-

透明导电氧化物(TCO)是光电子学中的关键材料, 与n型TCO相比, 关于p型TCO材料的选择较少, 其中NiO作为典型的p型TCO材料具有研发透明光电子器件的潜力. 本文使用脉冲激光沉积, 在MgO(001)衬底上成功地得到了不同厚度和Li掺杂浓度的LixNi1–xO薄膜. 结果表明, 厚度和Li掺杂的增加都显著地降低了薄膜的电阻率, 并且厚度为50 nm与3%Li掺杂时, 薄膜的带隙最大. 在薄膜厚度与Li掺杂浓度对其物性调控研究的基础上, 选择带隙最大的p型LixNi1–xO与n型La掺杂ASnO3薄膜构造了透明电子器件. I -V测试证实了该透明电子器件的整流特性以及基于透明导电材料pn结的成功构造. 这项工作通过将p型NiO与n型ASnO3集成, 拓展了透明电子器件的研究与潜在应用.Transparent conducting oxides (TCOs) are crucial materials in optoelectronics, but p-type TCOs are less studied than n-type TCOs. NiO, for typical p-type TCOs show promising potential applications in transparent optoelectronic devices. In this study, LixNi1–xO thin films with varying thickness and Li doping levels on MgO(001) substrates are successfully fabricated using pulsed laser deposition. The results demonstrate that increasing both thickness and Li doping level will reduce the resistivity of the films, with the maximum optical bandgap observed at a thickness of 50 nm and 3% Li doping level. Based on the control of physical properties through film thickness and Li doping, the p-type LixNi1–xO with the largest bandgap is selected to construct transparent electronic devices with n-type La-doped ASnO3 films. The I -V tests confirm the rectification properties of the heterostructures, successfully demonstrating the formation of pn junctions. This work expands the potential applications of transparent electronic devices by integrating p-type NiO with n-type ASnO3.

-

Keywords:

- transparent conducting oxide /

- thin film /

- doping /

- pn junction

[1] Xia H, Luo M, Wang W, Wang H, Li T, Wang Z, Xu H, Chen Y, Zhou Y, Wang F, Xie R, Wang P, Hu W, Lu W 2022 Light-Sci. Appl. 11 170

Google Scholar

Google Scholar

[2] Mistry B V, Bhatt P, Bhavsar K H, Trivedi S J, Trivedi U N, Joshi U S 2011 Thin Solid Films 519 3840

Google Scholar

Google Scholar

[3] Zhang J, Han S, Luo W, Xiang S, Zou J, Oropeza F E, Gu M, Zhang K H L 2018 Appl. Phys. Lett. 112 171605

Google Scholar

Google Scholar

[4] Joshi U S, Matsumoto Y, Itaka K, Sumiya M, Koinuma H 2006 Appl. Surf. Sci. 252 2524

Google Scholar

Google Scholar

[5] Yang A, Sakata O, Yamauchi R, Katsuya Y, Kumara L S R, Shimada Y, Matsuda A, Yoshimoto M 2014 Appl. Surf. Sci. 320 787

Google Scholar

Google Scholar

[6] Jang W L, Lu Y M, Hwang W S, Chen W C 2010 J. Eur. Ceram. Soc. 30 503

Google Scholar

Google Scholar

[7] Garduño-Wilches I, Alonso J C 2013 Int. J. Hydrogen Energy 38 4213

Google Scholar

Google Scholar

[8] Moulki H, Park D H, Min B K, Kwon H, Hwang S J, Choy J H, Toupance T, Campet G, Rougier A 2012 Electrochim. Acta 74 46

Google Scholar

Google Scholar

[9] Ohta H, Hirano M, Nakahara K, Maruta H, Tanabe T, Kamiya M, Kamiya T, Hosono H 2003 Appl. Phys. Lett. 83 1029

Google Scholar

Google Scholar

[10] Zhou T, Yang X M, Yuan J, Liu Q Z 2024 J. Alloys Compd. 984 173953

Google Scholar

Google Scholar

[11] Sikdar S, Sahu B P, Dhar S 2023 Appl. Phys. Lett. 122 023501

Google Scholar

Google Scholar

[12] Zhang K H L, Wu R, Tang F, Li W, Oropeza F E, Qiao L, Lazarov V K, Du Y, Payne D J, MacManus-Driscoll J L, Blamire M G 2017 ACS Appl. Mater. Interfaces 9 26549

Google Scholar

Google Scholar

[13] Dutta T, Gupta P, Gupta A, Narayan J 2010 J. Appl. Phys. 108 083715

Google Scholar

Google Scholar

[14] Jung M C, Leyden M R, Nikiforov G O, Lee M V, Lee H K, Shin T J, Takimiya K, Qi Y 2015 ACS Appl. Mater. Interfaces 7 1833

Google Scholar

Google Scholar

[15] Park K H, Ur S C, Kim I H, Choi S M, Seo W S 2010 J. Korean Phys. Soc. 57 1000

Google Scholar

Google Scholar

[16] Tauc J 1968 Mater. Res. Bull. 3 37

Google Scholar

Google Scholar

[17] Yang S, Kim J, Choi Y, Kim H, Lee D, Bae J S, Park S 2020 J. Alloys Compd. 815 152343

Google Scholar

Google Scholar

[18] Li Y, Li X H, Wang Z X, Guo H J, Li T 2016 Ceram. Int. 42 14565

Google Scholar

Google Scholar

[19] Liu Q Z, Liu J J, Li B, Li H, Zhu G P, Dai K, Liu Z L, Zhang P, Dai J M 2012 Appl. Phys. Lett. 101 241901

Google Scholar

Google Scholar

[20] Shanthi E, Dutta V, Banerjee A, Chopra K L 1980 J. Appl. Phys. 51 6243

Google Scholar

Google Scholar

[21] Burstein E 1954 Phys. Rev. 93 632

Google Scholar

Google Scholar

[22] Moss T S 1954 Proc. Phys. Soc. London, Sect. B 67 775

Google Scholar

Google Scholar

[23] Dakhel A A 2012 J. Alloys Compd. 539 26

Google Scholar

Google Scholar

[24] Gupta R K, Ghosh K, Kahol P K 2009 Physica E 41 617

Google Scholar

Google Scholar

[25] Shah J M, Li Y L, Gessmann T, Schubert E F 2003 J. Appl. Phys. 94 2627

Google Scholar

Google Scholar

[26] Ohta H, Kamiya M, Kamiya T, Hirano M, Hosono H 2003 Thin Solid Films 445 317

Google Scholar

Google Scholar

[27] Grundmann M, Klüpfel F, Karsthof R, Schlupp P, Schein F L, Splith D, Yang C, Bitter S, von Wenckstern H 2016 J. Phys. D: Appl. Phys. 49 213001

Google Scholar

Google Scholar

-

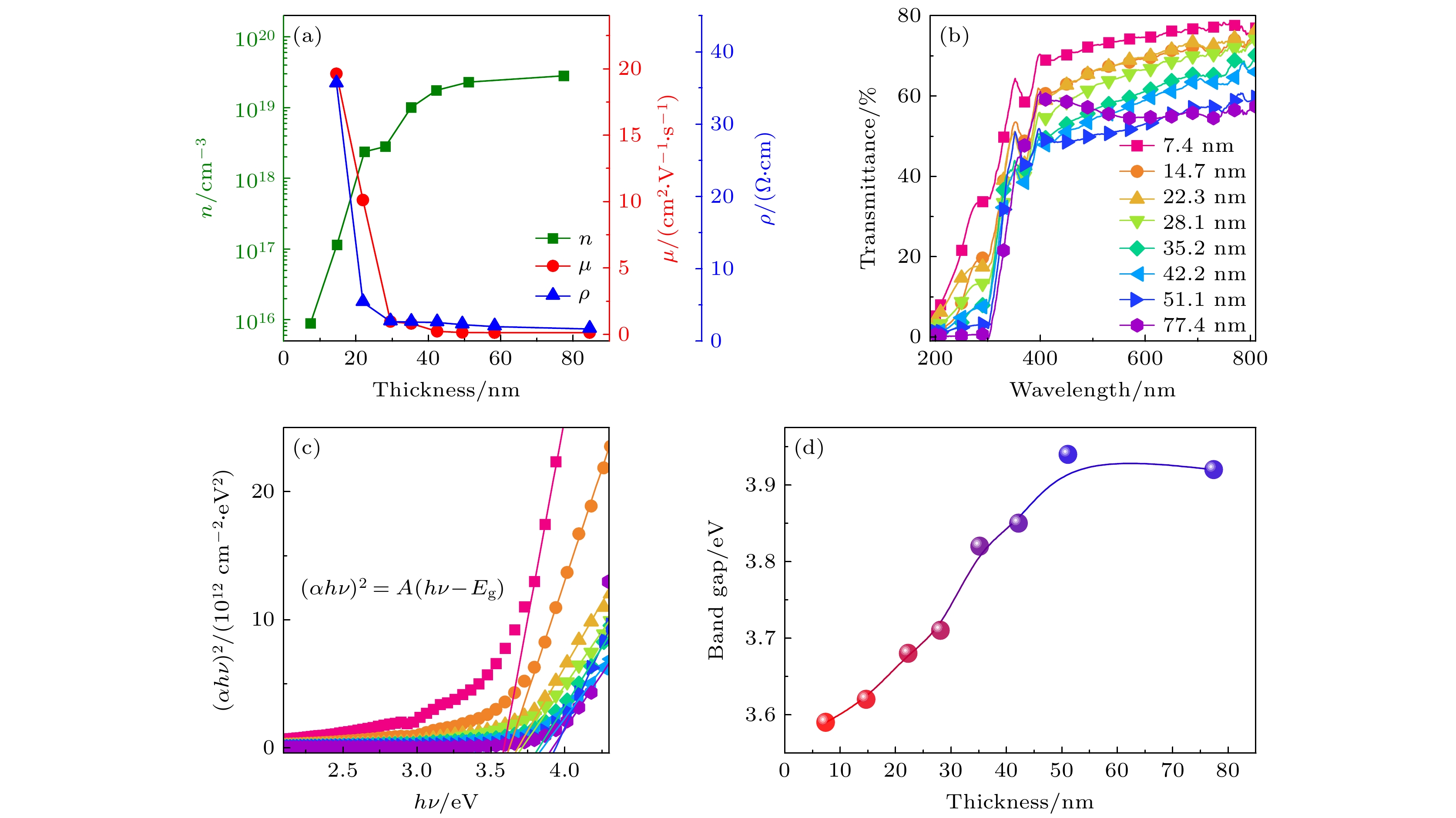

图 1 厚度对LNO单层膜(x = 0.07)物性的影响 (a)载流子浓度、迁移率和电阻率随厚度的变化; (b)光学透射率与厚度的关系; (c) hν与(αhν)2的关系; (d)光学带隙随薄膜厚度的变化

Fig. 1. Properties of LNO monolayers (x = 0.07) with varying thicknesses: (a) Variations of carrier concentration, mobility and resistivity of films with different thicknesses; (b) optical transmittance characterization of films with varying thicknesses; (c) plots of hν vs. (αhν)2; (d) relationship between optical band gap values and film thickness.

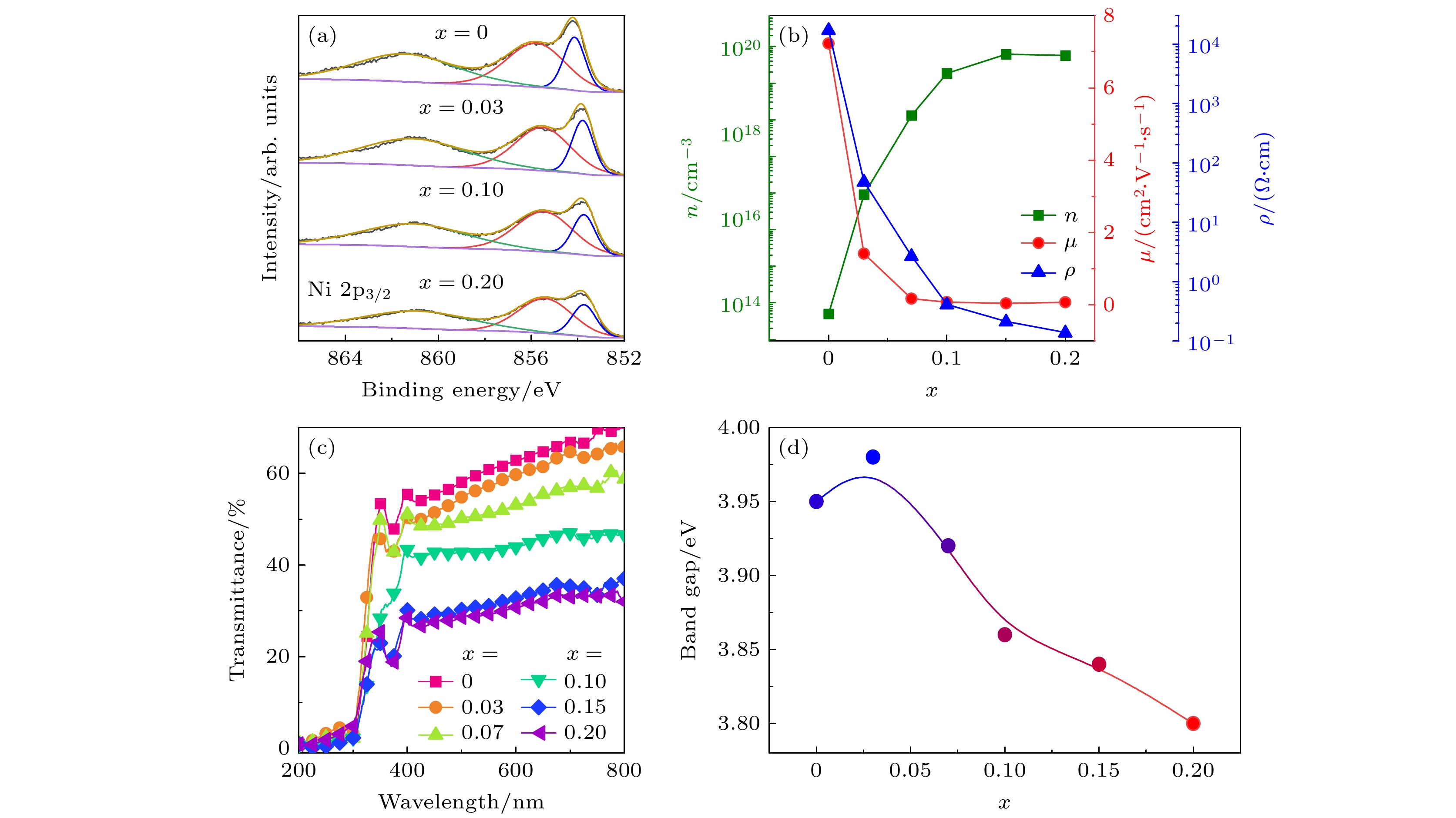

图 2 Li掺杂对LNO单层膜物性的影响 (a) LNO薄膜Ni 2p3/2的XPS; (b) LNO薄膜的载流子浓度、迁移率和电阻率随Li掺杂的变化; (c)薄膜的光学透射率随Li掺杂的变化; (d)光学带隙随Li掺杂的变化

Fig. 2. Properties of LNO films with varying Li-doping levels: (a) XPS of LNO films focusing on Ni 2p3/2; (b) relationship of carrier concentration, mobility, and resistivity of LNO films to Li doping levels; (c) optical transmittance characterization of the films; (d) relationship between optical band gap values and Li doping levels.

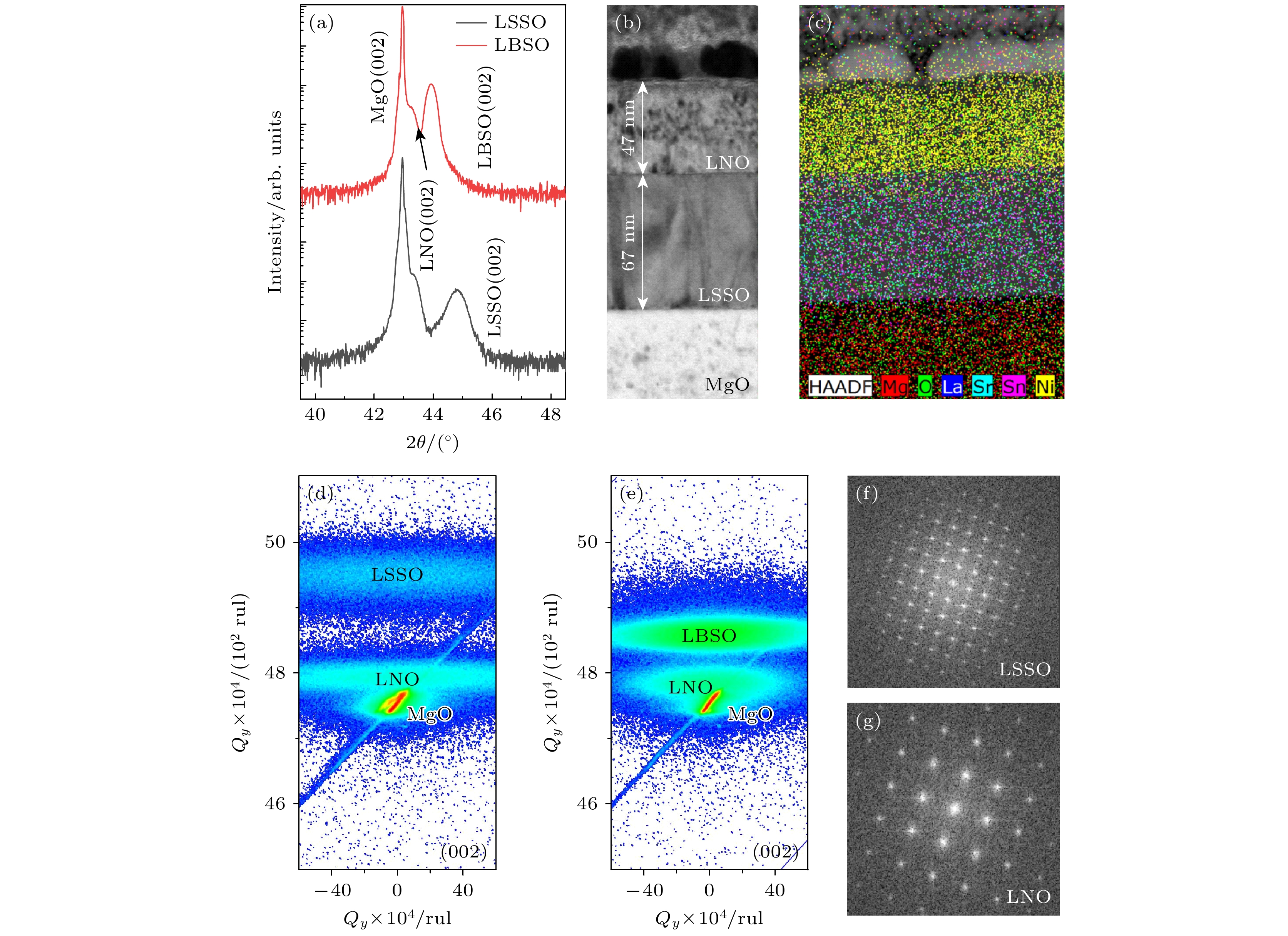

图 3 透明异质结的结构表征 (a) LNO/LSSO和LNO/LBSO异质结构的(00l)面的XRD线性扫描; (b) LNO/LSSO异质结构的横截面明场像和(c)各元素分布图像; (d), (e)异质结构的倒易空间衍射图; (f) LSSO和(g) LNO的快速傅里叶变换图案

Fig. 3. Structural characterization of heterostructures: (a) XRD (00l) linear scans of LNO/LSSO and LNO/LBSO heterostructures; (b) cross-sectional bright field image and (c) energy dispersive X-ray spectroscopy image of the LNO/LSSO heterostructure; (d), (e) RSM results for heterostructures; (f), (g) FFT patterns of (f) LSSO and (g) LNO.

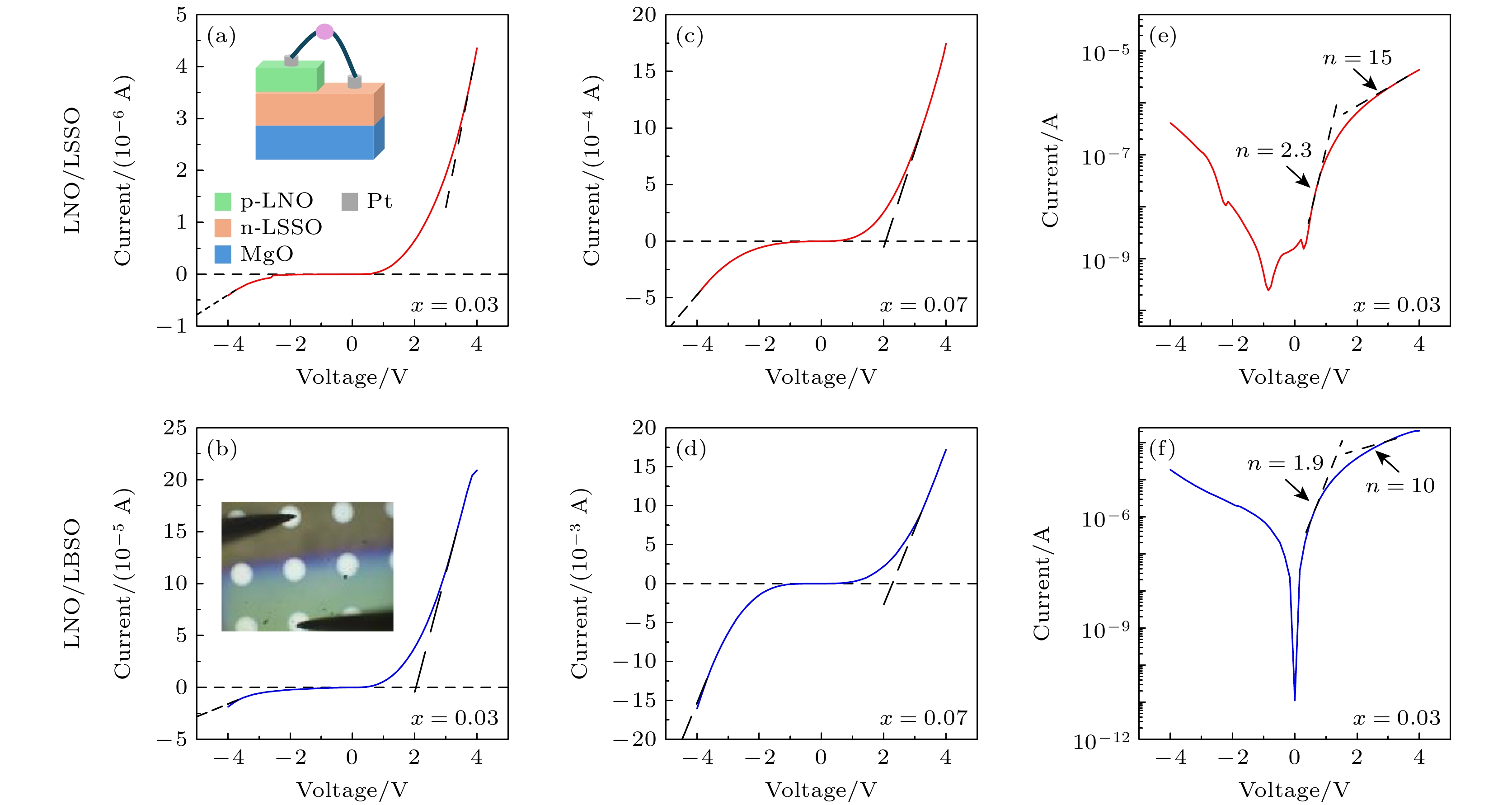

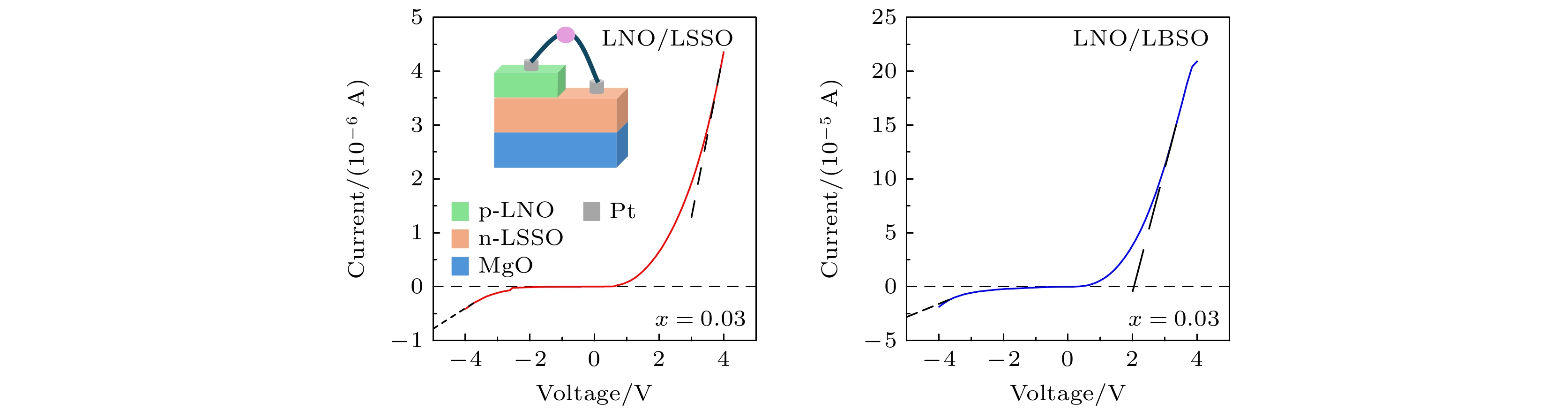

图 4 透明异质结构的整流特性 (a) LNO/LSSO (x = 0.03)的I -V曲线, 插图展示了样品的结构示意图; (b) LNO/LBSO (x = 0.03) 的I -V曲线, 插图为测试示意图; (c) LNO/LSSO (x = 0.07)的I -V曲线; (d) LNO/LBSO (x = 0.07)的I -V曲线; (e) LNO/LSSO (x = 0.03)的I -V曲线半对数图; (f) LNO/LBSO (x = 0.03)的I -V曲线半对数图

Fig. 4. Rectification characteristics of heterostructures: (a) I -V curve of LNO/LSSO (x = 0.03), with an inset showing the schematic of the heterostructure; (b) I -V curve of LNO/LBSO (x = 0.03), with an inset illustrating the tested sample; (c) I -V curve of LNO/LSSO (x = 0.07); (d) I -V curve of LNO/LBSO (x = 0.07); (e) I -V curve semilogarithmic plot of LNO/LSSO; (f) I -V curve semilogarithmic plot of LNO/LBSO.

-

[1] Xia H, Luo M, Wang W, Wang H, Li T, Wang Z, Xu H, Chen Y, Zhou Y, Wang F, Xie R, Wang P, Hu W, Lu W 2022 Light-Sci. Appl. 11 170

Google Scholar

Google Scholar

[2] Mistry B V, Bhatt P, Bhavsar K H, Trivedi S J, Trivedi U N, Joshi U S 2011 Thin Solid Films 519 3840

Google Scholar

Google Scholar

[3] Zhang J, Han S, Luo W, Xiang S, Zou J, Oropeza F E, Gu M, Zhang K H L 2018 Appl. Phys. Lett. 112 171605

Google Scholar

Google Scholar

[4] Joshi U S, Matsumoto Y, Itaka K, Sumiya M, Koinuma H 2006 Appl. Surf. Sci. 252 2524

Google Scholar

Google Scholar

[5] Yang A, Sakata O, Yamauchi R, Katsuya Y, Kumara L S R, Shimada Y, Matsuda A, Yoshimoto M 2014 Appl. Surf. Sci. 320 787

Google Scholar

Google Scholar

[6] Jang W L, Lu Y M, Hwang W S, Chen W C 2010 J. Eur. Ceram. Soc. 30 503

Google Scholar

Google Scholar

[7] Garduño-Wilches I, Alonso J C 2013 Int. J. Hydrogen Energy 38 4213

Google Scholar

Google Scholar

[8] Moulki H, Park D H, Min B K, Kwon H, Hwang S J, Choy J H, Toupance T, Campet G, Rougier A 2012 Electrochim. Acta 74 46

Google Scholar

Google Scholar

[9] Ohta H, Hirano M, Nakahara K, Maruta H, Tanabe T, Kamiya M, Kamiya T, Hosono H 2003 Appl. Phys. Lett. 83 1029

Google Scholar

Google Scholar

[10] Zhou T, Yang X M, Yuan J, Liu Q Z 2024 J. Alloys Compd. 984 173953

Google Scholar

Google Scholar

[11] Sikdar S, Sahu B P, Dhar S 2023 Appl. Phys. Lett. 122 023501

Google Scholar

Google Scholar

[12] Zhang K H L, Wu R, Tang F, Li W, Oropeza F E, Qiao L, Lazarov V K, Du Y, Payne D J, MacManus-Driscoll J L, Blamire M G 2017 ACS Appl. Mater. Interfaces 9 26549

Google Scholar

Google Scholar

[13] Dutta T, Gupta P, Gupta A, Narayan J 2010 J. Appl. Phys. 108 083715

Google Scholar

Google Scholar

[14] Jung M C, Leyden M R, Nikiforov G O, Lee M V, Lee H K, Shin T J, Takimiya K, Qi Y 2015 ACS Appl. Mater. Interfaces 7 1833

Google Scholar

Google Scholar

[15] Park K H, Ur S C, Kim I H, Choi S M, Seo W S 2010 J. Korean Phys. Soc. 57 1000

Google Scholar

Google Scholar

[16] Tauc J 1968 Mater. Res. Bull. 3 37

Google Scholar

Google Scholar

[17] Yang S, Kim J, Choi Y, Kim H, Lee D, Bae J S, Park S 2020 J. Alloys Compd. 815 152343

Google Scholar

Google Scholar

[18] Li Y, Li X H, Wang Z X, Guo H J, Li T 2016 Ceram. Int. 42 14565

Google Scholar

Google Scholar

[19] Liu Q Z, Liu J J, Li B, Li H, Zhu G P, Dai K, Liu Z L, Zhang P, Dai J M 2012 Appl. Phys. Lett. 101 241901

Google Scholar

Google Scholar

[20] Shanthi E, Dutta V, Banerjee A, Chopra K L 1980 J. Appl. Phys. 51 6243

Google Scholar

Google Scholar

[21] Burstein E 1954 Phys. Rev. 93 632

Google Scholar

Google Scholar

[22] Moss T S 1954 Proc. Phys. Soc. London, Sect. B 67 775

Google Scholar

Google Scholar

[23] Dakhel A A 2012 J. Alloys Compd. 539 26

Google Scholar

Google Scholar

[24] Gupta R K, Ghosh K, Kahol P K 2009 Physica E 41 617

Google Scholar

Google Scholar

[25] Shah J M, Li Y L, Gessmann T, Schubert E F 2003 J. Appl. Phys. 94 2627

Google Scholar

Google Scholar

[26] Ohta H, Kamiya M, Kamiya T, Hirano M, Hosono H 2003 Thin Solid Films 445 317

Google Scholar

Google Scholar

[27] Grundmann M, Klüpfel F, Karsthof R, Schlupp P, Schein F L, Splith D, Yang C, Bitter S, von Wenckstern H 2016 J. Phys. D: Appl. Phys. 49 213001

Google Scholar

Google Scholar

计量

- 文章访问数: 1059

- PDF下载量: 37

- 被引次数: 0

下载:

下载: