-

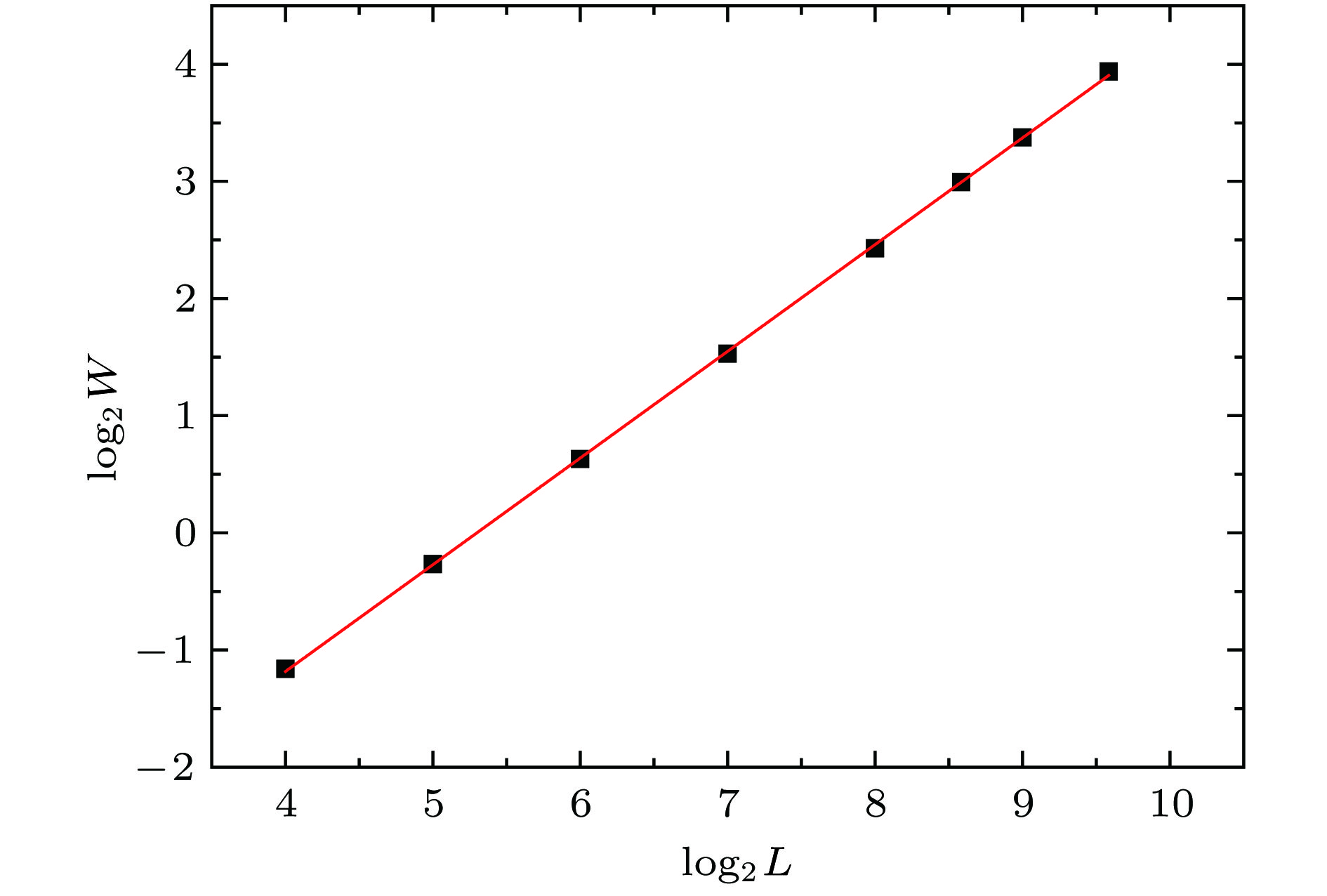

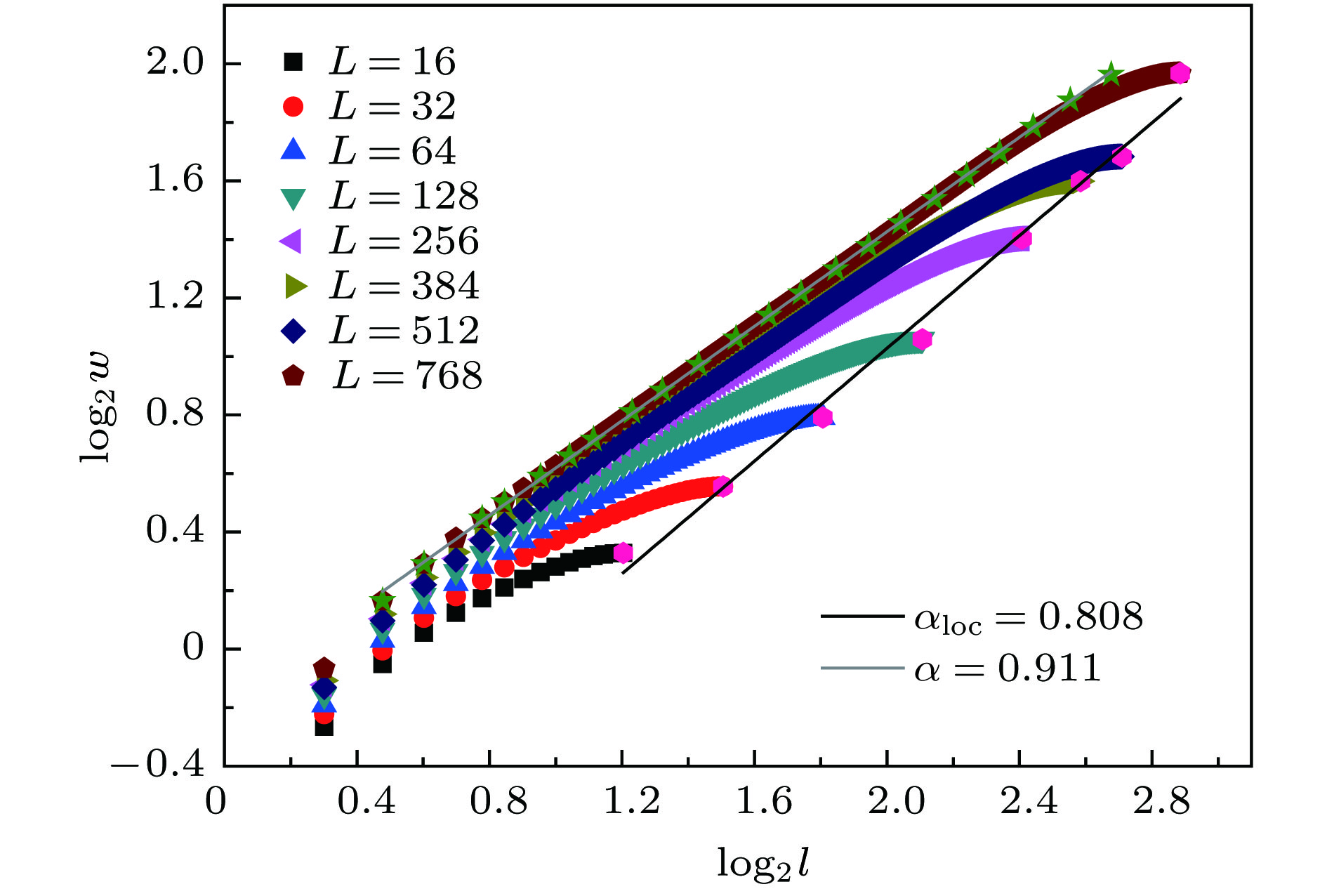

Graphene and other materials have a typical two-dimensional (2D) honeycomb structure. The random fuse model is a statistical physics model that is very effective in studying the fracture dynamics of heterogeneous materials. In order to study the current fusing process and the properties of the fractured surface of 2D honeycomb structure materials such as graphene, in this paper we attempt to numerically simulate and analyze the fusing process and melting profile properties of the 2D honeycomb structure random fuse network. The results indicate that the surface width exhibits a good scaling behavior and has a linear relationship with the system size, and that the out-of-plane roughness exponent displays a global value of

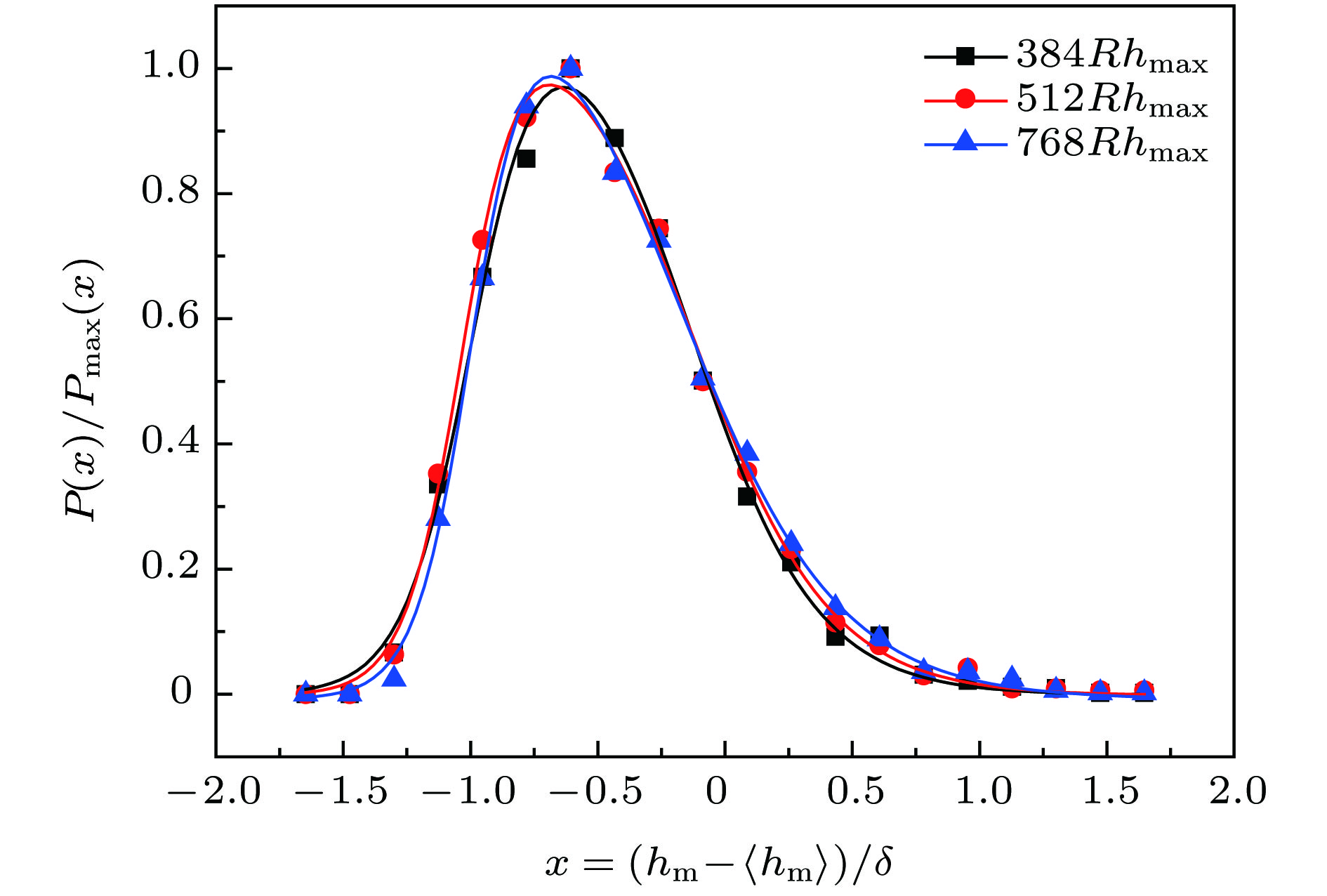

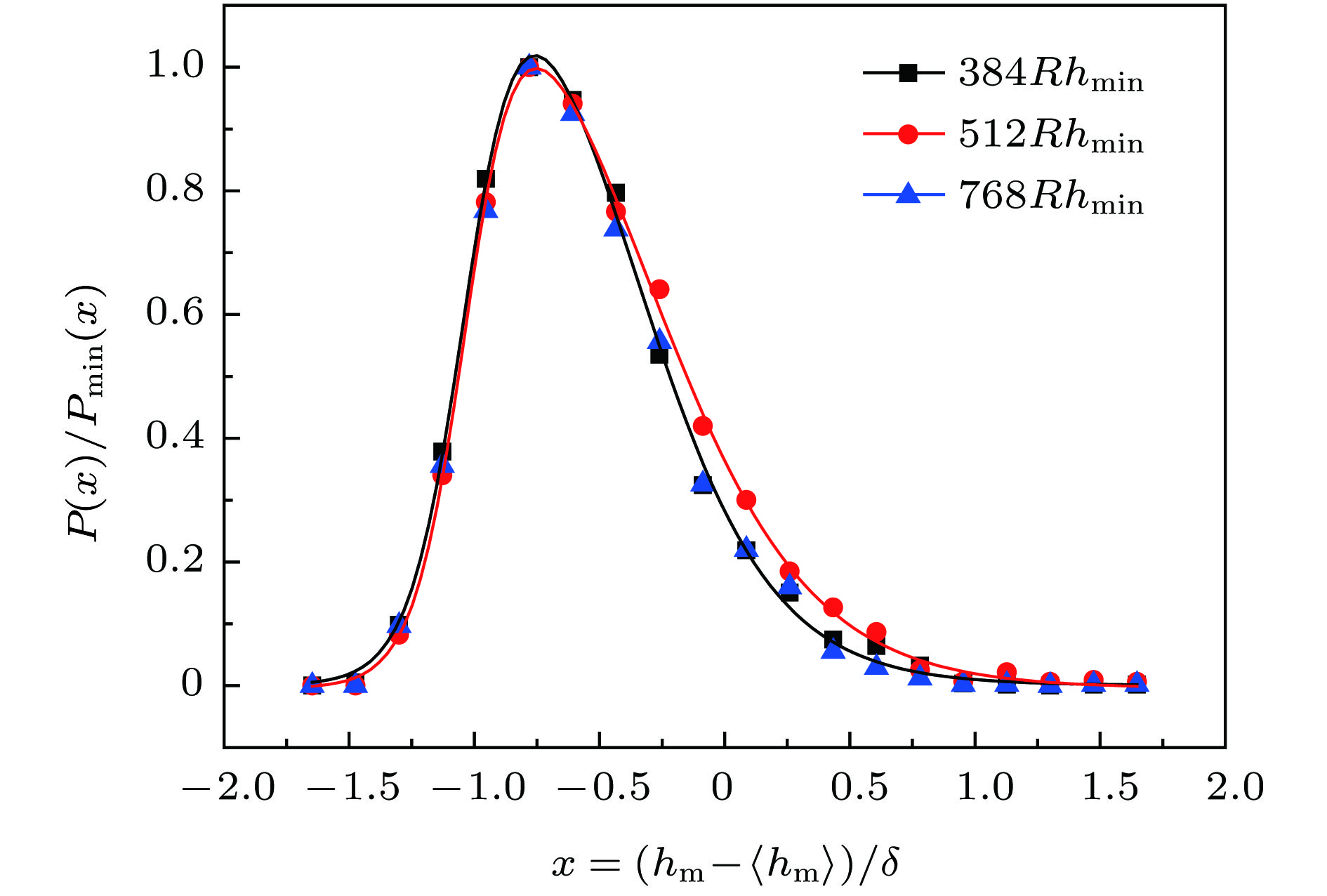

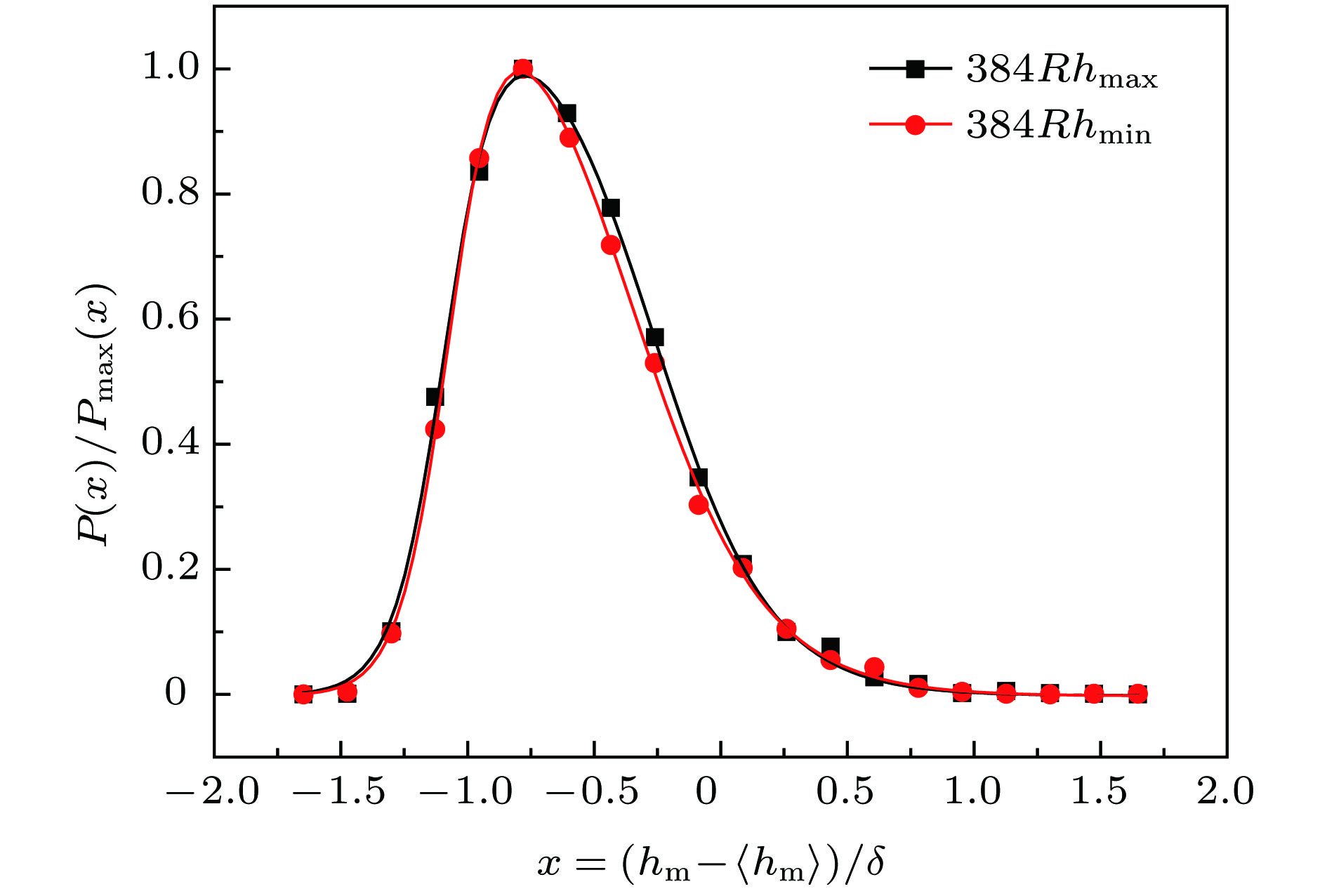

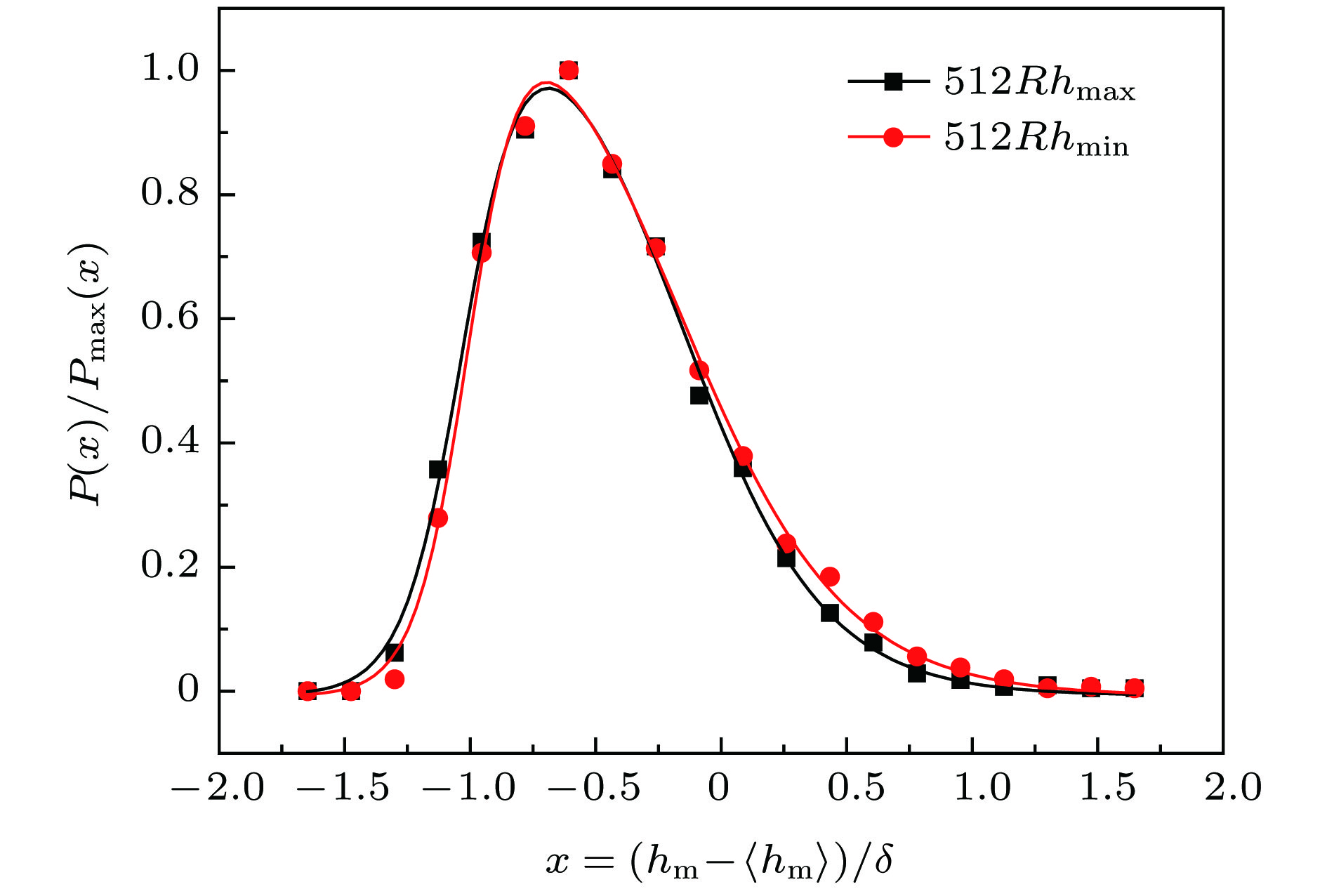

$\alpha = 0.911 \pm 0.005$ and a local value of${\alpha _{{\rm{loc}}}} = 0.808 \pm 0.003$ , approximate to those of the materials studied. The global and local roughness and their difference indicate that the fusing process and the fracture profile exhibit significant scale properties and have a strange scale. On the other hand, by analyzing the extreme values of the fused surface with different system sizes, the extreme heights can be collapsed very well, after a lot of trials and analysis, it is found that the extreme statistical distribution of the height of the fused surface can well satisfy the Asym2sig type distribution. The extreme height distributions of fracture surfaces can be fitted by Asym2Sig distribution, rather than the three kinds of usual extreme statistical distributions, i.e. Weibull, Gumbel, and Frechet distributions. The relative maximal and minimum height distribution of the fused surface at the same substrate size have a good symmetry. In the simulation calculation process of this paper, the coefficient matrix is constructed by using the node analysis method, and the Cholesky decomposition is performed on the coefficient matrix, and then the Sherman-Morrison-Woodbury algorithm is used to quickly invert the coefficient matrix, which greatly optimizes the calculation process and calculation. The efficiency makes the numerical simulation calculation and analysis performed smoothly. The research in this paper indicates that the random fuse model is a very effective theoretical model in the numerical analysis of the scaling properties of rough fracture surfaces, and it is also applicable to the current fusing process of the inhomogeneous material and the scaling surface analysis of the fusing surface. In this paper, it is found that materials with anisotropic structure can also find their fracture mode by energization, and the properties of fracture surface can provide reference for the study of mechanical properties of honeycomb structural materials. It is a very effective statistical physical model, and this will expand the field of applications of random fuse models.-

Keywords:

- graphene honeycomb structure /

- random fuse model /

- roughness /

- extreme statistics

[1] Abergel D S L, Apalkov V, Berashevich J 2010 Adv. Phys. 59 261

Google Scholar

Google Scholar

[2] Shin Y J, Gopinadhan K, Narayanapillai K 2013 Appl. Phys. Lett. 102 666

[3] Lu Y H, Shi L, Zhang C, Feng Y P 2009 Phys. Rev. B 80 233410

Google Scholar

Google Scholar

[4] Moura M J B, Marder M 2013 Phys. Rev. E 88 032405

Google Scholar

Google Scholar

[5] Ghorbanfekr-Kalashami H, Neek-Amal M, Peeters F M 2016 Phys. Rev. B 93 174112

Google Scholar

Google Scholar

[6] Alava M J, Nukala P K V V, Zapperi S 2006 Adv. Phys. 55 351

[7] Garcimart'ın A, Guarino A, Bellon L, Ciliberto S 1997 Phys. Rev. Lett. 79 3202

Google Scholar

Google Scholar

[8] Maes C, van Moffaert A, Frederix H, Strauven H 1998 Phys. Rev. B 57 4987

[9] Petri A, Paparo G, Vespignani A, Alippi A, Costantini M 1994 Phys. Rev. Lett. 73 3423

Google Scholar

Google Scholar

[10] Salminen L I, Tolvanen A I, Alava M J 2002 Phys. Rev. Lett. 89 185503

Google Scholar

Google Scholar

[11] Arcangelis L, Redner S, Herrmann H J 1985 J. Phys. Lett. 46 585

Google Scholar

Google Scholar

[12] Schramm O 2000 Israel J. Math. 118 221

Google Scholar

Google Scholar

[13] Claudio M, Ashivni S, Nukala P K V V, Alava M J, Sethna J P, Zapperi S 2012 Phys. Rev. Lett. 108 065504

Google Scholar

Google Scholar

[14] Duxbury P M, Beale P D, Leath P L 1986 Phys. Rev. Lett. 59 155

[15] Nukala P K V V, Srdan S, Zapperi S 2004 J. Stat. Mech. 8 P08001

[16] Toussaint R, Hansen A 2006 Phys. Rev. E 73 046103

Google Scholar

Google Scholar

[17] Jan Øystein H B, Hansen A 2008 Phys. Rev. Lett. 100 045501

Google Scholar

Google Scholar

[18] Davis T A, Hager W W 1999 Siam J. Matrix Anal. A 22 997

[19] Family F, Vicsek T 1985 J. Phys. A 18 L75

Google Scholar

Google Scholar

[20] Xun Z P, Tang G, Han K, Xia H, Hao D P, Li Y 2012 Phys. Rev. E 85 041126

Google Scholar

Google Scholar

[21] 寻之朋 2017 离散模型表面界面粗化的动力学标度性质(徐州: 中国矿业大学出版社) 第88页

Xun Z P 2017 The Dynamic Scale Properties of the Surface Roughness of the Discrete Growth Model (Xuzhou: China Mining University Press) p88

[22] Raychaudhuri S, Cranston M, Przybyla C, Shapir Y 2001 Phys. Rev. Lett. 87 136101

Google Scholar

Google Scholar

[23] Foltin G, Oerding K, Racz Z, Workman R L, Zia R K P 1994 Phys. Rev. E 50 639

Google Scholar

Google Scholar

[24] Majumdar S N, Comtet A 2004 Phys. Rev. Lett. 92 225501

Google Scholar

Google Scholar

[25] Derrida B, Lebowitz J L 1998 Phys. Rev. Lett. 80 209

Google Scholar

Google Scholar

[26] Majumdar S N, Comtet A 2005 Stat. Phys. 119 777

Google Scholar

Google Scholar

[27] Fisher R A, Tippett L H C 1928 Proc. Cambridge Philos. Soc. 24 180

Google Scholar

Google Scholar

[28] Bramwell S T, Christensen K, Fortin J, Holdsworth P C W, Jensen H J, Lise S, Lopez J M, Nicodemi M, Pinton J F, Sellitto M 2000 Phys. Rev. Lett. 84 3744

Google Scholar

Google Scholar

[29] Antal T, Droz M, Gyorgyi G, Racz Z 2001 Phys. Rev. Lett. 87 240601

Google Scholar

Google Scholar

[30] Lee D S 2005 Phys. Rev. Lett. 95 150601

Google Scholar

Google Scholar

[31] Lee S B, Jeong H C, Kim J M 2008 J. Stat. Mech. 9 P12013

[32] Wen R J, Tang G, Han K, Xia H, Hao D P, Xun Z P, Chen Y L 2011 Chin. J. Comput. Phys. 28 933

[33] Cui L J, Zhang Y, Zhang M Y, Li W, Zhao X S, Li S G, Wang Y F 2012 J. Environ. Mont. 14 3037

Google Scholar

Google Scholar

[34] Brar J 2011 M.S. Thesis (Ottawa: University of Ottawa) pp6-9

[35] 杨毅, 唐刚, 宋丽建, 寻之朋, 夏辉, 郝大鹏 2014 63 150501

Google Scholar

Google Scholar

Yang Y, Tang G, Song L J, Xun Z P, Xia H, Hao D P 2014 Acta Phys. Sin. 63 150501

Google Scholar

Google Scholar

[36] 杨毅, 唐刚, 张哲, 寻之朋, 宋丽建, 韩奎 2015 64 130501

Google Scholar

Google Scholar

Yang Y, Tang G, Zhang Z, Xun Z P, Song L J, Han K 2015 Acta Phys. Sin. 64 130501

Google Scholar

Google Scholar

[37] 王晓芳, 杨小玲, 刘洋 2018 化学工程师 274 7

Wang X F, Yang X L, Liu Y 2018 Chemical Engineer. Sum. 274 7

[38] 吴海华, 肖林楠, 王俊, 王亚迪 2018 激光与光电子学进展 55 011417

Wu H H, Xiao L N, Wang J, Wang Y D 2018 Laser Opt. Prog. 55 011417

[39] McGregor D J , Sameh T, William P K 2019 Addit. Manuf. 25 10

Google Scholar

Google Scholar

[40] Gibson L J, Ashby M F 1997 Cellular Solids: Structure and Properties (2nd Ed.)(Cambridge: Cambridge University Press) (Cambridge: Cambridge University Press) pp13-19

[41] Soriano J, Ramasco J J, Rodriguez M A, Hernandez-Machado A 2002 Phys. Rev. Lett. 89 026102

Google Scholar

Google Scholar

-

表 1 二维菱形、三角形及石墨烯蜂巢结构电阻丝网络熔断面整体与局域的粗糙度指数

Table 1. Roughness index of the global and local of the burnout surface of two-dimensional diamond, triangle and graphene honeycomb structures.

模型 $\alpha $ ${\alpha _{{\rm{loc}}}}$ 菱形 0.752 ± 0.008 0.758 ± 0.012 三角形 0.772 ± 0.013 0.776 ± 0.003 石墨烯蜂巢结构 0.911 ± 0.005 0.808 ± 0.003 表 2 系统尺寸为L = 384, 512, 768时Asym2sig函数拟合的参数

Table 2. Parameters of Asym2sig function fitting when the system size is L = 384, 512, 768.

384 max&min 512 max&min 768 max&min y0 –0.001 ± 0.012 –0.002 ± 0.011 –0.001 ± 0.010 –0.004 ± 0.008 –0.004 ± 0.007 –0.008 ± 0.007 xc –0.57 ± 0.02 –0.58 ± 0.02 –0.59 ± 0.02 –0.70 ± 0.02 –0.68 ± 0.02 –0.72 ± 0.02 A 1.18 ± 0.12 1.15 ± 0.08 1.28 ± 0.11 1.38 ± 0.13 1.38 ± 0.11 1.49 ± 0.15 ${\omega _1}$ 0.85 ± 0.08 0.90 ± 0.06 0.80 ± 0.07 0.65 ± 0.07 0.69 ± 0.06 0.58 ± 0.08 ${\omega _2}$ 0.13 ± 0.02 0.11 ± 0.01 0.11 ± 0.01 0.11 ± 0.01 0.10 ± 0.01 0.12 ± 0.01 ${\omega _3}$ 0.25 ± 0.03 0.27 ± 0.03 0.32 ± 0.03 0.28 ± 0.02 0.33 ± 0.02 0.30 ± 0.02 -

[1] Abergel D S L, Apalkov V, Berashevich J 2010 Adv. Phys. 59 261

Google Scholar

Google Scholar

[2] Shin Y J, Gopinadhan K, Narayanapillai K 2013 Appl. Phys. Lett. 102 666

[3] Lu Y H, Shi L, Zhang C, Feng Y P 2009 Phys. Rev. B 80 233410

Google Scholar

Google Scholar

[4] Moura M J B, Marder M 2013 Phys. Rev. E 88 032405

Google Scholar

Google Scholar

[5] Ghorbanfekr-Kalashami H, Neek-Amal M, Peeters F M 2016 Phys. Rev. B 93 174112

Google Scholar

Google Scholar

[6] Alava M J, Nukala P K V V, Zapperi S 2006 Adv. Phys. 55 351

[7] Garcimart'ın A, Guarino A, Bellon L, Ciliberto S 1997 Phys. Rev. Lett. 79 3202

Google Scholar

Google Scholar

[8] Maes C, van Moffaert A, Frederix H, Strauven H 1998 Phys. Rev. B 57 4987

[9] Petri A, Paparo G, Vespignani A, Alippi A, Costantini M 1994 Phys. Rev. Lett. 73 3423

Google Scholar

Google Scholar

[10] Salminen L I, Tolvanen A I, Alava M J 2002 Phys. Rev. Lett. 89 185503

Google Scholar

Google Scholar

[11] Arcangelis L, Redner S, Herrmann H J 1985 J. Phys. Lett. 46 585

Google Scholar

Google Scholar

[12] Schramm O 2000 Israel J. Math. 118 221

Google Scholar

Google Scholar

[13] Claudio M, Ashivni S, Nukala P K V V, Alava M J, Sethna J P, Zapperi S 2012 Phys. Rev. Lett. 108 065504

Google Scholar

Google Scholar

[14] Duxbury P M, Beale P D, Leath P L 1986 Phys. Rev. Lett. 59 155

[15] Nukala P K V V, Srdan S, Zapperi S 2004 J. Stat. Mech. 8 P08001

[16] Toussaint R, Hansen A 2006 Phys. Rev. E 73 046103

Google Scholar

Google Scholar

[17] Jan Øystein H B, Hansen A 2008 Phys. Rev. Lett. 100 045501

Google Scholar

Google Scholar

[18] Davis T A, Hager W W 1999 Siam J. Matrix Anal. A 22 997

[19] Family F, Vicsek T 1985 J. Phys. A 18 L75

Google Scholar

Google Scholar

[20] Xun Z P, Tang G, Han K, Xia H, Hao D P, Li Y 2012 Phys. Rev. E 85 041126

Google Scholar

Google Scholar

[21] 寻之朋 2017 离散模型表面界面粗化的动力学标度性质(徐州: 中国矿业大学出版社) 第88页

Xun Z P 2017 The Dynamic Scale Properties of the Surface Roughness of the Discrete Growth Model (Xuzhou: China Mining University Press) p88

[22] Raychaudhuri S, Cranston M, Przybyla C, Shapir Y 2001 Phys. Rev. Lett. 87 136101

Google Scholar

Google Scholar

[23] Foltin G, Oerding K, Racz Z, Workman R L, Zia R K P 1994 Phys. Rev. E 50 639

Google Scholar

Google Scholar

[24] Majumdar S N, Comtet A 2004 Phys. Rev. Lett. 92 225501

Google Scholar

Google Scholar

[25] Derrida B, Lebowitz J L 1998 Phys. Rev. Lett. 80 209

Google Scholar

Google Scholar

[26] Majumdar S N, Comtet A 2005 Stat. Phys. 119 777

Google Scholar

Google Scholar

[27] Fisher R A, Tippett L H C 1928 Proc. Cambridge Philos. Soc. 24 180

Google Scholar

Google Scholar

[28] Bramwell S T, Christensen K, Fortin J, Holdsworth P C W, Jensen H J, Lise S, Lopez J M, Nicodemi M, Pinton J F, Sellitto M 2000 Phys. Rev. Lett. 84 3744

Google Scholar

Google Scholar

[29] Antal T, Droz M, Gyorgyi G, Racz Z 2001 Phys. Rev. Lett. 87 240601

Google Scholar

Google Scholar

[30] Lee D S 2005 Phys. Rev. Lett. 95 150601

Google Scholar

Google Scholar

[31] Lee S B, Jeong H C, Kim J M 2008 J. Stat. Mech. 9 P12013

[32] Wen R J, Tang G, Han K, Xia H, Hao D P, Xun Z P, Chen Y L 2011 Chin. J. Comput. Phys. 28 933

[33] Cui L J, Zhang Y, Zhang M Y, Li W, Zhao X S, Li S G, Wang Y F 2012 J. Environ. Mont. 14 3037

Google Scholar

Google Scholar

[34] Brar J 2011 M.S. Thesis (Ottawa: University of Ottawa) pp6-9

[35] 杨毅, 唐刚, 宋丽建, 寻之朋, 夏辉, 郝大鹏 2014 63 150501

Google Scholar

Google Scholar

Yang Y, Tang G, Song L J, Xun Z P, Xia H, Hao D P 2014 Acta Phys. Sin. 63 150501

Google Scholar

Google Scholar

[36] 杨毅, 唐刚, 张哲, 寻之朋, 宋丽建, 韩奎 2015 64 130501

Google Scholar

Google Scholar

Yang Y, Tang G, Zhang Z, Xun Z P, Song L J, Han K 2015 Acta Phys. Sin. 64 130501

Google Scholar

Google Scholar

[37] 王晓芳, 杨小玲, 刘洋 2018 化学工程师 274 7

Wang X F, Yang X L, Liu Y 2018 Chemical Engineer. Sum. 274 7

[38] 吴海华, 肖林楠, 王俊, 王亚迪 2018 激光与光电子学进展 55 011417

Wu H H, Xiao L N, Wang J, Wang Y D 2018 Laser Opt. Prog. 55 011417

[39] McGregor D J , Sameh T, William P K 2019 Addit. Manuf. 25 10

Google Scholar

Google Scholar

[40] Gibson L J, Ashby M F 1997 Cellular Solids: Structure and Properties (2nd Ed.)(Cambridge: Cambridge University Press) (Cambridge: Cambridge University Press) pp13-19

[41] Soriano J, Ramasco J J, Rodriguez M A, Hernandez-Machado A 2002 Phys. Rev. Lett. 89 026102

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 8428

- PDF Downloads: 45

- Cited By: 0

DownLoad:

DownLoad: