-

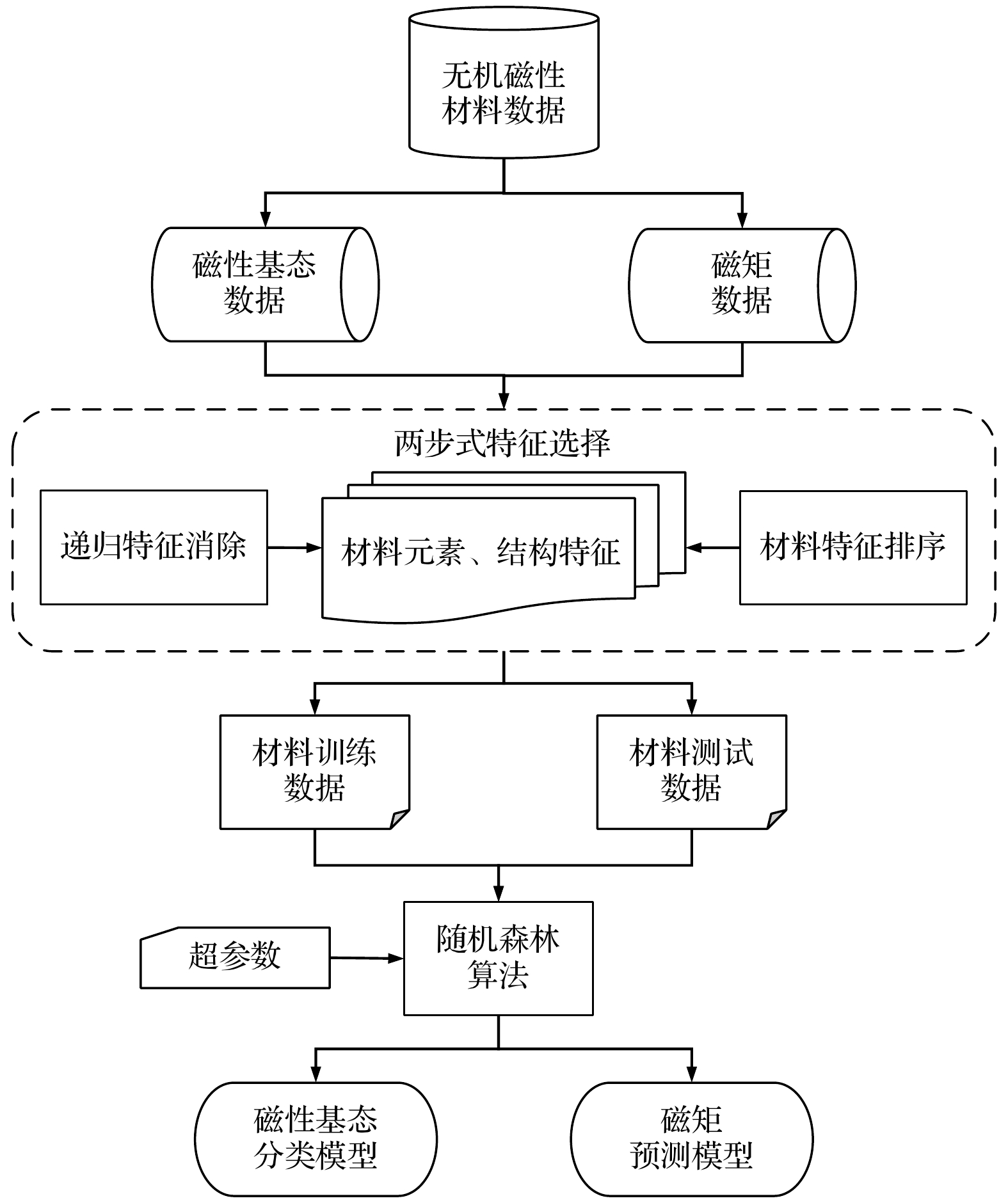

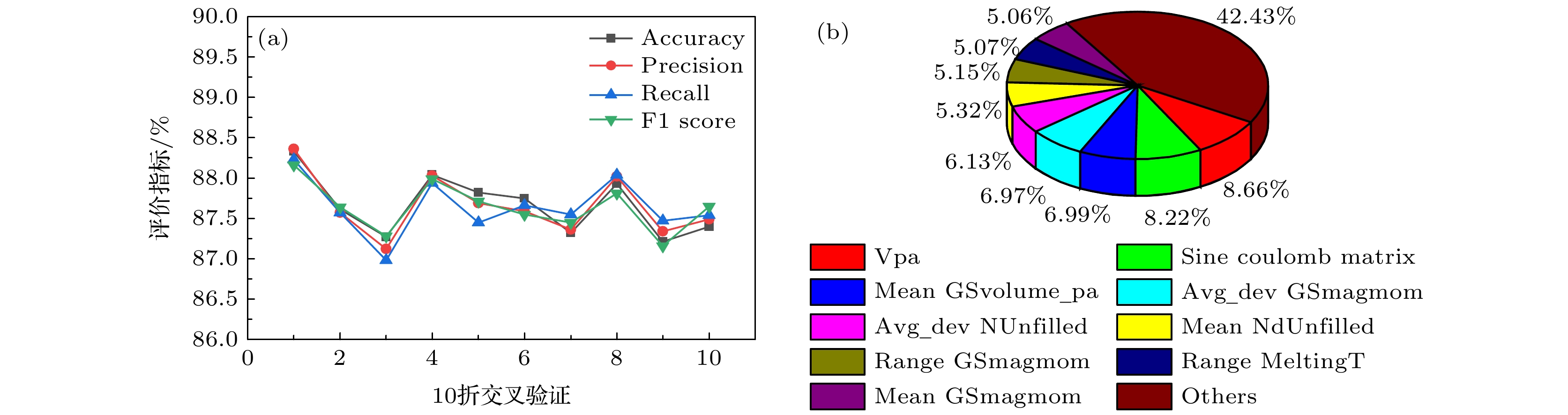

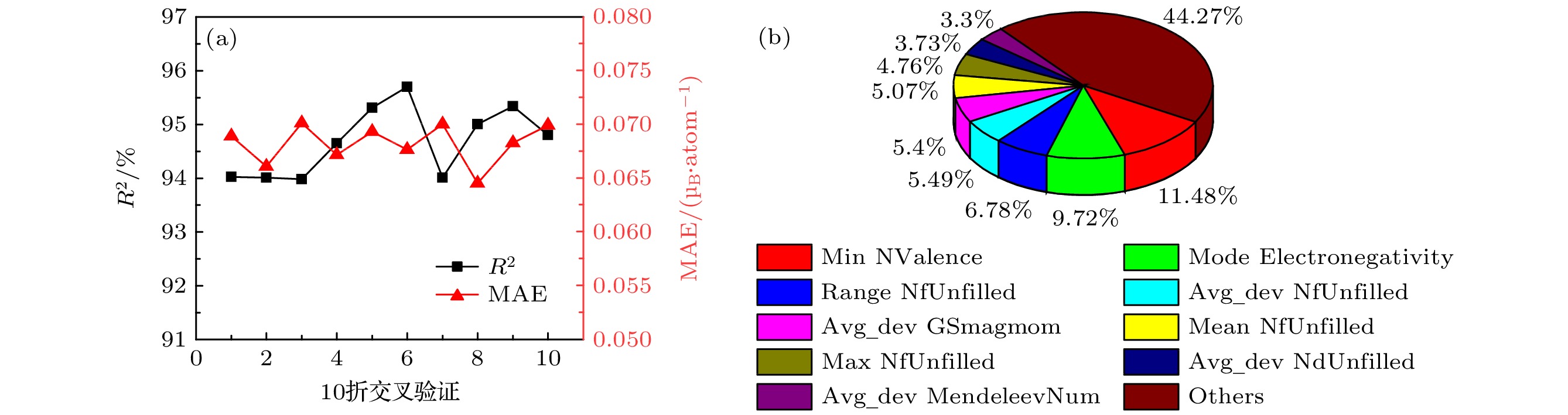

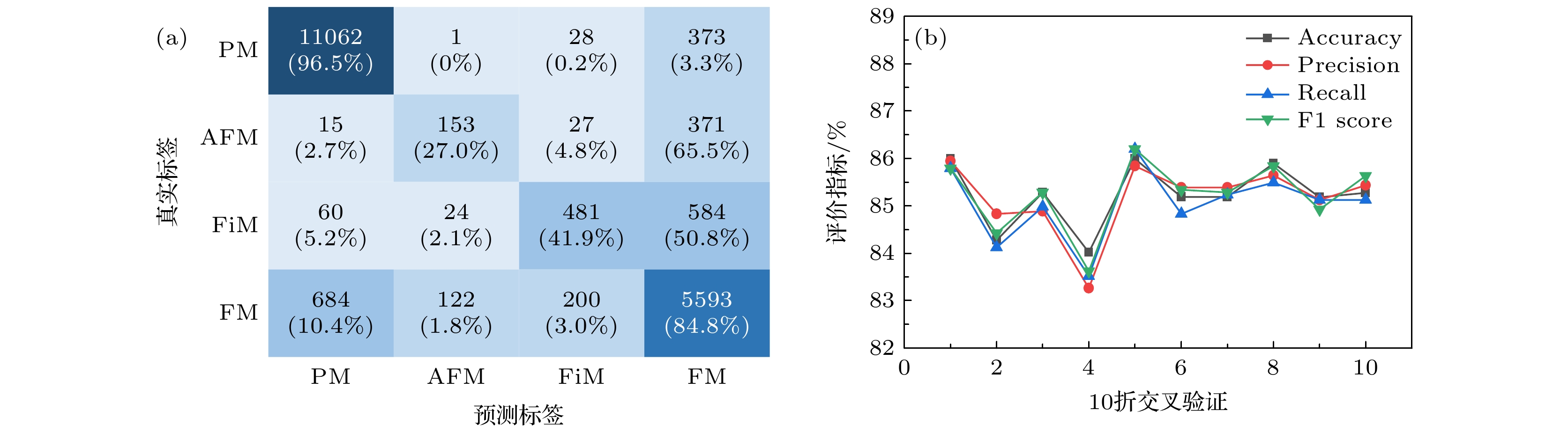

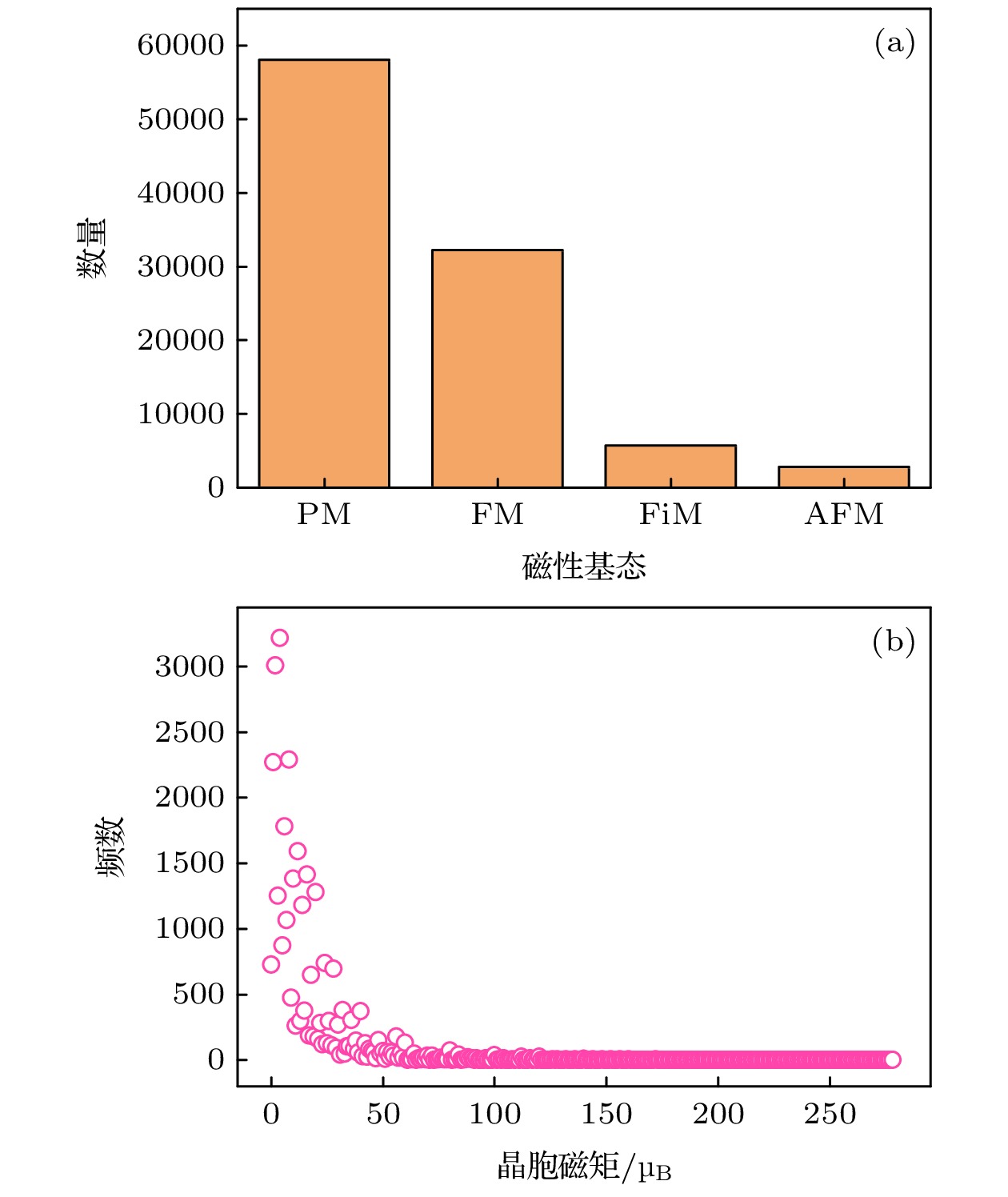

Magnetic materials are important basic materials in the information age. Different magnetic ground states are the prerequisite for the wide application of magnetic materials, among which the ferromagnetic ground state is a key requirement for future high-performance magnetic materials. In this paper, machine learning is used to study the classification of ferromagnetic, antiferromagnetic, ferrimagnetic and paramagnetic ground states of inorganic magnetic materials and the prediction of magnetic moments of inorganic ferromagnetic materials. We obtain 98888 inorganic magnetic materials data from the Materials Project database, containing material ids, chemical formulae, CIF files, magnetic ground states and magnetic moments, and extract 582 elemental and structural features for the inorganic magnetic materials by using Matminer. We design a two-step feature selection method. In the first step, RFECV is used to evaluate material features one by one to remove redundant features without degrading the model accuracy. In the second step, we rank the material features to further refine and select the most important material features for the model, and 20 material features are selected for the classification of magnetic ground states and the prediction of magnetic moments, respectively. Among the selected material features, it is found that the electronegativity, the atomic own magnetic moment and the number of unfilled electrons in the atomic peripheral orbitals all make important contributions to the classification of magnetic ground states and the prediction of magnetic moments. We build a magnetic ground state classification model and a magnetic moment prediction model by using the random forest, and quantitatively evaluate the machine learning models by using the 10-fold cross-validation approach, and the results show that the constructed machine learning models has sufficient accuracy and generalization capability. In the test set, the magnetic ground state classification model has an accuracy of 85.23%, a precision of 85.18%, a recall of 85.04%, and an F1 score of 85.24%; the magnetic moment prediction model has a goodness-of-fit of 91.58% and an average absolute error of 0.098 μB per atom. This study provides a new method and choice for high-throughput classification and screening of magnetic ground states of inorganic magnetic materials and predicting the magnetic moment of ferromagnetic materials.

-

Keywords:

- machine learning /

- random forest /

- magnetic ground state /

- magnetic moment

[1] 张志东 2015 64 067503

Google Scholar

Google Scholar

Zhang Z D 2015 Acta Phys. Sin. 64 067503

Google Scholar

Google Scholar

[2] 李绿洲, 蒋继乐, 卫荣汉, 李俊鹏, 田煜, 丁建宁 2016 65 018103

Google Scholar

Google Scholar

Li L Z, Jiang J L, Wei R H, Li J P, Tian Y, Ding J N 2016 Acta Phys. Sin. 65 018103

Google Scholar

Google Scholar

[3] Sander D, Valenzuela S O, Makarov D, Marrows C H, Fullerton E E, Fischer P, McCord J, Vavassori P, Mangin S, Pirro P, Hillebrands B, Kent A D, Jungwirth T, Gutfleisch O, Kim C G, Berger A 2017 J. Phys. D: Appl. Phys. 50 363001

Google Scholar

Google Scholar

[4] Vedmedenko E Y, Kawakami R K, Sheka D D, Gambardella P, Kirilyuk A, Hirohata A, Binek C, Chubykalo F O, Sanvito S, Kirby B J, Grollier J, Everschor S K, Kampfrath T, You C Y, Berger A 2020 J. Phys. D: Appl. Phys. 53 453001

Google Scholar

Google Scholar

[5] Long T, Fortunato N M, Zhang Y X, Gutfleisch O, Zhang H B 2021 Mater. Res. Lett. 9 169

Google Scholar

Google Scholar

[6] Yamada Y, Ueno K, Fukumura T, Yuan H T, Shimotani H, Iwasa Y, Gu L, Tsukimoto S, Ikuhara Y, Kawasaki M 2011 Science 332 1065

Google Scholar

Google Scholar

[7] Yao Q S, Lu M, Du Y P, Wu F, Deng K M, Kan E J 2018 J. Mater. Chem. C 6 1709

Google Scholar

Google Scholar

[8] 何聪丽, 许洪军, 汤建, 王潇, 魏晋武, 申世鹏, 陈庆强, 邵启明, 于国强, 张广宇, 王守国 2021 70 127501

Google Scholar

Google Scholar

He C L, Xu H J, Tang J, Wang X, Wei J W, Shen S P, Chen Q Q, Shao Q M, Yu G Q, Zhang G Y, Wang S G 2021 Acta Phys. Sin. 70 127501

Google Scholar

Google Scholar

[9] Gong C, Zhang X 2019 Science 363 eaav4450

Google Scholar

Google Scholar

[10] 王皓瑶, 刘海祎, 孙剑飞, 顾宁 2018 中国科学: 技术科学 48 921

Google Scholar

Google Scholar

Wang H Y, Liu H Y, Sun J F, Gu N 2018 Sci. Sin. Technol. 48 921

Google Scholar

Google Scholar

[11] Jha D, Choudhary K, Tavazza F, Liao W K, Choudhary A, Campbell C, Agrawal A 2020 Nat. Commun. 11 3643

Google Scholar

Google Scholar

[12] Belsky A, Hellenbrandt M, Karen V L, Luksch P 2002 Acta Crystallogr., Sect. B: Struct. Sci. 58 364

Google Scholar

Google Scholar

[13] Kirklin S, Saal J E, Meredig B, Thompson A, Doak J W, Aykol M, Ruhl S, Wolverton C 2015 NPJ Comput. Mater. 1 15010

Google Scholar

Google Scholar

[14] Jain A, Ong S P, Hautier G, Chen W, Richards W D, Dacek S, Cholia S, Gunter D, Skinner D, Ceder G, Persson K A 2013 APL Mater. 1 011002

Google Scholar

Google Scholar

[15] Schleder G R, Padilha A C M, Acosta C M, Costa M, Fazzio A 2019 J. Phys. Mater. 2 032001

Google Scholar

Google Scholar

[16] Liu Y, Zhao T L, Ju W W, Shi S Q 2017 J. Materialomics 3 159

Google Scholar

Google Scholar

[17] Isayev O, Oses C, Toher C, Gossett E, Curtarolo S, Tropsha A 2017 Nat. Commun. 8 15679

Google Scholar

Google Scholar

[18] 寇雯博, 董灏, 邹岷强, 韩均言, 贾西西 2021 70 030701

Google Scholar

Google Scholar

Kou W B, Dong H, Zou M Q, Han J Y, Jia X X 2021 Acta Phys. Sin. 70 030701

Google Scholar

Google Scholar

[19] 杨自欣, 高章然, 孙晓帆, 蔡宏灵, 张凤鸣, 吴小山 2019 68 210502

Google Scholar

Google Scholar

Yang Z X, Gao Z R, Sun X F, Cai H L, Zhang F M, Wu X S 2019 Acta Phys. Sin. 68 210502

Google Scholar

Google Scholar

[20] Lu S H, Zhou Q H, Ouyang Y X, Guo Y L, Li Q, Wang J L 2018 Nat. Commun. 9 3405

Google Scholar

Google Scholar

[21] Xu Y B, Yamazaki M, Villars P 2011 Jpn. J. Appl. Phys. 50 11RH02

Google Scholar

Google Scholar

[22] Frey N C, Horton M K, Munro J M, Griffin S M, Persson K A, Shenoy V B 2020 Sci. Adv. 6 eabd1076

Google Scholar

Google Scholar

[23] Yamamoto T https://storage.googleapis.com/rimcs_cgnn/cgnn_matsci_May_27_2019.pdf [2021-8-10]

[24] Materials Project API https://materialsproject.org/open [2021-8-10]

[25] Ward L, Dunn A, Faghaninia A, Zimmermann N E R, Bajaj S, Wang Q, Montoya J, Chen J M, Bystrom K, Dylla M, Chard K, Asta M, Persson K A, Snyder G J, Foster I, Jain A 2018 Comput. Mater. Sci. 152 60

Google Scholar

Google Scholar

[26] Breiman L 2001 Mach. Learn. 45 5

Google Scholar

Google Scholar

[27] Pedregosa F, Varoquaux G, Gramfort A, Michel V, Thirion B, Grisel O, Blondel M, Prettenhofer P, Weiss R, Dubourg V, Vanderplas J, Passos A, Cournapeau D, Brucher M, Perrot M, Duchesnay E 2011 J. Mach. Learn. Res. 12 2825

-

表 1 基于两步式特征选择法获得的材料特征

Table 1. Material features obtained by the two-step feature selection method.

特征类型 特征 元素 Mode Electronegativity* Mean NdUnfilled* Max MeltingT Min Electronegativity Avg_dev NdUnfilled* Mode Number Range NUnfilled Max NdUnfilled Max Number Avg_dev NUnfilled Mean GSmagmom* Min NValence Max NUnfilled Range GSmagmom Range NfValence Mode NfUnfilled Avg_dev GSmagmom* Avg_dev NfValence Mean NfUnfilled Max GSmagmom Avg_dev NdValence Range NfUnfilled* Max AtomicWeight Mode MendeleevNumber Avg_dev NfUnfilled Mode AtomicWeight Avg_dev MendeleevNumber Max NfUnfilled Mean GSvolume_pa Min MendeleevNumber Range NdUnfilled Range MeltingT 结构 Vpa Sine coulomb matrix 0 * 该特征同时用于磁性基态分类和磁矩预测. 表 2 本研究中机器学习模型的超参数

Table 2. Hyperparameters of the machine learning model in this study.

模型 超参数 RFC n = 400, features = 'log2', samples_split = 2, samples_leaf = 1 RFR n = 300, features = 'auto', samples_split = 2, samples_leaf = 1 表 3 本研究磁性基态分类模型与其他研究者工作的定量评估对比

Table 3. Quantitative evaluation of the magnetic ground state classification model in this study and in comparison with other works.

表 4 本研究磁矩预测模型与其他研究者工作的定量评估对比

Table 4. Quantitative evaluation of the magnetic moment prediction model in this study and in comparison with other works.

评价指标(平均值) 本研究模型 文献[23] R2/% 91.58 — MAE/(μB·atom-1) 0.098 0.119 表 A1 基于两步式特征选择法获得的材料特征及其物理含义

Table A1. Material features and their physical meanings obtained by the two-step feature selection method.

特征 物理含义 1 Mode Electronegativity* 材料组成元素电负性的众数 2 Min Electronegativity 材料组成元素电负性的最小值 3 Range NUnfilled 材料组成元素外围未充满电子数的范围 4 Avg_dev NUnfilled 材料组成元素外围未充满电子数的平均偏差 5 Max NUnfilled 材料组成元素外围未充满电子数的最大值 6 Mode NfUnfilled 材料组成元素f轨道未充满电子数的众数 7 Mean NfUnfilled 材料组成元素f轨道未充满电子数的平均值 8 Range NfUnfilled* 材料组成元素f轨道未充满电子数的范围 9 Avg_dev NfUnfilled 材料组成元素f轨道未充满电子数的平均偏差 10 Max NfUnfilled 材料组成元素f轨道未充满电子数的最大值 11 Range NdUnfilled 材料组成元素d轨道未充满电子数的范围 12 Mean NdUnfilled* 材料组成元素d轨道未充满电子数的平均值 13 Avg_dev NdUnfilled* 材料组成元素d轨道未充满电子数的平均偏差 14 Max NdUnfilled 材料组成元素d轨道未充满电子数的最大值 15 Mean GSmagmom* 材料组成元素磁矩的平均值 16 Range GSmagmom 材料组成元素磁矩的范围 17 Avg_dev GSmagmom* 材料组成元素磁矩的平均偏差 18 Max GSmagmom 材料组成元素磁矩的最大值 19 Max AtomicWeight 材料组成元素重量的最大值 20 Mode AtomicWeight 材料组成元素重量的众数 21 Mean GSvolume_pa 材料组成元素体积的平均值 22 Range MeltingT 材料组成元素熔点的范围 23 Max MeltingT 材料组成元素熔点的最大值 24 Mode Number 材料组成元素原子序数的众数 25 Max Number 材料组成元素原子序数的最大值 26 Min NValence 材料组成元素价电子的最小值 27 Range NfValence 材料组成元素f轨道价电子的范围 28 Avg_dev NfValence 材料组成元素f轨道价电子的平均偏差 29 Avg_dev NdValence 材料组成元素d轨道价电子的平均偏差 30 Mode MendeleevNumber 材料组成元素门捷列夫数的众数 31 Avg_dev MendeleevNumber 材料组成元素门捷列夫数的平均偏差 32 Min MendeleevNumber 材料组成元素门捷列夫数的最小值 33 Vpa 材料的晶胞体积 34 Sine coulomb matrix 0 正弦库仑矩阵的第0个特征值 * 该特征同时用于磁性基态分类和磁矩预测. -

[1] 张志东 2015 64 067503

Google Scholar

Google Scholar

Zhang Z D 2015 Acta Phys. Sin. 64 067503

Google Scholar

Google Scholar

[2] 李绿洲, 蒋继乐, 卫荣汉, 李俊鹏, 田煜, 丁建宁 2016 65 018103

Google Scholar

Google Scholar

Li L Z, Jiang J L, Wei R H, Li J P, Tian Y, Ding J N 2016 Acta Phys. Sin. 65 018103

Google Scholar

Google Scholar

[3] Sander D, Valenzuela S O, Makarov D, Marrows C H, Fullerton E E, Fischer P, McCord J, Vavassori P, Mangin S, Pirro P, Hillebrands B, Kent A D, Jungwirth T, Gutfleisch O, Kim C G, Berger A 2017 J. Phys. D: Appl. Phys. 50 363001

Google Scholar

Google Scholar

[4] Vedmedenko E Y, Kawakami R K, Sheka D D, Gambardella P, Kirilyuk A, Hirohata A, Binek C, Chubykalo F O, Sanvito S, Kirby B J, Grollier J, Everschor S K, Kampfrath T, You C Y, Berger A 2020 J. Phys. D: Appl. Phys. 53 453001

Google Scholar

Google Scholar

[5] Long T, Fortunato N M, Zhang Y X, Gutfleisch O, Zhang H B 2021 Mater. Res. Lett. 9 169

Google Scholar

Google Scholar

[6] Yamada Y, Ueno K, Fukumura T, Yuan H T, Shimotani H, Iwasa Y, Gu L, Tsukimoto S, Ikuhara Y, Kawasaki M 2011 Science 332 1065

Google Scholar

Google Scholar

[7] Yao Q S, Lu M, Du Y P, Wu F, Deng K M, Kan E J 2018 J. Mater. Chem. C 6 1709

Google Scholar

Google Scholar

[8] 何聪丽, 许洪军, 汤建, 王潇, 魏晋武, 申世鹏, 陈庆强, 邵启明, 于国强, 张广宇, 王守国 2021 70 127501

Google Scholar

Google Scholar

He C L, Xu H J, Tang J, Wang X, Wei J W, Shen S P, Chen Q Q, Shao Q M, Yu G Q, Zhang G Y, Wang S G 2021 Acta Phys. Sin. 70 127501

Google Scholar

Google Scholar

[9] Gong C, Zhang X 2019 Science 363 eaav4450

Google Scholar

Google Scholar

[10] 王皓瑶, 刘海祎, 孙剑飞, 顾宁 2018 中国科学: 技术科学 48 921

Google Scholar

Google Scholar

Wang H Y, Liu H Y, Sun J F, Gu N 2018 Sci. Sin. Technol. 48 921

Google Scholar

Google Scholar

[11] Jha D, Choudhary K, Tavazza F, Liao W K, Choudhary A, Campbell C, Agrawal A 2020 Nat. Commun. 11 3643

Google Scholar

Google Scholar

[12] Belsky A, Hellenbrandt M, Karen V L, Luksch P 2002 Acta Crystallogr., Sect. B: Struct. Sci. 58 364

Google Scholar

Google Scholar

[13] Kirklin S, Saal J E, Meredig B, Thompson A, Doak J W, Aykol M, Ruhl S, Wolverton C 2015 NPJ Comput. Mater. 1 15010

Google Scholar

Google Scholar

[14] Jain A, Ong S P, Hautier G, Chen W, Richards W D, Dacek S, Cholia S, Gunter D, Skinner D, Ceder G, Persson K A 2013 APL Mater. 1 011002

Google Scholar

Google Scholar

[15] Schleder G R, Padilha A C M, Acosta C M, Costa M, Fazzio A 2019 J. Phys. Mater. 2 032001

Google Scholar

Google Scholar

[16] Liu Y, Zhao T L, Ju W W, Shi S Q 2017 J. Materialomics 3 159

Google Scholar

Google Scholar

[17] Isayev O, Oses C, Toher C, Gossett E, Curtarolo S, Tropsha A 2017 Nat. Commun. 8 15679

Google Scholar

Google Scholar

[18] 寇雯博, 董灏, 邹岷强, 韩均言, 贾西西 2021 70 030701

Google Scholar

Google Scholar

Kou W B, Dong H, Zou M Q, Han J Y, Jia X X 2021 Acta Phys. Sin. 70 030701

Google Scholar

Google Scholar

[19] 杨自欣, 高章然, 孙晓帆, 蔡宏灵, 张凤鸣, 吴小山 2019 68 210502

Google Scholar

Google Scholar

Yang Z X, Gao Z R, Sun X F, Cai H L, Zhang F M, Wu X S 2019 Acta Phys. Sin. 68 210502

Google Scholar

Google Scholar

[20] Lu S H, Zhou Q H, Ouyang Y X, Guo Y L, Li Q, Wang J L 2018 Nat. Commun. 9 3405

Google Scholar

Google Scholar

[21] Xu Y B, Yamazaki M, Villars P 2011 Jpn. J. Appl. Phys. 50 11RH02

Google Scholar

Google Scholar

[22] Frey N C, Horton M K, Munro J M, Griffin S M, Persson K A, Shenoy V B 2020 Sci. Adv. 6 eabd1076

Google Scholar

Google Scholar

[23] Yamamoto T https://storage.googleapis.com/rimcs_cgnn/cgnn_matsci_May_27_2019.pdf [2021-8-10]

[24] Materials Project API https://materialsproject.org/open [2021-8-10]

[25] Ward L, Dunn A, Faghaninia A, Zimmermann N E R, Bajaj S, Wang Q, Montoya J, Chen J M, Bystrom K, Dylla M, Chard K, Asta M, Persson K A, Snyder G J, Foster I, Jain A 2018 Comput. Mater. Sci. 152 60

Google Scholar

Google Scholar

[26] Breiman L 2001 Mach. Learn. 45 5

Google Scholar

Google Scholar

[27] Pedregosa F, Varoquaux G, Gramfort A, Michel V, Thirion B, Grisel O, Blondel M, Prettenhofer P, Weiss R, Dubourg V, Vanderplas J, Passos A, Cournapeau D, Brucher M, Perrot M, Duchesnay E 2011 J. Mach. Learn. Res. 12 2825

Catalog

Metrics

- Abstract views: 11362

- PDF Downloads: 357

- Cited By: 0

DownLoad:

DownLoad: