-

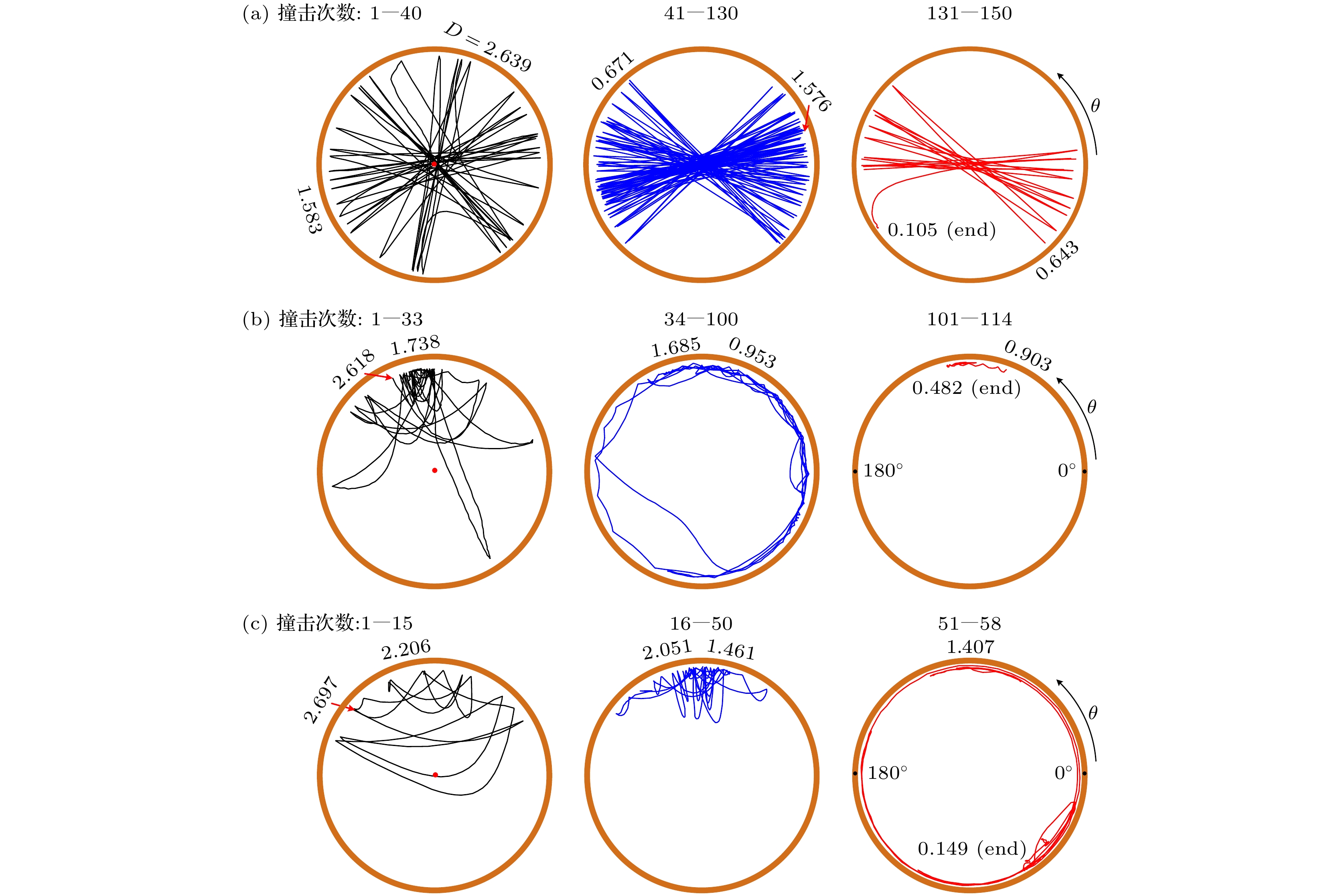

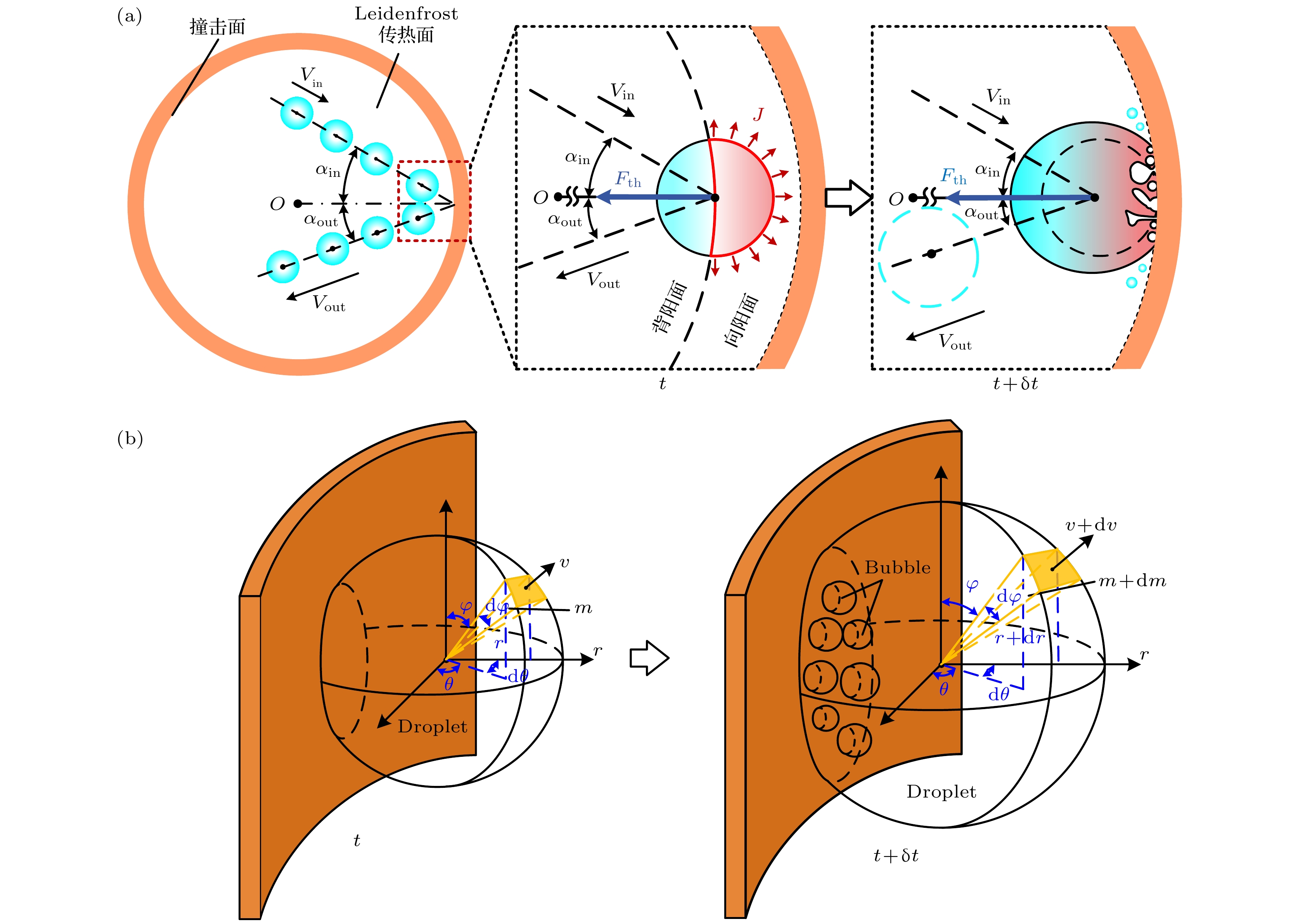

When a droplet is placed on a surface with a temperature higher than Leidenfrost temperature, it will be levitated on its own vapor cushion, which makes the droplet have amazing mobility. Generally, the vapor flow under the droplet is corrected by constructing asymmetry micro/nano textured surfaces to realize the self-propulsion of the droplet. However, the control of droplet dynamics becomes uncertain due to the complicated interaction among liquid-vapor-solid phases, and the direction of droplet motion and droplet transport velocity (10-40 cm/s) have limitations. Leidenfrost heat transfer surface and impact surface are constructed in this experiment. When the surface of Leidenfrost heat transfer for droplet levitation contacts the droplet which the sufficient energy flows towards, the rough ring surface acts as an igniter. When a warm Leidenfrsot droplet (fuel) contacts skirt ring (igniter), abundant micro/nano cavities of rough skirt ring not only generate additional radiation heat flux towards droplet but also provide nucleation sites to trigger explosive boiling on a ~10 ms time scale. The thrust force Fth generated by periodic explosive boiling realizes the self-propulsion of droplets. In the initial stage of droplet motion, the inertial force Fi is dominant, and the droplet impact is mostly specular reflection, and the droplet trajectory is chaotic. With the decrease of droplet diameter, the pulsed thrust Fth is dominant, and the droplet trajectory passes through the center of the Leidenfrost heat transfer surface. Our experimental results show that the droplet passes through the center of the Leidenfrost heat transfer surface in a wide diameter range (D = 0.671-1.576 mm). For the last (150th) collision with the rough ring, the curved trajectory exists instead of line trajectory with

$ D \sim 0.105 $ mm. For a very small droplet, the drag force Fd is dominant, which prevents the droplet from continuing to move. The droplet is followed by sessile droplet evaporation until it totally disappears. At the same time, the droplet transport velocity is as high as 68.91 cm/s, which has not been realized before. The present work provides a new method to manipulate droplet motion at a high temperature. Our Leidenfrost system is simple, cost-effective and lasts long-term operation because it does not depend on complicated micro/nano fabrications, which is expected to be used in microfluidic and heat transfer two-phase systems.-

Keywords:

- Leidenfrost /

- droplet dynamics /

- explosive boiling /

- heat transfer

[1] Leidenfrost J G 1966 Int. J. Heat Mass Transfer 9 1153

Google Scholar

Google Scholar

[2] Vakarelski I U, Marston J O, Chan D Y, Thoroddsen S T 2011 Phys. Rev. Lett. 106 214501

Google Scholar

Google Scholar

[3] Sengupta S, Patra D, Ortiz-Rivera I, Agrawal A, Shklyaev S, Dey K K, Cordova-Figueroa U, Mallouk T E, Sen A 2014 Nat. Chem. 6 415

Google Scholar

Google Scholar

[4] Baylis J R, Yeon J H, Thomson M H, Kazerooni A, Wang X, John A E S, Lim E B, Chien D, Lee A, Zhang J Q 2015 Sci. Adv. 1 e1500379

Google Scholar

Google Scholar

[5] Dittrich P S, Manz A 2006 Nat. Rev. Drug discovery 5 210

Google Scholar

Google Scholar

[6] Chen M Y, Jia Z H, Zhang T, Fei Y Y 2018 Appl. Surf. Sci. 433 336

Google Scholar

Google Scholar

[7] Chu F, Luo J, Hao C, Zhang J, Wu X, Wen D 2020 Langmuir 36 5855

Google Scholar

Google Scholar

[8] 王宏, 廖强, 朱恂 2007 化工学报 58 2313

Google Scholar

Google Scholar

Wang H, Liao Q, Zhu X 2007 J. Chem. Ind. Eng. 58 2313

Google Scholar

Google Scholar

[9] Li J, Hou Y, Liu Y, Hao C, Li M, Chaudhury M K, Yao S, Wang Z 2016 Nat. Phys. 12 606

Google Scholar

Google Scholar

[10] Sobac B, Rednikov A, Dorbolo S, Colinet P 2017 Phys. Fluids 29 082101

Google Scholar

Google Scholar

[11] Linke H, Aleman B J, Melling L D, Taormina M J, Francis M J, Dow-Hygelund C C, Narayanan V, Taylor R P, Stout A 2006 Phys. Rev. Lett. 96 154502

Google Scholar

Google Scholar

[12] Quéré D 2013 Annu. Rev. Fluid Mech. 45 197

Google Scholar

Google Scholar

[13] Scriven L, Sternling C 1960 Nature 187 186

Google Scholar

Google Scholar

[14] Jia Z H, Chen M Y, Zhu H T 2017 Appl. Phys. Lett. 110 091603

Google Scholar

Google Scholar

[15] Lagubeau G, Le Merrer M, Clanet C, Quéré D 2011 Nat. Phys. 7 395

Google Scholar

Google Scholar

[16] Wang B, Xu J L, Zhang W, Li Y X 2011 Sens. Actuators, A 169 194

Google Scholar

Google Scholar

[17] Xu J, Zhang W 2008 Int. J. Heat Mass Transfer 51 389

Google Scholar

Google Scholar

[18] Lyu S, Mathai V, Wang Y, Sobac B, Colinet P, Lohse D, Sun C 2019 Sci. Adv. 5 eaav8081

Google Scholar

Google Scholar

[19] Ok J T, Lopez-Oña E, Nikitopoulos D E, Wong H, Park S 2010 Microfluid. Nanofluid. 10 1045

[20] Grounds A, Still R, Takashina K 2012 Sci. Rep. 2 720

Google Scholar

Google Scholar

[21] Shahriari A, Wilson P S, Bahadur V 2018 Phys. Rev. E 98 013103

Google Scholar

Google Scholar

[22] Cole R 1974 Adv. Heat Transfer 10 85

Google Scholar

Google Scholar

[23] Kandlikar S G 2004 J. Heat Transfer 126 8

Google Scholar

Google Scholar

[24] Kandlikar S G 2020 J. Heat Transfer 142 100801

Google Scholar

Google Scholar

[25] Zhu B, Xu J, Yan C, Xie J 2020 Int. J. Heat Mass Transfer 148 119080

[26] 张海松, 朱鑫杰, 朱兵国, 徐进良, 刘欢 2020 69 064401

Google Scholar

Google Scholar

Zhang H S, Zhu X J, Zhu B G, Xu J L, Liu H 2020 Acta Phys. Sin. 69 064401

Google Scholar

Google Scholar

[27] Shati A K A, Blakey S G, Beck S B M 2011 Energy Build. 43 400

Google Scholar

Google Scholar

[28] Yan X, Xu J, Meng Z, Xie J, Wang H 2020 Small 16 e2001548

Google Scholar

Google Scholar

[29] Ishii M, Zuber N 1979 AIChE J. 25 843

Google Scholar

Google Scholar

-

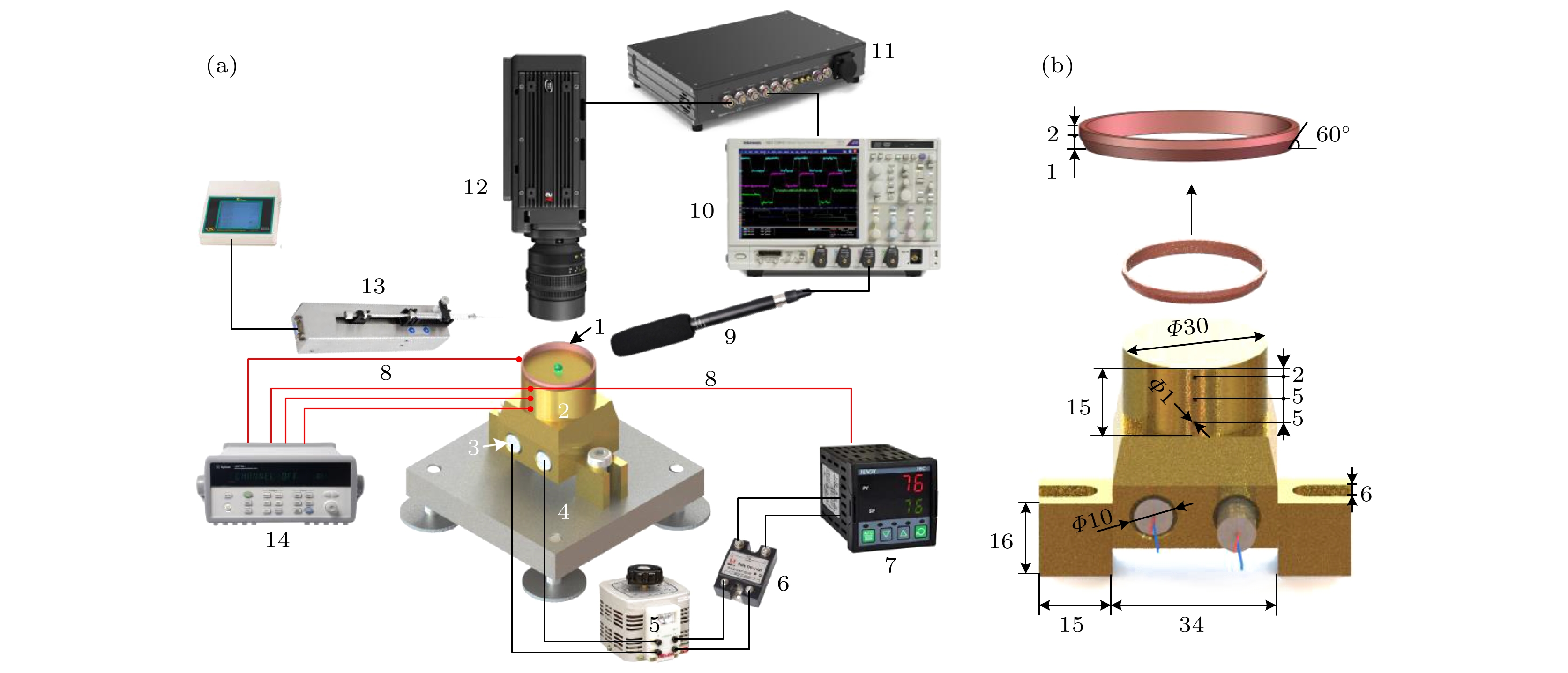

图 2 (a)实验装置图. 1, 紫铜环; 2, 黄铜加热块; 3, 加热棒; 4, 不锈钢底座; 5, 调压器; 6, 继电器; 7, PID温控仪; 8, K型热电偶; 9, 麦克风; 10, 高速数据采集仪(ScopeCorder DL750); 11, 同步器(MotionPro Timing Hub); 12, 高速相机(MotionPro Y4, IDT); 13, 微注射泵(RSP01-BDG); 14, 安捷伦34970A. (b) 黄铜加热块和紫铜环尺寸 (单位: mm)

Figure 2. (a) Experimental setup. 1, copper skirt ring; 2, brass heating block; 3, cartridge heater; 4, stainless steel base; 5, voltage transformer; 6, electric relay; 7, PID temperature controller; 8, K thermocouple; 9, microphone; 10, high speed data acquisition system (ScopeCorder DL750; 11, synchronizer (MotionPro Timing Hub); 12, high speed camera (MotionPro Y4, IDT); 13, micro-syringe pump (RSP01-BDG); 14, Agilent 34970A. (b) Brass heating block and copper ring size (all dimensions are in mm).

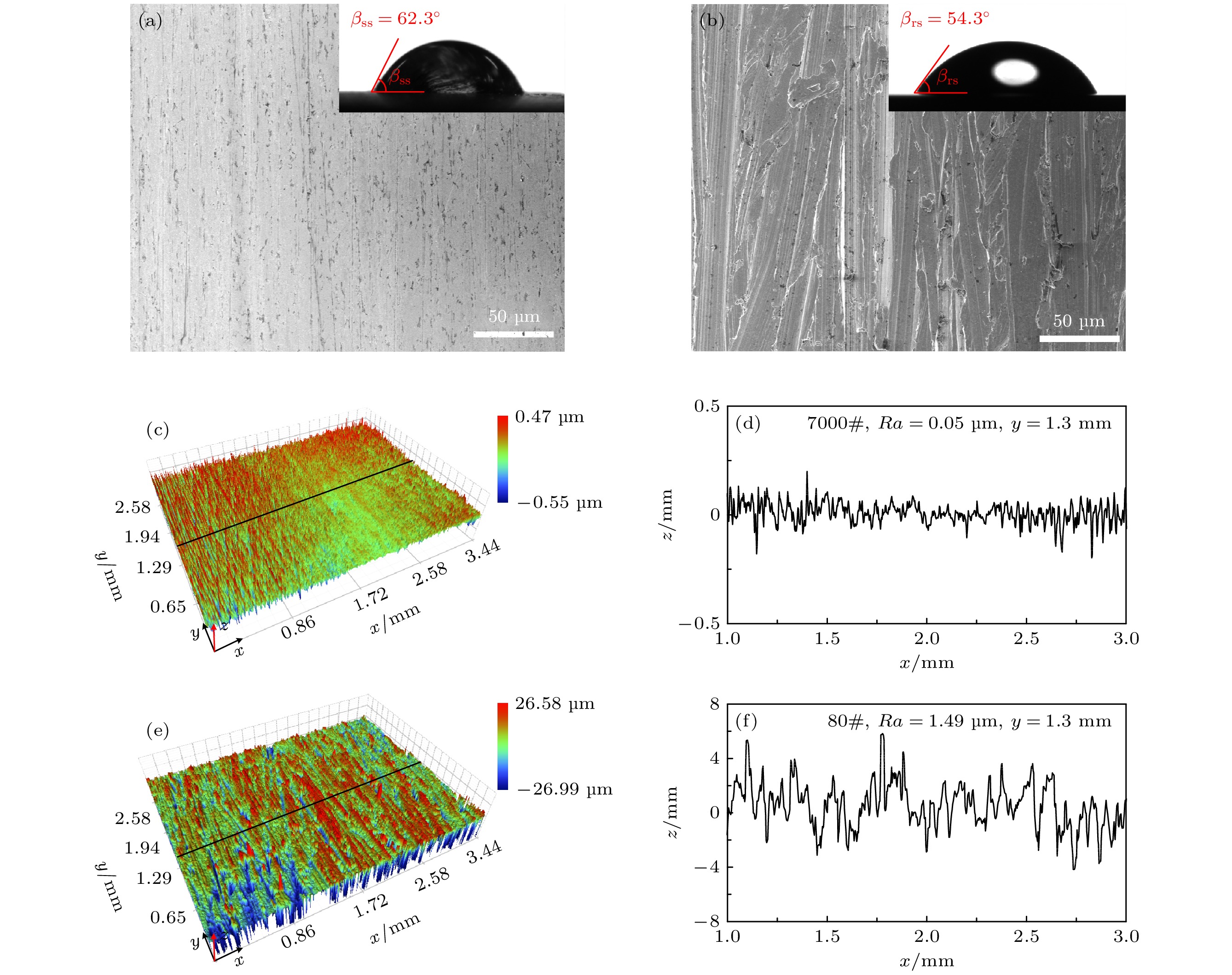

图 3 采用与两个圆环样品相同的制造技术制备的两个平表面的表征 (a)抛光紫铜表面的扫描电子显微镜图像和接触角; (b)粗糙紫铜表面的扫描电子显微镜图像和接触角; (c), (d)抛光紫铜表面的表面形貌测量; (e), (f) 粗糙紫铜表面的表面形貌测量

Figure 3. Characterization of two flat surfaces having the same fabrication technique as two skirt ring samples: (a) Scanning electronic microscope (ESEM) image and contact angles for polished copper surface; (b) ESME image and contact angles for rough copper surface; (c), (d) surface morphology measured for smooth copper surface; (e), (f) surface morphology measured for rough copper surface

图 4 液滴整个寿命周期内液滴运动轨迹 (a)在Tw = 223.0 ℃, Tr = 191.4 ℃下, 液滴在粗糙环的运动轨迹; (b)在Tw = 223.0 ℃, Tr = 191.4 ℃下, 液滴在抛光环的运动轨迹; (c)在Tw = 304.5 ℃, Tr = 256.3 ℃下, 液滴在粗糙环的运动轨迹

Figure 4. Droplet trajectory during the whole droplet lifetime: (a) Droplet trajectory on rough ring at Tw = 223.0 ℃, Tr = 191.4 ℃; (b) droplet trajectory on polished ring at Tw = 223.0 ℃, Tr = 191.4 ℃; (c) droplet trajectory on rough ring at Tw = 304.5 ℃, Tr = 256.3 ℃.

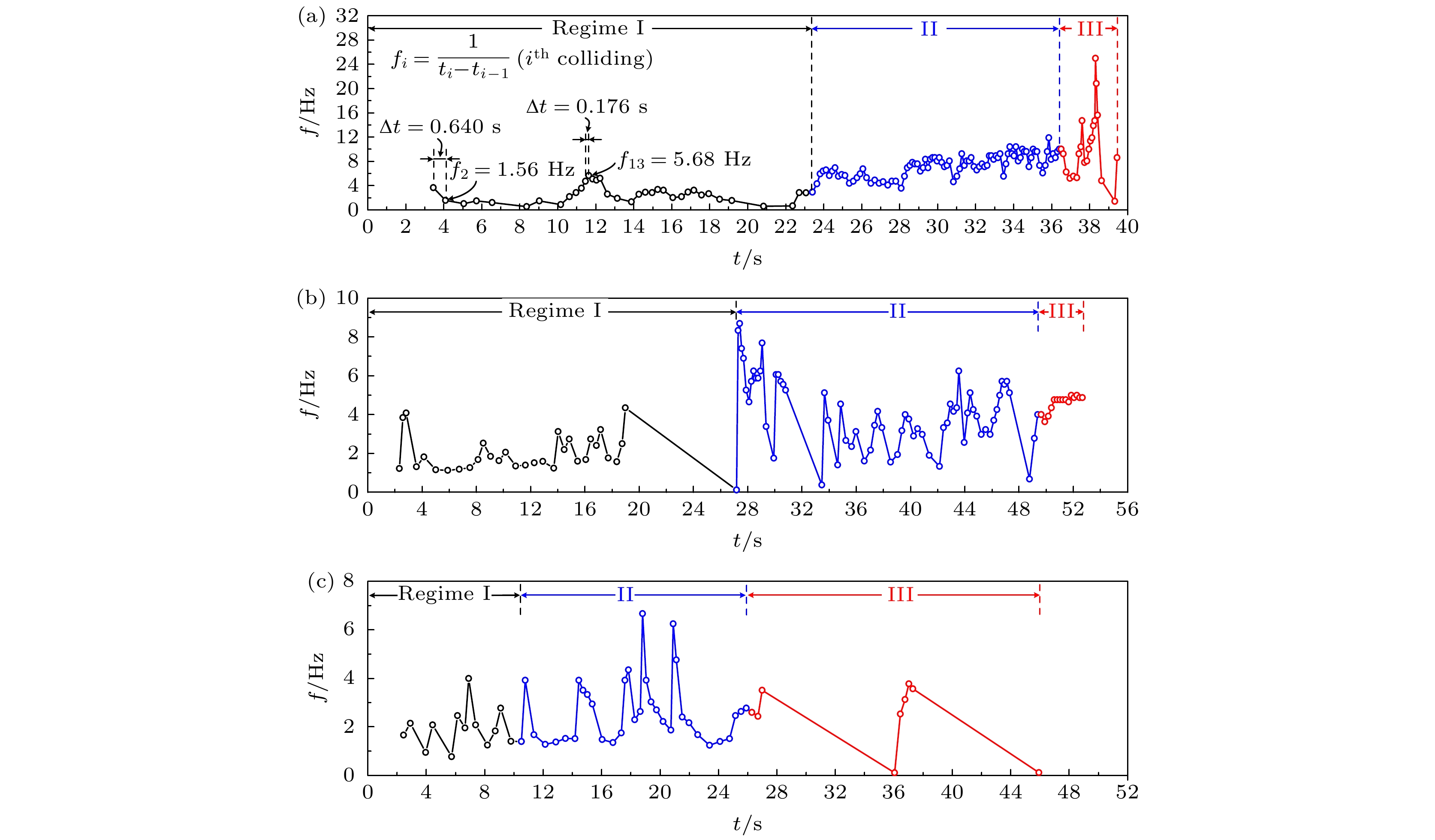

图 5 液滴整个寿命周期内液滴撞击频率 (a)在Tw = 223.0 ℃, Tr = 191.4 ℃下, 粗糙环; (b)在Tw = 223.0 ℃, Tr = 191.4 ℃下, 抛光环; (c) Tw = 304.5 ℃, Tr = 256.3 ℃下, 粗糙环

Figure 5. Droplet collision frequency during the whole droplet lifetime: (a) Tw = 223.0 ℃, Tr = 191.4 ℃, rough ring; (b) Tw = 223.0 ℃, Tr = 191.4 ℃, polished ring; (c) Tw = 304.5 ℃, Tr = 256.3 ℃, rough ring.

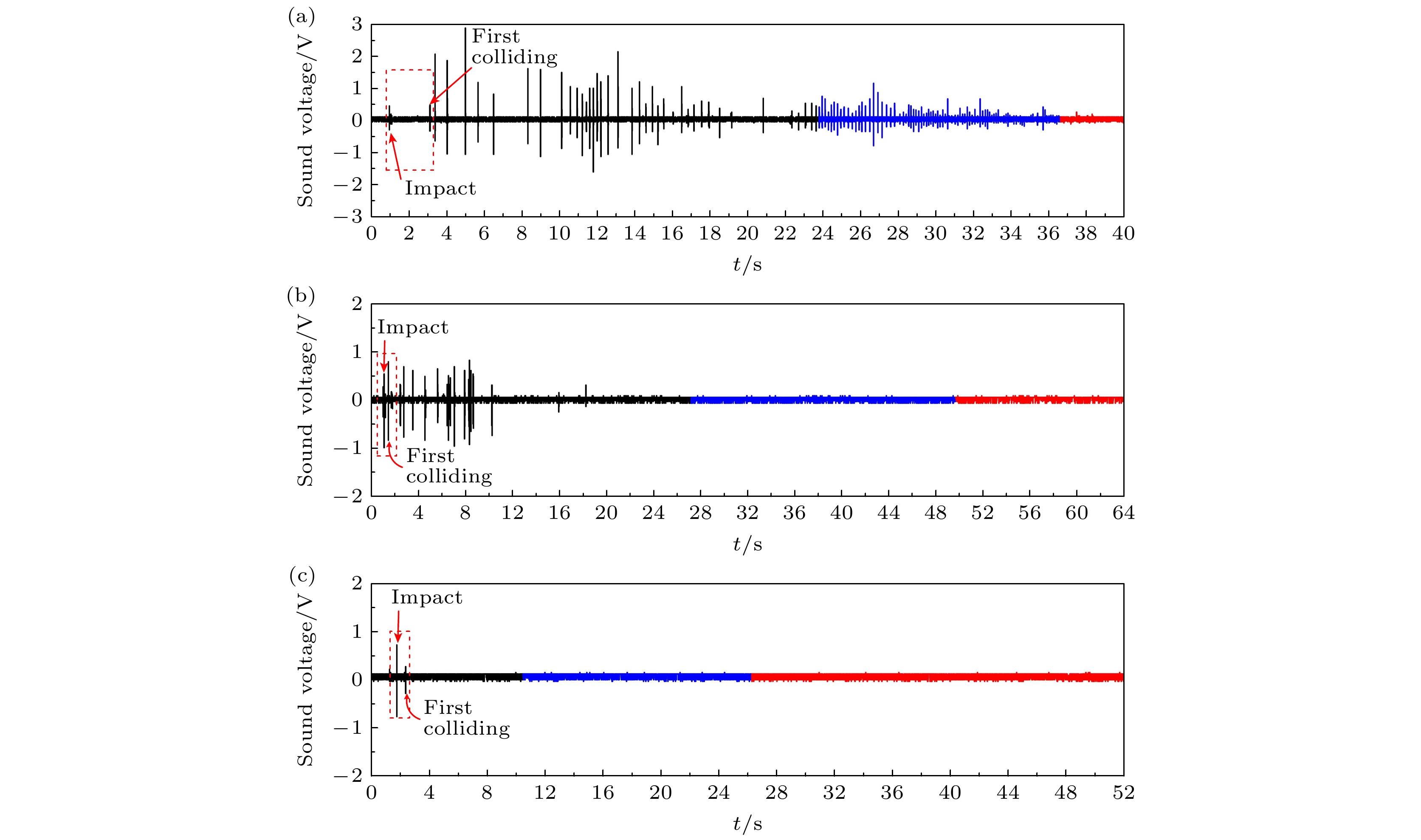

图 7 液滴整个寿命周期内液滴的声音信号 (a)在Tw = 223.0 ℃, Tr = 191.4 ℃下, 粗糙环; (b)在Tw = 223.0 ℃, Tr = 191.4 ℃下, 抛光环; (c) Tw = 304.5 ℃, Tr = 256.3 ℃下, 粗糙环

Figure 7. Droplet sound voltage during the whole droplet lifetime: (a) Tw = 223.0 ℃, Tr = 191.4 ℃, rough ring; (b) Tw = 223.0 ℃, Tr = 191.4 ℃, polished ring; (c) Tw = 304.5 ℃, Tr = 256.3 ℃, rough ring.

图 6 液滴整个寿命周期内液滴运动速度 (a) 在Tw = 223.0 ℃, Tr = 191.4 ℃下, 粗糙环; (b)在Tw = 223.0 ℃, Tr = 191.4 ℃下, 抛光环; (c) Tw = 304.5 ℃, Tr = 256.3 ℃下, 粗糙环

Figure 6. Droplet traveling velocity during the whole droplet lifetime: (a) Tw = 223.0 ℃, Tr = 191.4 ℃, rough ring; (b) Tw = 223.0 ℃, Tr = 191.4 ℃, polished ring; (c) Tw = 304.5 ℃, Tr = 256.3 ℃, rough ring.

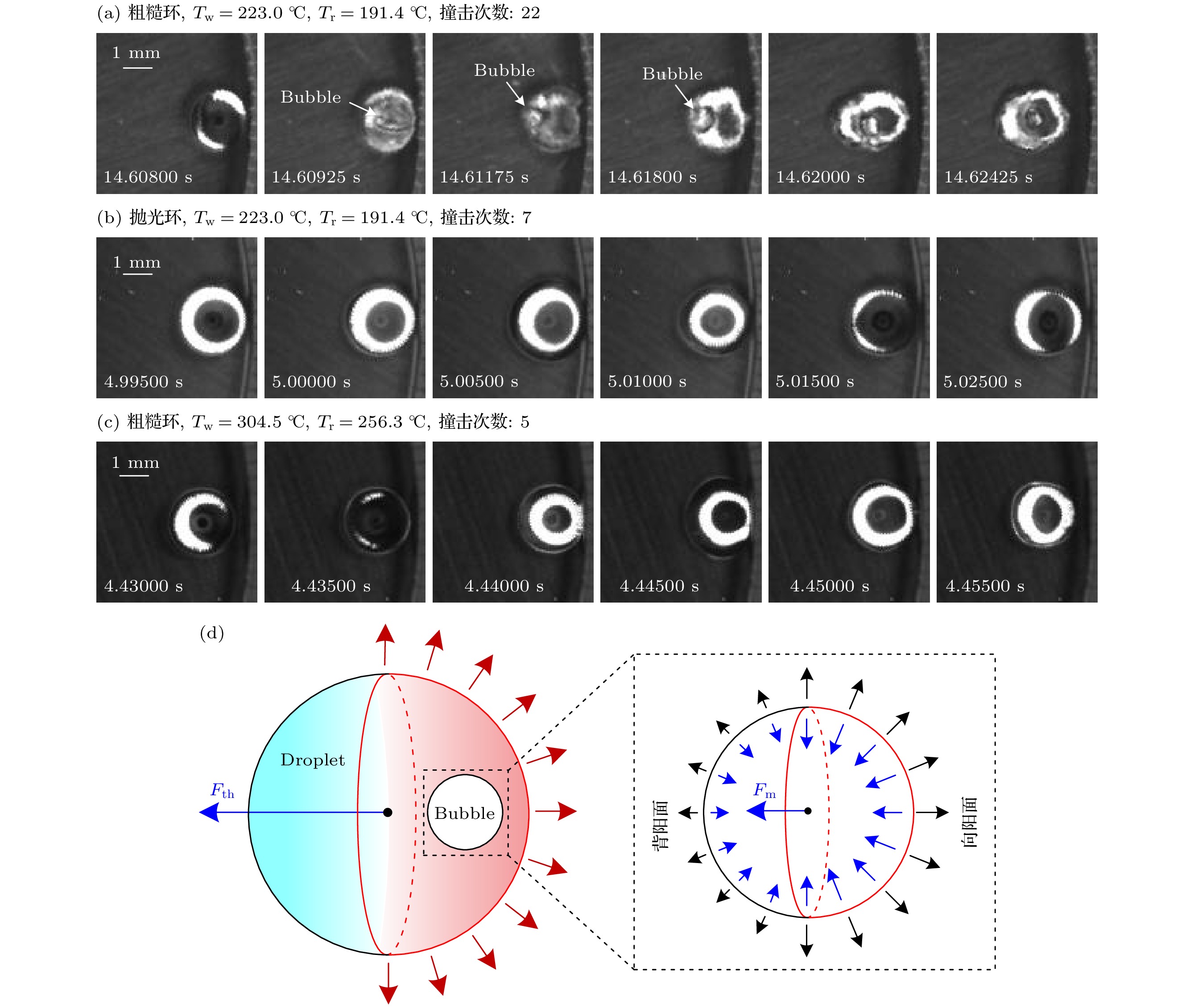

图 8 液滴撞击瞬间 (a)在Tw = 223.0 ℃, Tr = 191.4 ℃下, 粗糙环; (b)在Tw = 223.0 ℃, Tr = 191.4 ℃下, 抛光环; (c) Tw = 304.5 ℃, Tr = 256.3 ℃下, 粗糙环; (d)液滴内汽泡运动机理

Figure 8. Droplet impact moment: (a) Tw = 223.0 ℃, Tr = 191.4 ℃, rough ring; (b) Tw = 223.0 ℃, Tr = 191.4 ℃, polished ring; (c) Tw = 304.5 ℃, Tr = 256.3 ℃, rough ring; (d) movement mechanism of bubble in droplets.

-

[1] Leidenfrost J G 1966 Int. J. Heat Mass Transfer 9 1153

Google Scholar

Google Scholar

[2] Vakarelski I U, Marston J O, Chan D Y, Thoroddsen S T 2011 Phys. Rev. Lett. 106 214501

Google Scholar

Google Scholar

[3] Sengupta S, Patra D, Ortiz-Rivera I, Agrawal A, Shklyaev S, Dey K K, Cordova-Figueroa U, Mallouk T E, Sen A 2014 Nat. Chem. 6 415

Google Scholar

Google Scholar

[4] Baylis J R, Yeon J H, Thomson M H, Kazerooni A, Wang X, John A E S, Lim E B, Chien D, Lee A, Zhang J Q 2015 Sci. Adv. 1 e1500379

Google Scholar

Google Scholar

[5] Dittrich P S, Manz A 2006 Nat. Rev. Drug discovery 5 210

Google Scholar

Google Scholar

[6] Chen M Y, Jia Z H, Zhang T, Fei Y Y 2018 Appl. Surf. Sci. 433 336

Google Scholar

Google Scholar

[7] Chu F, Luo J, Hao C, Zhang J, Wu X, Wen D 2020 Langmuir 36 5855

Google Scholar

Google Scholar

[8] 王宏, 廖强, 朱恂 2007 化工学报 58 2313

Google Scholar

Google Scholar

Wang H, Liao Q, Zhu X 2007 J. Chem. Ind. Eng. 58 2313

Google Scholar

Google Scholar

[9] Li J, Hou Y, Liu Y, Hao C, Li M, Chaudhury M K, Yao S, Wang Z 2016 Nat. Phys. 12 606

Google Scholar

Google Scholar

[10] Sobac B, Rednikov A, Dorbolo S, Colinet P 2017 Phys. Fluids 29 082101

Google Scholar

Google Scholar

[11] Linke H, Aleman B J, Melling L D, Taormina M J, Francis M J, Dow-Hygelund C C, Narayanan V, Taylor R P, Stout A 2006 Phys. Rev. Lett. 96 154502

Google Scholar

Google Scholar

[12] Quéré D 2013 Annu. Rev. Fluid Mech. 45 197

Google Scholar

Google Scholar

[13] Scriven L, Sternling C 1960 Nature 187 186

Google Scholar

Google Scholar

[14] Jia Z H, Chen M Y, Zhu H T 2017 Appl. Phys. Lett. 110 091603

Google Scholar

Google Scholar

[15] Lagubeau G, Le Merrer M, Clanet C, Quéré D 2011 Nat. Phys. 7 395

Google Scholar

Google Scholar

[16] Wang B, Xu J L, Zhang W, Li Y X 2011 Sens. Actuators, A 169 194

Google Scholar

Google Scholar

[17] Xu J, Zhang W 2008 Int. J. Heat Mass Transfer 51 389

Google Scholar

Google Scholar

[18] Lyu S, Mathai V, Wang Y, Sobac B, Colinet P, Lohse D, Sun C 2019 Sci. Adv. 5 eaav8081

Google Scholar

Google Scholar

[19] Ok J T, Lopez-Oña E, Nikitopoulos D E, Wong H, Park S 2010 Microfluid. Nanofluid. 10 1045

[20] Grounds A, Still R, Takashina K 2012 Sci. Rep. 2 720

Google Scholar

Google Scholar

[21] Shahriari A, Wilson P S, Bahadur V 2018 Phys. Rev. E 98 013103

Google Scholar

Google Scholar

[22] Cole R 1974 Adv. Heat Transfer 10 85

Google Scholar

Google Scholar

[23] Kandlikar S G 2004 J. Heat Transfer 126 8

Google Scholar

Google Scholar

[24] Kandlikar S G 2020 J. Heat Transfer 142 100801

Google Scholar

Google Scholar

[25] Zhu B, Xu J, Yan C, Xie J 2020 Int. J. Heat Mass Transfer 148 119080

[26] 张海松, 朱鑫杰, 朱兵国, 徐进良, 刘欢 2020 69 064401

Google Scholar

Google Scholar

Zhang H S, Zhu X J, Zhu B G, Xu J L, Liu H 2020 Acta Phys. Sin. 69 064401

Google Scholar

Google Scholar

[27] Shati A K A, Blakey S G, Beck S B M 2011 Energy Build. 43 400

Google Scholar

Google Scholar

[28] Yan X, Xu J, Meng Z, Xie J, Wang H 2020 Small 16 e2001548

Google Scholar

Google Scholar

[29] Ishii M, Zuber N 1979 AIChE J. 25 843

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 7763

- PDF Downloads: 134

- Cited By: 0

DownLoad:

DownLoad: