-

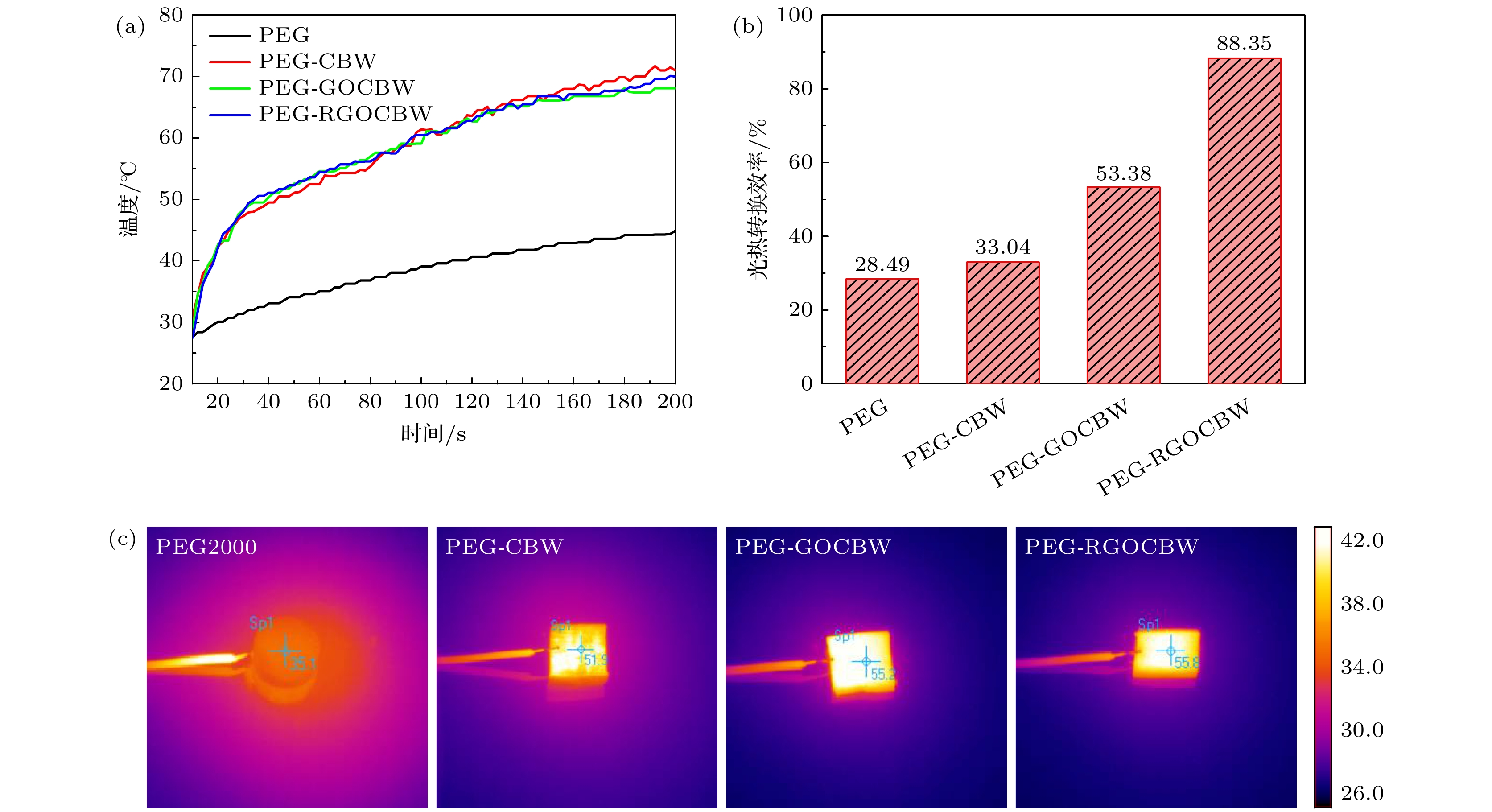

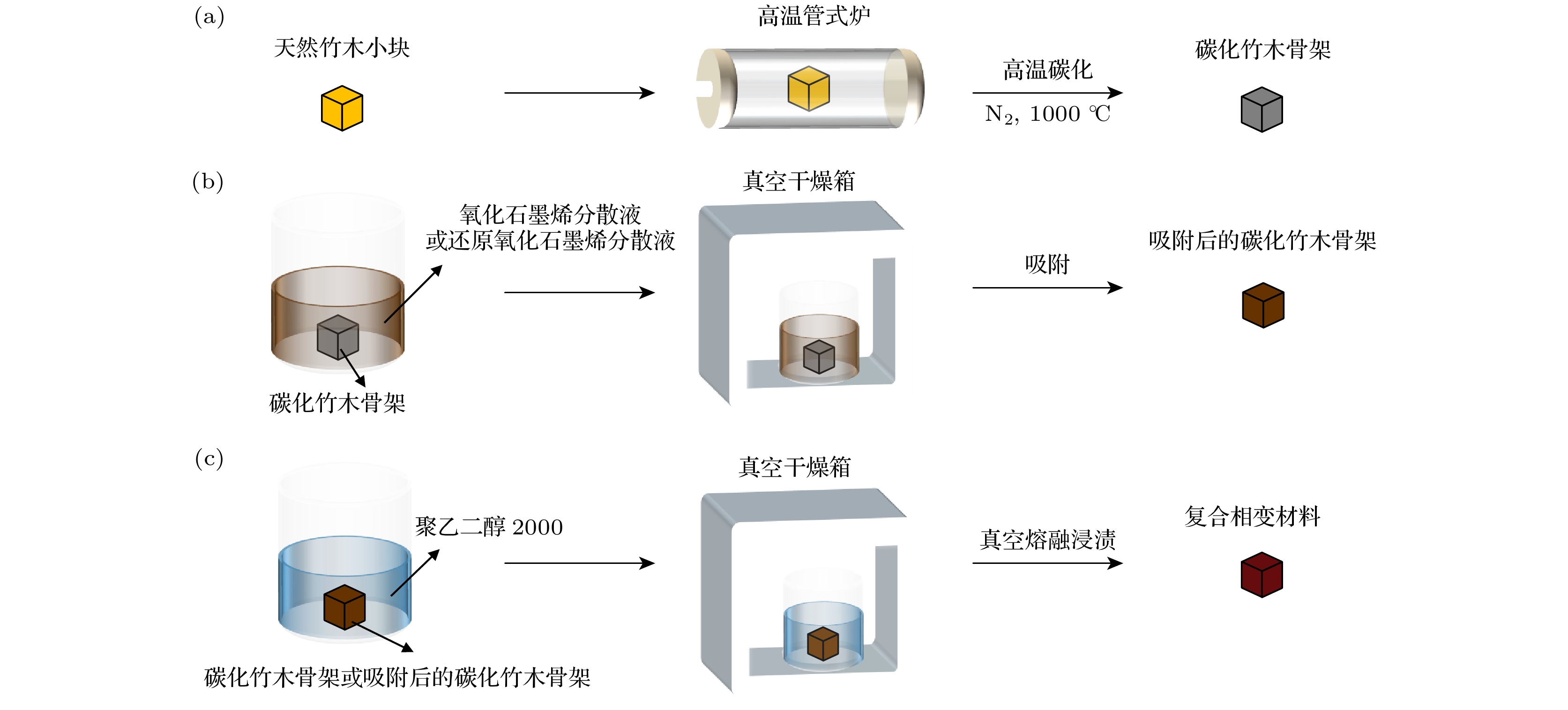

以相变芯材为核心的复合相变材料的潜热储存技术, 对解决可再生能源间歇性问题有着关键作用. 本研究以天然竹木为原材料, 使用高温碳化方法得到碳化竹木, 并使其分别吸附氧化石墨烯和还原氧化石墨烯, 最终与聚乙二醇(PEG2000)复合形成稳定的复合相变材料. 实验结果表明, 还原氧化石墨烯可以达到很好的包封率、热导率和光热转换效率提升效果. 碳化竹木/还原氧化石墨烯/聚乙二醇三元复合相变材料包封率高达81.11%, 熔化潜热为115.62 J/g, 凝固潜热为104.39 J/g, 热导率大幅提升至1.09 W/(m·K)(纯PEG2000的3.7倍), 光热转换效率大幅提高至88.35% (纯PEG2000的3.1倍).Thermal energy storage technology can shift the peak and fill the valley of heat, which lays the foundation for realizing the goal of “emission peak and carbon neutrality”. Among various thermal energy storage techniques, the latent heat storage technology based on composite phase change materials can provide large storage capacity with a small temperature variation, and shows great potential in solving the intermittency issue of renewable energy. As a sustainable and renewable material, natural wood has the advantages of a unique anisotropic three-dimensional structure, perfect natural channel, low price, and rich resources. Therefore, the carbonized wood obtained from high-temperature carbonization of natural wood is an excellent choice as a supporting skeleton of composite phase change materials. On the other hand, polyethylene glycol is widely used in energy storage because of its suitable phase transition temperature (46–65℃), high latent heat (145–175 J/g), and stable performance. In this study, carbonized bamboo is prepared at high temperatures. To improve heat storage, thermal conductivity, and photo-thermal conversion properties, the carbonized bamboo is functionalized by graphene oxide and reduced graphene oxide, respectively. Finally, polyethylene glycol is implanted into modified carbonized bamboo to form shape-stabilized phase change materials. Their microstructures, morphologies, and thermophysical properties are characterized. The experimental results show that graphene oxide and reduced graphene oxide can change the surface polarity of carbonized bamboo, thus reducing the interfacial thermal resistance between the carbonized bamboo skeleton and polyethylene glycol, and improving the encapsulation ratio, thermal conductivity, and photo-thermal conversion efficiency without affecting the crystallization behavior of polyethylene glycol. The encapsulation ratio of carbonized bamboo/reduced graphene oxide/polyethylene glycol ternary phase change material is as high as 81.11% (only 4.67% lower than the theoretical value), its latent heat of melting and solidification are 115.62 J/g and 104.39 J/g, its thermal conductivity is greatly increased to 1.09 W/(m·K) (3.7 times that of pure polyethylene glycol), accompanied by substantial growth in its photo-thermal conversion efficiency, reaching 88.35% (3.1 times that of pure polyethylene glycol). This research develops a biomass-derived porous composite phase change material with high heat storage density, high heat transfer rate, and high photo-thermal conversion ability.

-

Keywords:

- biomass carbonization /

- phase change material /

- thermal conductivity /

- photo-thermal conversion efficiency

[1] Shen F, Luo W, Dai J, Yao Y, Zhu M, Hitz E, Tang Y, ChenY, Sprenkle V L, Li X 2016 Adv. Mater. 28 1600377

[2] Qian T T, Li J 2018 Energy 142 234

Google Scholar

Google Scholar

[3] Zhang S, Wu W, Wang S 2017 Energy 130 228

Google Scholar

Google Scholar

[4] Wang C, Feng L, Li W, Zheng J, Tian W, Li X 2012 Sol. Energy Mater. Sol. Cells 105 21

Google Scholar

Google Scholar

[5] Yang H, Wang Y, Yu Q, Cao G, Yang R, Ke J, Di X, Liu, F, Zhang W, Wang C 2018 Appl. Energy 212 455

Google Scholar

Google Scholar

[6] Huang X, Alva G, Liu L, Fang G 2017 Appl. Energy 200 19

Google Scholar

Google Scholar

[7] Min X, Fang M H, Huang Z H, Liu Y G, Huang Y T, Wen R L, Qian T T, Wu X W 2015 Sci. Rep. 5 12964

Google Scholar

Google Scholar

[8] Feng L L, Zheng J, Yang H Z, Yan L 2011 Sol. Energy Mater. Sol. Cells 95 644

Google Scholar

Google Scholar

[9] Qian T T, Li J, Deng Y 2016 Sci. Rep. 6 32392

Google Scholar

Google Scholar

[10] Karaman S, Karaipekli A, Sar A, Bier A 2011 Sol. Energy Mater. Sol. Cells 95 1647

Google Scholar

Google Scholar

[11] Qi G Q, Liang C L, Bao R Y, Liu Z Y, Yang W, Xie B H, Yang M B 2014 Sol. Energy Mater. Sol. Cells 123 171

Google Scholar

Google Scholar

[12] Qian T T, Li J, Min X, Deng Y, Guan W, Ma H 2015 Energy 82 333

Google Scholar

Google Scholar

[13] Seki, Y, Ince, Seyma, Ezan M A, Turgut A, Erek A 2015 Sol. Energy Mater. Sol. Cells 140 457

Google Scholar

Google Scholar

[14] Zhang N, Yuan Y P, Wang X, Cao X L, Yang X J, Hu S C 2013 Chem. Eng. J. 231 214

Google Scholar

Google Scholar

[15] Li B, Liu T, Hu L, Wang Y, Nie S 2013 Chem. Eng. J. 215 819

[16] Zhao Y J, Min X, Huang Z H, Liu Y G, Wu X W, Fang M H 2018 Energy Build. 158 1049

Google Scholar

Google Scholar

[17] Zhang X G, Huang Z H, Yin Z Y, Zhang W Y, Huang Y T, Liu Y G, Fang M H, Wu X W, Min X 2017 Energy Build. 154 46

Google Scholar

Google Scholar

[18] Li Y Q, Samad Y A, Polychronopoulou K, Alhassan S M, Liao K 2014 J. Mater. Chem. A 2 7759

Google Scholar

Google Scholar

[19] Zhang Y, Song J W, Kierzewski, Iain, Li Y J, Gong Y H 2017 Energy Environ. Sci. 10 538

Google Scholar

Google Scholar

[20] Zhang Z T, Cao B Y 2022 Sci. China. Phys. Mech. 65 117003

Google Scholar

Google Scholar

[21] Qiang S, Jing O, Yi Z, Yang H 2017 Appl. Clay Sci. 146 14

Google Scholar

Google Scholar

[22] Zhang Y, Liu J, Su Z, Lu M, Liu S, Jiang T 2020 Constr. Build. Mater. 238 117717

Google Scholar

Google Scholar

[23] Zou T, Fu W W, Liang X L, Wang S F, Gao X N, Zhang Z G, Fang Y T, Henrik L, Mark J K 2020 Energy 190 116473

Google Scholar

Google Scholar

[24] Xie N, Li Z, Gao X, Fang Y, Zhang Z 2020 Int. J. Refrig. 110 178

Google Scholar

Google Scholar

[25] Yang J, Jia Y L, Bing N C, Wang L L, Xie H Q, Yu W 2019 Appl. Therm. Eng. 163 114412

Google Scholar

Google Scholar

[26] Zhang H, Wang L, Xi S, Xie H, Yu W 2021 Renew. Energy 175 307

Google Scholar

Google Scholar

[27] Liu Y, Yang Y, Li S 2016 J. Mater. Chem. A 10 1039

[28] Li Z, Yang W, Jiang Z, He F, Wu J 2017 Appl. Energy 197 354

Google Scholar

Google Scholar

[29] Ma X C, Liu Y J, Liu H, Zhang L, Xu B, Xiao F 2018 Sol. Energy Mater. Sol. Cells 188 73

Google Scholar

Google Scholar

[30] Feng D L, Zang Y Y, Li P, Feng Y H, Yan Y Y, Zhang X X 2021 Compos. Sci. Technol. 210 108832

Google Scholar

Google Scholar

[31] Yu Z P, Feng D L, Feng Y H, Zhang X X 2022 Compos. Part A: Appl. Sci. Manufact. 152 106703

Google Scholar

Google Scholar

[32] Yuan P, Zhang P, Liang T, Zhai S P 2019 Appl. Surf. Sci. 485 402

Google Scholar

Google Scholar

[33] Xie B, Li C, Zhang B, Yang L, Chen J 2020 Energy Built Environ. 1 187

[34] Hekimolu G, Sar A, Kar T, Kele S, Saleh T A 2021 J. Energy Storage 35 102288

Google Scholar

Google Scholar

[35] Wu S, Chen Y, Chen Z, Wang J, Cai M, Gao J 2021 Sci. Rep. 11 822

Google Scholar

Google Scholar

[36] Zhao Y J, Sun B, Du P P, Min X, Huang Z H, Liu Y G, Wu X W, Fang M H 2019 Mater. Res. Express 6 115515

Google Scholar

Google Scholar

[37] Chen Y, Cui Z, Ding H, Wan Y, Tang Z, Gao J 2018 Int. J. Mol. Sci. 19 3055

Google Scholar

Google Scholar

[38] Wan Y C, Chen Y, Cui Z X, Ding H, Gao S F, Han Z, Gao J K 2019 Sci. Rep. 9 11535

Google Scholar

Google Scholar

[39] Das D, Bordoloi U, Muigai H H, Kalita P 2020 J. Energy Storage 30 101403

Google Scholar

Google Scholar

[40] Yang H Y, Wang Y, Yu Q, Li G, Sun X, Yang R, Zhang Q, Liu F, Di X, Li J 2018 Energy 159 929

Google Scholar

Google Scholar

[41] Li C, Xie B, He Z, Chen J, Long Y 2019 Renew. Energy 140 862

Google Scholar

Google Scholar

[42] Zhang W, Zhang X, Zhang X, Yin Z, Liu Y, Fang M, Wu X, Min X, Huang Z 2019 Thermochim. Acta 674 21

Google Scholar

Google Scholar

[43] Atinafu D G, Dong W, Wang C, Wang G 2018 J. Mater. Chem. A 6 8969

Google Scholar

Google Scholar

[44] Wen R, Zhang W, Lv Z, Huang Z, Gao W 2018 Mater. Lett. 215 42

Google Scholar

Google Scholar

[45] Yang Z, Deng Y, Li J 2019 Appl. Therm. Eng. 150 967

Google Scholar

Google Scholar

-

图 6 (a) NBW, CBW, GOCBW, RGOCBW, PEG-CBW, PEG-GOCBW, PEG-RGOCBW和PEG2000的热导率; (b) 生物质复合相变材料的包封率和热导率比较

Fig. 6. (a) Thermal conductivities of NBW, CBW, GOCBW, RGOCBW, PEG-CBW, PEG-GOCBW, PEG-RGOCBW, and PEG2000; (b) comparison of encapsulation ratio and thermal conductivity of biomass composite phase change materials.

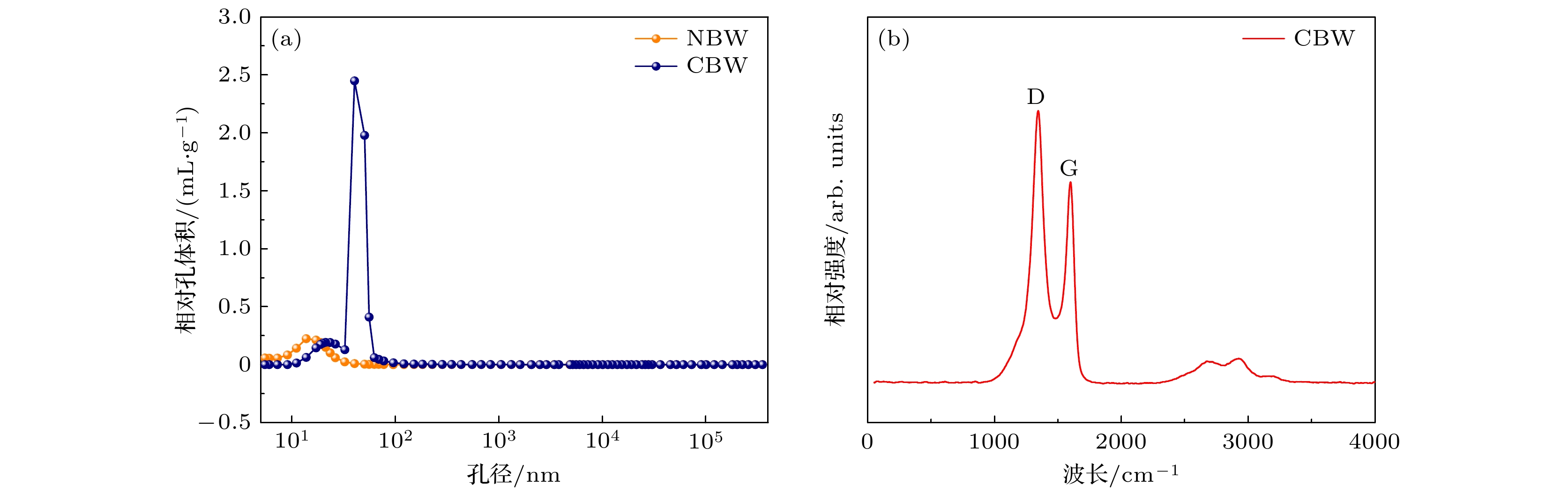

表 1 NBW和CBW的孔隙参数

Table 1. Pore parameters of NBW and CBW.

样品 孔隙率/% 平均孔径/nm 总孔容/

(cm3·g–1)总孔面积/

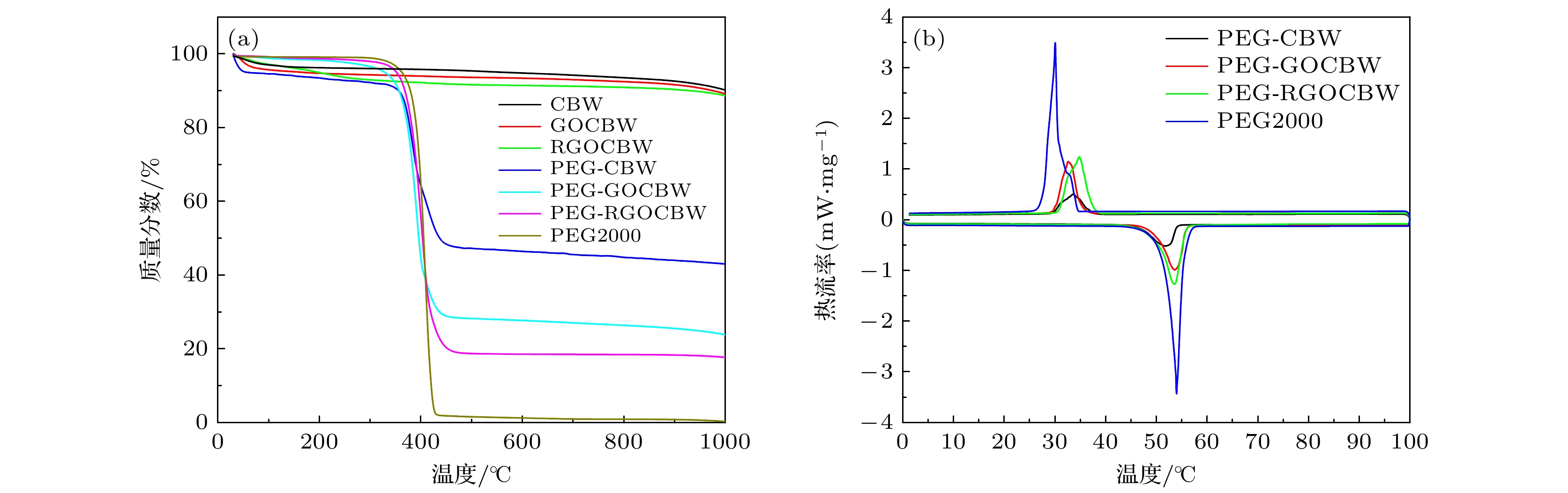

(m2·g–1)NBW 39.24 22.17 0.49 88.91 CBW 79.95 46.95 5.34 454.59 表 2 PEG-CBW, PEG-GOCBW, PEG-RGOCBW的相变参数

Table 2. Phase change parameters of PEG-CBW, PEG-GOCBW, PEG-RGOCBW.

样品 Tm/Tf ΔHm/ΔHf $ \gamma $/% PEG2000 52.47/30.86 193.00/176.60 — PEG-CBW 46.86/36.76 44.56/37.13 52.66 PEG-GOCBW 50.14/35.00 79.49/67.64 71.53 PEG-RGOCBW 50.06/37.15 115.62/104.39 81.11 -

[1] Shen F, Luo W, Dai J, Yao Y, Zhu M, Hitz E, Tang Y, ChenY, Sprenkle V L, Li X 2016 Adv. Mater. 28 1600377

[2] Qian T T, Li J 2018 Energy 142 234

Google Scholar

Google Scholar

[3] Zhang S, Wu W, Wang S 2017 Energy 130 228

Google Scholar

Google Scholar

[4] Wang C, Feng L, Li W, Zheng J, Tian W, Li X 2012 Sol. Energy Mater. Sol. Cells 105 21

Google Scholar

Google Scholar

[5] Yang H, Wang Y, Yu Q, Cao G, Yang R, Ke J, Di X, Liu, F, Zhang W, Wang C 2018 Appl. Energy 212 455

Google Scholar

Google Scholar

[6] Huang X, Alva G, Liu L, Fang G 2017 Appl. Energy 200 19

Google Scholar

Google Scholar

[7] Min X, Fang M H, Huang Z H, Liu Y G, Huang Y T, Wen R L, Qian T T, Wu X W 2015 Sci. Rep. 5 12964

Google Scholar

Google Scholar

[8] Feng L L, Zheng J, Yang H Z, Yan L 2011 Sol. Energy Mater. Sol. Cells 95 644

Google Scholar

Google Scholar

[9] Qian T T, Li J, Deng Y 2016 Sci. Rep. 6 32392

Google Scholar

Google Scholar

[10] Karaman S, Karaipekli A, Sar A, Bier A 2011 Sol. Energy Mater. Sol. Cells 95 1647

Google Scholar

Google Scholar

[11] Qi G Q, Liang C L, Bao R Y, Liu Z Y, Yang W, Xie B H, Yang M B 2014 Sol. Energy Mater. Sol. Cells 123 171

Google Scholar

Google Scholar

[12] Qian T T, Li J, Min X, Deng Y, Guan W, Ma H 2015 Energy 82 333

Google Scholar

Google Scholar

[13] Seki, Y, Ince, Seyma, Ezan M A, Turgut A, Erek A 2015 Sol. Energy Mater. Sol. Cells 140 457

Google Scholar

Google Scholar

[14] Zhang N, Yuan Y P, Wang X, Cao X L, Yang X J, Hu S C 2013 Chem. Eng. J. 231 214

Google Scholar

Google Scholar

[15] Li B, Liu T, Hu L, Wang Y, Nie S 2013 Chem. Eng. J. 215 819

[16] Zhao Y J, Min X, Huang Z H, Liu Y G, Wu X W, Fang M H 2018 Energy Build. 158 1049

Google Scholar

Google Scholar

[17] Zhang X G, Huang Z H, Yin Z Y, Zhang W Y, Huang Y T, Liu Y G, Fang M H, Wu X W, Min X 2017 Energy Build. 154 46

Google Scholar

Google Scholar

[18] Li Y Q, Samad Y A, Polychronopoulou K, Alhassan S M, Liao K 2014 J. Mater. Chem. A 2 7759

Google Scholar

Google Scholar

[19] Zhang Y, Song J W, Kierzewski, Iain, Li Y J, Gong Y H 2017 Energy Environ. Sci. 10 538

Google Scholar

Google Scholar

[20] Zhang Z T, Cao B Y 2022 Sci. China. Phys. Mech. 65 117003

Google Scholar

Google Scholar

[21] Qiang S, Jing O, Yi Z, Yang H 2017 Appl. Clay Sci. 146 14

Google Scholar

Google Scholar

[22] Zhang Y, Liu J, Su Z, Lu M, Liu S, Jiang T 2020 Constr. Build. Mater. 238 117717

Google Scholar

Google Scholar

[23] Zou T, Fu W W, Liang X L, Wang S F, Gao X N, Zhang Z G, Fang Y T, Henrik L, Mark J K 2020 Energy 190 116473

Google Scholar

Google Scholar

[24] Xie N, Li Z, Gao X, Fang Y, Zhang Z 2020 Int. J. Refrig. 110 178

Google Scholar

Google Scholar

[25] Yang J, Jia Y L, Bing N C, Wang L L, Xie H Q, Yu W 2019 Appl. Therm. Eng. 163 114412

Google Scholar

Google Scholar

[26] Zhang H, Wang L, Xi S, Xie H, Yu W 2021 Renew. Energy 175 307

Google Scholar

Google Scholar

[27] Liu Y, Yang Y, Li S 2016 J. Mater. Chem. A 10 1039

[28] Li Z, Yang W, Jiang Z, He F, Wu J 2017 Appl. Energy 197 354

Google Scholar

Google Scholar

[29] Ma X C, Liu Y J, Liu H, Zhang L, Xu B, Xiao F 2018 Sol. Energy Mater. Sol. Cells 188 73

Google Scholar

Google Scholar

[30] Feng D L, Zang Y Y, Li P, Feng Y H, Yan Y Y, Zhang X X 2021 Compos. Sci. Technol. 210 108832

Google Scholar

Google Scholar

[31] Yu Z P, Feng D L, Feng Y H, Zhang X X 2022 Compos. Part A: Appl. Sci. Manufact. 152 106703

Google Scholar

Google Scholar

[32] Yuan P, Zhang P, Liang T, Zhai S P 2019 Appl. Surf. Sci. 485 402

Google Scholar

Google Scholar

[33] Xie B, Li C, Zhang B, Yang L, Chen J 2020 Energy Built Environ. 1 187

[34] Hekimolu G, Sar A, Kar T, Kele S, Saleh T A 2021 J. Energy Storage 35 102288

Google Scholar

Google Scholar

[35] Wu S, Chen Y, Chen Z, Wang J, Cai M, Gao J 2021 Sci. Rep. 11 822

Google Scholar

Google Scholar

[36] Zhao Y J, Sun B, Du P P, Min X, Huang Z H, Liu Y G, Wu X W, Fang M H 2019 Mater. Res. Express 6 115515

Google Scholar

Google Scholar

[37] Chen Y, Cui Z, Ding H, Wan Y, Tang Z, Gao J 2018 Int. J. Mol. Sci. 19 3055

Google Scholar

Google Scholar

[38] Wan Y C, Chen Y, Cui Z X, Ding H, Gao S F, Han Z, Gao J K 2019 Sci. Rep. 9 11535

Google Scholar

Google Scholar

[39] Das D, Bordoloi U, Muigai H H, Kalita P 2020 J. Energy Storage 30 101403

Google Scholar

Google Scholar

[40] Yang H Y, Wang Y, Yu Q, Li G, Sun X, Yang R, Zhang Q, Liu F, Di X, Li J 2018 Energy 159 929

Google Scholar

Google Scholar

[41] Li C, Xie B, He Z, Chen J, Long Y 2019 Renew. Energy 140 862

Google Scholar

Google Scholar

[42] Zhang W, Zhang X, Zhang X, Yin Z, Liu Y, Fang M, Wu X, Min X, Huang Z 2019 Thermochim. Acta 674 21

Google Scholar

Google Scholar

[43] Atinafu D G, Dong W, Wang C, Wang G 2018 J. Mater. Chem. A 6 8969

Google Scholar

Google Scholar

[44] Wen R, Zhang W, Lv Z, Huang Z, Gao W 2018 Mater. Lett. 215 42

Google Scholar

Google Scholar

[45] Yang Z, Deng Y, Li J 2019 Appl. Therm. Eng. 150 967

Google Scholar

Google Scholar

计量

- 文章访问数: 6797

- PDF下载量: 156

- 被引次数: 0

下载:

下载: