-

高效铜基薄膜太阳电池通常采用无机n型半导体材料CdS作为缓冲层, 因此, 缓冲层与吸收层之间的界面质量和能带匹配对载流子的收集利用至关重要. 在优化CdS基础工艺的基础上, 在含硫气氛下对硫化镉/铜基薄膜异质结进行退火的策略进一步提高CdS薄膜质量, 并将其应用到铜基太阳电池, 调控铜基薄膜电池p-n异质结能带匹配. 研究表明, CdS薄膜在含硫的惰性气氛中退火可以有效提高CdS薄膜的结晶质量并抑制CZTS/CdS异质结界面的非辐射复合, 器件的开路电压得到大幅提升, 最高可达718 mV. 在器件效率方面, 基于溅射法的CZTS太阳电池效率从3.47%提升到5.68%, 约为不退火处理的2倍. 该研究为铜基薄膜太阳电池器件实现高开路电压提供了可靠的工艺窗口. 同时, 有力地说明了退火气氛选择对于CdS质量以及CZTS/CdS异质结能带匹配的重要性, 除了界面互扩散以外, 对薄膜材料组分及其结晶性等均实现了调控.

-

关键词:

- 铜基薄膜太阳电池 /

- 硫化镉缓冲层 /

- 退火气氛 /

- 硫化镉/铜基薄膜异质结

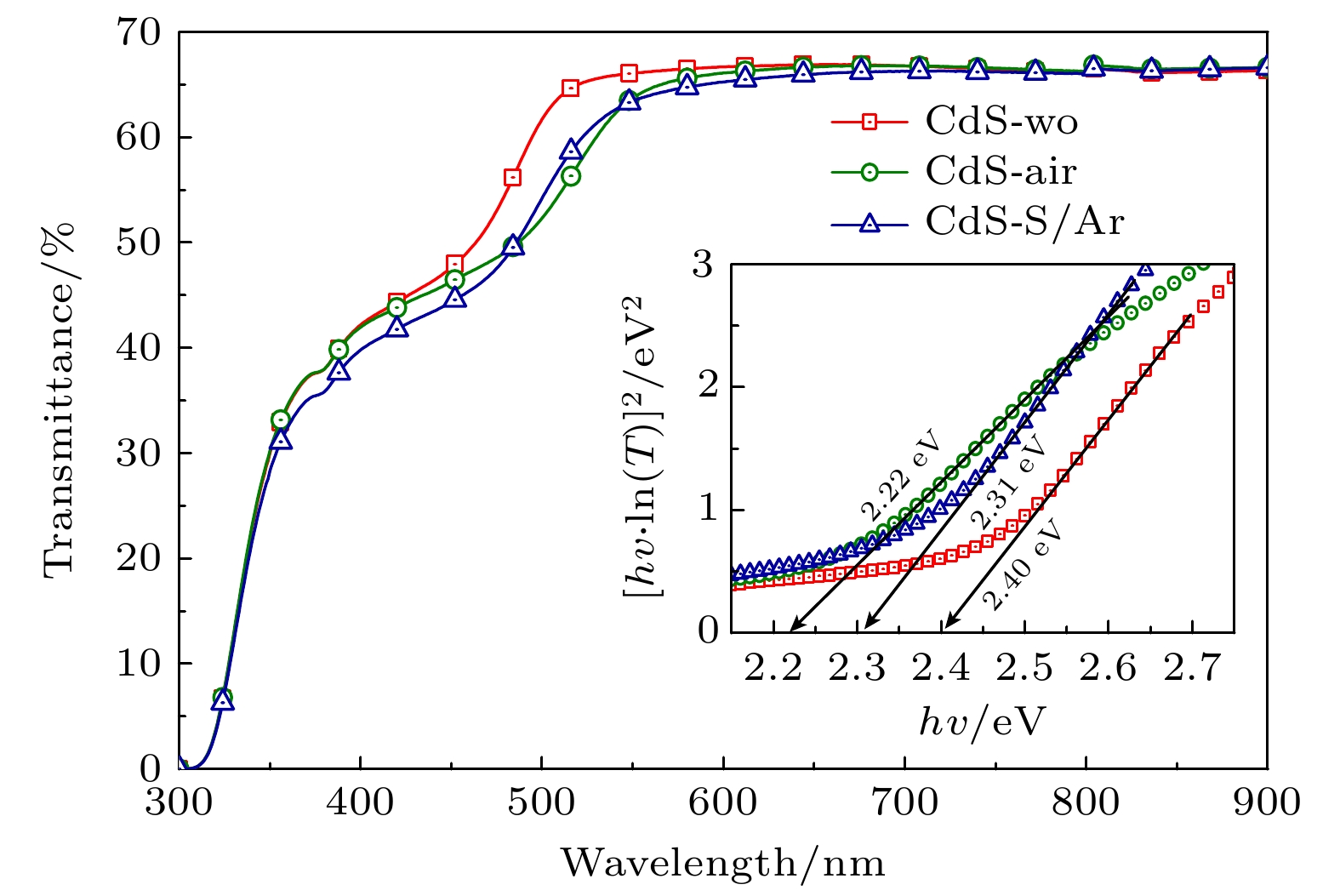

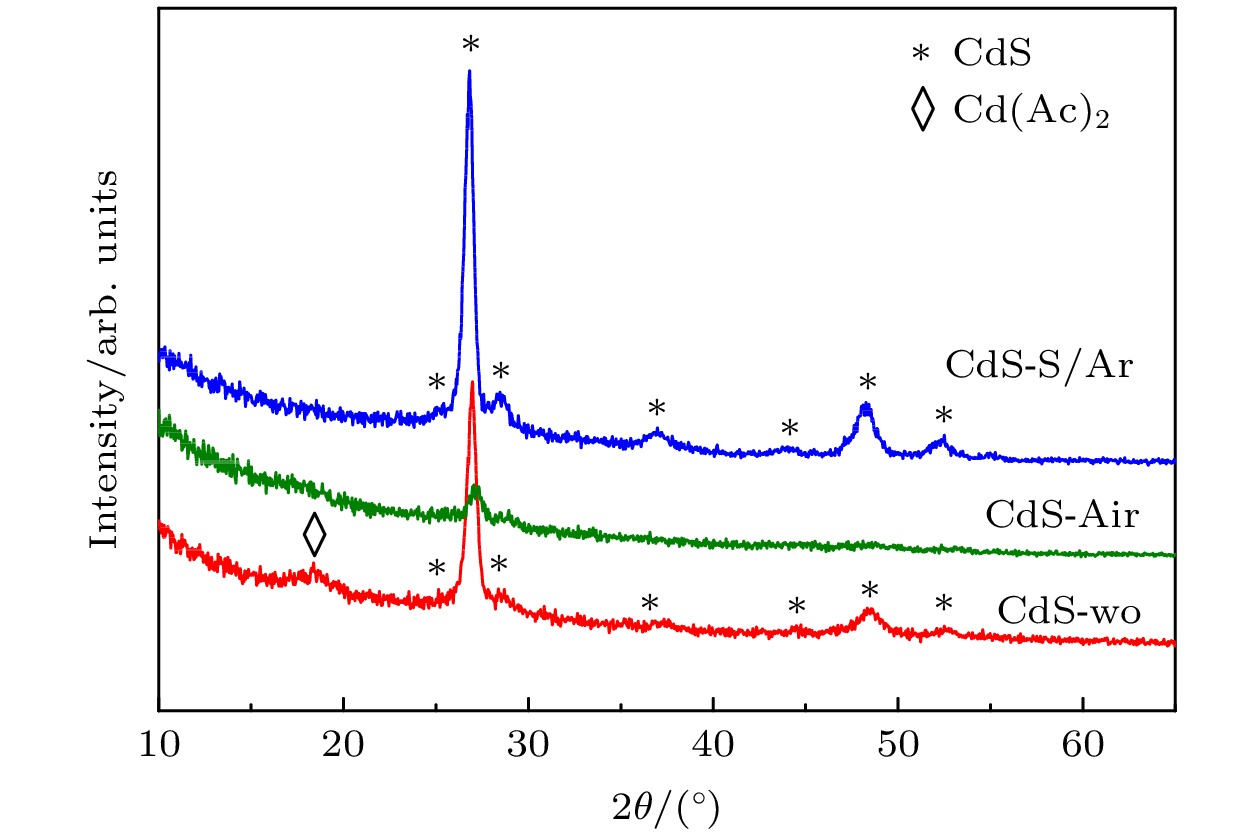

Efficient copper based thin film solar cells usually use inorganic n-type semiconductor material CdS as the buffer layer. Therefore, the interface quality and energy band matching between the buffer layer and the absorption layer are crucial to the collection and utilization of carriers. Heat treatment can promote the mutual diffusion of interface elements, the migration of ions in the material, and the change of defect state, and the appropriate temperature will change the Cu-Zn ordering degree in the absorption layer, so as to improve the efficiency of the solar cells. Based on the optimization of CdS basic process, the strategy of annealing CdS/copper-based thin film heterojunction in sulfur atmosphere further improves the quality of CdS thin film, and is applied to copper-based solar cells to regulate the p-n heterojunction energy band gap matching of copper-based thin film cells. The results show that the annealing of CdS thin film in sulfur-containing inert atmosphere can effectively improve the crystal quality of CdS thin film and inhibit the non-radiative recombination loss caused by defect trapping at the interface of CZTS/CdS heterojunction, and the open-circuit voltage of the device can significantly increase to 718 mV. In addition, annealing CZTS/CdS heterojunction in S/Ar atmosphere can effectively improve the p-n heterojunction energy band gap matching, which not only improves the electron transmission, but also reduces the carrier recombination, thus improving the Voc and FF of the device. Besides, the oxygen element in CdS film can be replaced by sulfur element in sulfur atmosphere to improve the quality of CdS film, and thus enhancing the short-wave absorption of solar cell device. Therefore, in terms of device efficiency, the efficiency of CZTS solar cell based on sputtering method increases from 3.47% to 5.68%, which is about twice that of non-annealing treatment. Its device structure is Glass/Mo/CZTS/CdS/i-ZnO/Al:ZnO/Ni/Al, providing a reliable process window for copper based thin film solar cell devices to achieve high open-circuit voltage. Meanwhile, this study strongly demonstrates the importance of annealing atmosphere selection for CdS quality and energy band matching of CZTS/CdS heterojunction. In addition to interface interdiffusion, the composition and crystallinity of thin film material are controlled.-

Keywords:

- copper based thin film solar cells /

- CdS buffer layer /

- annealing atmosphere /

- cadmium sulfide/copper-based thin film heterojunction

[1] Nakamura M, Yamaguchi K, Kimoto Y, Yasaki Y, Kato T, Sugimoto H 2019 IEEE J. Photovolt. 9 1863

Google Scholar

Google Scholar

[2] Gong Y, Zhu Q, Li B, Wang S, Duan B, Lou L, Xiang C, Jedlicka E, Giridharagopal R, Zhou Y, Dai Q, Yan W, Chen S, Meng Q, Xin H 2022 Nat. Energy 7 966

Google Scholar

Google Scholar

[3] Cheng T, Cai C, Huang W, Xu W, Tu L, Lai C 2020 ACS Appl. Mater. Interfaces 12 18157

Google Scholar

Google Scholar

[4] Islam M A, Hossain M S, Aliyu M M, Chelvanathan P, Huda Q, Karim M R, Sopian K, Amin N 2013 Energy Procedi 33 203

Google Scholar

Google Scholar

[5] Sivaraman T, Narasimman V, Nagarethinam V S, Balu A R 2015 Prog. Nat. Sci. 25 392

Google Scholar

Google Scholar

[6] Neuschitzer M, Sanchez Y, López-Marino S, Xie H B, Fairbrother A, Placidi M, Haass S, Izquierdo-Roca V, Perez-Rodriguez A, Saucedo E 2015 Prog. Photovolt. 23 1660

Google Scholar

Google Scholar

[7] Zhang S, Yu F, Yuan Q, Wang Y, Wei S, Tesfamichael T, Liang B, Wang H 2019 Sol. Energy Mater. and Sol. Cells 200 109892

Google Scholar

Google Scholar

[8] Martin N M, Platzer-Björkman C, Simonov K, Rensmo H, Törndahl T 2020 Phys. Status Solidi (b) 257 2000308

Google Scholar

Google Scholar

[9] Yang K J, Son D H, Sung S J, Sim J H, Kim Y I, Park S N, Jeon D H, Kim J, Hwang D K, Jeon C W, Nam D Y, Cheong H, Kang J K, Kim D H 2016 J. Mater. Chem. A 4 10151

Google Scholar

Google Scholar

[10] Cui X, Sun K, Huang J, Lee C Y, Yan C, Sun H, Zhang Y, Liu F, Hossain M A, Zakaria Y, Wong L H, Green M, Hoex B, Hao X 2018 Chem. Mater. 30 7860

Google Scholar

Google Scholar

[11] Guo H, Meng R, Wang G, Wang S, Wu L, Li J, Wang Z, Dong J, Hao X, Zhang Y 2022 Energy Environ. Sci. 15 693

Google Scholar

Google Scholar

[12] Gutiérrez Lazos C D, Rosendo E, Ortega M, Oliva A I, Tapia O, Díaz T, Juárez H, García G, Rubín M 2009 Mater. Sci. Eng. B 165 74

Google Scholar

Google Scholar

[13] Rizwan Z, Zakaria A, Mohd Ghazali M S, Jafari A, Din F U, Zamiri R 2011 Int J Mol Sci 12 1293

Google Scholar

Google Scholar

[14] Tajima S, Umehara M, Hasegawa M, Mise T, Itoh T 2017 Prog. Photovolt. 25 14

Google Scholar

Google Scholar

[15] Yan C, Huang J, Sun K, Johnston S, Zhang Y, Sun H, Pu A, He M, Liu F, Eder K, Yang L, Cairney J M, Ekins-Daukes N J, Hameiri Z, Stride J A, Chen S Y, Green M A, Hao X 2018 Nat. Energy 3 764

Google Scholar

Google Scholar

[16] Pham N D, Tiong V T, Yao D, Martens W, Guerrero A, Bisquert J, Wang H 2017 Nano Energy 41 476

Google Scholar

Google Scholar

[17] Diao A, Thiaw B, Boiro M, Mbodji S, Sissoko 2021 J. Mod. Phys. 12 635

Google Scholar

Google Scholar

[18] Nisika, Kaur K, Kumar M 2020 J. Mater. Chem. A 8 21547

Google Scholar

Google Scholar

[19] Scragg J J S, Choubrac L, Lafond A, Ericson T, Platzer-Björkman C 2014 Appl. Phys. Lett. 104 041911

Google Scholar

Google Scholar

[20] Gokmen T, Gunawan O, Todorov T K, Mitzi D B 2013 Appl. Phys. Lett. 103 103506

Google Scholar

Google Scholar

[21] Scragg J J, Ericson T, Kubart T, Edoff M, Platzer-Björkman C 2011 Chem. Mater. 23 4625

Google Scholar

Google Scholar

[22] Zhang S, Wu J, Guo H, Sun Y, Zhou Z, Zhang Y 2021 Phys. Status Solidi (a) 218 2100585

Google Scholar

Google Scholar

-

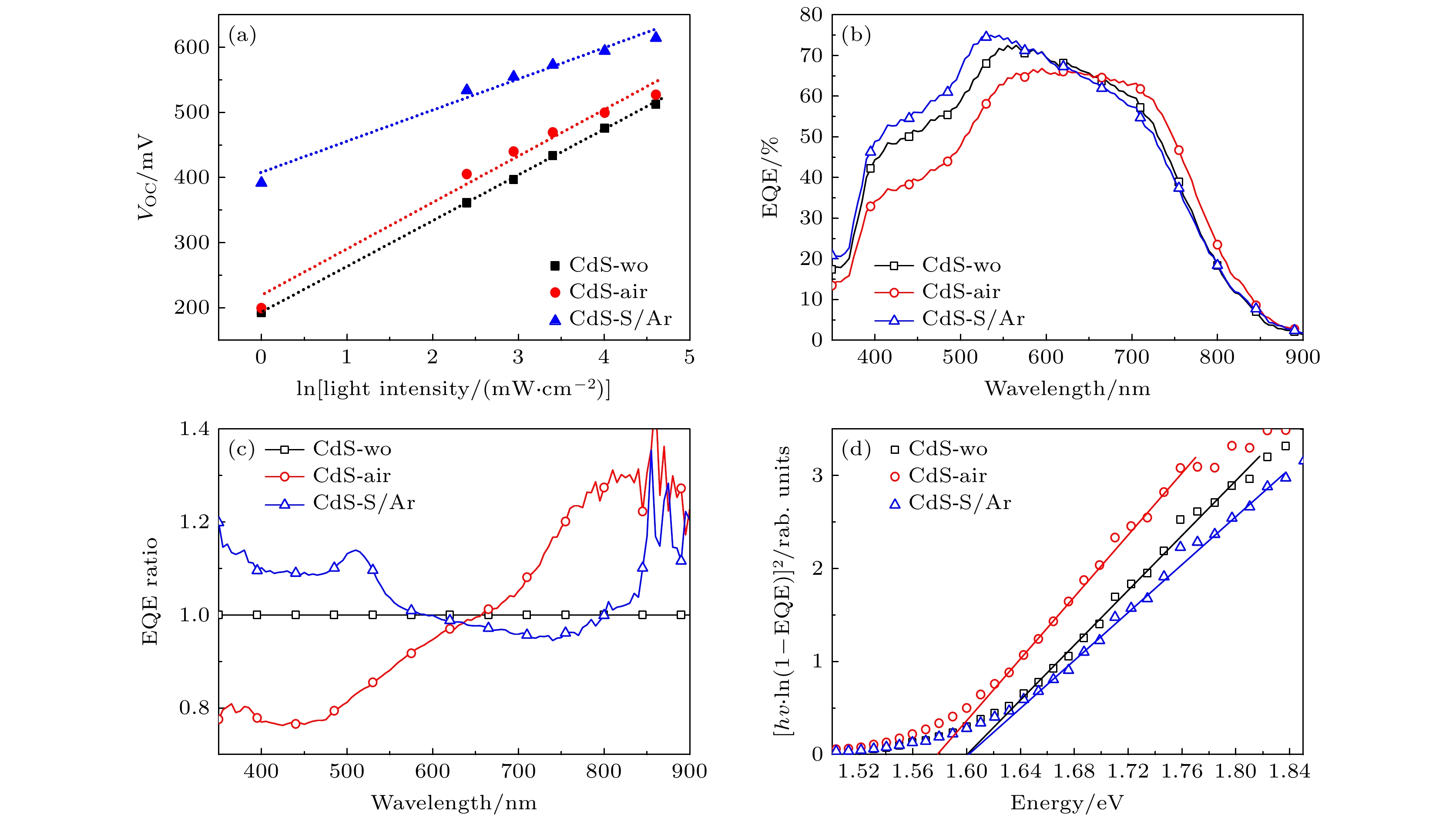

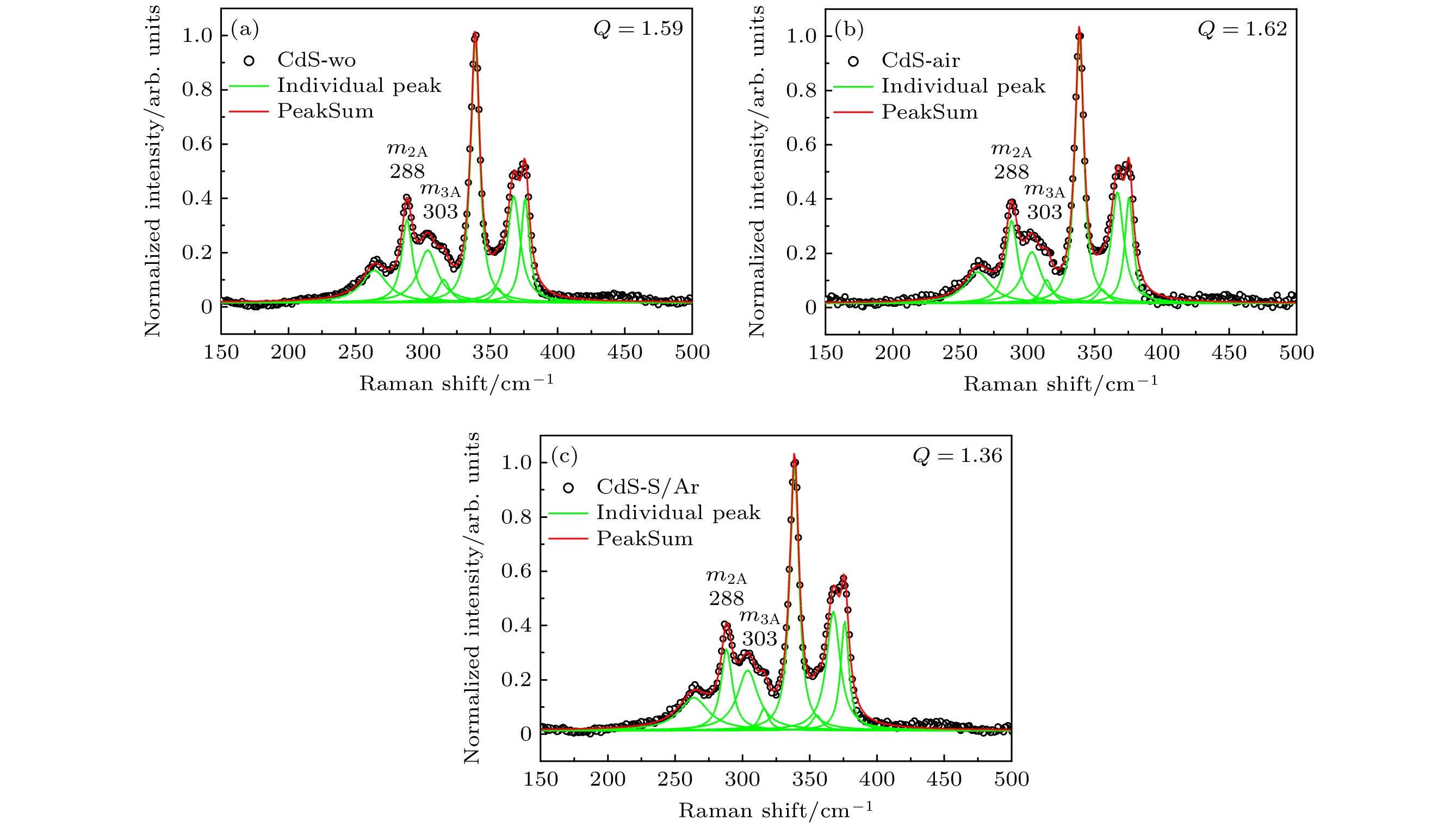

图 3 不同气氛下热处理CZTS/CdS异质结后电池性能 (a)开路电压与光强的关系; (b)外量子效率; (c)外量子效率比; (d) 根据外量子效率长波吸收边拟合吸收层禁带宽度曲线

Fig. 3. Characteritic of CZTS/CdS heterojunction treated by heat in different atmospheres (a) VOC versus illumination intensity; (b) external quantum efficiency; (c) external quantum efficiency ratio; (d) Eg curves of absorb layer fitted according to EQE of cells.

图 5 (a)不同气氛下热处理CZTS/CdS异质结后CdS表面XPS全谱; (b)—(d) 高分辨S 2p分峰拟合谱; (e) Cd 3d和(f) O 1s的高分辨率谱

Fig. 5. Full XPS spectra of CdS surface after heat treatment of CZTS/CdS heterojunction under different atmospheres; (b)–(d) high-solution XPS of S 2p split peak fitting spectra; (e) Cd 3d and (f) O 1s high-solution XPS spectra.

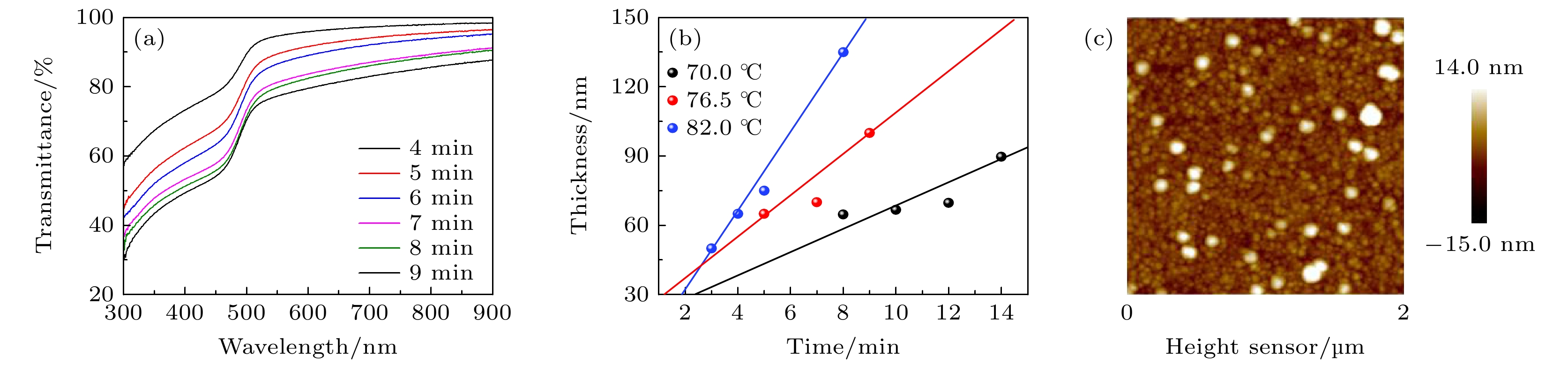

图 8 薄膜CdS在空气中(a), (b)和含硫气氛中(c), (d)退火后的AFM形貌和KPFM表面势分布; (e)薄膜CdS退火后KPFM表面势统计分布图

Fig. 8. AFM morphology and KPFM surface potential distribution after annealing of CdS thin films in air (a), (b) and sulfur-containing atmosphere (c), (d); (e) statistical distribution of KPFM surface potential after annealing of CdS thin films.

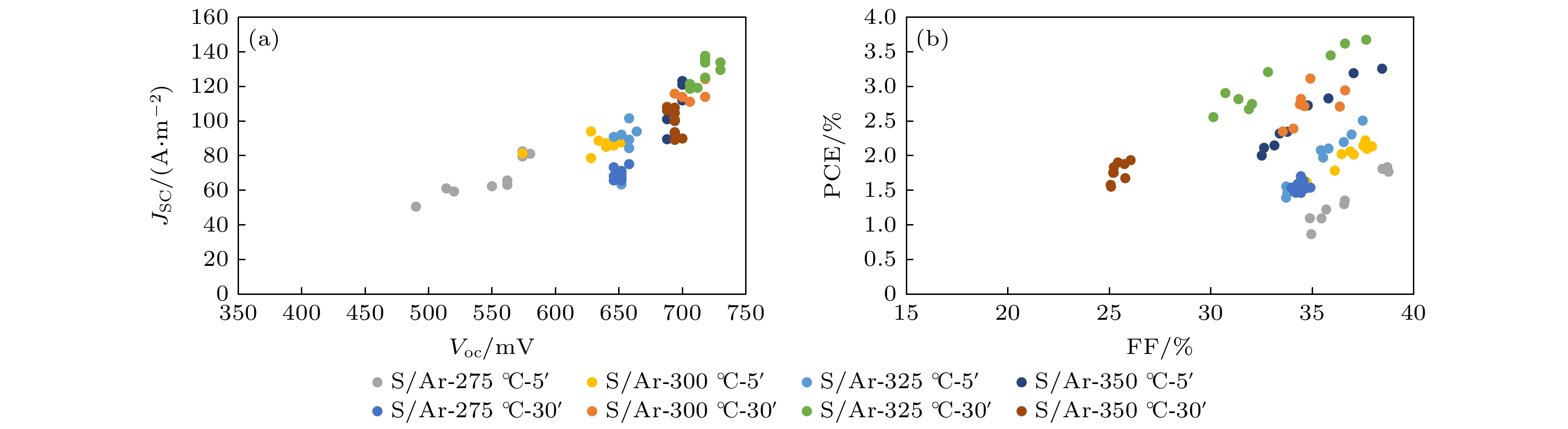

表 1 不同退火气氛下最高效CZTS电池的性能参数

Table 1. Detailed device performance parameters of the best CZTS in different atmospheres.

Device VOC/mV JSC/(mA·cm–2) FF/% PCE/% Rs/(Ω·cm2) Rsh/(Ω·cm2) nΦ JEQE/(mA·cm–2) CdS-wo 519 15.31 43.70 3.47 10.6 188 2.69 15.55 CdS-air 526 13.98 43.87 3.23 11.8 130 2.78 14.92 CdS-S/Ar 611 16.51 56.27 5.68 5.6 318 1.88 15.89 表 2 CZTS/CdS异质结在不同气氛中退火后CdS表面不同价态的硫的含量比和原子比例

Table 2. Ratio of sulfur content and atomic ratio of different valence states on the surface of CdS after annealing of CZTS/CdS heterojunction in different atmospheres.

[S2–]/[S]/% [S0]/[S]/% [S6+]/[S]/% [S]/[Cd] [O]/[S] [S2–]/[Cd] CdS-wo 90.04 0 9.96 0.47 2.05 0.43 CdS-Air 84.73 0 15.28 0.63 1.27 0.54 CdS-S/Ar 76.71 23.29 0 1.03 0.08 0.79 表 3 在0.5 atm的含硫氩气氛中不同温度和时长热处理CZTS/CdS异质结得到的CZTS电池器件特征参数

Table 3. Characteristic parameters of CZTS cell devices obtained by heat treatment of CZTS/CdS heterojunction at different temperatures and durations in sulfur-containing argon atmosphere at 0.5 atm.

Temperature/℃ Time/min Voc/mV PCE/% FF/% Jsc/(A·m-2) 275 5 574 1.83 38.70 82.5 300 5 628 2.22 37.62 93.9 325 5 658 2.51 37.49 101.6 350 5 700 3.26 38.44 121.0 275 30 658 1.70 34.44 75.1 300 30 718 3.11 34.91 124.2 325 30 718 3.67 37.66 135.9 350 30 688 1.93 26.05 107.9 -

[1] Nakamura M, Yamaguchi K, Kimoto Y, Yasaki Y, Kato T, Sugimoto H 2019 IEEE J. Photovolt. 9 1863

Google Scholar

Google Scholar

[2] Gong Y, Zhu Q, Li B, Wang S, Duan B, Lou L, Xiang C, Jedlicka E, Giridharagopal R, Zhou Y, Dai Q, Yan W, Chen S, Meng Q, Xin H 2022 Nat. Energy 7 966

Google Scholar

Google Scholar

[3] Cheng T, Cai C, Huang W, Xu W, Tu L, Lai C 2020 ACS Appl. Mater. Interfaces 12 18157

Google Scholar

Google Scholar

[4] Islam M A, Hossain M S, Aliyu M M, Chelvanathan P, Huda Q, Karim M R, Sopian K, Amin N 2013 Energy Procedi 33 203

Google Scholar

Google Scholar

[5] Sivaraman T, Narasimman V, Nagarethinam V S, Balu A R 2015 Prog. Nat. Sci. 25 392

Google Scholar

Google Scholar

[6] Neuschitzer M, Sanchez Y, López-Marino S, Xie H B, Fairbrother A, Placidi M, Haass S, Izquierdo-Roca V, Perez-Rodriguez A, Saucedo E 2015 Prog. Photovolt. 23 1660

Google Scholar

Google Scholar

[7] Zhang S, Yu F, Yuan Q, Wang Y, Wei S, Tesfamichael T, Liang B, Wang H 2019 Sol. Energy Mater. and Sol. Cells 200 109892

Google Scholar

Google Scholar

[8] Martin N M, Platzer-Björkman C, Simonov K, Rensmo H, Törndahl T 2020 Phys. Status Solidi (b) 257 2000308

Google Scholar

Google Scholar

[9] Yang K J, Son D H, Sung S J, Sim J H, Kim Y I, Park S N, Jeon D H, Kim J, Hwang D K, Jeon C W, Nam D Y, Cheong H, Kang J K, Kim D H 2016 J. Mater. Chem. A 4 10151

Google Scholar

Google Scholar

[10] Cui X, Sun K, Huang J, Lee C Y, Yan C, Sun H, Zhang Y, Liu F, Hossain M A, Zakaria Y, Wong L H, Green M, Hoex B, Hao X 2018 Chem. Mater. 30 7860

Google Scholar

Google Scholar

[11] Guo H, Meng R, Wang G, Wang S, Wu L, Li J, Wang Z, Dong J, Hao X, Zhang Y 2022 Energy Environ. Sci. 15 693

Google Scholar

Google Scholar

[12] Gutiérrez Lazos C D, Rosendo E, Ortega M, Oliva A I, Tapia O, Díaz T, Juárez H, García G, Rubín M 2009 Mater. Sci. Eng. B 165 74

Google Scholar

Google Scholar

[13] Rizwan Z, Zakaria A, Mohd Ghazali M S, Jafari A, Din F U, Zamiri R 2011 Int J Mol Sci 12 1293

Google Scholar

Google Scholar

[14] Tajima S, Umehara M, Hasegawa M, Mise T, Itoh T 2017 Prog. Photovolt. 25 14

Google Scholar

Google Scholar

[15] Yan C, Huang J, Sun K, Johnston S, Zhang Y, Sun H, Pu A, He M, Liu F, Eder K, Yang L, Cairney J M, Ekins-Daukes N J, Hameiri Z, Stride J A, Chen S Y, Green M A, Hao X 2018 Nat. Energy 3 764

Google Scholar

Google Scholar

[16] Pham N D, Tiong V T, Yao D, Martens W, Guerrero A, Bisquert J, Wang H 2017 Nano Energy 41 476

Google Scholar

Google Scholar

[17] Diao A, Thiaw B, Boiro M, Mbodji S, Sissoko 2021 J. Mod. Phys. 12 635

Google Scholar

Google Scholar

[18] Nisika, Kaur K, Kumar M 2020 J. Mater. Chem. A 8 21547

Google Scholar

Google Scholar

[19] Scragg J J S, Choubrac L, Lafond A, Ericson T, Platzer-Björkman C 2014 Appl. Phys. Lett. 104 041911

Google Scholar

Google Scholar

[20] Gokmen T, Gunawan O, Todorov T K, Mitzi D B 2013 Appl. Phys. Lett. 103 103506

Google Scholar

Google Scholar

[21] Scragg J J, Ericson T, Kubart T, Edoff M, Platzer-Björkman C 2011 Chem. Mater. 23 4625

Google Scholar

Google Scholar

[22] Zhang S, Wu J, Guo H, Sun Y, Zhou Z, Zhang Y 2021 Phys. Status Solidi (a) 218 2100585

Google Scholar

Google Scholar

计量

- 文章访问数: 7524

- PDF下载量: 96

- 被引次数: 0

下载:

下载: