-

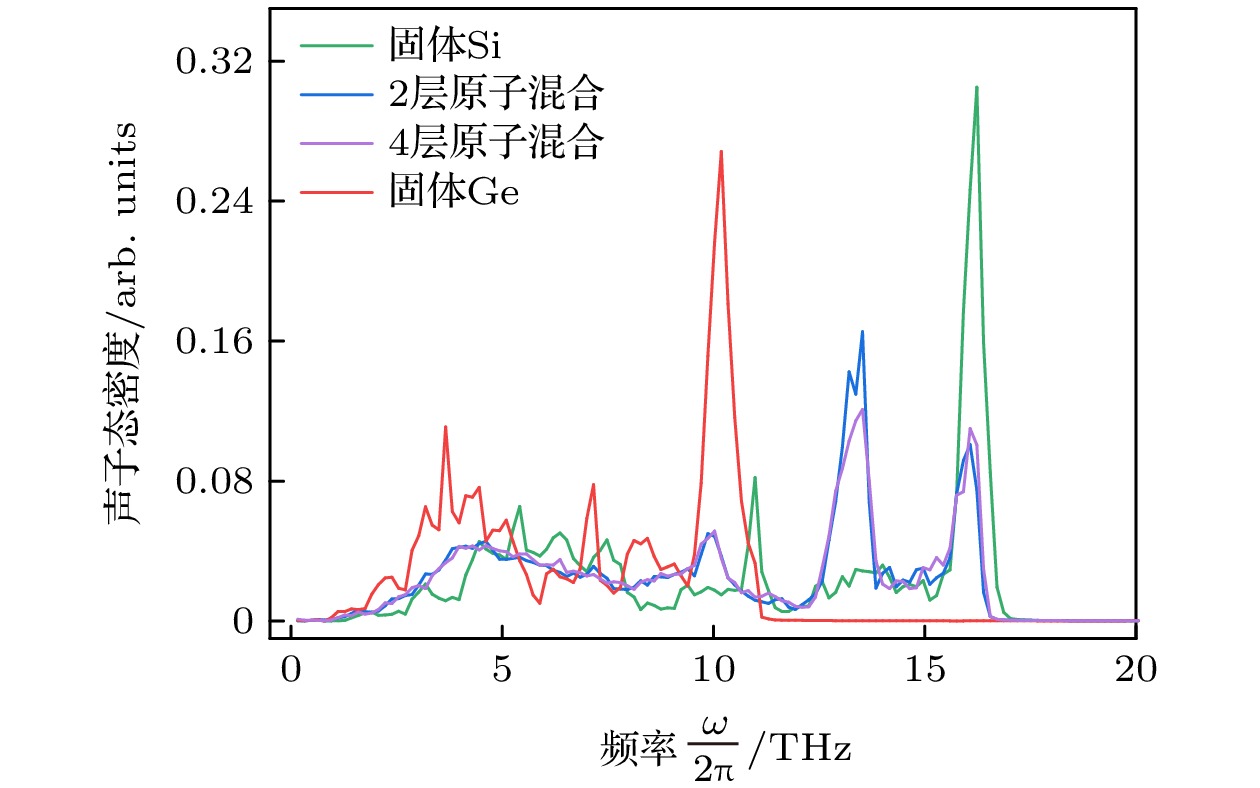

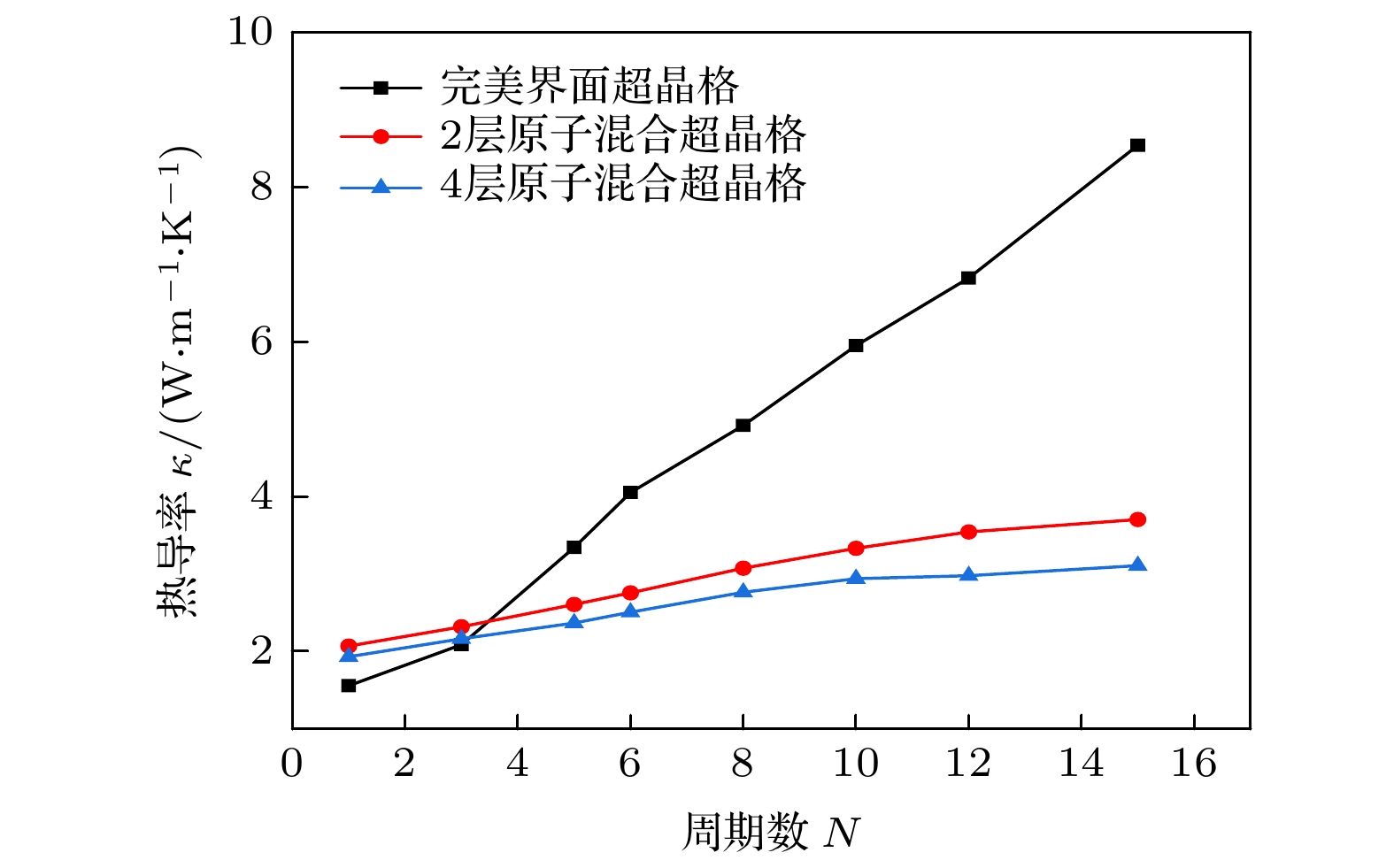

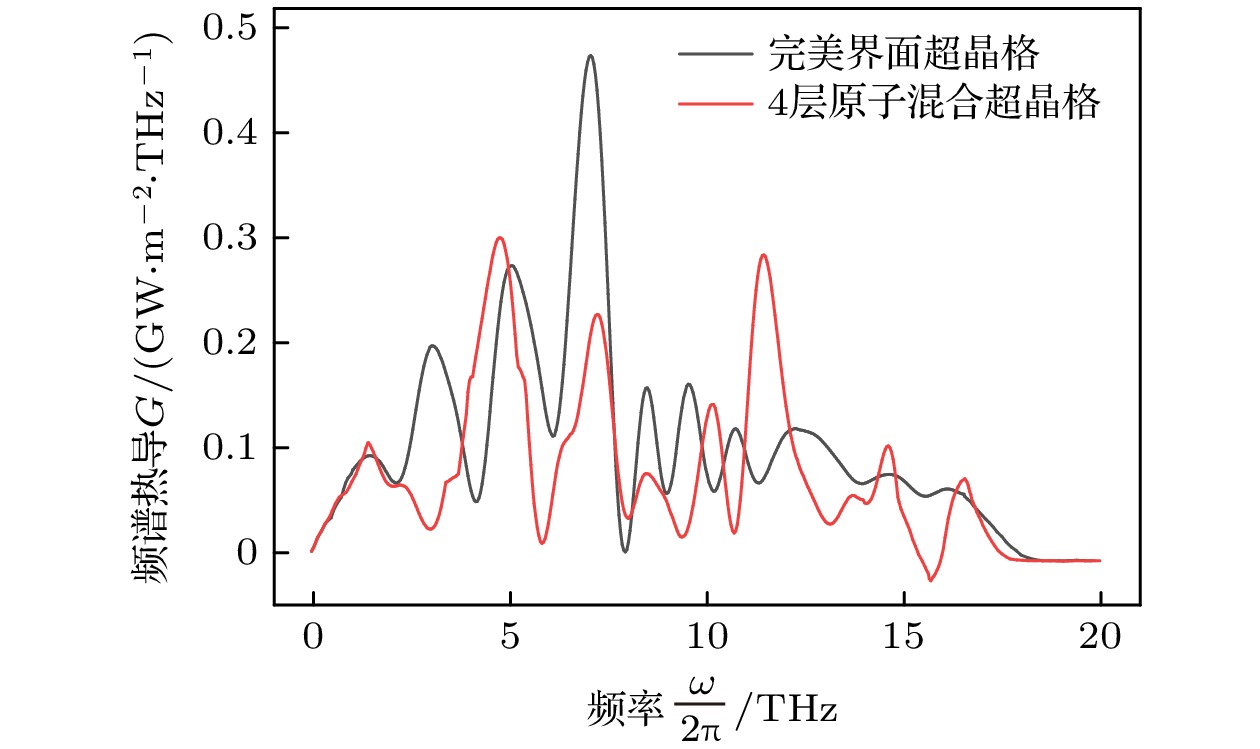

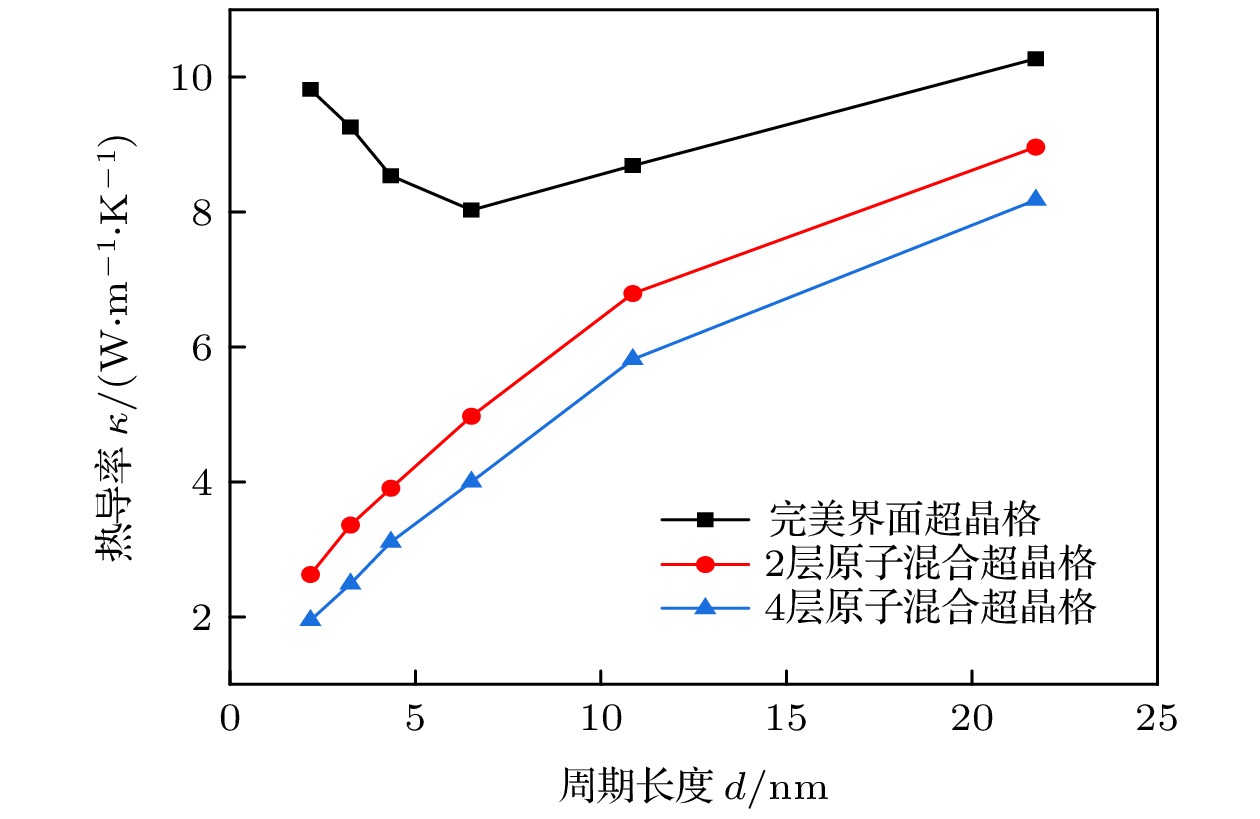

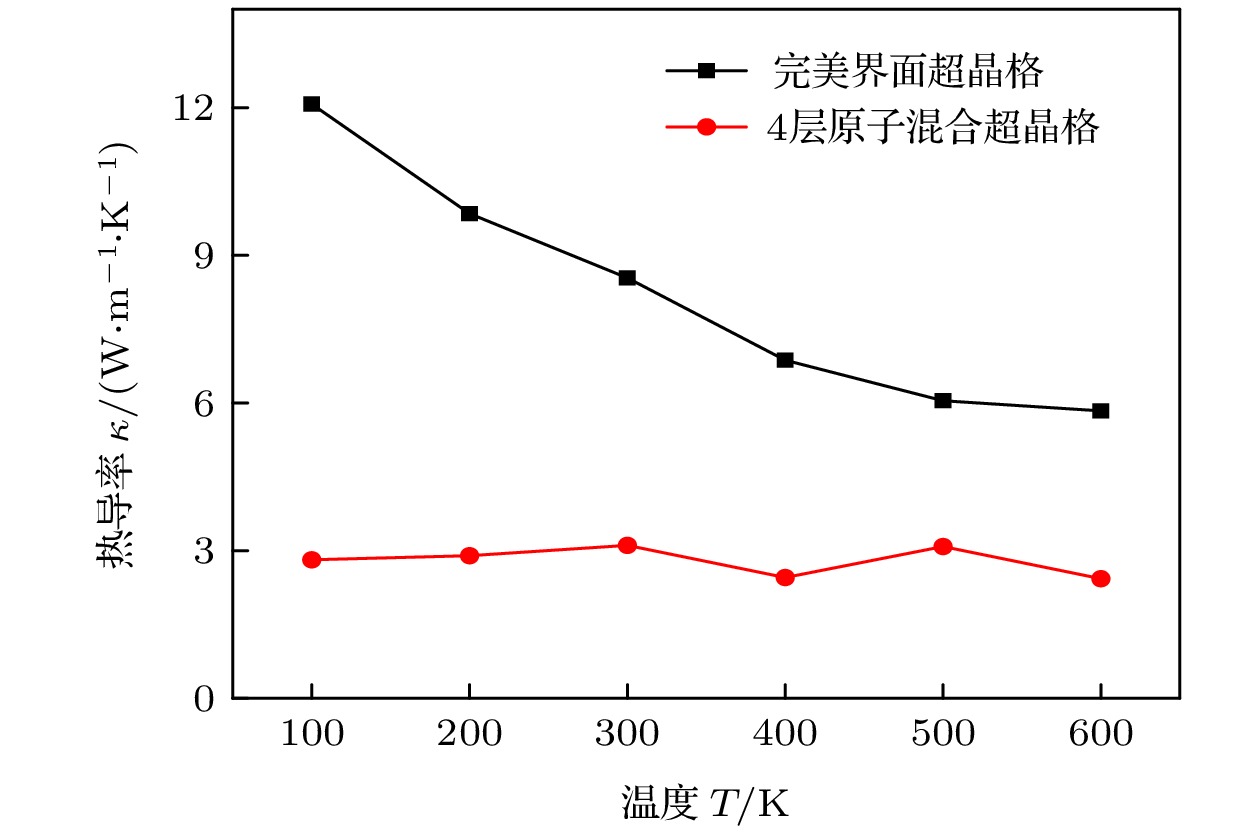

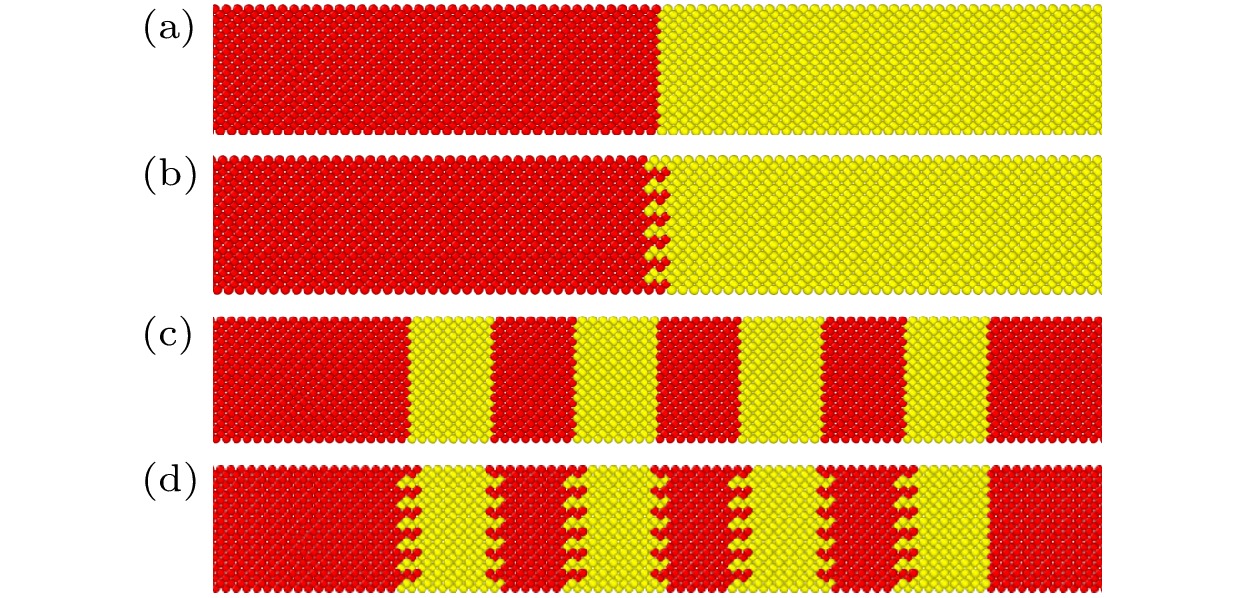

构造了界面具有原子混合的硅锗(Si/Ge)单界面和超晶格结构. 采用非平衡分子动力学模拟研究了界面原子混合对于单界面和超晶格结构热导率的影响, 重点研究了界面原子混合层数、环境温度、体系总长以及周期长度对不同晶格结构热导率的影响. 结果表明: 由于声子的“桥接”机制, 2层和4层界面原子混合能提高单一界面和少周期数的超晶格的热导率, 但是在多周期体系中, 具有原子混合时的热导率要低于完美界面时的热导率; 界面原子混合会破坏超晶格中声子的相干性输运, 一定程度引起热导率降低; 完美界面超晶格具有明显的温度效应, 而具有原子混合的超晶格热导率对温度的敏感性较低.The Si/Ge single interface and superlattice structure with atom mixing interfaces are constructed. The effects of interfacial atomic mixing on thermal conductivity of single interface and superlattice structures are studied by non-equilibrium molecular dynamics simulation. The effects of the number of atomic mixing layers, temperature, total length of the system and period length on the thermal conductivity for different lattice structures are studied. The results show that the mixing of two and four layers of atoms can improve the thermal conductivity of Si/Ge lattice with single interface and the few-period superlattice due to the “phonon bridging” mechanism. When the total length of the system is large, the thermal conductivity of the superlattice with atomic mixing interfaces decreases significantly compared with that of the perfect interface. The interfacial atom mixing will destroy the phonon coherent transport in the superlattice and reduce the thermal conductivity to some extent. The superlattce with perfect interface has obvious temperature effect, while the thermal conductivity of the superlattice with atomic mixing is less sensitive to temperature.

-

Keywords:

- single interface /

- superlattices /

- phonons /

- thermal conductivity

[1] Cahill D G, Ford W K, Goodson K E, Mahan G D, Majumdar A, Maris H J, Merlin R, Phillpot S R 2003 J. Appl. Phys. 93 793

Google Scholar

Google Scholar

[2] 唐道胜, 曹炳阳 2021 工程热 42 1546

Tang D S, Cao B Y 2021 J. Eng. Thermophys. 42 1546

[3] Liang Z, Tsai H L 2012 Int. J. Heat Mass Transf. 55 2999

Google Scholar

Google Scholar

[4] Chen W Y, Yang J K, Wei Z Y, Liu C H, Bi K D, Xu D Y, Li D Y, Chen Y F 2015 Phys. Rev. B 92 134113

Google Scholar

Google Scholar

[5] Tian Z T, Esfarjani K, Chen G 2014 Phys. Rev. B 89 235307

Google Scholar

Google Scholar

[6] Kechrakos D 1991 J. Phys. Condens. Matter 3 1443

Google Scholar

Google Scholar

[7] Liang Z, Tsai H L 2011 J. Phys. Condens. Matter 23 495303

Google Scholar

Google Scholar

[8] O'Brien P J, Shenogin S, Liu J X, Chow P K, Laurencin D, Mutin P H, Yamaguchi M, Keblinski P, Ramanath G 2013 Nat. Mater. 12 118

Google Scholar

Google Scholar

[9] English T S, Duda J C, Smoyer J L, Jordan D A, Norris P M, Zhigilei L V 2012 Phys. Rev. B 85 035438

Google Scholar

Google Scholar

[10] Shao C, Bao H 2015 Int. J. Heat Mass Transf. 85 33

Google Scholar

Google Scholar

[11] Zhou Y G, Zhang X L, Hu M 2016 Nanoscale 8 1994

Google Scholar

Google Scholar

[12] Stevens R J, Zhigilei L V, Norris P M 2007 Int. J. Heat Mass Transf. 50 3977

Google Scholar

Google Scholar

[13] Tian Z T, Esfarjani K, Chen G 2012 Phys. Rev. B 86 235304

Google Scholar

Google Scholar

[14] Jia L, Ju S H, Liang X G, Zhang X 2016 Mater. Res. Express 3 095024

Google Scholar

Google Scholar

[15] Merabia S, Termentzidis K 2014 Phys. Rev. B 89 054309

Google Scholar

Google Scholar

[16] Ravichandran J, Yadav A K, Cheaito R, Rossen P B, Soukiassian A, Suresha S J, Duda J C, Foley B M, Lee C H, Zhu Y, Lichtenberger A W, Moore J E, Muller D A, Schlom D G, Hopkins P E, Majumdar A, Ramesh R, Zurbuchen M A 2014 Nat. Mater. 13 168

Google Scholar

Google Scholar

[17] Luckyanova M N, Mendoza J, Lu H, Song B, Huang S, Zhou J, Li M, Dong Y, Zhou H, Garlow J, Wu L, Kirby B J, Grutter A J, Puretzky A A, Zhu Y, Dresselhaus M S, Gossard A, Chen G 2018 Sci. Adv. 4 eaat9460

Google Scholar

Google Scholar

[18] Chakraborty P, Chiu I A, Ma T F, Wang Y 2021 Nanotechnology 32 065401

Google Scholar

Google Scholar

[19] Plimpton S 1995 J. Comput. Phys. 117 1

Google Scholar

Google Scholar

[20] 臧毅, 马登科, 杨诺 2017 工程热 38 2686

Zang Y, Ma D K, Yang N 2017 J. Eng. Thermophys. 38 2686

[21] Qu X L, Gu J J 2020 RSC Adv. 10 1243

Google Scholar

Google Scholar

[22] Liang T, Zhou M, Zhang P, Yuan P, Yang D G 2020 Int. J. Heat Mass Transf. 151 119395

Google Scholar

Google Scholar

[23] Chen J, Zhang G, Li B W 2010 Nano Lett. 10 3978

Google Scholar

Google Scholar

[24] Wang Y, Vallabhaneni A, Hu J N, Qiu B, Chen Y P, Ruan X L 2014 Nano Lett. 14 592

Google Scholar

Google Scholar

[25] Zhang Z W, Chen Y P, Xie Y E, Zhang S B 2016 Appl. Therm. Eng. 102 1075

Google Scholar

Google Scholar

[26] Bodapati A, Schelling P K, Phillpot S R, Keblinski P 2006 Phys. Rev. B 74 245207

Google Scholar

Google Scholar

[27] Sun Y D, Zhou Y G, Han J, Hu M, Xu B, Liu W 2020 J. Appl. Phys. 127 045106

Google Scholar

Google Scholar

[28] Sääskilahti K, Oksanen J, Tulkki J, Volz S 2014 Phys. Rev. B 90 134312

Google Scholar

Google Scholar

[29] Ma Y L, Zhang Z W, Chen J G, Sääskilahti K, Volz S, Chen J 2018 Carbon 135 263

Google Scholar

Google Scholar

[30] Liu Y G, Bian Y Q, Chernatynskiy A, Han Z H 2019 Int. J. Heat Mass Transf. 145 118791

Google Scholar

Google Scholar

[31] 刘英光, 郝将帅, 任国梁, 张静文 2021 70 073101

Google Scholar

Google Scholar

Liu Y G, Hao J S, Ren G L, Zhang J W 2021 Acta Phys. Sin. 70 073101

Google Scholar

Google Scholar

[32] 惠治鑫, 贺鹏飞, 戴瑛, 吴艾辉 2014 63 074401

Google Scholar

Google Scholar

Hui Z X, He P F, Dai Y, Wu A H 2014 Acta Phys. Sin. 63 074401

Google Scholar

Google Scholar

-

-

[1] Cahill D G, Ford W K, Goodson K E, Mahan G D, Majumdar A, Maris H J, Merlin R, Phillpot S R 2003 J. Appl. Phys. 93 793

Google Scholar

Google Scholar

[2] 唐道胜, 曹炳阳 2021 工程热 42 1546

Tang D S, Cao B Y 2021 J. Eng. Thermophys. 42 1546

[3] Liang Z, Tsai H L 2012 Int. J. Heat Mass Transf. 55 2999

Google Scholar

Google Scholar

[4] Chen W Y, Yang J K, Wei Z Y, Liu C H, Bi K D, Xu D Y, Li D Y, Chen Y F 2015 Phys. Rev. B 92 134113

Google Scholar

Google Scholar

[5] Tian Z T, Esfarjani K, Chen G 2014 Phys. Rev. B 89 235307

Google Scholar

Google Scholar

[6] Kechrakos D 1991 J. Phys. Condens. Matter 3 1443

Google Scholar

Google Scholar

[7] Liang Z, Tsai H L 2011 J. Phys. Condens. Matter 23 495303

Google Scholar

Google Scholar

[8] O'Brien P J, Shenogin S, Liu J X, Chow P K, Laurencin D, Mutin P H, Yamaguchi M, Keblinski P, Ramanath G 2013 Nat. Mater. 12 118

Google Scholar

Google Scholar

[9] English T S, Duda J C, Smoyer J L, Jordan D A, Norris P M, Zhigilei L V 2012 Phys. Rev. B 85 035438

Google Scholar

Google Scholar

[10] Shao C, Bao H 2015 Int. J. Heat Mass Transf. 85 33

Google Scholar

Google Scholar

[11] Zhou Y G, Zhang X L, Hu M 2016 Nanoscale 8 1994

Google Scholar

Google Scholar

[12] Stevens R J, Zhigilei L V, Norris P M 2007 Int. J. Heat Mass Transf. 50 3977

Google Scholar

Google Scholar

[13] Tian Z T, Esfarjani K, Chen G 2012 Phys. Rev. B 86 235304

Google Scholar

Google Scholar

[14] Jia L, Ju S H, Liang X G, Zhang X 2016 Mater. Res. Express 3 095024

Google Scholar

Google Scholar

[15] Merabia S, Termentzidis K 2014 Phys. Rev. B 89 054309

Google Scholar

Google Scholar

[16] Ravichandran J, Yadav A K, Cheaito R, Rossen P B, Soukiassian A, Suresha S J, Duda J C, Foley B M, Lee C H, Zhu Y, Lichtenberger A W, Moore J E, Muller D A, Schlom D G, Hopkins P E, Majumdar A, Ramesh R, Zurbuchen M A 2014 Nat. Mater. 13 168

Google Scholar

Google Scholar

[17] Luckyanova M N, Mendoza J, Lu H, Song B, Huang S, Zhou J, Li M, Dong Y, Zhou H, Garlow J, Wu L, Kirby B J, Grutter A J, Puretzky A A, Zhu Y, Dresselhaus M S, Gossard A, Chen G 2018 Sci. Adv. 4 eaat9460

Google Scholar

Google Scholar

[18] Chakraborty P, Chiu I A, Ma T F, Wang Y 2021 Nanotechnology 32 065401

Google Scholar

Google Scholar

[19] Plimpton S 1995 J. Comput. Phys. 117 1

Google Scholar

Google Scholar

[20] 臧毅, 马登科, 杨诺 2017 工程热 38 2686

Zang Y, Ma D K, Yang N 2017 J. Eng. Thermophys. 38 2686

[21] Qu X L, Gu J J 2020 RSC Adv. 10 1243

Google Scholar

Google Scholar

[22] Liang T, Zhou M, Zhang P, Yuan P, Yang D G 2020 Int. J. Heat Mass Transf. 151 119395

Google Scholar

Google Scholar

[23] Chen J, Zhang G, Li B W 2010 Nano Lett. 10 3978

Google Scholar

Google Scholar

[24] Wang Y, Vallabhaneni A, Hu J N, Qiu B, Chen Y P, Ruan X L 2014 Nano Lett. 14 592

Google Scholar

Google Scholar

[25] Zhang Z W, Chen Y P, Xie Y E, Zhang S B 2016 Appl. Therm. Eng. 102 1075

Google Scholar

Google Scholar

[26] Bodapati A, Schelling P K, Phillpot S R, Keblinski P 2006 Phys. Rev. B 74 245207

Google Scholar

Google Scholar

[27] Sun Y D, Zhou Y G, Han J, Hu M, Xu B, Liu W 2020 J. Appl. Phys. 127 045106

Google Scholar

Google Scholar

[28] Sääskilahti K, Oksanen J, Tulkki J, Volz S 2014 Phys. Rev. B 90 134312

Google Scholar

Google Scholar

[29] Ma Y L, Zhang Z W, Chen J G, Sääskilahti K, Volz S, Chen J 2018 Carbon 135 263

Google Scholar

Google Scholar

[30] Liu Y G, Bian Y Q, Chernatynskiy A, Han Z H 2019 Int. J. Heat Mass Transf. 145 118791

Google Scholar

Google Scholar

[31] 刘英光, 郝将帅, 任国梁, 张静文 2021 70 073101

Google Scholar

Google Scholar

Liu Y G, Hao J S, Ren G L, Zhang J W 2021 Acta Phys. Sin. 70 073101

Google Scholar

Google Scholar

[32] 惠治鑫, 贺鹏飞, 戴瑛, 吴艾辉 2014 63 074401

Google Scholar

Google Scholar

Hui Z X, He P F, Dai Y, Wu A H 2014 Acta Phys. Sin. 63 074401

Google Scholar

Google Scholar

计量

- 文章访问数: 6003

- PDF下载量: 101

- 被引次数: 0

下载:

下载: