-

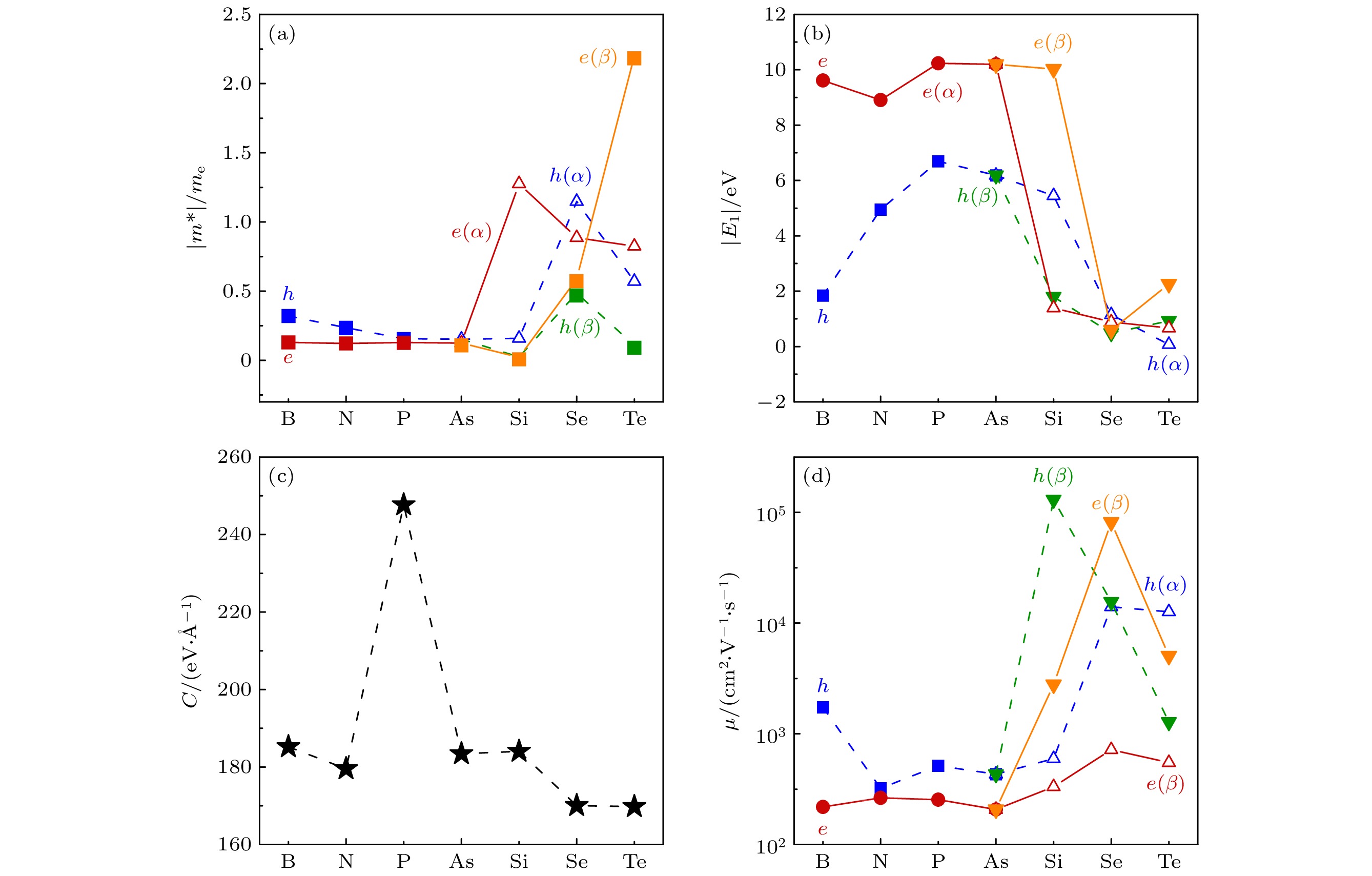

诱发非磁材料磁性并灵活调控其磁电子性质对于研发高性能磁器件非常重要. 基于密度泛函理论 (DFT), 系统研究了非金属原子X (X = B, N, P, Si, Se, Te)取代性掺杂扶手椅型砷烯纳米管AsANT的结构稳定性、磁电子性质、载流子迁移率以及应变对杂质管磁电子性质的调控效应. 计算的结合能和形成能证明了杂质管AsANT-X的结构稳定性, 可能在实验中实现. 杂质管电子结构的计算表明AsANT-X (X = B, N, P)为无磁半导体, 而AsANT-X (X = Si, Se, Te)表现为双极化磁性半导体, 磁性源于杂质原子与As之间未配对电子的出现. 此外, 掺杂可以灵活调控AsANT的载流子迁移率到一个较宽的范围, 并且呈现明显的载流子极性和自旋极性. 特别是, 应变可以导致AsANT-Si在双极化磁性半导体、半-半导体、磁金属和无磁金属之间的多磁相变过渡, 这种在无磁态和高磁化态之间的转换可用于设计由应变控制的自旋极化输运的机械开关. 本文研究为砷烯的应用提供了新途径.For the development of high performance magnetic devices, inducing magnetism in non-magnetic materials and flexibly regulating their magneto-electronic properties are very important. According to the density functional theory (DFT), we systematically study the structural stability, magneto-electronic properties, carrier mobility and strain effect for each of armchair arsenene nanotubes doped with non-metallic atoms X (X = B, N, P, Si, Se, Te). The calculated binding energy and formation energy confirm that the geometric stability of AsANT-X is high. With non-metal doping, each of AsANT-X (X = B, N, P) acts as a non-magnetic semiconductor, while each of AsANT-X (X = Si, Se, Te) behaves as a bipolar magnetic semiconductor, caused by the unpaired electrons occurring between X and As. Furthermore, by doping, the carrier mobility of AsANT-X can be flexibly moved to a wide region, and the carrier polarity and spin polarity in mobility can be observed as well. Especially, AsANT-Si can realize a transition among bipolar magnetic semiconductor, half-semiconductor, magnetic metal, and non-magnetic metal by applying strain, which is useful for designing a mechanical switch to control spin-polarized transport that can reversibly work between magnetism and demagnetism only by applying strain. This study provides a new way for the application of arsenene.

-

Keywords:

- armchair arenene nanotube /

- non-metallic doping /

- magneto-electronic properties /

- carrier mobility /

- strain effect

[1] Han L, Neal A T, Zhen Z, Zhe L, Xu X, David T, Ye P D 2014 ACS Nano 8 4033

Google Scholar

Google Scholar

[2] Zhang S, Yan Z, Li Y, Chen Z, Zeng H 2015 Angew. Chem. Int. Ed. Engl. 127 3155

Google Scholar

Google Scholar

[3] Kamal C, Ezawa M 2015 Phys. Rev. B 91 085423

Google Scholar

Google Scholar

[4] Kecik D, Durgun E, Ciraci S 2016 Phys. Rev. B 94 205410

Google Scholar

Google Scholar

[5] Zhang S L, Xie M Q, Li F Y, Yan Z, Li Y F, Kan E, Liu W, Chen Z F, Zeng H B 2016 Angew. Chem. Int. Ed. 55 1666

Google Scholar

Google Scholar

[6] Zhu Z, Guan J, Tomanek D 2015 Phys. Rev. B 91 161404

Google Scholar

Google Scholar

[7] Tsai H S, Wang S W, Hsiao C H, Chen C W, Ouyang H, Chueh Y L, Kuo H C, Liang J H 2016 Chem. Mater. 28 425

Google Scholar

Google Scholar

[8] Gusmao R, Sofer Z, Bousa D, Pumera M 2017 Angew. Chem. Int. Ed. Engl. 56 14417

Google Scholar

Google Scholar

[9] Qi M, Dai S, Wu P 2020 J. Phys. Condens. Mat. 32 085802

Google Scholar

Google Scholar

[10] Bai M, Zhang W X, He C 2017 J. Solid State Chem. 251 1

Google Scholar

Google Scholar

[11] Du J, Xia C, An Y, Wang T, Jia Y 2016 J. Mater. Sci. 51 9504

Google Scholar

Google Scholar

[12] Sun M L, Wang S K, Du Y H, Yu J, Tang W C 2016 Appl. Surf. Sci. 389 594

Google Scholar

Google Scholar

[13] Liu M, Chen Q, Huang Y, Cao C, He Y 2016 Superlattices Microstruct. 100 131

Google Scholar

Google Scholar

[14] Han J N, Zhang Z H, Fan Z, Zhou R 2020 Nanotechnology 31 315206

Google Scholar

Google Scholar

[15] Liu M Y, Chen Q Y, Huang Y, Li Z Y, Cao C, He Y 2018 Nanotechnology 29 095203

Google Scholar

Google Scholar

[16] Li G, Zhao Y, Zeng S, Ni J 2016 Appl. Surf. Sci. 390 60

Google Scholar

Google Scholar

[17] Li Z J, Xu W, Yu Y Q, Du H Y, Zhen K, Wang J, Luo L B, Qiu H L, Yang X B 2016 J. Mater. Chem. C 4 362

Google Scholar

Google Scholar

[18] Ersan F, Aktűrk E, Ciraci S 2016 J. Phys. Chem. C 120 14345

Google Scholar

Google Scholar

[19] Iordanidou K, Kioseoglou J, Afanas’ev V V 2017 Phys. Chem. Chem. Phys. 19 9862

Google Scholar

Google Scholar

[20] Sun X T, Liu Y X, Song Z G, Wang X, Cheng Y 2017 J. Mater. Chem. C 5 4159

Google Scholar

Google Scholar

[21] Song Y, Li D, Mi W B, Wang X C, Cheng Y C 2016 J. Phys. Chem. C 120 5613

Google Scholar

Google Scholar

[22] Xia C X, Xue B, Wang T X, Peng Y T, Jia Y 2015 Appl. Phys. Lett. 107 193107

Google Scholar

Google Scholar

[23] Lee Y, Bae S, Jang H, Jang S, Zhu S E, Sim S H, Song Y I, Hong B H, Ahn J H 2010 Nano Lett. 10 490

Google Scholar

Google Scholar

[24] Bae S K, Kim H K, Lee Y B, Xu F, Iijima S 2010 Nat. Nanotechnol. 5 574

Google Scholar

Google Scholar

[25] Saito R, Dresselhaus G, Dresselhaus M S 1999 Sci. World. J. 54 832

Google Scholar

Google Scholar

[26] Rubio A, Corkill J L, Cohen M L 1994 Phys. Rev. B 49 5081

Google Scholar

Google Scholar

[27] Blase X, Rubio A, Louie S G, Cohen M L 1995 Phys. Rev. B 51 6868

Google Scholar

Google Scholar

[28] Yu S, Zhu H, Eshun K, Arab A, Badwan A, Li Q A 2015 J. Appl. Phys. 118 164306

Google Scholar

Google Scholar

[29] Kuang W, Hu R, Fan Z Q, Zhang Z H 2019 Nanotechnology 30 145201

Google Scholar

Google Scholar

[30] Santos E J G, Sánchez-Portal D, Ayuela A 2010 Phys. Rev. B 81 125433

Google Scholar

Google Scholar

[31] Han J N, He X, Fan Z Q, Zhang Z H 2019 Phys. Chem. Chem. Phys. 21 1830

Google Scholar

Google Scholar

[32] Wang D, Zhang Z H, Deng X Q, Fan Z Q, Tang G P 2016 Carbon 98 204

Google Scholar

Google Scholar

[33] Fan Z Q, Zhang Z H, Ming Q, Zhang Z H 2012 Comp. Mater. Sci. 53 294

Google Scholar

Google Scholar

[34] Zhang H, Zhou W, Yang Z, Zhang Z H 2017 Mater. Res. Express 4 126301

Google Scholar

Google Scholar

[35] Liu J, Zhang Z H, Deng X Q, Zhang Z H 2015 Org. Electron. 18 135

Google Scholar

Google Scholar

[36] Bardeen J, Shockley W 1950 Phys. Rev. 80 72

Google Scholar

Google Scholar

[37] Zhang Z H, Guo C, Kwong D J, Li J, Deng X, Fan Z Q 2013 Adv. Funct. Mater. 23 2765

Google Scholar

Google Scholar

[38] Pan J B, Zhang Z H, Deng X Q, Qiu M, Guo C 2011 Appl. Phys. Lett. 98 013503

Google Scholar

Google Scholar

[39] Zhang Z H, Deng X Q, Tan X Q, Qiu M, Pan J B 2010 Appl. Phys. Lett. 97 183105

Google Scholar

Google Scholar

[40] Gao Y, Cheng Z, Wen M, Zhang X, Wu F, Dong H, Zhang G 2021 Nanotechnology 32 245702

Google Scholar

Google Scholar

[41] Wang D, Chen, L, Shi C, Wang X, Cui G, Zhang P, Chen Y 2016 Sci. Rep. 6 28487

Google Scholar

Google Scholar

[42] Rodríguez-Manzo J A, Cretu O, Banhart F 2010 ACS Nano 4 3422

Google Scholar

Google Scholar

[43] He Z, He K, Robertson A W, Kirkland A I, Kim D, Ihm J, Yoon E, Lee G D, Warner J H 2014 Nano Lett. 14 3766

Google Scholar

Google Scholar

[44] Kunstmann J, Özdoğan C, Quandt A, Fehske H 2011 Phys. Rev. B 83 045414

Google Scholar

Google Scholar

[45] Li X, Wu X, Yang J 2014 J. Am. Chem. Soc. 136 5664

Google Scholar

Google Scholar

[46] Yagi Y, Briere T M, Sluiter M H F, Kumar V, Farajian A A, Kawazoe Y 2004 Phys. Rev. B 69 075414

Google Scholar

Google Scholar

[47] Beleznay F B, Bogár F, Ladik J 2003 J Chem. Phys. 119 5690

Google Scholar

Google Scholar

[48] Cai Y, Zhang G, Zhang Y W 2014 J. Am. Chem. Soc. 136 6269

Google Scholar

Google Scholar

[49] Zhang X, Zhao X D, Wu D H, Jing Y, Zhou Z 2015 Nanoscale 7 16020

Google Scholar

Google Scholar

[50] Hu R, Li Y H, Zhang Z H, Fan Z Q, Sun L 2019 J. Mater. Chem. C 7 7745

Google Scholar

Google Scholar

-

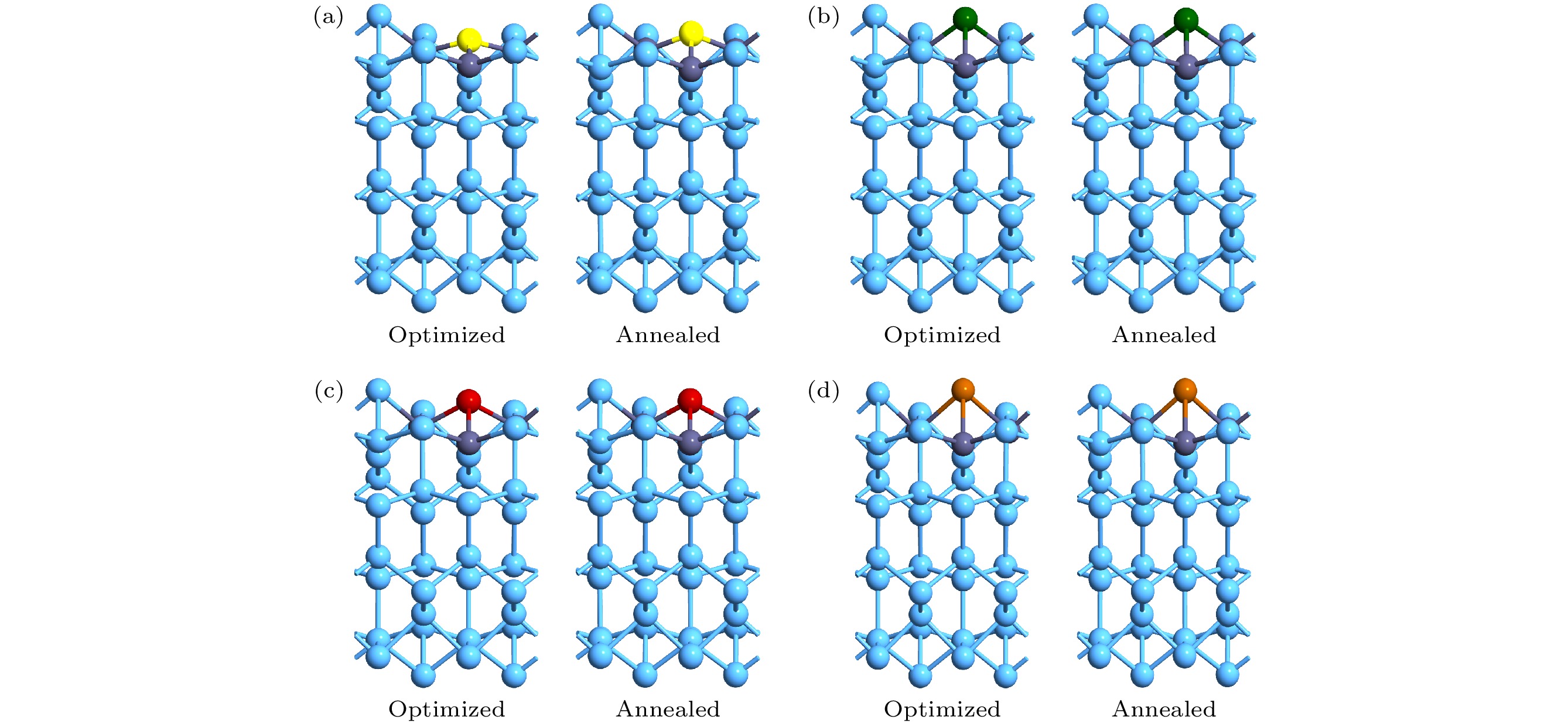

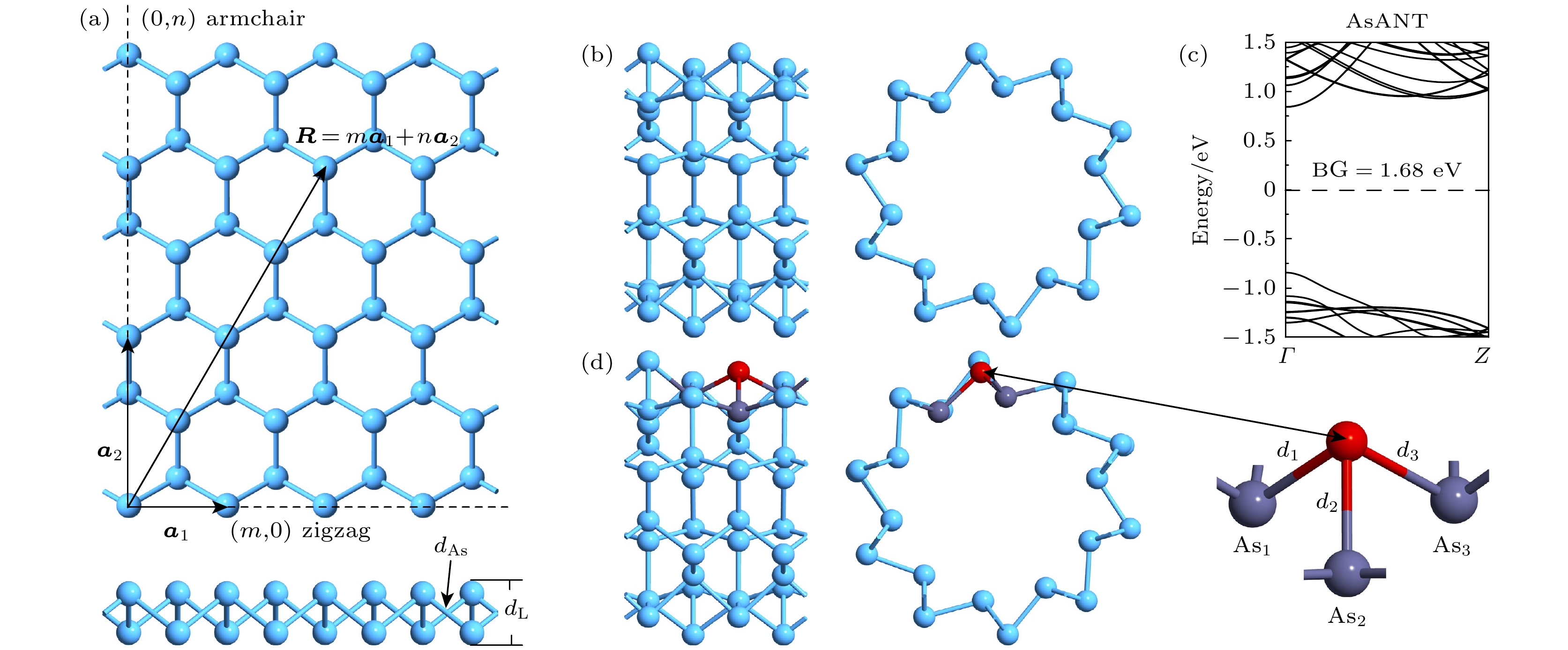

图 1 β-As的几何结构 (a) 2D砷烯的主视图和边视图; (b)本征单壁扶手椅型砷烯纳米管结构的顶视图和边视图; (c)本征砷纳米管的能带结构; (d)非金属原子 (B, N, P, Si, Se, Te) 取代性掺杂后单壁扶手椅型砷烯纳米管的顶视图和边视图和掺杂部分的局部放大图. As1, As2和As3为与杂质原子相连的3个内层As原子, d1, d2和d3为杂质原子和As1, As2, As3相连的键长

Fig. 1. Geometry structure of β-As: (a) Top and side views of 2D bucked arsenene; (b) top and side views of an arsenic armchair nanotube; (c) band structure of an intrinsic arsenic armchair nanotube; (d) top, side views of hybridized arsenene armchair nanotube substitutionally doped with non-metallic atoms (B, N, P, Si, Se, Te) in outermost atom layer and partial enlarged details. As1, As2 and As3 are three inner-layer arsenene atoms bonded to non-metallic atom, and d1, d2 and d3 are the bonds length between non-metallic atom and As1, As2, As3, respectively.

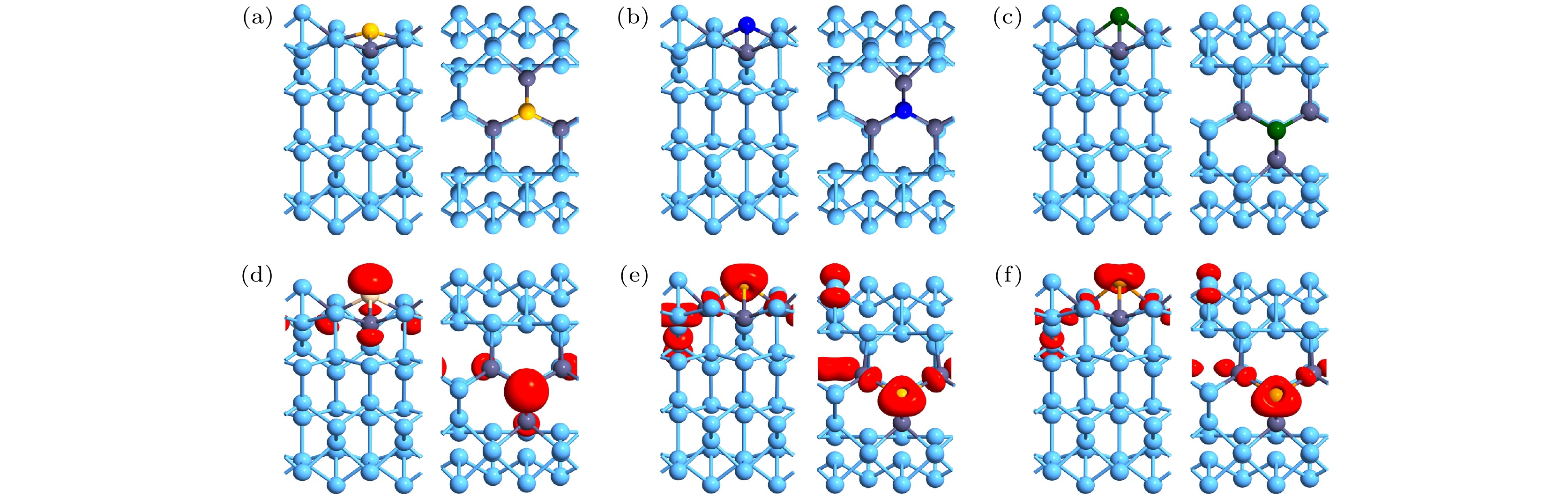

图 3 等值面为0.02 eV/Å3时, 纳米管在FM状态下计算的自旋极化密度(磁空间分布) (a) AsANT-B; (b) AsANT-N; (c) AsANT-P; (d) AsANT-Si; (e) AsANT-Se; (f) AsANT-Te

Fig. 3. Calculated spin polarized density (magnetic spatial distribution) for nanotube in FM state, where the isosurface is set to 0.02 eV/Å3: (a) AsANT-B; (b) AsANT-N; (c) AsANT-P; (d) AsANT-Si; (e) AsANT-Se; (f) AsANT-Te.

图 4 纳米管的能带、态密度及投影态密度图, 其中投影态密度投影在杂质原子上 (a) AsANT-B; (b) AsANT-N; (c) AsANT-P; (d) AsANT-Si; (e) AsANT-Se; (f) AsANT-Te

Fig. 4. Band structure and the DOS/PDOS for nanotube, and the orbital PDOS is projected on the impurity atom: (a) AsANT-B; (b) AsANT-N; (c) AsANT-P; (d) AsANT-Si; (e) AsANT-Se; (f) AsANT-Te.

图 6 应变调控效应 (a) 对AsANT-Si施加应力示意图; (b)—(d) 铁磁态下AsANT-Si的能带结构(b), 应变能和磁化能(c), 磁矩与应变(d)的关系

Fig. 6. Strain tuning effects: (a) Schematic for AsANT-Si applied by stretching strain; (b)–(d) band structures (b), strain energy and magnetic energy (c), and magnetic moment versus strain (d) for AsANT-Si in the FM state.

图 7 铁磁态下AsANT-Si不同因素随应变的变化, 其中θ1, θ2, θ3分别为d1与d2, d2与d3, d1与d3之间的夹角, 等值面设置为 0.02 eV/Å3 (a) 电荷转移; (b) 键长变化; (c) 键角变化; (d) 自旋极化电荷密度(磁空间分布)

Fig. 7. Changes of AsANT-Si factors with strain in ferromagnetic state, where θ1, θ2, θ3 are the angles between d1 and d2, d2 and d3, and d1 and d3, respectively, and the isosurface is set to 0.02 eV/Å3: (a) Charge transfer; (b) bond length; (c) change of bond angles; (d) spin polarized density (magnetic spatial distribution).

表 1 AsANT-X的结合能Eb, 形成能Ef, 键长d1, d2和d3及磁相. BMSC和NMS分别表示双极化磁性、无磁半导体

Table 1. Binding energy Eb, formation energy Ef, and bond lengths d1, d2 and d3, and magnetic phases of AsANT-X. BMSC and NMS indicate bipolar magnetic semiconductor and non-magnetic semiconductor, respectively.

结构 Eb/(eV/原子) Ef/(eV/原子) d1, d2, d3/Å 类型 AsANT-B –5.248 –0.004 2.055, 2.046, 2.055 NMS AsANT-N –5.279 –0.035 2.043, 2.043, 2.043 NMS AsANT-P –5.256 –0.012 2.421, 2.419, 2.422 NMS AsANT-Si –5.210 0.032 2.413, 2.424, 2.412 BMSC AsANT-Se –5.167 0.075 2.785, 2.503, 2.784 BMSC AsANT-Te –5.170 0.074 2.857, 2.638, 2.855 BMSC 表 2 AsANT-X (X = Si, Se和Te)的磁矩M, 磁化能EM, 磁交换能Eex及磁相

Table 2. Magnetic moment M, the magnetized energy EM, the magnetic exchange energy Eex and the magnetic phase for AsANT-X (X = Si, Se and Te).

Structure AsANT-Si AsANT-Se AsANT-Te M/μB X 0.502 0.368 0.310 As1 0.108 0.177 0.128 As2 0.104 –0.006 0.003 As3 0.108 0.174 0.126 Total 1.000 0.994 0.777 EM/meV 51.48 56.40 1.93 Eex/meV 20.92 56.40 1.89 磁相 BMSC BMSC BMSC -

[1] Han L, Neal A T, Zhen Z, Zhe L, Xu X, David T, Ye P D 2014 ACS Nano 8 4033

Google Scholar

Google Scholar

[2] Zhang S, Yan Z, Li Y, Chen Z, Zeng H 2015 Angew. Chem. Int. Ed. Engl. 127 3155

Google Scholar

Google Scholar

[3] Kamal C, Ezawa M 2015 Phys. Rev. B 91 085423

Google Scholar

Google Scholar

[4] Kecik D, Durgun E, Ciraci S 2016 Phys. Rev. B 94 205410

Google Scholar

Google Scholar

[5] Zhang S L, Xie M Q, Li F Y, Yan Z, Li Y F, Kan E, Liu W, Chen Z F, Zeng H B 2016 Angew. Chem. Int. Ed. 55 1666

Google Scholar

Google Scholar

[6] Zhu Z, Guan J, Tomanek D 2015 Phys. Rev. B 91 161404

Google Scholar

Google Scholar

[7] Tsai H S, Wang S W, Hsiao C H, Chen C W, Ouyang H, Chueh Y L, Kuo H C, Liang J H 2016 Chem. Mater. 28 425

Google Scholar

Google Scholar

[8] Gusmao R, Sofer Z, Bousa D, Pumera M 2017 Angew. Chem. Int. Ed. Engl. 56 14417

Google Scholar

Google Scholar

[9] Qi M, Dai S, Wu P 2020 J. Phys. Condens. Mat. 32 085802

Google Scholar

Google Scholar

[10] Bai M, Zhang W X, He C 2017 J. Solid State Chem. 251 1

Google Scholar

Google Scholar

[11] Du J, Xia C, An Y, Wang T, Jia Y 2016 J. Mater. Sci. 51 9504

Google Scholar

Google Scholar

[12] Sun M L, Wang S K, Du Y H, Yu J, Tang W C 2016 Appl. Surf. Sci. 389 594

Google Scholar

Google Scholar

[13] Liu M, Chen Q, Huang Y, Cao C, He Y 2016 Superlattices Microstruct. 100 131

Google Scholar

Google Scholar

[14] Han J N, Zhang Z H, Fan Z, Zhou R 2020 Nanotechnology 31 315206

Google Scholar

Google Scholar

[15] Liu M Y, Chen Q Y, Huang Y, Li Z Y, Cao C, He Y 2018 Nanotechnology 29 095203

Google Scholar

Google Scholar

[16] Li G, Zhao Y, Zeng S, Ni J 2016 Appl. Surf. Sci. 390 60

Google Scholar

Google Scholar

[17] Li Z J, Xu W, Yu Y Q, Du H Y, Zhen K, Wang J, Luo L B, Qiu H L, Yang X B 2016 J. Mater. Chem. C 4 362

Google Scholar

Google Scholar

[18] Ersan F, Aktűrk E, Ciraci S 2016 J. Phys. Chem. C 120 14345

Google Scholar

Google Scholar

[19] Iordanidou K, Kioseoglou J, Afanas’ev V V 2017 Phys. Chem. Chem. Phys. 19 9862

Google Scholar

Google Scholar

[20] Sun X T, Liu Y X, Song Z G, Wang X, Cheng Y 2017 J. Mater. Chem. C 5 4159

Google Scholar

Google Scholar

[21] Song Y, Li D, Mi W B, Wang X C, Cheng Y C 2016 J. Phys. Chem. C 120 5613

Google Scholar

Google Scholar

[22] Xia C X, Xue B, Wang T X, Peng Y T, Jia Y 2015 Appl. Phys. Lett. 107 193107

Google Scholar

Google Scholar

[23] Lee Y, Bae S, Jang H, Jang S, Zhu S E, Sim S H, Song Y I, Hong B H, Ahn J H 2010 Nano Lett. 10 490

Google Scholar

Google Scholar

[24] Bae S K, Kim H K, Lee Y B, Xu F, Iijima S 2010 Nat. Nanotechnol. 5 574

Google Scholar

Google Scholar

[25] Saito R, Dresselhaus G, Dresselhaus M S 1999 Sci. World. J. 54 832

Google Scholar

Google Scholar

[26] Rubio A, Corkill J L, Cohen M L 1994 Phys. Rev. B 49 5081

Google Scholar

Google Scholar

[27] Blase X, Rubio A, Louie S G, Cohen M L 1995 Phys. Rev. B 51 6868

Google Scholar

Google Scholar

[28] Yu S, Zhu H, Eshun K, Arab A, Badwan A, Li Q A 2015 J. Appl. Phys. 118 164306

Google Scholar

Google Scholar

[29] Kuang W, Hu R, Fan Z Q, Zhang Z H 2019 Nanotechnology 30 145201

Google Scholar

Google Scholar

[30] Santos E J G, Sánchez-Portal D, Ayuela A 2010 Phys. Rev. B 81 125433

Google Scholar

Google Scholar

[31] Han J N, He X, Fan Z Q, Zhang Z H 2019 Phys. Chem. Chem. Phys. 21 1830

Google Scholar

Google Scholar

[32] Wang D, Zhang Z H, Deng X Q, Fan Z Q, Tang G P 2016 Carbon 98 204

Google Scholar

Google Scholar

[33] Fan Z Q, Zhang Z H, Ming Q, Zhang Z H 2012 Comp. Mater. Sci. 53 294

Google Scholar

Google Scholar

[34] Zhang H, Zhou W, Yang Z, Zhang Z H 2017 Mater. Res. Express 4 126301

Google Scholar

Google Scholar

[35] Liu J, Zhang Z H, Deng X Q, Zhang Z H 2015 Org. Electron. 18 135

Google Scholar

Google Scholar

[36] Bardeen J, Shockley W 1950 Phys. Rev. 80 72

Google Scholar

Google Scholar

[37] Zhang Z H, Guo C, Kwong D J, Li J, Deng X, Fan Z Q 2013 Adv. Funct. Mater. 23 2765

Google Scholar

Google Scholar

[38] Pan J B, Zhang Z H, Deng X Q, Qiu M, Guo C 2011 Appl. Phys. Lett. 98 013503

Google Scholar

Google Scholar

[39] Zhang Z H, Deng X Q, Tan X Q, Qiu M, Pan J B 2010 Appl. Phys. Lett. 97 183105

Google Scholar

Google Scholar

[40] Gao Y, Cheng Z, Wen M, Zhang X, Wu F, Dong H, Zhang G 2021 Nanotechnology 32 245702

Google Scholar

Google Scholar

[41] Wang D, Chen, L, Shi C, Wang X, Cui G, Zhang P, Chen Y 2016 Sci. Rep. 6 28487

Google Scholar

Google Scholar

[42] Rodríguez-Manzo J A, Cretu O, Banhart F 2010 ACS Nano 4 3422

Google Scholar

Google Scholar

[43] He Z, He K, Robertson A W, Kirkland A I, Kim D, Ihm J, Yoon E, Lee G D, Warner J H 2014 Nano Lett. 14 3766

Google Scholar

Google Scholar

[44] Kunstmann J, Özdoğan C, Quandt A, Fehske H 2011 Phys. Rev. B 83 045414

Google Scholar

Google Scholar

[45] Li X, Wu X, Yang J 2014 J. Am. Chem. Soc. 136 5664

Google Scholar

Google Scholar

[46] Yagi Y, Briere T M, Sluiter M H F, Kumar V, Farajian A A, Kawazoe Y 2004 Phys. Rev. B 69 075414

Google Scholar

Google Scholar

[47] Beleznay F B, Bogár F, Ladik J 2003 J Chem. Phys. 119 5690

Google Scholar

Google Scholar

[48] Cai Y, Zhang G, Zhang Y W 2014 J. Am. Chem. Soc. 136 6269

Google Scholar

Google Scholar

[49] Zhang X, Zhao X D, Wu D H, Jing Y, Zhou Z 2015 Nanoscale 7 16020

Google Scholar

Google Scholar

[50] Hu R, Li Y H, Zhang Z H, Fan Z Q, Sun L 2019 J. Mater. Chem. C 7 7745

Google Scholar

Google Scholar

计量

- 文章访问数: 3439

- PDF下载量: 49

- 被引次数: 0

下载:

下载: