-

通过近几十年的研究, 人们对于块体及薄膜材料的热电性能已经有了较全面的认识, 热电优值ZT的提高取得了飞速的进展, 比如碲化铋相关材料、硒化亚铜相关材料、硒化锡相关材料的最大ZT值都突破了2. 但是, 这些体材料的热电优值距离大规模实用仍然有较大的差距. 通过理论计算得知, 当块体热电材料被制作成低维纳米结构材料时, 比如二维纳米薄膜、一维纳米线, 热电性能会得到显著的改善, 具有微纳米结构材料的热电性能研究引起了科研人员的极大兴趣. 当块体硅被制作成硅纳米线时, 热电优值改善了将近100倍. 然而, 微纳米材料的热电参数测量极具挑战, 因为块体材料的热电参数测量方法和测试平台已经不再适用于低维材料, 需要开发出新的测量方法和测试平台用来研究低维材料的热导率、电导率和塞贝克系数. 本文综述了几种用于精确测量微纳米材料热电参数的微机电结构, 包括双悬空岛、单悬空岛、悬空四探针结构, 详细介绍了每一种微机电结构的制备方法、测量原理以及对微纳米材料热电性能测试表征的实例.Through the research in recent decades, one has a comprehensive understanding of the thermoelectric properties of bulk and thin film materials, and made rapid progress of improving the thermoelectric figure of merit ZT, for instance, the maximum ZT values of bismuth telluride related materials, cuprous selenide related materials and tin selenide related materials all exceed 2. However, these bulk materials are still far from the requirements for their practical applications on a large scale. The theoretical calculations show that when bulk thermoelectric materials are made a low-dimensional nanostructured materials, such as two-dimensional nano-films and one-dimensional nanowires, their thermoelectric properties will be significantly improved. Taking silicon for example, when the bulk silicon is made silicon nanowires, the ZT value increases nearly a hundredfold. Hence, researches of the thermoelectric performances of materials with micro-nano structures have received great attention. However, the measurement of thermoelectric parameters of low-dimensional materials has brought challenges to researchers, for the traditional measurement methods or test platforms designed for bulk materials are no longer suitable for measuring thermoelectric parameters (thermal conductivity, electrical conductivity and Seebeck coefficient) of low-dimensional materials. Therefore, new measurement methods and test platforms need developing. In this case, micro-electromechanical system micro-suspended structure came into being. In this approach used are the separated samples and substrates, and isolated heat transfer channels, with which the thermal parameters of micro/nano materials can be accurately measured, and the sensitivity of thermal conductance can reach 10 PW/K. In this review, the structures of several micro-electromechanical systems used to measure the thermoelectric properties of low-dimensional nanostructures are introduced, including double suspended islands, single suspended islands and suspended four-probe structures. Meanwhile, the fabrication methods and measurement principles of these MEMS structures and thermoelectric properties of micro-nano structure materials are described in detail.

-

Keywords:

- thermoelectric effects /

- nanomaterials /

- micro-electromechanical system structure /

- thermal conductivity

[1] Wei J, Yang L, Ma Z, Song P, Zhang M, Ma J, Yang F, Wang X 2020 J. Mater. Sci. 55 12642

Google Scholar

Google Scholar

[2] 邓元, 张义政, 王瑶, 高洪利 2014 航空学报 35 2733

Google Scholar

Google Scholar

Deng Y, Zhang Y Z, Wang Y, Gao H L 2014 Acta Aeronaut. Astronaut. Sin. 35 2733

Google Scholar

Google Scholar

[3] Zhou Y, Zhao L 2017 Adv. Mater. 29 1702676

Google Scholar

Google Scholar

[4] LI P, Nie X, Tian Y, Fang W, Zhao W 2019 J. Inorg. Mater. 34 679

Google Scholar

Google Scholar

[5] DiSalvo F J 1999 Science 285 703

Google Scholar

Google Scholar

[6] Liu W, Jie Q, Kim H S, Ren Z 2015 Acta Mater. 87 357

Google Scholar

Google Scholar

[7] He W, Zhang G, Zhang X, Ji J, Li G, Zhao X 2015 Appl. Energy 143 1

Google Scholar

Google Scholar

[8] Chowdhury I, Prasher R, Lofgreen K, Chrysler G, Narasimhan S, Mahajan R, Koester D, Alley R, Venkatasubramanian R 2009 Nat. Nanotechnol. 4 235

Google Scholar

Google Scholar

[9] 王拓, 陈弘毅, 仇鹏飞, 史迅, 陈立东 2019 68 090201

Google Scholar

Google Scholar

Wang T, Chen H Y, Qiu P F, Shi X, Chen L D 2019 Acta Phys. Sin. 68 090201

Google Scholar

Google Scholar

[10] 秦丹丹, 李春鹤, 蔡伟, 隋解和 2020 功能材料 51 4023

Google Scholar

Google Scholar

Qin D D, Li C H, Cai W, Sui J H 2020 J. Funct. Mater. 51 4023

Google Scholar

Google Scholar

[11] Wang T, Huo T, Wang H, Wang C 2020 Sci. China-Mater. 63 8

Google Scholar

Google Scholar

[12] Wang L, Meng Q, Fan W 2012 J. Semicond. 33 113004

Google Scholar

Google Scholar

[13] Zhou Y, Guo Z, He J 2020 Appl. Phys. Lett. 116 043904

Google Scholar

Google Scholar

[14] 袁国才, 陈曦, 黄雨阳, 毛俊西, 禹劲秋, 雷晓波, 张勤勇 2019 68 117201

Google Scholar

Google Scholar

Yuan G C, Chen X, Huang Y Y, Mao J X, Yu J Q, Lei X B, Zhang Q Y 2019 Acta Phys. Sin. 68 117201

Google Scholar

Google Scholar

[15] 邱小小, 周细应, 王连军, 江莞 2020 人工晶体学报 49 920

Google Scholar

Google Scholar

Qiu X X, Zhou X Y, Wang L J, Jiang G 2020 J Synthetic. Cryst. 49 920

Google Scholar

Google Scholar

[16] 邹平, 吕丹, 徐桂英 2020 69 057201

Google Scholar

Google Scholar

Zou P, Lü D, Xu G Y 2020 Acta Phys. Sin. 69 057201

Google Scholar

Google Scholar

[17] 马瑞, 李宇洋, 刘光华, 李江涛, 韩叶茂, 周敏, 李来风 2017 陶瓷学报 38 466

Google Scholar

Google Scholar

Ma R, Li Y Y, Liu G H, Li J T, Han Y M, Zhou M, Li L F 2017 J. Ceram 38 466

Google Scholar

Google Scholar

[18] 吴子华, 谢华清, 曾庆峰 2013 62 097301

Google Scholar

Google Scholar

Wu Z H, Xie H Q, Zeng Q F 2013 Acta Phys. Sin. 62 097301

Google Scholar

Google Scholar

[19] 黄志成, 姚瑶, 裴俊, 董金峰, 张波萍, 李敬锋, 尚鹏鹏 2019 无机材料学报 34 321

Google Scholar

Google Scholar

Huang Z C, Yao Y, Pei J, Dong J F, Zhang B P, Li J F, Shang P P 2019 J. Inorg. Mater. 34 321

Google Scholar

Google Scholar

[20] Vining C B 2009 Nat. Mater. 8 83

Google Scholar

Google Scholar

[21] 沈家骏, 方腾, 傅铁铮, 忻佳展, 赵新兵, 朱铁军 2019 无机材料学报 34 30

Google Scholar

Google Scholar

Shen J J, Fang T, Fu T Z, Xin J Z, Zhao X B, Zhu T J 2019 J. Inorg. Mater. 34 30

Google Scholar

Google Scholar

[22] Sales B C, Mandrus D, Williams R K 1996 Science 272 1325

Google Scholar

Google Scholar

[23] Kim H S, Liu W, Chen G, Chu C W, Ren Z 2015 Proc. Natl. Acad. Sci. U S A 112 8205

Google Scholar

Google Scholar

[24] Goldsmid H J, Douglas R W 1954 Br. J. Appl. Phys. 5 386

Google Scholar

Google Scholar

[25] 陶颖, 祁宁, 王波, 陈志权, 唐新峰 2018 67 197201

Google Scholar

Google Scholar

Tao Y, Qi N, Wang B, Chen Z Q, Tang X F 2018 Acta Phys. Sin. 67 197201

Google Scholar

Google Scholar

[26] 陈立东, 熊震, 柏胜强 2010 无机材料学报 25 3

Google Scholar

Google Scholar

Chen L D, Xiong Z, Bai S Q 2010 J. Inorg. Mater. 25 3

Google Scholar

Google Scholar

[27] 胡慧珊, 杨君友, 辛集武, 李思慧, 姜庆辉 2019 无机材料学报 34 315

Google Scholar

Google Scholar

Hu H S, Yang J Y, Xin J W, Li S H, Jiang Q H 2019 J. Inorg. Mater. 34 315

Google Scholar

Google Scholar

[28] 陈萝娜, 刘叶烽, 张继业, 杨炯, 邢娟娟, 骆军, 张文清 2017 66 167201

Google Scholar

Google Scholar

Chen L N, Liu Y F, Zhang J Y, Yang J, Xing J J, Luo J, Zhang W Q 2017 Acta Phys. Sin. 66 167201

Google Scholar

Google Scholar

[29] Hicks L, Dresselhaus M S 1993 Phys. Rev. B 47 12727

Google Scholar

Google Scholar

[30] Hicks L, Dresselhaus M S 1993 Phys. Rev. B 47 16631

Google Scholar

Google Scholar

[31] Yang L, Wei J, Ma Z, Song P, Ma J, Zhao Y, Huang Z, Zhang M, Yang F, Wang X 2019 Nanomaterials 9 1789

Google Scholar

Google Scholar

[32] Shrestha R, Luan Y, Shin S, Zhang T, Luo X, Lundh J S, Gong W, Bockstaller M R, Choi S, Luo T, Chen R, Hippalgaonkar K, Shen S 2019 Sci. Adv. 5 eaax3777

Google Scholar

Google Scholar

[33] Choe H S, Li J, Zheng W, Lee J, Suh J, Allen F I, Liu H, Choi H J, Walukiewicz W, Zheng H, Wu J 2019 Appl. Phys. Lett. 114 152101

Google Scholar

Google Scholar

[34] Liu H, Yang C, Wei B, Jin L, Alatas A, Said A, Tongay S, Yang F, Javey A, Hong J, Wu J 2020 Adv. Sci. 7 1902071

Google Scholar

Google Scholar

[35] 霍建琴, 冯飞, 王文荣, 戈肖鸿, 李铁, 王跃林 2012 传感器与微系统 31 59

Google Scholar

Google Scholar

Huo J Q, Feng F, Wang W R, Ge X H, Li T, Wang Y L 2012 Transd. Microsyst. Technol. 31 59

Google Scholar

Google Scholar

[36] 张晖, 杨君友, 张建生, 吴进, 陈辉 2011 材料导报 25 32

Google Scholar

Google Scholar

Zhang H, Yang J Y, Zhang J S, Wu J, Chen H 2011 Mater Rev. 25 32

Google Scholar

Google Scholar

[37] Liu Y, Zhang M, Ji A, Yang F, Wang X 2016 RSC Adv. 6 48933

Google Scholar

Google Scholar

[38] Hernandez J A, Carpena-Nunez J, Fonseca L F, Pettes M T, Yacaman M J, Benitez A 2018 Nanotechnology 29 364001

Google Scholar

Google Scholar

[39] Rodriguez-Viejo J, Licea Jimenez L, Perez Garcia S A, Alvarez-Quintana J 2015 J. Adv. Therm. Sci. Res. 2 1

Google Scholar

Google Scholar

[40] Shi L, Li D Y, Yu C H, Jang W Y, Kim D, Yao Z, Kim P, Majumdar A 2003 J. Heat Transf Trans. ASME 125 881

Google Scholar

Google Scholar

[41] Sultan R, Avery A D, Stiehl G, Zink B L 2009 J. Appl. Phys. 105 043501

Google Scholar

Google Scholar

[42] Wingert M C, Chen Z C Y, Dechaumphai E, Moon J, Kim J H, Xiang J, Chen A R 2011 Nano Lett. 11 5507

Google Scholar

Google Scholar

[43] Lim J, Wang H T, Tang J, Andrews S C, So H, Lee J, Lee D H, Russell T P, Yang P 2016 ACS Nano 10 124

Google Scholar

Google Scholar

[44] Boukai A I, Bunimovich Y, Tahir-Kheli J, Yu J K, Goddard W A, Heath J R 2008 Nature 451 168

Google Scholar

Google Scholar

[45] Hochbaum A I, Chen R, Delgado R D, Liang W, Garnett E C, Najarian M, Majumdar A, Yang P 2008 Nature 451 163

Google Scholar

Google Scholar

[46] Zhao Y, Yang L, Kong L, Nai M H, Liu D, Wu J, Liu Y, Chiam S Y, Chim W K, Lim C T, Li B, Thong J T L, Hippalgaonkar K 2017 Adv. Funct. Mater. 27 1702824

Google Scholar

Google Scholar

[47] Ferrando-Villalba P, D'Ortenzi L, Dalkiranis G G, Cara E, Lopeandia A F, Abad L, Rurali R, Cartoixa X, De Leo N, Saghi Z, Jacob M, Gambacorti N, Boarino L, Rodriguez Viejo J 2018 Sci. Rep. 8 12796

Google Scholar

Google Scholar

[48] Ferrando-Villalba P, Lopeandia A F, Abad L, Llobet J, Molina Ruiz M, Garcia G, Gerboles M, Alvarez F X, Goni A R, Munoz Pascual F J, Rodriguez Viejo J 2014 Nanotechnology 25 185402

Google Scholar

Google Scholar

[49] Tang J, Wang H T, Lee D H, Fardy M, Huo Z, Russell T P, Yang P 2010 Nano Lett. 10 4279

Google Scholar

Google Scholar

[50] Park W, Romano G, Ahn E C, Kodama T, Park J, Barako M T, Sohn J, Kim S J, Cho J, Marconnet A M, Asheghi M, Kolpak A M, Goodson K E 2017 Sci. Rep. 7 6233

Google Scholar

Google Scholar

[51] Park W, Sohn J, Romano G, Kodama T, Sood A, Katz J S, Kim B S Y, So H, Ahn E C, Asheghi M, Kolpak A M, Goodson K E 2018 Nanoscale 10 11117

Google Scholar

Google Scholar

[52] Li D, Wu Y, Fan R, Yang P, Majumdar A 2003 Appl. Phys. Lett. 83 3186

Google Scholar

Google Scholar

[53] Lee E K, Yin L, Lee Y, Lee J W, Lee S J, Lee J, Cha S N, Whang D, Hwang G S, Hippalgaonkar K, Majumdar A, Yu C, Choi B L, Kim J M, Kim K 2012 Nano Lett. 12 2918

Google Scholar

Google Scholar

[54] Li G, Yarali M, Cocemasov A, Baunack S, Nika D L, Fomin V M, Singh S, Gemming T, Zhu F, Mavrokefalos A, Schmidt O G 2017 ACS Nano 11 8215

Google Scholar

Google Scholar

[55] Choe H S, Prabhakar R, Wehmeyer G, Allen F I, Lee W, Jin L, Li Y, Yang P, Qiu C W, Dames C, Scott M, Minor A, Bahk J H, Wu J 2019 Nano Lett. 19 3830

Google Scholar

Google Scholar

[56] Mavrokefalos A, Pettes M T, Zhou F, Shi L 2007 Rev. Sci. Instrum. 78 034901

Google Scholar

Google Scholar

[57] Karg S F, Troncale V, Drechsler U, Mensch P, Das Kanungo P, Schmid H, Schmidt V, Gignac L, Riel H, Gotsmann B 2014 Nanotechnology 25 305702

Google Scholar

Google Scholar

[58] Jin Q, Jiang S, Zhao Y, Wang D, Qiu J, Tang D M, Tan J, Sun D M, Hou P X, Chen X Q, Tai K, Gao N, Liu C, Cheng H M, Jiang X 2019 Nat. Mater. 18 62

Google Scholar

Google Scholar

[59] Xu E, Li Z, Acosta J A, Li N, Swartzentruber B, Zheng S, Sinitsyn N, Htoon H, Wang J, Zhang S 2016 Nano Res. 9 820

Google Scholar

Google Scholar

[60] Ko T Y, Shellaiah M, Sun K W 2016 Sci. Rep. 6 35086

Google Scholar

Google Scholar

[61] Wang Y, Lin R, Zhu P, Zheng Q, Wang Q, Li D, Zhu J 2018 Nano Lett. 18 2772

Google Scholar

Google Scholar

[62] Roh J, Hippalgaonkar K, Kang J, Lee S, Ham J, Chen R, Majumdar A, Kim W, Lee W 2010 IEEE 633

Google Scholar

Google Scholar

[63] Liu N, Zhu T, Rosul M G, Peters J, Bowers J E, Zebarjadi M 2020 Mater.Today Phys. 14 100224

Google Scholar

Google Scholar

[64] 吴健 2014 硕士学位论文 (南京: 东南大学)

Wu J 2014 M.D. Dissertation (Nanjing: Southeast University) (in Chinese)

[65] Xu X, Pereira L F C, Wang Y, Wu J, Zhang K, Zhao X, Bae S, Tinh Bui C, Xie R, Thong J T L, Hong B H, Loh K P, Donadio D, Li B, Ozyilmaz B 2014 Nat. Commun. 5 3689

Google Scholar

Google Scholar

[66] Alaie S, Goettler D F, Abbas K, Su M F, Reinke C M, El-Kady I, Leseman Z C 2013 Rev. Sci. Instrum. 84 105003

Google Scholar

Google Scholar

[67] Alaie S, Goettler D F, Su M, Leseman Z C, Reinke C M, El-Kady I 2015 Nat. Commun. 6 7228

Google Scholar

Google Scholar

[68] Haras M, Lacatena V, Bah T M, Didenko S, Robillard J-F, Monfray S, Skotnicki T, Dubois E 2016 IEEE Electron Device Lett. 37 1358

Google Scholar

Google Scholar

[69] 马维刚, 王海东, 张兴, 王玮 2011 60 421

Google Scholar

Google Scholar

Ma W G, Wang H D, Zhang X, Wang W 2011 Acta Phys. Sin. 60 421

Google Scholar

Google Scholar

[70] 朱丽丹 2012 博士学位论文 (北京: 中国科学院工程热物理研究所)

Zhu L D 2012 Ph. D. Dissertation (Beijing: Institute of Engineering Thermophysics, Chinese Academy of Sciences) (in Chinese)

[71] Maire J, Nomura M 2014 Jpn. J. Appl. Phys. 53 06je09 06JE09

Google Scholar

Google Scholar

[72] Wang H, Chu W, Chen G 2019 Adv. Electron. Mater. 5 1900167

Google Scholar

Google Scholar

[73] Jo I, Pettes M T, Kim J, Watanabe K, Taniguchi T, Yao Z, Shi L 2013 Nano Lett. 13 550

Google Scholar

Google Scholar

[74] Seol J H, Jo I, Moore A L, Lindsay L, Aitken Z H, Pettes M T, Li X, Yao Z, Huang R, Broido D, Mingo N, Ruoff R S, Shi L 2010 Science 328 213

Google Scholar

Google Scholar

[75] Kim J, Ou E, Sellan D P, Shi L 2015 Rev. Sci. Instrum. 86 044901

Google Scholar

Google Scholar

[76] Smith B, Vermeersch B, Carrete J, Ou E, Kim J, Mingo N, Akinwande D, Shi L 2017 Adv. Mater. 29 1603756

Google Scholar

Google Scholar

[77] Li D, Wu Y, Kim P, Shi L, Yang P, Majumdar A 2003 Appl. Phys. Lett. 83 2934

Google Scholar

Google Scholar

[78] Hippalgaonkar K, Huang B, Chen R, Sawyer K, Ercius P, Majumdar A 2010 Nano Lett. 10 4341

Google Scholar

Google Scholar

[79] 朱林, 赵扬, 杨决宽 2015 真空科学与技术学报 35 1352

Google Scholar

Google Scholar

Zhu L, Zhao Y, Yang J K 2015 Chin. J. Vac. Sci. Techno. 35 1352

Google Scholar

Google Scholar

[80] 朱林 2016 硕士学位论文 (南京: 东南大学)

Zhu L 2016 M. D. Dissertation (Nanjing: Southeast University) (in Chinese)

-

图 3 (a) 用于测量低温端电阻Rs的惠斯通电桥装置[42]; (b) 加热端和低温端测得的温升与功率的函数关系;电桥法的Ts灵敏度为1 mK, 热导的测量灵度可以达到10 pW/K[42]

Fig. 3. (a) Wheatstone bridge device for measuring resistance Rs at low temperature end[42]; (b) the temperature rise measured at the heating end and the low temperature end as a function of power. Ts sensitivity of bridge method is1 mK, thermal conductance sensitivity is 10 pW/K[42].

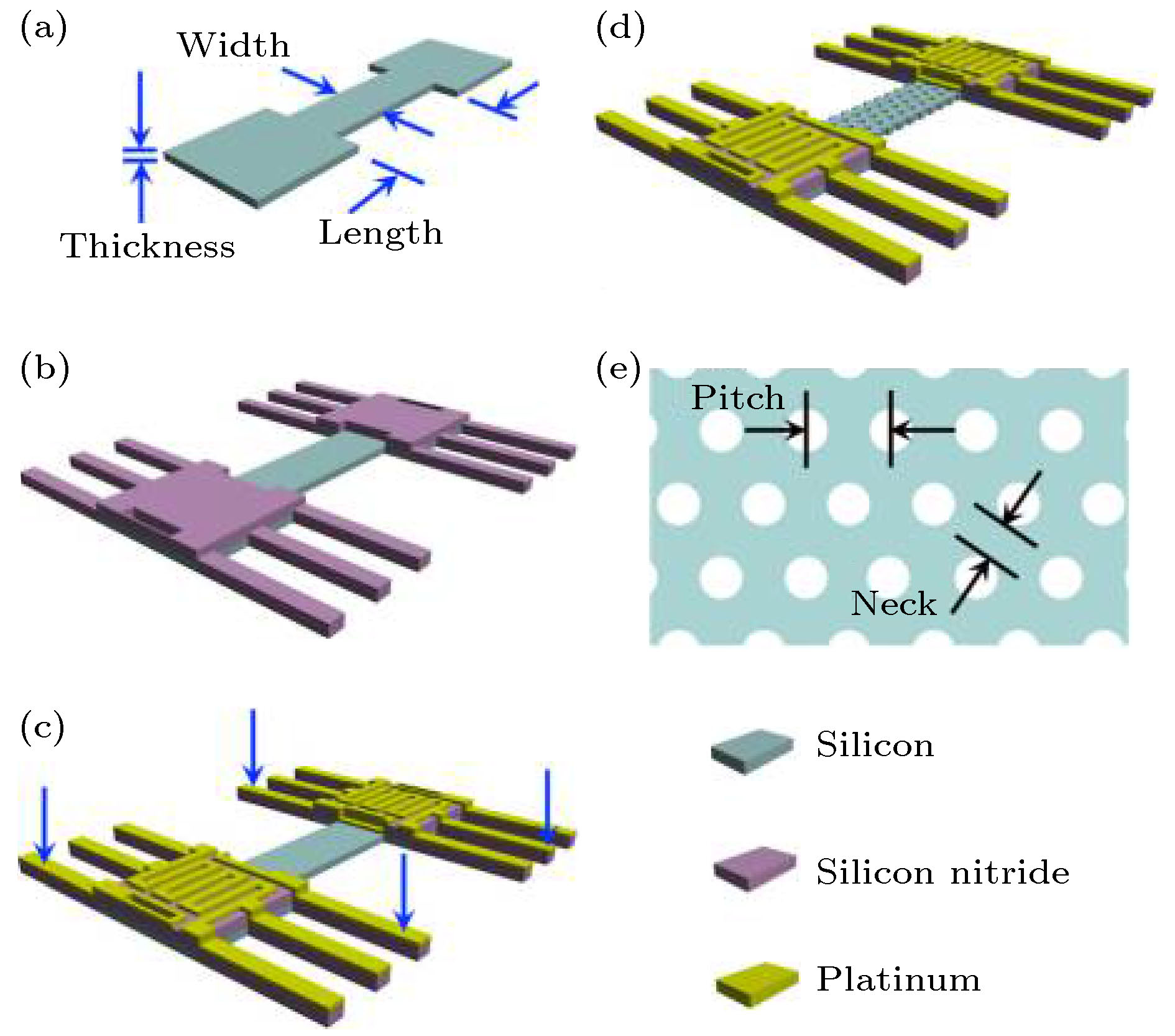

图 4 集成微器件示意图[43] (a) 硅微带连接两个悬空岛(30 µm × 40 µm), 用于与低应力SiNx薄膜进行热接触. 定义了硅带的长度, 宽度和厚度; (b) 每个悬空岛有6条低应力SiNx悬臂相连, 用来支撑微悬浮器件; (c) 通过四探针进行电测量; (Cr/Pt = 2/30 nm, 由蓝色箭头标记). 其余的悬臂用来测量两个蛇形电阻; (d) 多孔硅微带悬空器件. 纳米孔是通过BCP光刻制造的; (e) 多孔硅微带中孔间距和孔颈的定义示意图

Fig. 4. Schematic of the integrated microdevice[43]: (a) Silicon micro-ribbon connects two suspended islands(30 µm × 40 µm)for thermal contact with low stress SiNx films, length, width and thickness of silicon tape are defined; (b) each suspended island is connected by six low stress SiNx cantilevers to support micro suspended device; (c) electrical measurements are made with four probes (Cr/Pt = 2/30 nm, marked by the blue arrows), the rest of the cantilevers are used to measure two serpentine resistances; (d) porous silicon micro-ribbon suspended device, nanoholes are made by BCP lithography; (e) definition of pitch and neck in porous silicon micro-ribbon.

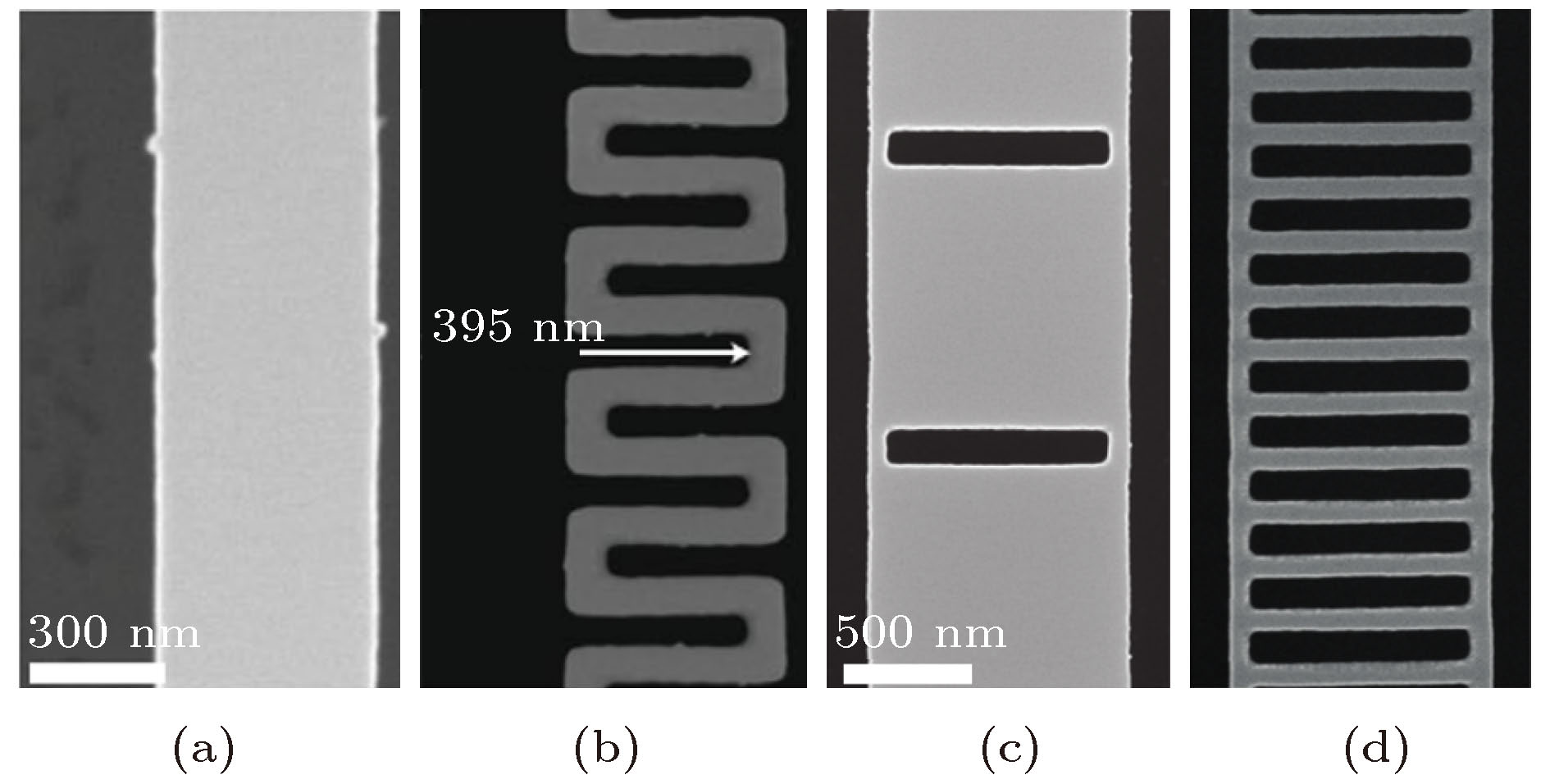

图 6 扫描电子显微镜 (SEM) 图像 (a) 纳米带 (470 nm宽, 80 nm厚)[50] (b) 蛇形纳米带 (470 nm宽, 80 nm厚, 狭缝长395 nm)[50]; (c) 梯状结构纳米带, 矩形孔间距为970 nm[51]; (d) 梯状结构纳米带, 矩形孔间距为70 nm[51]

Fig. 6. Scanning electron microscopy (SEM) images: (a) Nanoribbon (470 nm wide, 80 nm thick)[50]; (b) serpentine nanoribbon (470 nm wide, 80 nm thick, 395 nm long slit)[50]; (c) ladder-structured nanoribbon with rectangular hole of 970 nm[51]; (d) ladder-structured nanoribbon with rectangular hole of 70 nm[51].

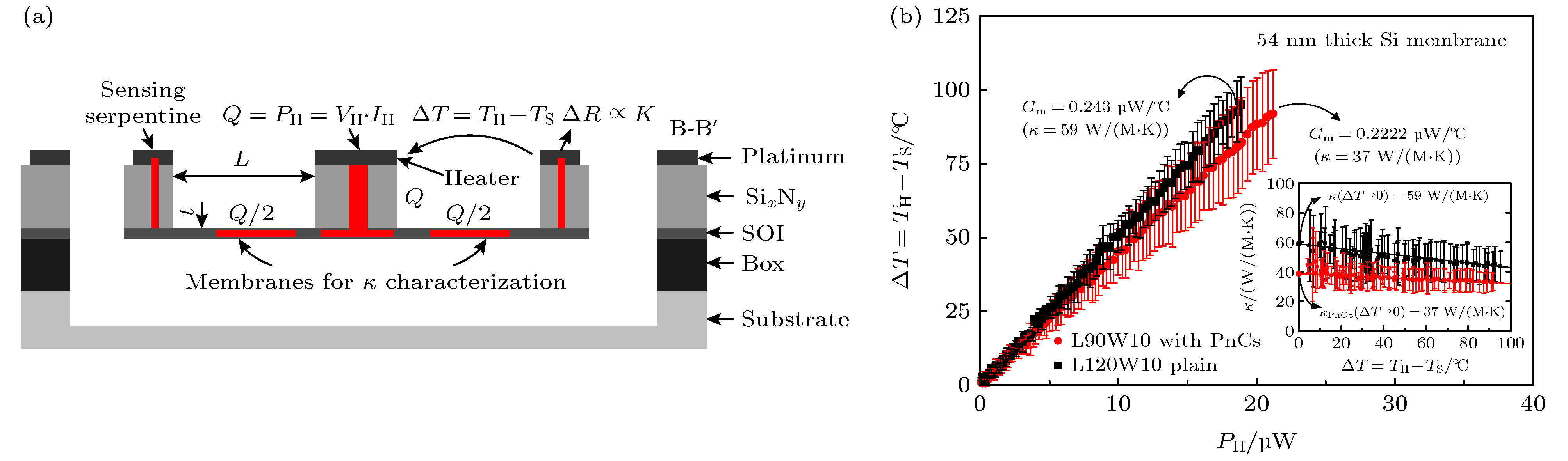

图 7 (a) MEMS悬空结构热电参数测量原理图[68]; (b) 普通薄膜和声子晶体薄膜低温端和高温端温度差和加热功率的关系, 其中插图为声子晶体热导率与温差ΔT的关系[68]

Fig. 7. (a) Schematic diagram of MEMS suspended structure thermoelectric parameter measurement[68]; (b) the relation between the temperature difference and heating power between the low temperature end and the high temperature end of the plain film and the phononic crystal film is shown in the figure. Inset plot presents the relation between κ of the phononic crystal and the temperature difference ΔT[68].

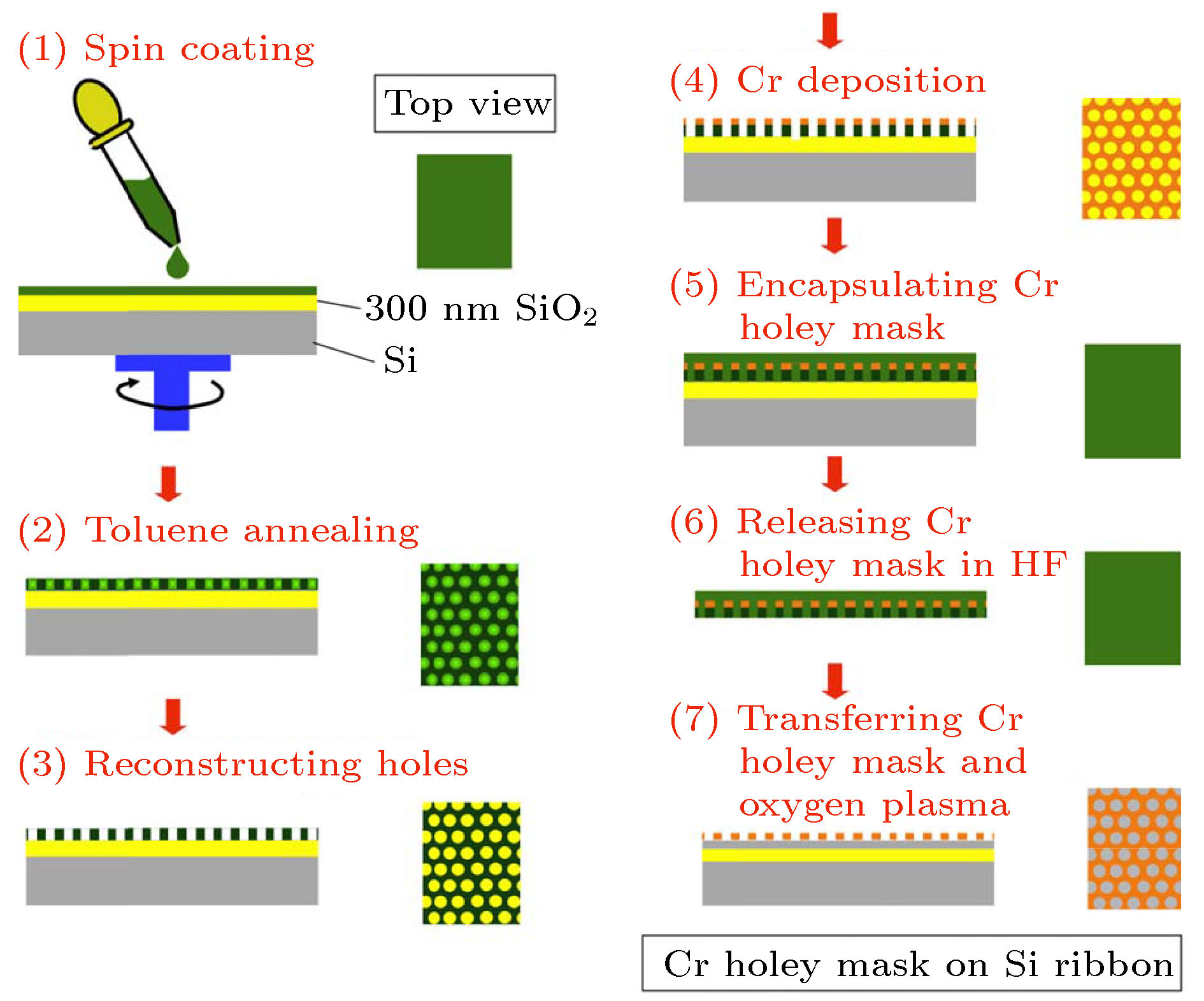

图 8 集成声子晶体悬浮硅薄膜热导率测量平台的制作顺序. 在加工的每个步骤之后, 均使用照片中沿A-A'和B-B'切割线的横截面图显示了工艺流程. 最左边的SEM图显示了整个微悬空设备, 中间的SEM图显示了放大的薄膜, 最右边的SEM图显示了声子晶体, 并突出了它们的维度[68]

Fig. 8. Manufacturing sequence of thermal conductivity measurement platform of suspended thin-film silicon with integrated phononic crystals. Process flow showed after each step of fabrication using cross-sectional view along A-A’ and B-B’ cutlines presented in the photo. The leftmost SEM image showed the entire micro-suspension device, the middle SEM image showed the enlarged film, the rightmost SEM image showed the phononic crystals and highlighted their dimensions[68].

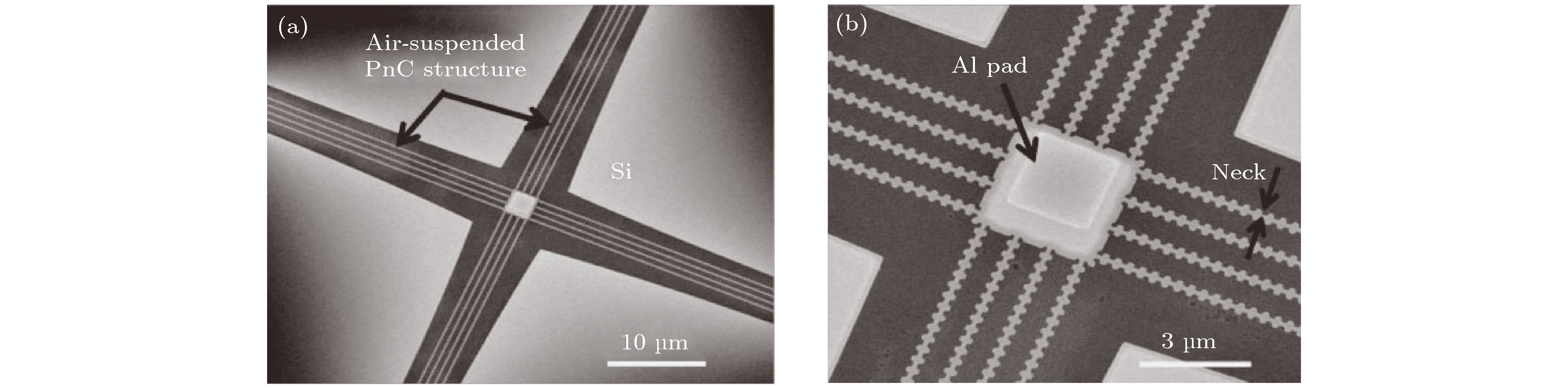

图 10 Si声子晶体纳米结构的SEM照片 (a) 悬浮结构的全局图像[71]; (b) 放大的器件结构图, 显示了中心金属垫和鱼骨形状的晶体, 其中颈部尺寸为89 nm[71]

Fig. 10. SEM images of Si phononic crystal nanostructure: (a) Global image of suspended structure[71]; (b) enlarged device structure diagram showing the central metal pad and fishbone shaped crystal, where in the neck size is 89 nm[71].

图 11 (a) 悬挂在微桥装置中央框架上的h-BN样品的相关尺寸的示意图[73]; (b)微悬浮结构的SEM图, 悬浮结构上的样品为h-BN1[73]; (c) 两个7.5 μm长, 11层和5层厚悬浮h-BN样品的导热系数随温度的变化关系, 并与其他人的实验结果进行了对比[73]

Fig. 11. (a) Schematic diagram of the relevant dimensions of the h-BN sample suspended on the central frame of the microbridge device[73]; (b) SEM image of micro-suspension structure, the sample on suspension structure was h-BN1[73]; (c) the relationship between the thermal conductivity of two samples of 7.5 μm long, 11 layer and 5 layer thick suspension h-BN and the temperature is studied and compared with the experimental results of others[73].

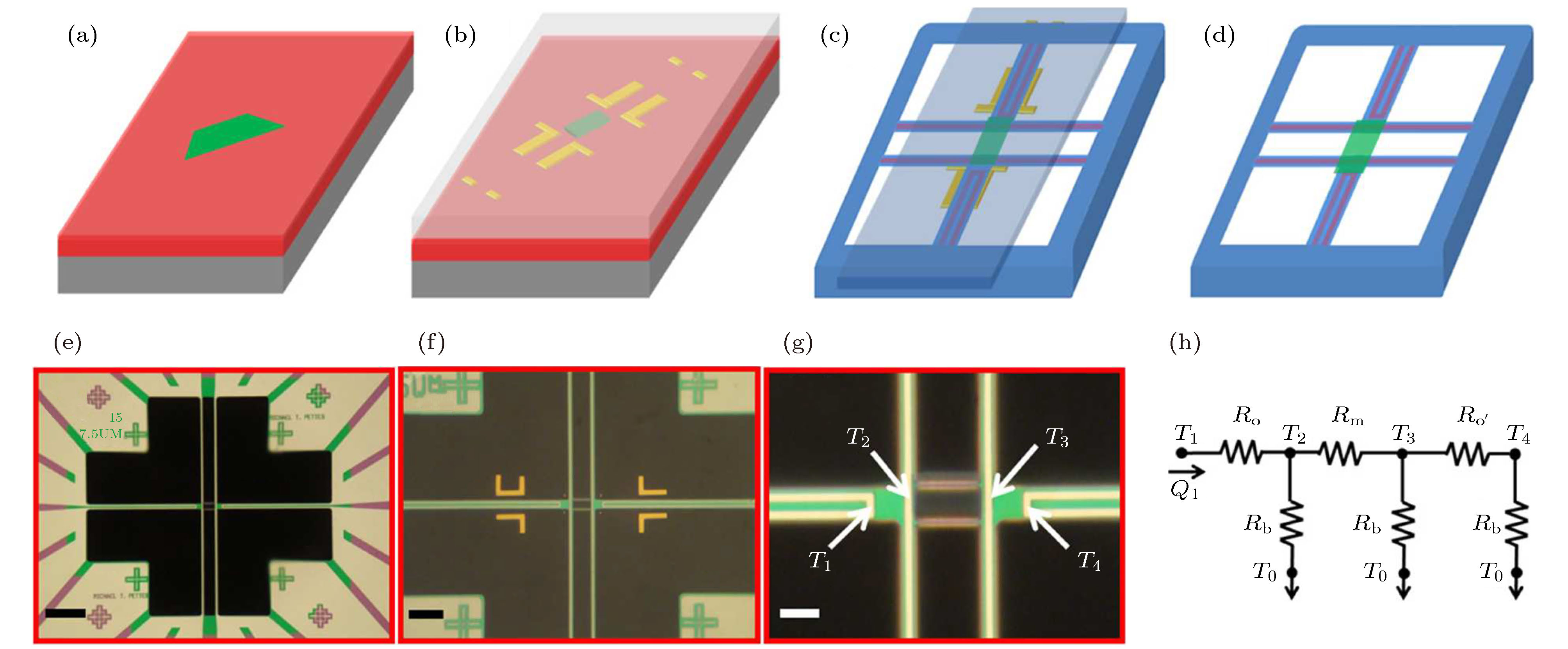

图 12 样品h-BN的转移和器件图[73] (a) 在被热氧化物 (红色) 覆盖的硅衬底 (灰色) 顶部剥落的几层h-BN薄片 (绿色); (b) 基底上的金标记 (金色) 和覆盖有图案的几层h-BN带的PMMA层 (半透明); (c) 转移到微桥设备顶部的PMMA载体层 (蓝色); (d)PMMA层溶解后, 少量h-BN层悬浮在微器件的中心SiNx框架上; (e) 微桥设备; (f) 在设备上对齐PMMA层; (g)溶解PMMA层后悬浮在装置上的11层h-BN样品; (h) 测量装置的等效热电路, (e)−(g)部分中刻度条分别代表25, 10和5 μm

Fig. 12. The h-BN sample transfer and device diagram[73]: (a) A few-layer h-BN flake (green) exfoliated on top of a Si substrate (gray) covered by thermal oxide (red); (b) Au marks (golden) on the substrate and a PMMA layer (semitransparent) covering the patterned few-layer h-BN ribbon; (c) PMMA carrier layer transferred on top of the microbridge device (blue); (d) few-layer h-BN suspended on the central SiNx frame of the microdevice after the dissolution of the PMMA layer; (e) microbridge device; (f) PMMA layer aligned on the device; (g) an 11-layer h-BN sample suspended on the device after dissolving of the PMMA layer; (h) equivalent thermal circuit of the measurement device, the scale bars in the (e)−(g) section represent 25, 10 and 5 μm, respectively.

图 13 器件的结构图和等效热阻图[75] (a) 240 nm宽, 220 nm厚的硅纳米线样品的光学显微照片 (左边) 和SEM照片 (右边), 如顶部SEM所示, 在从左侧开始的第一条温度计线的中心形成一个小的V形突起, 以帮助测量每个温度计线的中心和纳米结构的接触点之间的偏差 (di和dj); (b)740 nm宽, 220 nm厚的硅纳米线样品的光学显微照片, 装配在4条悬浮的Pt/SiNx线上, 以及沿着Pt/SiNx加热线 (第i条线) 和一条Pt/SiNx电阻温度计线 (第j条线, j ≠ i) 的温度分布示意图; (c) 当第一条Pt/SiNx线以 (IV)1的速率电加热时, 测量装置的热阻电路图

Fig. 13. Structure diagram and equivalent thermal resistance diagram of the device[75]: (a) Optical micrographs (left) and SEM images (right) of a 240 nm wide, 220 nm thick silicon nanowire sample, as shown in the top SEM, a small V-shape protrusion is patterned at the center of the first thermometer line from the left to assist in the measurement of the deviation (di and dj) between the center of each thermometer line and the contact point to the nanostructure; (b) optical micrograph of 740 nm wide and 220 nm thick silicon nanowire samples, assembled on four suspended Pt/SiNx lines, and schematic diagram of temperature distribution along the Pt/SiNx heating line (ith line) and one Pt/SiNx resistance thermometer line (jth line, j ≠ i); (c) thermal resistance circuit of the measurement device when the first Pt/SiNx line is electrically heated at a rate of (IV)1.

表 1 测量的悬浮h-BN样品的尺寸

Table 1. Measurement of the size of suspended h-BN samples.

原子层数 宽度/µm 悬浮的长度/µm h-BN1 12 ± 1 9.0 3.0 h-BN2 12 6.7 5.0 h-BN3 11 6.5 7.5 h-BN4 5 6.6 7.5 -

[1] Wei J, Yang L, Ma Z, Song P, Zhang M, Ma J, Yang F, Wang X 2020 J. Mater. Sci. 55 12642

Google Scholar

Google Scholar

[2] 邓元, 张义政, 王瑶, 高洪利 2014 航空学报 35 2733

Google Scholar

Google Scholar

Deng Y, Zhang Y Z, Wang Y, Gao H L 2014 Acta Aeronaut. Astronaut. Sin. 35 2733

Google Scholar

Google Scholar

[3] Zhou Y, Zhao L 2017 Adv. Mater. 29 1702676

Google Scholar

Google Scholar

[4] LI P, Nie X, Tian Y, Fang W, Zhao W 2019 J. Inorg. Mater. 34 679

Google Scholar

Google Scholar

[5] DiSalvo F J 1999 Science 285 703

Google Scholar

Google Scholar

[6] Liu W, Jie Q, Kim H S, Ren Z 2015 Acta Mater. 87 357

Google Scholar

Google Scholar

[7] He W, Zhang G, Zhang X, Ji J, Li G, Zhao X 2015 Appl. Energy 143 1

Google Scholar

Google Scholar

[8] Chowdhury I, Prasher R, Lofgreen K, Chrysler G, Narasimhan S, Mahajan R, Koester D, Alley R, Venkatasubramanian R 2009 Nat. Nanotechnol. 4 235

Google Scholar

Google Scholar

[9] 王拓, 陈弘毅, 仇鹏飞, 史迅, 陈立东 2019 68 090201

Google Scholar

Google Scholar

Wang T, Chen H Y, Qiu P F, Shi X, Chen L D 2019 Acta Phys. Sin. 68 090201

Google Scholar

Google Scholar

[10] 秦丹丹, 李春鹤, 蔡伟, 隋解和 2020 功能材料 51 4023

Google Scholar

Google Scholar

Qin D D, Li C H, Cai W, Sui J H 2020 J. Funct. Mater. 51 4023

Google Scholar

Google Scholar

[11] Wang T, Huo T, Wang H, Wang C 2020 Sci. China-Mater. 63 8

Google Scholar

Google Scholar

[12] Wang L, Meng Q, Fan W 2012 J. Semicond. 33 113004

Google Scholar

Google Scholar

[13] Zhou Y, Guo Z, He J 2020 Appl. Phys. Lett. 116 043904

Google Scholar

Google Scholar

[14] 袁国才, 陈曦, 黄雨阳, 毛俊西, 禹劲秋, 雷晓波, 张勤勇 2019 68 117201

Google Scholar

Google Scholar

Yuan G C, Chen X, Huang Y Y, Mao J X, Yu J Q, Lei X B, Zhang Q Y 2019 Acta Phys. Sin. 68 117201

Google Scholar

Google Scholar

[15] 邱小小, 周细应, 王连军, 江莞 2020 人工晶体学报 49 920

Google Scholar

Google Scholar

Qiu X X, Zhou X Y, Wang L J, Jiang G 2020 J Synthetic. Cryst. 49 920

Google Scholar

Google Scholar

[16] 邹平, 吕丹, 徐桂英 2020 69 057201

Google Scholar

Google Scholar

Zou P, Lü D, Xu G Y 2020 Acta Phys. Sin. 69 057201

Google Scholar

Google Scholar

[17] 马瑞, 李宇洋, 刘光华, 李江涛, 韩叶茂, 周敏, 李来风 2017 陶瓷学报 38 466

Google Scholar

Google Scholar

Ma R, Li Y Y, Liu G H, Li J T, Han Y M, Zhou M, Li L F 2017 J. Ceram 38 466

Google Scholar

Google Scholar

[18] 吴子华, 谢华清, 曾庆峰 2013 62 097301

Google Scholar

Google Scholar

Wu Z H, Xie H Q, Zeng Q F 2013 Acta Phys. Sin. 62 097301

Google Scholar

Google Scholar

[19] 黄志成, 姚瑶, 裴俊, 董金峰, 张波萍, 李敬锋, 尚鹏鹏 2019 无机材料学报 34 321

Google Scholar

Google Scholar

Huang Z C, Yao Y, Pei J, Dong J F, Zhang B P, Li J F, Shang P P 2019 J. Inorg. Mater. 34 321

Google Scholar

Google Scholar

[20] Vining C B 2009 Nat. Mater. 8 83

Google Scholar

Google Scholar

[21] 沈家骏, 方腾, 傅铁铮, 忻佳展, 赵新兵, 朱铁军 2019 无机材料学报 34 30

Google Scholar

Google Scholar

Shen J J, Fang T, Fu T Z, Xin J Z, Zhao X B, Zhu T J 2019 J. Inorg. Mater. 34 30

Google Scholar

Google Scholar

[22] Sales B C, Mandrus D, Williams R K 1996 Science 272 1325

Google Scholar

Google Scholar

[23] Kim H S, Liu W, Chen G, Chu C W, Ren Z 2015 Proc. Natl. Acad. Sci. U S A 112 8205

Google Scholar

Google Scholar

[24] Goldsmid H J, Douglas R W 1954 Br. J. Appl. Phys. 5 386

Google Scholar

Google Scholar

[25] 陶颖, 祁宁, 王波, 陈志权, 唐新峰 2018 67 197201

Google Scholar

Google Scholar

Tao Y, Qi N, Wang B, Chen Z Q, Tang X F 2018 Acta Phys. Sin. 67 197201

Google Scholar

Google Scholar

[26] 陈立东, 熊震, 柏胜强 2010 无机材料学报 25 3

Google Scholar

Google Scholar

Chen L D, Xiong Z, Bai S Q 2010 J. Inorg. Mater. 25 3

Google Scholar

Google Scholar

[27] 胡慧珊, 杨君友, 辛集武, 李思慧, 姜庆辉 2019 无机材料学报 34 315

Google Scholar

Google Scholar

Hu H S, Yang J Y, Xin J W, Li S H, Jiang Q H 2019 J. Inorg. Mater. 34 315

Google Scholar

Google Scholar

[28] 陈萝娜, 刘叶烽, 张继业, 杨炯, 邢娟娟, 骆军, 张文清 2017 66 167201

Google Scholar

Google Scholar

Chen L N, Liu Y F, Zhang J Y, Yang J, Xing J J, Luo J, Zhang W Q 2017 Acta Phys. Sin. 66 167201

Google Scholar

Google Scholar

[29] Hicks L, Dresselhaus M S 1993 Phys. Rev. B 47 12727

Google Scholar

Google Scholar

[30] Hicks L, Dresselhaus M S 1993 Phys. Rev. B 47 16631

Google Scholar

Google Scholar

[31] Yang L, Wei J, Ma Z, Song P, Ma J, Zhao Y, Huang Z, Zhang M, Yang F, Wang X 2019 Nanomaterials 9 1789

Google Scholar

Google Scholar

[32] Shrestha R, Luan Y, Shin S, Zhang T, Luo X, Lundh J S, Gong W, Bockstaller M R, Choi S, Luo T, Chen R, Hippalgaonkar K, Shen S 2019 Sci. Adv. 5 eaax3777

Google Scholar

Google Scholar

[33] Choe H S, Li J, Zheng W, Lee J, Suh J, Allen F I, Liu H, Choi H J, Walukiewicz W, Zheng H, Wu J 2019 Appl. Phys. Lett. 114 152101

Google Scholar

Google Scholar

[34] Liu H, Yang C, Wei B, Jin L, Alatas A, Said A, Tongay S, Yang F, Javey A, Hong J, Wu J 2020 Adv. Sci. 7 1902071

Google Scholar

Google Scholar

[35] 霍建琴, 冯飞, 王文荣, 戈肖鸿, 李铁, 王跃林 2012 传感器与微系统 31 59

Google Scholar

Google Scholar

Huo J Q, Feng F, Wang W R, Ge X H, Li T, Wang Y L 2012 Transd. Microsyst. Technol. 31 59

Google Scholar

Google Scholar

[36] 张晖, 杨君友, 张建生, 吴进, 陈辉 2011 材料导报 25 32

Google Scholar

Google Scholar

Zhang H, Yang J Y, Zhang J S, Wu J, Chen H 2011 Mater Rev. 25 32

Google Scholar

Google Scholar

[37] Liu Y, Zhang M, Ji A, Yang F, Wang X 2016 RSC Adv. 6 48933

Google Scholar

Google Scholar

[38] Hernandez J A, Carpena-Nunez J, Fonseca L F, Pettes M T, Yacaman M J, Benitez A 2018 Nanotechnology 29 364001

Google Scholar

Google Scholar

[39] Rodriguez-Viejo J, Licea Jimenez L, Perez Garcia S A, Alvarez-Quintana J 2015 J. Adv. Therm. Sci. Res. 2 1

Google Scholar

Google Scholar

[40] Shi L, Li D Y, Yu C H, Jang W Y, Kim D, Yao Z, Kim P, Majumdar A 2003 J. Heat Transf Trans. ASME 125 881

Google Scholar

Google Scholar

[41] Sultan R, Avery A D, Stiehl G, Zink B L 2009 J. Appl. Phys. 105 043501

Google Scholar

Google Scholar

[42] Wingert M C, Chen Z C Y, Dechaumphai E, Moon J, Kim J H, Xiang J, Chen A R 2011 Nano Lett. 11 5507

Google Scholar

Google Scholar

[43] Lim J, Wang H T, Tang J, Andrews S C, So H, Lee J, Lee D H, Russell T P, Yang P 2016 ACS Nano 10 124

Google Scholar

Google Scholar

[44] Boukai A I, Bunimovich Y, Tahir-Kheli J, Yu J K, Goddard W A, Heath J R 2008 Nature 451 168

Google Scholar

Google Scholar

[45] Hochbaum A I, Chen R, Delgado R D, Liang W, Garnett E C, Najarian M, Majumdar A, Yang P 2008 Nature 451 163

Google Scholar

Google Scholar

[46] Zhao Y, Yang L, Kong L, Nai M H, Liu D, Wu J, Liu Y, Chiam S Y, Chim W K, Lim C T, Li B, Thong J T L, Hippalgaonkar K 2017 Adv. Funct. Mater. 27 1702824

Google Scholar

Google Scholar

[47] Ferrando-Villalba P, D'Ortenzi L, Dalkiranis G G, Cara E, Lopeandia A F, Abad L, Rurali R, Cartoixa X, De Leo N, Saghi Z, Jacob M, Gambacorti N, Boarino L, Rodriguez Viejo J 2018 Sci. Rep. 8 12796

Google Scholar

Google Scholar

[48] Ferrando-Villalba P, Lopeandia A F, Abad L, Llobet J, Molina Ruiz M, Garcia G, Gerboles M, Alvarez F X, Goni A R, Munoz Pascual F J, Rodriguez Viejo J 2014 Nanotechnology 25 185402

Google Scholar

Google Scholar

[49] Tang J, Wang H T, Lee D H, Fardy M, Huo Z, Russell T P, Yang P 2010 Nano Lett. 10 4279

Google Scholar

Google Scholar

[50] Park W, Romano G, Ahn E C, Kodama T, Park J, Barako M T, Sohn J, Kim S J, Cho J, Marconnet A M, Asheghi M, Kolpak A M, Goodson K E 2017 Sci. Rep. 7 6233

Google Scholar

Google Scholar

[51] Park W, Sohn J, Romano G, Kodama T, Sood A, Katz J S, Kim B S Y, So H, Ahn E C, Asheghi M, Kolpak A M, Goodson K E 2018 Nanoscale 10 11117

Google Scholar

Google Scholar

[52] Li D, Wu Y, Fan R, Yang P, Majumdar A 2003 Appl. Phys. Lett. 83 3186

Google Scholar

Google Scholar

[53] Lee E K, Yin L, Lee Y, Lee J W, Lee S J, Lee J, Cha S N, Whang D, Hwang G S, Hippalgaonkar K, Majumdar A, Yu C, Choi B L, Kim J M, Kim K 2012 Nano Lett. 12 2918

Google Scholar

Google Scholar

[54] Li G, Yarali M, Cocemasov A, Baunack S, Nika D L, Fomin V M, Singh S, Gemming T, Zhu F, Mavrokefalos A, Schmidt O G 2017 ACS Nano 11 8215

Google Scholar

Google Scholar

[55] Choe H S, Prabhakar R, Wehmeyer G, Allen F I, Lee W, Jin L, Li Y, Yang P, Qiu C W, Dames C, Scott M, Minor A, Bahk J H, Wu J 2019 Nano Lett. 19 3830

Google Scholar

Google Scholar

[56] Mavrokefalos A, Pettes M T, Zhou F, Shi L 2007 Rev. Sci. Instrum. 78 034901

Google Scholar

Google Scholar

[57] Karg S F, Troncale V, Drechsler U, Mensch P, Das Kanungo P, Schmid H, Schmidt V, Gignac L, Riel H, Gotsmann B 2014 Nanotechnology 25 305702

Google Scholar

Google Scholar

[58] Jin Q, Jiang S, Zhao Y, Wang D, Qiu J, Tang D M, Tan J, Sun D M, Hou P X, Chen X Q, Tai K, Gao N, Liu C, Cheng H M, Jiang X 2019 Nat. Mater. 18 62

Google Scholar

Google Scholar

[59] Xu E, Li Z, Acosta J A, Li N, Swartzentruber B, Zheng S, Sinitsyn N, Htoon H, Wang J, Zhang S 2016 Nano Res. 9 820

Google Scholar

Google Scholar

[60] Ko T Y, Shellaiah M, Sun K W 2016 Sci. Rep. 6 35086

Google Scholar

Google Scholar

[61] Wang Y, Lin R, Zhu P, Zheng Q, Wang Q, Li D, Zhu J 2018 Nano Lett. 18 2772

Google Scholar

Google Scholar

[62] Roh J, Hippalgaonkar K, Kang J, Lee S, Ham J, Chen R, Majumdar A, Kim W, Lee W 2010 IEEE 633

Google Scholar

Google Scholar

[63] Liu N, Zhu T, Rosul M G, Peters J, Bowers J E, Zebarjadi M 2020 Mater.Today Phys. 14 100224

Google Scholar

Google Scholar

[64] 吴健 2014 硕士学位论文 (南京: 东南大学)

Wu J 2014 M.D. Dissertation (Nanjing: Southeast University) (in Chinese)

[65] Xu X, Pereira L F C, Wang Y, Wu J, Zhang K, Zhao X, Bae S, Tinh Bui C, Xie R, Thong J T L, Hong B H, Loh K P, Donadio D, Li B, Ozyilmaz B 2014 Nat. Commun. 5 3689

Google Scholar

Google Scholar

[66] Alaie S, Goettler D F, Abbas K, Su M F, Reinke C M, El-Kady I, Leseman Z C 2013 Rev. Sci. Instrum. 84 105003

Google Scholar

Google Scholar

[67] Alaie S, Goettler D F, Su M, Leseman Z C, Reinke C M, El-Kady I 2015 Nat. Commun. 6 7228

Google Scholar

Google Scholar

[68] Haras M, Lacatena V, Bah T M, Didenko S, Robillard J-F, Monfray S, Skotnicki T, Dubois E 2016 IEEE Electron Device Lett. 37 1358

Google Scholar

Google Scholar

[69] 马维刚, 王海东, 张兴, 王玮 2011 60 421

Google Scholar

Google Scholar

Ma W G, Wang H D, Zhang X, Wang W 2011 Acta Phys. Sin. 60 421

Google Scholar

Google Scholar

[70] 朱丽丹 2012 博士学位论文 (北京: 中国科学院工程热物理研究所)

Zhu L D 2012 Ph. D. Dissertation (Beijing: Institute of Engineering Thermophysics, Chinese Academy of Sciences) (in Chinese)

[71] Maire J, Nomura M 2014 Jpn. J. Appl. Phys. 53 06je09 06JE09

Google Scholar

Google Scholar

[72] Wang H, Chu W, Chen G 2019 Adv. Electron. Mater. 5 1900167

Google Scholar

Google Scholar

[73] Jo I, Pettes M T, Kim J, Watanabe K, Taniguchi T, Yao Z, Shi L 2013 Nano Lett. 13 550

Google Scholar

Google Scholar

[74] Seol J H, Jo I, Moore A L, Lindsay L, Aitken Z H, Pettes M T, Li X, Yao Z, Huang R, Broido D, Mingo N, Ruoff R S, Shi L 2010 Science 328 213

Google Scholar

Google Scholar

[75] Kim J, Ou E, Sellan D P, Shi L 2015 Rev. Sci. Instrum. 86 044901

Google Scholar

Google Scholar

[76] Smith B, Vermeersch B, Carrete J, Ou E, Kim J, Mingo N, Akinwande D, Shi L 2017 Adv. Mater. 29 1603756

Google Scholar

Google Scholar

[77] Li D, Wu Y, Kim P, Shi L, Yang P, Majumdar A 2003 Appl. Phys. Lett. 83 2934

Google Scholar

Google Scholar

[78] Hippalgaonkar K, Huang B, Chen R, Sawyer K, Ercius P, Majumdar A 2010 Nano Lett. 10 4341

Google Scholar

Google Scholar

[79] 朱林, 赵扬, 杨决宽 2015 真空科学与技术学报 35 1352

Google Scholar

Google Scholar

Zhu L, Zhao Y, Yang J K 2015 Chin. J. Vac. Sci. Techno. 35 1352

Google Scholar

Google Scholar

[80] 朱林 2016 硕士学位论文 (南京: 东南大学)

Zhu L 2016 M. D. Dissertation (Nanjing: Southeast University) (in Chinese)

计量

- 文章访问数: 15897

- PDF下载量: 327

- 被引次数: 0

下载:

下载: