-

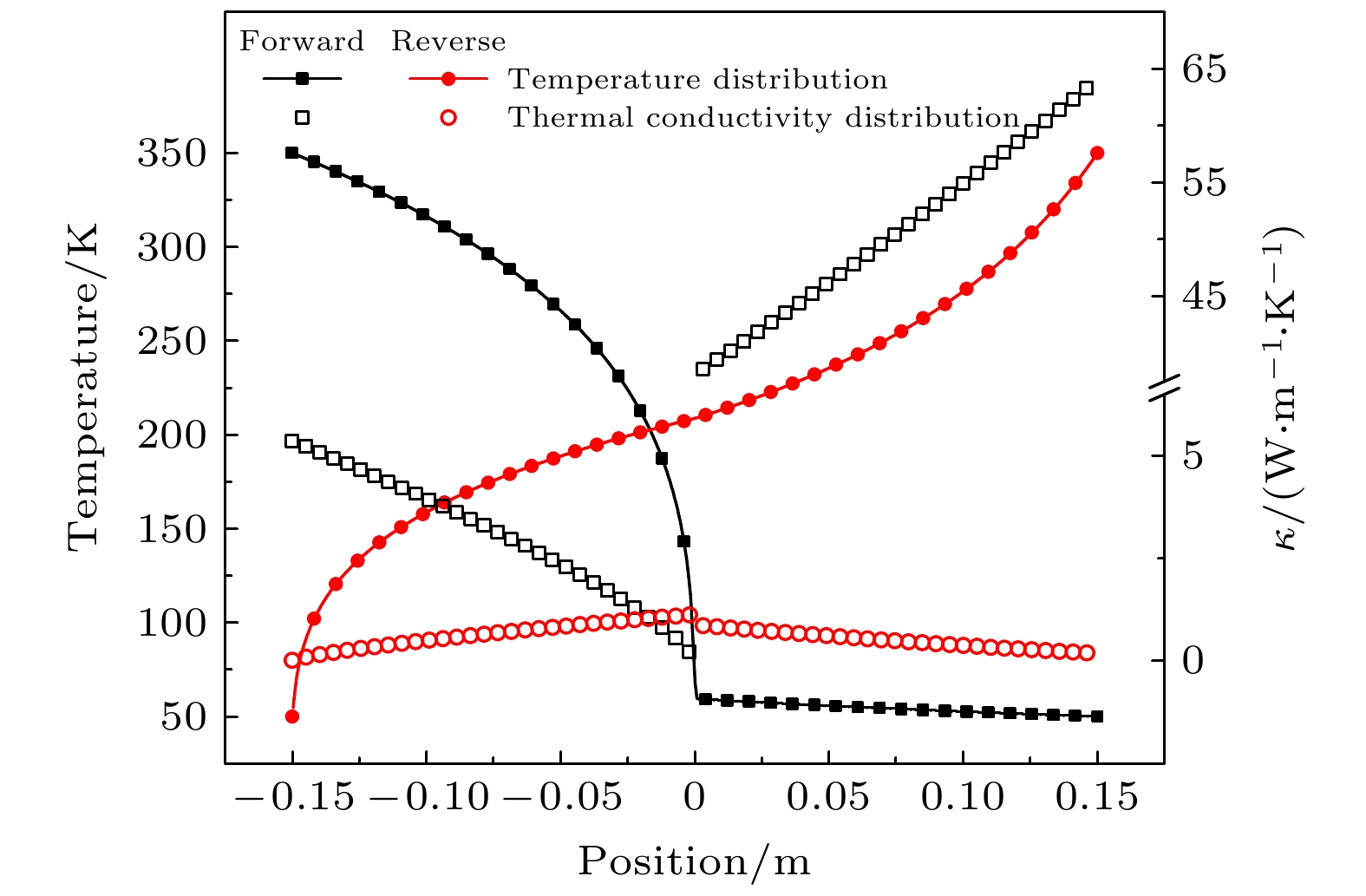

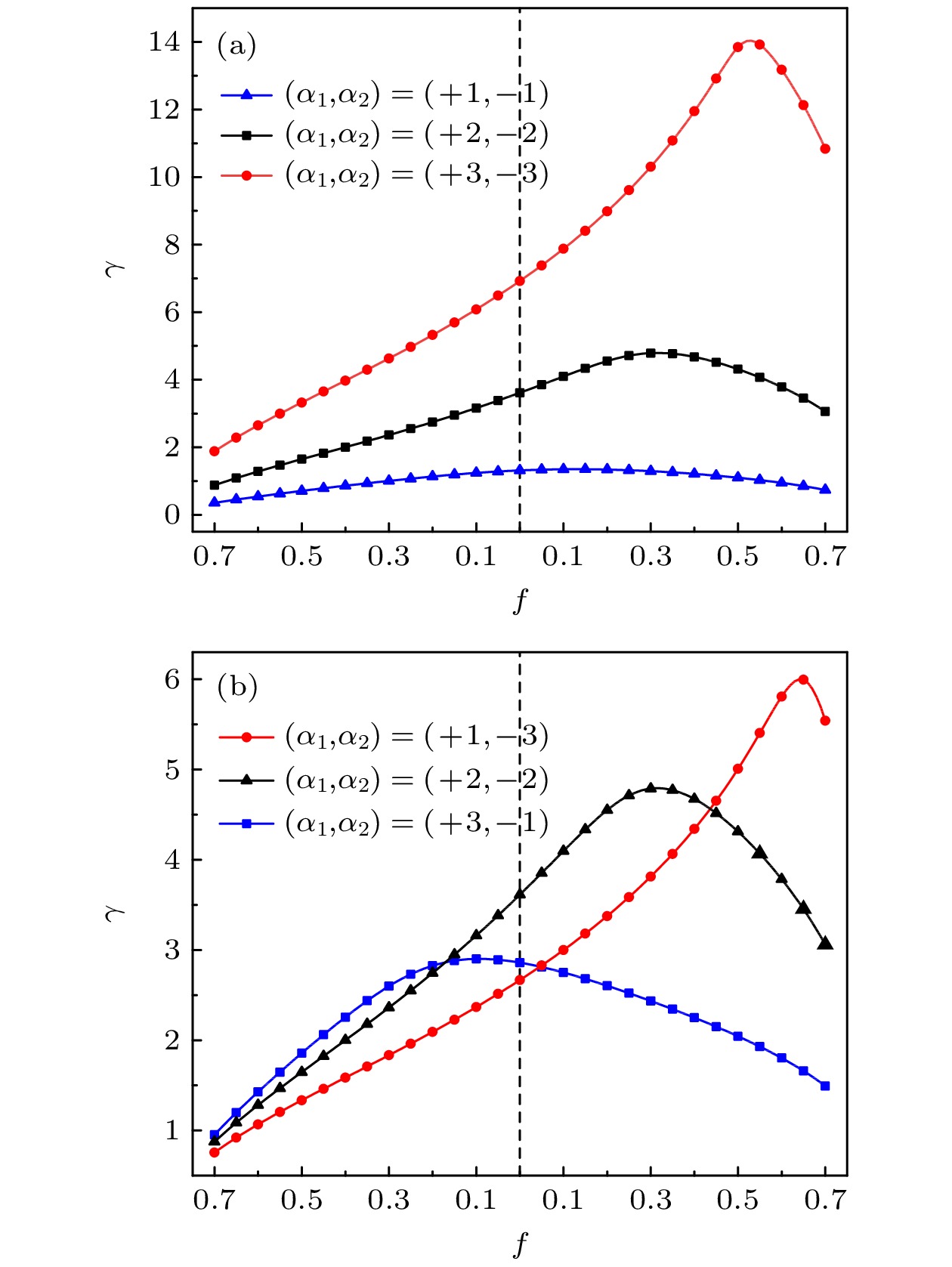

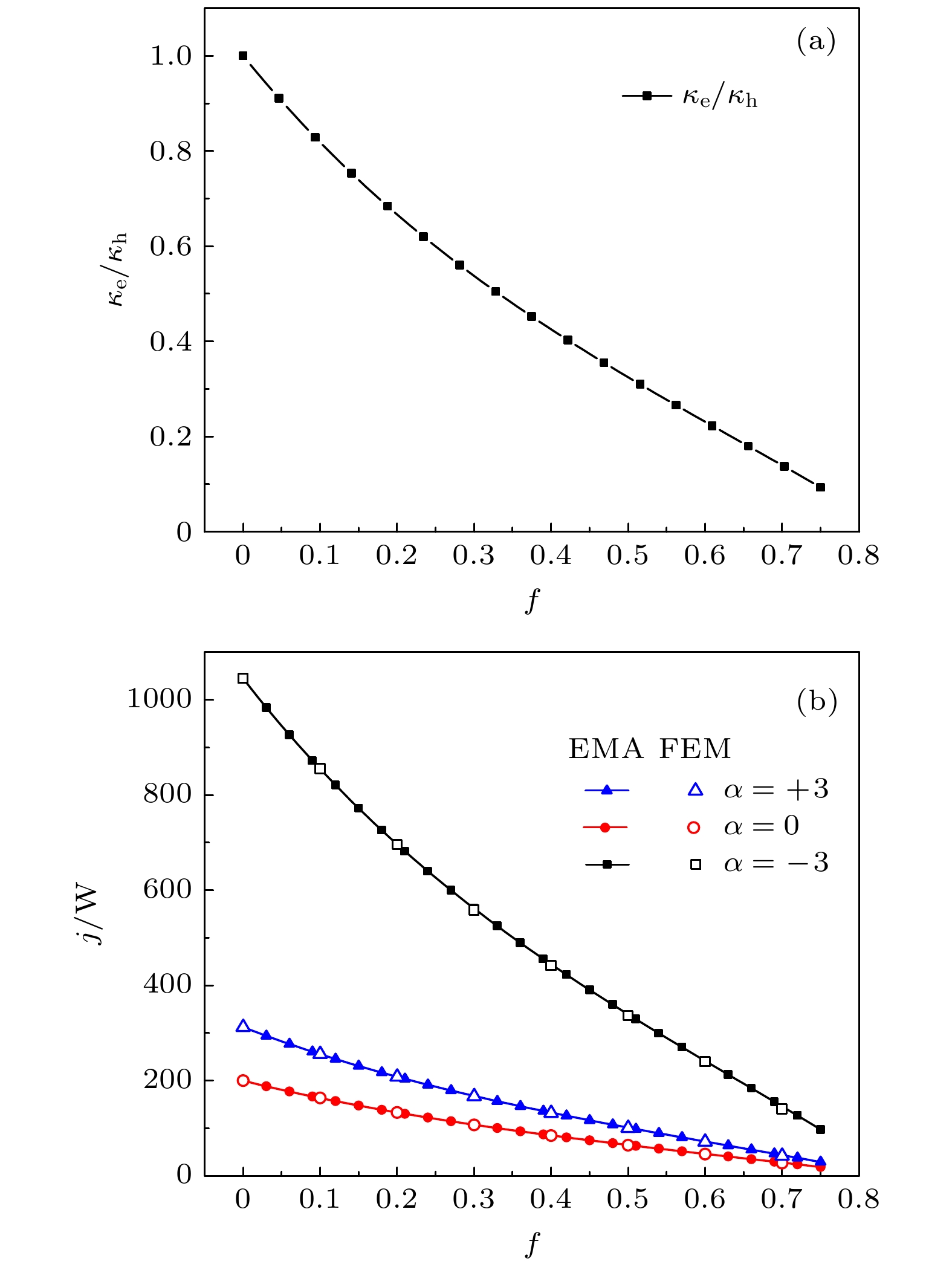

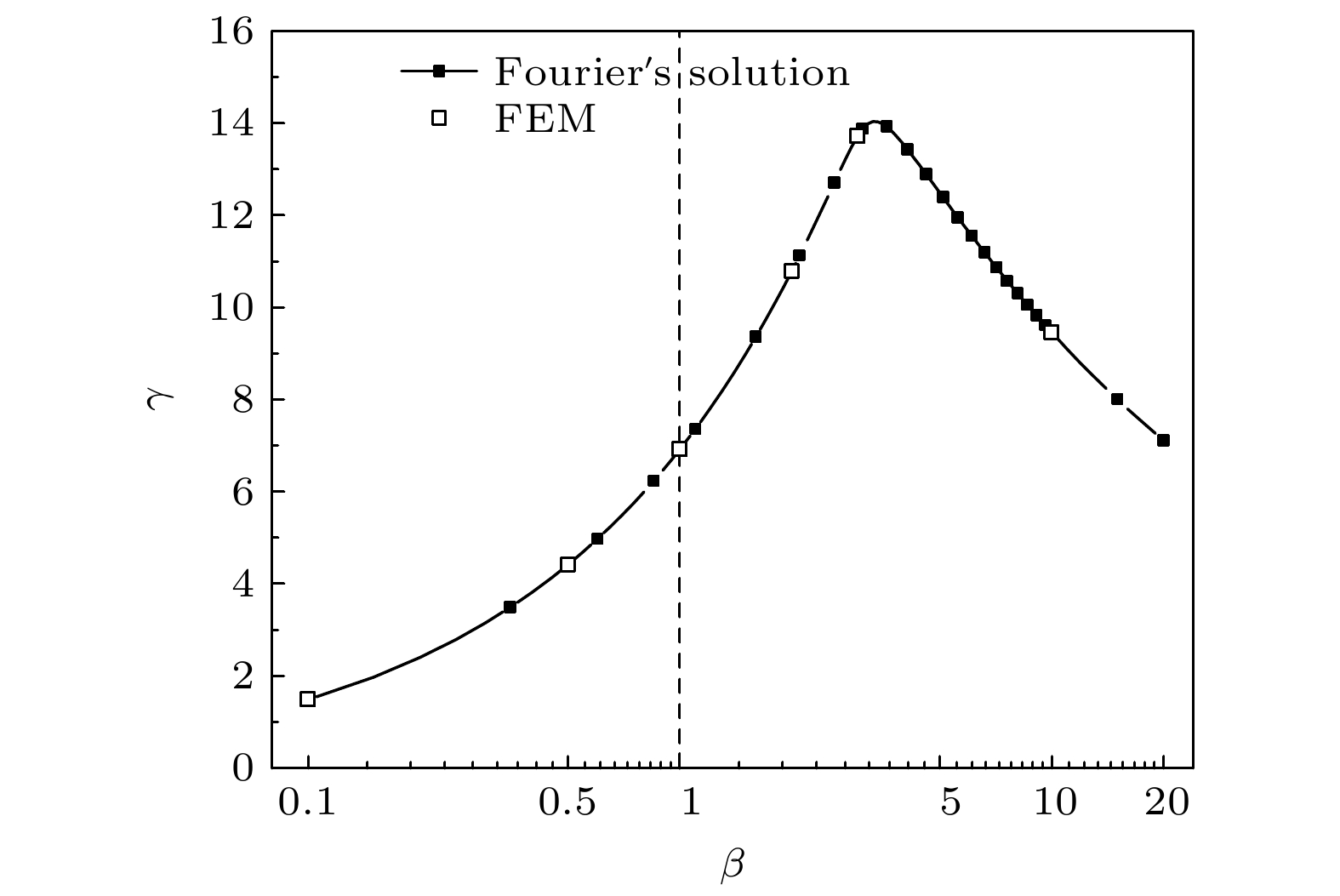

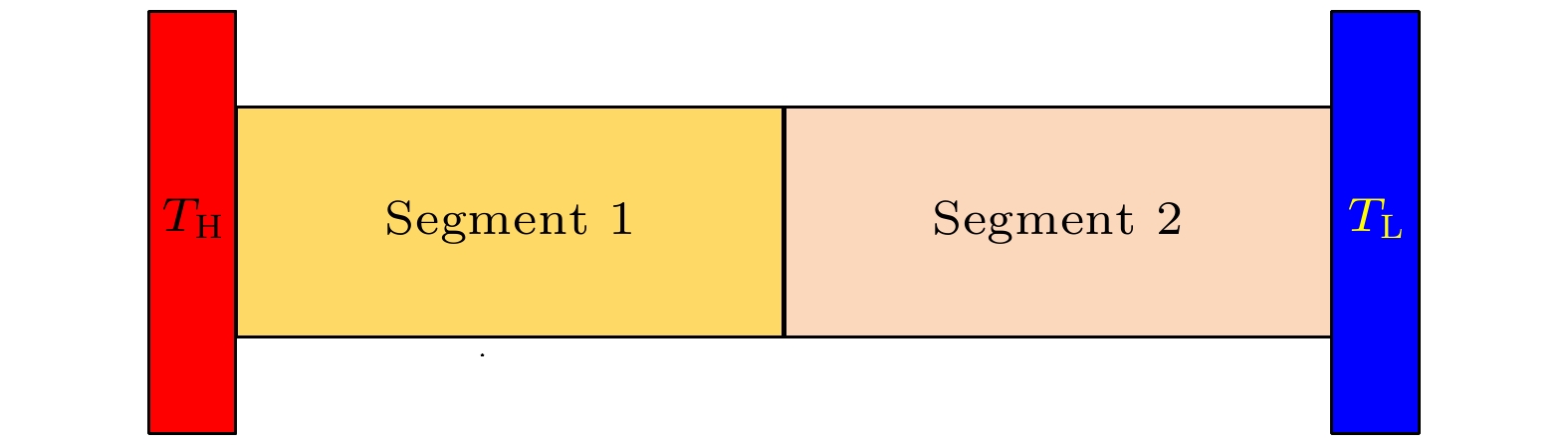

基于傅里叶导热定律, 两种具有不同热导率温度依赖特性的材料组合而成的两段式组合材料可以实现热整流效应. 本文提出在体材料上均匀布置多孔结构, 通过多孔结构孔隙率调整材料的热导率参数, 进而强化热整流效应. 基于有限元方法和有效介质理论, 计算并分析了温差和孔隙率等参数对体材料热整流系数的影响. 计算结果表明, 温差较大时, 孔隙率对对体材料热整流系数的影响较为明显. 在热导率随温度升高而增大的材料中布置多孔结构, 一般会降低系统的热整流系数; 若在热导率随温度升高而减小的材料中布置多孔结构, 则存在一个最佳的孔隙率, 相对于无多孔结构的系统, 其热整流系数可以提高2—3倍. 本文研究结果为体材料热整流系数的调控提供了新的思路.Thermal rectification effect refers to an asymmetric heat transfer phenomenon (namely, the amount of heat flux depends on the direction of temperature gradient). A two-segment bar made of two materials that have thermal conductivities with different temperature-dependence, can realize the thermal rectification effect. In the present paper, we propose to use porous structure on the bulk material to modify the thermal conductivity of bulk material. It is found that the thermal rectification effect can be enhanced by the porous structure. The finite element method and effective medium approximation are used to analyze the influence of porosity on the thermal rectification ratio of the two-segment system. The calculation results are consistent with each other. Under low temperature bias, the effect of the porosity is weak, while its influence becomes very significant when the temperature difference is high. Usually, thermal rectification ratio decreases if the porous structure is made on the segment whose thermal conductivity increases with temperature increasing. If the porous structure is made on the segment with negative temperature-dependent thermal conductivity, an optimal porosity can be found. For low porosity, the forward heat flux keeps almost unchanged while the reverse heat flux decreases by more than half, and the thermal rectification ratio can be increased to twice or more than thrice that in the case of no porous structure. For a fixed temperature difference, the influence of porosity on the thermal rectification ratio increases with the augment of the power exponent value.

-

Keywords:

- thermal rectification /

- thermal conductivity /

- porous media /

- effective medium approximation

[1] Roberts N A, Walker D G 2011 Inter. J. Therm. Sci. 50 648

Google Scholar

Google Scholar

[2] Wehmeyer G, Yabuki T, Monachon C, Wu J, Dames C 2017 Appl. Phys. Rev. 4 041304

Google Scholar

Google Scholar

[3] Li N, Ren J, Wang L, Zhang G, Hänggi P, Li B 2012 Rev. Mod. Phys. 84 1045

Google Scholar

Google Scholar

[4] Varga S, Oliveira A C, Afonso C F 2002 Energy and Buildings 34 227

Google Scholar

Google Scholar

[5] Kuo D M T, Chang Y C 2010 Phys. Rev. B 81 205321

Google Scholar

Google Scholar

[6] Wang L, Li B 2007 Phys. Rev. Lett. 99 177208

Google Scholar

Google Scholar

[7] Paolucci F, Marchegiani G, Strambini E, Giazotto F 2018 Phys. Rev. Appl. 10 024003

Google Scholar

Google Scholar

[8] Dames C 2009 J. Heat Trans. 131 061301

Google Scholar

Google Scholar

[9] Henry A, Prasher R, Majumdar A 2020 Nat. Energy 5 635

Google Scholar

Google Scholar

[10] Starr C 1935 J. Appl. Phys. 7 15

[11] Rogers G F C 1961 Intern. J. Heat Mass Tran. 2 150

Google Scholar

Google Scholar

[12] Somers R R, Fletcher L S, Flack R D 1987 AIAA J. 25 620

Google Scholar

Google Scholar

[13] Wang H, Hu S, Takahashi K, Zhang X, Takamatsu H, Chen J 2017 Nat. Commun. 8 15843

Google Scholar

Google Scholar

[14] Yang N, Zhang G, Li B 2009 Appl. Phys. Lett. 95 033107

Google Scholar

Google Scholar

[15] 李威, 冯妍卉, 唐晶晶, 张欣欣 2013 62 076107

Google Scholar

Google Scholar

Li W, Feng Y H, Tang J J, Zhang X X 2013 Acta Phys. Sin. 62 076107

Google Scholar

Google Scholar

[16] 鞠生宏, 梁新刚 2013 62 026101

Google Scholar

Google Scholar

Ju S H, Liang X G 2013 Acta Phys. Sin. 62 026101

Google Scholar

Google Scholar

[17] 温家乐, 徐志成, 古宇, 郑冬琴, 钟伟荣 2015 64 216501

Google Scholar

Google Scholar

Wen J L, Xu Z C, Gu Y, Zheng D Q, Zhong W R 2015 Acta Phys. Sin. 64 216501

Google Scholar

Google Scholar

[18] Li B, Wang L, Casati G 2004 Phys. Rev. Lett. 93 184301

Google Scholar

Google Scholar

[19] Hoff H 1985 Physica A:Stat. Mech. Appl. 131 449

Google Scholar

Google Scholar

[20] Hu B, He D, Yang L, Zhang Y 2006 Phys. Rev. E 74 060201

[21] Go D, Sen M 2010 J. Heat Trans. 132 124502

Google Scholar

Google Scholar

[22] Herrera F A, Luo T, Go D B 2017 J. Heat Trans. 139 091301

Google Scholar

Google Scholar

[23] 朱玉鑫, 王珏, 罗爽, 王军, 夏国栋 2016 中国科学: 技术科学 46 175

Google Scholar

Google Scholar

Zhu Y X, W Y, Luo S, Wang J, Xia G D 2016 Sci. Sin. Tech. 46 175

Google Scholar

Google Scholar

[24] 赵建宁, 刘冬欢, 魏东, 尚新春 2020 69 056501

Google Scholar

Google Scholar

Zhao J N, Liu D H, Wei D, Shang X C 2020 Acta Phys. Sin. 69 056501

Google Scholar

Google Scholar

[25] Sawaki D, Kobayashi W, Moritomo Y, Terasaki I 2011 Appl. Phys. Lett. 98 081915

Google Scholar

Google Scholar

[26] Kobayashi W, Teraoka Y, Terasaki I 2009 Appl. Phys. Lett. 95 171905

Google Scholar

Google Scholar

[27] Yang Y, Chen H, Wang H, Li N, Zhang L 2018 Phys. Rev. E 98 042131

[28] Ren J, Zhu J X 2013 Phys. Rev. B 87 241412

[29] Li B, Lan J, Wang L 2005 Phys. Rev. Lett. 95 104302

Google Scholar

Google Scholar

[30] Kang H, Yang F, Urban J 2018 Phys. Rev. Appl. 10 024034

Google Scholar

Google Scholar

[31] Zhao J, Wei D, Gao A, Dong H, Bao Y, Jiang Y, Liu D 2020 Appl. Thermal Engineering 176 115410

Google Scholar

Google Scholar

[32] Kasali S O, Ordonez-Miranda J, Joulain K 2020 Inter. J. Heat and Mass Transfer 154 119739

Google Scholar

Google Scholar

[33] Zhu W, Wu G, Chen H, Ren J 2018 Frontiers in Energy Research 6 9

Google Scholar

Google Scholar

[34] 王子, 张丹妹, 任捷 2019 68 220302

Google Scholar

Google Scholar

Wang Z, Zhang D M, Ren J 2019 Acta Phys. Sin. 68 220302

Google Scholar

Google Scholar

[35] Garnett J 1904 Philos. Trans. R. Soc. London 203 385

Google Scholar

Google Scholar

[36] Bruggeman D A G 1935 Annalen der Physik 416 636

Google Scholar

Google Scholar

[37] Levy O, Stroud D 1997 Phys. Rev. B 56 8035

Google Scholar

Google Scholar

[38] Huang J P, Yu K W 2006 Physics Reports 431 87

Google Scholar

Google Scholar

[39] Gu G, Yu K W, Hui P M 1998 Phys. Rev. B 58 3057

Google Scholar

Google Scholar

[40] Dai G, Huang J 2020 Intern. J. Heat and Mass Transfer 147 118917

Google Scholar

Google Scholar

[41] Touloukian Y S, Powell R W, Ho C Y, Klemens P 1970 Thermophysical Properties of Matter—The TPRC Data Series. (Vol.1) New York, pp1–1595

-

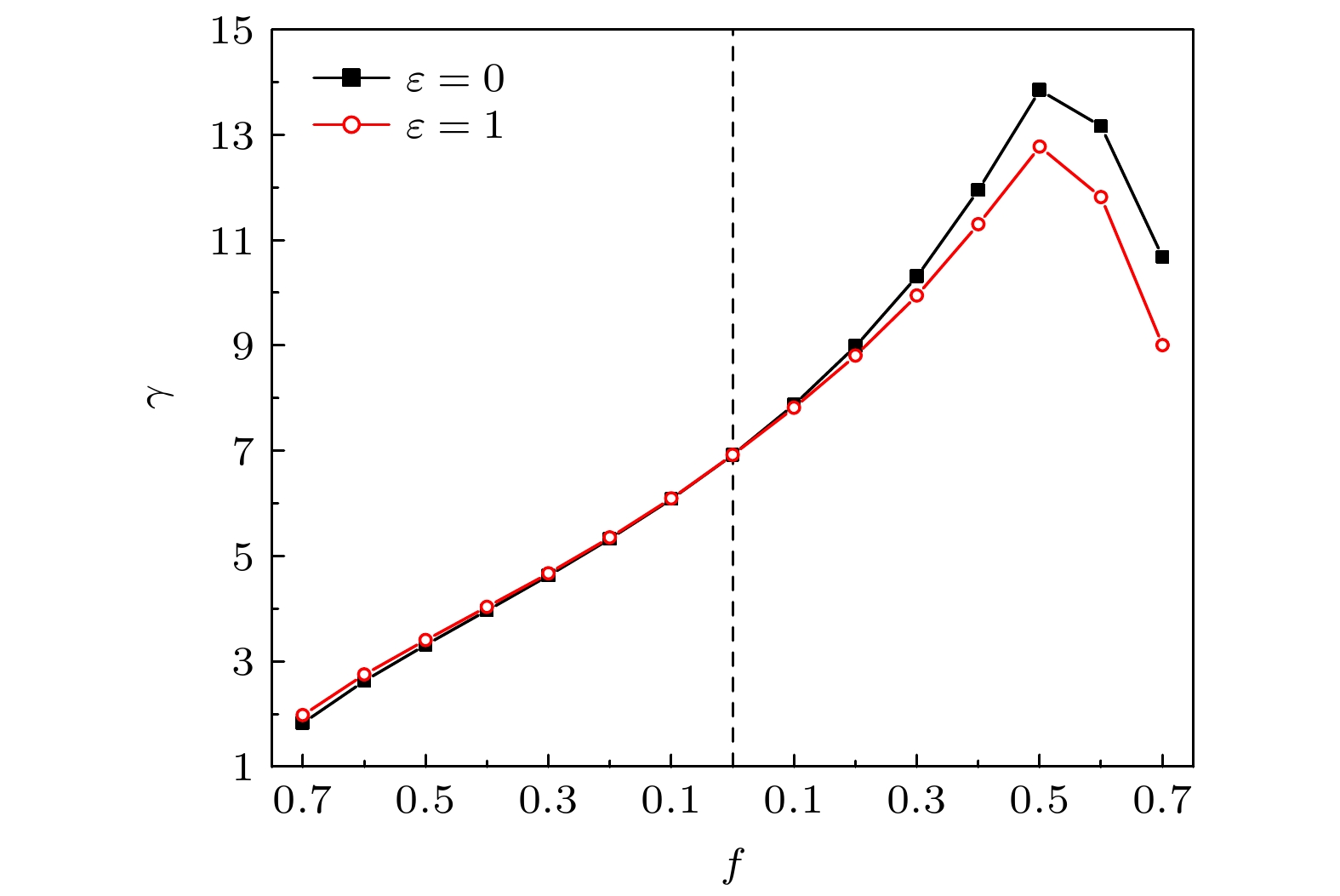

图 6 (α1, α2) = (+3, –3)时, (a) 不同温差下热整流系数随孔隙率的变化趋势, (b) 不同温差下无孔热整流系数和有孔最佳热整流系数及对应孔隙率

Fig. 6. For the case of (α1, α2) = (+3, –3), (a) thermal rectification ratio versus porosity under different dimensionless temperature differences, (b) thermal rectification ratio without porous structure and the optimal thermal rectification ratio under different dimensionless temperature differences.

-

[1] Roberts N A, Walker D G 2011 Inter. J. Therm. Sci. 50 648

Google Scholar

Google Scholar

[2] Wehmeyer G, Yabuki T, Monachon C, Wu J, Dames C 2017 Appl. Phys. Rev. 4 041304

Google Scholar

Google Scholar

[3] Li N, Ren J, Wang L, Zhang G, Hänggi P, Li B 2012 Rev. Mod. Phys. 84 1045

Google Scholar

Google Scholar

[4] Varga S, Oliveira A C, Afonso C F 2002 Energy and Buildings 34 227

Google Scholar

Google Scholar

[5] Kuo D M T, Chang Y C 2010 Phys. Rev. B 81 205321

Google Scholar

Google Scholar

[6] Wang L, Li B 2007 Phys. Rev. Lett. 99 177208

Google Scholar

Google Scholar

[7] Paolucci F, Marchegiani G, Strambini E, Giazotto F 2018 Phys. Rev. Appl. 10 024003

Google Scholar

Google Scholar

[8] Dames C 2009 J. Heat Trans. 131 061301

Google Scholar

Google Scholar

[9] Henry A, Prasher R, Majumdar A 2020 Nat. Energy 5 635

Google Scholar

Google Scholar

[10] Starr C 1935 J. Appl. Phys. 7 15

[11] Rogers G F C 1961 Intern. J. Heat Mass Tran. 2 150

Google Scholar

Google Scholar

[12] Somers R R, Fletcher L S, Flack R D 1987 AIAA J. 25 620

Google Scholar

Google Scholar

[13] Wang H, Hu S, Takahashi K, Zhang X, Takamatsu H, Chen J 2017 Nat. Commun. 8 15843

Google Scholar

Google Scholar

[14] Yang N, Zhang G, Li B 2009 Appl. Phys. Lett. 95 033107

Google Scholar

Google Scholar

[15] 李威, 冯妍卉, 唐晶晶, 张欣欣 2013 62 076107

Google Scholar

Google Scholar

Li W, Feng Y H, Tang J J, Zhang X X 2013 Acta Phys. Sin. 62 076107

Google Scholar

Google Scholar

[16] 鞠生宏, 梁新刚 2013 62 026101

Google Scholar

Google Scholar

Ju S H, Liang X G 2013 Acta Phys. Sin. 62 026101

Google Scholar

Google Scholar

[17] 温家乐, 徐志成, 古宇, 郑冬琴, 钟伟荣 2015 64 216501

Google Scholar

Google Scholar

Wen J L, Xu Z C, Gu Y, Zheng D Q, Zhong W R 2015 Acta Phys. Sin. 64 216501

Google Scholar

Google Scholar

[18] Li B, Wang L, Casati G 2004 Phys. Rev. Lett. 93 184301

Google Scholar

Google Scholar

[19] Hoff H 1985 Physica A:Stat. Mech. Appl. 131 449

Google Scholar

Google Scholar

[20] Hu B, He D, Yang L, Zhang Y 2006 Phys. Rev. E 74 060201

[21] Go D, Sen M 2010 J. Heat Trans. 132 124502

Google Scholar

Google Scholar

[22] Herrera F A, Luo T, Go D B 2017 J. Heat Trans. 139 091301

Google Scholar

Google Scholar

[23] 朱玉鑫, 王珏, 罗爽, 王军, 夏国栋 2016 中国科学: 技术科学 46 175

Google Scholar

Google Scholar

Zhu Y X, W Y, Luo S, Wang J, Xia G D 2016 Sci. Sin. Tech. 46 175

Google Scholar

Google Scholar

[24] 赵建宁, 刘冬欢, 魏东, 尚新春 2020 69 056501

Google Scholar

Google Scholar

Zhao J N, Liu D H, Wei D, Shang X C 2020 Acta Phys. Sin. 69 056501

Google Scholar

Google Scholar

[25] Sawaki D, Kobayashi W, Moritomo Y, Terasaki I 2011 Appl. Phys. Lett. 98 081915

Google Scholar

Google Scholar

[26] Kobayashi W, Teraoka Y, Terasaki I 2009 Appl. Phys. Lett. 95 171905

Google Scholar

Google Scholar

[27] Yang Y, Chen H, Wang H, Li N, Zhang L 2018 Phys. Rev. E 98 042131

[28] Ren J, Zhu J X 2013 Phys. Rev. B 87 241412

[29] Li B, Lan J, Wang L 2005 Phys. Rev. Lett. 95 104302

Google Scholar

Google Scholar

[30] Kang H, Yang F, Urban J 2018 Phys. Rev. Appl. 10 024034

Google Scholar

Google Scholar

[31] Zhao J, Wei D, Gao A, Dong H, Bao Y, Jiang Y, Liu D 2020 Appl. Thermal Engineering 176 115410

Google Scholar

Google Scholar

[32] Kasali S O, Ordonez-Miranda J, Joulain K 2020 Inter. J. Heat and Mass Transfer 154 119739

Google Scholar

Google Scholar

[33] Zhu W, Wu G, Chen H, Ren J 2018 Frontiers in Energy Research 6 9

Google Scholar

Google Scholar

[34] 王子, 张丹妹, 任捷 2019 68 220302

Google Scholar

Google Scholar

Wang Z, Zhang D M, Ren J 2019 Acta Phys. Sin. 68 220302

Google Scholar

Google Scholar

[35] Garnett J 1904 Philos. Trans. R. Soc. London 203 385

Google Scholar

Google Scholar

[36] Bruggeman D A G 1935 Annalen der Physik 416 636

Google Scholar

Google Scholar

[37] Levy O, Stroud D 1997 Phys. Rev. B 56 8035

Google Scholar

Google Scholar

[38] Huang J P, Yu K W 2006 Physics Reports 431 87

Google Scholar

Google Scholar

[39] Gu G, Yu K W, Hui P M 1998 Phys. Rev. B 58 3057

Google Scholar

Google Scholar

[40] Dai G, Huang J 2020 Intern. J. Heat and Mass Transfer 147 118917

Google Scholar

Google Scholar

[41] Touloukian Y S, Powell R W, Ho C Y, Klemens P 1970 Thermophysical Properties of Matter—The TPRC Data Series. (Vol.1) New York, pp1–1595

计量

- 文章访问数: 10721

- PDF下载量: 272

- 被引次数: 0

下载:

下载: