-

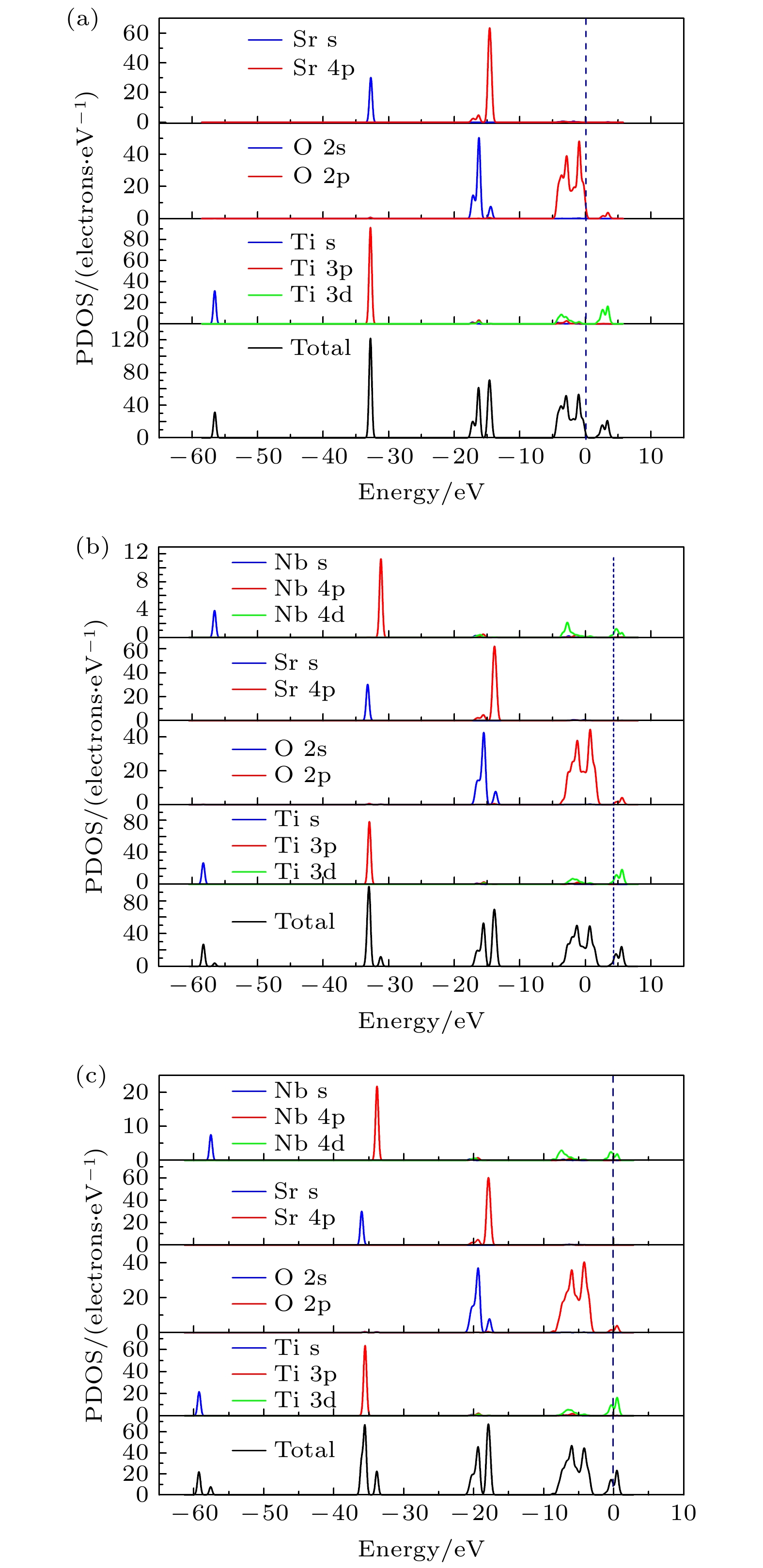

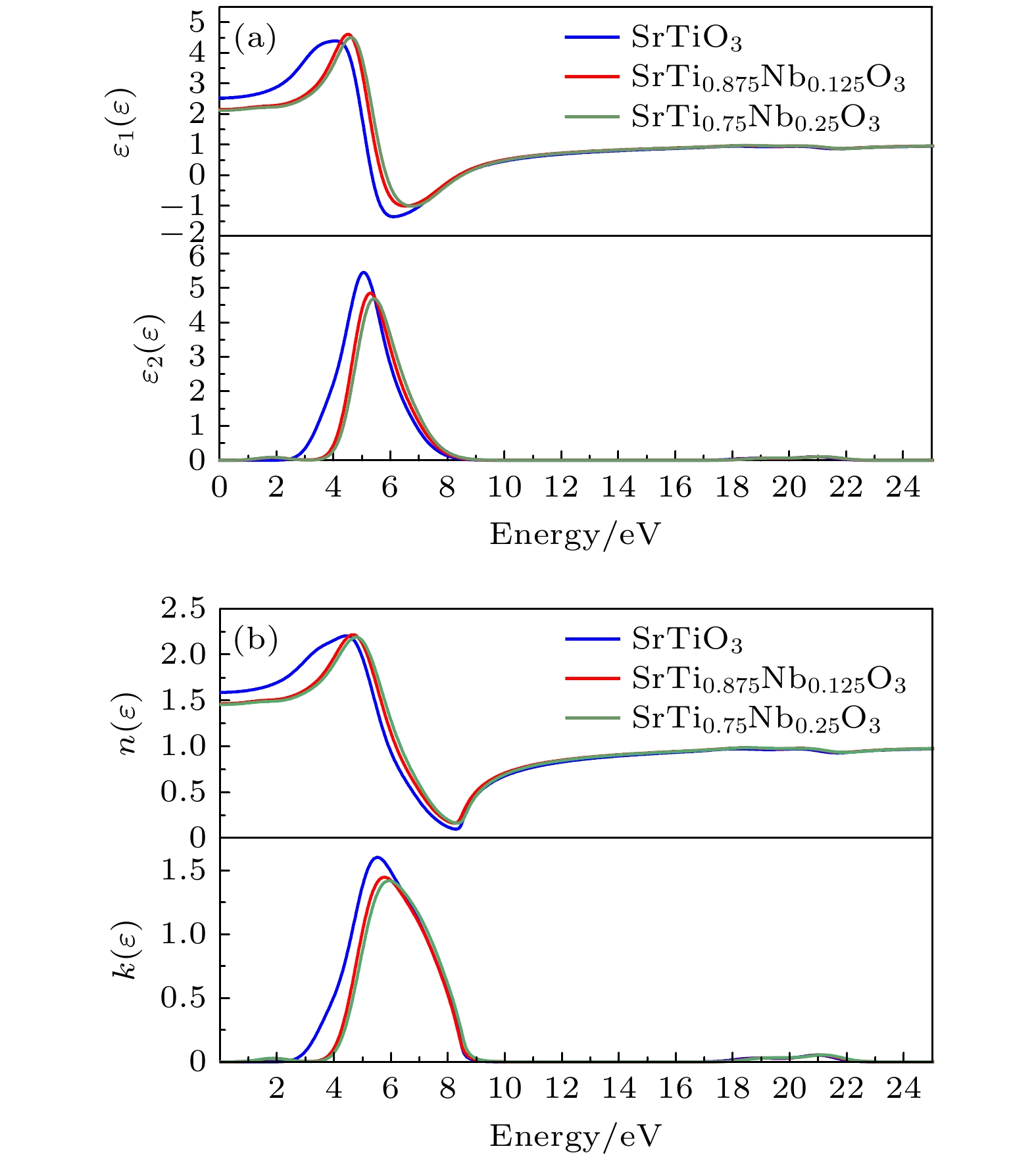

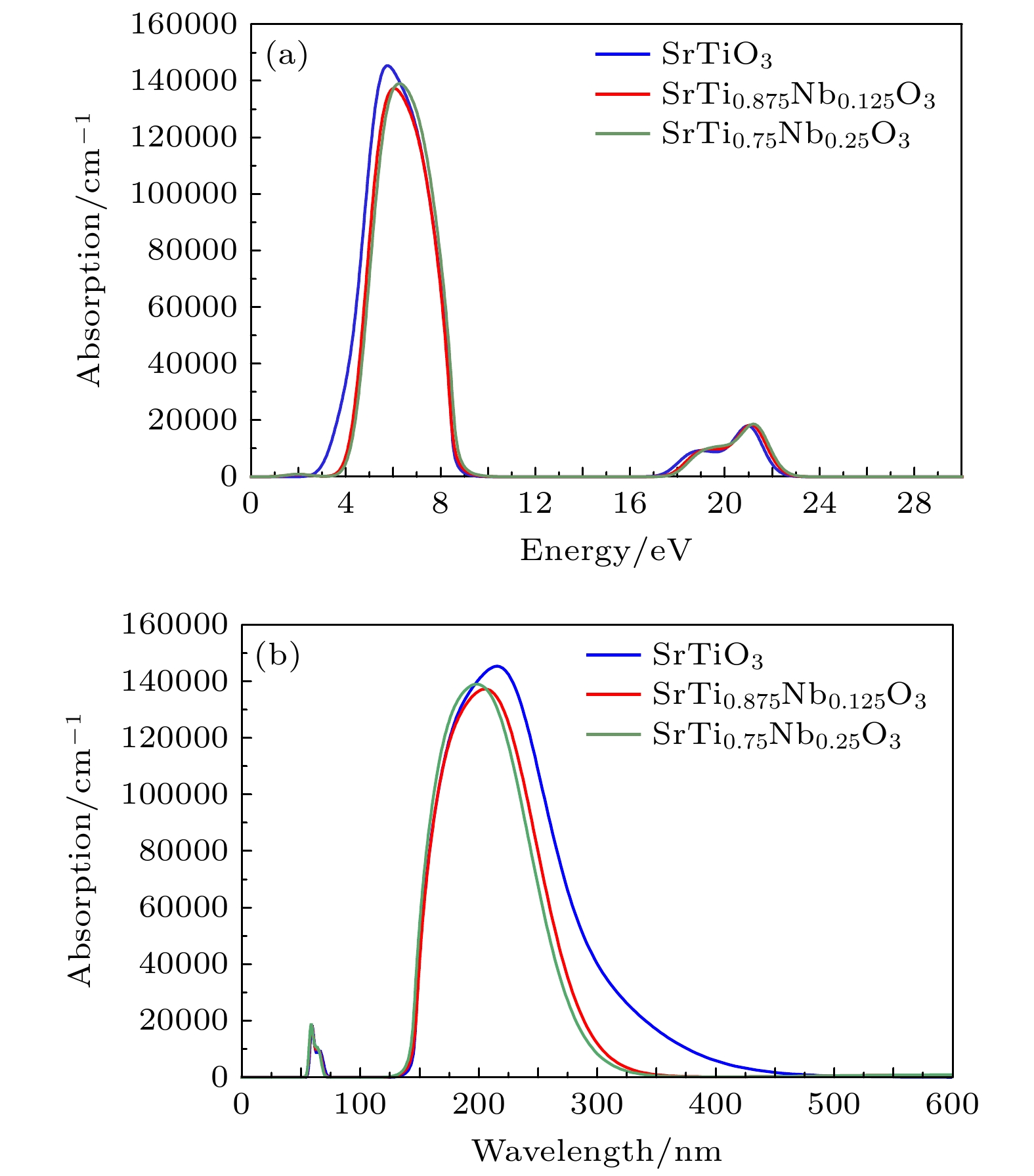

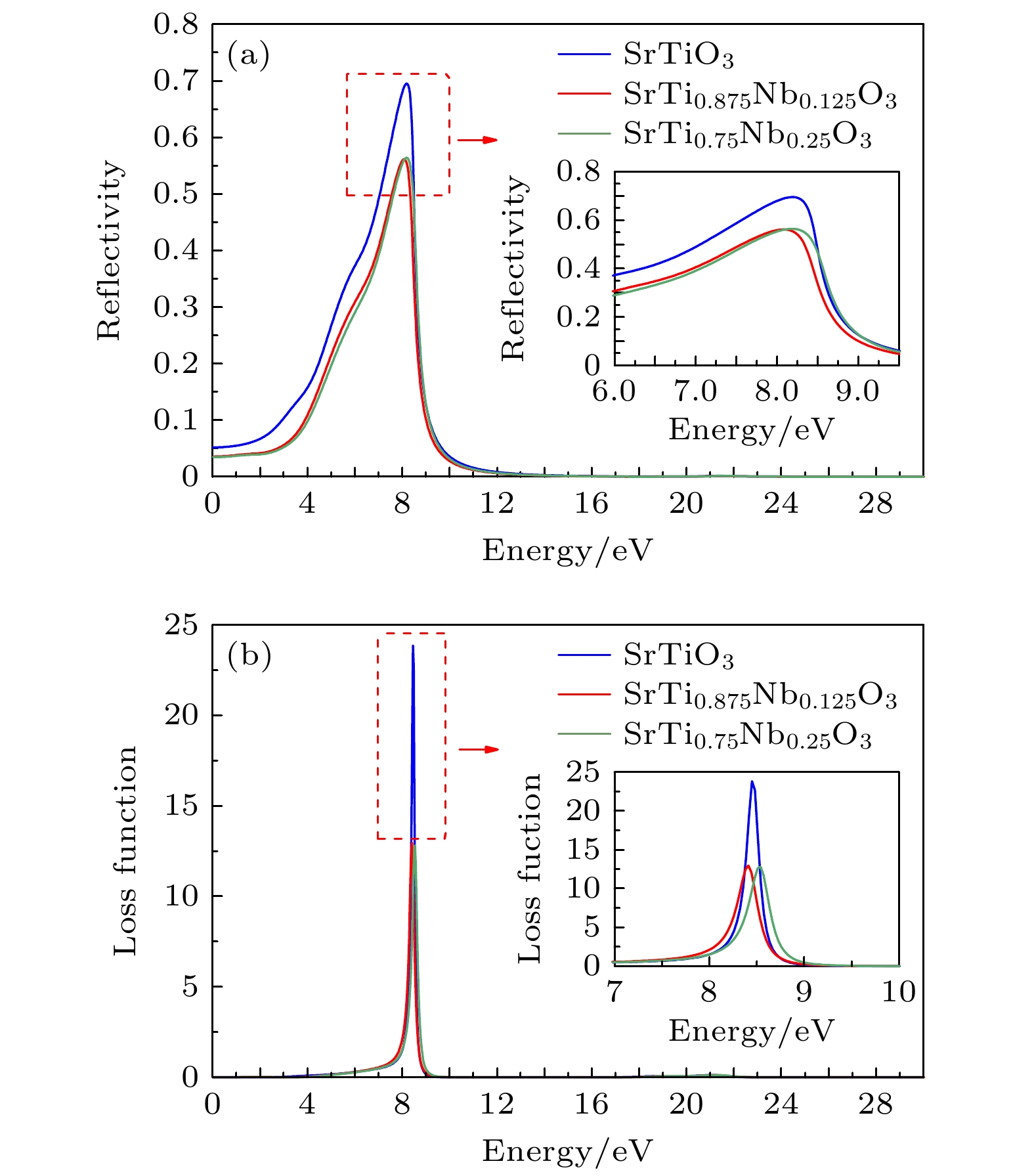

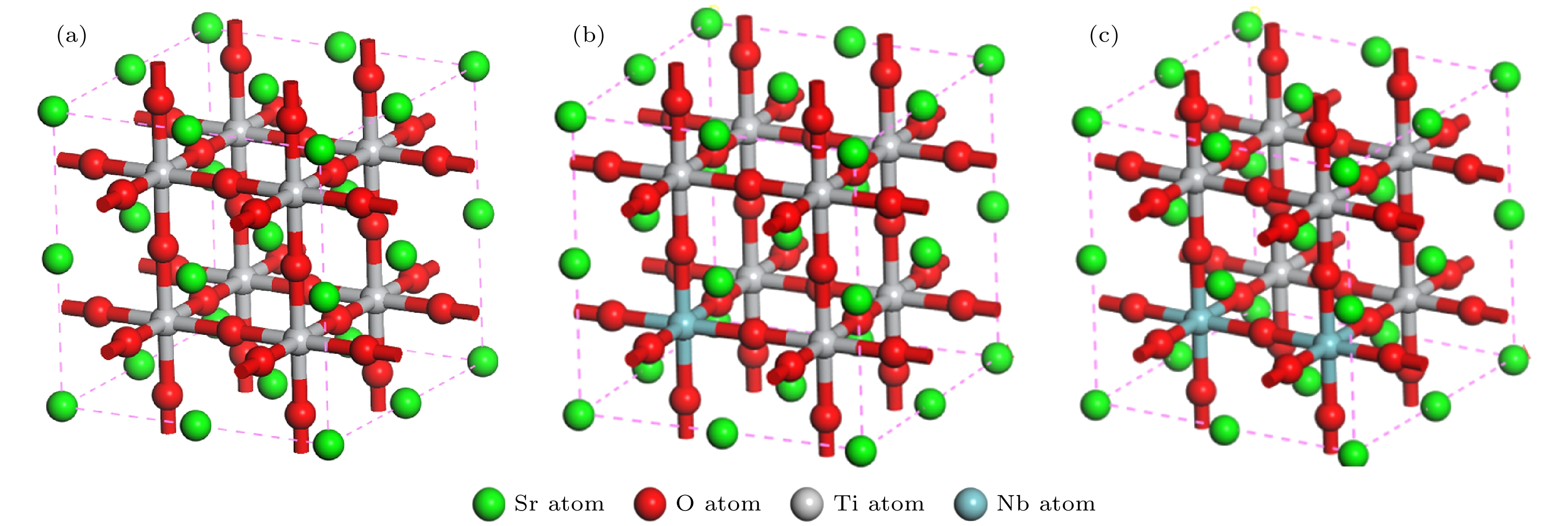

The modification of SrTiO3 materials by doping Nb5+ ions in B-site is studied through using the first-principles method to calculate the electronic structure, optical properties, mechanical properties and thermal properties at different Nb5+ doping concentrations. The calculation results show that as the doping content of Nb5+ increases, the lattice parameters increase. After being doped with Nb5+, SrTiO3 changes from an indirect band gap compound into a direct band gap compound. Doping Nb5+ can reduce the reflection coefficient, absorption coefficient, and energy loss of SrTiO3 material, which can be used to modify its optical properties. Additionally, the brittleness of SrTiO3 material is improved through doping Nb5+. As the doping content of Nb5+ increases, the elastic modulus of the material hardly changes, the shear modulus and Young's modulus decrease, the Poisson's ratio increases, and the Debye temperature decreases, and both the lattice thermal conductivity and the theoretical minimum lattice thermal conductivity decrease as well.

-

Keywords:

- Nb5+ doping SrTiO3 /

- first principles /

- optical properties /

- thermal properties

[1] Huang W, Nechache R, Li S, Chaker M, Rosei F 2016 Am. Ceram. Soc. 99 226

Google Scholar

Google Scholar

[2] 李守委 2015 硕士学位论文 (哈尔滨: 哈尔滨工业大学)

Li S W 2015 M. Dissertation (Harbin: Harbin Institute of Technology) (in Chinese)

[3] Jing P P, Lan W, Su Q, Xie E Q 2015 Beilstein J. Nanotechnol. 6 1281

Google Scholar

Google Scholar

[4] Zhang T F, Tang X G, Xiang Q, Jiang Y P 2018 J. Alloys Compd. 730 516

Google Scholar

Google Scholar

[5] Blennow P, Hagen A, HansenK K, Wallenberg L R, Mogensen M 2008 Solid State Ion. 179 2047

Google Scholar

Google Scholar

[6] Gerblinger J, Meixner H 1991 Sens. Actuators B Chem. 4 99

Google Scholar

Google Scholar

[7] Ham Y S, Koh J H 2009 Ferroelectrics 382 85

Google Scholar

Google Scholar

[8] Nakano Y, Ichinose N 1990 J. Mater. Res. 5 2910

Google Scholar

Google Scholar

[9] Iwashina K, Kudo A 2011 J. Am. Chem. Soc. 133 13272

Google Scholar

Google Scholar

[10] Rheinheimer W, Bäurer M, Handwerker C A, Blendell J E, Hoffmann M J 2015 Acta Mater. 95 111

Google Scholar

Google Scholar

[11] 王欣 2017 硕士学位论文 (西安: 西安理工大学)

Wang X 2017 M. S. Thesis (Xi'an: Xi'an University of Technology) (in Chinese)

[12] 常亮亮 2014 材料开发与应用 29 89

Chang L L 2014 Development and Application of Materials 29 89

[13] Ohta S, Ohta H, Koumoto K 2006 J. Ceram. Soc. Japan 114 102

Google Scholar

Google Scholar

[14] Tomio T, Miki H, Tabata H, Kawai T, Kawai S 1994 J. Appl. Phys. 76 5886

Google Scholar

Google Scholar

[15] Bakhshi H, Sarraf M R, Yourdkhania A, AbdelNabi A A, Mozharivskyj Y 2020 Ceram. Int. 46 3224

Google Scholar

Google Scholar

[16] Benrekia A R, Benkhettou N, Nassour A, Driz M, Sahnoun M, Lebèguec S 2012 Phys. Rev., B Condens. Matter 407 2632

Google Scholar

Google Scholar

[17] Ghebouli B, Ghebouli M A, Chihi T, Fatmi M, Boucetta S, Reffas M 2009 Solid State Commun. 149 2244

Google Scholar

Google Scholar

[18] 贠江妮 2010 博士学位论文 (西安: 西北大学)

Yun J N 2010 Ph. D. Dissertation (Xi'an: Northwest University) (in Chinese)

[19] Guo X G, Chen X S, Lu W 2003 Solid State Commun. 126 441

Google Scholar

Google Scholar

[20] Eglitis R I, Kotomin E A 2010 Phys. B:Condens. Matter 405 3164

Google Scholar

Google Scholar

[21] Nishiyama J, Kanehara K, Takeda H, Tsurumi T, Hoshina T 2019 J. Ceram. Soc. Japan 127 357

Google Scholar

Google Scholar

[22] Guo X G, Chen X, Sun Y L, Sun L Z, Zhou X H, Lu W 2003 Phys. Lett. A 317 501

Google Scholar

Google Scholar

[23] Blöchl P E, Jepsen O, Andersen O K 1994 Phys. Rev. B:Condens. Matter 49 16223

Google Scholar

Google Scholar

[24] Kohn W, Sham L J 1965 Phys. Rev. A 140 A1133

Google Scholar

Google Scholar

[25] Benthem K V, Elsässer C, French R H 2001 J. Appl. Phys. 90 6156

Google Scholar

Google Scholar

[26] 陈敏强, 李廷鱼, 王开鹰, 胡杰, 李朋伟, 胡文秀, 李刚 2017 固体电子学研究与进展 37 316

Chen M Q, Li Y Y, Wang K Y, Hu J, Li P W, Hu W X, Li G 2017 Res. Prog. Solid State Electron. 37 316

[27] Chen Q, Gao F, Xu J, Cao S Y, Guo Y T, Cheng G H 2019 Ceram. Int. 45 9967

Google Scholar

Google Scholar

[28] Kato H, Kudo A 2002 J. Phys. Chem. B 106 5029

Google Scholar

Google Scholar

[29] 侯清玉, 吕致远, 赵春旺 2015 64 017201

Google Scholar

Google Scholar

Hou Q Y, Lv Z Y, Zhao C W 2015 Acta Phys. Sin. 64 017201

Google Scholar

Google Scholar

[30] Kumar A, Dho J 2013 Curr. Appl. Phys. 13 768

Google Scholar

Google Scholar

[31] 刘娜娜, 宋仁伯, 孙翰英, 杜大伟 2008 57 7145

Google Scholar

Google Scholar

Liu N N, Song R B, Sun H Y, Du D W 2008 Acta Phys. Sin. 57 7145

Google Scholar

Google Scholar

[32] Piskunov S, Heifets E, Eglitis R I, Borstel G 2004 Comput. Mater. Sci. 29 165

[33] 项建英, 黄继华, 陈树海, 梁文建, 赵兴科, 张华 2012 航空材料学报 32 1

Google Scholar

Google Scholar

Xiang J Y, Huang J H, Chen H S, Liang W J, Zhao X K, Zhang H 2012 J Aeron. Mater. 32 1

Google Scholar

Google Scholar

[34] Pugh S F 1954 Philos. Mag. 45 823

Google Scholar

Google Scholar

[35] Xiang H M, Feng Z H, Li Z P, Zhou Y C 2017 J. Eur. Ceram. Soc. 37 2491

[36] Wan C L, Pan W, Xu Q, Qin Y X, Wang J D, Qu Z X, Fang M H 2006 Phys. Rev. B 74 144

[37] Slack G A 1973 J. Phys. Chem. Solids. 34 321

Google Scholar

Google Scholar

[38] Clarke D R 2003 Surf. Coat. Technol. 163-164 67

[39] Zhang B Y, Wang J, Zou T, Zhang S, Yaer X B, Ding N, Liu C Y, Miao L, Li Y, Wu Y 2015 J. Mater. Chem. C 3 11406

Google Scholar

Google Scholar

[40] Okhay O, Zlotnik S, Xie W, Orlinski K, Gallo M J, Otero G, Fernandes A, Pawlak D, Weidenkaff A, Tkach A 2019 Carbon 143 215

Google Scholar

Google Scholar

[41] Wang K, Wang J, Li Y, Zou T, Wang X H, Li J B, Cao Z, Shi W J, Year X 2018 Chin. Phys. B 27 121

[42] Liu D, Zhang Y, Kang H, Li J L, Chen Z N, Wang T M 2018 J. Eur. Ceram. Soc. 38 807

Google Scholar

Google Scholar

-

表 1 SrTi1–xNbxO3晶胞参数(a = b = c, 单位: nm)

Table 1. Cell parameters of SrTi1–xNbxO3 (a = b = c, unit: nm).

表 2 SrTi1–xNbxO3弹性刚度张量 (单位: GPa)

Table 2. Elastic constants (Unit: GPa) of SrTi1–xNbxO3.

表 3 SrTi1–xNbxO3力学性能参数

Table 3. Mechanical property parameters of SrTi1–xNbxO3.

Parameters Symbel SrTiO3 SrTi0.875Nb0.125O3 SrTi0.75Nb0.25O3 Bulk elastic modulus/GPa B 168.8 169.7 166.0 Shear modulus/GPa G 108.3 100.8 78.3 G/B / 0.64 0.59 0.47 Young's modulus/GPa E 267.7 252.4 202.9 Poisson's ratio/(m·s–1) σ 0.236 0.252 0.296 表 4 SrTi1–xNbxO3的声速和德拜温度

Table 4. Calculated sound velocity and Debye temperature of SrTi1–xNbxO3.

Parameters Symbel SrTiO3 SrTi0.875Nb0.125O3 SrTi0.75Nb0.25O3 Compression wave velocity/(m·s–1) vp 7916.5 7745.6 7241.4 Shear wave velocity/(m·s–1) vs 4655.3 4460.2 3897.8 Average wave velocity/(m·s–1) vm 4876.2 4694.3 4351.6 Debye temperature/K ΘD 630.7 603.9 557.7 -

[1] Huang W, Nechache R, Li S, Chaker M, Rosei F 2016 Am. Ceram. Soc. 99 226

Google Scholar

Google Scholar

[2] 李守委 2015 硕士学位论文 (哈尔滨: 哈尔滨工业大学)

Li S W 2015 M. Dissertation (Harbin: Harbin Institute of Technology) (in Chinese)

[3] Jing P P, Lan W, Su Q, Xie E Q 2015 Beilstein J. Nanotechnol. 6 1281

Google Scholar

Google Scholar

[4] Zhang T F, Tang X G, Xiang Q, Jiang Y P 2018 J. Alloys Compd. 730 516

Google Scholar

Google Scholar

[5] Blennow P, Hagen A, HansenK K, Wallenberg L R, Mogensen M 2008 Solid State Ion. 179 2047

Google Scholar

Google Scholar

[6] Gerblinger J, Meixner H 1991 Sens. Actuators B Chem. 4 99

Google Scholar

Google Scholar

[7] Ham Y S, Koh J H 2009 Ferroelectrics 382 85

Google Scholar

Google Scholar

[8] Nakano Y, Ichinose N 1990 J. Mater. Res. 5 2910

Google Scholar

Google Scholar

[9] Iwashina K, Kudo A 2011 J. Am. Chem. Soc. 133 13272

Google Scholar

Google Scholar

[10] Rheinheimer W, Bäurer M, Handwerker C A, Blendell J E, Hoffmann M J 2015 Acta Mater. 95 111

Google Scholar

Google Scholar

[11] 王欣 2017 硕士学位论文 (西安: 西安理工大学)

Wang X 2017 M. S. Thesis (Xi'an: Xi'an University of Technology) (in Chinese)

[12] 常亮亮 2014 材料开发与应用 29 89

Chang L L 2014 Development and Application of Materials 29 89

[13] Ohta S, Ohta H, Koumoto K 2006 J. Ceram. Soc. Japan 114 102

Google Scholar

Google Scholar

[14] Tomio T, Miki H, Tabata H, Kawai T, Kawai S 1994 J. Appl. Phys. 76 5886

Google Scholar

Google Scholar

[15] Bakhshi H, Sarraf M R, Yourdkhania A, AbdelNabi A A, Mozharivskyj Y 2020 Ceram. Int. 46 3224

Google Scholar

Google Scholar

[16] Benrekia A R, Benkhettou N, Nassour A, Driz M, Sahnoun M, Lebèguec S 2012 Phys. Rev., B Condens. Matter 407 2632

Google Scholar

Google Scholar

[17] Ghebouli B, Ghebouli M A, Chihi T, Fatmi M, Boucetta S, Reffas M 2009 Solid State Commun. 149 2244

Google Scholar

Google Scholar

[18] 贠江妮 2010 博士学位论文 (西安: 西北大学)

Yun J N 2010 Ph. D. Dissertation (Xi'an: Northwest University) (in Chinese)

[19] Guo X G, Chen X S, Lu W 2003 Solid State Commun. 126 441

Google Scholar

Google Scholar

[20] Eglitis R I, Kotomin E A 2010 Phys. B:Condens. Matter 405 3164

Google Scholar

Google Scholar

[21] Nishiyama J, Kanehara K, Takeda H, Tsurumi T, Hoshina T 2019 J. Ceram. Soc. Japan 127 357

Google Scholar

Google Scholar

[22] Guo X G, Chen X, Sun Y L, Sun L Z, Zhou X H, Lu W 2003 Phys. Lett. A 317 501

Google Scholar

Google Scholar

[23] Blöchl P E, Jepsen O, Andersen O K 1994 Phys. Rev. B:Condens. Matter 49 16223

Google Scholar

Google Scholar

[24] Kohn W, Sham L J 1965 Phys. Rev. A 140 A1133

Google Scholar

Google Scholar

[25] Benthem K V, Elsässer C, French R H 2001 J. Appl. Phys. 90 6156

Google Scholar

Google Scholar

[26] 陈敏强, 李廷鱼, 王开鹰, 胡杰, 李朋伟, 胡文秀, 李刚 2017 固体电子学研究与进展 37 316

Chen M Q, Li Y Y, Wang K Y, Hu J, Li P W, Hu W X, Li G 2017 Res. Prog. Solid State Electron. 37 316

[27] Chen Q, Gao F, Xu J, Cao S Y, Guo Y T, Cheng G H 2019 Ceram. Int. 45 9967

Google Scholar

Google Scholar

[28] Kato H, Kudo A 2002 J. Phys. Chem. B 106 5029

Google Scholar

Google Scholar

[29] 侯清玉, 吕致远, 赵春旺 2015 64 017201

Google Scholar

Google Scholar

Hou Q Y, Lv Z Y, Zhao C W 2015 Acta Phys. Sin. 64 017201

Google Scholar

Google Scholar

[30] Kumar A, Dho J 2013 Curr. Appl. Phys. 13 768

Google Scholar

Google Scholar

[31] 刘娜娜, 宋仁伯, 孙翰英, 杜大伟 2008 57 7145

Google Scholar

Google Scholar

Liu N N, Song R B, Sun H Y, Du D W 2008 Acta Phys. Sin. 57 7145

Google Scholar

Google Scholar

[32] Piskunov S, Heifets E, Eglitis R I, Borstel G 2004 Comput. Mater. Sci. 29 165

[33] 项建英, 黄继华, 陈树海, 梁文建, 赵兴科, 张华 2012 航空材料学报 32 1

Google Scholar

Google Scholar

Xiang J Y, Huang J H, Chen H S, Liang W J, Zhao X K, Zhang H 2012 J Aeron. Mater. 32 1

Google Scholar

Google Scholar

[34] Pugh S F 1954 Philos. Mag. 45 823

Google Scholar

Google Scholar

[35] Xiang H M, Feng Z H, Li Z P, Zhou Y C 2017 J. Eur. Ceram. Soc. 37 2491

[36] Wan C L, Pan W, Xu Q, Qin Y X, Wang J D, Qu Z X, Fang M H 2006 Phys. Rev. B 74 144

[37] Slack G A 1973 J. Phys. Chem. Solids. 34 321

Google Scholar

Google Scholar

[38] Clarke D R 2003 Surf. Coat. Technol. 163-164 67

[39] Zhang B Y, Wang J, Zou T, Zhang S, Yaer X B, Ding N, Liu C Y, Miao L, Li Y, Wu Y 2015 J. Mater. Chem. C 3 11406

Google Scholar

Google Scholar

[40] Okhay O, Zlotnik S, Xie W, Orlinski K, Gallo M J, Otero G, Fernandes A, Pawlak D, Weidenkaff A, Tkach A 2019 Carbon 143 215

Google Scholar

Google Scholar

[41] Wang K, Wang J, Li Y, Zou T, Wang X H, Li J B, Cao Z, Shi W J, Year X 2018 Chin. Phys. B 27 121

[42] Liu D, Zhang Y, Kang H, Li J L, Chen Z N, Wang T M 2018 J. Eur. Ceram. Soc. 38 807

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 11100

- PDF Downloads: 259

- Cited By: 0

DownLoad:

DownLoad: