-

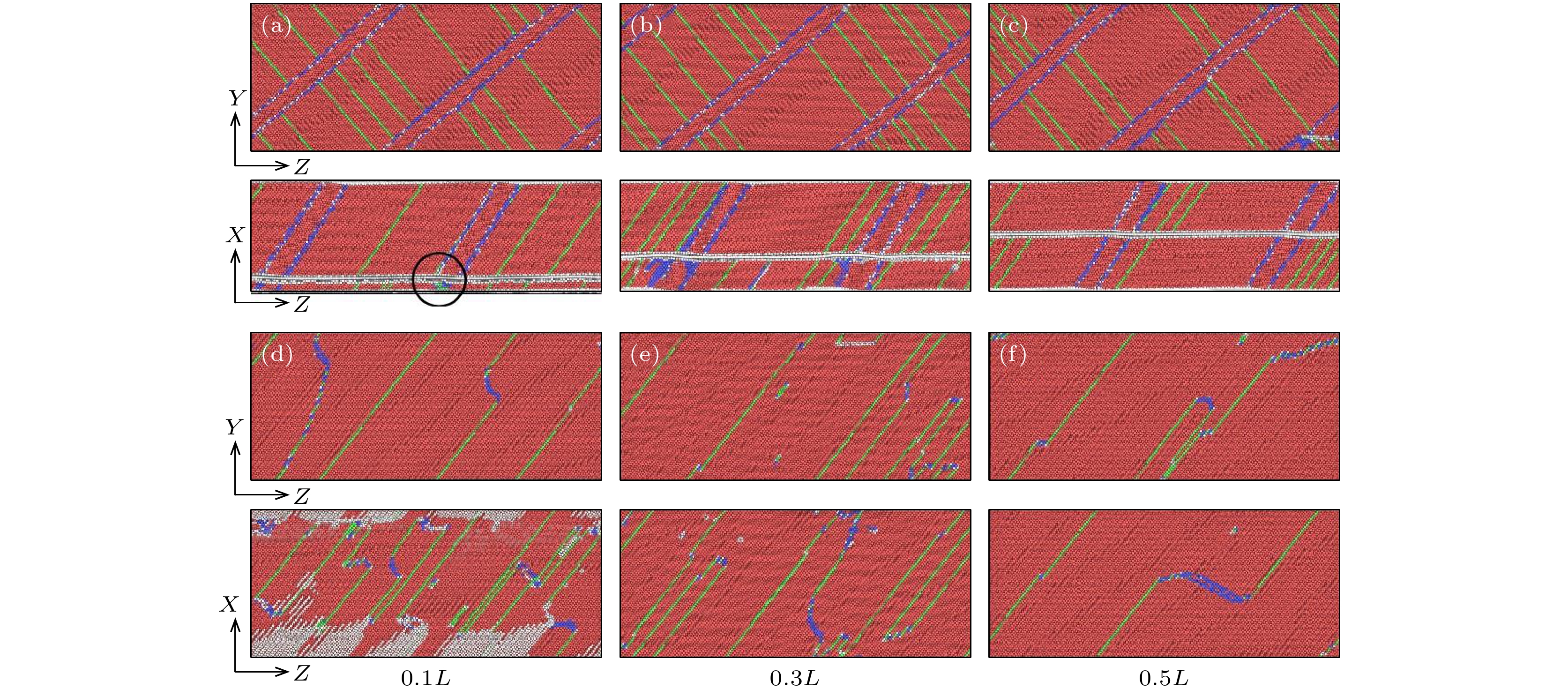

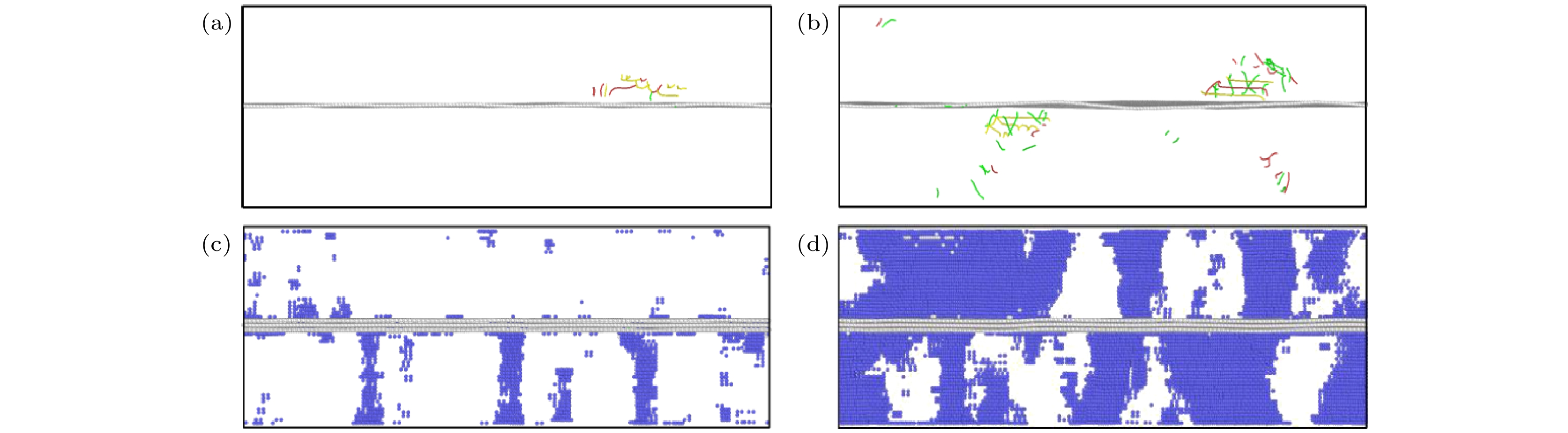

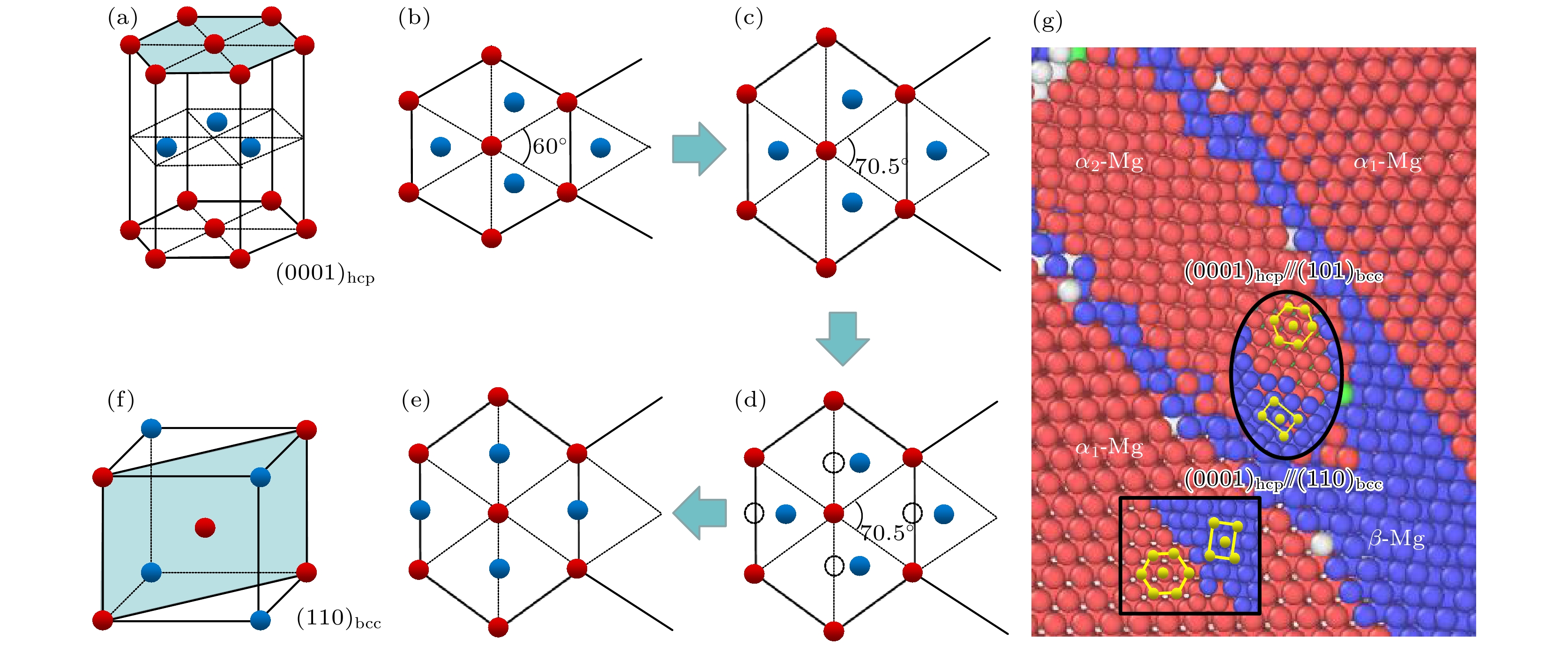

镁合金因其低密度被视为最轻的工程结构金属材料, 但因较差的塑性变形行为限制了其广泛应用, 因此增强镁合金的综合力学性能已经成为当前材料领域的研究热点. 本文采用分子动力学模拟方法, 研究了在拉伸载荷下石墨烯对金属镁变形行为和力学性能的影响. 研究结果表明, 石墨烯的嵌入能够明显提升金属镁的强度和杨氏模量, 并对其塑性变形阶段的第二次应变强化产生较大影响. 研究指出, 石墨烯镁基(GR/Mg)复合材料和纯镁的塑性变形行为相同, 在塑性变形过程中均发生了从密排六方到体心立方再到密排六方结构的相变. 石墨烯嵌入位置对GR/Mg复合材料上下两部分镁基体的塑性变形行为有较大的影响. 当石墨烯嵌入高度较小时, 石墨烯下方的镁基体塑性变形能力较强, 容易发生位错滑移, 而当石墨烯嵌入高度较大时, 石墨烯上下方的两部分镁基体的塑性变形能力相当, 它们的塑性变形行为趋于同步. 此外, 本文对镁基体的相变机制也进行了详细分析. 本文的研究结果对于设计高性能的石墨烯金属基复合材料具有一定的理论指导意义.Magnesium alloy is regarded as a lightest engineering structural metal material due to its low density, but its wide application is limited due to poor plastic deformation behavior. Therefore, the comprehensive mechanical properties of enhanced magnesium alloy have become a research focus in the material science. Here, the effect of graphene on the deformation behavior and that on the mechanical properties of magnesium under tensile loading are studied by molecular dynamics simulation. The results show that the introduction of graphene can significantly improve the mechanical properties of pure magnesium. Comparing with pure magnesium, the Young's modulus and the first peak stress of the graphene magnesium matrix (GR/Mg) composites are increased by about 27.5% and 36.5% respectively, which is mainly due to the excellent mechanical properties of graphene. The results also indicate that the embedded position of graphene has little effect on the Young's modulus or peak stress of the GR/Mg composites, but it will significantly affect the plastic deformation behavior of the GR/Mg composites after the second peak stress. With the increase of the embedded height of graphene, the average flow stress of the GR/Mg composites first increases in the later stage of plastic deformation. When the embedded height reaches 0.4L, the average flow stress of the GR/Mg composites reaches a maximum value, and then decreases. This phenomenon of the Gr/Mg composites can be explained by the plastic deformation behavior of the magnesium matrix above and below graphene. The embedded position of graphene has a great influence on the plastic deformation behavior of the upper and lower magnesium matrix of the GR/Mg composites. When the embedded height of graphene is small, the plastic deformation capability of magnesium matrix under graphene is strong and dislocation slip is easy to occur. And when the embedded height of graphene is large, the plastic deformation capabilities of the two parts of magnesium matrix above and below graphene are equal, and their plastic deformation behavior tends to be synchronous. The results show that the plastic deformation behavior of the GR/Mg composite is the same as that of pure magnesium, and the phase transition from HCP to BCC and then to HCP occurs in the process of the plastic deformation. The phase transition mechanism of magnesium matrix is also analyzed in detail. The results of this study have certain theoretical guiding significance in designing the high performance graphene metal matrix composites.

-

Keywords:

- graphene /

- magnesium alloy /

- mechanical property /

- deformation behavior /

- molecular dynamics simulation

[1] Song J, She J, Chen D, Pan F 2020 J. Magnes. Alloys 8 1

Google Scholar

Google Scholar

[2] Meng L, Hu X, Wang X, Zhang C, Shi H, Xiang Y, Liu N, Wu K 2018 Mater. Sci. Eng. A 733 414

Google Scholar

Google Scholar

[3] 王宏明, 朱弋, 李桂荣, 郑瑞 2016 65 146101

Google Scholar

Google Scholar

Wang H M, Zhu Y, Li G R, Zheng R 2016 Acta Phys. Sin. 65 146101

Google Scholar

Google Scholar

[4] Song H Y, Li Y L 2015 Phys. Lett. A 379 2087

Google Scholar

Google Scholar

[5] Wu G, Chan K C, Zhu L, Sun L, Lu J 2017 Nature 545 80

Google Scholar

Google Scholar

[6] Ding Z, Liu W, Sun H, Li S, Zhang D, Zhao Y, Lavernia E J, Zhu Y 2018 Acta Mater. 146 265

Google Scholar

Google Scholar

[7] Huang H, Tang X, Chen F, Liu J, Li H, Chen D 2016 Sci. Rep. 6 39391

Google Scholar

Google Scholar

[8] He Y, Huang F, Li H, Sui Y, Wei F, Meng Q 2016 Physica E 87 233

Google Scholar

Google Scholar

[9] Long X J, Li B, Wang L, Huang J Y, Zhu J, Luo S N 2016 Carbon 103 457

Google Scholar

Google Scholar

[10] 汉芮岐, 宋海洋, 安敏荣, 李卫卫, 马佳丽 2021 70 066201

Google Scholar

Google Scholar

Han R Q, Song H Y, An M R, Li W W, Ma J L 2021 Acta Phys. Sin. 70 066201

Google Scholar

Google Scholar

[11] Shen C, Oyadiji S O 2020 Mater. Today Phys. 15 100257

Google Scholar

Google Scholar

[12] Tiwari S K, Sahoo S, Wang N, Huczko A 2020 J. Sci.-Adv. Mater. Devices. 5 10

Google Scholar

Google Scholar

[13] 周海涛, 熊希雅, 罗飞, 罗炳威, 刘大博, 申承民 2021 70 086201

Google Scholar

Google Scholar

Zhou H T, Xiong X Y, Luo F, Luo B W, Liu D B, Shen C M 2021 Acta Phys. Sin. 70 086201

Google Scholar

Google Scholar

[14] Kim Y, Lee J, Yeom M S, Shin J W, Kim H, Cui Y, Kysar J W, Hone J, Jung Y, Jeon S, Han S M 2013 Nat. Commun. 4 2114

Google Scholar

Google Scholar

[15] Rezaei R 2018 Comput. Mater. Sci. 151 181

Google Scholar

Google Scholar

[16] Wang X, Xiao W, Wang L, Shi J, Sun L, Cui J, Wang J 2020 Physica E 123 114172

Google Scholar

Google Scholar

[17] 周霞, 刘霄霞 2020 金属学报 56 240

Google Scholar

Google Scholar

Zhou X, Liu X 2020 Acta Metall. Sin. 56 240

Google Scholar

Google Scholar

[18] Xiang S, Wang X, Gupta M, Wu K, Hu X, Zheng M 2016 Sci. Rep. 6 38824

Google Scholar

Google Scholar

[19] Silvestre N, Faria B, Canongia Lopes J N 2014 Compos. Sci. Technol. 90 16

Google Scholar

Google Scholar

[20] Du X, Du W, Wang Z, Liu K, Li S 2018 Mater. Sci. Eng., A. 711 633

Google Scholar

Google Scholar

[21] Sun D Y, Mendelev M I, Becker C A, Kudin K, Haxhimali T, Asta M, Hoyt J J, Karma A, Srolovitz D J 2006 Phys. Rev. B 73 024116

Google Scholar

Google Scholar

[22] Stuart S J, Tutein A B, Harrison J A 2000 J. Chem. Phys. 112 6472

Google Scholar

Google Scholar

[23] Zhou X, Song S, Li L, Zhang R 2015 J. Compos. Mater. 50 191

Google Scholar

Google Scholar

[24] Stukowski A 2010 Modell. Simul. Mater. Sci. Eng. 18 015012

Google Scholar

Google Scholar

[25] Faken D, Jónsson H 1994 Comput. Mater. Sci. 2 279

Google Scholar

Google Scholar

[26] An M R, Su M J, Deng Q, Song H Y, Wang C, Shang Y 2020 Chinese Phys. B 29 046201

Google Scholar

Google Scholar

[27] Chen P, Wang F, Li B 2019 Acta Mater. 171 65

Google Scholar

Google Scholar

[28] 宋海洋, 李玉龙 2012 61 226201

Google Scholar

Google Scholar

Song H Y, Li Y L 2012 Acta Phys. Sin. 61 226201

Google Scholar

Google Scholar

[29] Zhang C, Lu C, Pei L, Li J, Wang R, Tieu K 2019 Carbon 143 125

Google Scholar

Google Scholar

[30] An M R, Song H Y, Deng Q, Su M J, Liu Y M 2019 J. Appl. Phys. 125 165307

Google Scholar

Google Scholar

-

-

[1] Song J, She J, Chen D, Pan F 2020 J. Magnes. Alloys 8 1

Google Scholar

Google Scholar

[2] Meng L, Hu X, Wang X, Zhang C, Shi H, Xiang Y, Liu N, Wu K 2018 Mater. Sci. Eng. A 733 414

Google Scholar

Google Scholar

[3] 王宏明, 朱弋, 李桂荣, 郑瑞 2016 65 146101

Google Scholar

Google Scholar

Wang H M, Zhu Y, Li G R, Zheng R 2016 Acta Phys. Sin. 65 146101

Google Scholar

Google Scholar

[4] Song H Y, Li Y L 2015 Phys. Lett. A 379 2087

Google Scholar

Google Scholar

[5] Wu G, Chan K C, Zhu L, Sun L, Lu J 2017 Nature 545 80

Google Scholar

Google Scholar

[6] Ding Z, Liu W, Sun H, Li S, Zhang D, Zhao Y, Lavernia E J, Zhu Y 2018 Acta Mater. 146 265

Google Scholar

Google Scholar

[7] Huang H, Tang X, Chen F, Liu J, Li H, Chen D 2016 Sci. Rep. 6 39391

Google Scholar

Google Scholar

[8] He Y, Huang F, Li H, Sui Y, Wei F, Meng Q 2016 Physica E 87 233

Google Scholar

Google Scholar

[9] Long X J, Li B, Wang L, Huang J Y, Zhu J, Luo S N 2016 Carbon 103 457

Google Scholar

Google Scholar

[10] 汉芮岐, 宋海洋, 安敏荣, 李卫卫, 马佳丽 2021 70 066201

Google Scholar

Google Scholar

Han R Q, Song H Y, An M R, Li W W, Ma J L 2021 Acta Phys. Sin. 70 066201

Google Scholar

Google Scholar

[11] Shen C, Oyadiji S O 2020 Mater. Today Phys. 15 100257

Google Scholar

Google Scholar

[12] Tiwari S K, Sahoo S, Wang N, Huczko A 2020 J. Sci.-Adv. Mater. Devices. 5 10

Google Scholar

Google Scholar

[13] 周海涛, 熊希雅, 罗飞, 罗炳威, 刘大博, 申承民 2021 70 086201

Google Scholar

Google Scholar

Zhou H T, Xiong X Y, Luo F, Luo B W, Liu D B, Shen C M 2021 Acta Phys. Sin. 70 086201

Google Scholar

Google Scholar

[14] Kim Y, Lee J, Yeom M S, Shin J W, Kim H, Cui Y, Kysar J W, Hone J, Jung Y, Jeon S, Han S M 2013 Nat. Commun. 4 2114

Google Scholar

Google Scholar

[15] Rezaei R 2018 Comput. Mater. Sci. 151 181

Google Scholar

Google Scholar

[16] Wang X, Xiao W, Wang L, Shi J, Sun L, Cui J, Wang J 2020 Physica E 123 114172

Google Scholar

Google Scholar

[17] 周霞, 刘霄霞 2020 金属学报 56 240

Google Scholar

Google Scholar

Zhou X, Liu X 2020 Acta Metall. Sin. 56 240

Google Scholar

Google Scholar

[18] Xiang S, Wang X, Gupta M, Wu K, Hu X, Zheng M 2016 Sci. Rep. 6 38824

Google Scholar

Google Scholar

[19] Silvestre N, Faria B, Canongia Lopes J N 2014 Compos. Sci. Technol. 90 16

Google Scholar

Google Scholar

[20] Du X, Du W, Wang Z, Liu K, Li S 2018 Mater. Sci. Eng., A. 711 633

Google Scholar

Google Scholar

[21] Sun D Y, Mendelev M I, Becker C A, Kudin K, Haxhimali T, Asta M, Hoyt J J, Karma A, Srolovitz D J 2006 Phys. Rev. B 73 024116

Google Scholar

Google Scholar

[22] Stuart S J, Tutein A B, Harrison J A 2000 J. Chem. Phys. 112 6472

Google Scholar

Google Scholar

[23] Zhou X, Song S, Li L, Zhang R 2015 J. Compos. Mater. 50 191

Google Scholar

Google Scholar

[24] Stukowski A 2010 Modell. Simul. Mater. Sci. Eng. 18 015012

Google Scholar

Google Scholar

[25] Faken D, Jónsson H 1994 Comput. Mater. Sci. 2 279

Google Scholar

Google Scholar

[26] An M R, Su M J, Deng Q, Song H Y, Wang C, Shang Y 2020 Chinese Phys. B 29 046201

Google Scholar

Google Scholar

[27] Chen P, Wang F, Li B 2019 Acta Mater. 171 65

Google Scholar

Google Scholar

[28] 宋海洋, 李玉龙 2012 61 226201

Google Scholar

Google Scholar

Song H Y, Li Y L 2012 Acta Phys. Sin. 61 226201

Google Scholar

Google Scholar

[29] Zhang C, Lu C, Pei L, Li J, Wang R, Tieu K 2019 Carbon 143 125

Google Scholar

Google Scholar

[30] An M R, Song H Y, Deng Q, Su M J, Liu Y M 2019 J. Appl. Phys. 125 165307

Google Scholar

Google Scholar

计量

- 文章访问数: 7756

- PDF下载量: 157

- 被引次数: 0

下载:

下载: