-

单层C3B是典型的类石墨烯二维材料, 已在实验上成功制备. 采用密度泛函理论方法(DFT)研究了扶手椅型单层C3B纳米带的结构稳定性、电子性质及物理调控效应, 计算结果表明: 对于裸边纳米带, 如果带边缘全由C原子组成(AA型), 则电子相为半导体; 两个带边缘均由C与B原子混合组成时(BB型), 则纳米带的电子相为金属; 而纳米带的一边由C原子组成、另一边由B与C原子混合构成(AB型), 则纳米带的电子相为金属. 这说明纳米带边缘的B原子对于纳米带成为金属或半导体起决定作用. 而对于H端接的纳米带, 它们全部为直接或间接带隙半导体. H端接的纳米带载流子迁移率一般比裸边纳米带低, 这与它们较大的有效质量及较高的形变势有密切关系. 同时发现半导体性质的纳米带对物理调控非常敏感, 特别是在压应变和外电场作用下, 纳米带的带隙明显变小, 这有利于对光能的吸收和研发光学器件.C3B monolayer is a typical graphene-like two-dimensional material, which has been successfully prepared experimentally. Here, we use the density functional theory to study the structural stability, electronic properties and physical regulation effects of its armchair-edged nanoribbons. The results show that for the bare-edged nanoribbons, if the ribbon edges are composed of C atoms completely (AA-type), their electronic phase is a semiconductor; when both ribbons edges consist of C and B atoms (BB-type) jointly, their electronic phase is a metal; if one edge of the ribbon is composed of C atoms and the other edge is comprised of B and C atoms (AB-type), their electronic phase is also a metal. This suggests that the B atom located at the ribbon edge plays an important role in determining whether nanoribbons is a metal or semiconductor. While for the H-terminated nanoribbons, they are all direct or indirect band-gap semiconductors. The carrier mobility of H-terminated nanoribbons is generally lower than that of bare-edged nanoribbon, which is closely related to their larger effective mass and higher deformation potential values. Meanwhile, it is found that the semiconducting nanoribbons are very sensitive to physical regulation, especially under applied compressive strain and external electric field, the band gap of the nanoribbons becomes very smaller, which is favorable for the absorption of light energy and development of novel optical devices.

-

Keywords:

- C3B nanoribbon /

- structural stability /

- electronic properties /

- carrier mobility /

- physical regulation

[1] Novoselov K S, Geim A K, Morozov S V, Jiang D, Zhang Y, Dubonosn S V, Grigorieva I V, Firsov A A 2004 Science 306 666

Google Scholar

Google Scholar

[2] Novoselov K S, Geim A K, Morozov S V, Jiang D, Katsnelson M I, Grigorieva1 I V, Dubonos S V, Firsov A A 2005 Nature 438 197

Google Scholar

Google Scholar

[3] Zhang Y, Tan Y W, Stormer H L, Kim P 2005 Nature 438 201

Google Scholar

Google Scholar

[4] Kim Y J, Bae G Y, Chun S, Park W 2016 J. Nanosci. Nanotechnol 16 2769

Google Scholar

Google Scholar

[5] Blase X, Rubio A, Louie S G, Cohen M L 1995 Phys. Rev. B 51 6868

Google Scholar

Google Scholar

[6] Cahangirov S, Topsakal M, Aktürk E, Sahin H, Ciraci S 2009 Phys. Rev. Lett. 102 236804

Google Scholar

Google Scholar

[7] Kuang W, Hu R, Fan Z Q, Zhang Z H 2019 Nanotechnology 30 145201

Google Scholar

Google Scholar

[8] Xiao D, Liu G B, Feng W, Xu X, Yao W 2012 Phys. Rev. Lett. 108 196802

Google Scholar

Google Scholar

[9] Zhang S, Yan Z, Li Y, Chen Z, Zeng H 2015 Angew. Chem. Int. Ed. 54 3112

Google Scholar

Google Scholar

[10] Zhang S, Xie M, Li F, Yan Z, Li Y, Kan E, Liu W, Chen Z, Zeng H 2016 Angew. Chem. 128 1698

Google Scholar

Google Scholar

[11] Yang B, Zhang X, Zhao M 2017 Nanoscale 9 8740

Google Scholar

Google Scholar

[12] Ding C, Gao H, Geng W, Zhao M 2021 Nanoscale Adv 3 1127

Google Scholar

Google Scholar

[13] Palsgaard M, Gunst T, Markussen T, Thygesen K, Brandbyge M 2018 Nano. Lett. 18 7275

Google Scholar

Google Scholar

[14] Wines D, Ersan F, Ataca C 2020 ACS Appl. Mater. Interfaces 12 46416

Google Scholar

Google Scholar

[15] Zhu M, Zhang L, Li X, He Y, Li X, Guo F, Zang X, Wang K, Xie D, Li X, Wei B, Zhu H. 2015 J. Mater. Chem. A 3 8133

Google Scholar

Google Scholar

[16] Midya A, Ghorai A, Mukherjee S, Maiti R, Ray S 2016 J. Mater. Chem. A 4 4534

Google Scholar

Google Scholar

[17] Sun F, Liu R, Suo Y Q, Niu L L, Fu H Y, Ji W F, Li Z L 2019 Acta. Phys. Sin. 68 178502

Google Scholar

Google Scholar

[18] Liu R, Bao D L, Jiao Y, Wan L W, Li Z L, Wang C K 2014 Acta. Phys. Sin. 6 068501

Google Scholar

Google Scholar

[19] Hu Y, Zhang S, Sun S, Xie M, Cai B, Zeng H 2015 Appl. Phys. Lett. 107 122107

Google Scholar

Google Scholar

[20] Pereira V M, Neto A H C 2009 Phys. Rev. Lett. 103 046801

Google Scholar

Google Scholar

[21] Son Y W, Cohen M L, Louie. S. G 2006 Phys. Rev. Lett. 97 216803

Google Scholar

Google Scholar

[22] Son Y W, Cohen M L, Louie S G 2006 Nature 444 347

Google Scholar

Google Scholar

[23] Niu L L, Fu H Y, Suo Y Q, Liu R, Sun F, Wang S S, Zhang G P, Wang C K, Li Z L 2021 Physica E 128 114542

Google Scholar

Google Scholar

[24] Fu H Y, Sun F, Liu R, Suo Y Q, Bi J J, Wang C K, Li Z L 2019 Phys. Lett. A 383 867

Google Scholar

Google Scholar

[25] Aftab S, Samiya M, Liao W, Iqbal M W, Ishfaq M, Ramachandraiah K, Ajmal H M S, Haque H M U, Yousuf S, Ahmed Z, khan M U, Rehman A U, Iqbal M Z 2021 J. Mater. Chem. C 9 3998

Google Scholar

Google Scholar

[26] He T, Lan C, Zhou S, Li Y, Yin Y, Li C, Liu Y 2021 J. Mater. Chem. C 9 3846

Google Scholar

Google Scholar

[27] Liu S Y, Liu S, Li D J, Dang H, Liu Y, Xue S, Xue W, Wang S 2013 Phys. Rev. B 88 115434

Google Scholar

Google Scholar

[28] Tanaka H, Kawamata Y, Simizu H, Fujita T, Yanagisawa H, Otani S, Oshima C 2005 Solid. State. Commun. 136 22

Google Scholar

Google Scholar

[29] Ding Y, Wang Y, Ni J 2009 Appl. Phys. Lett. 94 073111

Google Scholar

Google Scholar

[30] Miyamoto Y, Rubio A, Louie S G, Cohen M L 1994 Phys. Rev. B 50 18360

Google Scholar

Google Scholar

[31] Zhang Y, Wu Z F, Gao P F, Fang D Q, Zhang E H, Zhang S L 2018 RSC. Adv. 8 1686

Google Scholar

Google Scholar

[32] Senturk A E, Oktem A S, Konukman A E S 2020 Mol. Simul. 46 879

Google Scholar

Google Scholar

[33] Su Y, Cao S, Shi L B, Qian P 2020 Appl. Surf. Sci. 531 147341

Google Scholar

Google Scholar

[34] Liu G, Wu M S, Ouyang C Y, Xu B 2013 Mod. Phys. Lett. B 27 1350110

Google Scholar

Google Scholar

[35] Wu Y, Xia W, Zhang Y, Zhu W, Zhang W, Zhang P 2020 Phys. Rev. Appl. 14 014073

Google Scholar

Google Scholar

[36] Ozdemir B, Barone V 2015 Comput. Mater. Sci. 109 248

Google Scholar

Google Scholar

[37] Yang Z, Ni J 2012 Appl. Phys. Lett. 100 183109

Google Scholar

Google Scholar

[38] Yang Z, Ni J 2010 Appl. Phys. Lett. 97 253117

Google Scholar

Google Scholar

[39] Zhang H, Tang Y, Chai H, Chen W, Zhao M, Dai X 2019 Mol. Phys. 117 125

Google Scholar

Google Scholar

[40] Meng C, Zhao K, Yang M, Liang Y, Bu X 2021 Phys. E 132 114762

Google Scholar

Google Scholar

[41] Qie Y, Liu J, Wang S, Gong S, Sun Q 2018 Carbon 129 38

Google Scholar

Google Scholar

[42] Zhao J, Cheng N, He Y 2019 Phys. Chem. Chem. Phys. 21 19567

Google Scholar

Google Scholar

[43] Zhang C, Jiao Y, He T, Bottle S, Frauenheim T, Du A 2018 J. Phys. Chem. Lett. 9 858

Google Scholar

Google Scholar

[44] Zhao P, Wan Y, Zhang S, Gao A, Guo P, Jiang Z, Zheng J 2020 Phys. Status. Solidi. RRL 14 2000012

Google Scholar

Google Scholar

[45] Dutta S, Wakabayashi K 2013 J. Mater. Chem. C. Mater. 1 4854

Google Scholar

Google Scholar

[46] Brandbyge M, Mozos J L, Ordejon P, Taylor J, Stokbro K 2002 Phys. Rev. B 65 165401

Google Scholar

Google Scholar

[47] Taylor J, Guo H, Wang J 2001 Phys. Rev. B 63 245407

Google Scholar

Google Scholar

[48] Hu J K, Tan J X, Wu D, Zhang Z H, Fan Z Q 2021 Appl. Surf. Sci. 560 149858

Google Scholar

Google Scholar

[49] 徐永虎, 邓小清, 孙琳, 范志强, 张振华 2022 71 046102

Google Scholar

Google Scholar

Xu Y H, Deng X Q, Sun L, Fan Z Q, Zhang Z H 2022 Acta. Phys. Sin. 71 046102

Google Scholar

Google Scholar

[50] 汤家鑫, 范志强, 邓小清, 张振华 2022 71 116101

Google Scholar

Google Scholar

Tang J X, Fan Z Q, Deng X Q, Zhang Z H 2022 Acta. Phys. Sin. 71 116101

Google Scholar

Google Scholar

[51] He X, Deng X Q, Sun L, Zhang Z H, Fan Z Q 2022 Appl. Surf. Sci. 578 151844

Google Scholar

Google Scholar

[52] Chen H L, Han J N, Deng X Q, Fan Z Q, Sun L, Zhang Z H 2022 Appl. Surf. Sci. 598 153756

Google Scholar

Google Scholar

[53] Chen H L, Zhang L, Deng, X Q, Sun L, Zhang Z H , Fan Z Q 2021 J. Mater. Chem. C 9 12904

[54] Hwang E, Sarma S D 2008 Phys. Rev. B 77 115449

Google Scholar

Google Scholar

[55] Bardeen J, Shockley W. 1950 Phys. Rev. 80 72

Google Scholar

Google Scholar

[56] Hu R, Li Y H, Zhang Z H, Fan Z Q, Sun L 2019 J. Mater. Chem. C 7 7745

Google Scholar

Google Scholar

[57] Dong Q X, Hu R, Fan Z Q, Zhang Z H 2018 Carbon 130 206

Google Scholar

Google Scholar

[58] Han J N, He X, Fan Z Q, Zhang Z H 2019 Phys. Chem. Chem. Phys. 21 1830

Google Scholar

Google Scholar

-

图 1 (a) C3B单层原子结构, 其中浅绿色菱形表示它的原胞, 考虑沿X轴方向剪裁形成各种扶手椅型纳米带, 其中蓝色、黄色阴影分别表示A型、B型边缘; (b)—(k)分别表示13-AA(Ⅰ), 15-AA(Ⅱ), 15-BB(Ⅰ), 13-BB(Ⅱ), 14-AB, 13H-AA(Ⅰ), 15H-AA(Ⅱ), 15H-BB(Ⅰ), 13AH-BB(Ⅱ), 14H-AB纳米带, 黑色虚线框表示纳米带单胞

Fig. 1. (a) Atomic structure C3B monolayer, where light green rhombus represents its primitive cell, tailoring C3B monolayer along the X-axis direction to form various armchair edged nanoribbons, the blue and yellow shadows indicate the A-type and B-type edges, respectively; (b)–(k) several typical ribbons 13-AA(Ⅰ), 15-AA(Ⅱ), 15-BB(Ⅰ), 13-BB(Ⅱ), 14-AB, 13H-AA(Ⅰ), 15H-AA(Ⅱ), 15H-BB(Ⅰ), 13AH-BB(Ⅱ), and 14H-AB respectively, the black dashed box denotes the unit cell of nanoribbons.

图 2 裸边和H端接C3B纳米带的热力学稳定性模拟, 即在NVT系综件下使用温度为500 K的Nose Hoover热浴, 按每步1 fs运行8 ps后获得的结果 (a) 13-AA(Ⅰ), (b) 15-AA(Ⅱ), (c) 15-BB(Ⅰ), (d) 13-BB(Ⅱ), (e) 14-AB, (f) 13H-AA(Ⅰ), (g) 15H-AA(Ⅱ), (h) 15H-BB(Ⅰ), (i) 13AH-BB(Ⅱ), (j) 14H-AB; (k)裸边C3B纳米带边能随宽度变化; (l) H端接C3B纳米带边能随宽度变化

Fig. 2. Examining the thermal stability of bare-edge and H-terminated C3B ribbons, the obtained results for running the simulation by 8 ps with a time step of 1 fs under the Nosé heat bath scheme, which is used in the NVT ensemble at 500 K: (a)13-AA(Ⅰ), (b)15-AA(Ⅱ), (c)15-BB(Ⅰ), (d)13-BB(Ⅱ), (e)14-AB, (f)13H-AA(Ⅰ), (g)15H-AA(Ⅱ), (h)15H-BB(Ⅰ), (i)13AH-BB(Ⅱ), (j)14H-AB; (k) edge energy versus widths of the bare-edge C3B nanoribbons; (l)edge energy versus widths of the H-terminated C3B nanoribbons.

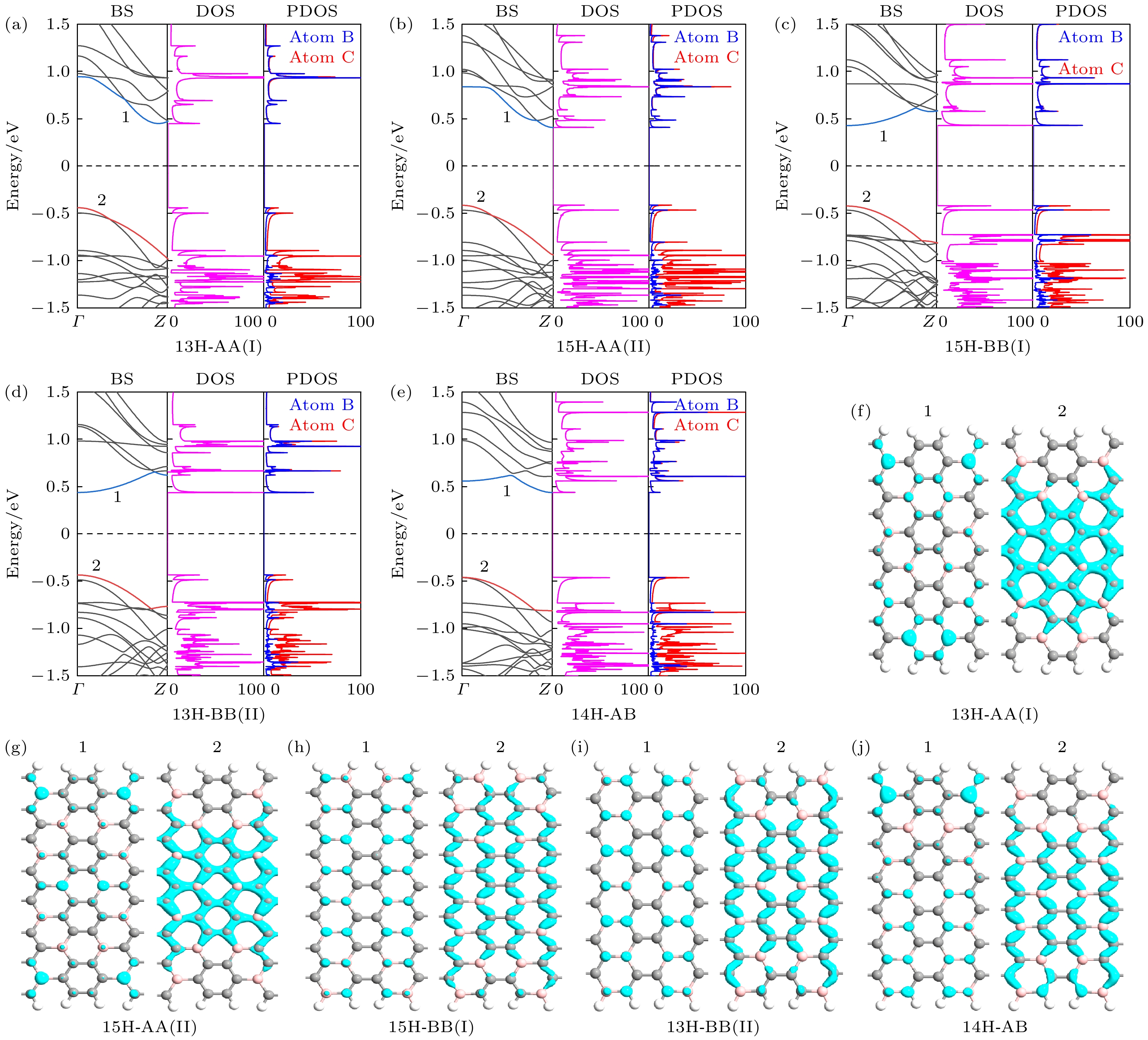

图 3 几种典型裸边C3B纳米带的能带结构、态密度(DOS)和原子投影态密度(PDOS) (a) 13-AA(Ⅰ), (b) 15-AA(Ⅱ), (c) 15-BB(Ⅰ), (d) 13-BB(Ⅱ), (e) 14-AB; 相对应纳米带的能带1和2的部分电荷密度: (f) 13-AA(Ⅰ), (g) 15-AA(Ⅱ), (h) 15-BB(Ⅰ), (i) 13-BB(Ⅱ), (j) 14-AB, 部分电荷密度等值面设置为0.03 |e|·Å–3

Fig. 3. Band structure, density of states (DOS) , and atom-projected density of states (PDOS) of several typical bare-edge C3B ribbons: (a) 13-AA(Ⅰ), (b) 15-AA(Ⅱ), (c) 15-BB(Ⅰ), (d) 13-BB(Ⅱ), (e) 14-AB. Partial charge density of subbands 1 and 2 for the corresponding ribbons: (f) 13-AA(Ⅰ), (g) 15-AA(Ⅱ), (h) 15-BB(Ⅰ), (i) 13-BB(Ⅱ), (j) 14-AB. The isosurface for partial charge density is set to 0.03 |e|·Å–3.

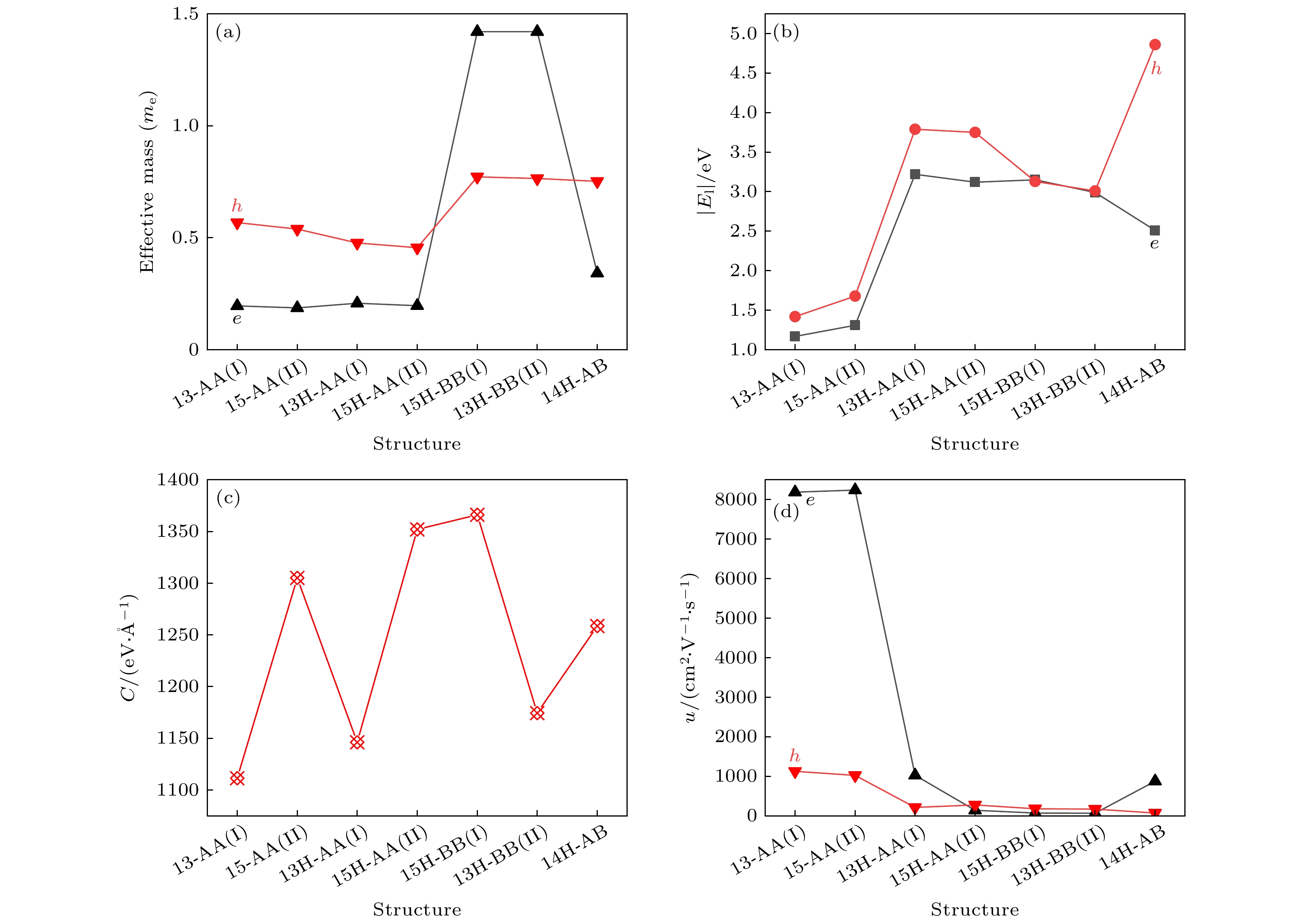

图 4 几种典型的H端接的C3B纳米带的能带结构, 态密度(DOS)和原子投影态密度(PDOS) (a) 13H-AA(Ⅰ), (b) 15H-AA(Ⅱ), (c) 15H-BB(Ⅰ), (d) 13AH-BB(Ⅱ), (e) 14H-AB; 相对应纳米带的能带1和2的部分电荷密度: (f) 13H-AA(Ⅰ), (g) 15H-AA(Ⅱ), (h) 15H-BB(Ⅰ), (i) 13AH-BB(Ⅱ), (j) 14H-AB, 部分电荷密度等值设为0.03 |e|·Å–3

Fig. 4. Band structure, density of states (DOS) and atom-projected density of states (PDOS) for several typical H-terminated C3B ribbons: (a)13H-AA(Ⅰ), (b)15H-AA(Ⅱ), (c)15H-BB(Ⅰ), (d)13AH-BB(Ⅱ), and (e)14H-AB. Partial charge density of subbands 1 and 2 for the corresponding ribbons: (f) 13H-AA(Ⅰ), (g)15H-AA(Ⅱ), (h)15H-BB(Ⅰ), (i)13AH-BB(Ⅱ), and (j)14H-AB. The isosurface for partial charge density is set to 0.03 |e|·Å–3.

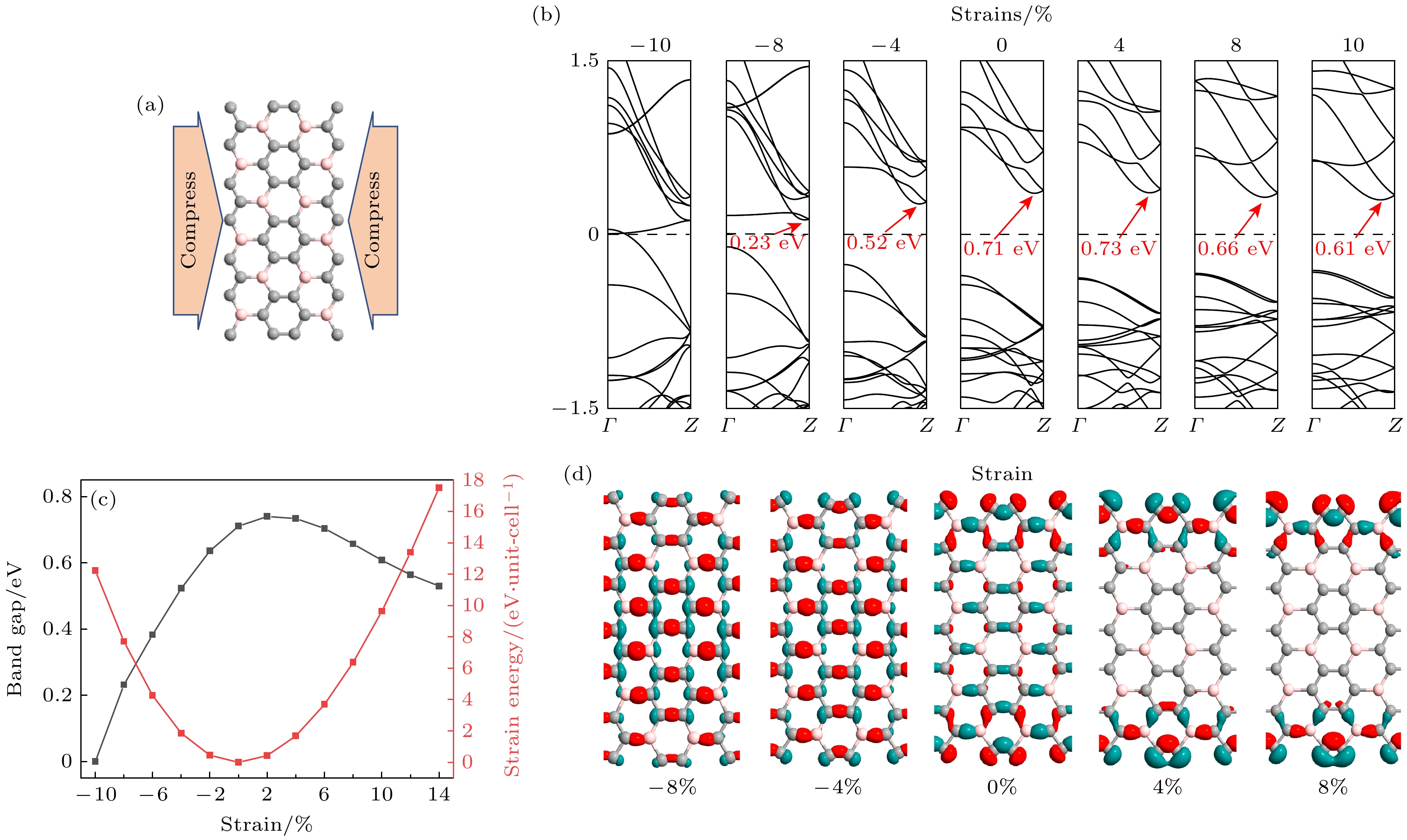

图 6 13-AA(Ⅰ)纳米带的应变调控效应 (a)纳米带压应力示意图; (b)能带结构随施加应变值的变化; (c)带隙及应变能随施加应变值的变化; (d) 13-AA(Ⅰ) VBM在Gama点的布洛赫态, 布洛赫态等值面为0.1 |e|·Å–3

Fig. 6. The strain regulation effect of 13-AA(Ⅰ) ribbon: (a) Schematic diagram of compressive stress in nanoribbons; (b) variation of energy band structure with applied strain; (c) band gap and the strain energy with the applied strain; (d) 13-AA(Ⅰ) bloch state of VBM at Gama point. The isosurface value is set as 0.1 |e|·Å–3.

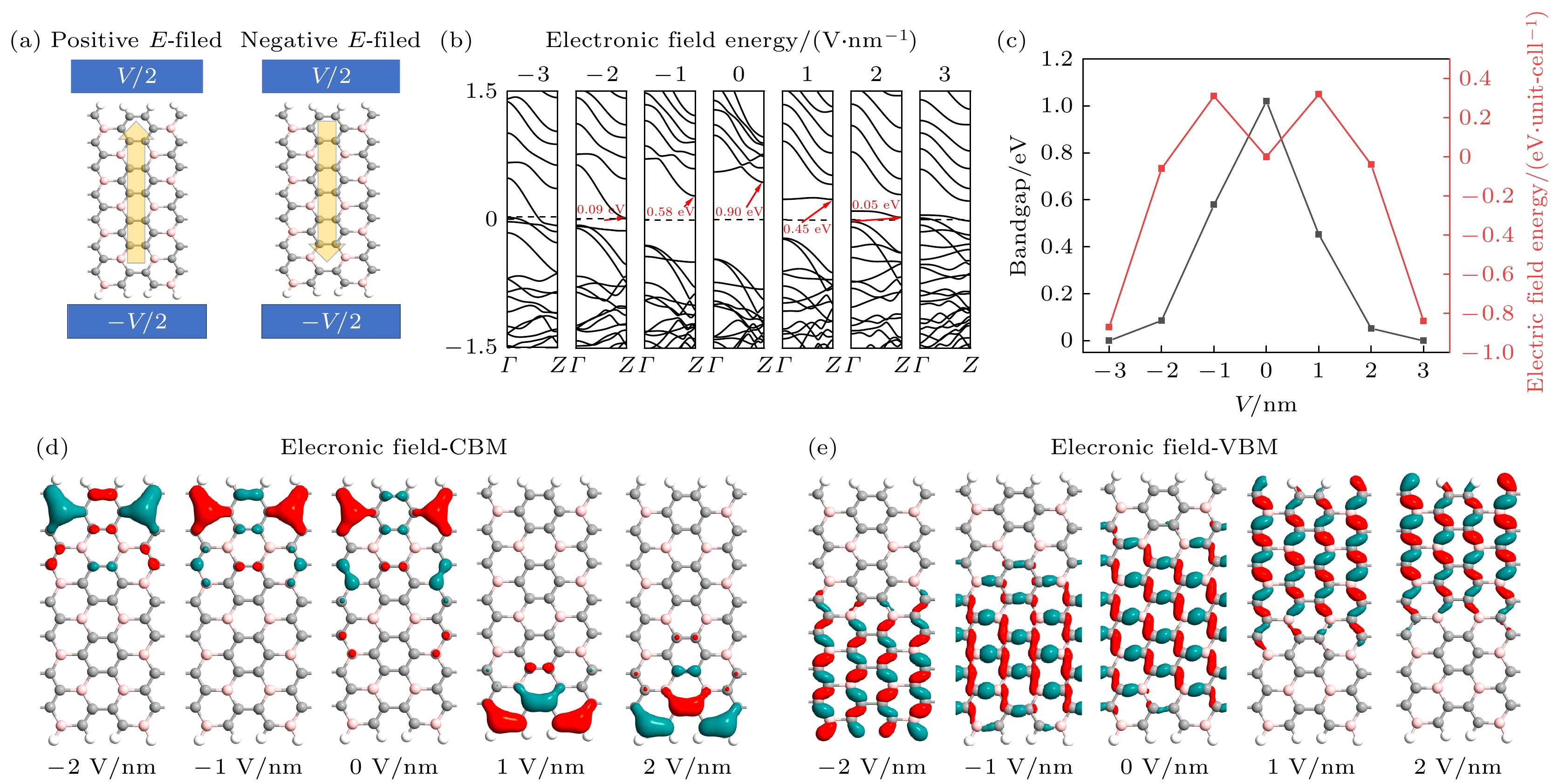

图 8 (a) 14H-AB纳米带的电场调控效应; (b)能带结构随电场变化; (c)带隙及电场能随电场变化; (d), (e) CBM和VBM的布洛赫态能随电场变化, 布洛赫态等值面为0.1 |e|·Å–3

Fig. 8. (a) Electric field regulation effect of ribbon14H-AB; (b) band structure changes with the electric field; (c) band gap and electric field energy changes with the electric field; (d), (e) Bloch states of CBM and VBM changes with the electric field, their isosurface is set to 0.1 |e|·Å–3.

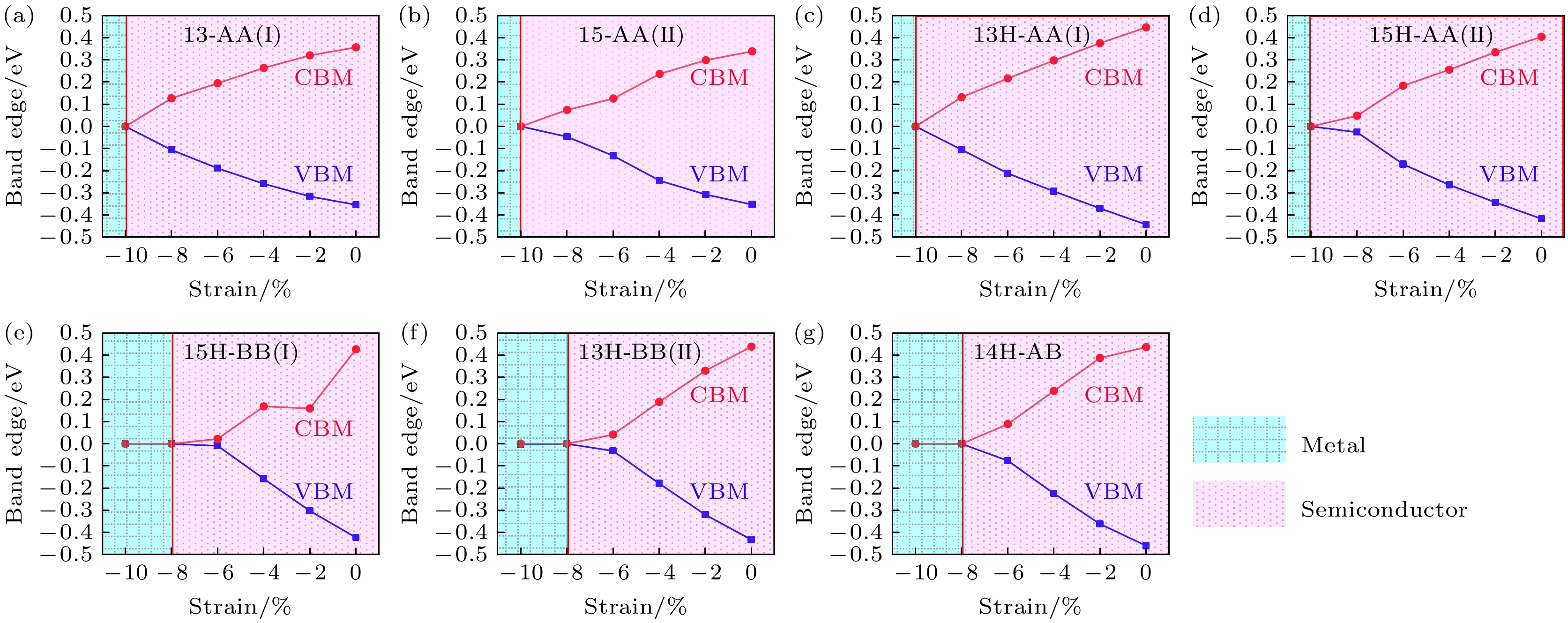

图 9 C3B纳米带带边(CBM、VBM)随外部电场的变化 (a) 13-AA(Ⅰ); (b) 15-AA(Ⅱ); (c) 13H-AA(Ⅰ); (d) 15H-AA(Ⅱ); (e) 15H-BB(Ⅰ); (f) 13AH-BB(Ⅱ); (g) 14H-AB

Fig. 9. Band edges for the C3B nanoribbon varies with external electric field: (a) 13-AA(Ⅰ); (b) 15-AA(Ⅱ); (c) 13H-AA(Ⅰ); (d) 15H-AA(Ⅱ); (e) 15H-BB(Ⅰ); (f) 13AH-BB(Ⅱ); (g) 14H-AB.

表 1 不同宽度裸边C3B纳米带带隙

Table 1. Band gaps of bare-edge C3B nanoribbons with different widths.

Structure Band gap/eV Structure Band gap/eV Structure Band gap/eV 5-AA(Ⅰ) 0.928 19-AA(Ⅱ) 0.696 13-BB(Ⅱ) 0 9-AA(Ⅰ) 0.730 7-BB(Ⅰ) 0 17-BB(Ⅱ) 0 13-AA(Ⅰ) 0.710 11-BB(Ⅰ) 0 8-AB 0 17-AA(Ⅰ) 0.710 15-BB(Ⅰ) 0 10-AB 0 7-AA(Ⅱ) 0.718 19-BB(Ⅰ) 0 12-AB 0 11-AA(Ⅱ) 0.675 5-BB(Ⅱ) 0 14-AB 0 15-AA(Ⅱ) 0.692 9-BB(Ⅱ) 0 16-AB 0 表 2 H端接C3B纳米带的带隙

Table 2. Band gaps for H-terminated C3B nanoribbons.

Structure Bandgap/eV Structure Bandgap/eV Structure Bandgap/eV 5 H-AA(Ⅰ) 1.753 19 H-AA(Ⅱ) 0.774 13 H-BB(Ⅱ) 0.872 9 H-AA(Ⅰ) 1.098 7 H-BB(Ⅰ) 1.040 17 H-BB(Ⅱ) 0.833 13 H-AA(Ⅰ) 0.890 11 H-BB(Ⅰ) 0.907 8 H-AA(Ⅱ) 1.157 17 H-AA(Ⅰ) 0.809 15 H-BB(Ⅰ) 0.850 10 H-AA(Ⅱ) 1.014 7 H-AA(Ⅱ) 1.263 19 H-BB(Ⅰ) 0.820 12 H-AB(Ⅰ) 0.953 11 H-AA(Ⅱ) 0.930 5 H-BB(Ⅱ) 0.976 14 H-AB(Ⅰ) 0.897 15 H-AA(Ⅱ) 0.823 9 H-BB(Ⅱ) 0.948 16 H-AB(Ⅰ) 0.869 -

[1] Novoselov K S, Geim A K, Morozov S V, Jiang D, Zhang Y, Dubonosn S V, Grigorieva I V, Firsov A A 2004 Science 306 666

Google Scholar

Google Scholar

[2] Novoselov K S, Geim A K, Morozov S V, Jiang D, Katsnelson M I, Grigorieva1 I V, Dubonos S V, Firsov A A 2005 Nature 438 197

Google Scholar

Google Scholar

[3] Zhang Y, Tan Y W, Stormer H L, Kim P 2005 Nature 438 201

Google Scholar

Google Scholar

[4] Kim Y J, Bae G Y, Chun S, Park W 2016 J. Nanosci. Nanotechnol 16 2769

Google Scholar

Google Scholar

[5] Blase X, Rubio A, Louie S G, Cohen M L 1995 Phys. Rev. B 51 6868

Google Scholar

Google Scholar

[6] Cahangirov S, Topsakal M, Aktürk E, Sahin H, Ciraci S 2009 Phys. Rev. Lett. 102 236804

Google Scholar

Google Scholar

[7] Kuang W, Hu R, Fan Z Q, Zhang Z H 2019 Nanotechnology 30 145201

Google Scholar

Google Scholar

[8] Xiao D, Liu G B, Feng W, Xu X, Yao W 2012 Phys. Rev. Lett. 108 196802

Google Scholar

Google Scholar

[9] Zhang S, Yan Z, Li Y, Chen Z, Zeng H 2015 Angew. Chem. Int. Ed. 54 3112

Google Scholar

Google Scholar

[10] Zhang S, Xie M, Li F, Yan Z, Li Y, Kan E, Liu W, Chen Z, Zeng H 2016 Angew. Chem. 128 1698

Google Scholar

Google Scholar

[11] Yang B, Zhang X, Zhao M 2017 Nanoscale 9 8740

Google Scholar

Google Scholar

[12] Ding C, Gao H, Geng W, Zhao M 2021 Nanoscale Adv 3 1127

Google Scholar

Google Scholar

[13] Palsgaard M, Gunst T, Markussen T, Thygesen K, Brandbyge M 2018 Nano. Lett. 18 7275

Google Scholar

Google Scholar

[14] Wines D, Ersan F, Ataca C 2020 ACS Appl. Mater. Interfaces 12 46416

Google Scholar

Google Scholar

[15] Zhu M, Zhang L, Li X, He Y, Li X, Guo F, Zang X, Wang K, Xie D, Li X, Wei B, Zhu H. 2015 J. Mater. Chem. A 3 8133

Google Scholar

Google Scholar

[16] Midya A, Ghorai A, Mukherjee S, Maiti R, Ray S 2016 J. Mater. Chem. A 4 4534

Google Scholar

Google Scholar

[17] Sun F, Liu R, Suo Y Q, Niu L L, Fu H Y, Ji W F, Li Z L 2019 Acta. Phys. Sin. 68 178502

Google Scholar

Google Scholar

[18] Liu R, Bao D L, Jiao Y, Wan L W, Li Z L, Wang C K 2014 Acta. Phys. Sin. 6 068501

Google Scholar

Google Scholar

[19] Hu Y, Zhang S, Sun S, Xie M, Cai B, Zeng H 2015 Appl. Phys. Lett. 107 122107

Google Scholar

Google Scholar

[20] Pereira V M, Neto A H C 2009 Phys. Rev. Lett. 103 046801

Google Scholar

Google Scholar

[21] Son Y W, Cohen M L, Louie. S. G 2006 Phys. Rev. Lett. 97 216803

Google Scholar

Google Scholar

[22] Son Y W, Cohen M L, Louie S G 2006 Nature 444 347

Google Scholar

Google Scholar

[23] Niu L L, Fu H Y, Suo Y Q, Liu R, Sun F, Wang S S, Zhang G P, Wang C K, Li Z L 2021 Physica E 128 114542

Google Scholar

Google Scholar

[24] Fu H Y, Sun F, Liu R, Suo Y Q, Bi J J, Wang C K, Li Z L 2019 Phys. Lett. A 383 867

Google Scholar

Google Scholar

[25] Aftab S, Samiya M, Liao W, Iqbal M W, Ishfaq M, Ramachandraiah K, Ajmal H M S, Haque H M U, Yousuf S, Ahmed Z, khan M U, Rehman A U, Iqbal M Z 2021 J. Mater. Chem. C 9 3998

Google Scholar

Google Scholar

[26] He T, Lan C, Zhou S, Li Y, Yin Y, Li C, Liu Y 2021 J. Mater. Chem. C 9 3846

Google Scholar

Google Scholar

[27] Liu S Y, Liu S, Li D J, Dang H, Liu Y, Xue S, Xue W, Wang S 2013 Phys. Rev. B 88 115434

Google Scholar

Google Scholar

[28] Tanaka H, Kawamata Y, Simizu H, Fujita T, Yanagisawa H, Otani S, Oshima C 2005 Solid. State. Commun. 136 22

Google Scholar

Google Scholar

[29] Ding Y, Wang Y, Ni J 2009 Appl. Phys. Lett. 94 073111

Google Scholar

Google Scholar

[30] Miyamoto Y, Rubio A, Louie S G, Cohen M L 1994 Phys. Rev. B 50 18360

Google Scholar

Google Scholar

[31] Zhang Y, Wu Z F, Gao P F, Fang D Q, Zhang E H, Zhang S L 2018 RSC. Adv. 8 1686

Google Scholar

Google Scholar

[32] Senturk A E, Oktem A S, Konukman A E S 2020 Mol. Simul. 46 879

Google Scholar

Google Scholar

[33] Su Y, Cao S, Shi L B, Qian P 2020 Appl. Surf. Sci. 531 147341

Google Scholar

Google Scholar

[34] Liu G, Wu M S, Ouyang C Y, Xu B 2013 Mod. Phys. Lett. B 27 1350110

Google Scholar

Google Scholar

[35] Wu Y, Xia W, Zhang Y, Zhu W, Zhang W, Zhang P 2020 Phys. Rev. Appl. 14 014073

Google Scholar

Google Scholar

[36] Ozdemir B, Barone V 2015 Comput. Mater. Sci. 109 248

Google Scholar

Google Scholar

[37] Yang Z, Ni J 2012 Appl. Phys. Lett. 100 183109

Google Scholar

Google Scholar

[38] Yang Z, Ni J 2010 Appl. Phys. Lett. 97 253117

Google Scholar

Google Scholar

[39] Zhang H, Tang Y, Chai H, Chen W, Zhao M, Dai X 2019 Mol. Phys. 117 125

Google Scholar

Google Scholar

[40] Meng C, Zhao K, Yang M, Liang Y, Bu X 2021 Phys. E 132 114762

Google Scholar

Google Scholar

[41] Qie Y, Liu J, Wang S, Gong S, Sun Q 2018 Carbon 129 38

Google Scholar

Google Scholar

[42] Zhao J, Cheng N, He Y 2019 Phys. Chem. Chem. Phys. 21 19567

Google Scholar

Google Scholar

[43] Zhang C, Jiao Y, He T, Bottle S, Frauenheim T, Du A 2018 J. Phys. Chem. Lett. 9 858

Google Scholar

Google Scholar

[44] Zhao P, Wan Y, Zhang S, Gao A, Guo P, Jiang Z, Zheng J 2020 Phys. Status. Solidi. RRL 14 2000012

Google Scholar

Google Scholar

[45] Dutta S, Wakabayashi K 2013 J. Mater. Chem. C. Mater. 1 4854

Google Scholar

Google Scholar

[46] Brandbyge M, Mozos J L, Ordejon P, Taylor J, Stokbro K 2002 Phys. Rev. B 65 165401

Google Scholar

Google Scholar

[47] Taylor J, Guo H, Wang J 2001 Phys. Rev. B 63 245407

Google Scholar

Google Scholar

[48] Hu J K, Tan J X, Wu D, Zhang Z H, Fan Z Q 2021 Appl. Surf. Sci. 560 149858

Google Scholar

Google Scholar

[49] 徐永虎, 邓小清, 孙琳, 范志强, 张振华 2022 71 046102

Google Scholar

Google Scholar

Xu Y H, Deng X Q, Sun L, Fan Z Q, Zhang Z H 2022 Acta. Phys. Sin. 71 046102

Google Scholar

Google Scholar

[50] 汤家鑫, 范志强, 邓小清, 张振华 2022 71 116101

Google Scholar

Google Scholar

Tang J X, Fan Z Q, Deng X Q, Zhang Z H 2022 Acta. Phys. Sin. 71 116101

Google Scholar

Google Scholar

[51] He X, Deng X Q, Sun L, Zhang Z H, Fan Z Q 2022 Appl. Surf. Sci. 578 151844

Google Scholar

Google Scholar

[52] Chen H L, Han J N, Deng X Q, Fan Z Q, Sun L, Zhang Z H 2022 Appl. Surf. Sci. 598 153756

Google Scholar

Google Scholar

[53] Chen H L, Zhang L, Deng, X Q, Sun L, Zhang Z H , Fan Z Q 2021 J. Mater. Chem. C 9 12904

[54] Hwang E, Sarma S D 2008 Phys. Rev. B 77 115449

Google Scholar

Google Scholar

[55] Bardeen J, Shockley W. 1950 Phys. Rev. 80 72

Google Scholar

Google Scholar

[56] Hu R, Li Y H, Zhang Z H, Fan Z Q, Sun L 2019 J. Mater. Chem. C 7 7745

Google Scholar

Google Scholar

[57] Dong Q X, Hu R, Fan Z Q, Zhang Z H 2018 Carbon 130 206

Google Scholar

Google Scholar

[58] Han J N, He X, Fan Z Q, Zhang Z H 2019 Phys. Chem. Chem. Phys. 21 1830

Google Scholar

Google Scholar

计量

- 文章访问数: 7500

- PDF下载量: 113

- 被引次数: 0

下载:

下载: