-

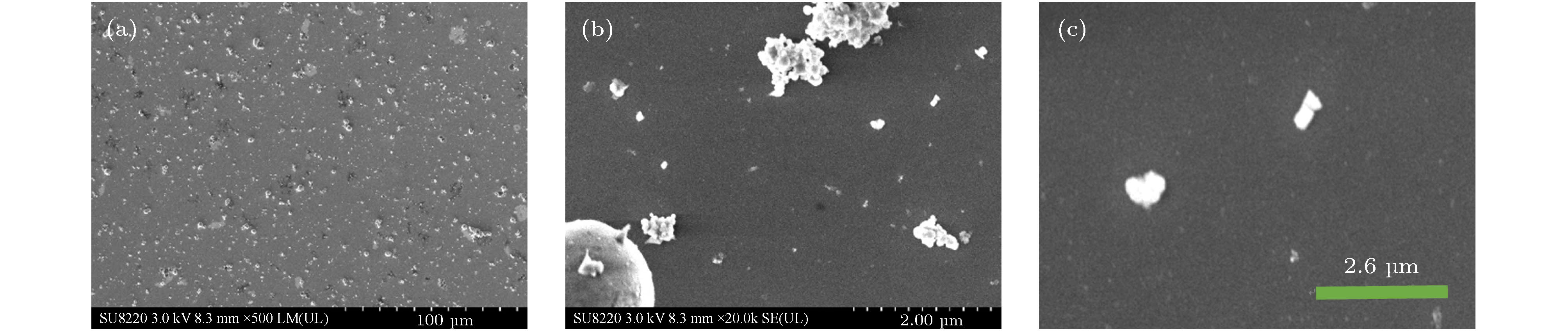

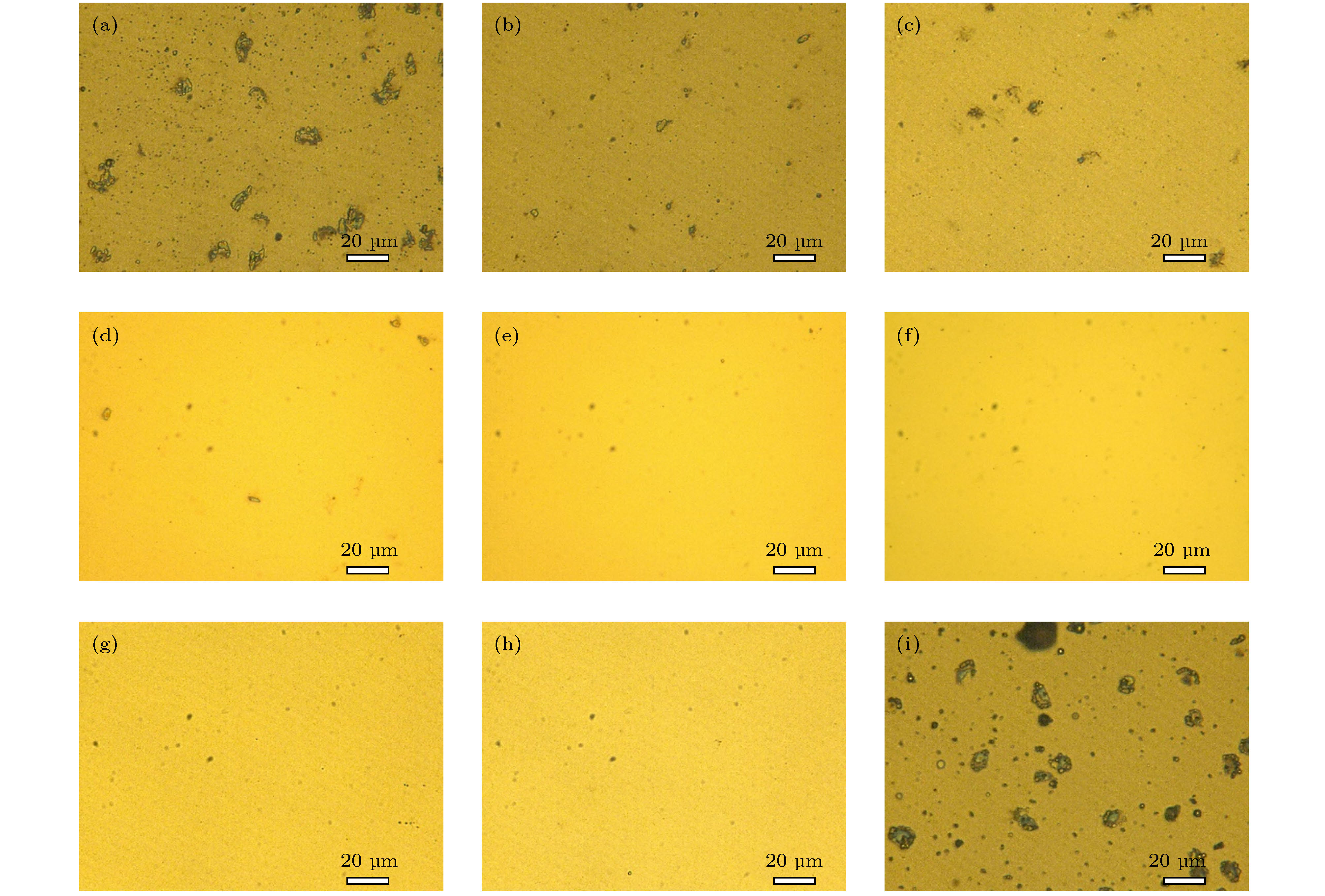

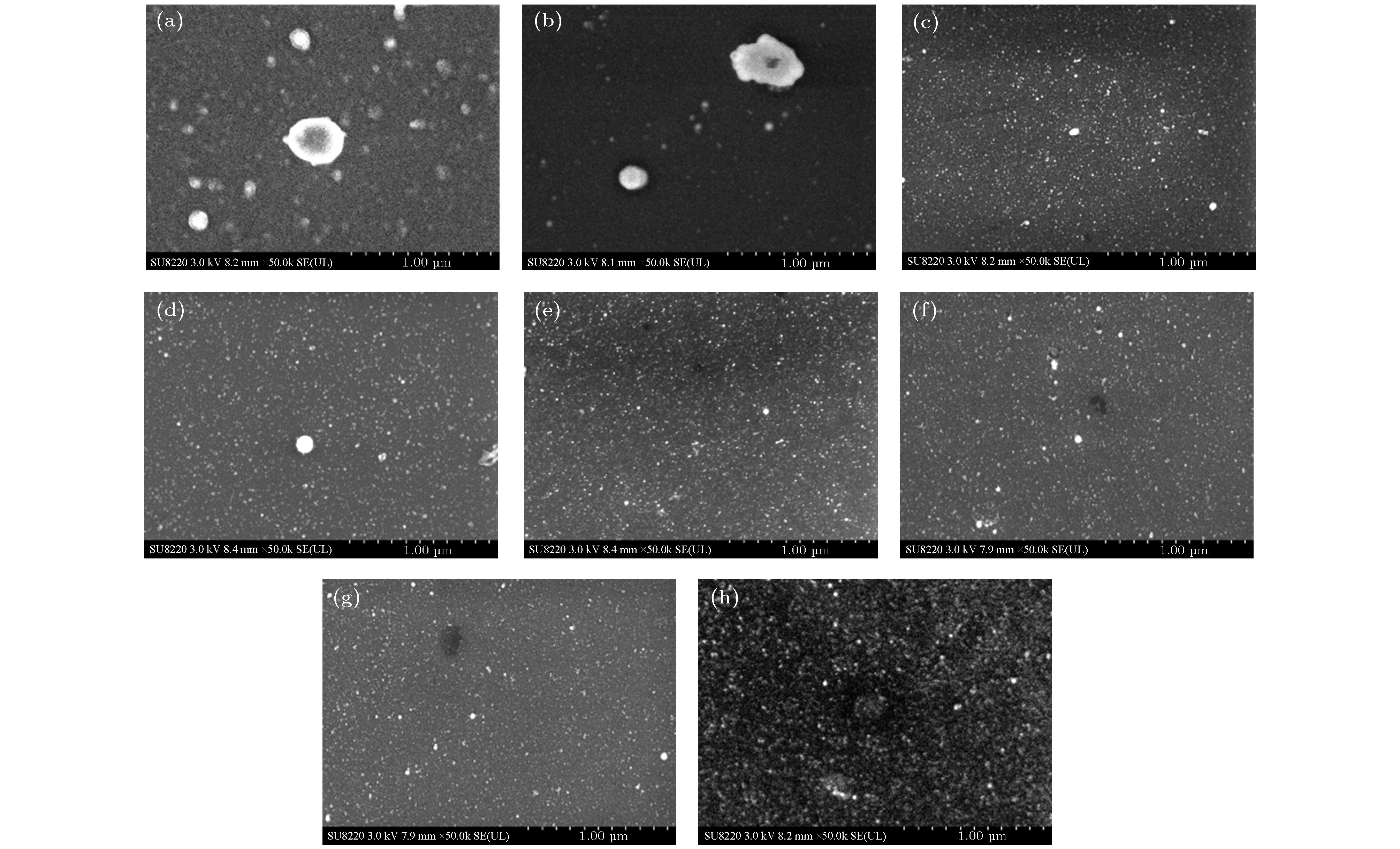

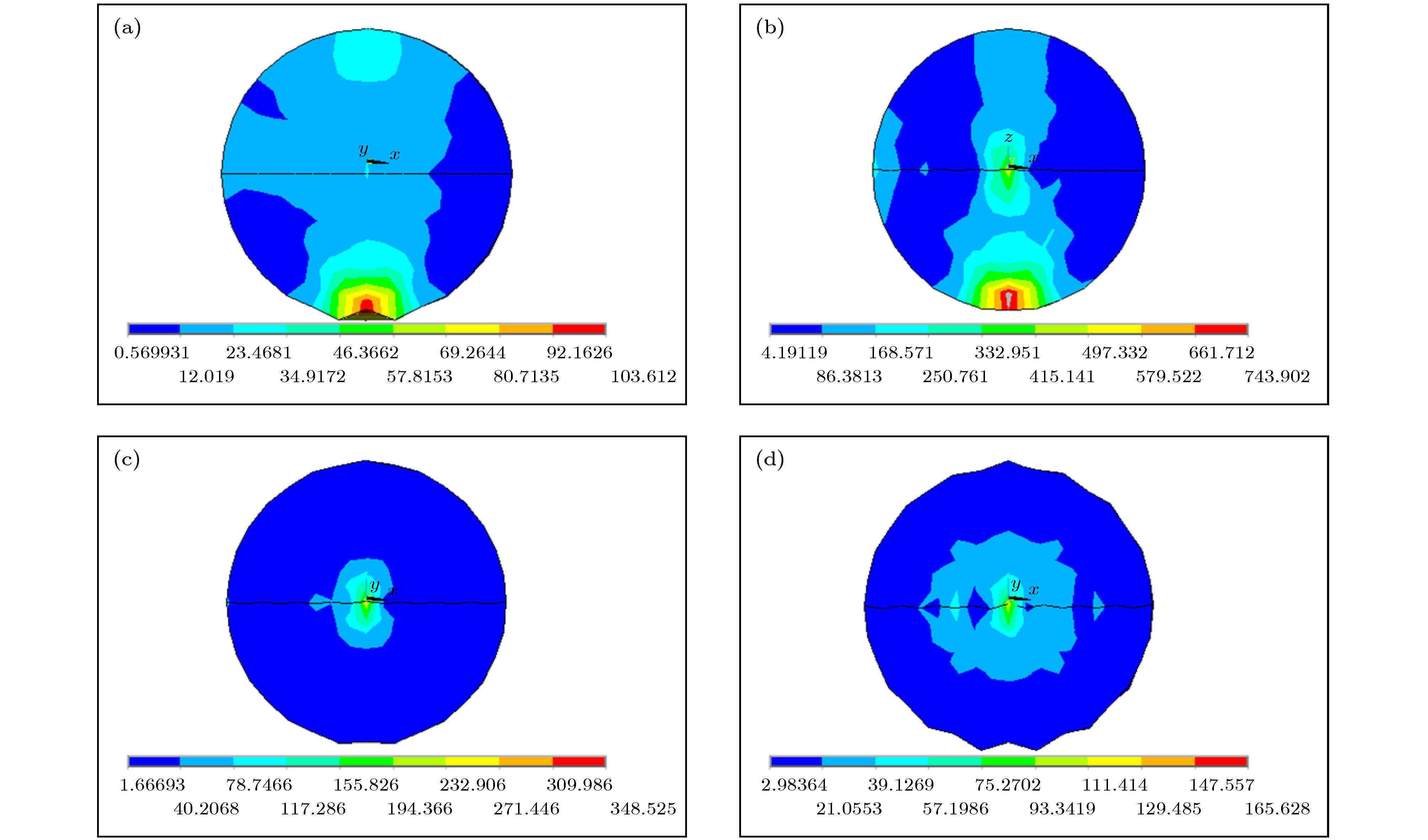

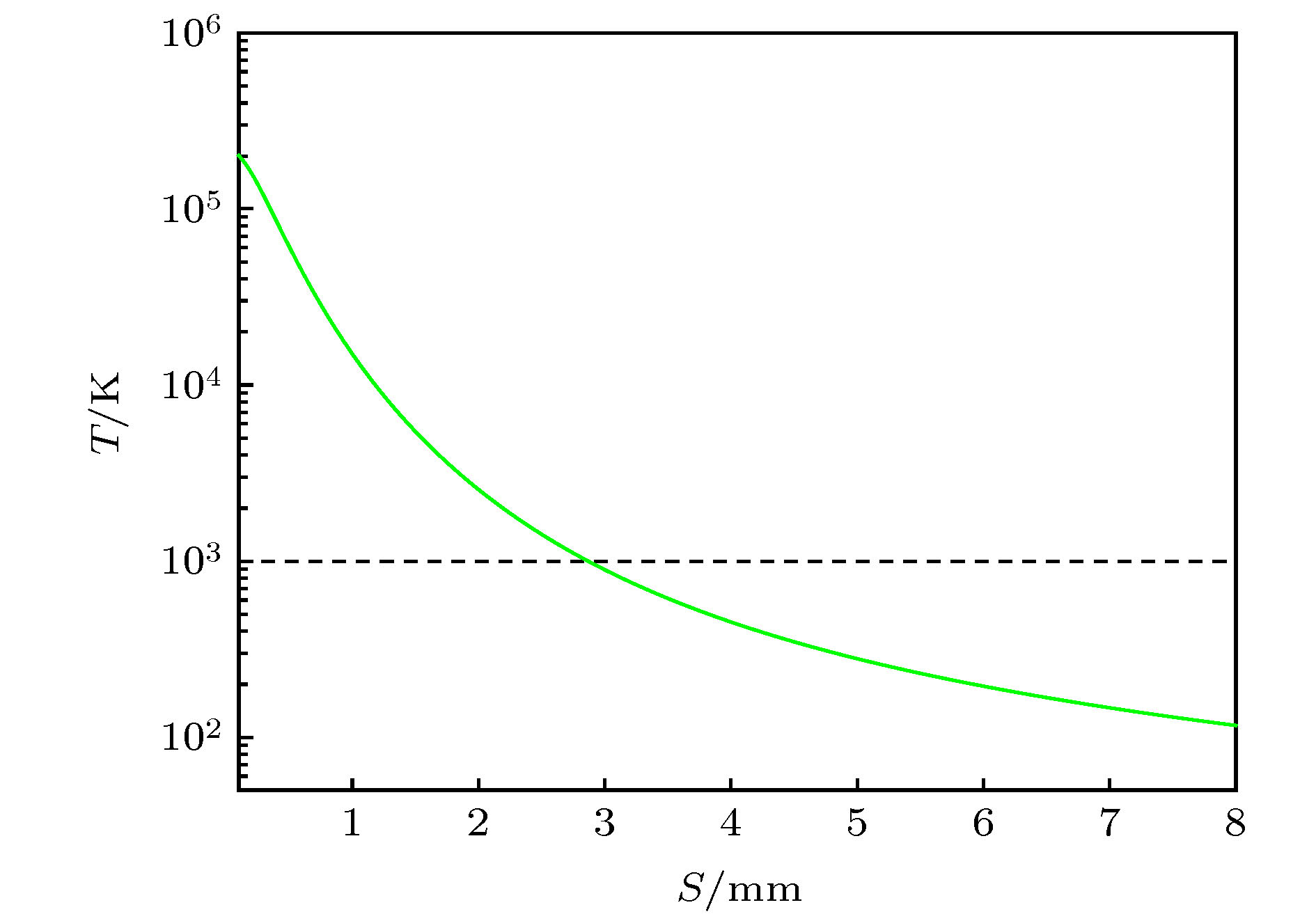

Micro-impurity pollution is always one of the key factors affecting the quality and service life of precision devices. Micro-nano impurity particles are difficult to remove by traditional cleaning methods (ultrasonic cleaning, etc.) and low removal efficiency by laser cleaning methods (dry laser cleaning, etc.). The laser plasma shock wave has high pressure and high temperature characteristics, which can remove nano-scaled impurity particles, and has great potential applications. In this work, we mainly study the thermodynamic effect of the laser plasma in the process of removing micro- and nano-particles. In this work, the Al particles on the Si substrate are removed by laser plasma shock wave, and the transformation of the particle state is discussed through the changes of the experimental sample morphology after different pulse effects. The experimental results show as follows With the increase of the pulse number, the micro- and nano-particle residues gradually decrease. At the same time, on the surface of the sample after these particles are removed, it can be found that large particles break up into small particles, and some of the particles will change into smooth spheres when their temperatures reach the melting point. These phenomena are the result of the interaction of the thermodynamic effect of the plasma. In order to study the transformation process of particle state, based on the plasma shock wave propagation theory, the evolution law of pressure characteristic and temperature characteristic of shock wave are obtained. From the evolution law, it can be seen that with the increase of shock wave radius, the pressure and temperature gradually decrease. When the shock wave propagates to the surface of a sample, it can reach the compression threshold and correspondingly the surface temperature arrives at melting temperature of particles, which are consistent with the experimental results. By using the finite element simulation method, the pressure and temperature of laser plasma shock wave acting on particles are studied. The stress distribution and temperature distribution in particles varying with time are obtained. The analysis results are consistent with the experimental results, and therefore the thermodynamic mechanism of plasma on particles is obtained.

-

Keywords:

- plasma shock wave /

- particle fragmentation /

- particle phase transition /

- thermodynamic analysis

[1] Varghese I, Peri M D M, Dunbar T, Maynard B, Thomas D A, Cetinkaya C 2008 J. Adhes. Sci. Technol. 22 651

Google Scholar

Google Scholar

[2] Zhang P, Bian B M, Li Z H 2007 Appl. Surf. Sci. 254 1444

Google Scholar

Google Scholar

[3] Cetinkaya C, Vanderwood R, Rowell M 2002 J. Adhes. Sci. Technol. 16 1201

Google Scholar

Google Scholar

[4] Han J H, Luo L, Zhang Y B, Hu R F, Feng G Y 2016 Chin. Phys. B 25 095204

Google Scholar

Google Scholar

[5] Lee J M, Watkins K G 2001 J. Appl. Phys. 89 6496

Google Scholar

Google Scholar

[6] Lim H, Jang D, Kim D, Lee J W, Lee J M 2005 J. Appl. Phys. 97 054903

Google Scholar

Google Scholar

[7] Vanderwood R, Cetinkaya C 2003 J. Adhes. Sci. Technol. 17 129

Google Scholar

Google Scholar

[8] 李晓溪, 贾天卿, 冯东海, 徐至展 2004 53 2154

Google Scholar

Google Scholar

Li X X, Jia T Q, Feng D H, Xu Z Z 2004 Acta Phys. Sin. 53 2154

Google Scholar

Google Scholar

[9] Hooper T, Cetinkaya C 2003 J. Adhes. Sci. Technol. 17 763

Google Scholar

Google Scholar

[10] Lee S H, Kang Y J, Park J G, Busnaina A A, Lee J M, Kim T H, Zhang G, Eschbach F, Ramamoorthy A 2005 Jpn. J. Appl. Phys. 44 5560

Google Scholar

Google Scholar

[11] 余本海, 戴能利, 王英, 李玉华, 季玲玲, 郑启光, 陆培祥 2007 56 5821

Google Scholar

Google Scholar

Yu B H, Dai N L, Wang Y, Li Y H, Ji L L, Zheng Q G, Lu P X 2007 Acta Phys. Sin. 56 5821

Google Scholar

Google Scholar

[12] Kim T H, Cho H, Busnaina A, Park J G, Kim D 2013 J. Appl. Phys. 114 063104

Google Scholar

Google Scholar

[13] Jang D, Oh J H, Lee J M, Kim D 2009 J. Appl. Phys. 106 014913

Google Scholar

Google Scholar

[14] Oh B, Lee J W, Lee J M, Kim D 2008 J. Adhes. Sci. Technol. 22 635

Google Scholar

Google Scholar

[15] de Giacomo A, Hermann J 2017 J. Phys. D: Appl. Phys. 50 183002

Google Scholar

Google Scholar

[16] Su M G, Cao S Q, Sun D X, Min Q, Dong C Z 2016 Phys. Plasmas 23 033302

Google Scholar

Google Scholar

[17] Gu Q Q, Feng G Y, Zhou G R, Han J H, Luo J, Men J L, Jiang Y 2018 Appl. Surf. Sci. 457 604

Google Scholar

Google Scholar

[18] Thompson P A, Carofano G C, Kim Y G 1986 J. Fluid Mech. 166 57

Google Scholar

Google Scholar

[19] Chen X, Bian B M, Shen Z H, Lu J, Ni X W 2003 Microwave Opt. Technol. Lett. 38 75

Google Scholar

Google Scholar

[20] Harith M A, Palleschi V, Salvetti A, Singh D P, Tropiano G, Vaselli M 1989 Opt. Commun. 71 76

Google Scholar

Google Scholar

[21] Kumar S S S, Raghu T 2014 Mater. Des. 57 114

Google Scholar

Google Scholar

[22] Liu Z F, Zhang Z H, Lu J F, Korznikov A V, Korznikova E, Wang F C 2014 Mater. Des. 64 625

Google Scholar

Google Scholar

[23] Akbarpour M R, Torknik F S, Manafi S A 2017 J. Mater. Eng. Perform. 26 4902

Google Scholar

Google Scholar

[24] Pleasants S, Kane D M 2003 J. Appl. Phys. 93 8862

Google Scholar

Google Scholar

[25] Zheng Y W, Luk’yanchuk B S, Lu Y F, Song W D, Mai Z H 2001 J. Appl. Phys. 90 2135

Google Scholar

Google Scholar

[26] Levitas V I, Pantoya M L, Chauhan G, Rivero I 2009 J. Phys. Chem. C 113 14088

Google Scholar

Google Scholar

[27] Sun J, Simon S L 2007 Thermochim. Acta 463 32

Google Scholar

Google Scholar

-

表 1 Al颗粒和Si基底的相关参数

Table 1. Related parameters of Al particles and silicon substrate.

参数 导热系数/pW·μm–1·K–1 密度/kg·μm–3 比热容/pJ·kg–1·K–1 泊松比 弹性模量/MPa 热膨胀系数 铝 237 × 106 2700 × 10–18 880 × 1012 0.330 70 × 103 23.21 × 10–6 Si 150 × 106 2328 × 10–18 618 × 1012 0.278 190 × 103 0.50 × 10–6 -

[1] Varghese I, Peri M D M, Dunbar T, Maynard B, Thomas D A, Cetinkaya C 2008 J. Adhes. Sci. Technol. 22 651

Google Scholar

Google Scholar

[2] Zhang P, Bian B M, Li Z H 2007 Appl. Surf. Sci. 254 1444

Google Scholar

Google Scholar

[3] Cetinkaya C, Vanderwood R, Rowell M 2002 J. Adhes. Sci. Technol. 16 1201

Google Scholar

Google Scholar

[4] Han J H, Luo L, Zhang Y B, Hu R F, Feng G Y 2016 Chin. Phys. B 25 095204

Google Scholar

Google Scholar

[5] Lee J M, Watkins K G 2001 J. Appl. Phys. 89 6496

Google Scholar

Google Scholar

[6] Lim H, Jang D, Kim D, Lee J W, Lee J M 2005 J. Appl. Phys. 97 054903

Google Scholar

Google Scholar

[7] Vanderwood R, Cetinkaya C 2003 J. Adhes. Sci. Technol. 17 129

Google Scholar

Google Scholar

[8] 李晓溪, 贾天卿, 冯东海, 徐至展 2004 53 2154

Google Scholar

Google Scholar

Li X X, Jia T Q, Feng D H, Xu Z Z 2004 Acta Phys. Sin. 53 2154

Google Scholar

Google Scholar

[9] Hooper T, Cetinkaya C 2003 J. Adhes. Sci. Technol. 17 763

Google Scholar

Google Scholar

[10] Lee S H, Kang Y J, Park J G, Busnaina A A, Lee J M, Kim T H, Zhang G, Eschbach F, Ramamoorthy A 2005 Jpn. J. Appl. Phys. 44 5560

Google Scholar

Google Scholar

[11] 余本海, 戴能利, 王英, 李玉华, 季玲玲, 郑启光, 陆培祥 2007 56 5821

Google Scholar

Google Scholar

Yu B H, Dai N L, Wang Y, Li Y H, Ji L L, Zheng Q G, Lu P X 2007 Acta Phys. Sin. 56 5821

Google Scholar

Google Scholar

[12] Kim T H, Cho H, Busnaina A, Park J G, Kim D 2013 J. Appl. Phys. 114 063104

Google Scholar

Google Scholar

[13] Jang D, Oh J H, Lee J M, Kim D 2009 J. Appl. Phys. 106 014913

Google Scholar

Google Scholar

[14] Oh B, Lee J W, Lee J M, Kim D 2008 J. Adhes. Sci. Technol. 22 635

Google Scholar

Google Scholar

[15] de Giacomo A, Hermann J 2017 J. Phys. D: Appl. Phys. 50 183002

Google Scholar

Google Scholar

[16] Su M G, Cao S Q, Sun D X, Min Q, Dong C Z 2016 Phys. Plasmas 23 033302

Google Scholar

Google Scholar

[17] Gu Q Q, Feng G Y, Zhou G R, Han J H, Luo J, Men J L, Jiang Y 2018 Appl. Surf. Sci. 457 604

Google Scholar

Google Scholar

[18] Thompson P A, Carofano G C, Kim Y G 1986 J. Fluid Mech. 166 57

Google Scholar

Google Scholar

[19] Chen X, Bian B M, Shen Z H, Lu J, Ni X W 2003 Microwave Opt. Technol. Lett. 38 75

Google Scholar

Google Scholar

[20] Harith M A, Palleschi V, Salvetti A, Singh D P, Tropiano G, Vaselli M 1989 Opt. Commun. 71 76

Google Scholar

Google Scholar

[21] Kumar S S S, Raghu T 2014 Mater. Des. 57 114

Google Scholar

Google Scholar

[22] Liu Z F, Zhang Z H, Lu J F, Korznikov A V, Korznikova E, Wang F C 2014 Mater. Des. 64 625

Google Scholar

Google Scholar

[23] Akbarpour M R, Torknik F S, Manafi S A 2017 J. Mater. Eng. Perform. 26 4902

Google Scholar

Google Scholar

[24] Pleasants S, Kane D M 2003 J. Appl. Phys. 93 8862

Google Scholar

Google Scholar

[25] Zheng Y W, Luk’yanchuk B S, Lu Y F, Song W D, Mai Z H 2001 J. Appl. Phys. 90 2135

Google Scholar

Google Scholar

[26] Levitas V I, Pantoya M L, Chauhan G, Rivero I 2009 J. Phys. Chem. C 113 14088

Google Scholar

Google Scholar

[27] Sun J, Simon S L 2007 Thermochim. Acta 463 32

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 7945

- PDF Downloads: 131

- Cited By: 0

DownLoad:

DownLoad: