-

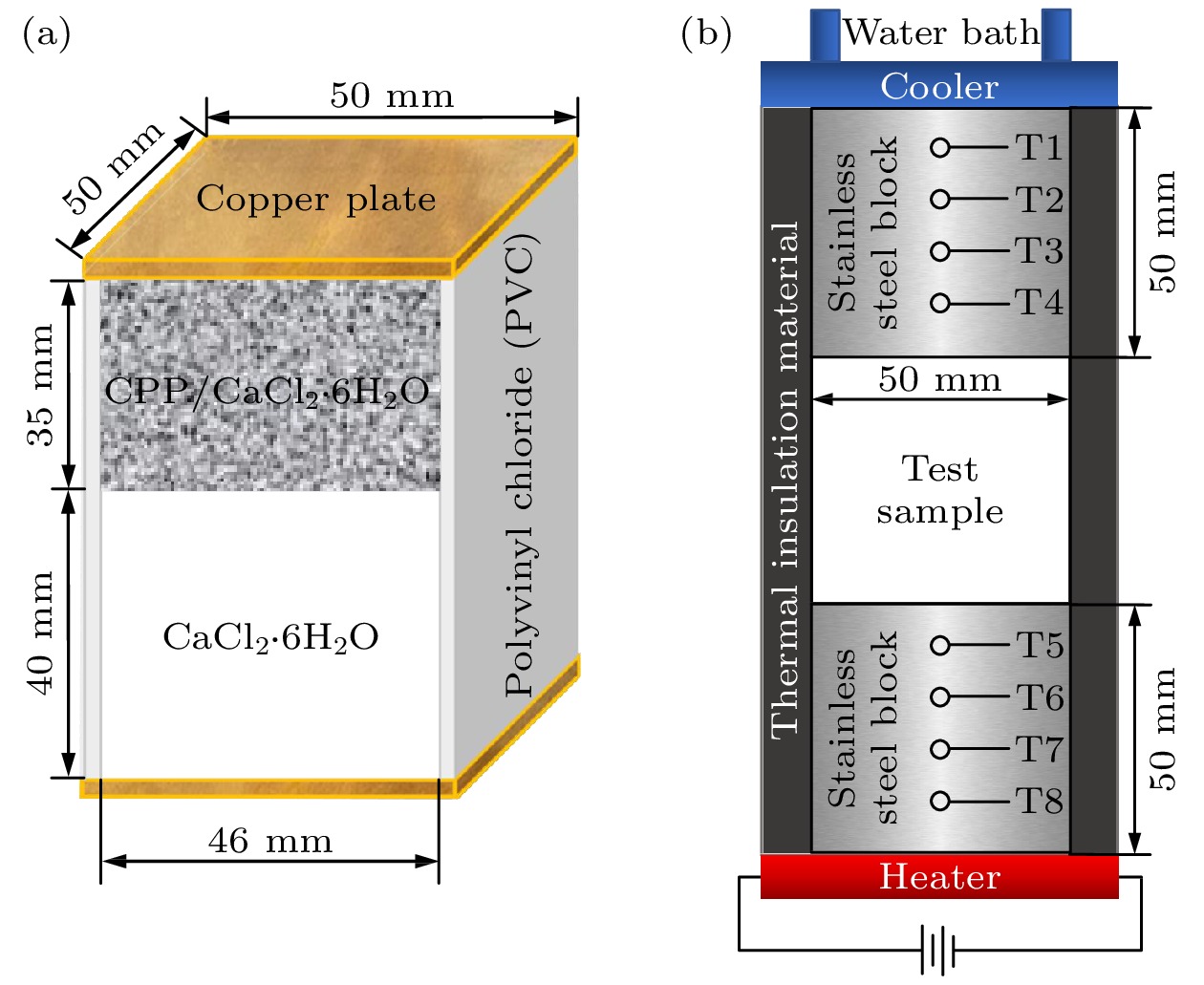

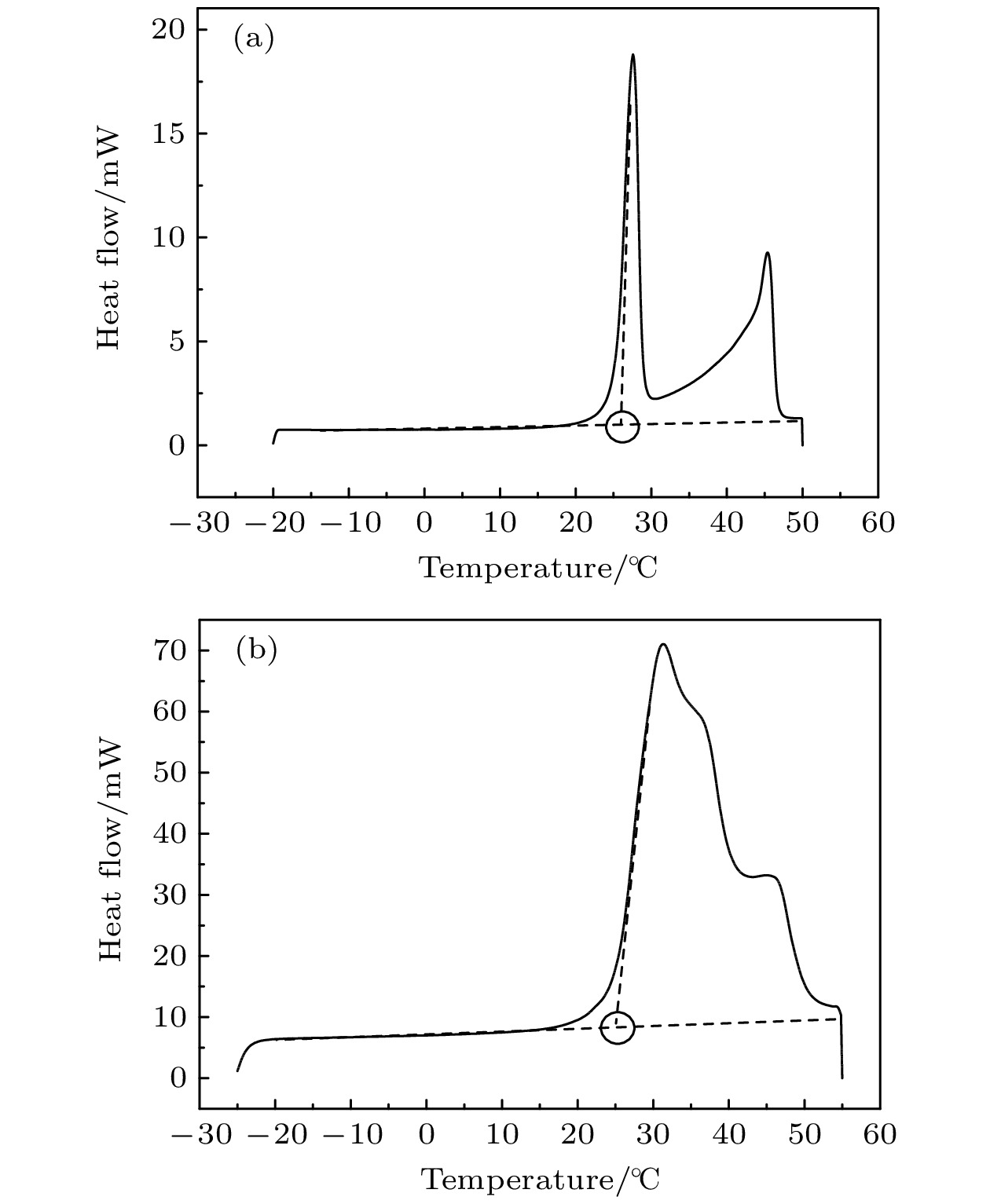

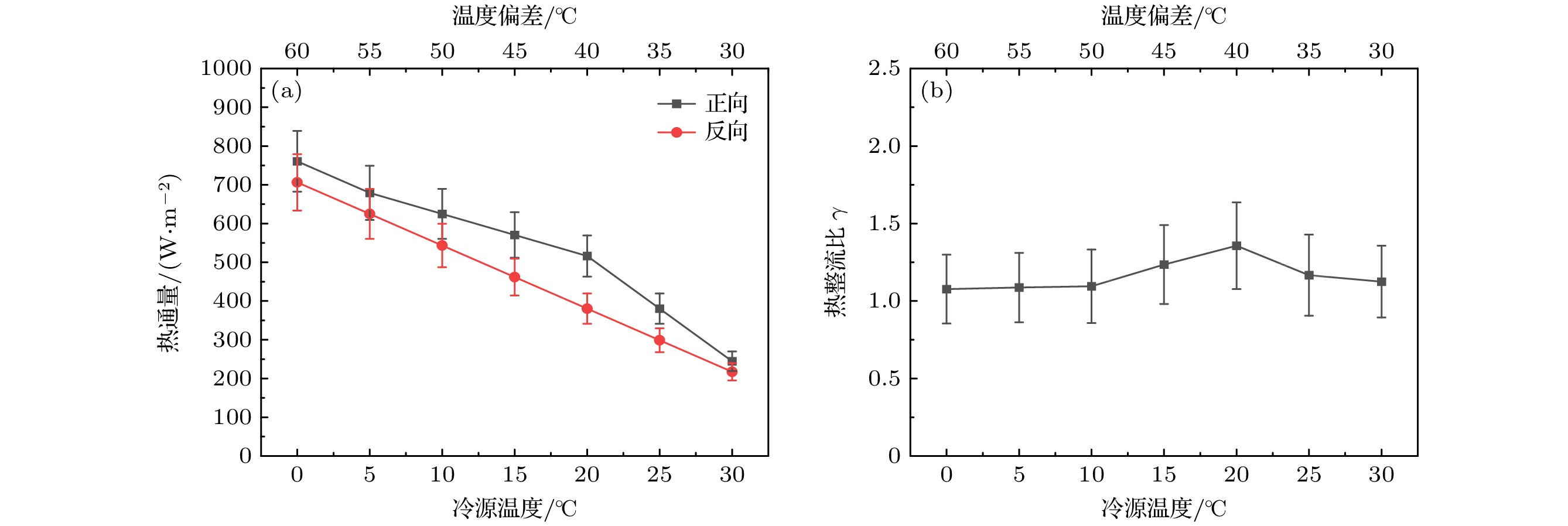

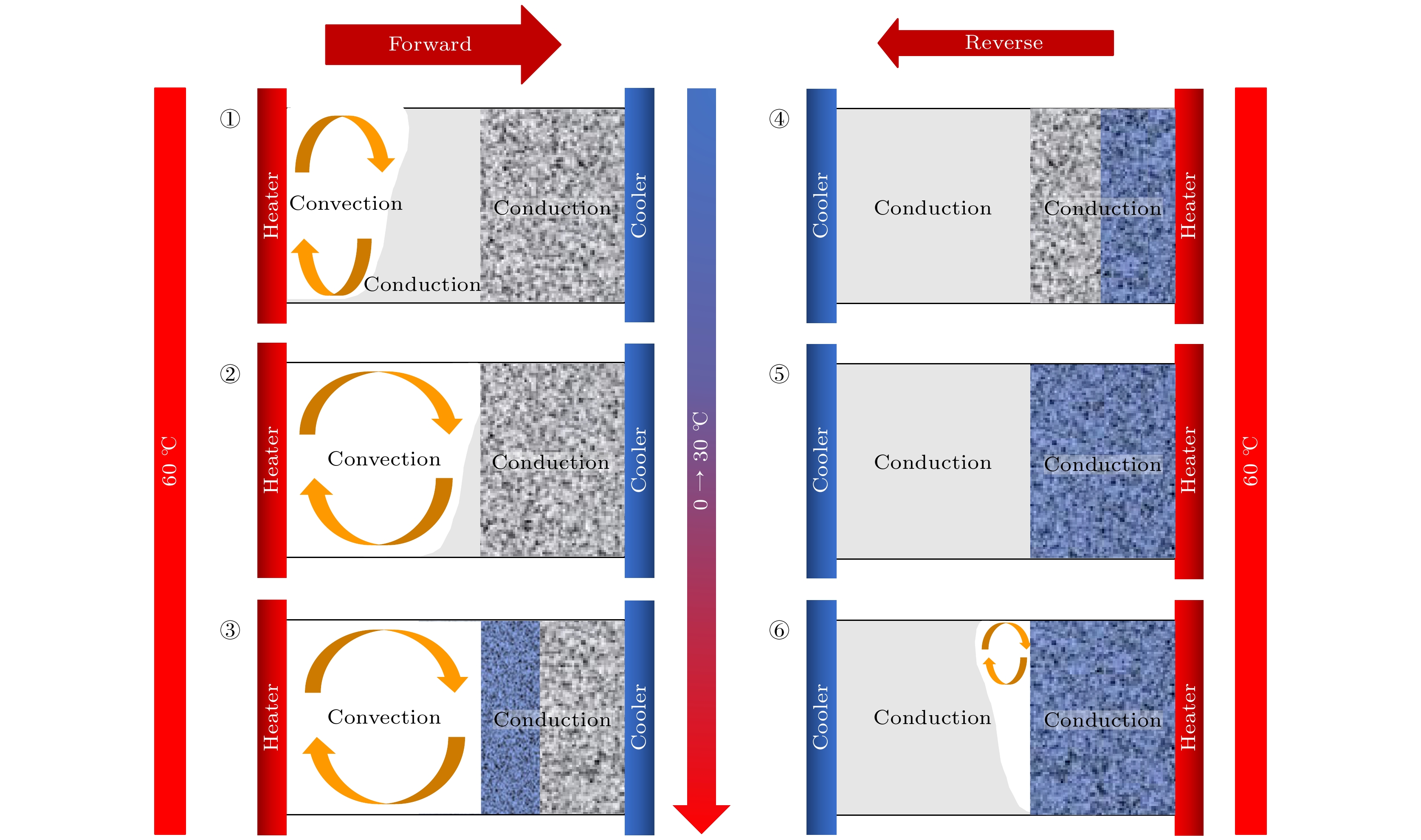

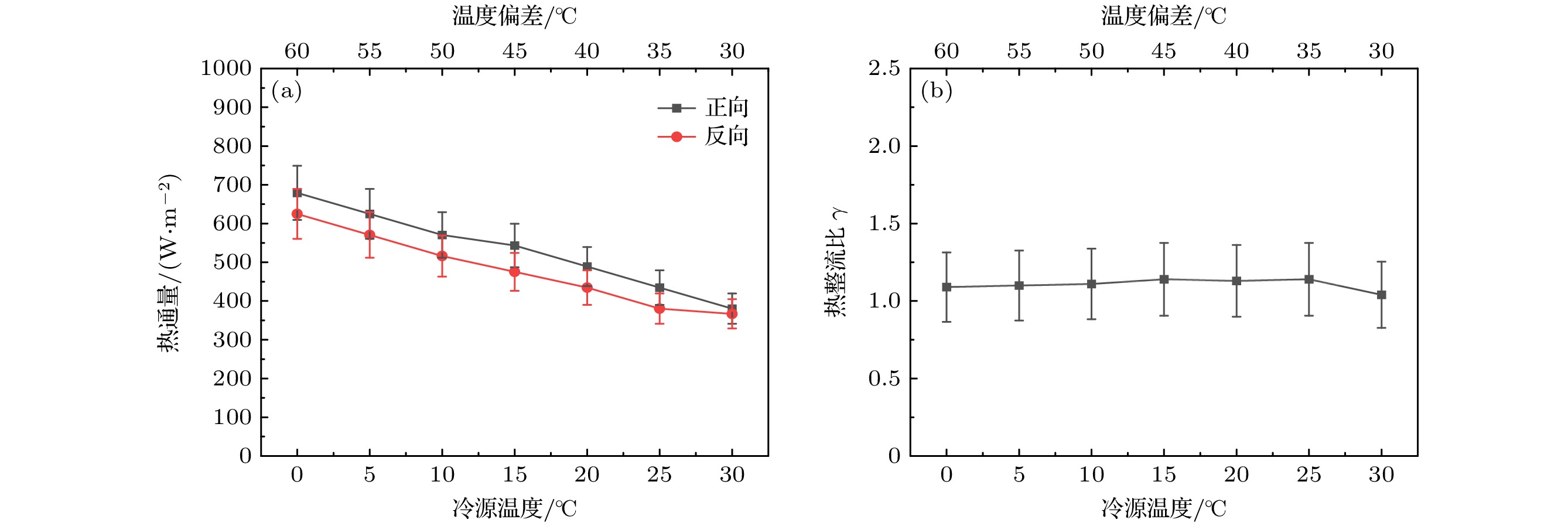

基于相反传热方向上相变程度不同引起的传热形式和系数差异设计的相变材料热二极管被认为是有潜力的热管理器件. 然而多种材料的使用或仅依靠数值模拟的研究使其结构复杂或理想化, 降低了其实际应用的可能性. 因此, 本文结合材料固液相变和自然对流过程的传热形式和传热系数变化, 提出了一个仅含有CaCl2·6H2O单相变材料的简单热二极管结构, 并制备了相应的器件, 搭建了稳态热通量测试系统用于实验研究, 其测量结果与文献记载值相近, 具有良好的准确度, 实验研究了冷热端温差和正反传热方向对热二极管热整流效果的影响规律. 结果表明: 热二极管的热通量随冷热源温差的减小而降低, 正向和反向分别沿逆重力和重力方向时, 热整流比最高可达1.58, 最佳冷源温度范围为20—25 ℃, 接近室温, 所提出的相变材料热二极管结构在建筑节能和热管理等方面具有一定的应用潜力.Phase change material thermal diodes designed on the basis of different heat transfer forms and coefficients caused by different phase transition degrees in opposite heat transfer directions are considered as potential thermal management devices. However, the use of a variety of materials or only relying on numerical simulation research makes its structure complex or idealized, which reduces the possibility of practical application. Therefore, in this work, a simple thermal diode structure containing only CaCl2·6H2O single-phase variable material is proposed in combination with changes in heat transfer form and heat transfer coefficient in solid-liquid phase change and natural convection process. The corresponding device is prepared, and a steady-state heat flux test system is set up for experimental study, the measured results are close to those recorded in the literature with good accuracy. The influence of the temperature difference between hot end and cold end and the direction of positive heat transfer and negative heat transfer on the thermal rectification effect of the thermal diode are studied experimentally. The results show that the heat flux of the thermal diode decreases with the decrease of the difference in temperature between the cold source and hot source, and the thermal rectification ratio reaches to 1.58 when the forward and reverse along the antigravity direction and gravity direction, respectively. The optimal cold source temperature range is 20–25 ℃, which is close to room temperature. The proposed phase change material thermal diode structure has a certain application potential in energy saving and thermal management of building.

[1] Pehl M, Arvesen A, Humpenoeder F, Popp A, Hertwich E G, Luderer G 2017 Nat. Energy 2 939

Google Scholar

Google Scholar

[2] McGlade C, Ekins P 2015 Nature 517 187

Google Scholar

Google Scholar

[3] 赖明东, 雍熙, 史文静 , rhhz_volume 2022 rhhz_volume 自然辩证法研究 38 69

Google Scholar

Google Scholar

Lai M D, Yong X, Shi W J 2022 Stud. Dialectics. Nat. 38 69

Google Scholar

Google Scholar

[4] Yang L, Yan H Y, Lam J C 2014 Appl. Energ. 115 164

Google Scholar

Google Scholar

[5] Guan L 2023 Ordnance Mater. Sci. Eng. 46 126 [关玲 2023 兵器材料科学与工程 46 126]

Google Scholar

Google Scholar

Guan L 2023 Ordnance Mater. Sci. Eng.46 126  Google Scholar

Google Scholar

[6] Zhu H, Wang J J 2023 hydraul. Pneumatics Seals 43 55 [朱浩, 王晶晶 2023 液压气动与密封 43 55]

Google Scholar

Google Scholar

Zhu H, Wang J J 2023 hydraul. Pneumatics Seals43 55  Google Scholar

Google Scholar

[7] Zhang X H, Li Z, Luo L G, Fan Y L, Du Z Y 2022 Energy 238 121652

Google Scholar

Google Scholar

[8] Ma S, Jiang M D, Tao P, Song C Y, Wu J B, Wang J, Deng T, Shang W 2018 Prog. Nat. Sci. Mater. 28 653

Google Scholar

Google Scholar

[9] Tran M-K, Mevawalla A, Aziz A, Panchal S, Xie Y, Fowler M 2022 Processes 10 6

[10] Yuan K J, Shi J M, Aftab W, Qin M L, Usman A, Zhou F, Lv Y, Gao S, Zou R Q 2020 Adv. Funct. Mater. 30 8

Google Scholar

Google Scholar

[11] Alva G, Lin Y X, Liu L K, Fang G Y 2017 Energ. Buildings 144 276

Google Scholar

Google Scholar

[12] Giro-Paloma J, Martinez M, Cabeza L F, Ines F A 2016 Renew. Sust. Energ. Rev. 53 1059

Google Scholar

Google Scholar

[13] Ghanekar A, Ji J, Zheng Y 2016 Appl. Phys. Lett. 109 5

Google Scholar

Google Scholar

[14] Traipattanakul B, Tso C Y, Chao C Y H 2019 Int. J. Heat Mass Transf. 135 294

Google Scholar

Google Scholar

[15] Meng Z N, Gulfam R, Zhang P, Ma F 2021 Int. J. Therm. Sci. 164 9

Google Scholar

Google Scholar

[16] Kasali S O, Ordonez-Miranda J, Joulain K. 2020 Int. J. Therm. Sci. 153 106393

Google Scholar

Google Scholar

[17] Ordonez-Miranda J, Hill J M, Joulain K, Ezzahri Y, Drevillon J 2018 J. Appl. Phys. 123 085102

Google Scholar

Google Scholar

[18] Wehmeyer G, Yabuki T, Monachon C, Wu J Q, Dames C 2017 Appl. Phys. Rev. 4 041304

Google Scholar

Google Scholar

[19] Zhang N, Yuan Y P, Cao X L, Du Y X, Zhang Z L, Gui Y W 2018 Adv. Eng. Mater. 20 1700753

Google Scholar

Google Scholar

[20] Incropera F P, DeWitt D P, Bergman T L, Lavine A S 1996 Fundamentals of Heat and Mass Transfer (5th Ed.) (New York: Wiley) pp563–601

[21] Tao W, Kong X F, Bao A Y, Fan C G, Zhang Y 2020 Materials 13 22

Google Scholar

Google Scholar

[22] Wang Y, Ge S X, Huang B J, Zheng Z 2019 Mater. Chem. Phys. 223 723

Google Scholar

Google Scholar

[23] Nagano K, Mochida T, Takeda S, Domanski R, Rebow M 2003 Appl. Therm. Eng. 23 229

Google Scholar

Google Scholar

[24] Cui W W, Zhang H Z, Xia Y P, Zou Y J, Xiang C L, Chu H L, Qiu S J, Xu F, Sun L X 2018 J. Therm. Anal. Calorim. 131 57

Google Scholar

Google Scholar

[25] Li G, Zhang B B, Li X, Zhou Y, Sun Q G, Yun Q 2014 Sol. Energ. Mater. Sol. C. 126 51

Google Scholar

Google Scholar

[26] Meng Z N, Gulfam R, Zhang P, Ma F 2020 Int. J. Heat Mass Transf. 147 118915

Google Scholar

Google Scholar

[27] Pallecchi E, Chen Z, Fernandes G E, Wan Y, Kim J H, Xu J 2015 Mater. Horiz. 2 125

Google Scholar

Google Scholar

[28] Chen R J, Cui Y L, Tian H, Yao R M, Liu Z P, Shu Y, Li C, Yang Y, Ren T L, Zhang G, Zou R Q 2015 Sci. Rep. 5 8

Google Scholar

Google Scholar

[29] Lyu J, Sheng Z Z, Xu Y Y, Liu C M, Zhang X T 2022 Adv. Funct. Mater. 32 19

Google Scholar

Google Scholar

[30] Wong M Y, Traipattanakul B, Tso C Y, Chao C Y H, Qiu H H 2019 Int. J. Heat Mass Transf. 138 173

Google Scholar

Google Scholar

[31] Swoboda T, Klinar K, Abbasi S, Brem G, Kitanovski A, Rojo M M 2021 Iscience 24 8

Google Scholar

Google Scholar

[32] Zhang X X, Zhou Y, Li X, Shen Y, Hi C X, Dong O Y, Ren X F, Zeng J B, Sun Y X, Wang S J, Yang X B 2018 Energy Storage Sci. Technol. 7 40 [张新星, 周园, 李翔, 申月, 海春喜, 董欧阳, 任秀峰, 曾金波, 孙艳霞, 王石军, 杨小波 2018 储能科学与技术 7 40]

Google Scholar

Google Scholar

Zhang X X, Zhou Y, Li X, Shen Y, Hi C X, Dong O Y, Ren X F, Zeng J B, Sun Y X, Wang S J, Yang X B 2018 Energy Storage Sci. Technol.7 40  Google Scholar

Google Scholar

[33] Li S W, Fu B B, Li J 2022 Acta Materiae Compositae Sin. 39 2885 [李绍伟, 傅彬彬, 李静 2022 复合材料学报 39 2885]

Google Scholar

Google Scholar

Li S W, Fu B B, Li J 2022 Acta Materiae Compositae Sin.39 2885  Google Scholar

Google Scholar

[34] Luo F B, He Y F, Cui W Q, Guo Y Y, Jin Y C, Li H Z, Huang B Q, Qian Q R 2022 Acs Appl. Polym. Mater. 4 2160

Google Scholar

Google Scholar

[35] Cottrill A L, Wang S, Liu A T, Wang W J, Strano M S 2018 Adv. Energy Mater. 8 11

Google Scholar

Google Scholar

[36] Moench S, Dittrich R 2022 Energies 15 11

Google Scholar

Google Scholar

-

表 1 测试系统测量结果

Table 1. Results of the measurement system.

表 2 CaCl2·6H2O和CPP/CaCl2·6H2O的热物理性质

Table 2. Thermophysical properties of CaCl2·6H2O and CPP/CaCl2·6H2O.

材料及其相态 等效导热系数

K/(W·(m·K)–1)固态 CaCl2·6H2O 0.74 自然对流态CaCl2·6H2O 1.10 相变前CPP/CaCl2·6H2O 1.02 相变后CPP/CaCl2·6H2O 0.61 表 3 CaCl2·6H2O和CPP/CaCl2·6H2O的相变相关温度点

Table 3. Temperature points related to phase transitions of CaCl2·6H2O and CPP/CaCl2·6H2O.

材料 CaCl2·6H2O

初始相变

温度

Tm1/℃CaCl2·6H2O

相变峰值

温度

Tp1/℃CaCl2·4H2O

相变峰值

温度

Tp2/℃CaCl2·6H2O 25.2 27.6 45.13 CPP/CaCl2·6H2O 24.0 29.9 44.83 -

[1] Pehl M, Arvesen A, Humpenoeder F, Popp A, Hertwich E G, Luderer G 2017 Nat. Energy 2 939

Google Scholar

Google Scholar

[2] McGlade C, Ekins P 2015 Nature 517 187

Google Scholar

Google Scholar

[3] 赖明东, 雍熙, 史文静 , rhhz_volume 2022 rhhz_volume 自然辩证法研究 38 69

Google Scholar

Google Scholar

Lai M D, Yong X, Shi W J 2022 Stud. Dialectics. Nat. 38 69

Google Scholar

Google Scholar

[4] Yang L, Yan H Y, Lam J C 2014 Appl. Energ. 115 164

Google Scholar

Google Scholar

[5] Guan L 2023 Ordnance Mater. Sci. Eng. 46 126 [关玲 2023 兵器材料科学与工程 46 126]

Google Scholar

Google Scholar

Guan L 2023 Ordnance Mater. Sci. Eng.46 126  Google Scholar

Google Scholar

[6] Zhu H, Wang J J 2023 hydraul. Pneumatics Seals 43 55 [朱浩, 王晶晶 2023 液压气动与密封 43 55]

Google Scholar

Google Scholar

Zhu H, Wang J J 2023 hydraul. Pneumatics Seals43 55  Google Scholar

Google Scholar

[7] Zhang X H, Li Z, Luo L G, Fan Y L, Du Z Y 2022 Energy 238 121652

Google Scholar

Google Scholar

[8] Ma S, Jiang M D, Tao P, Song C Y, Wu J B, Wang J, Deng T, Shang W 2018 Prog. Nat. Sci. Mater. 28 653

Google Scholar

Google Scholar

[9] Tran M-K, Mevawalla A, Aziz A, Panchal S, Xie Y, Fowler M 2022 Processes 10 6

[10] Yuan K J, Shi J M, Aftab W, Qin M L, Usman A, Zhou F, Lv Y, Gao S, Zou R Q 2020 Adv. Funct. Mater. 30 8

Google Scholar

Google Scholar

[11] Alva G, Lin Y X, Liu L K, Fang G Y 2017 Energ. Buildings 144 276

Google Scholar

Google Scholar

[12] Giro-Paloma J, Martinez M, Cabeza L F, Ines F A 2016 Renew. Sust. Energ. Rev. 53 1059

Google Scholar

Google Scholar

[13] Ghanekar A, Ji J, Zheng Y 2016 Appl. Phys. Lett. 109 5

Google Scholar

Google Scholar

[14] Traipattanakul B, Tso C Y, Chao C Y H 2019 Int. J. Heat Mass Transf. 135 294

Google Scholar

Google Scholar

[15] Meng Z N, Gulfam R, Zhang P, Ma F 2021 Int. J. Therm. Sci. 164 9

Google Scholar

Google Scholar

[16] Kasali S O, Ordonez-Miranda J, Joulain K. 2020 Int. J. Therm. Sci. 153 106393

Google Scholar

Google Scholar

[17] Ordonez-Miranda J, Hill J M, Joulain K, Ezzahri Y, Drevillon J 2018 J. Appl. Phys. 123 085102

Google Scholar

Google Scholar

[18] Wehmeyer G, Yabuki T, Monachon C, Wu J Q, Dames C 2017 Appl. Phys. Rev. 4 041304

Google Scholar

Google Scholar

[19] Zhang N, Yuan Y P, Cao X L, Du Y X, Zhang Z L, Gui Y W 2018 Adv. Eng. Mater. 20 1700753

Google Scholar

Google Scholar

[20] Incropera F P, DeWitt D P, Bergman T L, Lavine A S 1996 Fundamentals of Heat and Mass Transfer (5th Ed.) (New York: Wiley) pp563–601

[21] Tao W, Kong X F, Bao A Y, Fan C G, Zhang Y 2020 Materials 13 22

Google Scholar

Google Scholar

[22] Wang Y, Ge S X, Huang B J, Zheng Z 2019 Mater. Chem. Phys. 223 723

Google Scholar

Google Scholar

[23] Nagano K, Mochida T, Takeda S, Domanski R, Rebow M 2003 Appl. Therm. Eng. 23 229

Google Scholar

Google Scholar

[24] Cui W W, Zhang H Z, Xia Y P, Zou Y J, Xiang C L, Chu H L, Qiu S J, Xu F, Sun L X 2018 J. Therm. Anal. Calorim. 131 57

Google Scholar

Google Scholar

[25] Li G, Zhang B B, Li X, Zhou Y, Sun Q G, Yun Q 2014 Sol. Energ. Mater. Sol. C. 126 51

Google Scholar

Google Scholar

[26] Meng Z N, Gulfam R, Zhang P, Ma F 2020 Int. J. Heat Mass Transf. 147 118915

Google Scholar

Google Scholar

[27] Pallecchi E, Chen Z, Fernandes G E, Wan Y, Kim J H, Xu J 2015 Mater. Horiz. 2 125

Google Scholar

Google Scholar

[28] Chen R J, Cui Y L, Tian H, Yao R M, Liu Z P, Shu Y, Li C, Yang Y, Ren T L, Zhang G, Zou R Q 2015 Sci. Rep. 5 8

Google Scholar

Google Scholar

[29] Lyu J, Sheng Z Z, Xu Y Y, Liu C M, Zhang X T 2022 Adv. Funct. Mater. 32 19

Google Scholar

Google Scholar

[30] Wong M Y, Traipattanakul B, Tso C Y, Chao C Y H, Qiu H H 2019 Int. J. Heat Mass Transf. 138 173

Google Scholar

Google Scholar

[31] Swoboda T, Klinar K, Abbasi S, Brem G, Kitanovski A, Rojo M M 2021 Iscience 24 8

Google Scholar

Google Scholar

[32] Zhang X X, Zhou Y, Li X, Shen Y, Hi C X, Dong O Y, Ren X F, Zeng J B, Sun Y X, Wang S J, Yang X B 2018 Energy Storage Sci. Technol. 7 40 [张新星, 周园, 李翔, 申月, 海春喜, 董欧阳, 任秀峰, 曾金波, 孙艳霞, 王石军, 杨小波 2018 储能科学与技术 7 40]

Google Scholar

Google Scholar

Zhang X X, Zhou Y, Li X, Shen Y, Hi C X, Dong O Y, Ren X F, Zeng J B, Sun Y X, Wang S J, Yang X B 2018 Energy Storage Sci. Technol.7 40  Google Scholar

Google Scholar

[33] Li S W, Fu B B, Li J 2022 Acta Materiae Compositae Sin. 39 2885 [李绍伟, 傅彬彬, 李静 2022 复合材料学报 39 2885]

Google Scholar

Google Scholar

Li S W, Fu B B, Li J 2022 Acta Materiae Compositae Sin.39 2885  Google Scholar

Google Scholar

[34] Luo F B, He Y F, Cui W Q, Guo Y Y, Jin Y C, Li H Z, Huang B Q, Qian Q R 2022 Acs Appl. Polym. Mater. 4 2160

Google Scholar

Google Scholar

[35] Cottrill A L, Wang S, Liu A T, Wang W J, Strano M S 2018 Adv. Energy Mater. 8 11

Google Scholar

Google Scholar

[36] Moench S, Dittrich R 2022 Energies 15 11

Google Scholar

Google Scholar

计量

- 文章访问数: 4767

- PDF下载量: 62

- 被引次数: 0

下载:

下载: