-

Photochromic material, as an adaptive smart material, has a wide range of applications in smart windows, photoelectric sensors, optical storage, etc. Oxygen-containing rare-earth metal hydride (REHxOy) film, a new type of photochromic material, has attracted the attention of researchers for its efficient and reversible color-changing properties, simple and reproducible preparation methods, and fast darkening-bleaching time. In this paper we review the current research status of structural composition, color change mechanism, and property modulation of oxygen-containing rare-earth metal hydride films. Exposure to visible light and ultraviolet (UV) light can lead the optical transmission of visible and infrared (IR) light to degrade. The photochromic mechanisms can be grouped into four mechanisms: lattice contraction mechanism, oxygen exchange mechanism, local metal phase change, and hydrogen migration mechanism. Currently, performance can be tuned by controlling film morphology, designing chemical components, improving substrate adaptation, multilayer film structure design, etc. Finally, the future research focus of thin film is prospected.

-

Keywords:

- photochromic materials /

- REHxOy thin film /

- structural composition /

- mechanism /

- property modulation

[1] Ke Y, Chen J, Lin G, Wang S, Zhou Y, Yin J, Pooi S L, Long Y 2019 Adv. Energy Mater. 9 1902066

Google Scholar

Google Scholar

[2] Ma Y, Yu Y, She P, Lu J, Liu S, Huang W, Zhao Q 2020 Sci. Adv. 6 2386

Google Scholar

Google Scholar

[3] Barachevsky V A, Strokach Y P, Krayushkin M M 2007 J. Phys. Org. Chem. 20 1007

Google Scholar

Google Scholar

[4] Qin M, Huang Y, Li F, Song Y 2015 J. Mater. Chem. C 3 9265

Google Scholar

Google Scholar

[5] Gavrilyuk A I 2013 Appl. Surf. Sci. 273 735

Google Scholar

Google Scholar

[6] Eglitis R, Zukuls A, Viter R 2020 Photochem. Photobiol. Sci. 19 1072

Google Scholar

Google Scholar

[7] Zhu Y, Yao Y, Chen, Zhang Z, Zhang P, Cheng Z, Gao Y 2022 Sol. Energy Mater. Sol. Cells 239 111664

Google Scholar

Google Scholar

[8] Tang W 2022 Chem. Eng. J. 435 134670

Google Scholar

Google Scholar

[9] Huiberts J N, Griessen R, Rector J H, Wijngaarden R J, Dekker J P 1996 Nature 380 231

Google Scholar

Google Scholar

[10] Hoekstra A F T, Roy A S, Rosenbaum T F, Griessen R 2001 Phys. Rev. Lett. 86 5349

Google Scholar

Google Scholar

[11] Ngene P, Longo A, Moojj L 2017 Nat. Commun. 8 1846

Google Scholar

Google Scholar

[12] Ohumura A, Machida A, Watanuki T 2007 Appl. Phys. Lett. 91 151904

Google Scholar

Google Scholar

[13] Mongstad T, Platzer-Bjorkman C, Maehlen J, Lennard P A M, Yevheniy P, Dam B, Marstein E, Karazhanov S Z 2011 Sol. Energy Mater. Sol. Cells 95 3596

Google Scholar

Google Scholar

[14] Nafezarefi F, Schreuders H, Dam B 2017 Appl. Phys. Lett. 111 103903

Google Scholar

Google Scholar

[15] Colombi G, Dekrom T, Chaykina D 2021 ACS Photonics 8 709

Google Scholar

Google Scholar

[16] Baba E M, Montero J, Moldarev D, Moro M V, Wolff M, Primetzhofer D, Sartori S, Zayim E, Karazhanov S Z 2020 Molecules 25 3181

Google Scholar

Google Scholar

[17] Moldarev D, Moro M V, You C C, Elbruz M B, Karazhanov S Z 2018 Phys. Rev. Mater. 2 115203

Google Scholar

Google Scholar

[18] Chai J, Shao Z, Wang H, Ming C, Oh W, Ye T, Zhang Y, Cao X, Ping Jin, Sun Y 2020 Sci. China Mater. 63 1579

Google Scholar

Google Scholar

[19] Colombi G, Cornelius S, Longo A 2020 J. Phys. Chem. C 124 13541

Google Scholar

Google Scholar

[20] Pishtshev A, Strougovshchikov E, Karazhanov S 2019 Cryst. Growth Des. 19 2574

Google Scholar

Google Scholar

[21] Chaykin D, Nafezarefi F, Colombi G, Cornelius S, Lars J 2022 J. Phys. Chem. C 126 2276

Google Scholar

Google Scholar

[22] Montero J, Martinsen F A, Lelis M, Karazhanov S Z, Hauback B C, Marstein E S 2018 Sol. Energy Mater. Sol. Cells 177 106

[23] Pishtshev A, Karazhanov S Z 2014 Solid State Commun. 194 39

Google Scholar

Google Scholar

[24] You C C, Moldarev D, Mongstada T, Primetzhofer D, Wolffb M, Marsteina E S, Karazhanov S Z 2017 Sol. Energy Mater. Sol. Cells. 166 185

Google Scholar

Google Scholar

[25] You C C, Mongstad T, Marstein E S, Karazhanov S Z 2019 Materialia 6 100307

Google Scholar

Google Scholar

[26] Kantre K, Moro M V, Moldarev D 2020 Scr. Mater. 186 352

Google Scholar

Google Scholar

[27] Mongstad T, Subrahmanyam A, Karazhanov S 2014 Sol. Energy Mater. Sol. Cells 128 270

Google Scholar

Google Scholar

[28] Komatsu Y, Sato R, Wilde M, Nishio K, Katase T, Matsumura D, Saitoh H, Miyauchi M, Adelman J R, McFadden R M L, MacFarlane W A, Sugiyama J, Komatsu T H Y 2022 Chem. Mater. 34 3616

Google Scholar

Google Scholar

[29] Montero J, Galeckas A, Karazhanov S Z 2018 Phys. Status Solidi B 255 1800139

Google Scholar

Google Scholar

[30] You C C, Karazhanov S Z 2020 J. Appl. Phys. 128 013106

Google Scholar

Google Scholar

[31] Shao Z, Cao X, Zhang Q, Long S, Chang T, Xu F, Jin P. 2019 Sol. Energy Mater. Sol. Cells 200 110044

Google Scholar

Google Scholar

[32] Moro M V 2019 Sol. Energy Mater. Sol. Cells 201 110119

Google Scholar

Google Scholar

[33] Baba E M, Weiser P M, Karazhanov S 2021 Phys. Status Solidi RRL Rapid Res. Lett. 15 2000459

Google Scholar

Google Scholar

[34] Zhang Q, Xie L, Zhu Y, Tao Y, Li R, Xua J, Bao S, Jin P 2019 Sol. Energy Mater. Sol. Cells 20 109930

[35] Dam B, Remhof A, Heijna M C R, Rector J H, Borsa D, Kerssemakers J W J 2003 J. Alloys Compd. 356–357 526

Google Scholar

Google Scholar

[36] 田民波, 李正操 2011 薄膜技术与薄膜材料 (北京: 清华大学出版社) 第251页

Tian M B, Li Z C 2011 Thin Film Technology and Thin-Film Materials (Beijing: Tsinghua University Press) p251 (in Chinese)

[37] Maehlen J P, Mongstad T T, You C C, Karazhanov S 2013 J. Alloys Compd. 580 119

Google Scholar

Google Scholar

[38] Plokkera M P, Eijta S W H, Nazirisa F, Schutb H, Nafezarefic F, Schreudersc H, Corneliusc S, Dam B 2018 Sol. Energy Mater. Sol. Cells 177 97

Google Scholar

Google Scholar

[39] Eijta S W H, Kroma T W H, Chaykinab D, Schuta H, Colombib G, Eggerc W, Dickmannc M, Hugenschmidtd C, Dam B 2020 Acta Phys. Pol. A 137 205

Google Scholar

Google Scholar

[40] Montero J, Martinsen F A, García-Tecedor M, Karazhanov S Z, Maestre D, Hauback B, Marstein E S 2017 Phys. Rev. B 95 201301

Google Scholar

Google Scholar

[41] Baba E M, Montero J, Strugovshchikov E, Zayim E, Karazhanov S 2020 Phys. Rev. Mater. 4 025201

Google Scholar

Google Scholar

[42] Moldarev D, Stolz L, Marcos V 2021 Phys. Status Solidi RRL Rapid Res. Lett. 15 2000608

Google Scholar

Google Scholar

[43] Moldarev D, Stolz L, Moro M V, Aðalsteinsson S M, Chioar I A, Karazhanov S Z, Primetzhofer D, Wolff M 2021 J. Appl. Phys. 129 153101

Google Scholar

Google Scholar

[44] Hans M, Tran T T, Aðalsteinsson S M, Moldarev D, Moro M V, Wolff M, Primetzhofer D 2020 Adv. Opt. Mater. 8 2000822

Google Scholar

Google Scholar

[45] Chandran C V, Schreuders H, Dam B, Janssen J W G, Bart J, Kentgens A P M 2014 J. Phys. Chem. C 118 22935

Google Scholar

Google Scholar

[46] Nafezarefi F, Cornelius S, Dam B 2019 Sol. Energy Mater. Sol. Cells 200 109923

Google Scholar

Google Scholar

[47] Moldarev D, Wolff M, Baba E M, Moro M V, You C C, Primetzhofer D, Karazhanov S Z 2020 Materialia 11 100706

Google Scholar

Google Scholar

[48] Mayer M, Eckstein W, Langhuth H, Schiettekatte F, Toussaint U 2011 Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 269 3006

Google Scholar

Google Scholar

[49] 陈赟斐, 魏峰, 王赫, 赵未昀, 邓元 2021 70 207303

Google Scholar

Google Scholar

Chen Y F, Wei F, Wang H, Zhao W H, Deng Y 2021 Acta Phys. Sin. 70 207303

Google Scholar

Google Scholar

[50] Chen J K, Mao W, Ge B, Wang J, Ke X Y, Wang V, Wang Y P, Döbeli M, Geng W T, Matsuzaki H, Shi J, Jiang Y 2019 Nat. Commun. 10 694

Google Scholar

Google Scholar

[51] 白刚, 韩宇航, 高存法 2022 71 097701

Google Scholar

Google Scholar

Bai G, Han Y H, Gao C F 2022 Acta Phys. Sin. 71 097701

Google Scholar

Google Scholar

[52] You C C, Mongstad T, Maehlen J P 2015 Sol. Energy Mater. Sol. Cells 143 623

Google Scholar

Google Scholar

[53] You C C, Mongstad T, Maehlen J P, Karazhanov S 2014 Appl. Phys. Lett. 105 031910

Google Scholar

Google Scholar

[54] Moldarev D, Primetzhofer D, You C C, Karazhanov S Z, Montero J, Martinsen F, Mongstad T, Marstein E S, Wolff M 2018 Sol. Energy Mater. Sol. Cells 177 66

Google Scholar

Google Scholar

[55] Strugovshchikov E, Pishtshev A, Karazhanov S 2021 Phys. Status Solidi B 258 2100179

Google Scholar

Google Scholar

[56] 拉毛, 包山虎, 莎仁 2018 化学学报 77 90

Google Scholar

Google Scholar

La M, Bao S H, Sha R 2018 Acta Chim. Sin. 77 90

Google Scholar

Google Scholar

-

图 3 氧浓度对薄膜带隙的影响 (a)梯度氧含量制备样品; (b)横向尺度上O/Y化学计量比; (c)横向尺度上带隙变化[24]

Figure 3. Effect of oxygen concentration on the band gap of thin films: (a) Samples prepared with gradient oxygen content; (b) the O/Y stoichiometric ratio in the horizontal direction; (c) the band gap variation in the horizontal direction[24].

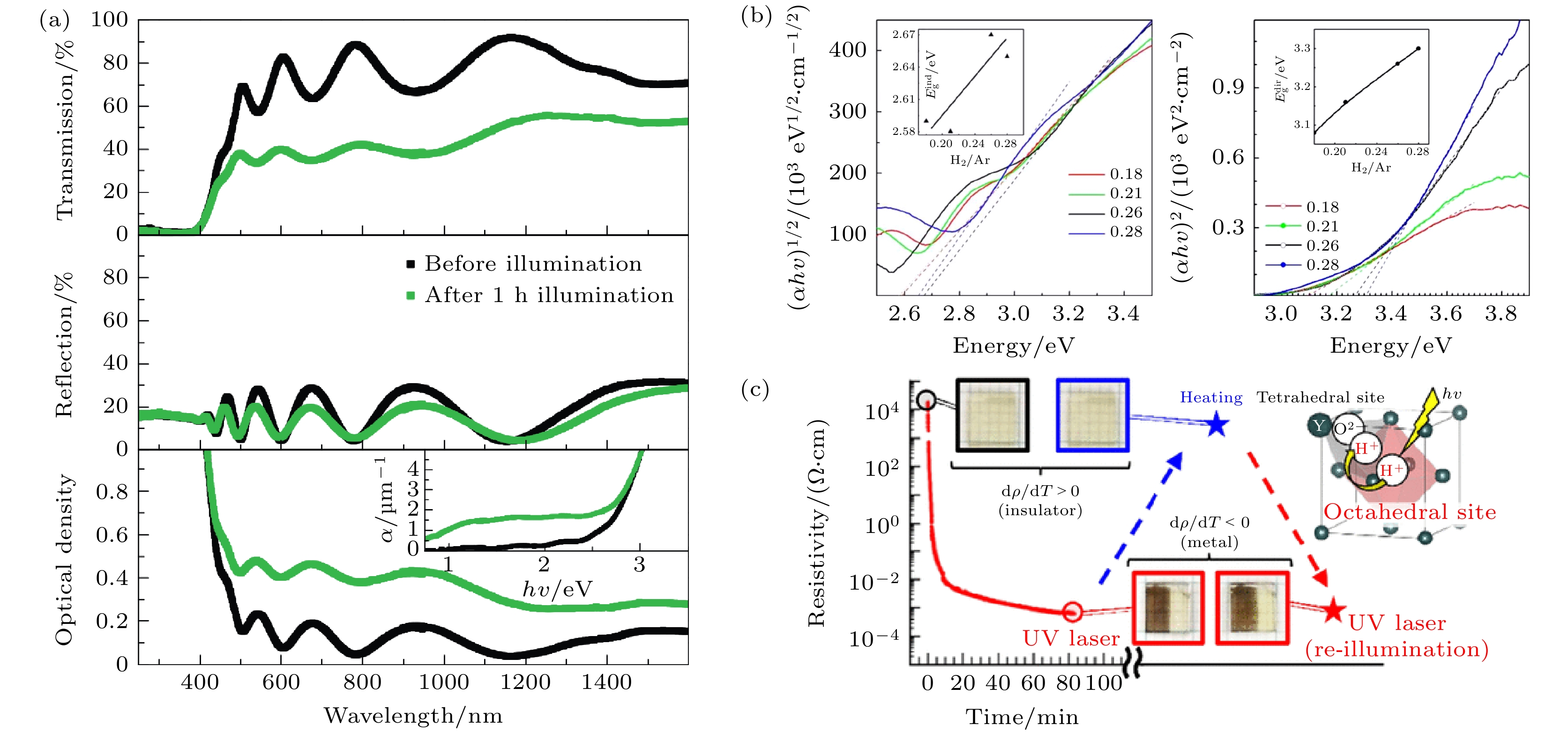

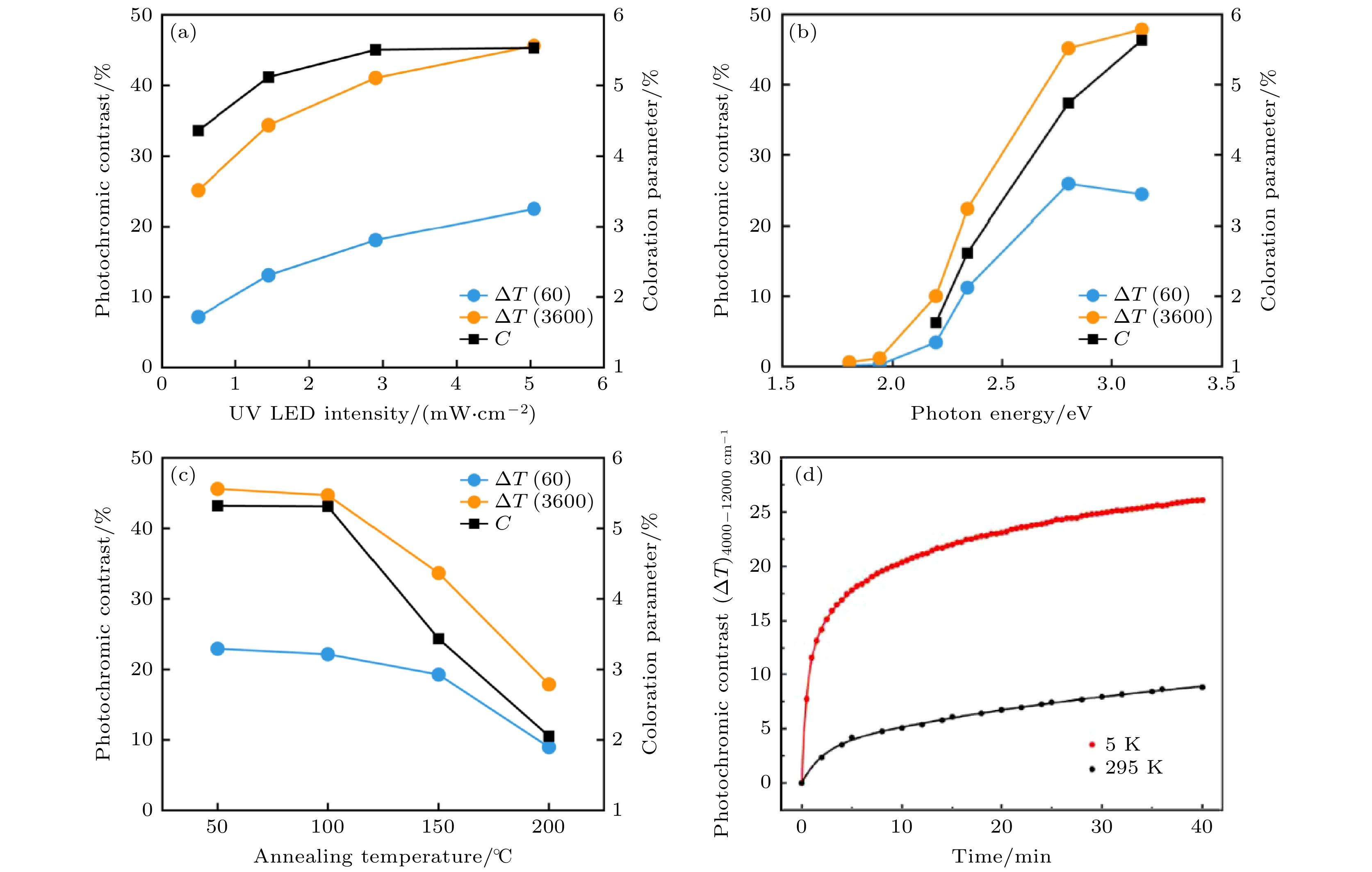

图 4 YHxOy薄膜光学性能和电学性能 (a)光照前后样品透过率、反射率和光学密度的变化[13]; (b) Tauc-plot法计算样品直接带隙与间接带隙[29]; (c)光照前后样品的电阻变化[28]

Figure 4. Optical and electrical properties of YHxOy films: (a) The changes in transmission, reflection, and optical density of YHxOy films before and after light exposure[13]; (b) the direct and indirect bandgap of YHxOy films[29]; (c) the changes in resistivity of YHxOy films under light induction[28].

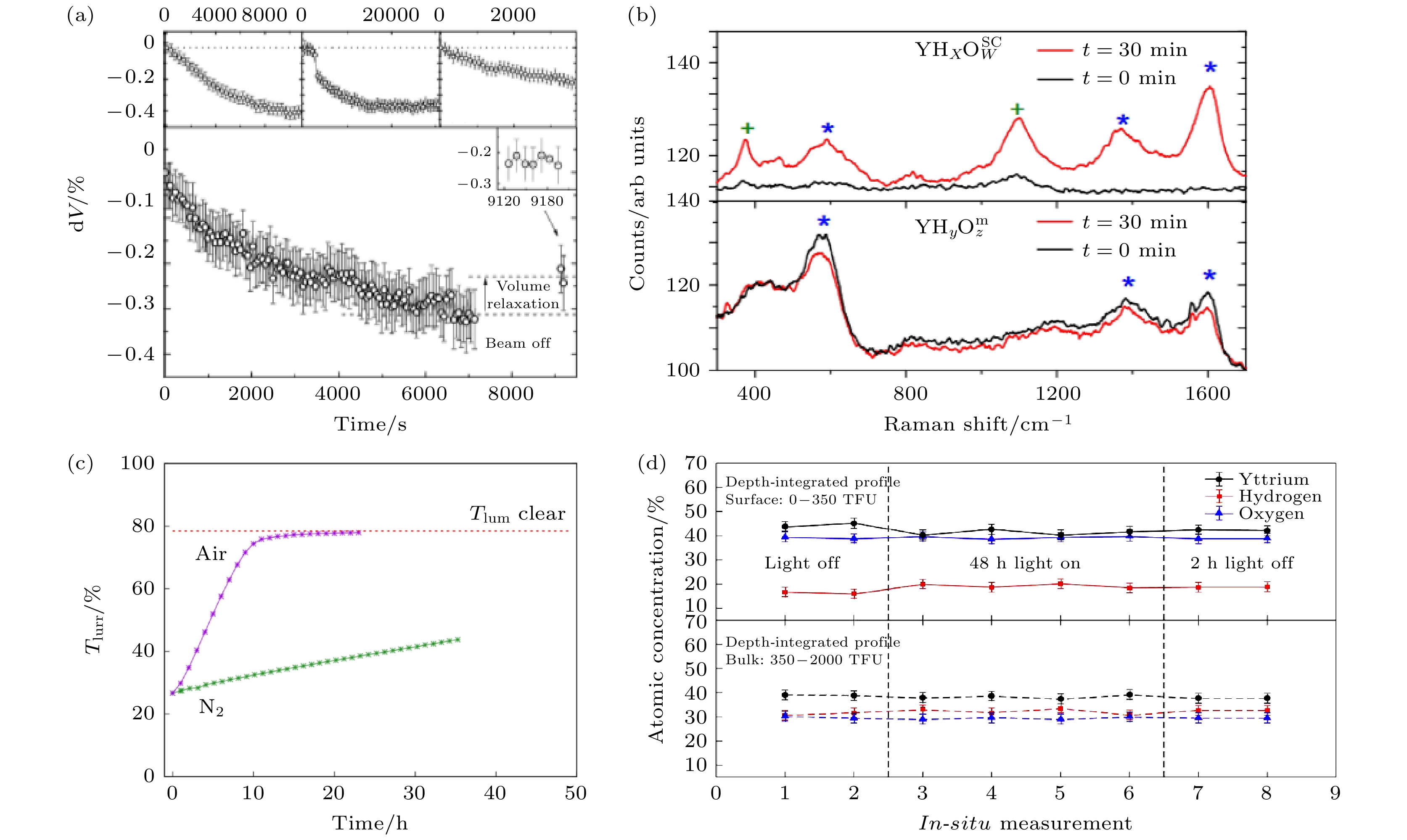

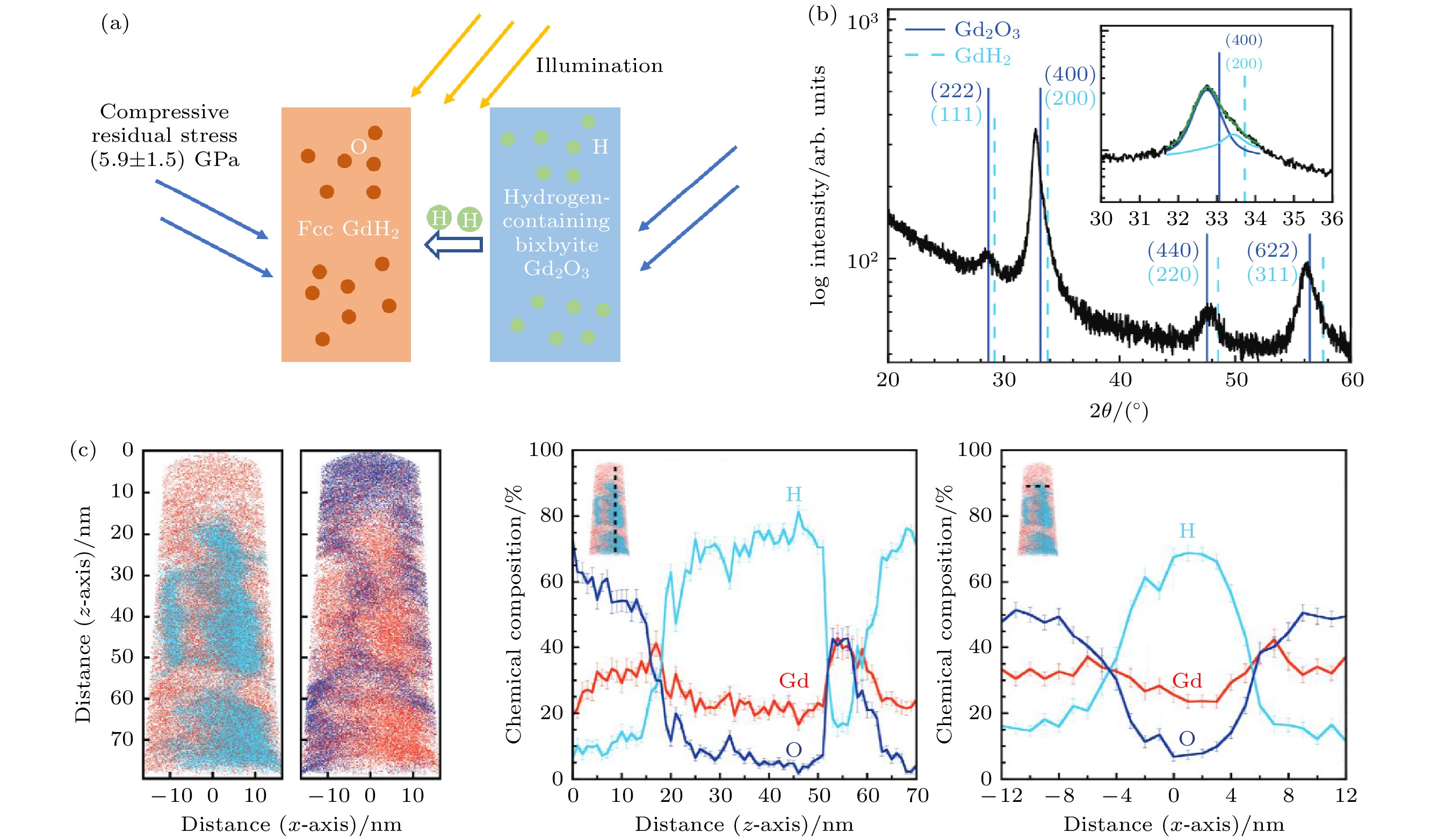

图 6 (a)同步X射线原位表征光照下样品晶格变化[37]; (b)光照之后拉曼光谱中出现金属相峰位[40]; (c)不同气氛下样品光照后的褪色速度[41]; (d)光致变色前后薄膜成分变化[32]

Figure 6. (a) Simultaneous X-ray in situ characterization of sample lattice changes under illumination[37]; (b) appearance of metal phase peaks in Raman spectra after illumination[40]; (c) recovery rate of samples under different atmospheres after illumination[41]; (d) the change in film composition before and after photochromic[32].

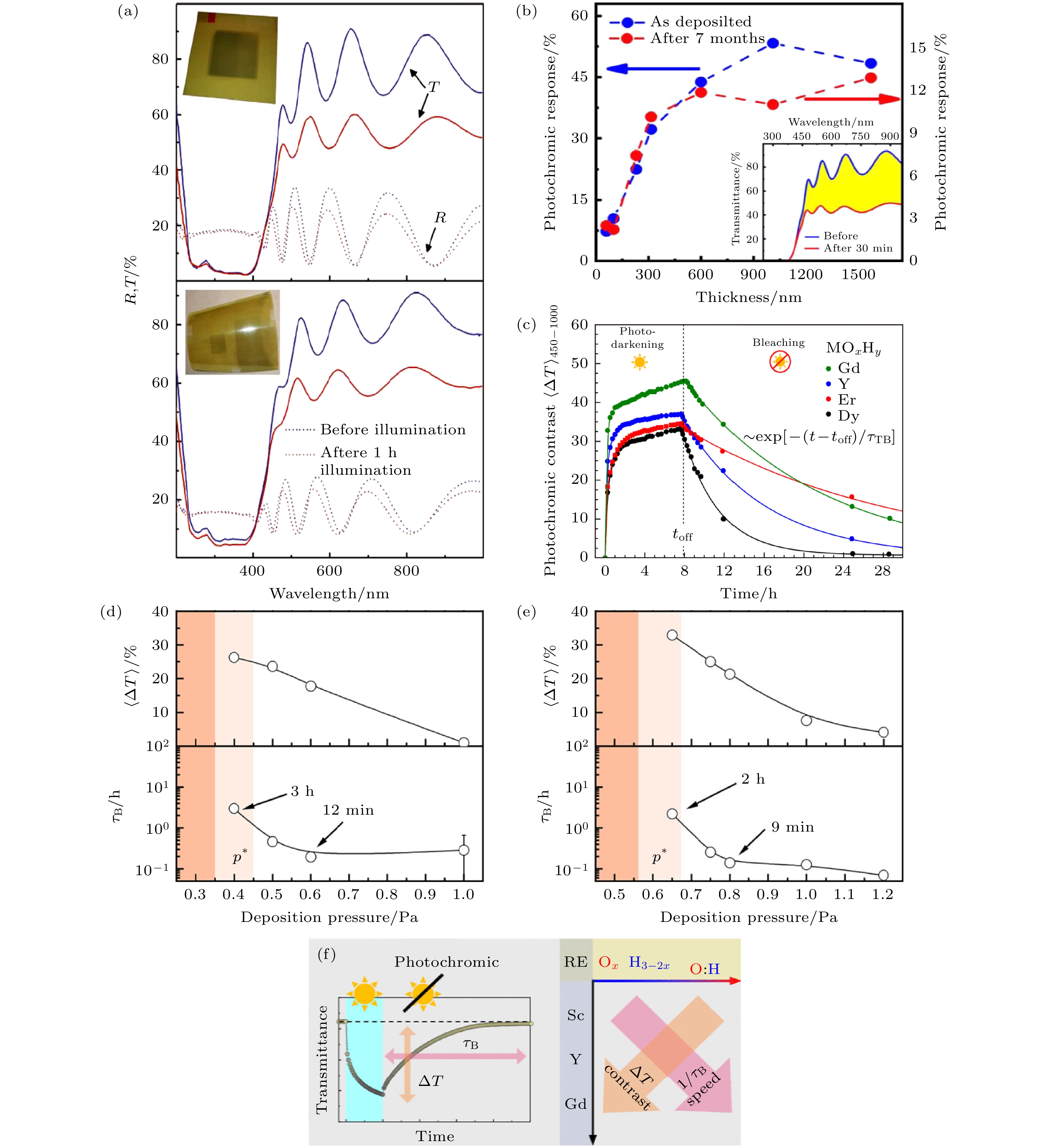

图 9 (a)不同衬底样品的光致变色响应[52]; (b) 不同厚度样品的光致变色响应[47]; (c)不同稀土元素样品的光致变色响应[14]; 不同溅射压力样品(d) YHxOy薄膜和(e) GdHxOy薄膜的光致变色响应[15], 以及(f)光致变色性能与化学组分之间的关系[15]

Figure 9. (a) Photochromic response of samples with different substrates[52]; (b) photochromic response of samples with different thicknesses[47]; (c) photochromic response of different rare earth element samples[14]. The photochromic response of different sputtering pressure samples: (d) YHxOy film; (e) GdHxOy film[15]; (f) relationship between photochromic properties and chemical components[15].

Type of the material Name of material Photochromism principle Method of bleaching Color change Organic Diarylethenes Photocyclization reaction Expose to visible light Colorless → red Fulgide Photochemical conrotatory Expose to visible light Pale yellow → red Spriopyran Hetetolytic cleavage/photocyclization Expose to visible light/heating Colorless → purple Naphthopyarn Hetetolytic cleavage/photocyclization Removing UV Colorless → gray Inorganic TMOs WO3 Photon prompted redox reaction Removing UV Colorless → blue TiO2 Photon prompted redox reaction Removing UV and

exposing to airFaint yellow → black MoO3 Intercalation-deintercalation of univalent cations Removing UV White → blue Metal halides Lead chloride [Pb3Cl6(CV)]H2O]n Light-triggered electron transfer Removing UV/

anneal in airPale yellow → blue AgCl Light-triggered reversible decomposition Removing UV Transparent → brown 表 2 已有报道稀土元素的性质

Table 2. Properties of reported rare earth element.

-

[1] Ke Y, Chen J, Lin G, Wang S, Zhou Y, Yin J, Pooi S L, Long Y 2019 Adv. Energy Mater. 9 1902066

Google Scholar

Google Scholar

[2] Ma Y, Yu Y, She P, Lu J, Liu S, Huang W, Zhao Q 2020 Sci. Adv. 6 2386

Google Scholar

Google Scholar

[3] Barachevsky V A, Strokach Y P, Krayushkin M M 2007 J. Phys. Org. Chem. 20 1007

Google Scholar

Google Scholar

[4] Qin M, Huang Y, Li F, Song Y 2015 J. Mater. Chem. C 3 9265

Google Scholar

Google Scholar

[5] Gavrilyuk A I 2013 Appl. Surf. Sci. 273 735

Google Scholar

Google Scholar

[6] Eglitis R, Zukuls A, Viter R 2020 Photochem. Photobiol. Sci. 19 1072

Google Scholar

Google Scholar

[7] Zhu Y, Yao Y, Chen, Zhang Z, Zhang P, Cheng Z, Gao Y 2022 Sol. Energy Mater. Sol. Cells 239 111664

Google Scholar

Google Scholar

[8] Tang W 2022 Chem. Eng. J. 435 134670

Google Scholar

Google Scholar

[9] Huiberts J N, Griessen R, Rector J H, Wijngaarden R J, Dekker J P 1996 Nature 380 231

Google Scholar

Google Scholar

[10] Hoekstra A F T, Roy A S, Rosenbaum T F, Griessen R 2001 Phys. Rev. Lett. 86 5349

Google Scholar

Google Scholar

[11] Ngene P, Longo A, Moojj L 2017 Nat. Commun. 8 1846

Google Scholar

Google Scholar

[12] Ohumura A, Machida A, Watanuki T 2007 Appl. Phys. Lett. 91 151904

Google Scholar

Google Scholar

[13] Mongstad T, Platzer-Bjorkman C, Maehlen J, Lennard P A M, Yevheniy P, Dam B, Marstein E, Karazhanov S Z 2011 Sol. Energy Mater. Sol. Cells 95 3596

Google Scholar

Google Scholar

[14] Nafezarefi F, Schreuders H, Dam B 2017 Appl. Phys. Lett. 111 103903

Google Scholar

Google Scholar

[15] Colombi G, Dekrom T, Chaykina D 2021 ACS Photonics 8 709

Google Scholar

Google Scholar

[16] Baba E M, Montero J, Moldarev D, Moro M V, Wolff M, Primetzhofer D, Sartori S, Zayim E, Karazhanov S Z 2020 Molecules 25 3181

Google Scholar

Google Scholar

[17] Moldarev D, Moro M V, You C C, Elbruz M B, Karazhanov S Z 2018 Phys. Rev. Mater. 2 115203

Google Scholar

Google Scholar

[18] Chai J, Shao Z, Wang H, Ming C, Oh W, Ye T, Zhang Y, Cao X, Ping Jin, Sun Y 2020 Sci. China Mater. 63 1579

Google Scholar

Google Scholar

[19] Colombi G, Cornelius S, Longo A 2020 J. Phys. Chem. C 124 13541

Google Scholar

Google Scholar

[20] Pishtshev A, Strougovshchikov E, Karazhanov S 2019 Cryst. Growth Des. 19 2574

Google Scholar

Google Scholar

[21] Chaykin D, Nafezarefi F, Colombi G, Cornelius S, Lars J 2022 J. Phys. Chem. C 126 2276

Google Scholar

Google Scholar

[22] Montero J, Martinsen F A, Lelis M, Karazhanov S Z, Hauback B C, Marstein E S 2018 Sol. Energy Mater. Sol. Cells 177 106

[23] Pishtshev A, Karazhanov S Z 2014 Solid State Commun. 194 39

Google Scholar

Google Scholar

[24] You C C, Moldarev D, Mongstada T, Primetzhofer D, Wolffb M, Marsteina E S, Karazhanov S Z 2017 Sol. Energy Mater. Sol. Cells. 166 185

Google Scholar

Google Scholar

[25] You C C, Mongstad T, Marstein E S, Karazhanov S Z 2019 Materialia 6 100307

Google Scholar

Google Scholar

[26] Kantre K, Moro M V, Moldarev D 2020 Scr. Mater. 186 352

Google Scholar

Google Scholar

[27] Mongstad T, Subrahmanyam A, Karazhanov S 2014 Sol. Energy Mater. Sol. Cells 128 270

Google Scholar

Google Scholar

[28] Komatsu Y, Sato R, Wilde M, Nishio K, Katase T, Matsumura D, Saitoh H, Miyauchi M, Adelman J R, McFadden R M L, MacFarlane W A, Sugiyama J, Komatsu T H Y 2022 Chem. Mater. 34 3616

Google Scholar

Google Scholar

[29] Montero J, Galeckas A, Karazhanov S Z 2018 Phys. Status Solidi B 255 1800139

Google Scholar

Google Scholar

[30] You C C, Karazhanov S Z 2020 J. Appl. Phys. 128 013106

Google Scholar

Google Scholar

[31] Shao Z, Cao X, Zhang Q, Long S, Chang T, Xu F, Jin P. 2019 Sol. Energy Mater. Sol. Cells 200 110044

Google Scholar

Google Scholar

[32] Moro M V 2019 Sol. Energy Mater. Sol. Cells 201 110119

Google Scholar

Google Scholar

[33] Baba E M, Weiser P M, Karazhanov S 2021 Phys. Status Solidi RRL Rapid Res. Lett. 15 2000459

Google Scholar

Google Scholar

[34] Zhang Q, Xie L, Zhu Y, Tao Y, Li R, Xua J, Bao S, Jin P 2019 Sol. Energy Mater. Sol. Cells 20 109930

[35] Dam B, Remhof A, Heijna M C R, Rector J H, Borsa D, Kerssemakers J W J 2003 J. Alloys Compd. 356–357 526

Google Scholar

Google Scholar

[36] 田民波, 李正操 2011 薄膜技术与薄膜材料 (北京: 清华大学出版社) 第251页

Tian M B, Li Z C 2011 Thin Film Technology and Thin-Film Materials (Beijing: Tsinghua University Press) p251 (in Chinese)

[37] Maehlen J P, Mongstad T T, You C C, Karazhanov S 2013 J. Alloys Compd. 580 119

Google Scholar

Google Scholar

[38] Plokkera M P, Eijta S W H, Nazirisa F, Schutb H, Nafezarefic F, Schreudersc H, Corneliusc S, Dam B 2018 Sol. Energy Mater. Sol. Cells 177 97

Google Scholar

Google Scholar

[39] Eijta S W H, Kroma T W H, Chaykinab D, Schuta H, Colombib G, Eggerc W, Dickmannc M, Hugenschmidtd C, Dam B 2020 Acta Phys. Pol. A 137 205

Google Scholar

Google Scholar

[40] Montero J, Martinsen F A, García-Tecedor M, Karazhanov S Z, Maestre D, Hauback B, Marstein E S 2017 Phys. Rev. B 95 201301

Google Scholar

Google Scholar

[41] Baba E M, Montero J, Strugovshchikov E, Zayim E, Karazhanov S 2020 Phys. Rev. Mater. 4 025201

Google Scholar

Google Scholar

[42] Moldarev D, Stolz L, Marcos V 2021 Phys. Status Solidi RRL Rapid Res. Lett. 15 2000608

Google Scholar

Google Scholar

[43] Moldarev D, Stolz L, Moro M V, Aðalsteinsson S M, Chioar I A, Karazhanov S Z, Primetzhofer D, Wolff M 2021 J. Appl. Phys. 129 153101

Google Scholar

Google Scholar

[44] Hans M, Tran T T, Aðalsteinsson S M, Moldarev D, Moro M V, Wolff M, Primetzhofer D 2020 Adv. Opt. Mater. 8 2000822

Google Scholar

Google Scholar

[45] Chandran C V, Schreuders H, Dam B, Janssen J W G, Bart J, Kentgens A P M 2014 J. Phys. Chem. C 118 22935

Google Scholar

Google Scholar

[46] Nafezarefi F, Cornelius S, Dam B 2019 Sol. Energy Mater. Sol. Cells 200 109923

Google Scholar

Google Scholar

[47] Moldarev D, Wolff M, Baba E M, Moro M V, You C C, Primetzhofer D, Karazhanov S Z 2020 Materialia 11 100706

Google Scholar

Google Scholar

[48] Mayer M, Eckstein W, Langhuth H, Schiettekatte F, Toussaint U 2011 Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 269 3006

Google Scholar

Google Scholar

[49] 陈赟斐, 魏峰, 王赫, 赵未昀, 邓元 2021 70 207303

Google Scholar

Google Scholar

Chen Y F, Wei F, Wang H, Zhao W H, Deng Y 2021 Acta Phys. Sin. 70 207303

Google Scholar

Google Scholar

[50] Chen J K, Mao W, Ge B, Wang J, Ke X Y, Wang V, Wang Y P, Döbeli M, Geng W T, Matsuzaki H, Shi J, Jiang Y 2019 Nat. Commun. 10 694

Google Scholar

Google Scholar

[51] 白刚, 韩宇航, 高存法 2022 71 097701

Google Scholar

Google Scholar

Bai G, Han Y H, Gao C F 2022 Acta Phys. Sin. 71 097701

Google Scholar

Google Scholar

[52] You C C, Mongstad T, Maehlen J P 2015 Sol. Energy Mater. Sol. Cells 143 623

Google Scholar

Google Scholar

[53] You C C, Mongstad T, Maehlen J P, Karazhanov S 2014 Appl. Phys. Lett. 105 031910

Google Scholar

Google Scholar

[54] Moldarev D, Primetzhofer D, You C C, Karazhanov S Z, Montero J, Martinsen F, Mongstad T, Marstein E S, Wolff M 2018 Sol. Energy Mater. Sol. Cells 177 66

Google Scholar

Google Scholar

[55] Strugovshchikov E, Pishtshev A, Karazhanov S 2021 Phys. Status Solidi B 258 2100179

Google Scholar

Google Scholar

[56] 拉毛, 包山虎, 莎仁 2018 化学学报 77 90

Google Scholar

Google Scholar

La M, Bao S H, Sha R 2018 Acta Chim. Sin. 77 90

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 7963

- PDF Downloads: 95

- Cited By: 0

DownLoad:

DownLoad: