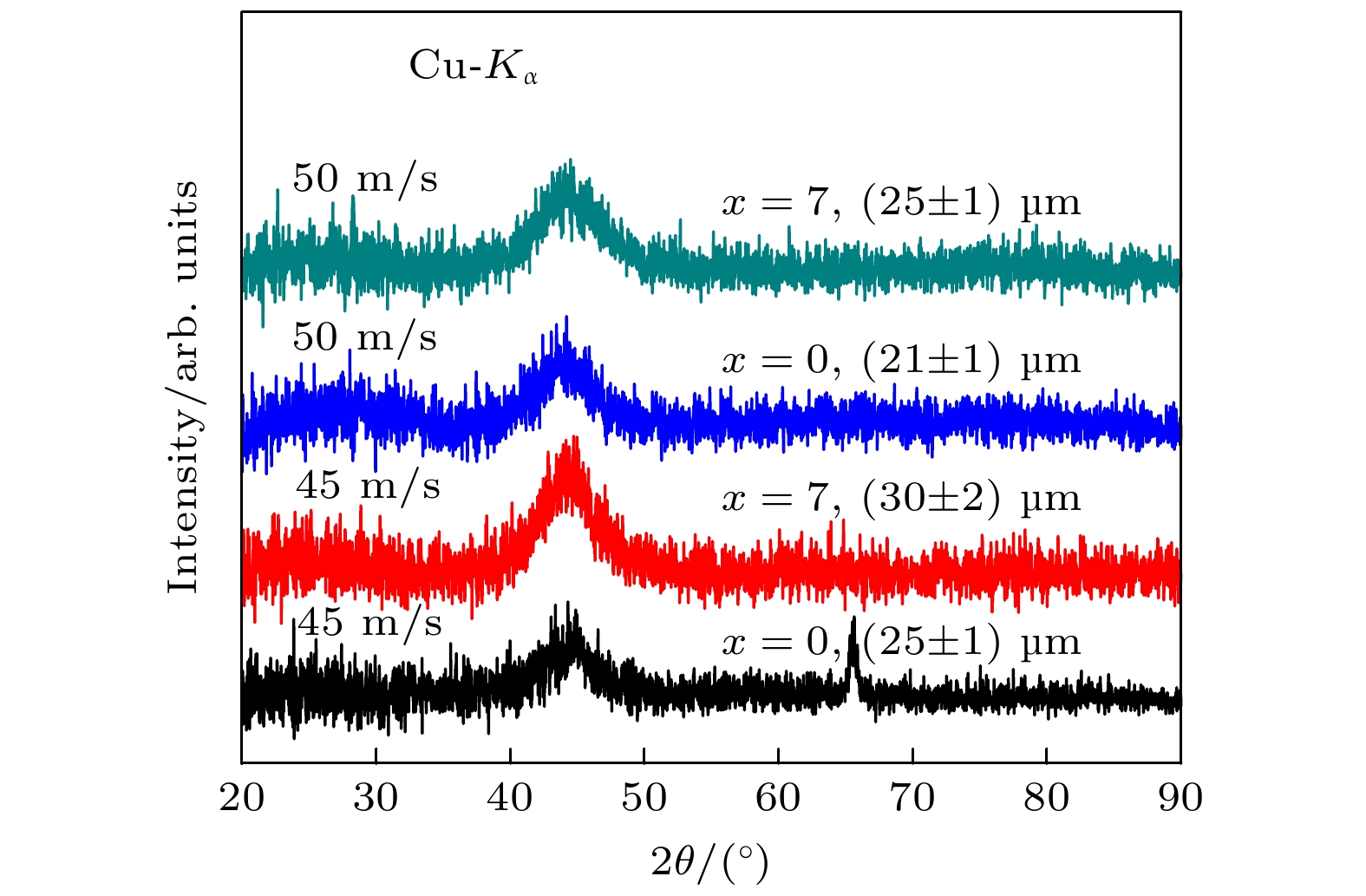

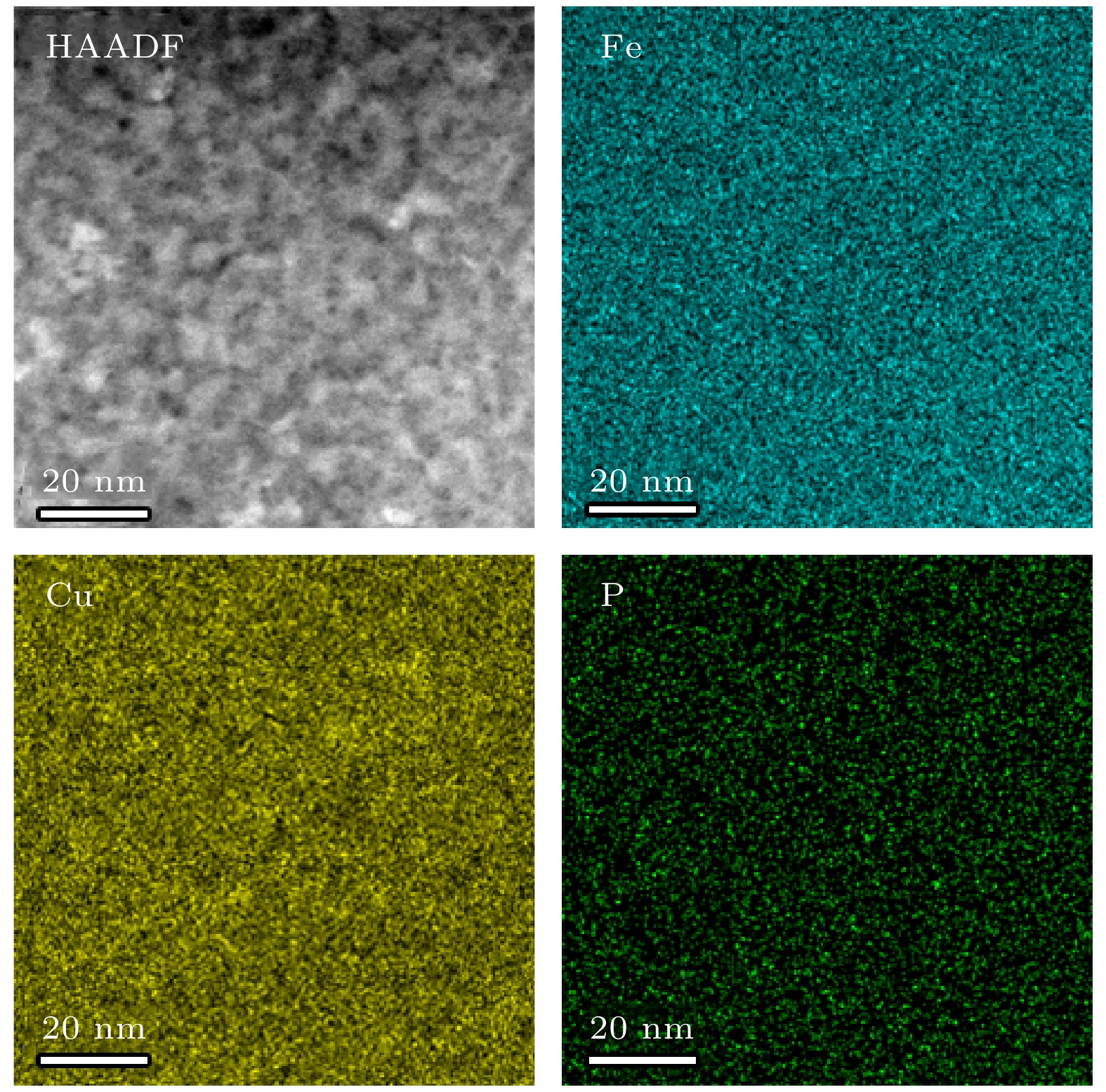

Fe-based amorphous alloys are widely used in power electronics fields such as transformers and reactors due to their low coercivity, high permeability and low loss. However, the relatively low saturation magnetization (Bs) limits their further applications. Generally speaking, the adjustable magnetic Fe content as an effective strategy can ameliorate the magnetic properties, and the higher the Fe content, the higher the obtained Bs is, but the decrease of the corresponding non-magnetic element content will result in the drop of the ability of alloys to form amorphous phase, leading to the deterioration of the magnetic softness and bending ductility of nanocrystalline alloys. To address this critical issue, in this work, based on the metal-metalloid hybridization, the FePBCCu amorphous ribbons, each with a thickness of ~25 μm, are prepared by the single-roller melt spinning method via 7% (atomic percent) B substitution for P, and the effects of B element addition on the ability to form amorphous phase, magnetic properties and mechanical properties of ribbons are investigated. Thermodynamic behavior shows that the addition of small quantities of B element can reduce the structural heterogeneity of alloy and the crystallization driving force as well, thus effectively improving the thermal stability of the amorphous matrix. The melting and solidification curves show that the addition of B can promote alloy to approach to the eutectic composition, and there is a large degree of undercooling. As a result, the critical thickness of ribbons increases from ~21 μm for B-free alloy to ~30 μm for B-added alloy due to the micro-alloying effect. The addition of B increases the effective magnetic moment of magnetic atoms in alloy, resulting in the increase of the saturation magnetization. Furthermore, the results of nanoindentation tests show that the modulus value of the B-added alloy decreases greatlyr and fluctuates in a smaller range than that of the B-free alloy, which is closely associated with the structural uniformity of the alloy.

-

Keywords:

- Fe-based amorphous ribbon /

- amorphous forming ability /

- saturation magnetization /

- reduced modulus

[1] Inoue A, Shen B L, Chang C T 2004 Acta Mater. 52 4093

Google Scholar

Google Scholar

[2] Xu D D, Zhou B L, Wang Q Q, Zhou J, Yang W M, Yuan C C, Xue L, Fan X D, Ma L Q, Shen B L 2018 Corros. Sci. 138 20

Google Scholar

Google Scholar

[3] Li F C, Liu T, Zhang J Y, Shuang S, Wang Q, Wang A D, Wang J G, Yang Y 2019 Mater. Today Adv. 4 100027

Google Scholar

Google Scholar

[4] McHenry M E, Willard M A, Laughlin D E 1999 Prog. Mater. Sci. 44 291

Google Scholar

Google Scholar

[5] Wang A D, Zhao C L, He A N, Men H, Chang C T, Wang X M 2016 J. Alloy. Compd. 656 729

Google Scholar

Google Scholar

[6] 姚可夫, 施凌翔, 陈双琴, 邵洋, 陈娜, 贾蓟丽 2018 67 016101

Google Scholar

Google Scholar

Yao K F, Shi L X, Chen S Q, Shao Y, Chen N, Jia J L 2018 Acta Phys. Sin. 67 016101

Google Scholar

Google Scholar

[7] McHenry M E, Laughlin D E 2014 hysical Metallurgy (5th Ed.) (Elsevier) p1881

[8] Hou L, Fan X D, Wang Q Q, Yang W M, Shen B L 2019 J. Mater. Sci. Technol. 35 1655

Google Scholar

Google Scholar

[9] Meng S Y, Ling H B, Li Q, Zhang J 2014 Scr. Mater. 81 24

Google Scholar

Google Scholar

[10] Wang C J, He A N, Wang A D, Pang J, Ling X, Li Q, Chang C, Qiu K, Wang X 2017 Intermetallics 84 142

Google Scholar

Google Scholar

[11] Mizoguchi T 1976 AIP Conf. Proc. 34 286

[12] Xu J, Yang Y Z, Li W, Xie Z, Chen X 2017 Mater. Res. Bull. 97 452

[13] Shi L X, Qin X L, Yao K F 2020 Prog. Nat. Sci-Mater. 30 208

Google Scholar

Google Scholar

[14] Zuo M Q, Meng S Y, Li Q, Li H X, Chang C T, Sun Y F 2017 Intermetallics 83 83

Google Scholar

Google Scholar

[15] Jin Y L, Fan X D, He M, Liu X C, Shen B L 2012 Sci. China Technol. Sci. 55 3419

Google Scholar

Google Scholar

[16] Wang Q Q, Chen M X, Lin P H, Cui Z Q, Chu C L, Shen B L 2018 J. Mater. Chem. A 6 10686

Google Scholar

Google Scholar

[17] Wang Q Q, Yun L, Chen M X, Xu D D, Cui Z Q, Zeng Q S, Lin P H, Chu C L, Shen B L 2019 ACS Appl. Nano Mater. 2 214

Google Scholar

Google Scholar

[18] Jafari S, Beitollahi A, Eftekhari Yekta B, Ohkubo T, Budinsky V, Marsilius M, Herzer G, Hono K 2016 J. Alloy. Compd. 674 136

Google Scholar

Google Scholar

[19] Fan X D, Zhang T, Jiang M F, Yang W M, Shen B L 2019 J. Non-Cryst. Solid. 503 36

[20] Hou L, Yang W M, Luo Q, Fan X D, Liu H S, Shen B L 2020 J. Non-Cryst. Solid. 530 119800

Google Scholar

Google Scholar

[21] Li Y L, Dou Z X, Chen X M, Lv K, Li F S, Hui X D 2020 Mater. Sci. Eng. B 262 114740

Google Scholar

Google Scholar

[22] Hono K, Ping D H, Ohnuma M, Onodera H 1999 Acta Mater. 47 997

Google Scholar

Google Scholar

[23] Hu F, Yuan C C, Luo Q, Yang W M, Shen B L 2019 J. Alloy. Compd. 807 151675

Google Scholar

Google Scholar

[24] Ohnuma M, Ping D H, Abe T, Onodera H, Hono K, Yoshizawa Y 2003 J. Appl. Phys. 93 9186

Google Scholar

Google Scholar

[25] Yang W M, Li J W, Liu H S, Dun C C, Zhang H L, Huo J T, Xue L, Zhao Y C, Shen B L, Dou L M, Inoue A 2014 Intermetallics 49 52

Google Scholar

Google Scholar

[26] Lan S, Ren Y, Wei X Y, Wang B, Gilbert E P, Shibayama T, Watanabe S, Ohnuma M, Wang X L 2017 Nat. Commun. 8 14679

Google Scholar

Google Scholar

[27] Takeuchi A, Inoue A 2005 Mater. Trans. 46 2817

Google Scholar

Google Scholar

[28] 耿遥祥, 王英敏 2020 金属学报 56 1558

Google Scholar

Google Scholar

Geng Y X, Wang Y M 2020 Acta Metall. Sin. 56 1558

Google Scholar

Google Scholar

[29] Fan X D, Jiang M F, Zhang T, Hou L, Wang C X, Shen B L 2020 J. Non-Cryst. Solid. 533 119941

Google Scholar

Google Scholar

[30] Hou L, Li M R, Jiang C, Fan X D, Luo Q, Chen S S, Song P D, Li W H 2021 J. Alloy. Compd. 853 157071

Google Scholar

Google Scholar

[31] 严密, 彭晓领 2011 磁学基础与磁性材料 (杭州: 浙江大学出版社)

Yan M, Peng X L 2011 Fundamentals of Magnetism and Magnetic Materials (Hangzhou: Zhejiang University Press) (in Chinese)

[32] Zhang J H, Chang C T, Wang A D Shen B L 2012 J. Non-Crystal. Solids 358 1443

Google Scholar

Google Scholar

[33] Wang F, Inoue A, Han Y, Kong F L, Zhu S L, Shalaan E, Al-Marzouki F, Obaid A 2017 J. Alloy. Compd. 723 376

Google Scholar

Google Scholar

[34] Sun B R, Xin S W, Shen T D 2018 J. Mag. Magn. Mater. 466 130

Google Scholar

Google Scholar

[35] Sarac B, Ivanov Y P, Chuvilin A, Schoberl T, Stoica M, Zhang Z L, Eckert J 2018 Nat. Commun. 9 1333

Google Scholar

Google Scholar

[36] Liu Y H, Wang G, Wang R J, Zhao D Q, Pan, M X, Wang W H 2007 Science 315 1385

Google Scholar

Google Scholar

-

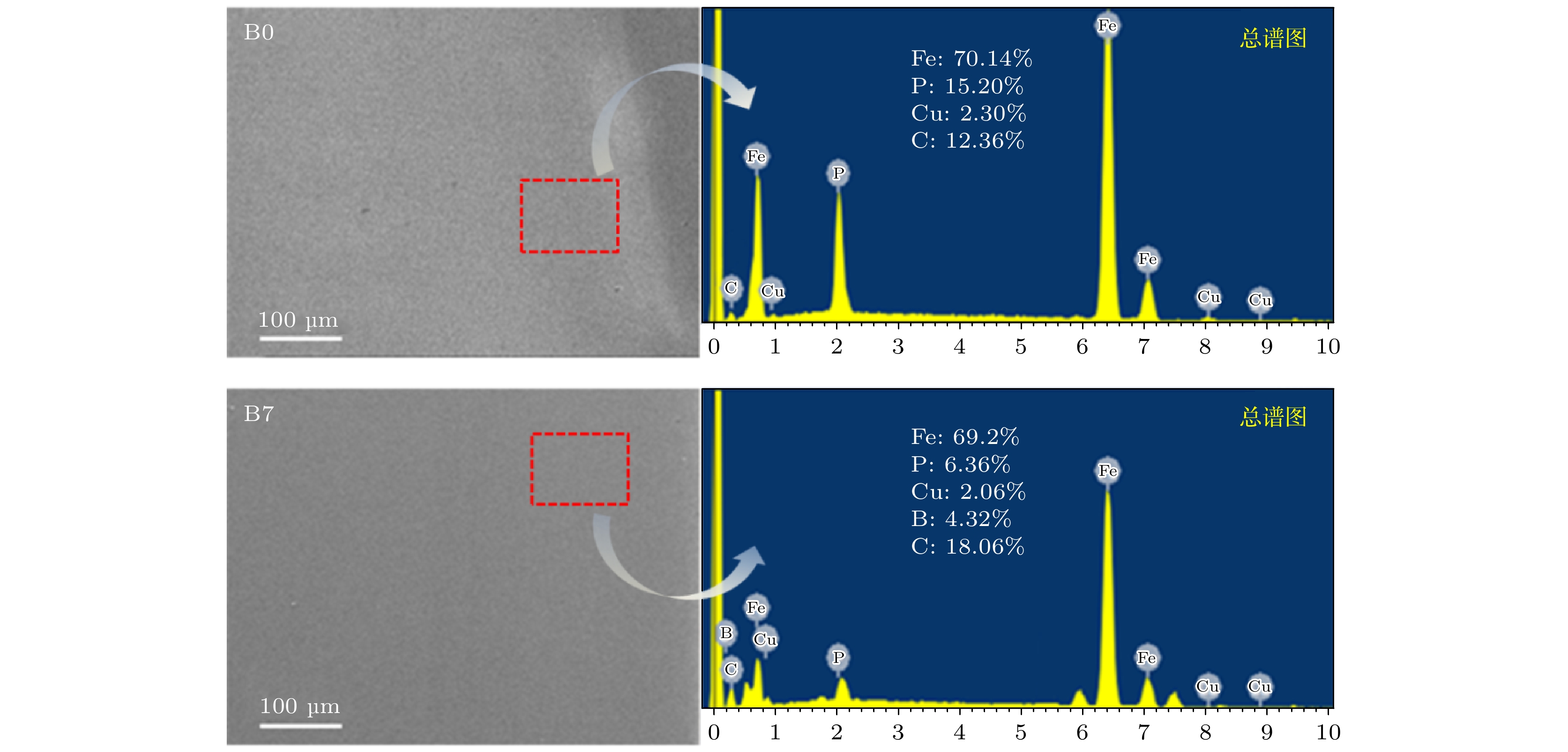

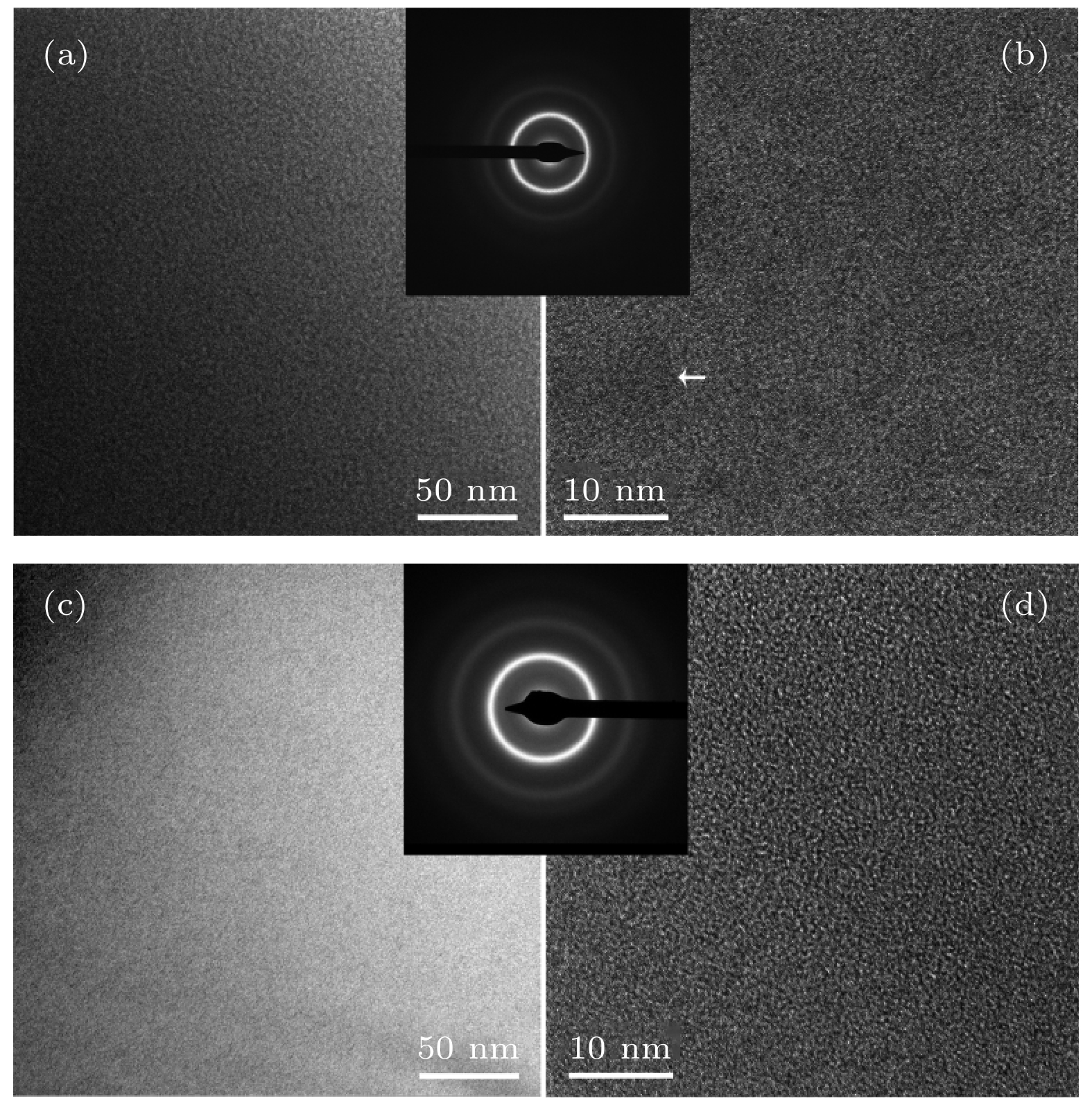

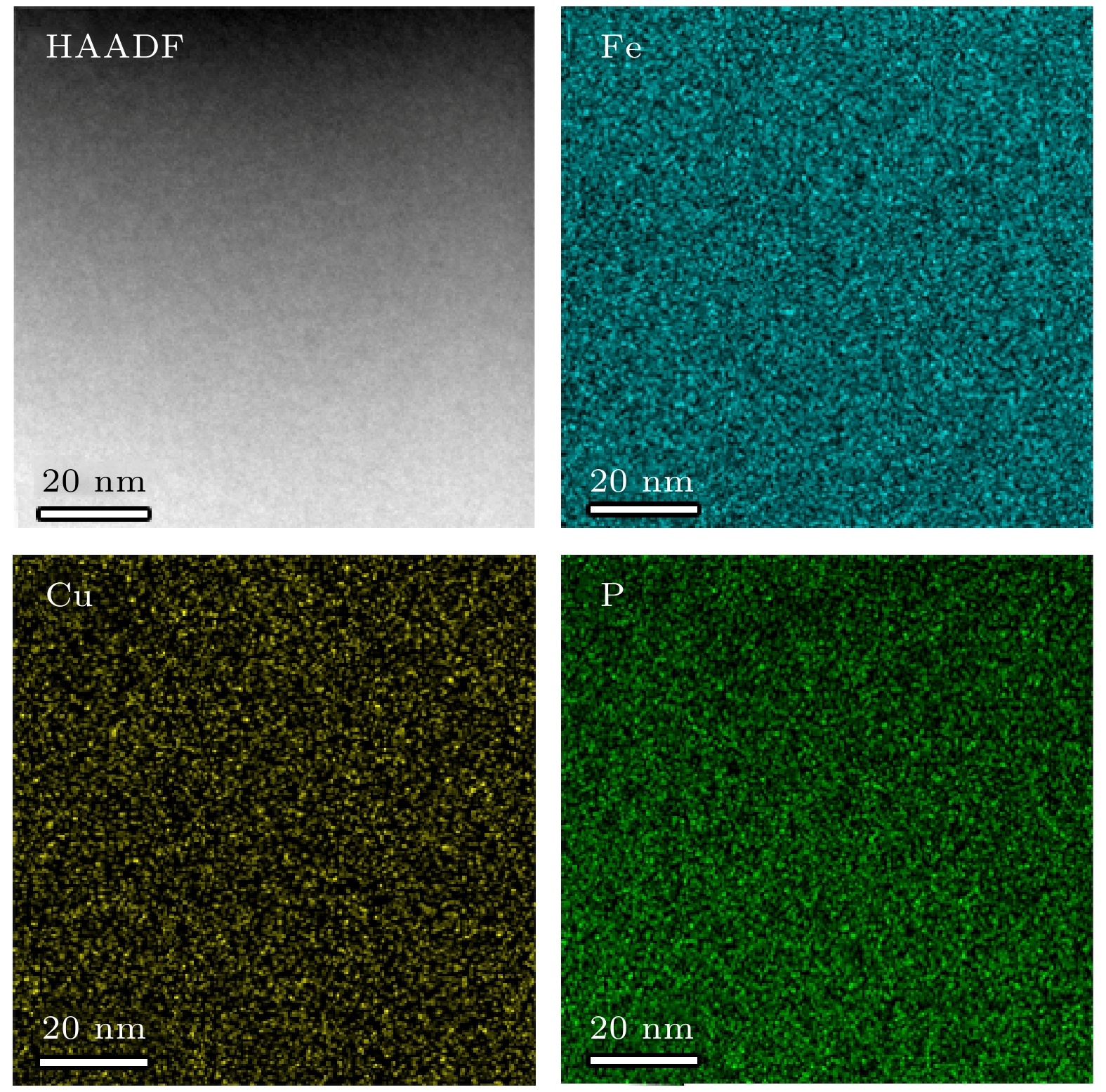

图 4 淬态Fe78.8P14–xBxC6Cu1.2非晶薄带的明场TEM图像 (a) x = 0; (b) (a)的局部放大图; (c) x = 7; (d) (c)的局部放大图. 插图分别为对应合金的SAED花样

Figure 4. Bright-field TEM images of as-quenched Fe78.8P14–xBxC6Cu1.2 amorphous ribbons: (a) x = 0, (b) locally enlarged image in (a); (c) x = 7; (d) locally enlarged image in (c). The insets correspond to the SAED patterns, respectively.

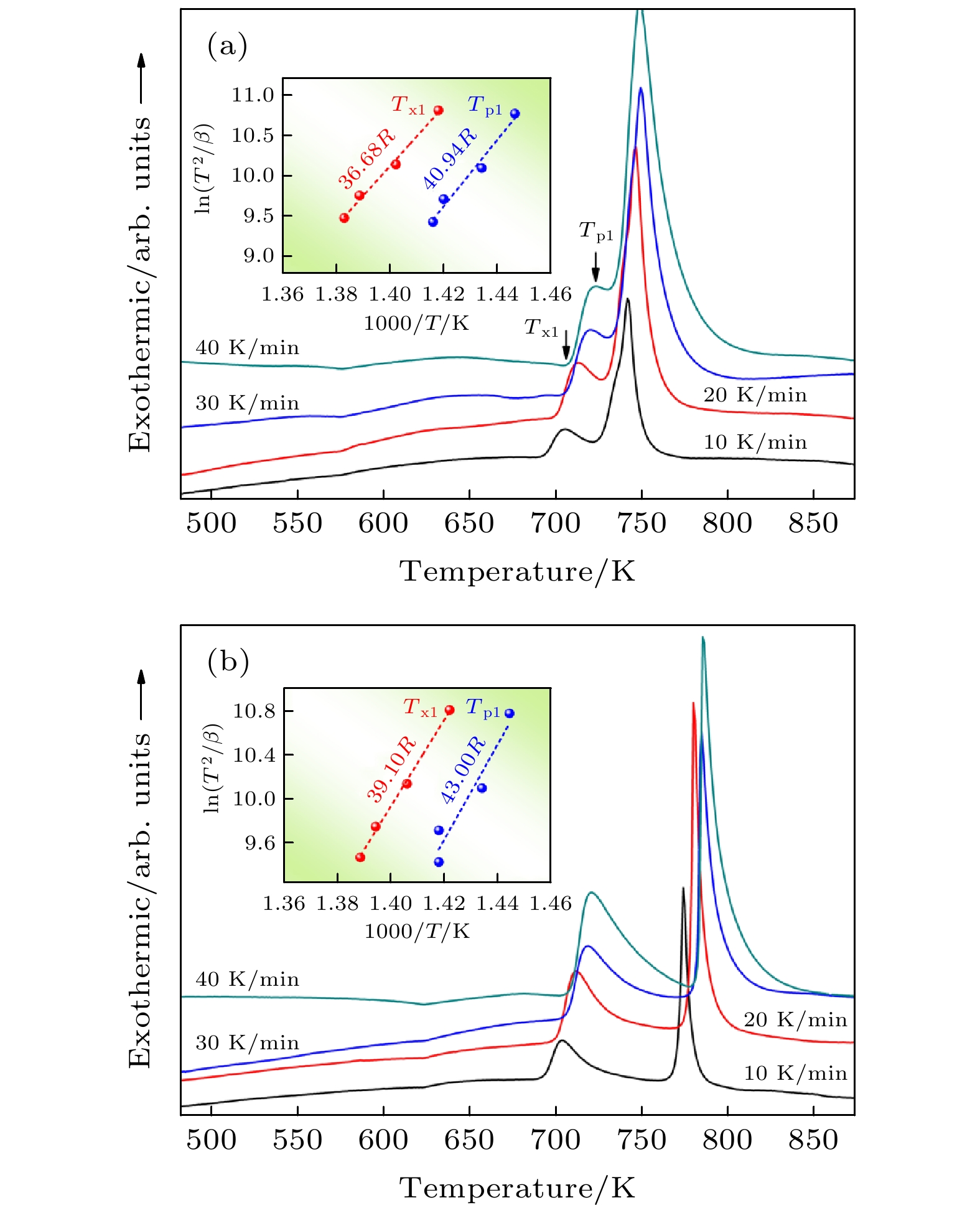

图 9 不同升温速率下的淬态Fe78.8P14–xBxC6Cu1.2 (x = 0, 7%)非晶薄带的DSC曲线 (a) x = 0; (b) x = 7. 插图分别为ln(T 2/β)与1000/T的线性关系

Figure 9. The DSC curves of as-quenched Fe78.8P14–xBxC6Cu1.2 (x = 0, 7%) amorphous ribbons under the different heating rates: (a) x = 0; (b) x = 7. The insets correspond to the relationship of ln(T 2/β) and 1000/T, respectively.

图 10 淬态Fe78.8P14–xBxC6Cu1.2 (x = 0, 7%)非晶薄带的磁滞回线, 插图(左上)为局部放大的磁滞回线, 插图(右下)为磁性Fe与类金属B, P原子间的电子杂化机制图示

Figure 10. Hysteresis loops of as-quenched Fe78.8P14–xBxC6Cu1.2 (x = 0, 7%) amorphous ribbons. The inset (top-left) is the locally enlarged hysteresis loops, and the inset (bottom-right) is the mechanism of electron hybridization between magnetic Fe and metalloid B, P atoms.

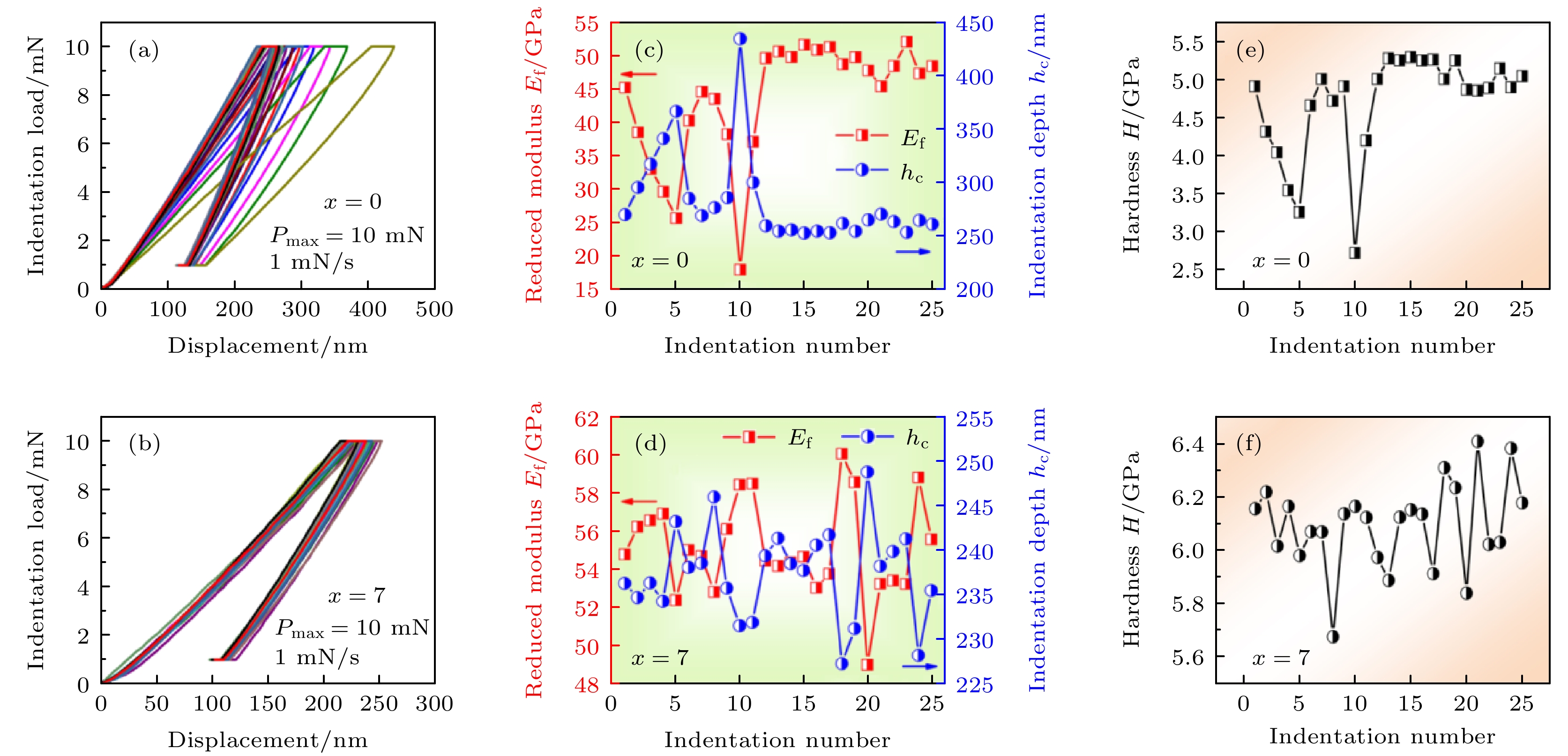

图 11 淬态Fe78.8P14–xBxC6Cu1.2 (x = 0, 7%)非晶薄带的纳米压痕实验 (a), (b) B0和B7合金的载荷-位移曲线; (c), (d) 合金的约化模量与压入深度值; (e), (f)合金的硬度变化值

Figure 11. The nanoindentation tests of as-quenched Fe78.8P14–xBxC6Cu1.2 (x = 0, 7%) amorphous ribbons: (a) , (b) The load-displacement curves of B0 and B7 alloys, respectively; (c), (d) the reduced modulus and indentation depth of alloys, respectively; (e), (f) the variations in hardness of alloys, respectively

-

[1] Inoue A, Shen B L, Chang C T 2004 Acta Mater. 52 4093

Google Scholar

Google Scholar

[2] Xu D D, Zhou B L, Wang Q Q, Zhou J, Yang W M, Yuan C C, Xue L, Fan X D, Ma L Q, Shen B L 2018 Corros. Sci. 138 20

Google Scholar

Google Scholar

[3] Li F C, Liu T, Zhang J Y, Shuang S, Wang Q, Wang A D, Wang J G, Yang Y 2019 Mater. Today Adv. 4 100027

Google Scholar

Google Scholar

[4] McHenry M E, Willard M A, Laughlin D E 1999 Prog. Mater. Sci. 44 291

Google Scholar

Google Scholar

[5] Wang A D, Zhao C L, He A N, Men H, Chang C T, Wang X M 2016 J. Alloy. Compd. 656 729

Google Scholar

Google Scholar

[6] 姚可夫, 施凌翔, 陈双琴, 邵洋, 陈娜, 贾蓟丽 2018 67 016101

Google Scholar

Google Scholar

Yao K F, Shi L X, Chen S Q, Shao Y, Chen N, Jia J L 2018 Acta Phys. Sin. 67 016101

Google Scholar

Google Scholar

[7] McHenry M E, Laughlin D E 2014 hysical Metallurgy (5th Ed.) (Elsevier) p1881

[8] Hou L, Fan X D, Wang Q Q, Yang W M, Shen B L 2019 J. Mater. Sci. Technol. 35 1655

Google Scholar

Google Scholar

[9] Meng S Y, Ling H B, Li Q, Zhang J 2014 Scr. Mater. 81 24

Google Scholar

Google Scholar

[10] Wang C J, He A N, Wang A D, Pang J, Ling X, Li Q, Chang C, Qiu K, Wang X 2017 Intermetallics 84 142

Google Scholar

Google Scholar

[11] Mizoguchi T 1976 AIP Conf. Proc. 34 286

[12] Xu J, Yang Y Z, Li W, Xie Z, Chen X 2017 Mater. Res. Bull. 97 452

[13] Shi L X, Qin X L, Yao K F 2020 Prog. Nat. Sci-Mater. 30 208

Google Scholar

Google Scholar

[14] Zuo M Q, Meng S Y, Li Q, Li H X, Chang C T, Sun Y F 2017 Intermetallics 83 83

Google Scholar

Google Scholar

[15] Jin Y L, Fan X D, He M, Liu X C, Shen B L 2012 Sci. China Technol. Sci. 55 3419

Google Scholar

Google Scholar

[16] Wang Q Q, Chen M X, Lin P H, Cui Z Q, Chu C L, Shen B L 2018 J. Mater. Chem. A 6 10686

Google Scholar

Google Scholar

[17] Wang Q Q, Yun L, Chen M X, Xu D D, Cui Z Q, Zeng Q S, Lin P H, Chu C L, Shen B L 2019 ACS Appl. Nano Mater. 2 214

Google Scholar

Google Scholar

[18] Jafari S, Beitollahi A, Eftekhari Yekta B, Ohkubo T, Budinsky V, Marsilius M, Herzer G, Hono K 2016 J. Alloy. Compd. 674 136

Google Scholar

Google Scholar

[19] Fan X D, Zhang T, Jiang M F, Yang W M, Shen B L 2019 J. Non-Cryst. Solid. 503 36

[20] Hou L, Yang W M, Luo Q, Fan X D, Liu H S, Shen B L 2020 J. Non-Cryst. Solid. 530 119800

Google Scholar

Google Scholar

[21] Li Y L, Dou Z X, Chen X M, Lv K, Li F S, Hui X D 2020 Mater. Sci. Eng. B 262 114740

Google Scholar

Google Scholar

[22] Hono K, Ping D H, Ohnuma M, Onodera H 1999 Acta Mater. 47 997

Google Scholar

Google Scholar

[23] Hu F, Yuan C C, Luo Q, Yang W M, Shen B L 2019 J. Alloy. Compd. 807 151675

Google Scholar

Google Scholar

[24] Ohnuma M, Ping D H, Abe T, Onodera H, Hono K, Yoshizawa Y 2003 J. Appl. Phys. 93 9186

Google Scholar

Google Scholar

[25] Yang W M, Li J W, Liu H S, Dun C C, Zhang H L, Huo J T, Xue L, Zhao Y C, Shen B L, Dou L M, Inoue A 2014 Intermetallics 49 52

Google Scholar

Google Scholar

[26] Lan S, Ren Y, Wei X Y, Wang B, Gilbert E P, Shibayama T, Watanabe S, Ohnuma M, Wang X L 2017 Nat. Commun. 8 14679

Google Scholar

Google Scholar

[27] Takeuchi A, Inoue A 2005 Mater. Trans. 46 2817

Google Scholar

Google Scholar

[28] 耿遥祥, 王英敏 2020 金属学报 56 1558

Google Scholar

Google Scholar

Geng Y X, Wang Y M 2020 Acta Metall. Sin. 56 1558

Google Scholar

Google Scholar

[29] Fan X D, Jiang M F, Zhang T, Hou L, Wang C X, Shen B L 2020 J. Non-Cryst. Solid. 533 119941

Google Scholar

Google Scholar

[30] Hou L, Li M R, Jiang C, Fan X D, Luo Q, Chen S S, Song P D, Li W H 2021 J. Alloy. Compd. 853 157071

Google Scholar

Google Scholar

[31] 严密, 彭晓领 2011 磁学基础与磁性材料 (杭州: 浙江大学出版社)

Yan M, Peng X L 2011 Fundamentals of Magnetism and Magnetic Materials (Hangzhou: Zhejiang University Press) (in Chinese)

[32] Zhang J H, Chang C T, Wang A D Shen B L 2012 J. Non-Crystal. Solids 358 1443

Google Scholar

Google Scholar

[33] Wang F, Inoue A, Han Y, Kong F L, Zhu S L, Shalaan E, Al-Marzouki F, Obaid A 2017 J. Alloy. Compd. 723 376

Google Scholar

Google Scholar

[34] Sun B R, Xin S W, Shen T D 2018 J. Mag. Magn. Mater. 466 130

Google Scholar

Google Scholar

[35] Sarac B, Ivanov Y P, Chuvilin A, Schoberl T, Stoica M, Zhang Z L, Eckert J 2018 Nat. Commun. 9 1333

Google Scholar

Google Scholar

[36] Liu Y H, Wang G, Wang R J, Zhao D Q, Pan, M X, Wang W H 2007 Science 315 1385

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 6792

- PDF Downloads: 116

- Cited By: 0

DownLoad:

DownLoad: