-

以氧化铟锡(indium tin oxide, ITO)为代表的透明导电氧化物(transparent conducting oxide, TCO)在当前光电器件中的重要性日益增长. 通过在TCO中引入金属网格构成复合电极, 可以在保持良好透明性的前提下有效提升电学性能, 同时降低对铟的需求量, 并为可穿戴设备所需的柔性电极提供可能方案. 对此类电极的电学性能分析, 如复合电极方阻随金属网格结构参数的变化, 可为电极设计与制备提供基本的出发点, 但相关理论尚十分缺乏. 本文针对典型的方孔方格型金属网格-TCO复合电极, 分别展开基于瑞利模型和基于有限元仿真的电学性能分析. 结果表明, 孔型近似导致的金属通道显著畸变是复合电极的电学计算中瑞利模型在中高开口率下失效的主要原因. 据此, 我们采用格型修正, 通过提升瑞利模型中的原胞外边界对称性来改善金属通道的畸变. 与电极仿真的对比表明, 修正后瑞利模型的适用范围明显扩大, 其结果可与实验数据很好地拟合, 为此类复合透明电极的电学数据分析与结构设计提供了简洁高效的理论工具.Transparent conducting oxides (TCOs), especially indium tin oxides (ITOs), have played an important role in realizing optoelectronics devices. Composite electrodes fabricated by introducing different types of metal-meshes into TCO have exhibited improved electric properties as well as good transparency. This technology can also reduce the demand for ITO and provide the candidates of flexible electrodes for wearable devices. Analysis of the electric properties of this type of electrode, such as the variance of the sheet resistance of the composite electrodes with the embedded mesh structure parameters, can provide a theoretical basis for designing and fabricating this electrode. But detailed studies are still lacking. This work focuses on the electrical property analysis of the typical square hole and grid shaped metal mesh-TCO composite electrodes based on Rayleigh model and finite-element simulation, respectively. The electric potential distribution and current density distribution are obtained from the finite element calculations, revealing that the dramatic deformation of the metallic channels in the composite results in the failure of a conventional Rayleigh model for the moderate and high opening rates. Accordingly, we adopt a lattice correction to the Rayleigh model to reduce the channel deformation by increasing the symmetry of the exterior boundary of the lattice cell. A comparison of the results from the simulations with those from the second-order approximation of the lattice-adapted Rayleigh model shows that the new analytic form of the effective conductivity is applicable to a much larger opening-rate range for both the monolayer and the sandwich structures of metal-mesh TCO composite electrodes. The variances of the sheet resistance and the effective conductivity with different material and structure parameters of the composite electrodes are calculated and discussed based on the lattice-adapted Rayleigh approximation. The results are well consistent with experimental results. A comparison of our model with other theoretical models is also made, showing that this lattice-adapted Rayleigh approximation can be used as a simple and efficient theoretical tool to analyze and design the concerned transparent composite electrodes.

-

Keywords:

- transparent conductors /

- metal mesh electrodes /

- composites medium /

- finite element simulation

[1] Gao J W, Kempa K, Giersig M, Akinoglu E M, Han B, Li R P 2016 Adv. Phys. 65 553

Google Scholar

Google Scholar

[2] Shen J J 2021 Synth. Met. 271 116582

Google Scholar

Google Scholar

[3] Lu X, Zhang Y K, Zheng Z J 2021 Adv. Electron. Mater. 7 2001121

Google Scholar

Google Scholar

[4] 王利, 张晓丹, 杨旭, 魏长春, 张德坤, 王广才, 孙建, 赵颖 2014 63 028801

Google Scholar

Google Scholar

Wang L, Zhang X D, Yang X, Wei C C, Zhang D K, Wang G C, Sun J, Zhao Y 2014 Acta Phys. Sin. 63 028801

Google Scholar

Google Scholar

[5] Spencer J A, Mock A L, Jacobs A G, Schubert M, Zhang Y H, Tadjer M J 2022 Appl. Phys. Rev. 9 011315

Google Scholar

Google Scholar

[6] Fortunato E, Ginley D, Hosono H, Paine D C 2007 MRS Bull. 32 242

Google Scholar

Google Scholar

[7] Peng W, Li L X, Yu S H, Yang P, Xu K L 2022 Ceram. Int. 48 381

Google Scholar

Google Scholar

[8] Wei W Z, Hong R J, Wang J X, Tao C X, Zhang D W 2017 J. Mater. Sci. Technol. 33 1107

Google Scholar

Google Scholar

[9] Guillen C, Herrero J 2008 Sol. Energy Mater. Sol. Cells 92 938

Google Scholar

Google Scholar

[10] Sivaramakrishnan K, Alford T L 2009 Appl. Phys. Lett. 94 052104

Google Scholar

Google Scholar

[11] Jeong J A, Park Y S, Kim H K 2010 J. Appl. Phys. 107 023111

Google Scholar

Google Scholar

[12] Mohamedi M, Challali F, Touam T, Konstantakopoulou M, Bockelee V, Mendil D, Ouhenia S, Djouadi D, Chelouche A 2023 Appl. Phys. A 129 545

Google Scholar

Google Scholar

[13] Kim S, Montero J, Yoon J, Choi Y, Park S, Song P, Österlund L 2022 ACS Appl. Mater. Interfaces 14 15756

Google Scholar

Google Scholar

[14] Lee S Y, Cho E S, Kwon S J 2019 Appl. Surf. Sci. 487 990

Google Scholar

Google Scholar

[15] Cho E S, Kwon S J 2021 J. Semicond. Technol. Sci. 21 348

Google Scholar

Google Scholar

[16] Khan A, Lee S, Jang T, Xiong Z, Zhang C P, Tang J Y, Guo L J, Li W D 2016 Small 12 3021

Google Scholar

Google Scholar

[17] Jiang Z, Fukuda K, Xu X M, Park S, Inoue D, Jin H, Saito M, Osaka I, Takimiya K, Someya T 2018 Adv. Mater. 30 1707526

Google Scholar

Google Scholar

[18] Yuan S Q, Fan Z B, Wang G J, Chai Z M, Wang T Q, Zhao D W, Busnaina A A, Lu X C 2023 Adv. Sci. 10 2304990

[19] Yu J S, Jung G H, Jo J, Kim J S, Kim J W, Kwak S W, Lee J L, Kim I, Kim D 2013 Sol. Energy Mater. Sol. Cells 109 142

Google Scholar

Google Scholar

[20] Sun M D, Kik P G 2020 Opt. Express 28 18112

Google Scholar

Google Scholar

[21] Lee H B, Jin W Y, Ovhal M M, Kumar N, Kang J W 2019 J. Mater. Chem. C 7 1087

Google Scholar

Google Scholar

[22] Jeong J A, Kim H K 2009 Sol. Energy Mater. Sol. Cells 93 1801

Google Scholar

Google Scholar

[23] Strutt J W 1892 Philos. Mag. 34 481

Google Scholar

Google Scholar

[24] Perrins W T, McKenzie D R, McPhedran R C 1979 P. Roy. Soc. A-Math. Phy. 369 207

[25] Keller J B 1963 J. Appl. Phys. 34 991

Google Scholar

Google Scholar

[26] McKenzie D R, McPhedran R C 1977 Nature 265 128

Google Scholar

Google Scholar

[27] Lu S Y 1995 J. Compos. Mater. 29 483

Google Scholar

Google Scholar

[28] Zen N, Puurtinen T A, Isotalo T J, Chaudhuri S, Maasilta I J 2014 Nat. Commun. 5 3435

Google Scholar

Google Scholar

[29] Obnosov Y V 1999 SIAM J. Appl. Math. 59 1267

Google Scholar

Google Scholar

[30] Guralnik B, Hansen O, Henrichsen H H, Caridad J M, Wei W, Hansen M F, Nielsen P F, Petersen D H 2021 Nanotechnology 32 185706

Google Scholar

Google Scholar

[31] Ding G W, Clavero C, Schweigert D, Le M 2015 AIP Adv. 5 117234

Google Scholar

Google Scholar

[32] Kim J, Truskett T M 2022 Appl. Phys. Lett. 120 211108

Google Scholar

Google Scholar

-

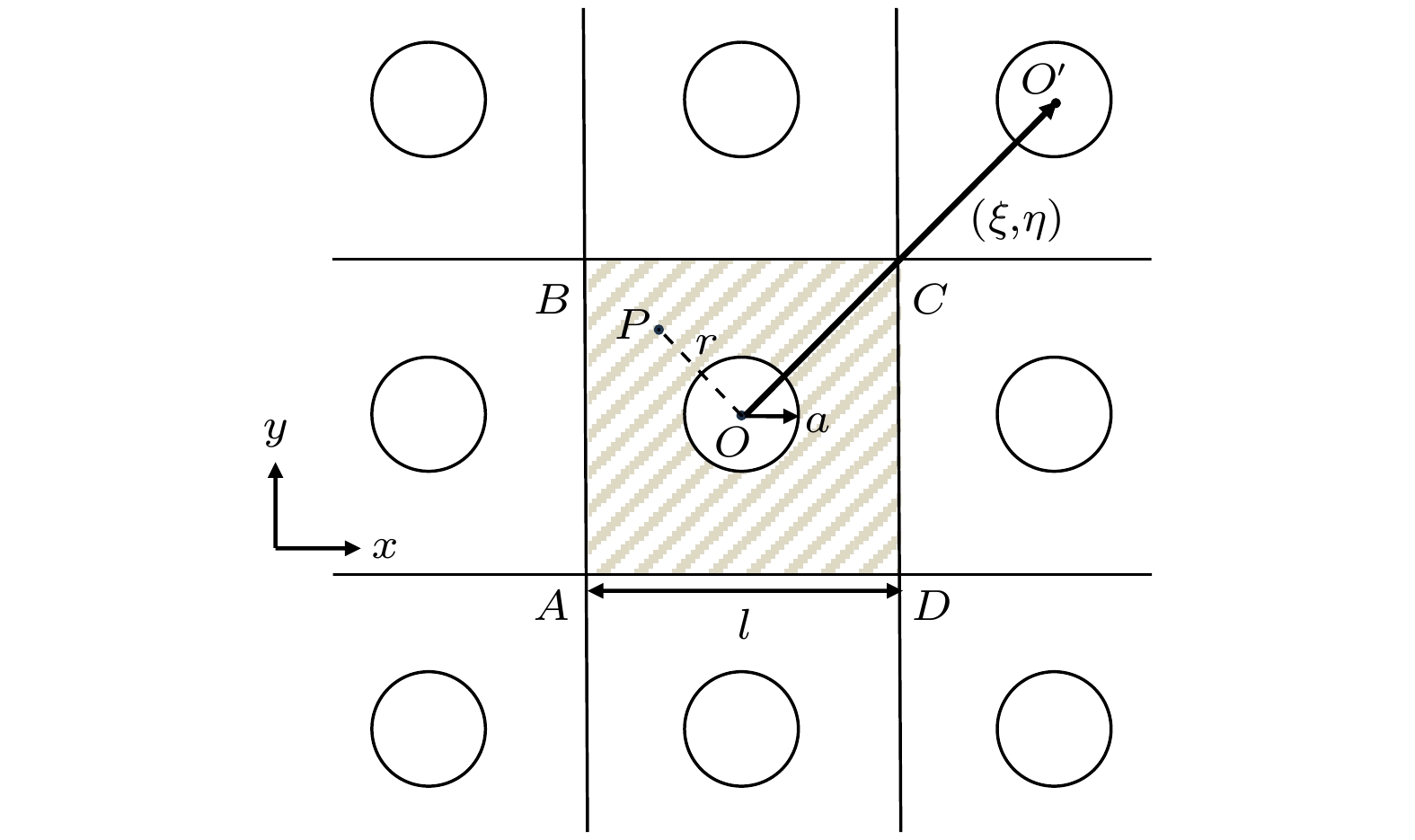

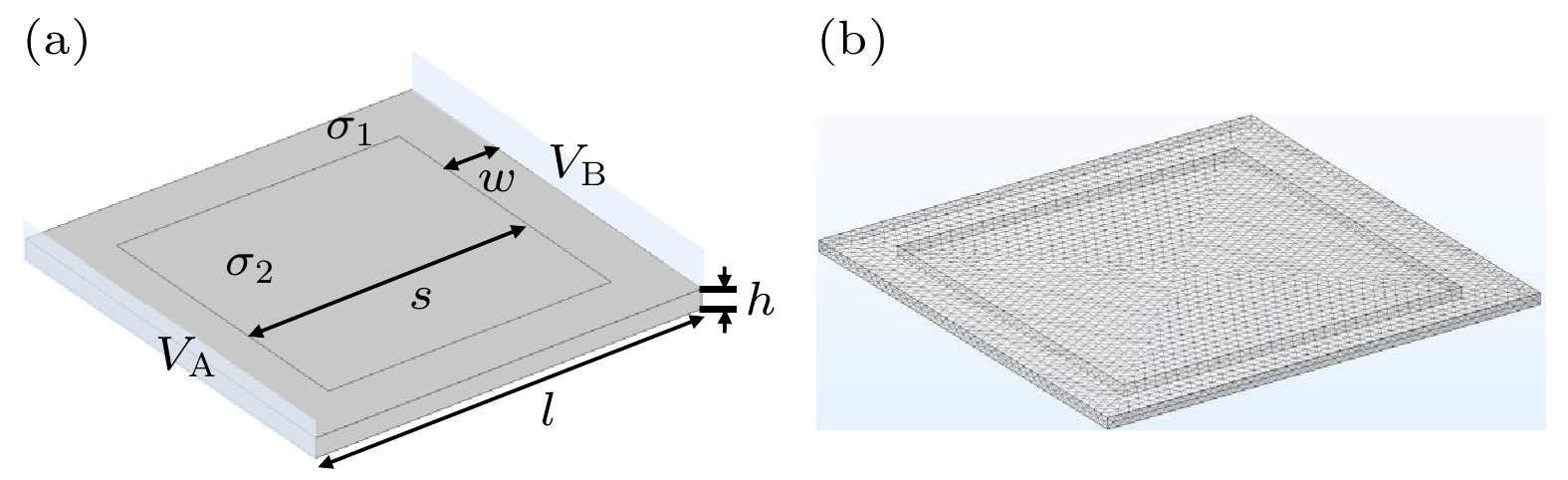

图 1 (a) TCO/纳米金属膜/TCO三明治结构示意图; (b) TCO/金属网格/TCO复合电极结构示意图; (c) 典型的方格方孔型金属网格结构; (d) 典型的二维瑞利复合介质结构, w为金属网格的线宽, s为线间距, h为线高

Fig. 1. (a) Scheme of the TCO/metal-nanofilm/TCO sandwich structure; (b) scheme of the TCO/metal-mesh/TCO composite electrode structure; (c) typical structure of a metal mesh with bi-periodic square order; (d) typical structure of the two-dimensional Rayleigh composite, w is line-width of the metal mesh, s is line spacing; h is line height.

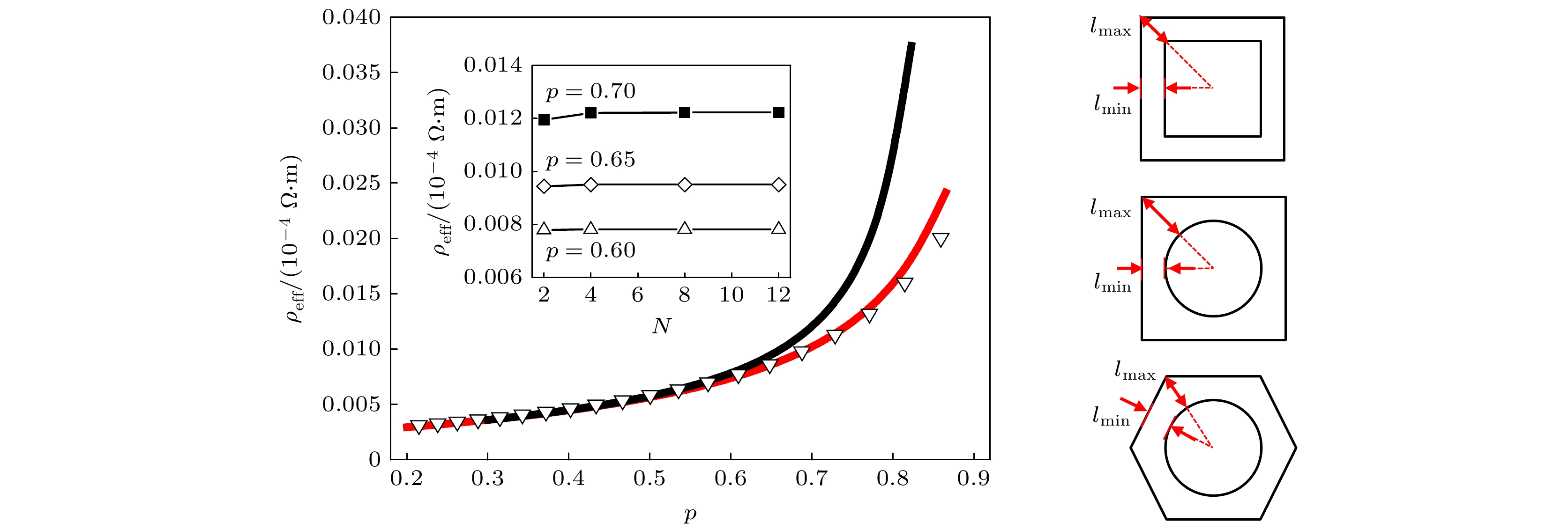

图 4 单层金属网格-TCO复合电极的仿真结果与修正前后的瑞利近似结果对比 (a) 金属网格-TCO单层复合电极的有效${\rho _{{\text{eff}}}}$电阻率随开口率$p$的变化, 三角点为图3所示结构的仿真结果, 黑色曲线为方格瑞利模型的二阶近似, 红色曲线为六角格瑞利模型的二阶近似, 插图为方格瑞利模型的有效电阻率随截断阶数$N$的变化, 计算中采用的组分材料为Ag和ITO, 其电阻率从文献[22]提取, $ {\rho _{\text{m}}} = {\rho _1} = 2 \times {10^{ - 7}} $$\Omega \cdot {\mathrm{m}}$, $ {\rho _{{\text{TCO}}}} = {\rho _2} = 8.0096 \times {10^{ - 6}} $$\Omega \cdot{\mathrm{ m}}$; (b) 3种金属网格形态的对比, (由上至下)仿真中采用的方格方孔、瑞利方格、瑞利六角格, ${l_{\min }}$为网格金属通道内最窄处, ${l_{\max }}$为网格金属通道内最宽处

Fig. 4. Comparison between simulation results and Rayleigh approximations before and after correction for the mesh-TCO layer resistivity: (a) Dependence of the effective resistivity ${\rho _{{\text{eff}}}}$ vs. open ratio $p$, triangles is the simulation results for a layer of metal mesh embedded in TCO with the structure shown in Fig. 3, black line is the calculated results from a square-lattice Rayleigh model in the 2nd order, red line is the calculated results from a hexagonal-lattice Rayleigh model in the 2nd order, inset is the convergence of the effective resistivity of the square Rayleigh model with the truncation order $N$ for different open-ratios, the components in the calculations are Ag and ITO with resistivity, $ {\rho _{\text{m}}} = {\rho _1} = 2 \times {10^{ - 7}} $$\Omega \cdot {\mathrm{m}}$, $ {\rho _{{\text{TCO}}}} = {\rho _2} = 8.0096 \times {10^{ - 6}} $$\Omega \cdot {\mathrm{m}}$[22]; (b) comparison of different mesh structure, downward is the square lattice with square hole as adopted in simulations, square lattice with circular hole as adopted in the square Rayleigh model, hexagonal lattice with circular hole as adopted in the hexagonal Rayleigh model, ${l_{\min }}$ is the minimum of the metallic channel width, ${l_{\max }}$ is the maximum of the metallic channel width.

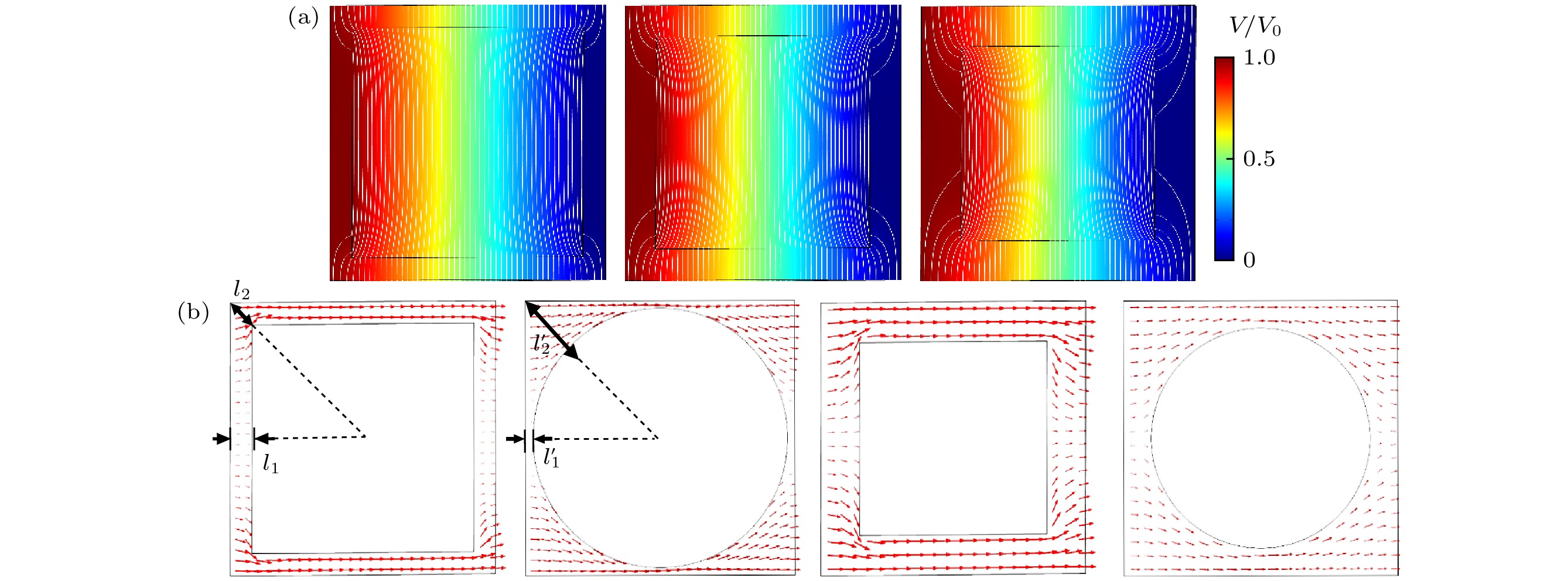

图 5 单层金属网格/TCO复合电极仿真的电势分布与电流密度矢量分布 (a) 不同开口率下方孔方格的电势分布, 由左至右$p = $$ 0.7, \;0.6, \;0.5$; (b) 方格方孔型与方格圆孔型的金属通道电流密度分布仿真结果对比, 左二图开口率$p = 0.7$, 右二图开口率$p = 0.5$, ${l_1}, {l_1}'$表示网格金属通道内最窄处, ${l_2}, {l_2}'$表示网格金属通道内最宽处, 组分电阻率设置同图4(a)

Fig. 5. Distributions of electric potential and current density vector from the simulations for a layer of metal mesh embedded in TCO: (a) The electric potential distribution for the mesh of a square array with square opens, from left to right $p = 0.7, \;0.6, \;0.5$; (b) the current distributions in the metallic region for different meshes, open ratio $p = 0.7$ in the second figure from the left, open ratio $p = 0.5$ in the second figure from the right, ${l_1}, {l_1}'$ represents minimum of the metallic channel width, ${l_2}, {l_2}'$ represents maximum of the metallic channel width.

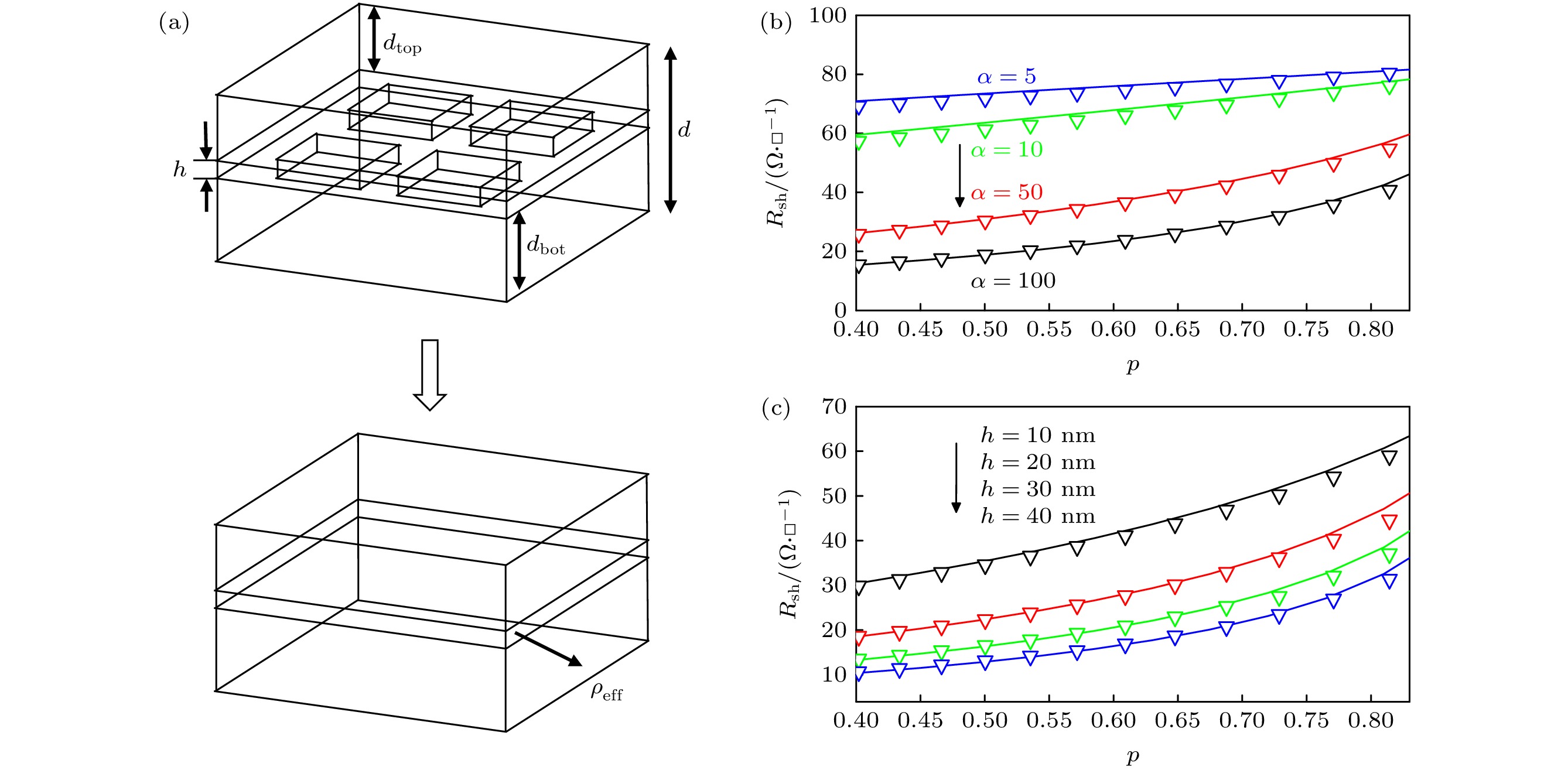

图 6 三明治结构复合电极方阻的仿真计算结果与修正后的瑞利近似结果的对比 (a) TCO/金属网格/TCO三明治结构的有效介质近似示意图; (b) 不同组分电阻率比$\alpha $下复合电极方阻${R_{{\text{sh}}}}$随开口率$p$的变化曲线($h = 10\;{\text{nm}}$, ${\rho _1} = 2 \times {10^{ - 7}}\;\Omega \cdot {\text{m}}$, ${\rho _2} = \alpha {\rho _1}$); (c) 不同网格层厚度$h$下复合电极方阻${R_{{\text{sh}}}}$随开口率$p$的变化曲线(组分电阻率比$\alpha = 50$, ${\rho _1} = 2 \times {10^{ - 7}}\;\Omega \cdot {\text{m}}$, ${\rho _2} = \alpha {\rho _1}$), 三角点为仿真结果, 实线为修正后的瑞利近似结果

Fig. 6. Comparison between the simulations results and the corrected Rayleigh approximation for the sheet resistance ${R_{{\text{sh}}}}$ of the sandwich TCO/metal-mesh/TCO electrode: (a) Scheme of the effective medium approximation of the sandwich electrode; (b) ${R_{{\text{sh}}}}$ vs. open-ratio $p$curves for different component resistivity ratio $\alpha $ ($h = 10\;{\text{nm}}$, ${\rho _1} = 2 \times {10^{ - 7}}~\Omega {\cdot} {\text{m}}$, ${\rho _2} = \alpha {\rho _1}$); (c) ${R_{{\text{sh}}}}$ vs. open-ratio $p$curves for different mesh thickness $h$ ($\alpha = 50$, ${\rho _1} = 2 \times {10^{ - 7}}\;\Omega \cdot {\text{m}}$, ${\rho _2} = \alpha {\rho _1}$). Triangles represent simulation results, solid lines represent results from the corrected Rayleigh approximation.

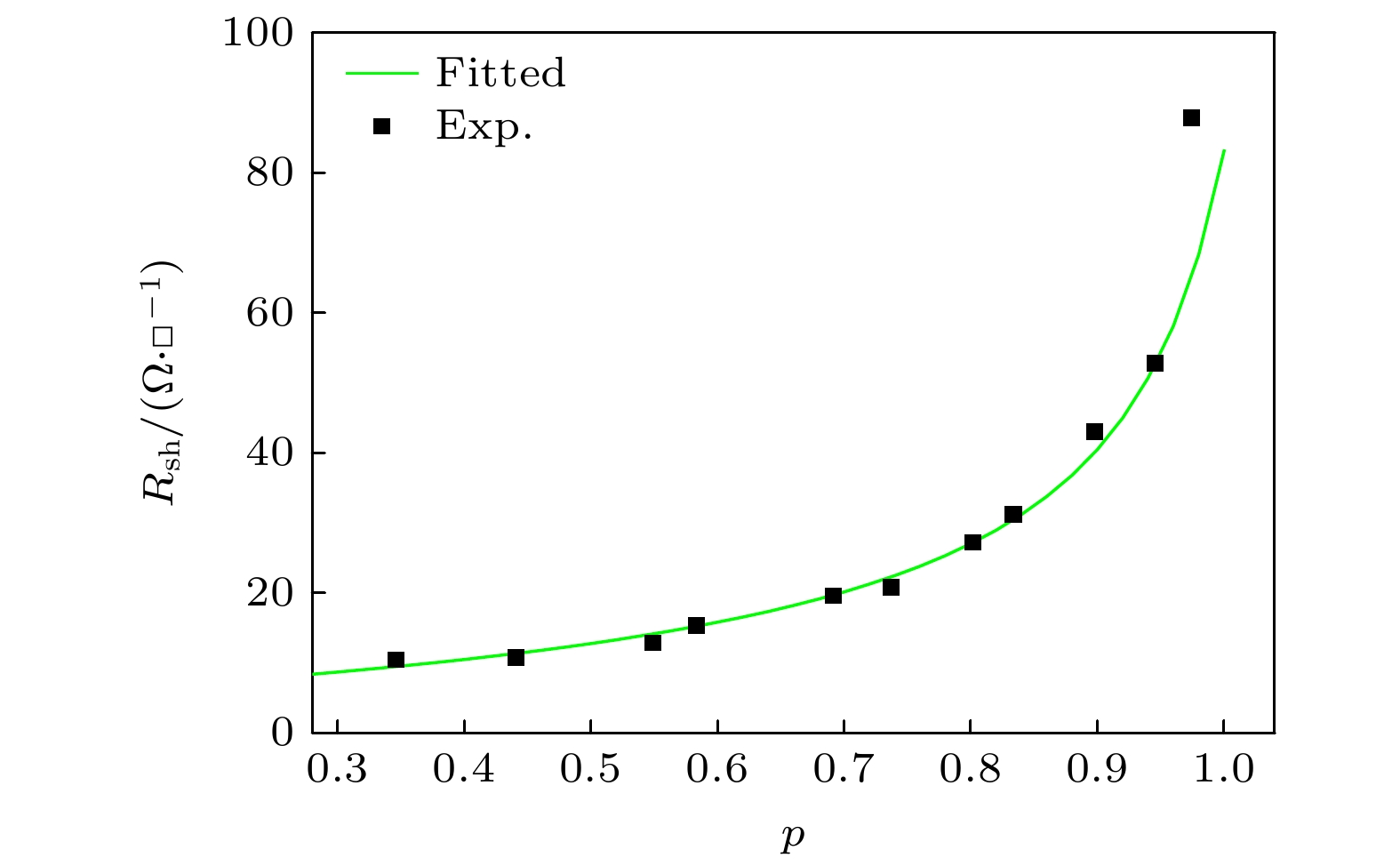

图 7 ITO/Ag网格/ITO三明治复合电极方阻${R_{{\text{sh}}}}$随Ag网格开口率$p$的变化, 方点取自文献[14]的实验结果, 实线采用格型修正后的瑞利模型拟合得到的曲线, 相关结构参数与材料参数如正文所述

Fig. 7. The variance of the sheet resistance ${R_{{\text{sh}}}}$ with mesh open-ratio $p$ for an ITO/Ag-mesh/ITO composite sandwich electrode. Square represents experimental results for the experiments in Ref.[14], solid line represents the fitted result with the lattice-modified Rayleigh model, the relevant structure and material parameters are as described in the main text.

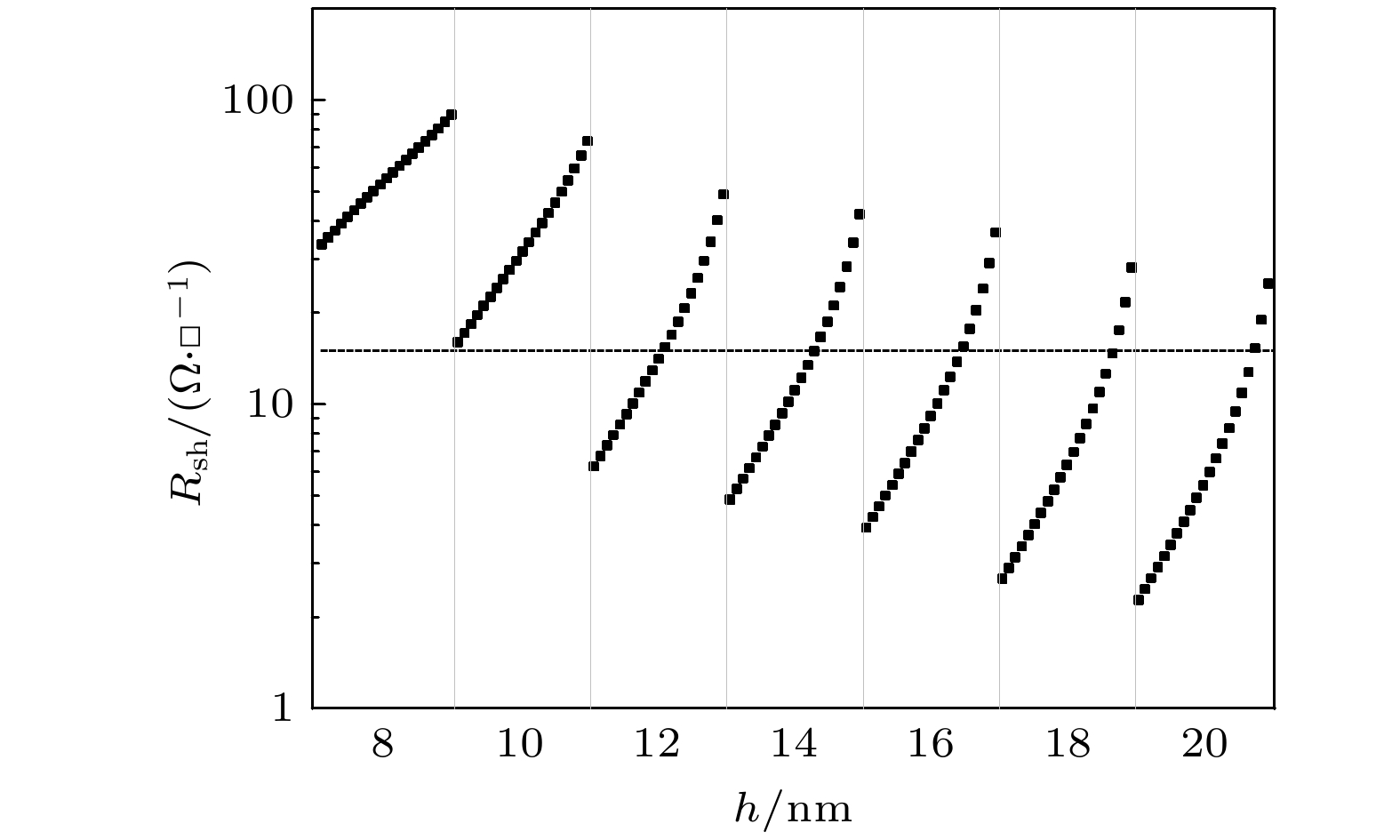

图 8 金属网格厚度$h$与开口率$p$对ITO/Ag网格/ITO复合电极方阻${R_{{\text{sh}}}}$的影响, 从左到右6组数据点分别对应$h = 8\;{\text{, 10, 12, 14, }} {\text{16, }} {\text{18, 20}}\;{\text{nm}}$, 每组数据点对应开口率从$p = 0$到$p = 0.85$, 步长均匀, 计算结果采用修正后的瑞利模型得到, 相关参数设置如正文所述

Fig. 8. The dependence of the ITO/Ag-mesh/ITO composite electrode on the mesh thickness $h$ and open-ratio $p$, rightward corresponding $h = 8\;{\text{, 10, 12, 14, }} {\text{16, }} {\text{18, 20}}\;{\text{nm}}$, each dataset corresponding $p = 0$ to $p = 0.85$, with uniform step, other parameters are set up as described in the main text.

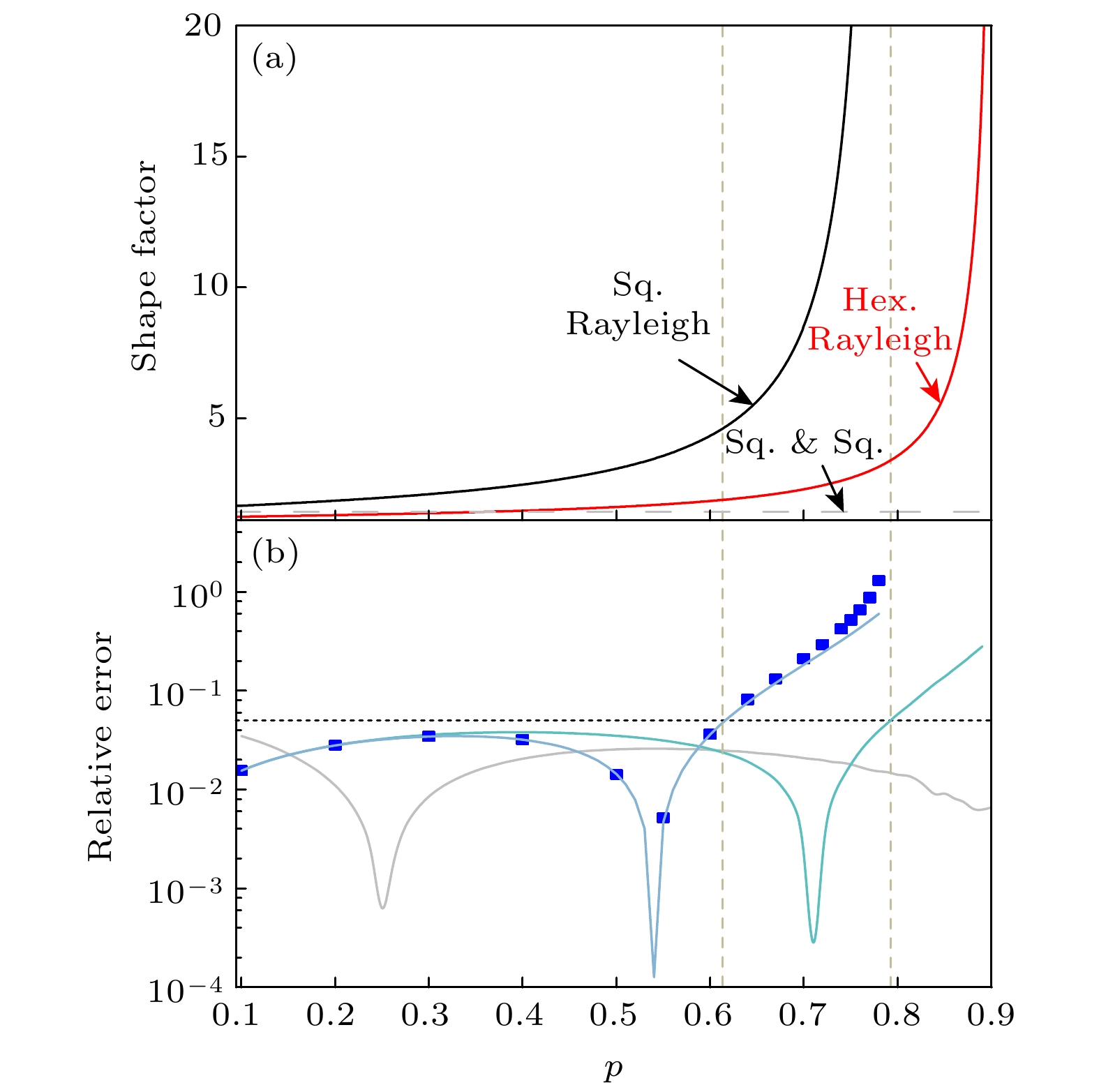

图 9 (a) 3种不同的格型孔型下金属通道的形状因子随开口率的变化, 灰色虚线标注为Sq.&Sq., 代表具有方格方孔形态的金属网格; 黑色实线标注为Sq. Rayleigh, 代表瑞利方格; 红色实线, 标注为Hex. Rayleigh, 代表瑞利六角格; (b) 不同近似结果与仿真结果的相对误差随开口率的变化, 浅灰色实线为等效电路近似, 蓝灰色实线为二阶瑞利方格近似, 蓝绿色实线为二级瑞利六角格近似, 蓝色方点为瑞利方格高阶截断近似

Fig. 9. (a) The variance of the shape factor of metal channels with open ratio for different mesh type, gray dash line labeled Sq.&Sq., mesh of a bi-periodic square lattice, black solid line labeled Sq. Rayleigh, Rayleigh model of a square lattice, red solid line labeled Hex, Rayleigh represents Rayleigh model of a hexagonal lattice; (b) the variance of the relative error of different approximations with respect to the simulation results, light-gray solid represents equivalent circuit approximation; blue-gray solid represents square Rayleigh approximation in the 2nd order; blue-green solid represents hexagonal Rayleigh approximation in the 2nd order; blue squares represents high-order square Rayleigh approximation.

表 1 金属网格厚度对三明治结构复合电极的影响

Table 1. Effects of the metal mesh thickness on the sandwich-structured composite electrodes.

$h$/${\text{nm}}$ 8 10 12 14 16 18 20 ${\rho _{{\text{Ag}}}}$/(${\text{μ}}\,\Omega{\cdot} {\text{cm}}$) $37.8$ $18.6$ $7.94$ $7.10$ $6.51$ $4.91$ $4.64$ ${p_{\text{c}}}$ — 0 0.4675 0.5525 0.6375 0.7225 0.7650 -

[1] Gao J W, Kempa K, Giersig M, Akinoglu E M, Han B, Li R P 2016 Adv. Phys. 65 553

Google Scholar

Google Scholar

[2] Shen J J 2021 Synth. Met. 271 116582

Google Scholar

Google Scholar

[3] Lu X, Zhang Y K, Zheng Z J 2021 Adv. Electron. Mater. 7 2001121

Google Scholar

Google Scholar

[4] 王利, 张晓丹, 杨旭, 魏长春, 张德坤, 王广才, 孙建, 赵颖 2014 63 028801

Google Scholar

Google Scholar

Wang L, Zhang X D, Yang X, Wei C C, Zhang D K, Wang G C, Sun J, Zhao Y 2014 Acta Phys. Sin. 63 028801

Google Scholar

Google Scholar

[5] Spencer J A, Mock A L, Jacobs A G, Schubert M, Zhang Y H, Tadjer M J 2022 Appl. Phys. Rev. 9 011315

Google Scholar

Google Scholar

[6] Fortunato E, Ginley D, Hosono H, Paine D C 2007 MRS Bull. 32 242

Google Scholar

Google Scholar

[7] Peng W, Li L X, Yu S H, Yang P, Xu K L 2022 Ceram. Int. 48 381

Google Scholar

Google Scholar

[8] Wei W Z, Hong R J, Wang J X, Tao C X, Zhang D W 2017 J. Mater. Sci. Technol. 33 1107

Google Scholar

Google Scholar

[9] Guillen C, Herrero J 2008 Sol. Energy Mater. Sol. Cells 92 938

Google Scholar

Google Scholar

[10] Sivaramakrishnan K, Alford T L 2009 Appl. Phys. Lett. 94 052104

Google Scholar

Google Scholar

[11] Jeong J A, Park Y S, Kim H K 2010 J. Appl. Phys. 107 023111

Google Scholar

Google Scholar

[12] Mohamedi M, Challali F, Touam T, Konstantakopoulou M, Bockelee V, Mendil D, Ouhenia S, Djouadi D, Chelouche A 2023 Appl. Phys. A 129 545

Google Scholar

Google Scholar

[13] Kim S, Montero J, Yoon J, Choi Y, Park S, Song P, Österlund L 2022 ACS Appl. Mater. Interfaces 14 15756

Google Scholar

Google Scholar

[14] Lee S Y, Cho E S, Kwon S J 2019 Appl. Surf. Sci. 487 990

Google Scholar

Google Scholar

[15] Cho E S, Kwon S J 2021 J. Semicond. Technol. Sci. 21 348

Google Scholar

Google Scholar

[16] Khan A, Lee S, Jang T, Xiong Z, Zhang C P, Tang J Y, Guo L J, Li W D 2016 Small 12 3021

Google Scholar

Google Scholar

[17] Jiang Z, Fukuda K, Xu X M, Park S, Inoue D, Jin H, Saito M, Osaka I, Takimiya K, Someya T 2018 Adv. Mater. 30 1707526

Google Scholar

Google Scholar

[18] Yuan S Q, Fan Z B, Wang G J, Chai Z M, Wang T Q, Zhao D W, Busnaina A A, Lu X C 2023 Adv. Sci. 10 2304990

[19] Yu J S, Jung G H, Jo J, Kim J S, Kim J W, Kwak S W, Lee J L, Kim I, Kim D 2013 Sol. Energy Mater. Sol. Cells 109 142

Google Scholar

Google Scholar

[20] Sun M D, Kik P G 2020 Opt. Express 28 18112

Google Scholar

Google Scholar

[21] Lee H B, Jin W Y, Ovhal M M, Kumar N, Kang J W 2019 J. Mater. Chem. C 7 1087

Google Scholar

Google Scholar

[22] Jeong J A, Kim H K 2009 Sol. Energy Mater. Sol. Cells 93 1801

Google Scholar

Google Scholar

[23] Strutt J W 1892 Philos. Mag. 34 481

Google Scholar

Google Scholar

[24] Perrins W T, McKenzie D R, McPhedran R C 1979 P. Roy. Soc. A-Math. Phy. 369 207

[25] Keller J B 1963 J. Appl. Phys. 34 991

Google Scholar

Google Scholar

[26] McKenzie D R, McPhedran R C 1977 Nature 265 128

Google Scholar

Google Scholar

[27] Lu S Y 1995 J. Compos. Mater. 29 483

Google Scholar

Google Scholar

[28] Zen N, Puurtinen T A, Isotalo T J, Chaudhuri S, Maasilta I J 2014 Nat. Commun. 5 3435

Google Scholar

Google Scholar

[29] Obnosov Y V 1999 SIAM J. Appl. Math. 59 1267

Google Scholar

Google Scholar

[30] Guralnik B, Hansen O, Henrichsen H H, Caridad J M, Wei W, Hansen M F, Nielsen P F, Petersen D H 2021 Nanotechnology 32 185706

Google Scholar

Google Scholar

[31] Ding G W, Clavero C, Schweigert D, Le M 2015 AIP Adv. 5 117234

Google Scholar

Google Scholar

[32] Kim J, Truskett T M 2022 Appl. Phys. Lett. 120 211108

Google Scholar

Google Scholar

计量

- 文章访问数: 3501

- PDF下载量: 80

- 被引次数: 0

下载:

下载: