-

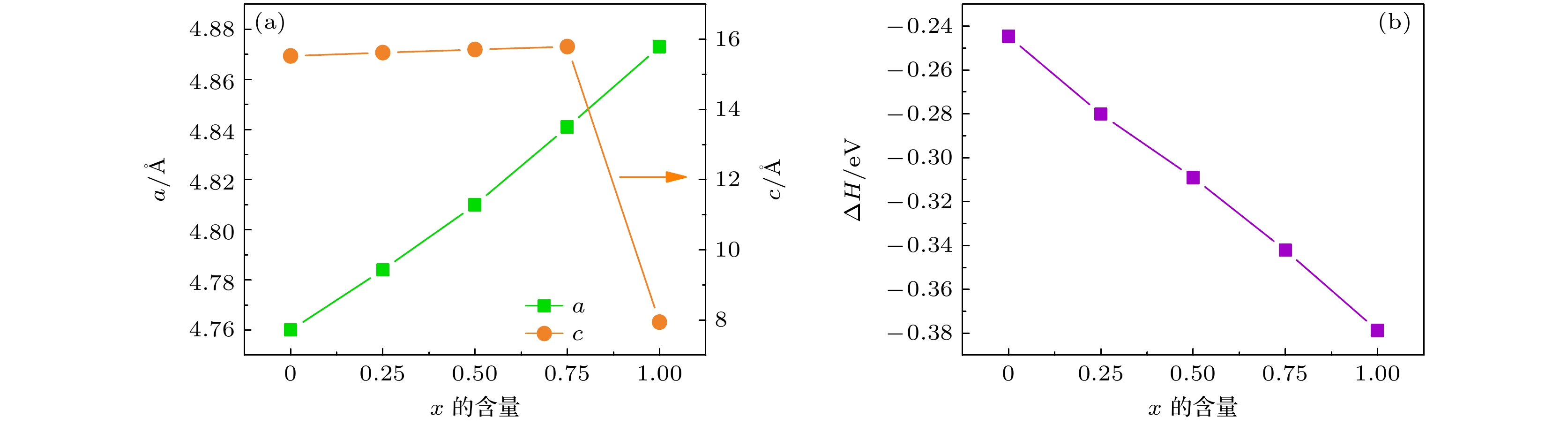

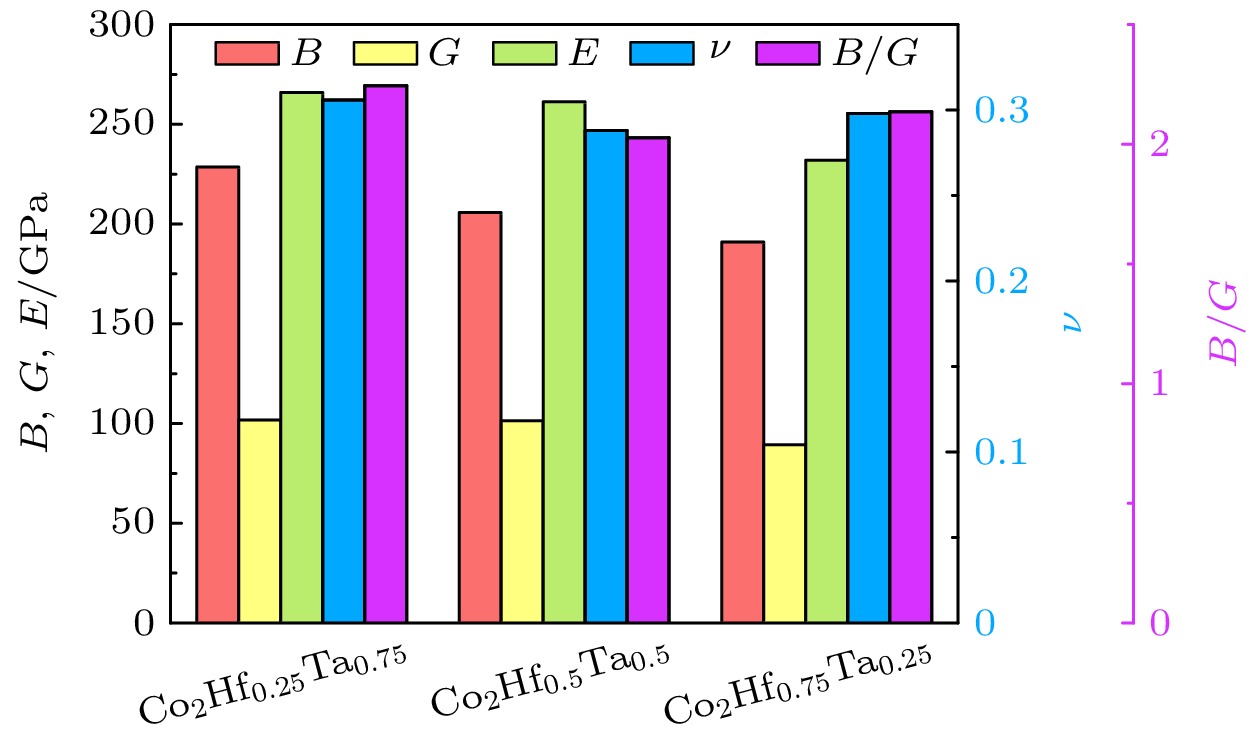

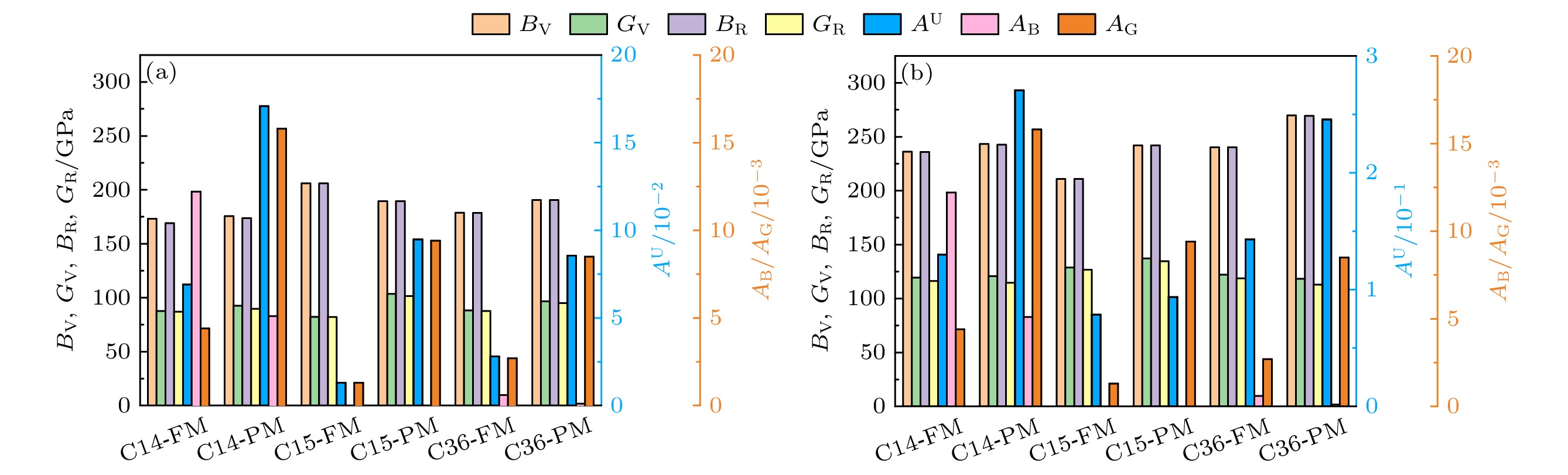

基于第一性原理计算方法, 在考虑磁效应的基础上, 对不同温度下合金Co2(Hf Ta)中的稳定结构、电子性质和热力学性质展开了研究. 通过第一性原理计算形成能、弹性性质及声子色散关系, 结果表明合金Co2(HfxTa1–x) 在x ≤ 0.75时基态是C36, 当x > 0.75时基态是C14. 这一发现提示了合金成分对其基态结构的影响, 并为合金的稳定性提供了重要线索. 值得注意的是, 考虑了振动熵和电子熵的贡献后, Co2Hf相对稳定的结构变为C36, Co2Ta变为C14, 这表明温度会对合金结构稳定性的影响. Co2(HfxTa1–x)合金在弹性方面呈现出本征脆性. 热力学分析表明其在高温下热容趋于稳定, 德拜温度近似为常数, 振动熵随温度递增且与压强负相关. 电子态密度分析揭示了Co2(Hf Ta)合金三个结构的相稳定性.

-

关键词:

- Co2(Hf Ta) /

- Laves相稳定性 /

- 热物性质 /

- 第一性原理计算

There exists still the controversy over the stable structure of Laves-phase Co2(Hf Ta) alloys with the C14, C15 or C36 structures. In this study, the stability, electronic and thermodynamic properties of Laves-phase Co2(Hf Ta) are investigated. In order to fully understand the influence of magnetic state and temperature on phase stability, we systematically study the free energy change at finite temperature, elastic stability, and phonon dispersion. The low Curie temperature can be estimated, which suggests that the Co2(Hf Ta) alloys possess the paramagnetic state in a wide temperature range. Results indicate that the lattice vibration and electronic excitation have an important effect on the phase stability. The ground state of Co2Hf compound has a C14-type structure, while the ground state of Co2Ta has a C36-type structure, without the effect of temperature. After doping Hf with different concentrations (0.25, 0.50, 0.75) into Co2Ta, the most stable structure still possesses the C36-type structure. After considering the contribution of vibration entropy and electron entropy, the relatively stable structures of Co2Hf and Co2Ta undergo the C36 and C14 phase transition, respectively. In addition, the thermodynamic properties, including Debye temperature, heat capacity, and vibration entropy, which vary with pressure and temperature, are studied. The electronic properties of Co2Hf and Co2Ta compounds are analyzed by the charge difference and density of states. The similar electronic density of states between different phases suggest that the Lave phases have the similar stability. The Hf-Co bonding with a certain direction is revealed. Our results are of great significance in understanding the structure and properties of Co2Hf and Co2Ta compounds.-

Keywords:

- Co2(Hf Ta) /

- Laves phase stability /

- thermo-physical properties /

- first-principles calculation

[1] Schulze G E 1939 Zeitschrift Für Elektrochemie und Angewandte Physikalische Chemie 45 849

Google Scholar

Google Scholar

[2] Stein F, Leineweber A 2021 J. Mater. Sci. 56 5321

Google Scholar

Google Scholar

[3] 张硕鑫, 刘士余, 严达利, 余浅, 任海涛, 于彬, 李德军 2021 70 117102

Google Scholar

Google Scholar

Zhang S X, Liu S Y, Yan D L, Yu Q, Ren H T, Yu B, Li D J 2021 Acta Phys. Sin. 70 117102

Google Scholar

Google Scholar

[4] Zhang Y, Fu H, He J, Xie J 2022 J. Alloys Compd. 891 162016

Google Scholar

Google Scholar

[5] Burzo E, Gratz E, Pop V 1993 J. Magn. Magn. Mater. 123 159

Google Scholar

Google Scholar

[6] Chen K C, Peterson E J, Thoma D J 2001 Intermetallics 9 771

Google Scholar

Google Scholar

[7] Chen K C, Chu F, Kotula P G, Thoma D 2001 Intermetallics 9 785

Google Scholar

Google Scholar

[8] Concas G, Congiu F, Belošević-Čavor J, Cekić B 2007 Zeitschrift für Naturforschung A 62 452

Google Scholar

Google Scholar

[9] Wang C, Chen X, Yang P, Zhang Q, Yang S, Lu Y, Guo Y, Liu X 2022 J. Alloys Compd. 925 166723

Google Scholar

Google Scholar

[10] Ooshima M, Tanaka K, Okamoto N L, Kishida K, Inui H 2010 J. Alloys Compd. 508 71

Google Scholar

Google Scholar

[11] Omori T, Oikawa K, Sato J, Ohnuma I, Kattner U R, Kainuma R, Ishida K 2013 Intermetallics 32 274

Google Scholar

Google Scholar

[12] Povstugar I, Choi P P, Neumeier S, Bauer A, Zenk C H, Göken M, Raabe D 2014 Acta Mater. 78 78

Google Scholar

Google Scholar

[13] Dragsdorf R, Foreing W 1962 Acta Crystallogr. 15 531

Google Scholar

Google Scholar

[14] Baheti V A, Roy S, Ravi R, Paul A 2013 Intermetallics 33 87

Google Scholar

Google Scholar

[15] Shinagawa K, Chinen H, Omori T, Oikawa K, Ohnuma I, Ishida K, Kainuma R 2014 Intermetallics 49 87

Google Scholar

Google Scholar

[16] Wang P, Koßmann J, Kattner U R, Palumbo M, Hammerschmidt T, Olson G B 2019 Calphad 64 205

Google Scholar

Google Scholar

[17] Zhou C, Guo C, Li C, Du Z 2019 Calphad 66 101649

Google Scholar

Google Scholar

[18] Asano S, Ishida S 1988 J. Phys. F: Metal Phys. 18 501

Google Scholar

Google Scholar

[19] Stein F, Palm M, Sauthoff G 2004 Intermetallics 12 713

Google Scholar

Google Scholar

[20] Von Keitz A, Sauthoff G 2002 Intermetallics 10 497

Google Scholar

Google Scholar

[21] Thoma D, Perepezko J 1995 J. Alloys Compd. 224 330

Google Scholar

Google Scholar

[22] Wang L, Kong Y, Oehring M, Song M, Pyczak F 2022 J. Alloys Compd. 906 164261

Google Scholar

Google Scholar

[23] Levy O, Hart G L, Curtarolo S 2010 Acta Mater. 58 2887

Google Scholar

Google Scholar

[24] Segall M, Lindan P J, Probert M A, Pickard C J, Hasnip P J, Clark S, Payne M 2002 J. Phys.: Condens. Matter 14 2717

Google Scholar

Google Scholar

[25] Clark S J, Segall M D, Pickard C J, Hasnip P J, Probert M I, Refson K, Payne M C 2005 Z. Krist. -Cryst. Mater. 220 567

Google Scholar

Google Scholar

[26] Perdew J P, Ruzsinszky A, Csonka G I, Vydrov O A, Scuseria G E, Constantin L A, Zhou X, Burke K 2008 Phys. Rev. Lett. 100 136406

Google Scholar

Google Scholar

[27] Monkhorst H J, Pack J D 1976 Phys. Rev. B 13 5188

Google Scholar

Google Scholar

[28] Pfrommer B G, Côté M, Louie S G, Cohen M L 1997 J. Comput. Phys. 131 233

Google Scholar

Google Scholar

[29] Wang Q, Li Q, Ding H, Tian F 2022 Comput. Condens. Matter 32 e00721

Google Scholar

Google Scholar

[30] Sun Y, Zhou Y, Gurunathan R, Zhang J Y, Hu M, Liu W, Xu B, Snyder G J 2021 J. Mater. Chem. C 9 8506

Google Scholar

Google Scholar

[31] Wu R, Wang Y P, Shao L, Wang W, Tang B Y 2021 Chin. J. Chem. Eng. 40 315

Google Scholar

Google Scholar

[32] Gao J, Liu Q, Jiang C, Fan D, Zhang M, Liu F, Tang B 2022 Chin. J. High Press. Phys 36 051101

Google Scholar

Google Scholar

[33] Jana A, Sridar S, Fries S G, Hammerschmidt T, Kumar K H 2020 Intermetallics 116 106640

Google Scholar

Google Scholar

[34] Chen S, Sun Y, Duan Y H, Huang B, Peng M J 2015 J. Alloys Compd. 630 202

Google Scholar

Google Scholar

[35] Özer T 2020 Canadian J. Phys. 98 357

Google Scholar

Google Scholar

[36] Cheng T M, Yu G L, Zhang X X 2022 Physica B 645 414268

Google Scholar

Google Scholar

[37] Xu Y, Cao Y, Hu C, Zhang C, Tian C, Alzoabi S, Santos N, Zhou S 2021 Solid State Sci. 115 106580

Google Scholar

Google Scholar

[38] Xu N, Chen Y, Chen S, Zhang W, Li S, Song R, Zhang J 2023 J. Mater. Res. Technol. 26 4825

Google Scholar

Google Scholar

[39] Jian Y, Huang Z, Xing J, Sun L, Liu Y, Gao P 2019 Mater. Chem. Phys. 221 311

Google Scholar

Google Scholar

[40] Ranganathan S I, Ostoja-Starzewski M 2008 Phys. Rev. Lett. 101 055504

Google Scholar

Google Scholar

[41] Hong D, Zeng W, Liu F S, Tang B, Liu Q J 2019 Physica B 558 100

Google Scholar

Google Scholar

-

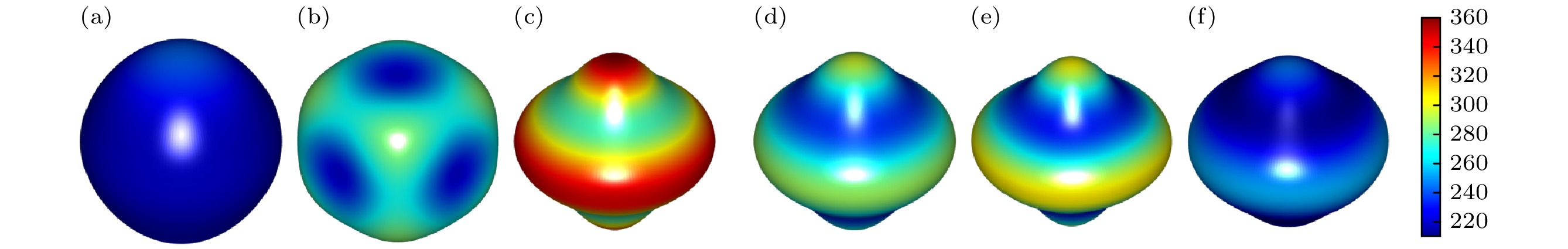

图 7 Co2Ta1–xHfx稳定结构的杨氏模量 (E)的三维图(颜色刻度值以GPa为单位) (a) 铁磁态C14相Co2Hf; (b) 顺磁态C15相Co2Hf; (c) 铁磁态C36相 Co2Ta; (d)—(f) 铁磁C36相 Co2Hf0.25Ta0.75, Co2Hf0.5Ta0.5, Co2Hf0.75Ta0.25

Fig. 7. Anisotropy of Young’s modulus (E) of Co2Ta1–xHfx along different crystalline directions: (a) Ferromagnetic C14 Co2Hf; (b) paramagnetic C15 Co2Hf; (c) ferromagnetic C36 Co2Ta; (d)–(f) ferromagnetic C36 Co2Hf0.25Ta0.75, Co2Hf0.5Ta0.5 and Co2Hf0.75Ta0.25. The color scale is in GPa.

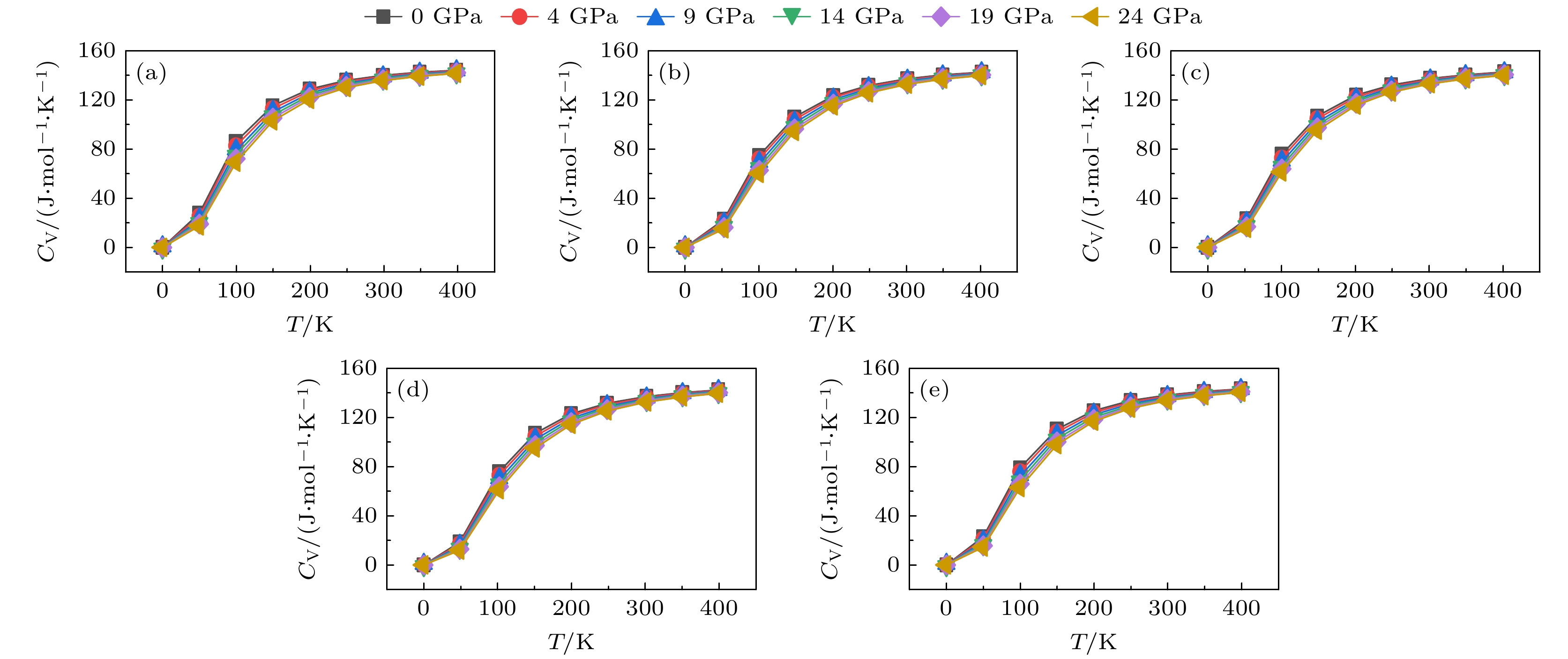

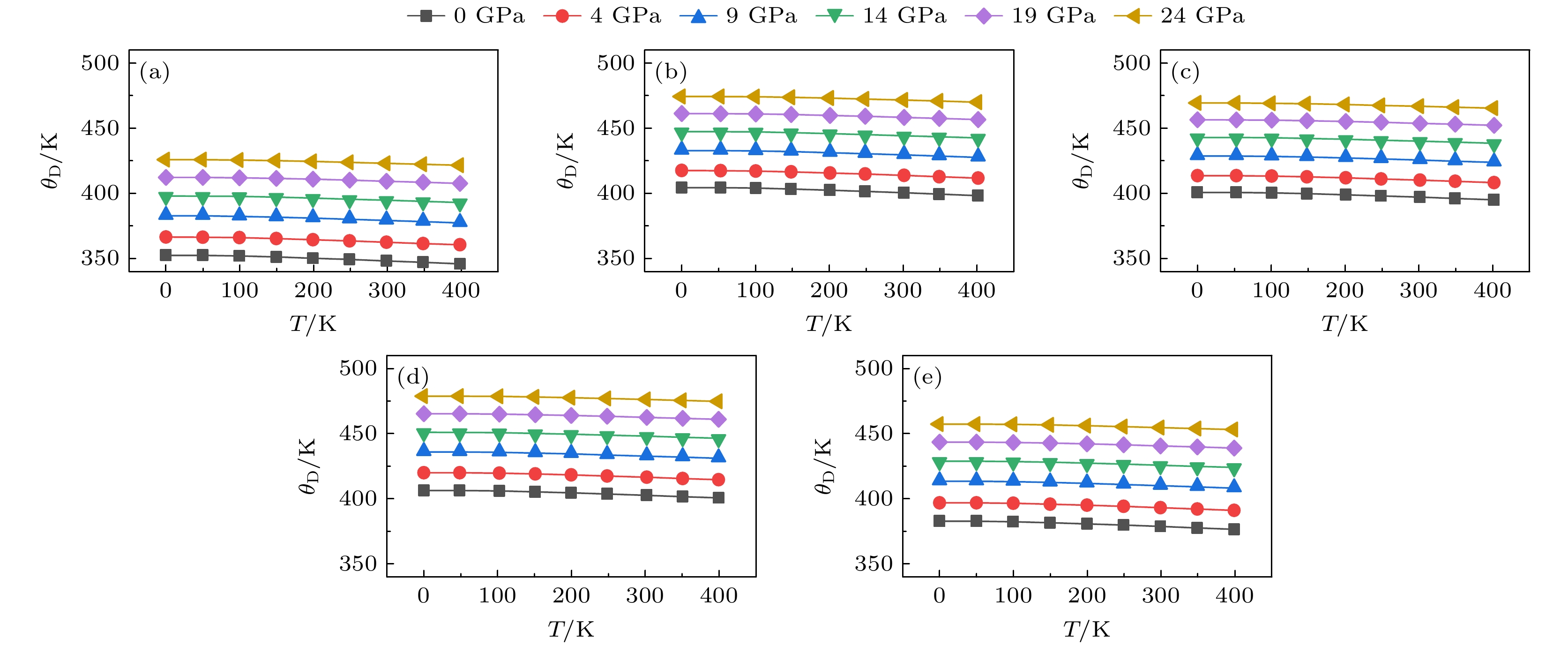

图 8 不同压强下热容随温度的变化 (a) C14-PM Co2Hf; (b) C36-PM Co2Ta; (c) C36- PM Co2Hf0.25Ta0.75; (d) C36-PM Co2Hf0.5Ta0.5; (e) C36-PM Co2Hf0.75Ta0.25

Fig. 8. Heat capacity with temperature under different pressures: (a) C14-PM Co2Hf; (b) C36-PM Co2Ta; (c) C36-PM Co2Hf0.25Ta0.75; (d) C36-PM Co2Hf0.5Ta0.5; (e) C36-PM Co2Hf0.75Ta0.25.

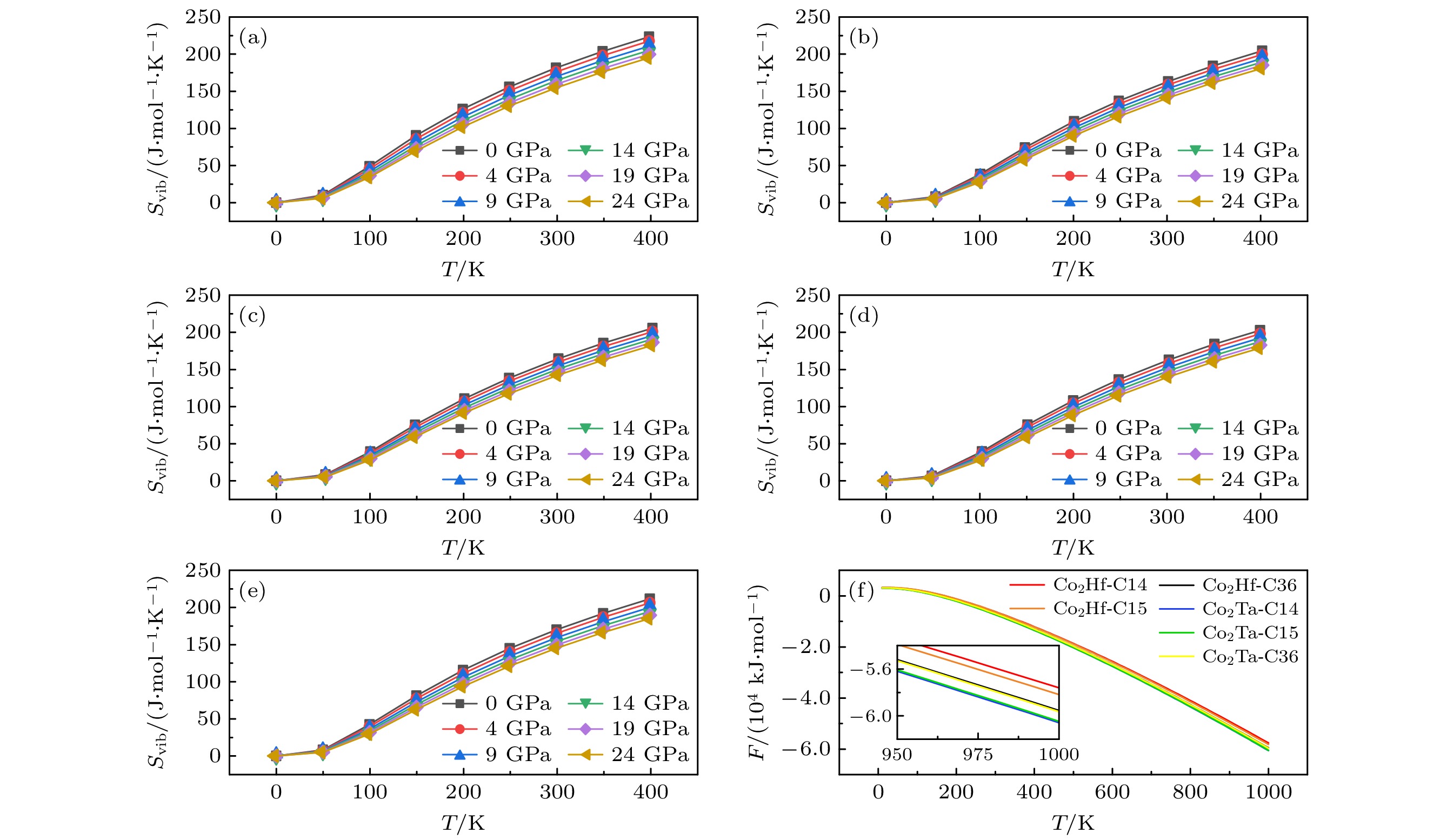

图 10 不同压强下, 振动熵与温度的变化关系, 其中(a) C15 Co2Hf; (b) C36 Co2Ta; (c)—(e) C36 Co2Hf0.25Ta0.75, Co2Hf0.5Ta0.5, Co2Hf0.75Ta0.25; (f) Co2Hf和Co2Ta 的自由能随温度的变化

Fig. 10. Vibrational entropy versus temperature under different pressures: (a) C15 Co2Hf; (b) C36 Co2Ta; (c)–(e) C36 Co2Hf0.25Ta0.75, Co2Hf0.5Ta0.5, Co2Hf0.75Ta0.25. (f) The free energy versus temperature for Co2Hf and Co2Ta.

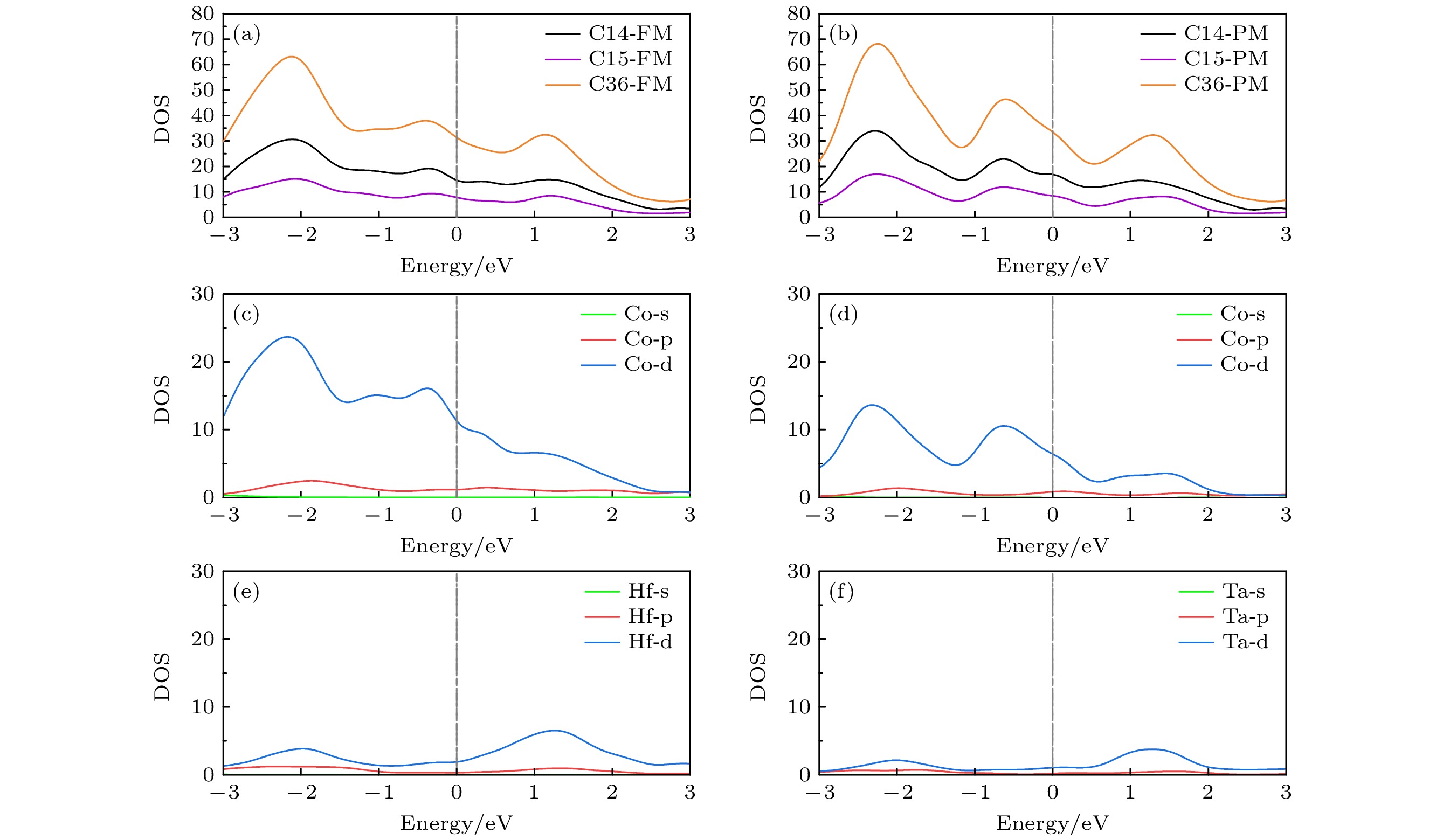

图 11 Co2Hf和Co2Ta总态密度和分态密度(垂直虚线表示费米能级) (a), (b) C14, C15, C36相的Co2Hf和 Co2Ta的总电子态密度; (c), (e) C14相 Co2Hf的分态密度; (d), (f) C36相Co2Ta的分态密度

Fig. 11. Total density of states and partial density of states of Co2Hf and Co2Ta : (a), (b) The total electronic density of states of Co2Hf and Co2Ta in C14, C15 and C36 phases; (c), (e) the partial density of states of C14 phase Co2Hf; (d), (f) the partial density of states of C36 phase Co2Ta. The vertical dotted line represents the Fermi level.

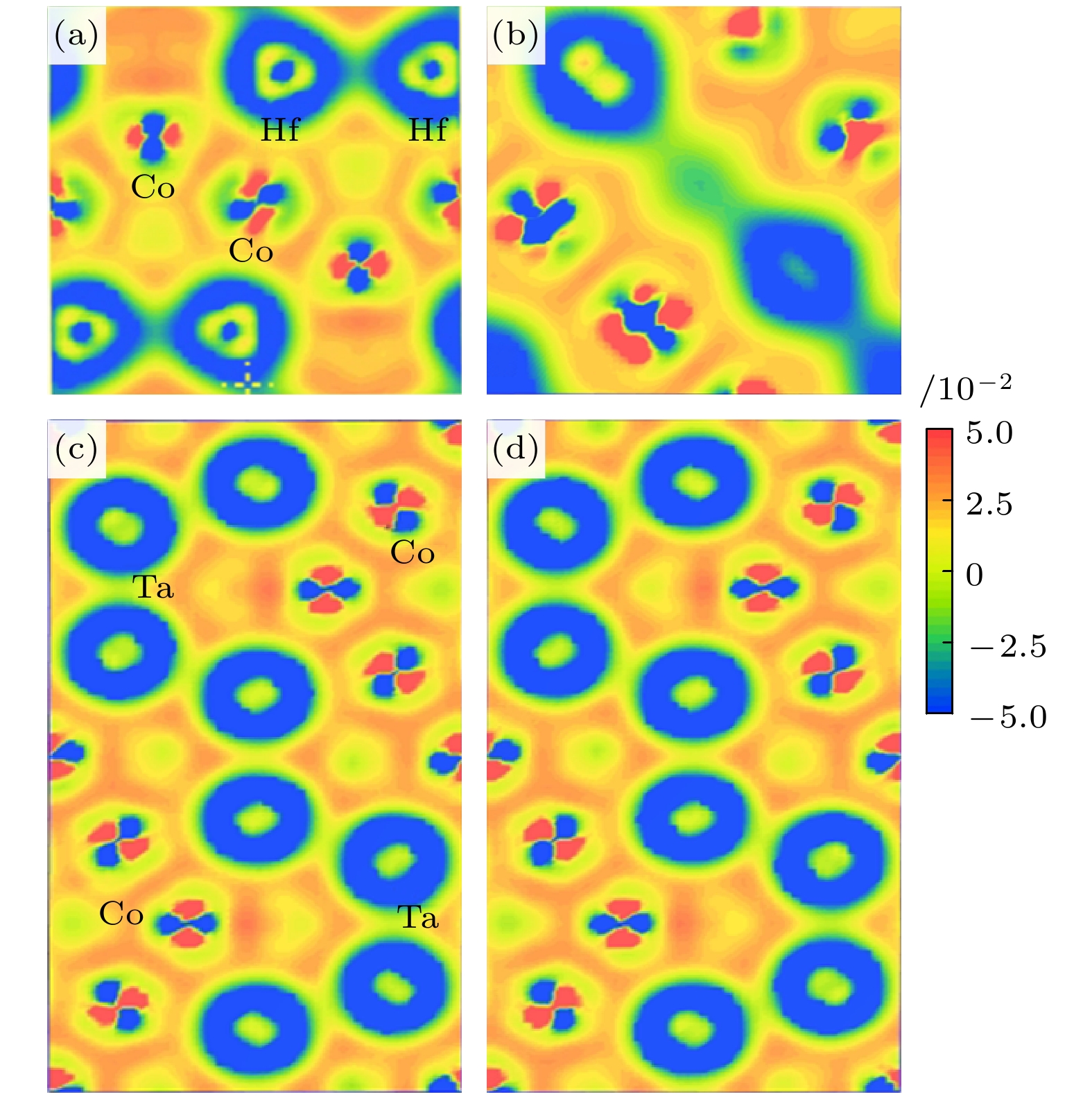

图 12 差分电荷密度图 (a) Co2Hf 的C14结构$ (11 \bar{2} 0)$面; (b) Co2Hf 的C15结构的(110)面; (c), (d) 代表为铁磁和顺磁Co2Ta的C36 的$(11 \bar{2}0) $面

Fig. 12. Differential charge density diagram: (a) C14-FM $ (11\bar{2}0) $ plane of C14 structure of Co2Hf; (b) C15-FM (110) plane of C15 structure of Co2Hf; (c), (d) the $ (11\bar{2} 0)$ plane of C36 with ferromagnetic and paramagnetic Co2Ta.

表 1 Laves相晶体结构的基本信息; 表中x = 1/6, z (C14-A1) = 9/16, z (C36-A1) = 21/32, z (C36-A2) = 3/32, z (C36-B3) = 1/8理想原子位置附近, 随A和B的不同, 6h和4e, 4f位的位置参数x和z会有微小的变化[2]

Table 1. Details on Laves phase crystal structure. Depending on A and B sites, the position parameters x and z of the 6h and 4e, 4f sites slightly vary around the ideal atom position values of x = 1/6, z (C14-A1) = 9/16, z (C36-A1) = 21/32, z (C36-A2) = 3/32, z (C36-B3) = 1/8[2].

结构名称 结构类型 空间群 原子 亚格点位置以及占位 x y z C15 MgCu2 227 A 8a 0 0 0 B 16d 5/8 5/8 5/8 C14 MgZn2 194 A 4f 1/3 2/3 z B1 6h x 2x 1/4 B2 2a 0 0 0 C36 MgNi2 194 A1 4f 1/3 2/3 z A2 4e 0 0 z B1 6h

x2x 1/4 B2 6g 1/2 0 0 B3 4f 1/3 2/3 z 表 2 Co2Hf和Co2Ta Laves相的晶格常数a和c、体积V、钴的局域磁矩M、形成能ΔH、有无自旋极化状态下的能量差ΔE, 及可利用的实验或模拟数据

Table 2. Lattice constants a, c, volume V, local magnetic moment M, formation energy ΔH, energy difference ΔE with and without spin polarization state , and available experimental or simulated data of Co2Hf and Co2Ta Laves phases.

体系 结构 a/Å c/Å V/(Å3·atom–1) M/(μB·atom–1) ΔH/(eV·atom–1) ΔE/(eV·atom–1) Refs. Co2Hf C14 4.873 7.939 13.605 0.69

0.79–0.3788 –0.017 C15 4.870 13.615 0.76 –0.3752 –0.002 4.824

4.909

13.945Cal.[22]

Cal.[34]C36 4.876 15.837 13.585 0.68

0.70

0.58–0.3779 –0.007 4.816 15.650 Cal.[22] Co2Ta C14 4.766 7.750 12.703 0.33

0.68–0.2378 –0.002 4.797 7.827 12.730 Exp.[13] C15 4.759 12.702 0.40 –0.2442 –0.005 4.791 12.957 Cal.[34] C36 4.760 15.529 12.698 0.39

0.41

0.27–0.2447 –0.003 表 3 Co2Hf和Co2Ta的C14, C15和C36结构以及Co2(Ta1–xHfx)基态结构的弹性常数cij (GPa), 其中, 结构部分, FM和PM代表铁磁和顺磁态, 数字156, 186表示空间群

Table 3. Elastic constants cij (GPa) of C14, C15, C36Co2Hf and Co2Ta as well as Co2(Ta1–xHfx), where the structural part, FM and PM represent ferromagnetic and paramagnetic states, and the numbers 156, 186 represent the space group.

体系 结构 c11 c33 c44 c12 c13 $c_{66}, {c_{14}}^* $ Refs. Co2Hf C14-FM 274.14 332.76 81.86 86.14 126.48 94.00 C14-PM 299.75 348.07 73.80 90.11 113.04 104.82 C15-FM 308.80 85.60 154.53 C15-PM 298.50 106.00 139.12 C15 270.20 85.50 117.50 Cal.[34] C36-FM 308.11 293.50 80.53 121.99 113.90 93.06 C36-PM 329.08 343.58 81.90 120.83 117.89 104.12 Co2Ta C14-FM 407.15 430.80 97.10 138.20 151.11 134.48 C14-PM 442.04 421.53 89.27 167.32 137.34 137.36 C15-FM 357.11 141.47 137.90 C15-PM 395.37 151.94 165.32 C15 383.50 143.90 173.40 Cal.[34] C36-FM 424.64 429.32 98.18 154.27 143.77 135.19 C36-PM 444.08 481.10 88.70 174.90 177.34 134.59 Co2Hf0.25Ta0.75 156-FM 390.67 383.02 80.43 153.72 146.41 –1.13 Co2Hf0.5Ta0.5 186-FM 358.36 362.80 84.35 132.40 126.78 Co2Hf0.75Ta0.25 156-FM 327.16 312.04 77.66 130.90 122.88 0.68 *: c66, c14数据列, 其中后3行时c14数值, 其他行为c66数值. -

[1] Schulze G E 1939 Zeitschrift Für Elektrochemie und Angewandte Physikalische Chemie 45 849

Google Scholar

Google Scholar

[2] Stein F, Leineweber A 2021 J. Mater. Sci. 56 5321

Google Scholar

Google Scholar

[3] 张硕鑫, 刘士余, 严达利, 余浅, 任海涛, 于彬, 李德军 2021 70 117102

Google Scholar

Google Scholar

Zhang S X, Liu S Y, Yan D L, Yu Q, Ren H T, Yu B, Li D J 2021 Acta Phys. Sin. 70 117102

Google Scholar

Google Scholar

[4] Zhang Y, Fu H, He J, Xie J 2022 J. Alloys Compd. 891 162016

Google Scholar

Google Scholar

[5] Burzo E, Gratz E, Pop V 1993 J. Magn. Magn. Mater. 123 159

Google Scholar

Google Scholar

[6] Chen K C, Peterson E J, Thoma D J 2001 Intermetallics 9 771

Google Scholar

Google Scholar

[7] Chen K C, Chu F, Kotula P G, Thoma D 2001 Intermetallics 9 785

Google Scholar

Google Scholar

[8] Concas G, Congiu F, Belošević-Čavor J, Cekić B 2007 Zeitschrift für Naturforschung A 62 452

Google Scholar

Google Scholar

[9] Wang C, Chen X, Yang P, Zhang Q, Yang S, Lu Y, Guo Y, Liu X 2022 J. Alloys Compd. 925 166723

Google Scholar

Google Scholar

[10] Ooshima M, Tanaka K, Okamoto N L, Kishida K, Inui H 2010 J. Alloys Compd. 508 71

Google Scholar

Google Scholar

[11] Omori T, Oikawa K, Sato J, Ohnuma I, Kattner U R, Kainuma R, Ishida K 2013 Intermetallics 32 274

Google Scholar

Google Scholar

[12] Povstugar I, Choi P P, Neumeier S, Bauer A, Zenk C H, Göken M, Raabe D 2014 Acta Mater. 78 78

Google Scholar

Google Scholar

[13] Dragsdorf R, Foreing W 1962 Acta Crystallogr. 15 531

Google Scholar

Google Scholar

[14] Baheti V A, Roy S, Ravi R, Paul A 2013 Intermetallics 33 87

Google Scholar

Google Scholar

[15] Shinagawa K, Chinen H, Omori T, Oikawa K, Ohnuma I, Ishida K, Kainuma R 2014 Intermetallics 49 87

Google Scholar

Google Scholar

[16] Wang P, Koßmann J, Kattner U R, Palumbo M, Hammerschmidt T, Olson G B 2019 Calphad 64 205

Google Scholar

Google Scholar

[17] Zhou C, Guo C, Li C, Du Z 2019 Calphad 66 101649

Google Scholar

Google Scholar

[18] Asano S, Ishida S 1988 J. Phys. F: Metal Phys. 18 501

Google Scholar

Google Scholar

[19] Stein F, Palm M, Sauthoff G 2004 Intermetallics 12 713

Google Scholar

Google Scholar

[20] Von Keitz A, Sauthoff G 2002 Intermetallics 10 497

Google Scholar

Google Scholar

[21] Thoma D, Perepezko J 1995 J. Alloys Compd. 224 330

Google Scholar

Google Scholar

[22] Wang L, Kong Y, Oehring M, Song M, Pyczak F 2022 J. Alloys Compd. 906 164261

Google Scholar

Google Scholar

[23] Levy O, Hart G L, Curtarolo S 2010 Acta Mater. 58 2887

Google Scholar

Google Scholar

[24] Segall M, Lindan P J, Probert M A, Pickard C J, Hasnip P J, Clark S, Payne M 2002 J. Phys.: Condens. Matter 14 2717

Google Scholar

Google Scholar

[25] Clark S J, Segall M D, Pickard C J, Hasnip P J, Probert M I, Refson K, Payne M C 2005 Z. Krist. -Cryst. Mater. 220 567

Google Scholar

Google Scholar

[26] Perdew J P, Ruzsinszky A, Csonka G I, Vydrov O A, Scuseria G E, Constantin L A, Zhou X, Burke K 2008 Phys. Rev. Lett. 100 136406

Google Scholar

Google Scholar

[27] Monkhorst H J, Pack J D 1976 Phys. Rev. B 13 5188

Google Scholar

Google Scholar

[28] Pfrommer B G, Côté M, Louie S G, Cohen M L 1997 J. Comput. Phys. 131 233

Google Scholar

Google Scholar

[29] Wang Q, Li Q, Ding H, Tian F 2022 Comput. Condens. Matter 32 e00721

Google Scholar

Google Scholar

[30] Sun Y, Zhou Y, Gurunathan R, Zhang J Y, Hu M, Liu W, Xu B, Snyder G J 2021 J. Mater. Chem. C 9 8506

Google Scholar

Google Scholar

[31] Wu R, Wang Y P, Shao L, Wang W, Tang B Y 2021 Chin. J. Chem. Eng. 40 315

Google Scholar

Google Scholar

[32] Gao J, Liu Q, Jiang C, Fan D, Zhang M, Liu F, Tang B 2022 Chin. J. High Press. Phys 36 051101

Google Scholar

Google Scholar

[33] Jana A, Sridar S, Fries S G, Hammerschmidt T, Kumar K H 2020 Intermetallics 116 106640

Google Scholar

Google Scholar

[34] Chen S, Sun Y, Duan Y H, Huang B, Peng M J 2015 J. Alloys Compd. 630 202

Google Scholar

Google Scholar

[35] Özer T 2020 Canadian J. Phys. 98 357

Google Scholar

Google Scholar

[36] Cheng T M, Yu G L, Zhang X X 2022 Physica B 645 414268

Google Scholar

Google Scholar

[37] Xu Y, Cao Y, Hu C, Zhang C, Tian C, Alzoabi S, Santos N, Zhou S 2021 Solid State Sci. 115 106580

Google Scholar

Google Scholar

[38] Xu N, Chen Y, Chen S, Zhang W, Li S, Song R, Zhang J 2023 J. Mater. Res. Technol. 26 4825

Google Scholar

Google Scholar

[39] Jian Y, Huang Z, Xing J, Sun L, Liu Y, Gao P 2019 Mater. Chem. Phys. 221 311

Google Scholar

Google Scholar

[40] Ranganathan S I, Ostoja-Starzewski M 2008 Phys. Rev. Lett. 101 055504

Google Scholar

Google Scholar

[41] Hong D, Zeng W, Liu F S, Tang B, Liu Q J 2019 Physica B 558 100

Google Scholar

Google Scholar

计量

- 文章访问数: 3772

- PDF下载量: 92

- 被引次数: 0

下载:

下载: