-

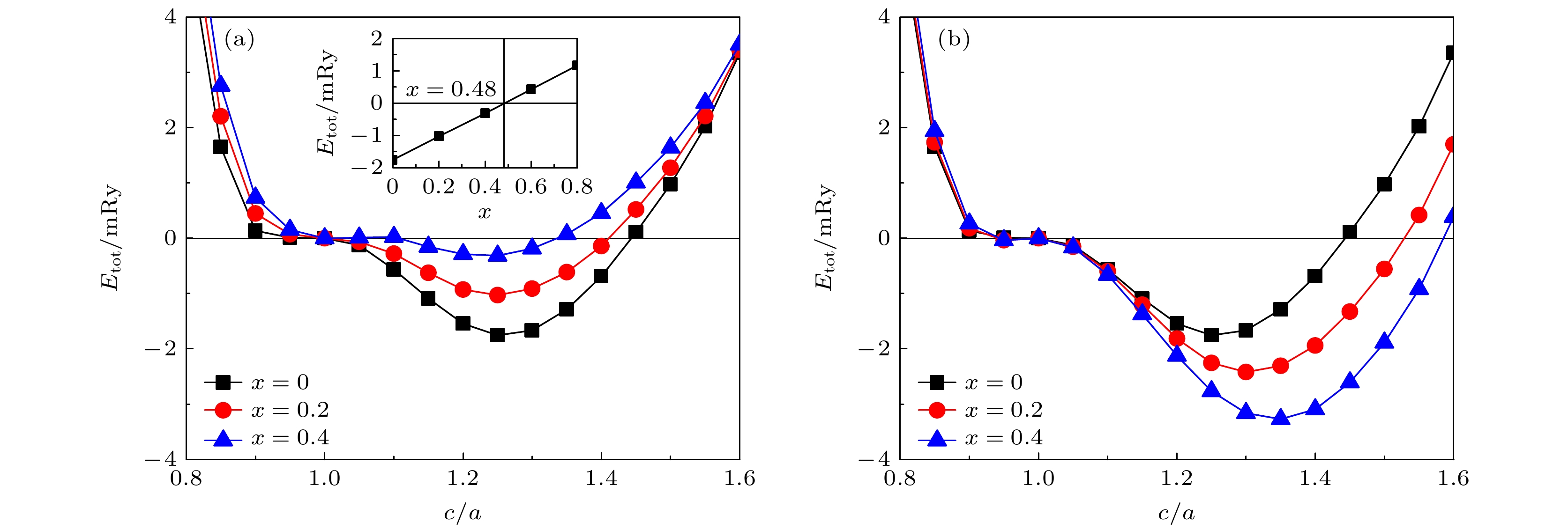

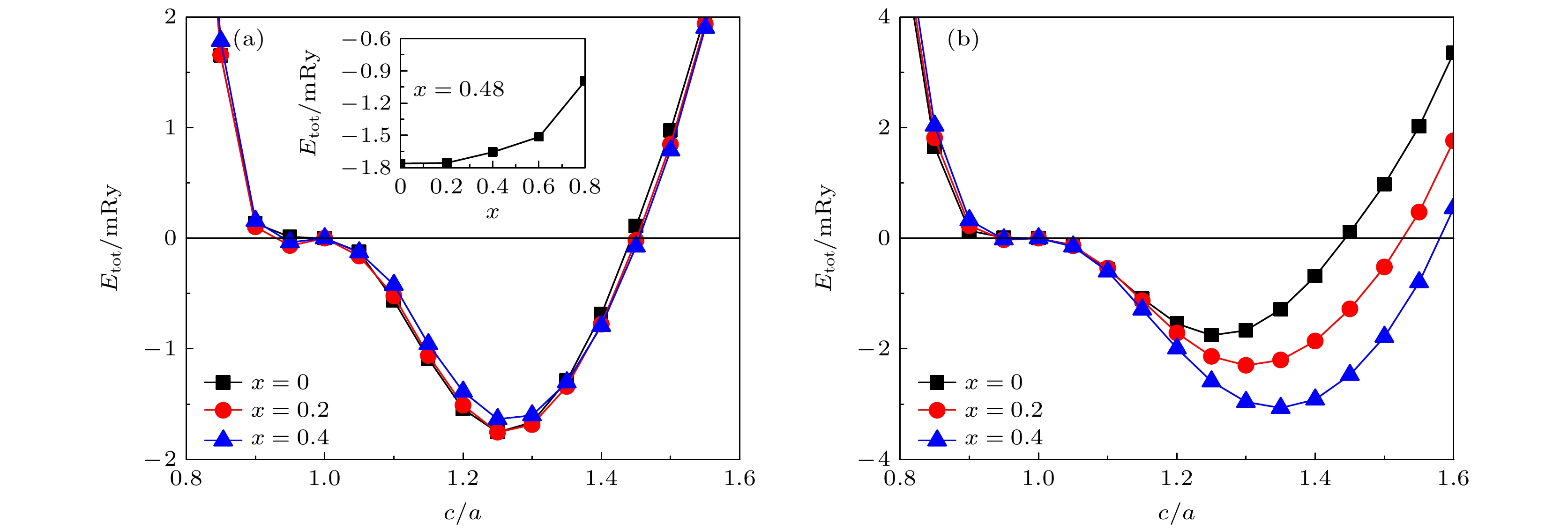

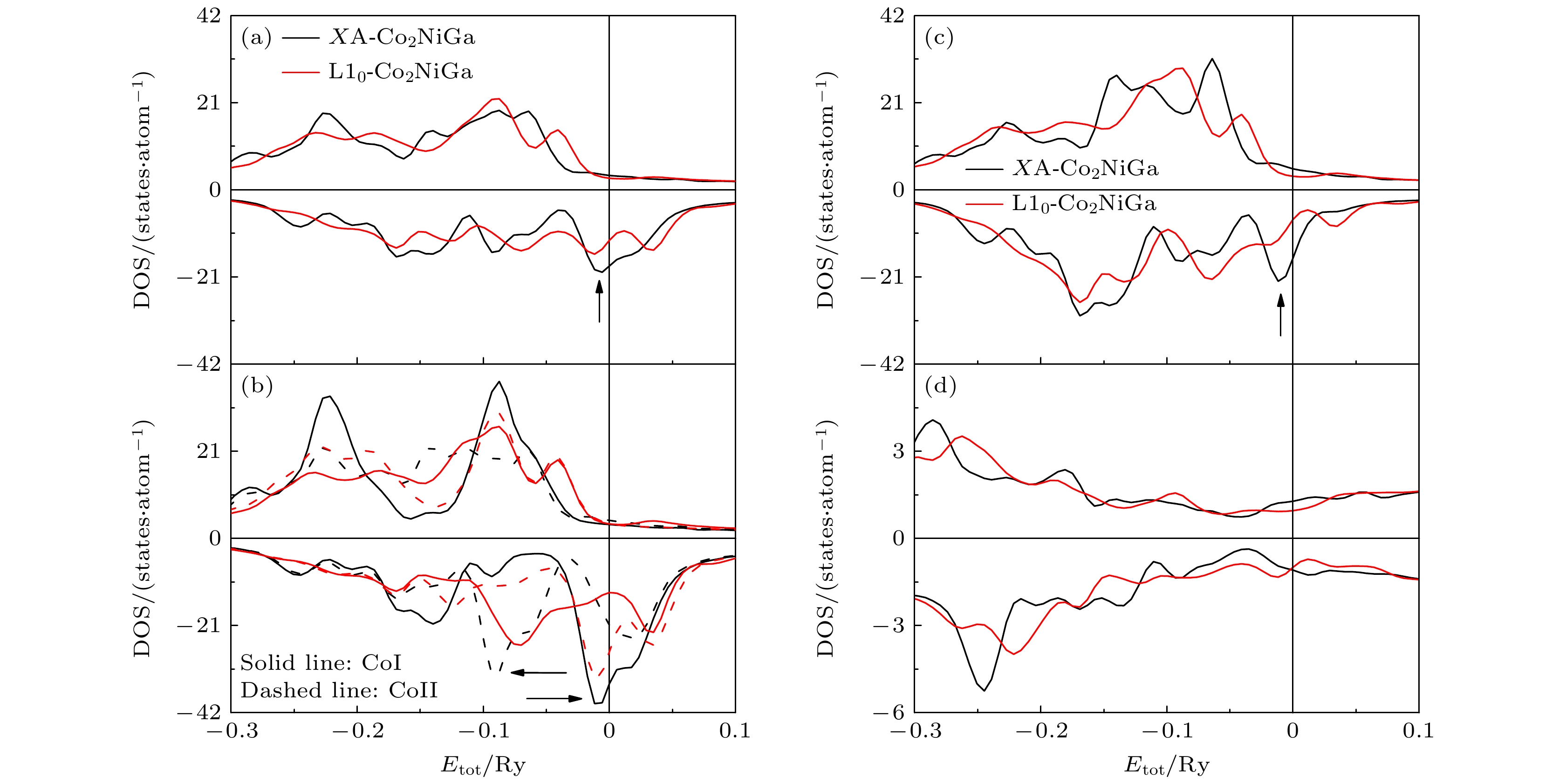

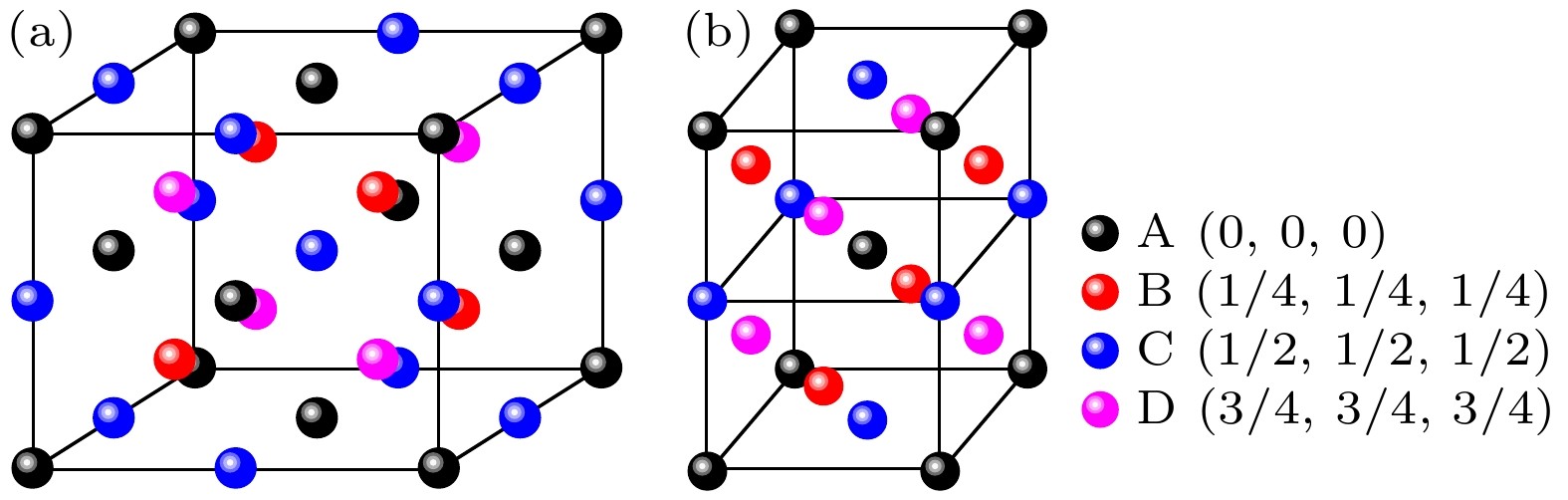

采用精确的Muffin-Tin轨道结合相干势近似方法, 系统计算研究了0 K下Co和Ni过量对Co2+xNi1–xGa, Co2+xNiGa1–x, Co2–xNi1+xGa和Co2Ni1+xGa1–x (0 ≤ x ≤ 0.4)合金晶体结构及原子占位、马氏体相变、磁矩和弹性常数的影响规律及其物理机理. 研究结果表明: 绝大多数合金奥氏体相均具有XA稳定结构, 且过量Co和Ni原子均占据在不足原子位置, 仅当Ni取代Ga时其处于反常占位; 随x的增加, 仅有两组Ga不足合金的L10相对于XA的电子总能逐渐降低, 前者四方剪切弹性常数逐渐增加, 而后者其则逐渐减小, 在能量和力学上Co和Ni取代Ga均促进了马氏体相变的发生, 并有望提高马氏体相变温度; 各合金XA和L10相总磁矩(μtot)主要源于Co原子的贡献, Ni原子仅贡献较小部分, 且两相μtot在四组合金中随x变化关系相同, 在同一组分下, 它们相差不超过约0.32 μB; 电子结构计算分析表明, 相对于XA相而言, L10-Co2NiGa合金的稳定性主要源于Co和Ni原子在费米能级附近自旋向下的电子态密度分布, 即归结于Jahn-Teller效应. 上述结果有望为实验上Co2NiGa基三元合金结构与性能的优化设计提供理论参考.Using the first-principles exact muffin-tin orbital method combined with the coherent potential approximation, the crystal structure and site occupation, martensitic transformation, magnetic moment and elastic constant for each of Co2+xNi1–xGa, Co2+xNiGa1–x, Co2–xNi1+xGa and Co2Ni1+xGa1–x (0 ≤ x ≤ 0.4) alloys with Co and Ni excess at 0 K are systematically investigated. It is shown that most of the austenitic phases of the alloys have XA stable structure, and the excess Co and Ni atoms occupy the insufficient atomic positions, and it is inversely occupied only when Ni replaces Ga. With the increase of x, the total electron energy of L10 relative to XA of only two Ga-insufficient alloys gradually decreases, for the former, the tetragonal shear elastic constant gradually increases, but for the latter, it gradually decreases. It is indicated that the martensitic transformation is promoted by the substitution of both Co and Ni for Ga in the energy and mechanics, and the martensitic transformation temperature is expected to increase. The values of total magnetic moment (μtot) of the XA phase and L10 phase of each alloy are mainly contributed by Co atoms, but onlya relatively small portion by Ni atoms. And the values of μtot of two phases in the four alloys have the same relationship with x, and the difference between them with the same compositions is not more than about 0.32 μB . The analyses of electronic structure calculations show that the distributions of spin-down electronic density of states of Co and Ni atoms near the Fermi energy level have contributed significantly to the stability of L10 relative to the XA phase, which is attributed to the Jahn-Teller effect. The above results are expected to provide a theoretical reference for the optimal design of the structure and properties of Co2NiGa-based ternary alloys.

-

Keywords:

- first principles calculations /

- site occupation /

- phase stability /

- Co2NiGa alloy

[1] Heusler F 1903 Verh. Dtsch. Phys. Ges. 5 219

[2] Wuttig M, Li J, Craciunescu C 2001 Scr. Mater. 44 2393

Google Scholar

Google Scholar

[3] Ahmad A, Guchhait S, Ahmad H, Srivastava S K, Das A K 2019 International Conference on Advances in Basic Sciences Bahal, India, February 07–09, 2019 p090006

[4] XU X, Nagasako M, Ito W, Umetsu R Y, Kanomata T, Kainuma R 2013 Acta Mater. 61 6712

Google Scholar

Google Scholar

[5] 杜音, 王文洪, 张小明, 刘恩克, 吴光恒 2012 61 147304

Google Scholar

Google Scholar

Du Y, Wang W H, Zhang X M, Liu E K, Wu G H 2012 Acta Phys. Sin. 61 147304

Google Scholar

Google Scholar

[6] Kierstead H A, Dunlap B D, Malik S K, Umarji A M, Shenoy G K 1985 Phys. Rev. B 32 135

Google Scholar

Google Scholar

[7] Terada M, Fujita Y, Endo K 1974 J. Phys. Soc. Jpn. 36 620

Google Scholar

Google Scholar

[8] Li Y, Xin Y, Chai L, Ma Y Q, Xu H B 2010 Acta Mater. 58 3655

Google Scholar

Google Scholar

[9] Guezlane M, Baaziz H, Hassan F E H, Charifi C, Djaballah Y 2016 J. Magn. Magn. Mater. 414 219

Google Scholar

Google Scholar

[10] Planes A, Mañosa L, Acet M 2009 J. Phys. :Condens. Matter 21 233201

Google Scholar

Google Scholar

[11] Chabungbam S, Borgohain P, Ghosh S, Singh N, Sahariah M B 2016 J. Alloys Compd. 689 199

Google Scholar

Google Scholar

[12] Shreder E I, Lukoyanov A V, Makhnev A A, Baglasov E D, Suresh K G 2019 Phys. Met. Metall. 120 729

Google Scholar

Google Scholar

[13] Sokolovskiy V, Miroshkina O N, Sanosyan A, Baigutlin D, Buchelnikov V, Gruner M E 2022 J. Magn. Magn. Mater. 546 168728

Google Scholar

Google Scholar

[14] Pereira M J, Santos T, Correia R, Amaral J S, Amaral V S, Fabbrici S, Albertini F 2021 J. Magn. Magn. Mater. 538 168283

Google Scholar

Google Scholar

[15] Yan S M, Pu J, Chi B, Li J 2011 Chin. Sci. Bull. 56 796

Google Scholar

Google Scholar

[16] Craciunescu C, Kishi Y, Lograsso T A, Wuttig M 2002 Scr. Mater. 47 285

Google Scholar

Google Scholar

[17] Biswas C, Rawat R, Barman S R 2005 Appl. Phys. Lett. 86 202508

Google Scholar

Google Scholar

[18] Li C M, Yang S J, Zhou J P 2022 Chin. Phys. B 31 056105

Google Scholar

Google Scholar

[19] Siewert M, Gruner M E, Hucht A, Herper H C, Dannenberg A, Chakrabarti A, Singh N, Arróyave R, Entel P 2012 Adv. Eng. Mater. 14 530

Google Scholar

Google Scholar

[20] Opeil C P, Mihaila B, Schulze R K, Mañosa L, Planes A, Hults W L, Fisher R A, Riseborough P S, Littlewood P B, Smith J L, Lashley J C 2008 Phys. Rev. Lett. 100 165703

Google Scholar

Google Scholar

[21] Roy T, Pandey D, Chakrabarti A 2016 Phys. Rev. B 93 184102

Google Scholar

Google Scholar

[22] Vitos L, Abrilsosv I A, Johansson B 2001 Phys. Rev. Lett. 87 156401

Google Scholar

Google Scholar

[23] Gyorff B L 1972 Phys. Rev. B 5 2382

Google Scholar

Google Scholar

[24] Bain E C 1924 Trans. Am. Inst. Min. Metall. Eng. 70 25

[25] Cao P Y, Tian F Y, Li W, Vitos L, Wang Y D 2021 Acta Mater. 210 116816

Google Scholar

Google Scholar

[26] Vitos L 2007 Computational Quantum Mechanics for Materials Engineers (London: Spring-Verlag) pp98–121

[27] Li C M, Zhang Y, Feng W J, Huang R Z, Gao M 2020 Phys. Rev. B 101 054106

Google Scholar

Google Scholar

[28] 胡岩菲 2020 硕士学位论文 (沈阳: 沈阳师范大学)

Hu Y F 2020 M. S. Thesis (Shenyang: Shangyang Normal University) (in Chinese)

[29] 杨顺杰, 李春梅, 周金萍 2022 71 106201

Google Scholar

Google Scholar

Yang S J, Li C M, Zhou J P 2022 Acta Phys. Sin. 71 106201

Google Scholar

Google Scholar

[30] Perdew J P, Burke K, Emzerhof M 1996 Phys. Rev. Lett. 77 3865

Google Scholar

Google Scholar

[31] Entel P, Dannenberg A, Siewert M, Herper H C, Gruner M E, Buchelnikov V D, Chernenko V A 2011 Materials Science Forum (Switzerland: Trans Tech Publications) p1

[32] Siewert M, Gruner M E, Dannenberg A, Hucht A, Shapiro S M, Xu G, Schlagel D L, Lograsso T A, Entel P 2010 Phys. Rev. B 82 064420

Google Scholar

Google Scholar

[33] Eleno L T F, Chivukula A, Arróyave R, Schön C G 2010 TOFA 2010-Discusion Meeting on Thermodynamics of Alloys Porto, Portugual, September 14, 2010

[34] Olivos E, Miranda A L, Singh N, Arróyave R, Romero A H 2012 Ann. Phys. 524 212

Google Scholar

Google Scholar

[35] Arróyave R, Junkaew A, Chivukula A, Bajaj S, Yao C Y, Garay A 2010 Acta Mater. 58 5220

Google Scholar

Google Scholar

[36] Li Q S, Liang Z Y, Sun K C, Luo H Z 2019 Comput. Mater. Sci. 168 11

Google Scholar

Google Scholar

[37] Matsushita Y I, Madjarova G, Dewhurst J K, Shallcross S, Felser C, Sharma S, Gross E K U 2017 J. Phys. D:Appl. Phys. 50 095002

Google Scholar

Google Scholar

[38] Talapatra A, Arróyave R, Entel P, Valencia-Jaime I, Romero A H 2015 Phys. Rev. B 92 054107

Google Scholar

Google Scholar

[39] Bai J, Liu D, Huang R K, Zhang Z Y, Yang Y, Gu J L, Yan H L, Zhao X, Zuo L 2020 Mater. Today Commun. 22 100810

Google Scholar

Google Scholar

[40] Wang Y, Perdew J P 1991 Phys. Rev. B 44 13298

Google Scholar

Google Scholar

[41] Ghosh S, Ghosh S 2019 Phys. Rev. B 99 064112

Google Scholar

Google Scholar

[42] Shi X Y, Gao R R, Li J Q, Lu T Y, Luo H Z 2022 J. Magn. Magn. Mater. 547 168815

Google Scholar

Google Scholar

[43] Singh N, Dogan E, Karaman I, Arróyave R 2011 Phys. Rev. B 84 184201

Google Scholar

Google Scholar

-

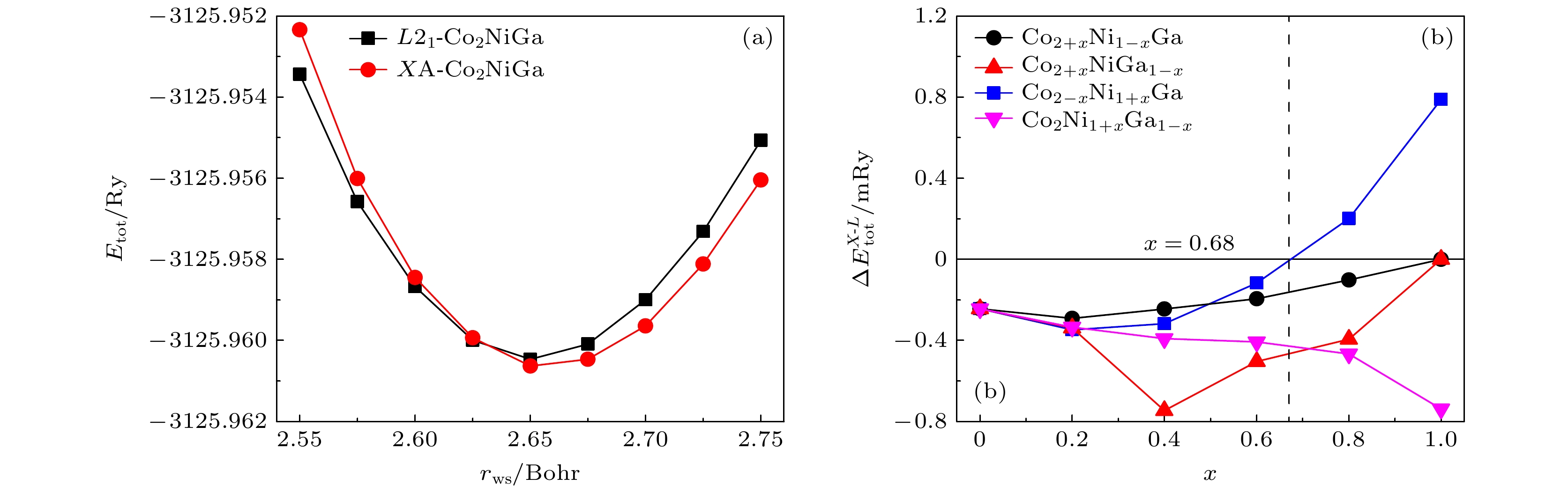

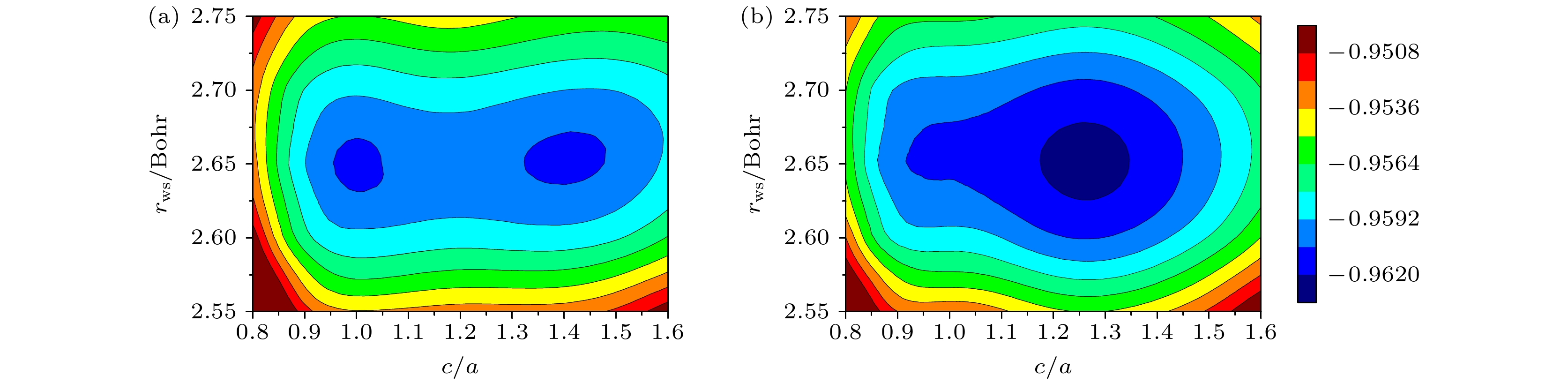

图 2 L21-和XA-Co2NiGa合金Etot随rws的变化关系, 及四组非化学计量比合金平衡体积下

$\Delta E_{{\text{tot}}}^{X\text-L} \text{-} x$ 关系 (a) Etot; (b)$\Delta E_{{\text{tot}}}^{X\text-L}$ Fig. 2. Etot of L21- and XA-Co2NiGa alloys change with respect to rws, together with the trends of

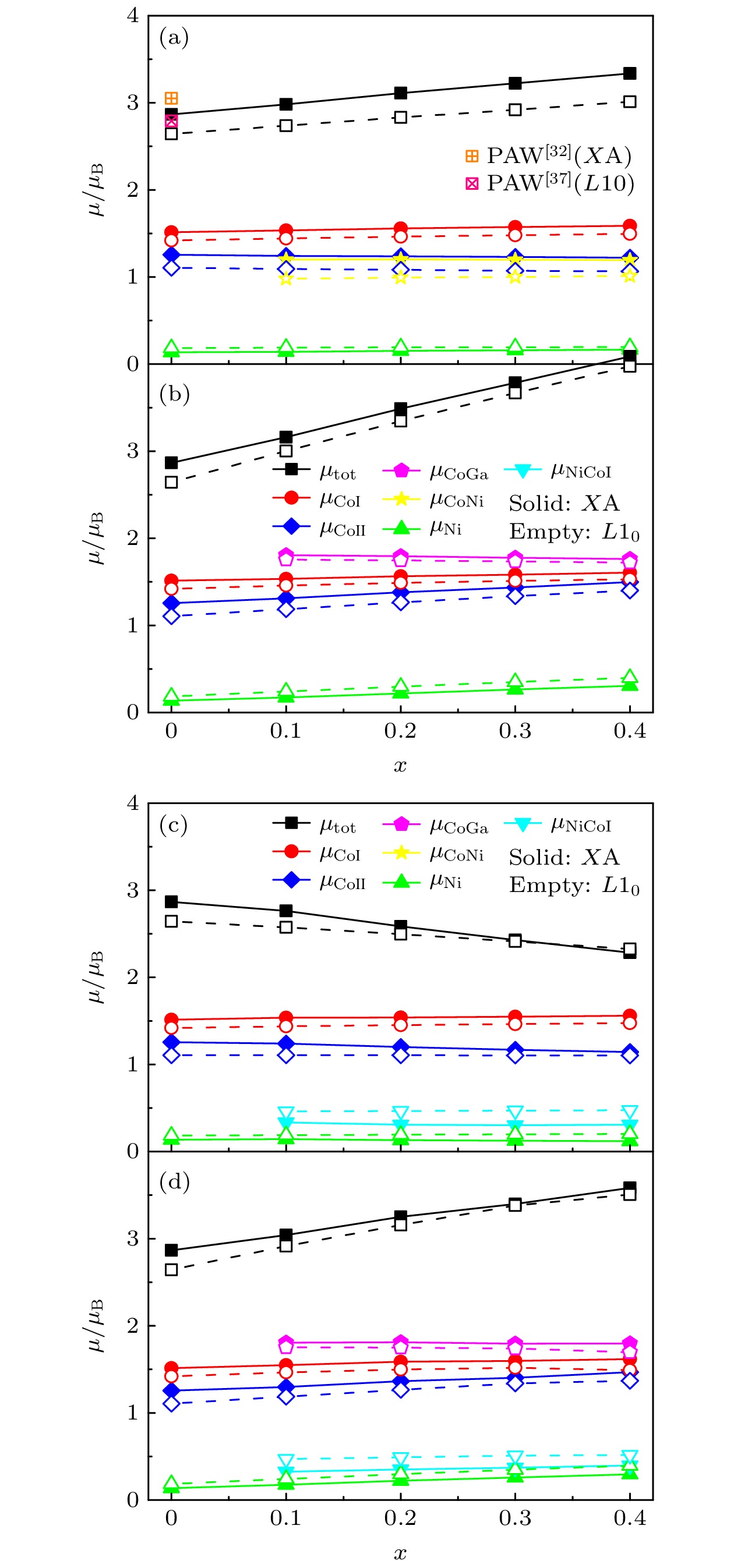

$\Delta E_{{\text{tot}}}^{X{\text{-}}L} \text{-} x$ of the four off-stoichiometric alloys at equilibrium volume: (a) Etot; (b)$\Delta E_{{\text{tot}}}^{X\text-L}$ .图 6 四组非化学计量比合金两相各原子的磁矩以及μtot随x的变化关系 (a) Co2+xNi1–xGa; (b) Co2+xNiGa1–x; (c) Co2–xNi1+xGa; (d) Co2Ni1+xGa1–x

Fig. 6. x-dependence of the magnetic moments for each atom in both phases and the μtot of the four off-stoichiometric alloys: (a) Co2+xNi1–xGa; (b) Co2+xNiGa1–x; (c) Co2–xNi1+xGa; (d) Co2Ni1+xGa1–x.

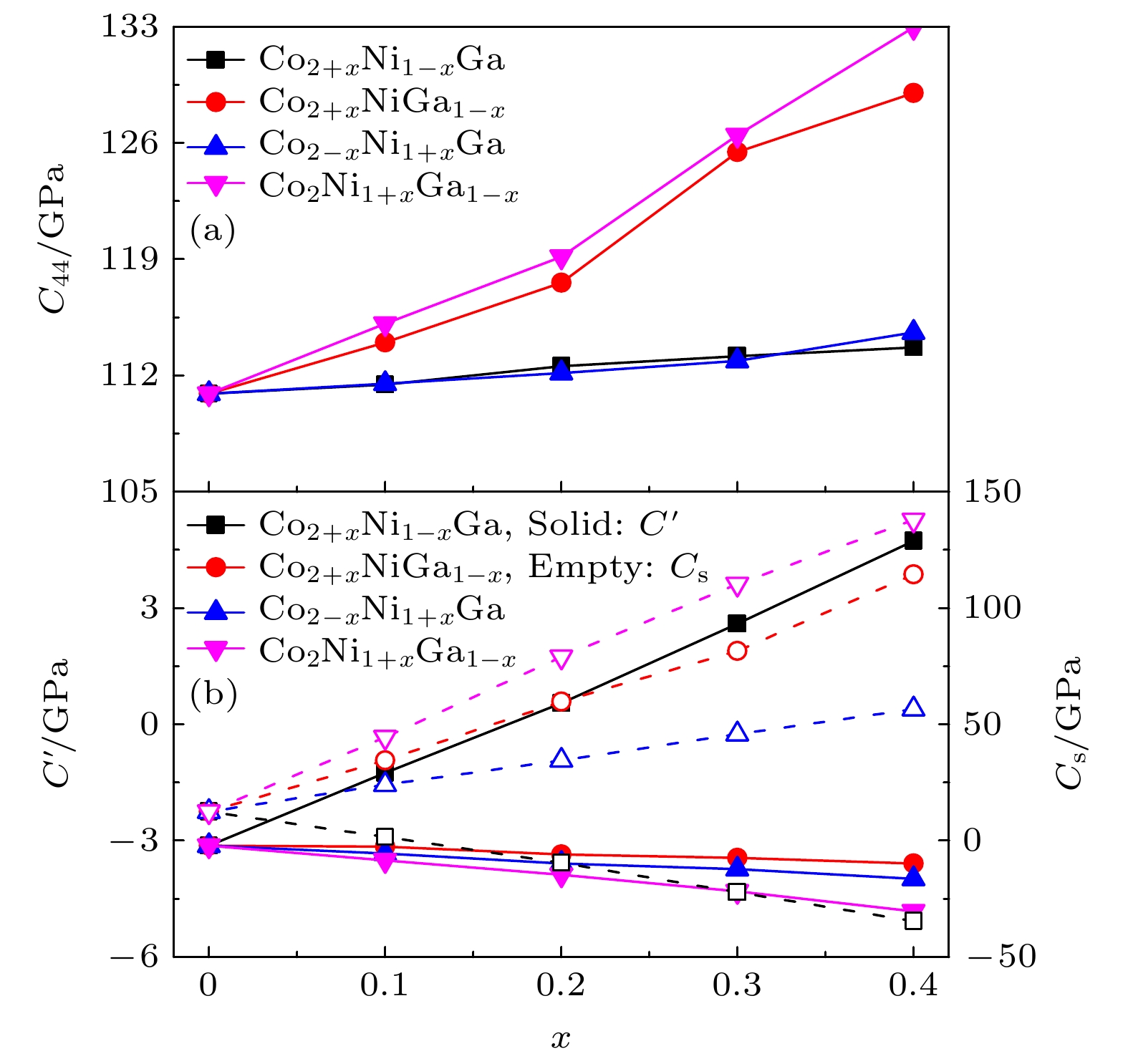

图 7 XA-Co2+xNi1–xGa, Co2+xNiGa1–x, Co2–xNi1+xGa和Co2Ni1+xGa1–x (0 ≤ x ≤ 0.4)合金的C44和C′以及四组合金L10相的Cs随x的变化关系 (a) C44; (b) C' and Cs

Fig. 7. x-dependence of both C44 and C' of the XA-Co2+xNi1–xGa, Co2+xNiGa1–x, Co2–xNi1+xGa and Co2Ni1+xGa1–x (0 ≤ x ≤ 0.4) alloys and Cs of the four alloys with L10 phase: (a) C44; (b) C' and Cs.

表 1 XA-Co2.2Ni0.8Ga, Co2.2NiGa0.8, Co1.8Ni1.2Ga和Co2Ni1.2Ga0.8合金在铁磁和非自旋极化下各原子占位的∆Etot和

$ \Delta {E'_{{\text{tot}}}} $ , 及它们在铁磁状态下的体积和μtot的理论值Table 1. ∆Etot and

$ \Delta {E'_{{\text{tot}}}} $ for respective site occupations of the ferromagnetic and non-spin-polarized XA-Co2.2Ni0.8Ga, Co2.2NiGa0.8, Co1.8Ni1.2Ga and Co2Ni1.2Ga0.8 alloys, together with their theoretical values of the volume and μtot in the ferromagnetic state.Alloys Site occupancy ∆Etot/mRy $ \Delta {E'_{{\text{tot}}}} $/mRy V/(Å3·atom–1) μtot/μB Co2.2Ni0.8Ga Co2(Ni0.8Co0.2)Ga 0 0 11.706 3.064 Co2(Ni0.8Ga0.2)(Ga0.8Co0.2) 5.395 5.568 11.801 3.356 Co2.2NiGa0.8 Co2Ni(Ga0.8Co0.2) 0 0 11.630 3.488 Co2(Ni0.8Co0.2)(Ga0.8Ni0.2) 0.688 0.211 11.624 3.402 Co1.8Ni1.2Ga (Co0.8Ni0.2)CoNiGa 0 0 11.700 2.539 Co(Co0.8Ni0.2)NiGa 0.317 0.681 11.710 2.559 (Co0.8Ga0.2)CoNi(Ga0.8Ni0.2) 2.441 1.953 11.748 2.569 Co(Co0.8Ga0.2)Ni(Ga0.8Ni0.2) 5.791 5.798 11.855 2.798 Co2Ni1.2Ga0.8 Co2Ni(Ga0.8Ni0.2) 0 0 11.607 3.167 (Co0.8Ni0.2)CoNi(Ga0.8Co0.2) –1.023 –0.617 11.648 3.253 Co(Co0.8Ni0.2)Ni(Ga0.8Co0.2) –0.717 –0.153 11.615 3.255 表 2 XA-Co2+xNi1–xGa, Co2+xNiGa1–x, Co2–xNi1+xGa和Co2Ni1+xGa1–x (0 ≤ x ≤ 0.4)合金的e/a、体积和电子密度, 以及L10相对应的体积和c/a的EMTO计算结果

Table 2. The e/a, volume and electron density of the XA-Co2+xNi1–xGa, Co2+xNiGa1–x, Co2–xNi1+xGa and Co2Ni1+xGa1–x (0 ≤ x ≤ 0.4) alloys, and the corresponding volume and c/a of L10 by EMTO calculations.

Alloys e/a XA L10 V/Å3 n/Å–3 V/Å3 c/a Co2NiGa 7.0 11.706 0.598 11.629 1.260 11.650[32] 0.601[32] 11.550[32] — Co2.1Ni0.9Ga 6.9 11.709 0.590 11.630 1.254 Co2.2Ni0.8Ga 6.8 11.706 0.581 11.630 1.248 Co2.3Ni0.7Ga 6.7 11.700 0.573 11.628 1.242 Co2.4Ni0.6Ga 6.6 11.694 0.564 11.627 1.236 Co2.1NiGa0.9 7.6 11.661 0.652 11.579 1.282 Co2.2NiGa0.8 8.2 11.630 0.705 11.525 1.305 Co2.3NiGa0.7 8.8 11.494 0.766 11.466 1.326 Co2.4NiGa0.6 9.4 11.458 0.820 11.405 1.344 Co1.9Ni1.1Ga 7.1 11.710 0.606 11.634 1.260 Co1.8Ni1.2Ga 7.2 11.700 0.615 11.635 1.263 Co1.7Ni1.3Ga 7.3 11.698 0.624 11.636 1.266 Co1.6Ni1.4Ga 7.4 11.691 0.633 11.637 1.269 Co2Ni1.1Ga0.9 7.7 11.660 0.660 11.580 1.284 Co2Ni1.2Ga0.8 8.4 11.648 0.721 11.525 1.306 Co2Ni1.3Ga0.7 9.1 11.445 0.795 11.467 1.327 Co2Ni1.4Ga0.6 9.8 11.439 0.857 11.405 1.346 表 3 L21-和XA-Co2NiGa合金的单晶弹性常数(C11, C12, C44和C' = (C11 – C12)/2)、多晶剪切弹性模量G和杨氏模量E的EMTO计算结果与理论参考值的对比

Table 3. Single crystal elastic constants (C11, C12, C44 and C' = (C11 – C12)/2), polycrystalline shear elastic modulus G and Young’s modulus E of the L21- and XA-Co2NiGa alloys calculated by EMTO are in comparison with the theoretical reference values.

-

[1] Heusler F 1903 Verh. Dtsch. Phys. Ges. 5 219

[2] Wuttig M, Li J, Craciunescu C 2001 Scr. Mater. 44 2393

Google Scholar

Google Scholar

[3] Ahmad A, Guchhait S, Ahmad H, Srivastava S K, Das A K 2019 International Conference on Advances in Basic Sciences Bahal, India, February 07–09, 2019 p090006

[4] XU X, Nagasako M, Ito W, Umetsu R Y, Kanomata T, Kainuma R 2013 Acta Mater. 61 6712

Google Scholar

Google Scholar

[5] 杜音, 王文洪, 张小明, 刘恩克, 吴光恒 2012 61 147304

Google Scholar

Google Scholar

Du Y, Wang W H, Zhang X M, Liu E K, Wu G H 2012 Acta Phys. Sin. 61 147304

Google Scholar

Google Scholar

[6] Kierstead H A, Dunlap B D, Malik S K, Umarji A M, Shenoy G K 1985 Phys. Rev. B 32 135

Google Scholar

Google Scholar

[7] Terada M, Fujita Y, Endo K 1974 J. Phys. Soc. Jpn. 36 620

Google Scholar

Google Scholar

[8] Li Y, Xin Y, Chai L, Ma Y Q, Xu H B 2010 Acta Mater. 58 3655

Google Scholar

Google Scholar

[9] Guezlane M, Baaziz H, Hassan F E H, Charifi C, Djaballah Y 2016 J. Magn. Magn. Mater. 414 219

Google Scholar

Google Scholar

[10] Planes A, Mañosa L, Acet M 2009 J. Phys. :Condens. Matter 21 233201

Google Scholar

Google Scholar

[11] Chabungbam S, Borgohain P, Ghosh S, Singh N, Sahariah M B 2016 J. Alloys Compd. 689 199

Google Scholar

Google Scholar

[12] Shreder E I, Lukoyanov A V, Makhnev A A, Baglasov E D, Suresh K G 2019 Phys. Met. Metall. 120 729

Google Scholar

Google Scholar

[13] Sokolovskiy V, Miroshkina O N, Sanosyan A, Baigutlin D, Buchelnikov V, Gruner M E 2022 J. Magn. Magn. Mater. 546 168728

Google Scholar

Google Scholar

[14] Pereira M J, Santos T, Correia R, Amaral J S, Amaral V S, Fabbrici S, Albertini F 2021 J. Magn. Magn. Mater. 538 168283

Google Scholar

Google Scholar

[15] Yan S M, Pu J, Chi B, Li J 2011 Chin. Sci. Bull. 56 796

Google Scholar

Google Scholar

[16] Craciunescu C, Kishi Y, Lograsso T A, Wuttig M 2002 Scr. Mater. 47 285

Google Scholar

Google Scholar

[17] Biswas C, Rawat R, Barman S R 2005 Appl. Phys. Lett. 86 202508

Google Scholar

Google Scholar

[18] Li C M, Yang S J, Zhou J P 2022 Chin. Phys. B 31 056105

Google Scholar

Google Scholar

[19] Siewert M, Gruner M E, Hucht A, Herper H C, Dannenberg A, Chakrabarti A, Singh N, Arróyave R, Entel P 2012 Adv. Eng. Mater. 14 530

Google Scholar

Google Scholar

[20] Opeil C P, Mihaila B, Schulze R K, Mañosa L, Planes A, Hults W L, Fisher R A, Riseborough P S, Littlewood P B, Smith J L, Lashley J C 2008 Phys. Rev. Lett. 100 165703

Google Scholar

Google Scholar

[21] Roy T, Pandey D, Chakrabarti A 2016 Phys. Rev. B 93 184102

Google Scholar

Google Scholar

[22] Vitos L, Abrilsosv I A, Johansson B 2001 Phys. Rev. Lett. 87 156401

Google Scholar

Google Scholar

[23] Gyorff B L 1972 Phys. Rev. B 5 2382

Google Scholar

Google Scholar

[24] Bain E C 1924 Trans. Am. Inst. Min. Metall. Eng. 70 25

[25] Cao P Y, Tian F Y, Li W, Vitos L, Wang Y D 2021 Acta Mater. 210 116816

Google Scholar

Google Scholar

[26] Vitos L 2007 Computational Quantum Mechanics for Materials Engineers (London: Spring-Verlag) pp98–121

[27] Li C M, Zhang Y, Feng W J, Huang R Z, Gao M 2020 Phys. Rev. B 101 054106

Google Scholar

Google Scholar

[28] 胡岩菲 2020 硕士学位论文 (沈阳: 沈阳师范大学)

Hu Y F 2020 M. S. Thesis (Shenyang: Shangyang Normal University) (in Chinese)

[29] 杨顺杰, 李春梅, 周金萍 2022 71 106201

Google Scholar

Google Scholar

Yang S J, Li C M, Zhou J P 2022 Acta Phys. Sin. 71 106201

Google Scholar

Google Scholar

[30] Perdew J P, Burke K, Emzerhof M 1996 Phys. Rev. Lett. 77 3865

Google Scholar

Google Scholar

[31] Entel P, Dannenberg A, Siewert M, Herper H C, Gruner M E, Buchelnikov V D, Chernenko V A 2011 Materials Science Forum (Switzerland: Trans Tech Publications) p1

[32] Siewert M, Gruner M E, Dannenberg A, Hucht A, Shapiro S M, Xu G, Schlagel D L, Lograsso T A, Entel P 2010 Phys. Rev. B 82 064420

Google Scholar

Google Scholar

[33] Eleno L T F, Chivukula A, Arróyave R, Schön C G 2010 TOFA 2010-Discusion Meeting on Thermodynamics of Alloys Porto, Portugual, September 14, 2010

[34] Olivos E, Miranda A L, Singh N, Arróyave R, Romero A H 2012 Ann. Phys. 524 212

Google Scholar

Google Scholar

[35] Arróyave R, Junkaew A, Chivukula A, Bajaj S, Yao C Y, Garay A 2010 Acta Mater. 58 5220

Google Scholar

Google Scholar

[36] Li Q S, Liang Z Y, Sun K C, Luo H Z 2019 Comput. Mater. Sci. 168 11

Google Scholar

Google Scholar

[37] Matsushita Y I, Madjarova G, Dewhurst J K, Shallcross S, Felser C, Sharma S, Gross E K U 2017 J. Phys. D:Appl. Phys. 50 095002

Google Scholar

Google Scholar

[38] Talapatra A, Arróyave R, Entel P, Valencia-Jaime I, Romero A H 2015 Phys. Rev. B 92 054107

Google Scholar

Google Scholar

[39] Bai J, Liu D, Huang R K, Zhang Z Y, Yang Y, Gu J L, Yan H L, Zhao X, Zuo L 2020 Mater. Today Commun. 22 100810

Google Scholar

Google Scholar

[40] Wang Y, Perdew J P 1991 Phys. Rev. B 44 13298

Google Scholar

Google Scholar

[41] Ghosh S, Ghosh S 2019 Phys. Rev. B 99 064112

Google Scholar

Google Scholar

[42] Shi X Y, Gao R R, Li J Q, Lu T Y, Luo H Z 2022 J. Magn. Magn. Mater. 547 168815

Google Scholar

Google Scholar

[43] Singh N, Dogan E, Karaman I, Arróyave R 2011 Phys. Rev. B 84 184201

Google Scholar

Google Scholar

计量

- 文章访问数: 4527

- PDF下载量: 115

- 被引次数: 0

下载:

下载: