-

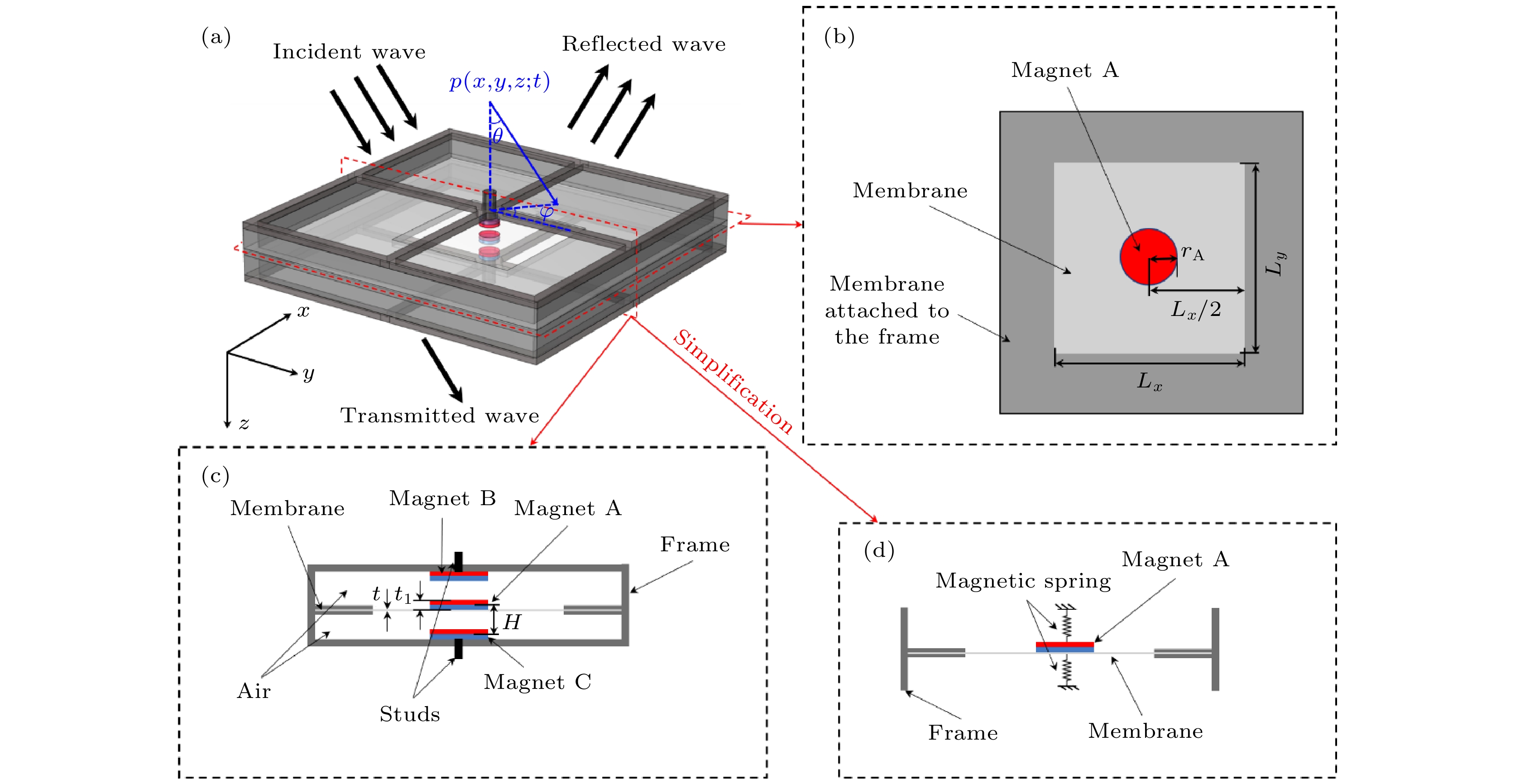

For improving the low-frequency sound insulation properties of membrane/plate structures, a new quasi-zero stiffness membrane acoustic metamaterial with dynamic magnetic negative stiffness is proposed. When the equivalent magnetic charge theory is used to investigate the dynamic magnetic negative stiffness, a theoretical model of proposed metamaterial with finite dimension is established based on the Galerkin method. Through a combination of theoretical analysis, numerical simulation and experimental measurement, the low-frequency (1–1000 Hz) sound insulation performance of the metamaterial is investigated from several perspectives, including structural modality, vibration mode, average velocity, phase curve, equivalent mass density, and equivalent spring-mass dynamics model. The results show that at a certain initial membrane tension, the decreasing of the magnetic gap or the increasing of the residual flux density can increase the dynamic magnetic negative stiffness. This in turn leads the peak frequency to decrease and the bandwidth of sound insulation to increase, thus achieving effective low-frequency sound insulation over a wide frequency band. Further, when the magnetic gap is larger than the second critical magnetic gap and smaller than the first critical magnetic gap, the first-order modal resonance of the metamaterial disappears, and the corresponding value of sound insulation valley increases significantly, thus demonstrating superior sound insulation effect in a wide frequency band. The proposed method of using dynamic magnetic negative stiffness to improve low-frequency sound insulation valleys due to modal resonance provides useful theoretical guidance for designing membrane/plate type low-frequency sound insulation metamaterials.

-

Keywords:

- membrane-type acoustic metamaterial /

- tunable acoustic insulation /

- magnetic negative stiffness /

- low frequency broadband

[1] Gao N S, Wu J G, Lu K, Zhong H B 2021 Mech. Syst. Sig. Process. 154 107504

Google Scholar

Google Scholar

[2] Kang Z X, Song R X, Zhang H J, Liu Q 2021 Appl. Acoust. 174 107785

Google Scholar

Google Scholar

[3] Ma G C, Sheng P 2016 Sci. Adv. 2 e1501595

Google Scholar

Google Scholar

[4] Mei J, Ma G C, Yang M, Yang Z Y, Wen W J, Sheng P 2012 Nat. Commun. 3 756

Google Scholar

Google Scholar

[5] Deng K, Ding Y Q, He Z J, Zhao H P, Shi J, Liu Z Y 2009 J. Appl. Phys. 105 124909

Google Scholar

Google Scholar

[6] Peng S S, He Z J, Jia H, Zhang A Q, Qiu C Y, Ke M Z, Liu Z Y 2010 Appl. Phys. Lett. 96 263502

Google Scholar

Google Scholar

[7] Zhu X F, Liang B, Kan W W, Zou X Y, Cheng J C 2011 Phys. Rev. Lett. 106 014301

Google Scholar

Google Scholar

[8] Liu Z Y, Zhang X, Mao Y, Zhu Y Y, Yang Z, Chan C T, Sheng P 2000 Science 289 1734

Google Scholar

Google Scholar

[9] Kushwaha M S, Halevi P, Dobrzynski L, Djafari-Rouhani B 1993 Phys. Rev. Lett. 71 2022

Google Scholar

Google Scholar

[10] Gao N, Qu S C, Li J, Wang J, Chen W Q 2021 Int. J. Mech. Sci. 208 106695

Google Scholar

Google Scholar

[11] Nguyen H, Wu Q, Xu X C, Chen H, Tracy S, Huang G L 2020 Appl. Phys. Lett. 117 134103

Google Scholar

Google Scholar

[12] Demelofilho N G R, Claeys C, Deckers E, Desmet W 2020 Mech. Syst. Sig. Process. 139 106624

Google Scholar

Google Scholar

[13] Xiao Y, Wen J H, Wen X S 2012 J. Sound Vib. 331 5408

Google Scholar

Google Scholar

[14] Yang J, Lee J S, Lee H R, Kang Y J 2018 Appl. Phys. Lett. 112 091901

Google Scholar

Google Scholar

[15] Zhao X Z, Liu G Q, Zhang C, Xia D, Lu Z M 2018 Appl. Phys. Lett. 113 074101

Google Scholar

Google Scholar

[16] Wang X N, Zhou Y D, Sang J Q, Zhu W Y 2020 Appl. Acoust. 158 107045

Google Scholar

Google Scholar

[17] Lin Q H, Lin Q L, Wang Y H, Di G Q 2021 Compos. Struct. 273 114312

Google Scholar

Google Scholar

[18] Wang X L, Zhao H, Luo X D, Huang Z Y 2016 Appl. Phys. Lett. 108 041905

Google Scholar

Google Scholar

[19] Langfeldt F, Riecken J, Gleine W, von Estorff O 2016 J. Sound Vib. 373 1

Google Scholar

Google Scholar

[20] Langfeldt F, Kemsies H, Gleine W, von Estorff O 2017 Phys. Lett. A 381 1457

Google Scholar

Google Scholar

[21] Li Y L, Zhang Y L, Xie S C 2020 Appl. Acoust. 168 107427

Google Scholar

Google Scholar

[22] Xu Q S, Qiao J, Sun J Y, Zhang G Y, Li L Q 2021 J. Sound Vib. 493 115823

Google Scholar

Google Scholar

[23] Yang Z Y, Mei J, Yang M, Chan N H, Sheng P 2008 Phys. Rev. Lett. 101 204301

Google Scholar

Google Scholar

[24] Lu Z B, Yu X, Lau S K, Khoo B C, Cui F S 2020 Appl. Acoust. 157 107003

Google Scholar

Google Scholar

[25] Li X Y, Zhao J J, Wang W J, Xing T, Zhu L Y, Liu Y N, Li X H 2022 Appl. Acoust. 187 108514

Google Scholar

Google Scholar

[26] 贺子厚, 赵静波, 姚宏, 陈鑫 2019 68 214302

Google Scholar

Google Scholar

He Z H, Zhao J B, Yao H, Chen X 2019 Acta Phys. Sin. 68 214302

Google Scholar

Google Scholar

[27] Naify C J, Chang C M, McKnight G, Nutt S 2011 J. Appl. Phys. 110 124903

Google Scholar

Google Scholar

[28] Tan X J, Wang B, Wang L C, Zhu S W, Chen S, Yao K L 2022 Compos. Struct. 286 115308

Google Scholar

Google Scholar

[29] Wang K, Zhou J X, Cai C Q, Xu D L, Ouyang H J 2019 Appl. Math. Modell. 73 581

Google Scholar

Google Scholar

[30] Yuan S J, Sun Y, Zhao J L, Meng K, Wang M, Pu H Y, Peng Y, Luo J, Xie S R 2020 J. Sound Vib. 482 115449

Google Scholar

Google Scholar

[31] 胥强荣, 沈承, 韩峰, 卢天健 2021 70 244302

Google Scholar

Google Scholar

Xu Q R, Shen C, Han F, Lu T J 2021 Acta Phys. Sin. 70 244302

Google Scholar

Google Scholar

[32] Allag H, Yonnet J P 2009 Ieee. Trans. Magn. 45 3969

Google Scholar

Google Scholar

[33] Oyelade A O, Chen Y, Zhang R J, Hu G K 2018 Int. J. Appl. Mech. 10 1850054

Google Scholar

Google Scholar

[34] Wu J S, Luo S S 1997 J. Sound Vib. 200 179

Google Scholar

Google Scholar

[35] 张光玉 2014 博士学位论文 (长沙: 国防科技大学)

Zhang G Y 2014 Ph. D. Dissertation (Changsha: National University of Defense Technology) (in Chinese)

[36] Meirovitch L 2001 Fundamentals of Vibrations (New York: McGraw-Hill Higher Education) pp529–530

[37] Lee J H, Kim J 2002 J. Sound Vib. 251 349

Google Scholar

Google Scholar

-

图 15 (a) 三种工况的传输损失对比(I: MAMM, II: QZSMAMM); (b) 三种工况的等效质量面密度对比(I: MAMM, II: QZSMAMM)

Figure 15. (a) Comparison of transmission loss curves among three working conditions (I: MAMM, II: QZSMAMM); (b) comparison of equivalent mass surface density curves among three working conditions (I: MAMM, II: QZSMAMM).

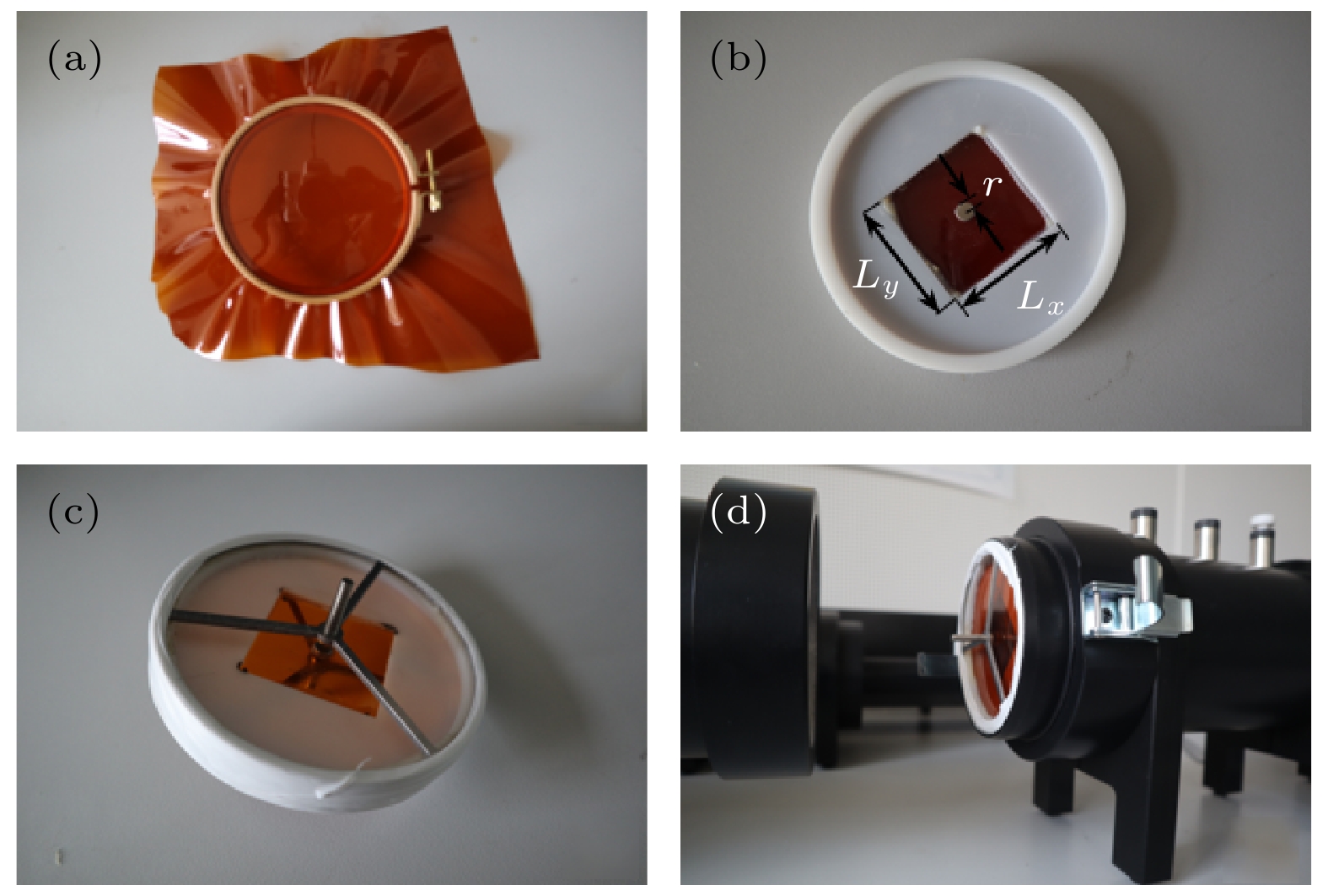

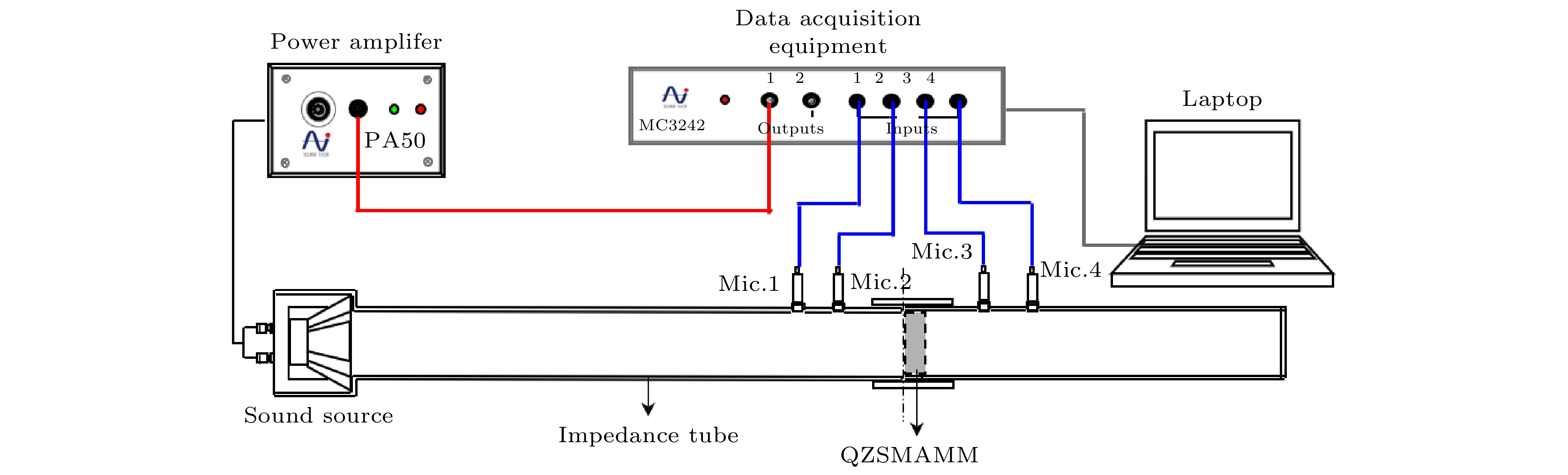

图 16 QZSMAMM单元的制备过程 (a) 施加薄膜张力; (b) 将中心贴敷有磁铁的张力薄膜粘接于支撑框架; (c) 添加外围磁铁; (d) 将样件置于阻抗管

Figure 16. Schematic of the preparation process of QZSMAMM unit: (a) Applying membrane tension; (b) tension membrane with a magnet applied to the center is bonded to the support frame; (c) adding peripheral magnets; (d) test sample positioned in impedance tube.

表 1 QZSMAMM单元几何参数和材料参数

Table 1. Geometric and material parameters of QZSMAMM unit.

Lx

/mmLy

/mmlx

/mmly

/mmt/mm t1/mm Br

/TT

/(N·m–1)${\rho _{{\text{mem}}}}$

/(kg·m–2)${\rho _{{\text{mag}}}}$/(kg·m–2) 40 40 5.32 5.32 0.2 2.0 1.0 500 0.24 15.6 表 2 理论和数值模拟的峰/谷频率

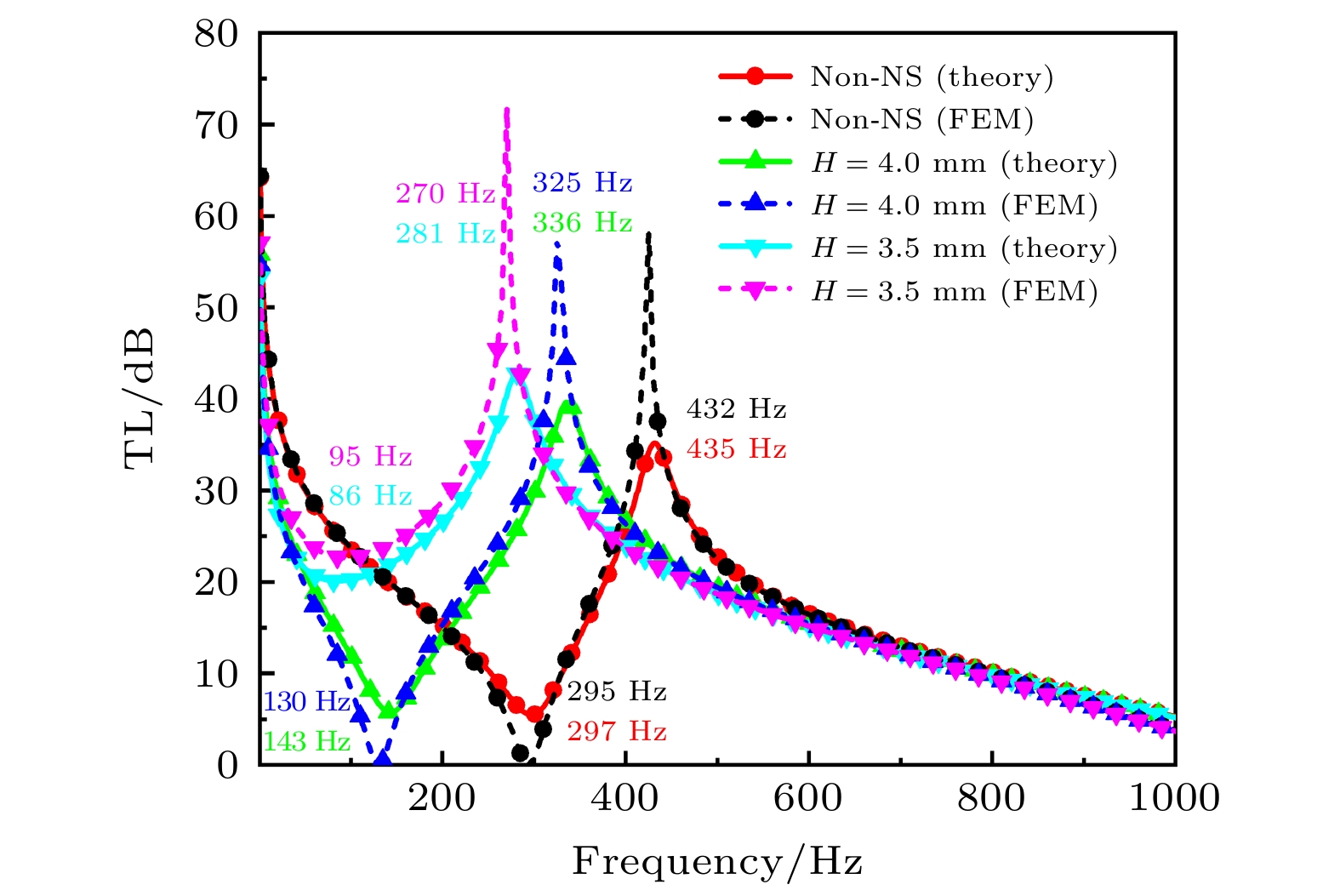

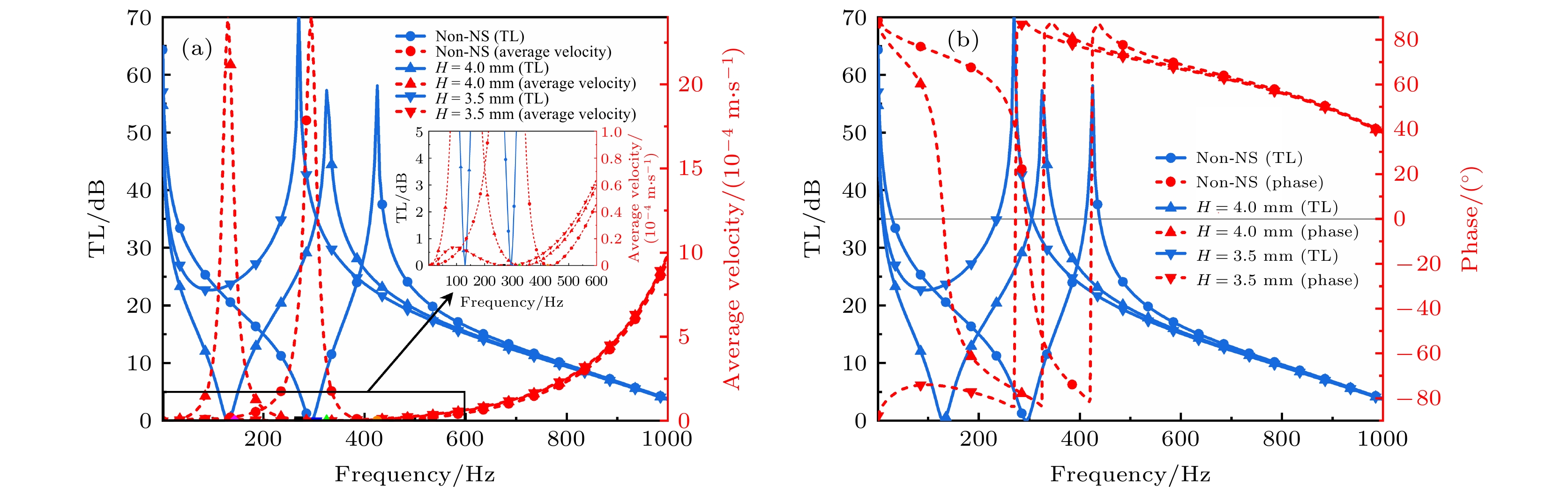

Table 2. Theoretical and numerical results for peak/valley frequencies.

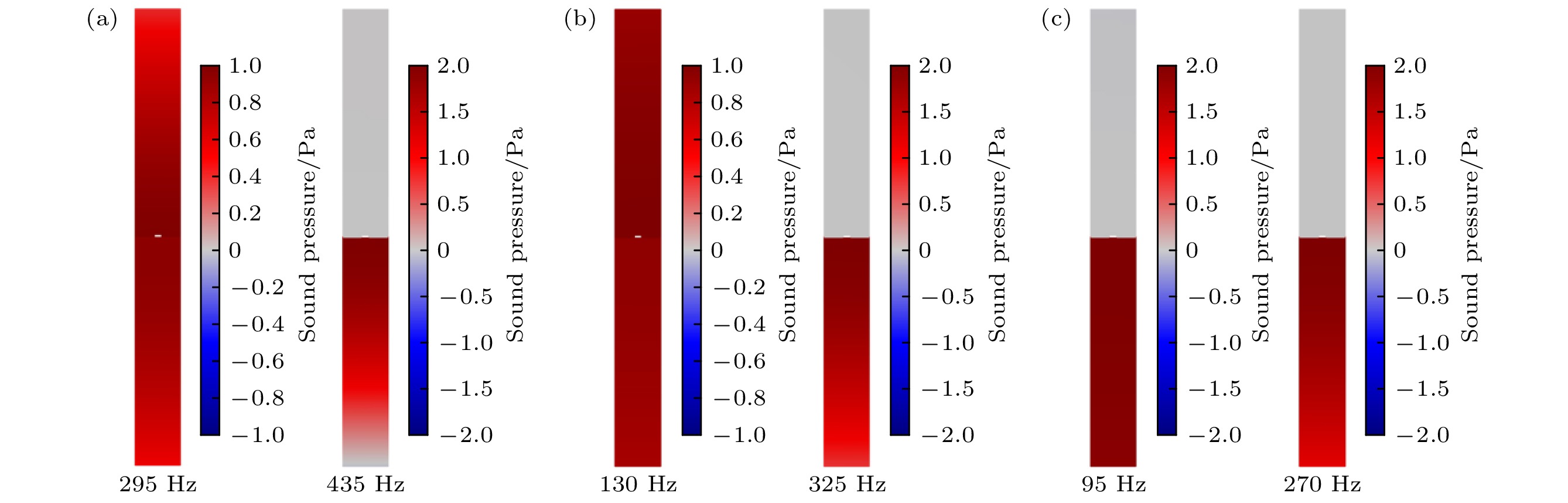

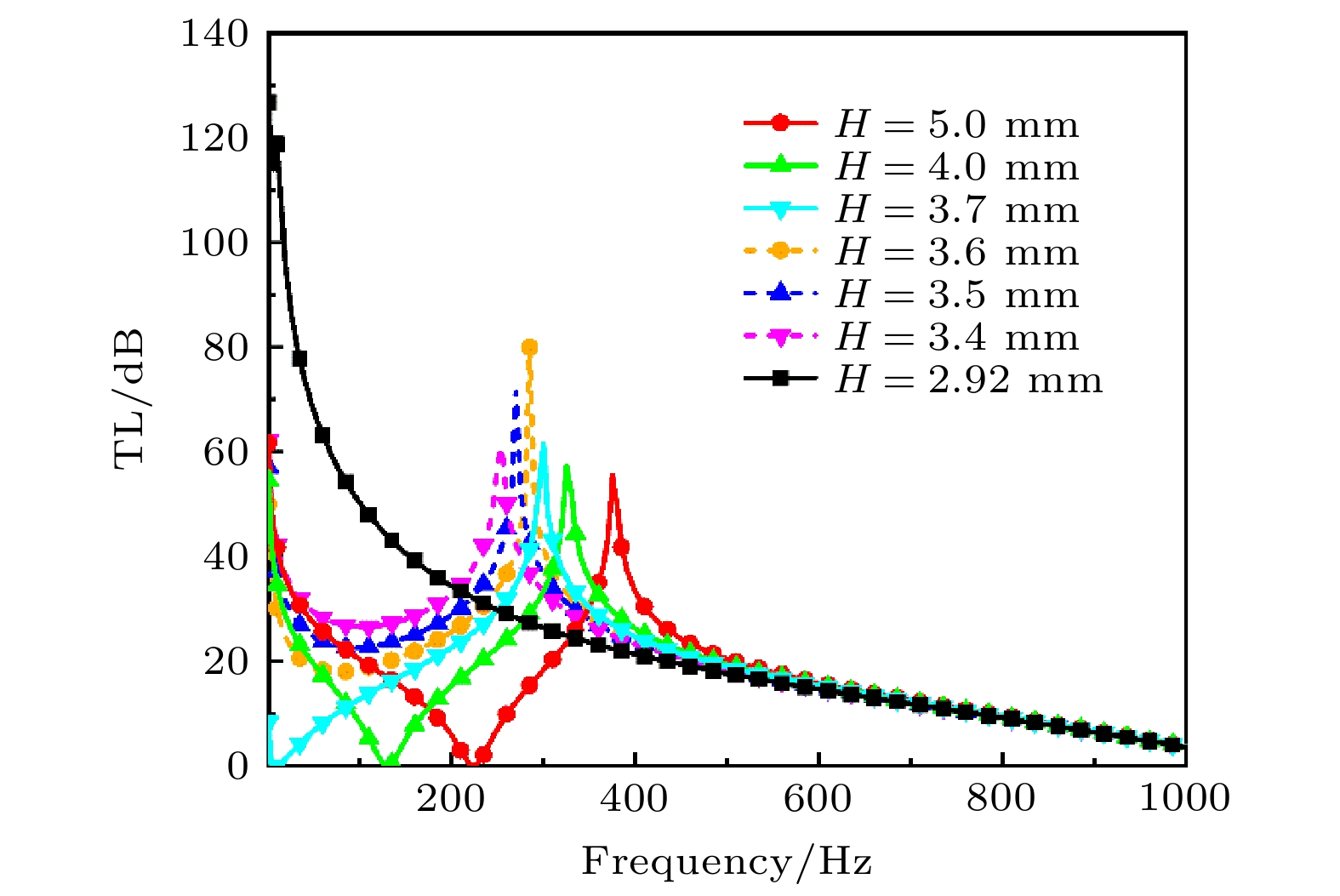

Peak/valley frequency/Hz Non-NS Br = 1.0 T, H = 4.0 mm Br = 1.0 T, H = 3.5 mm Theory 435/297 336/143 281/86 FEM 432/295 325/130 270/95 表 3 三种不同工况的结构参数和目标频率

Table 3. Structural parameters and target frequencies for three different operating conditions.

Configuration T/(N·m–1) Kmag/(N·m–1) f/Hz A I 400 0 386 II 500 –670 386 B I 200 0 274 II 400 –1300 274 C I 50 0 138 II 200 –970 138 表 4 实验样件的相关材料参数

Table 4. Material parameters of experimental samples.

Density/

(kg·m–3)Young’s

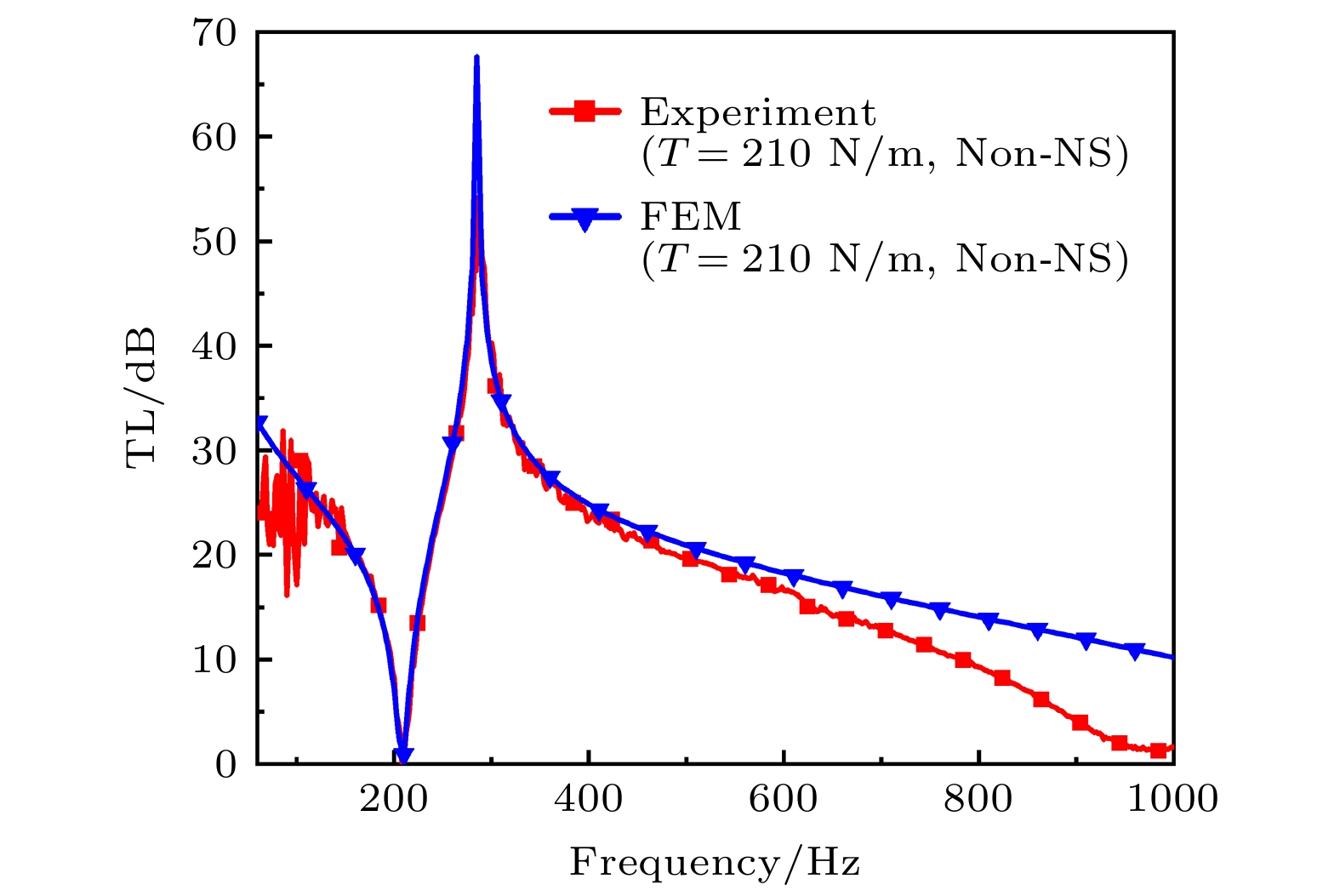

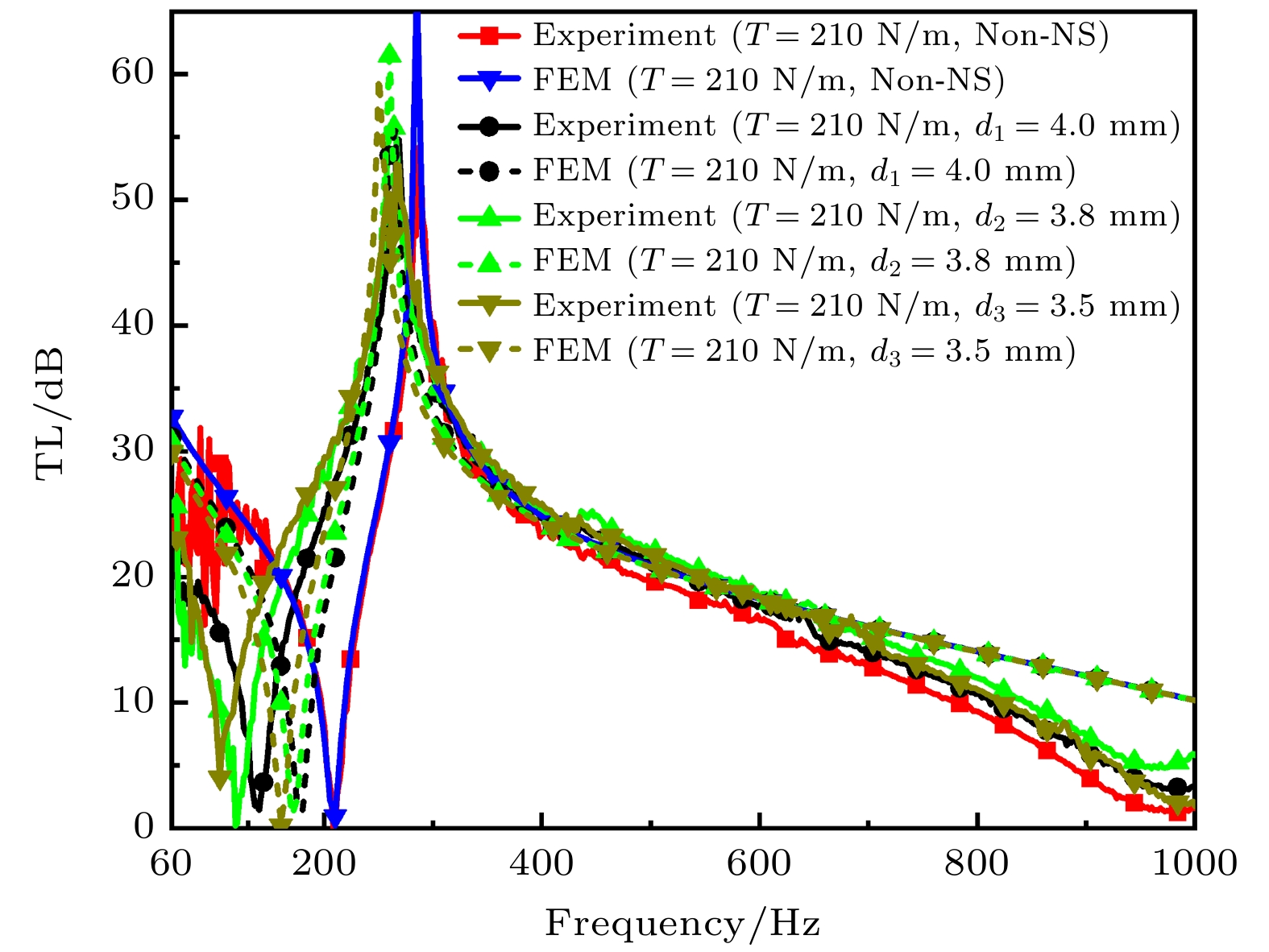

modulus/GPaPoisson ratio Membrane 1200 1.8 0.38 Magnets 7594 200 0.29 Epoxy resin 1150 4.35 0.38 表 5 实验和数值模拟的峰/谷频率

Table 5. Experimentally measured and numerically predicted peak/valley frequencies.

Peak/valley frequency/Hz T = 210 N/m T = 210 N/m T = 210 N/m T = 210 N/m d1 = 4.0 mm d2 = 3.8 mm d3 = 3.5 mm Experiment 286/208 268/140 262/118 259/104 FEM 286/211 264/178 259/167 251/158 -

[1] Gao N S, Wu J G, Lu K, Zhong H B 2021 Mech. Syst. Sig. Process. 154 107504

Google Scholar

Google Scholar

[2] Kang Z X, Song R X, Zhang H J, Liu Q 2021 Appl. Acoust. 174 107785

Google Scholar

Google Scholar

[3] Ma G C, Sheng P 2016 Sci. Adv. 2 e1501595

Google Scholar

Google Scholar

[4] Mei J, Ma G C, Yang M, Yang Z Y, Wen W J, Sheng P 2012 Nat. Commun. 3 756

Google Scholar

Google Scholar

[5] Deng K, Ding Y Q, He Z J, Zhao H P, Shi J, Liu Z Y 2009 J. Appl. Phys. 105 124909

Google Scholar

Google Scholar

[6] Peng S S, He Z J, Jia H, Zhang A Q, Qiu C Y, Ke M Z, Liu Z Y 2010 Appl. Phys. Lett. 96 263502

Google Scholar

Google Scholar

[7] Zhu X F, Liang B, Kan W W, Zou X Y, Cheng J C 2011 Phys. Rev. Lett. 106 014301

Google Scholar

Google Scholar

[8] Liu Z Y, Zhang X, Mao Y, Zhu Y Y, Yang Z, Chan C T, Sheng P 2000 Science 289 1734

Google Scholar

Google Scholar

[9] Kushwaha M S, Halevi P, Dobrzynski L, Djafari-Rouhani B 1993 Phys. Rev. Lett. 71 2022

Google Scholar

Google Scholar

[10] Gao N, Qu S C, Li J, Wang J, Chen W Q 2021 Int. J. Mech. Sci. 208 106695

Google Scholar

Google Scholar

[11] Nguyen H, Wu Q, Xu X C, Chen H, Tracy S, Huang G L 2020 Appl. Phys. Lett. 117 134103

Google Scholar

Google Scholar

[12] Demelofilho N G R, Claeys C, Deckers E, Desmet W 2020 Mech. Syst. Sig. Process. 139 106624

Google Scholar

Google Scholar

[13] Xiao Y, Wen J H, Wen X S 2012 J. Sound Vib. 331 5408

Google Scholar

Google Scholar

[14] Yang J, Lee J S, Lee H R, Kang Y J 2018 Appl. Phys. Lett. 112 091901

Google Scholar

Google Scholar

[15] Zhao X Z, Liu G Q, Zhang C, Xia D, Lu Z M 2018 Appl. Phys. Lett. 113 074101

Google Scholar

Google Scholar

[16] Wang X N, Zhou Y D, Sang J Q, Zhu W Y 2020 Appl. Acoust. 158 107045

Google Scholar

Google Scholar

[17] Lin Q H, Lin Q L, Wang Y H, Di G Q 2021 Compos. Struct. 273 114312

Google Scholar

Google Scholar

[18] Wang X L, Zhao H, Luo X D, Huang Z Y 2016 Appl. Phys. Lett. 108 041905

Google Scholar

Google Scholar

[19] Langfeldt F, Riecken J, Gleine W, von Estorff O 2016 J. Sound Vib. 373 1

Google Scholar

Google Scholar

[20] Langfeldt F, Kemsies H, Gleine W, von Estorff O 2017 Phys. Lett. A 381 1457

Google Scholar

Google Scholar

[21] Li Y L, Zhang Y L, Xie S C 2020 Appl. Acoust. 168 107427

Google Scholar

Google Scholar

[22] Xu Q S, Qiao J, Sun J Y, Zhang G Y, Li L Q 2021 J. Sound Vib. 493 115823

Google Scholar

Google Scholar

[23] Yang Z Y, Mei J, Yang M, Chan N H, Sheng P 2008 Phys. Rev. Lett. 101 204301

Google Scholar

Google Scholar

[24] Lu Z B, Yu X, Lau S K, Khoo B C, Cui F S 2020 Appl. Acoust. 157 107003

Google Scholar

Google Scholar

[25] Li X Y, Zhao J J, Wang W J, Xing T, Zhu L Y, Liu Y N, Li X H 2022 Appl. Acoust. 187 108514

Google Scholar

Google Scholar

[26] 贺子厚, 赵静波, 姚宏, 陈鑫 2019 68 214302

Google Scholar

Google Scholar

He Z H, Zhao J B, Yao H, Chen X 2019 Acta Phys. Sin. 68 214302

Google Scholar

Google Scholar

[27] Naify C J, Chang C M, McKnight G, Nutt S 2011 J. Appl. Phys. 110 124903

Google Scholar

Google Scholar

[28] Tan X J, Wang B, Wang L C, Zhu S W, Chen S, Yao K L 2022 Compos. Struct. 286 115308

Google Scholar

Google Scholar

[29] Wang K, Zhou J X, Cai C Q, Xu D L, Ouyang H J 2019 Appl. Math. Modell. 73 581

Google Scholar

Google Scholar

[30] Yuan S J, Sun Y, Zhao J L, Meng K, Wang M, Pu H Y, Peng Y, Luo J, Xie S R 2020 J. Sound Vib. 482 115449

Google Scholar

Google Scholar

[31] 胥强荣, 沈承, 韩峰, 卢天健 2021 70 244302

Google Scholar

Google Scholar

Xu Q R, Shen C, Han F, Lu T J 2021 Acta Phys. Sin. 70 244302

Google Scholar

Google Scholar

[32] Allag H, Yonnet J P 2009 Ieee. Trans. Magn. 45 3969

Google Scholar

Google Scholar

[33] Oyelade A O, Chen Y, Zhang R J, Hu G K 2018 Int. J. Appl. Mech. 10 1850054

Google Scholar

Google Scholar

[34] Wu J S, Luo S S 1997 J. Sound Vib. 200 179

Google Scholar

Google Scholar

[35] 张光玉 2014 博士学位论文 (长沙: 国防科技大学)

Zhang G Y 2014 Ph. D. Dissertation (Changsha: National University of Defense Technology) (in Chinese)

[36] Meirovitch L 2001 Fundamentals of Vibrations (New York: McGraw-Hill Higher Education) pp529–530

[37] Lee J H, Kim J 2002 J. Sound Vib. 251 349

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 7701

- PDF Downloads: 166

- Cited By: 0

DownLoad:

DownLoad: