-

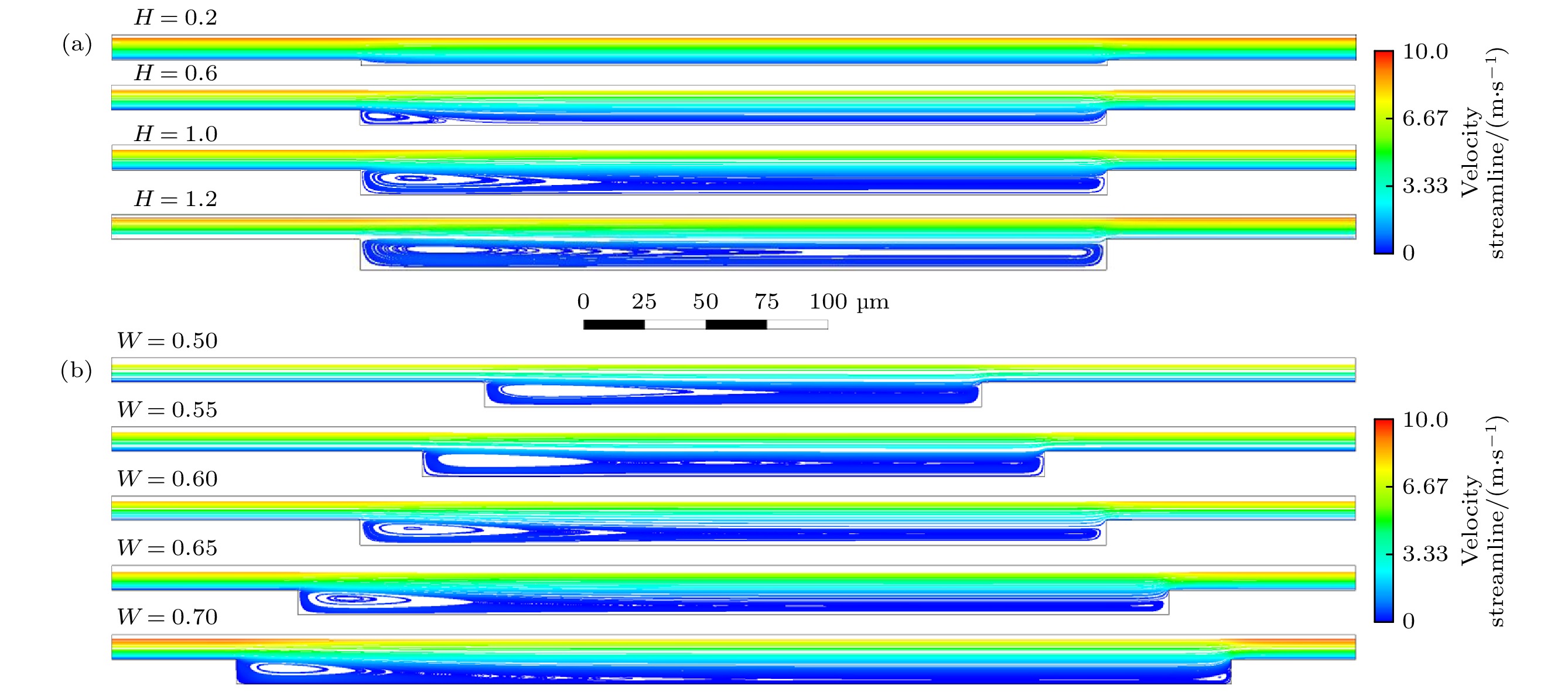

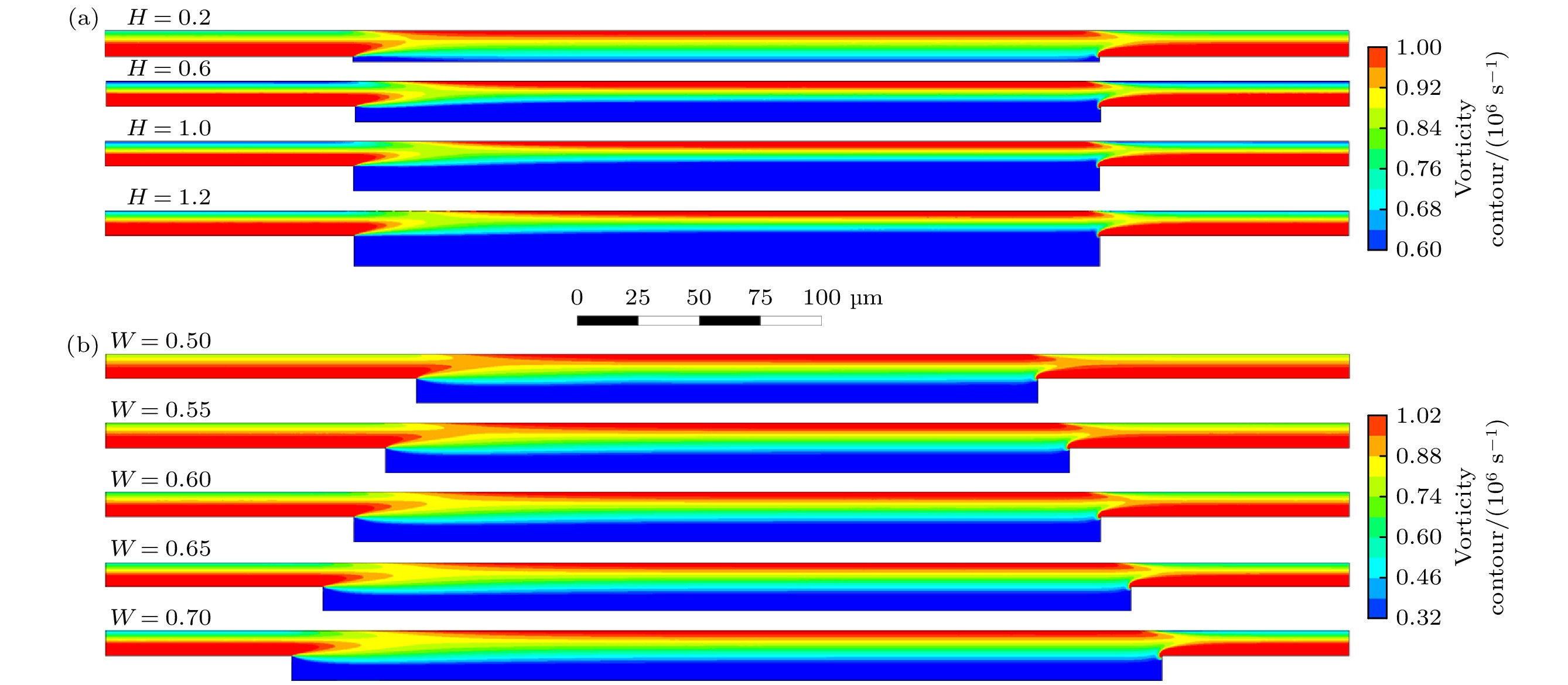

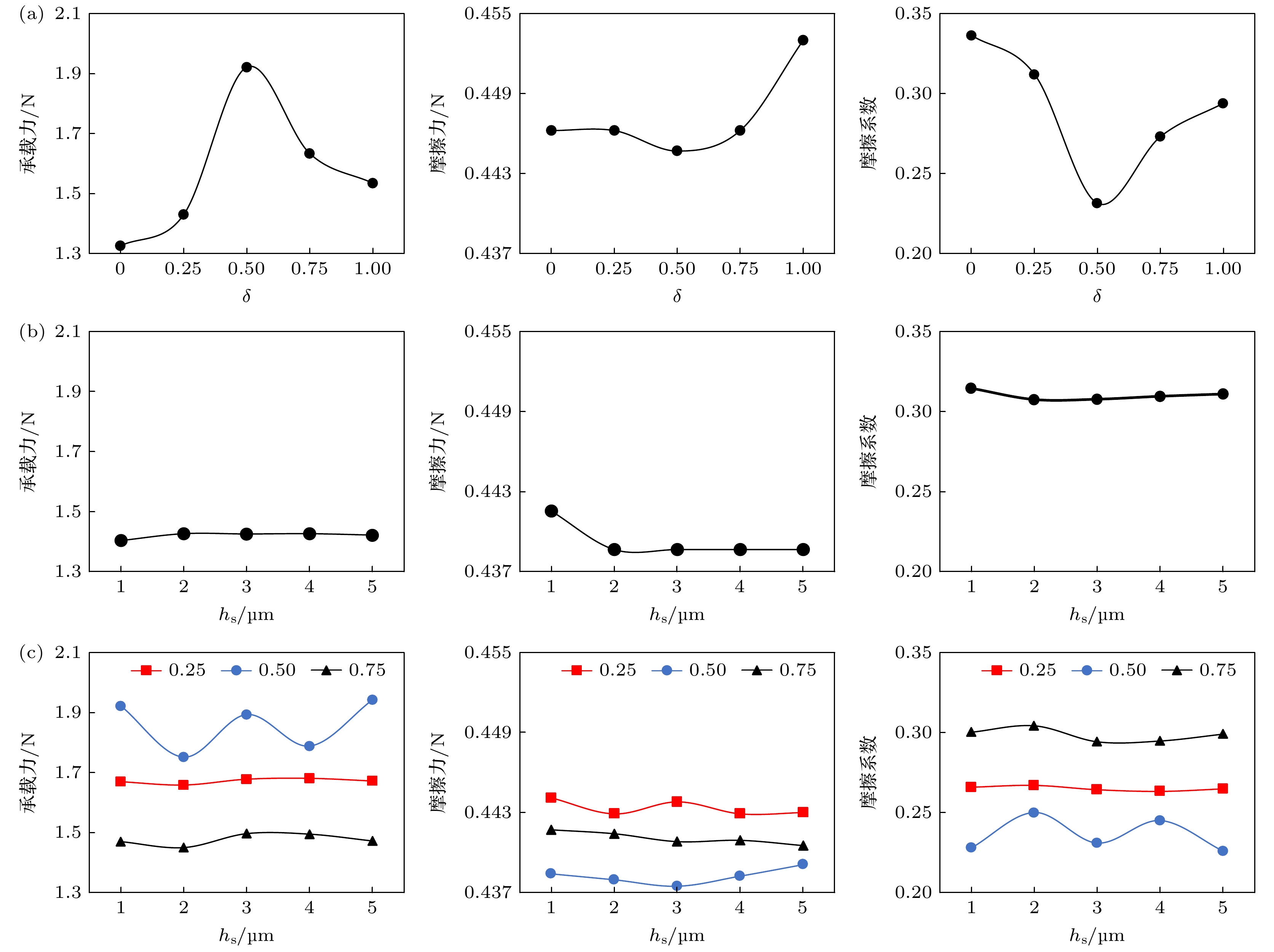

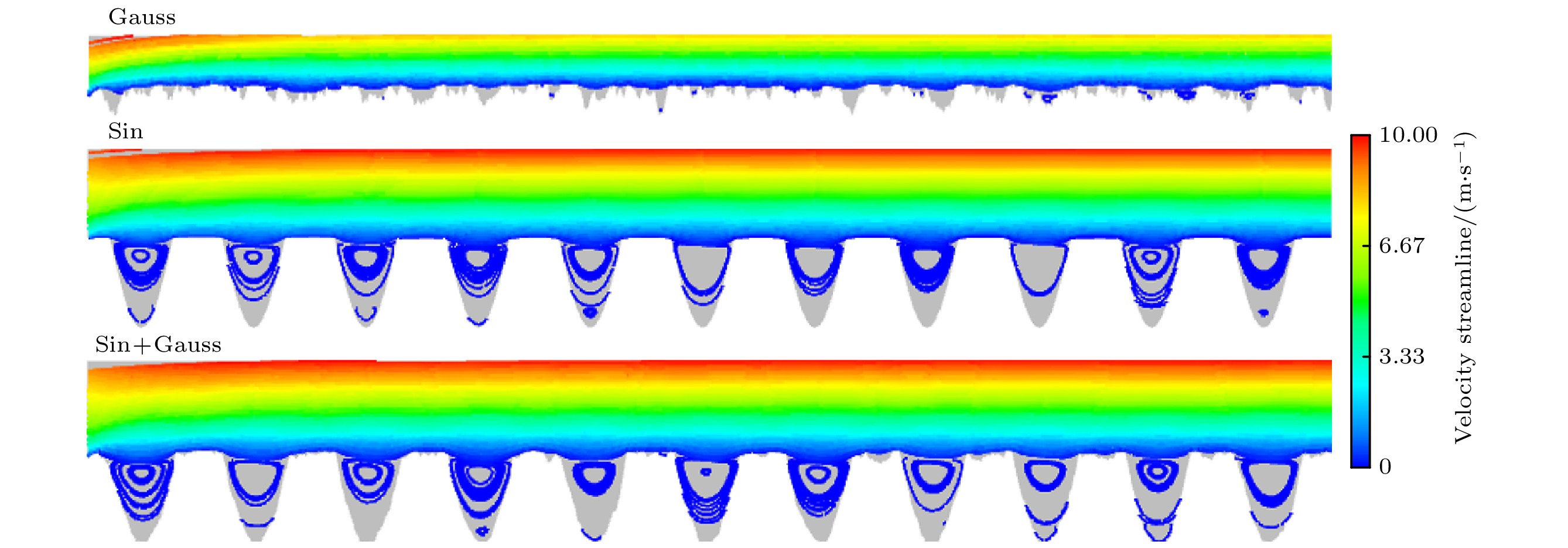

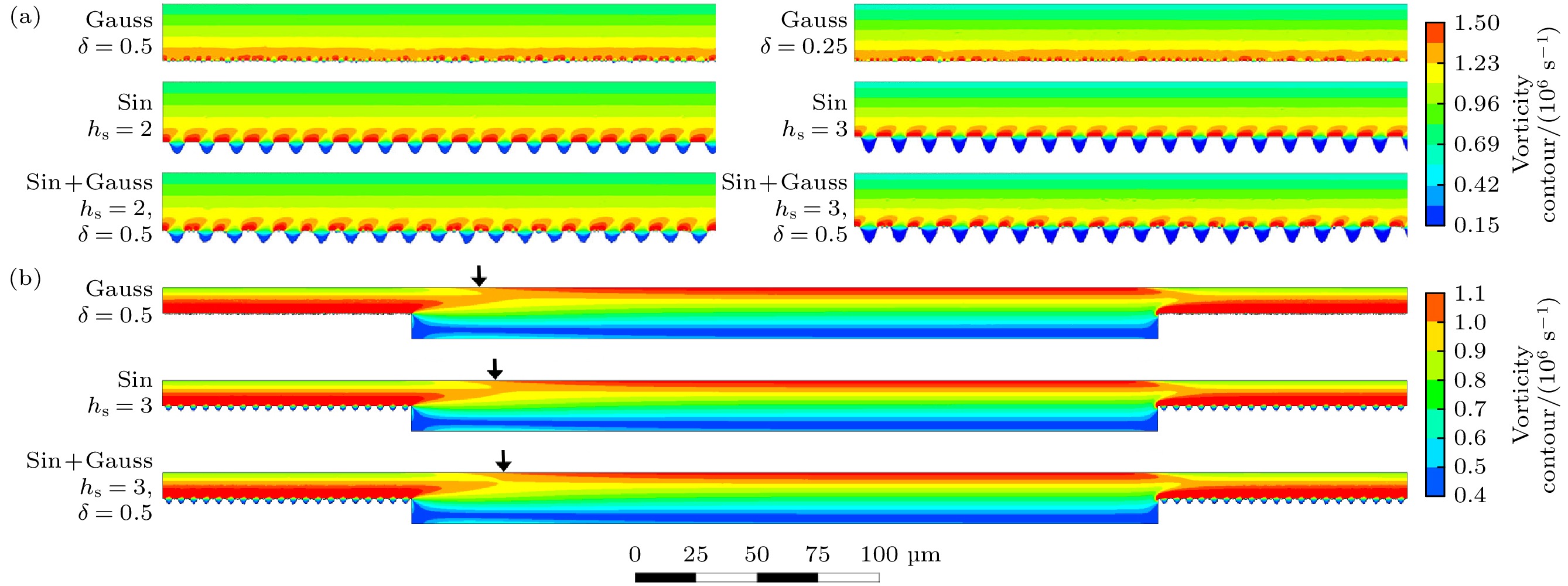

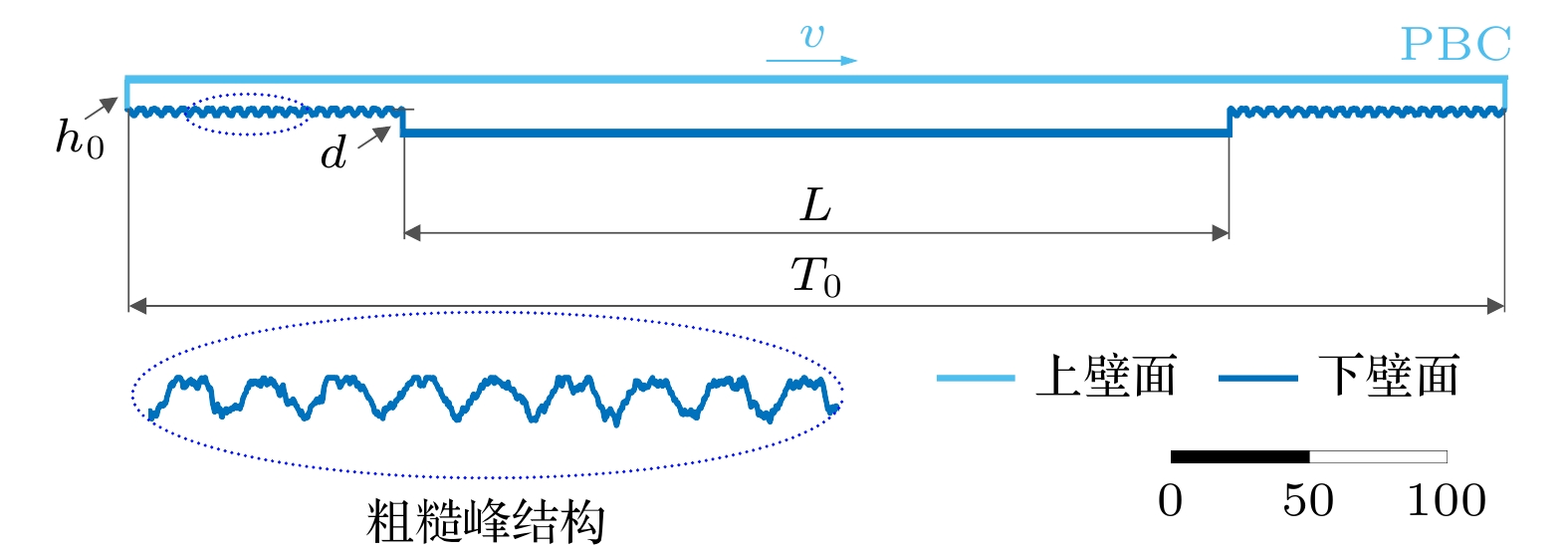

随着表面精密加工技术与润滑减摩研究的发展, 利用表面织构化技术提升其表面减摩效果的研究已引起广泛关注, 但少有研究考虑摩擦副表面粗糙形貌对润滑特性带来影响. 本研究采用计算流体动力学(CFD)模拟方法, 建立了矩形织构模型, 并在其表面计入粗糙峰结构, 讨论水润滑条件下不同粗糙峰结构模型润滑特性变化规律. 结果表明: 调节微纳复合表面结构参数, 将改变润滑水膜承载力, 进而影响微纳复合结构表面的动压润滑效果. 此外, 织构内涡流生成导致涡量变化, 引起能量耗散并影响摩擦力. 对矩形织构模型, 适当的深度比(H = 0.6)可使其表面动压润滑效应达到最优; 而增大织构宽度比(W), 动压润滑效应增强. 在微织构表面引入高斯随机粗糙峰后, 当随机粗糙峰高度变化标准差δ为0.5时, 承载力可提升44%, 摩擦系数降低30.9%. 若引入半正弦粗糙峰, 承载力和摩擦系数的变化范围均小于10%, 对润滑效果的影响不明显. 若同时引入高斯随机粗糙峰和半正弦粗糙峰, 承载力可提升42%, 摩擦系数下降31.1%, 即表面动压润滑效果提升也较为显著.With the development of surface precision machining technology and extensive studies on lubrication and friction reduction, the use of surface texture to reduce friction has attracted widespread attention, but few studies have considered the influence of surface roughness on lubrication characteristics. By employing the computational fluid dynamics (CFD) simulation method, the lubrication models with rectangular textures and the introduction of rough asperity structures at the same time are established. The effects of the corresponding structure parameters on the lubrication performance of textured and roughed surfaces are studied under water lubrication conditions. Our results suggest that the adjustment of geometric parameters on the micro-/nano-structured surfaces can influence the load-bearing capacity of the water lubrication film, thus affecting the hydrodynamic lubrication performance on the surface. In addition, the generation of vortex in the micro-textures can bring changes in vorticity, which causes energy dissipation and affects frictional forces. In the lubrication model with rectangular textures, optimal hydrodynamic lubrication performance is obtained under the appropriate depth ratio H = 0.6. Meanwhile, the corresponding lubrication performance can be enhanced by increasing the width ratio (W) of surface texture. After introducing random asperity structures on the micro-textured surface with a standard deviation δ = 0.5, the bearing capacity is increased by 44%, and the friction coefficient is reduced by 30.9%. Moreover, the introduction of half-sine rough asperity structures can only result in relatively minor differences in the lubrication performance, i.e. the changes of bearing capacity and friction coefficient are less than 10%. However, the introduction of compound hierarchical structure consisting of random asperity structures and half-sine rough asperity structures can result in an increase in the corresponding bearing capacity by 42% and a reduction in the friction coefficient by 31.1%, which implies a significant enhancement in the hydrodynamic lubrication performance.

-

Keywords:

- micro-texture /

- roughness /

- hydrodynamic lubrication /

- computational fluid dynamics simulation

[1] Hamilton D B, Walowit J A, Allen C M 1966 J. Fluids Eng. 88 177

[2] Zhong Y H, Zheng L, Gao Y H, Liu Z N 2019 Tribol. Int. 129 151

Google Scholar

Google Scholar

[3] Mourier L, Mazuyer D, Ninove F P, Lubrecht A A 2010 Proc. Inst. Mech. Eng. , Part J: J. Eng. Tribol. 224 697.

Google Scholar

Google Scholar

[4] Zhang J Y, Meng Y G 2012 Tribol. Lett. 46 147

Google Scholar

Google Scholar

[5] Gropper D, Wang L, Harvey T J 2016 Tribol. Int. 94 509

Google Scholar

Google Scholar

[6] Braun D, Greiner C, Schneider J, Gumbsch P 2014 Tribol. Int. 77 142

Google Scholar

Google Scholar

[7] Hsu S M, Jing Y, Hua D, Zhang H 2014 J. Phys. D: Appl. Phys. 47 335307

Google Scholar

Google Scholar

[8] 安书董, 王晓燕, 陈仙, 王炎武, 王晓波, 赵玉清 2015 64 036801

Google Scholar

Google Scholar

An S D, Wang X Y, Chen X, Wang Y W, Wang X B, Zhao Y Q 2015 Acta Phys. Sin. 64 036801

Google Scholar

Google Scholar

[9] Rosenkranz A, Szurdak A, Gachot C, Hirt G, Mücklich F 2016 Tribol. Int. 95 290.

Google Scholar

Google Scholar

[10] 纪敬虎, 管采薇, 符昊, 华希俊, 符永宏 2018 润滑与密封 43 20

Google Scholar

Google Scholar

Ji J H, Guan C W, Fu H, Hua X J, Fu Y H 2018 Lubr. Eng. 43 20

Google Scholar

Google Scholar

[11] Qiu Y, Khonsari M M 2011 J. Tribol. 133 021704

Google Scholar

Google Scholar

[12] Lahayne O, Pichler B, Reihsner R, Eberhardsteiner J, Suh J, Kim D, Nam S, Paek H, Lorenz B, Persson B N J 2016 Tribol. Lett. 62 17

Google Scholar

Google Scholar

[13] Feng D, Shen M X, Peng X D, Meng X K 2017 Tribol. Lett. 65 1

Google Scholar

Google Scholar

[14] Sedlaček M, Podgornik B, Vižintin J 2009 Wear 266 482

Google Scholar

Google Scholar

[15] Menezes P L, Kishore, Kailas S V, Lovell M R 2011 Tribol. Lett. 41 1

Google Scholar

Google Scholar

[16] Rasp W, Wichern C M 2002 J. Mater. Process. Technol. 125 379

[17] 王悦昶, 刘莹, 黄伟峰, 郭飞, 王玉明 2016 摩擦学学报 36 520

Wang Y C, Liu Y, Huang W F, Guo F, Wang Y M 2016 Tribology 36 520

[18] Rosenkranz A, Costa H L, Profito F, Gachot C, Medina S, Dini D 2019 Tribol. Int. 134 190

Google Scholar

Google Scholar

[19] Brajdic-Mitidieri P, Gosman A D, Ioannides E, Spikes H A 2005 J. Tribol. 127 803

Google Scholar

Google Scholar

[20] Sahlin F, Glavatskih S B, Almqvist T, Larsson R 2005 J. Tribol. 127 96

Google Scholar

Google Scholar

[21] Vilhena L, Sedlaček M, Podgornik B, Rek Z, Žun I 2018 Lubricants 6 15

Google Scholar

Google Scholar

[22] Zhang L, Luo J, Yuan R B, He M 2012 Procedia Eng. 31 220

Google Scholar

Google Scholar

[23] 禄晓敏, 王权岱, 肖继明, 杨振朝 2016 润滑与密封 41 70

Google Scholar

Google Scholar

Lu X M, Wang Q D, Xiao J M, Yang Z C 2016 Lubr. Eng. 41 70

Google Scholar

Google Scholar

[24] Mao Y, Zeng L C, Lu Y 2016 Tribol. Int. 104 212

Google Scholar

Google Scholar

[25] Ma X 2023 Lubricants 11 270

Google Scholar

Google Scholar

[26] Li Q, Zhang S, Wang Y J, Xu W W, Wang Z B 2019 Ind. Lubr. Tribol. 71 109

Google Scholar

Google Scholar

[27] He T, Li J M, Deng H S, Wang C L, Shi R, Chen G Y, Li Z P 2021 AIP Adv. 11 015222

Google Scholar

Google Scholar

[28] Singhal A K, Athavale M M, Li H, Jiang Y 2002 ASME J. Fluids Eng. 124 617

Google Scholar

Google Scholar

[29] Pellone C, Franc J P, Perrin M 2004 C. R. Math. 332 827

[30] Buscaglia G C, El Alaoui Talibi M, Jai M 2015 Math. Comput. Simul 118 130

Google Scholar

Google Scholar

[31] Wei Y, Tomkowski R, Archenti A 2020 Metals 10 361

Google Scholar

Google Scholar

[32] Wang W, He Y Y, Li Y, Wei B, Hu Y T, Luo J B 2018 Ind. Lubr. Tribol. 70 754

Google Scholar

Google Scholar

[33] Gao G Y, Yin Z W, Jiang D, Zhang X L 2014 Tribol. Int. 75 31

Google Scholar

Google Scholar

[34] Podgornik B, Vilhena L M, Sedlaček M, Rek Z, Žun I 2012 Meccanica 47 1613

Google Scholar

Google Scholar

[35] Shankar P N, Deshpande M D 2000 Annu. Rev. Fluid Mech. 32 93

Google Scholar

Google Scholar

[36] Sahlin F, Almqvist A, Larsson R, Glavatskih S 2007 Tribol. Int. 40 1294

Google Scholar

Google Scholar

[37] Ausas R, Ragot P, Leiva J, Jai M, Bayada G, Buscaglia G C 2007 J. Tribol. 129 868

Google Scholar

Google Scholar

[38] Wahl R, Schneider J, Gumbsch P 2012 Tribol. Int. 55 81.

Google Scholar

Google Scholar

[39] 刘天霞, 李靖, 卢星, 江志波 2023 润滑与密封 48 74

Google Scholar

Google Scholar

Liu T X, Li J, Lu X, Jiang Z B 2023 Lubr. Eng. 48 74

Google Scholar

Google Scholar

[40] Babu P V, Ismail S, Ben B S 2021 Proc. Inst. Mech. Eng. , Part J: J. Eng. Tribol. 235 360

Google Scholar

Google Scholar

[41] Wos S, Koszela W, Pawlus P 2020 Tribol. Int. 146 106205.

Google Scholar

Google Scholar

[42] Wang J H, Yan Z J, Fang X, Shen Z Y, Pan X X 2020 Lubr. Sci. 32 404

Google Scholar

Google Scholar

[43] Venkateswara Babu P, Syed I, Benbeera S 2020 Mater. Today Proc. 24 1112

Google Scholar

Google Scholar

[44] 樊智敏, 马瑞磷, 江峰 2021 润滑与密封 46 44

Google Scholar

Google Scholar

Fan Z M, Ma R L, Jiang F 2021 Lubr. Eng. 46 44

Google Scholar

Google Scholar

[45] 纪敬虎, 周加鹏, 王沫阳, 王伟, 符永宏 2019 表面技术 48 139

Ji J H, Zhou J P, Wang M Y, Wang W, Fu Y H 2019 Surf. Technol. 48 139

[46] Jiang Y Y, Yan Z J, Zhang S W, Shen Z Y, Sun H C 2022 Sci. Rep. 12 13455

Google Scholar

Google Scholar

[47] Wang Y, Jacobs G, König F, Zhang S, von Goeldel S 2023 Lubricants 11 20

Google Scholar

Google Scholar

[48] Huang J Y, Guan Y C, Ramakrishna S 2021 Tribol. Int. 162 107115

Google Scholar

Google Scholar

-

图 2 润滑模型Ⅰ和Ⅱ的润滑特性 (a) 模型Ⅰ的承载力与摩擦力; (b) 模型Ⅰ的摩擦系数; (c) 模型Ⅱ的承载力与摩擦力; (d) 模型Ⅱ的摩擦系数

Fig. 2. The lubrication performance in models I and II: (a) Bearing capacity and friction force in model I; (b) frictional coefficient in model I; (c) bearing capacity and friction force in model II; (d) frictional coefficient in model II.

图 6 计入不同粗糙峰结构的润滑模型的润滑特性 (a) Gauss模型中承载力、摩擦力与摩擦系数; (b) Sin模型中承载力、摩擦力与摩擦系数; (c) Sin+Gauss模型中承载力、摩擦力与摩擦系数

Fig. 6. The lubrication performance on the textured models with rough peaks: (a) The bearing capacity, frictional force and frictional coefficient in the Gauss model; (b) the bearing capacity, frictional force and frictional coefficient in the Sin model; (c) the bearing capacity, frictional force and frictional coefficient in the Sin+Gauss model.

表 1 水润滑微织构模型参数变化

Table 1. The geometrical parameters for textured models.

模型 T0 W H 模型Ⅰ (恒定宽度比W ) 500/600 0.60 0.2/ 0.4/ 0.6/ 0.8 /1.0/ 1.2 模型Ⅱ (恒定深度比H ) 400/500/600 0.50/ 0.55/ 0.60 /0.65/ 0.70 1.0 表 2 润滑模型中的下壁面微观形貌示意图

Table 2. Sketch maps of textures on the lower wall surfaces of the lubrication models.

模型名称 微织构表面粗糙峰轮廓 函数变化参数 光滑表面

(Smooth)

δ = 0

hs = 0Gauss

δ = 0.25/0.5/0.75/1

hs = 0Sin

δ = 0

hs = 1/2/3/4/5

l = 3

i = 1Sin+Gauss

δ = 0.25/0.5/0.75/1

hs = 1/2/3/4/5

l = 3

i = 3 -

[1] Hamilton D B, Walowit J A, Allen C M 1966 J. Fluids Eng. 88 177

[2] Zhong Y H, Zheng L, Gao Y H, Liu Z N 2019 Tribol. Int. 129 151

Google Scholar

Google Scholar

[3] Mourier L, Mazuyer D, Ninove F P, Lubrecht A A 2010 Proc. Inst. Mech. Eng. , Part J: J. Eng. Tribol. 224 697.

Google Scholar

Google Scholar

[4] Zhang J Y, Meng Y G 2012 Tribol. Lett. 46 147

Google Scholar

Google Scholar

[5] Gropper D, Wang L, Harvey T J 2016 Tribol. Int. 94 509

Google Scholar

Google Scholar

[6] Braun D, Greiner C, Schneider J, Gumbsch P 2014 Tribol. Int. 77 142

Google Scholar

Google Scholar

[7] Hsu S M, Jing Y, Hua D, Zhang H 2014 J. Phys. D: Appl. Phys. 47 335307

Google Scholar

Google Scholar

[8] 安书董, 王晓燕, 陈仙, 王炎武, 王晓波, 赵玉清 2015 64 036801

Google Scholar

Google Scholar

An S D, Wang X Y, Chen X, Wang Y W, Wang X B, Zhao Y Q 2015 Acta Phys. Sin. 64 036801

Google Scholar

Google Scholar

[9] Rosenkranz A, Szurdak A, Gachot C, Hirt G, Mücklich F 2016 Tribol. Int. 95 290.

Google Scholar

Google Scholar

[10] 纪敬虎, 管采薇, 符昊, 华希俊, 符永宏 2018 润滑与密封 43 20

Google Scholar

Google Scholar

Ji J H, Guan C W, Fu H, Hua X J, Fu Y H 2018 Lubr. Eng. 43 20

Google Scholar

Google Scholar

[11] Qiu Y, Khonsari M M 2011 J. Tribol. 133 021704

Google Scholar

Google Scholar

[12] Lahayne O, Pichler B, Reihsner R, Eberhardsteiner J, Suh J, Kim D, Nam S, Paek H, Lorenz B, Persson B N J 2016 Tribol. Lett. 62 17

Google Scholar

Google Scholar

[13] Feng D, Shen M X, Peng X D, Meng X K 2017 Tribol. Lett. 65 1

Google Scholar

Google Scholar

[14] Sedlaček M, Podgornik B, Vižintin J 2009 Wear 266 482

Google Scholar

Google Scholar

[15] Menezes P L, Kishore, Kailas S V, Lovell M R 2011 Tribol. Lett. 41 1

Google Scholar

Google Scholar

[16] Rasp W, Wichern C M 2002 J. Mater. Process. Technol. 125 379

[17] 王悦昶, 刘莹, 黄伟峰, 郭飞, 王玉明 2016 摩擦学学报 36 520

Wang Y C, Liu Y, Huang W F, Guo F, Wang Y M 2016 Tribology 36 520

[18] Rosenkranz A, Costa H L, Profito F, Gachot C, Medina S, Dini D 2019 Tribol. Int. 134 190

Google Scholar

Google Scholar

[19] Brajdic-Mitidieri P, Gosman A D, Ioannides E, Spikes H A 2005 J. Tribol. 127 803

Google Scholar

Google Scholar

[20] Sahlin F, Glavatskih S B, Almqvist T, Larsson R 2005 J. Tribol. 127 96

Google Scholar

Google Scholar

[21] Vilhena L, Sedlaček M, Podgornik B, Rek Z, Žun I 2018 Lubricants 6 15

Google Scholar

Google Scholar

[22] Zhang L, Luo J, Yuan R B, He M 2012 Procedia Eng. 31 220

Google Scholar

Google Scholar

[23] 禄晓敏, 王权岱, 肖继明, 杨振朝 2016 润滑与密封 41 70

Google Scholar

Google Scholar

Lu X M, Wang Q D, Xiao J M, Yang Z C 2016 Lubr. Eng. 41 70

Google Scholar

Google Scholar

[24] Mao Y, Zeng L C, Lu Y 2016 Tribol. Int. 104 212

Google Scholar

Google Scholar

[25] Ma X 2023 Lubricants 11 270

Google Scholar

Google Scholar

[26] Li Q, Zhang S, Wang Y J, Xu W W, Wang Z B 2019 Ind. Lubr. Tribol. 71 109

Google Scholar

Google Scholar

[27] He T, Li J M, Deng H S, Wang C L, Shi R, Chen G Y, Li Z P 2021 AIP Adv. 11 015222

Google Scholar

Google Scholar

[28] Singhal A K, Athavale M M, Li H, Jiang Y 2002 ASME J. Fluids Eng. 124 617

Google Scholar

Google Scholar

[29] Pellone C, Franc J P, Perrin M 2004 C. R. Math. 332 827

[30] Buscaglia G C, El Alaoui Talibi M, Jai M 2015 Math. Comput. Simul 118 130

Google Scholar

Google Scholar

[31] Wei Y, Tomkowski R, Archenti A 2020 Metals 10 361

Google Scholar

Google Scholar

[32] Wang W, He Y Y, Li Y, Wei B, Hu Y T, Luo J B 2018 Ind. Lubr. Tribol. 70 754

Google Scholar

Google Scholar

[33] Gao G Y, Yin Z W, Jiang D, Zhang X L 2014 Tribol. Int. 75 31

Google Scholar

Google Scholar

[34] Podgornik B, Vilhena L M, Sedlaček M, Rek Z, Žun I 2012 Meccanica 47 1613

Google Scholar

Google Scholar

[35] Shankar P N, Deshpande M D 2000 Annu. Rev. Fluid Mech. 32 93

Google Scholar

Google Scholar

[36] Sahlin F, Almqvist A, Larsson R, Glavatskih S 2007 Tribol. Int. 40 1294

Google Scholar

Google Scholar

[37] Ausas R, Ragot P, Leiva J, Jai M, Bayada G, Buscaglia G C 2007 J. Tribol. 129 868

Google Scholar

Google Scholar

[38] Wahl R, Schneider J, Gumbsch P 2012 Tribol. Int. 55 81.

Google Scholar

Google Scholar

[39] 刘天霞, 李靖, 卢星, 江志波 2023 润滑与密封 48 74

Google Scholar

Google Scholar

Liu T X, Li J, Lu X, Jiang Z B 2023 Lubr. Eng. 48 74

Google Scholar

Google Scholar

[40] Babu P V, Ismail S, Ben B S 2021 Proc. Inst. Mech. Eng. , Part J: J. Eng. Tribol. 235 360

Google Scholar

Google Scholar

[41] Wos S, Koszela W, Pawlus P 2020 Tribol. Int. 146 106205.

Google Scholar

Google Scholar

[42] Wang J H, Yan Z J, Fang X, Shen Z Y, Pan X X 2020 Lubr. Sci. 32 404

Google Scholar

Google Scholar

[43] Venkateswara Babu P, Syed I, Benbeera S 2020 Mater. Today Proc. 24 1112

Google Scholar

Google Scholar

[44] 樊智敏, 马瑞磷, 江峰 2021 润滑与密封 46 44

Google Scholar

Google Scholar

Fan Z M, Ma R L, Jiang F 2021 Lubr. Eng. 46 44

Google Scholar

Google Scholar

[45] 纪敬虎, 周加鹏, 王沫阳, 王伟, 符永宏 2019 表面技术 48 139

Ji J H, Zhou J P, Wang M Y, Wang W, Fu Y H 2019 Surf. Technol. 48 139

[46] Jiang Y Y, Yan Z J, Zhang S W, Shen Z Y, Sun H C 2022 Sci. Rep. 12 13455

Google Scholar

Google Scholar

[47] Wang Y, Jacobs G, König F, Zhang S, von Goeldel S 2023 Lubricants 11 20

Google Scholar

Google Scholar

[48] Huang J Y, Guan Y C, Ramakrishna S 2021 Tribol. Int. 162 107115

Google Scholar

Google Scholar

计量

- 文章访问数: 4546

- PDF下载量: 112

- 被引次数: 0

下载:

下载: