-

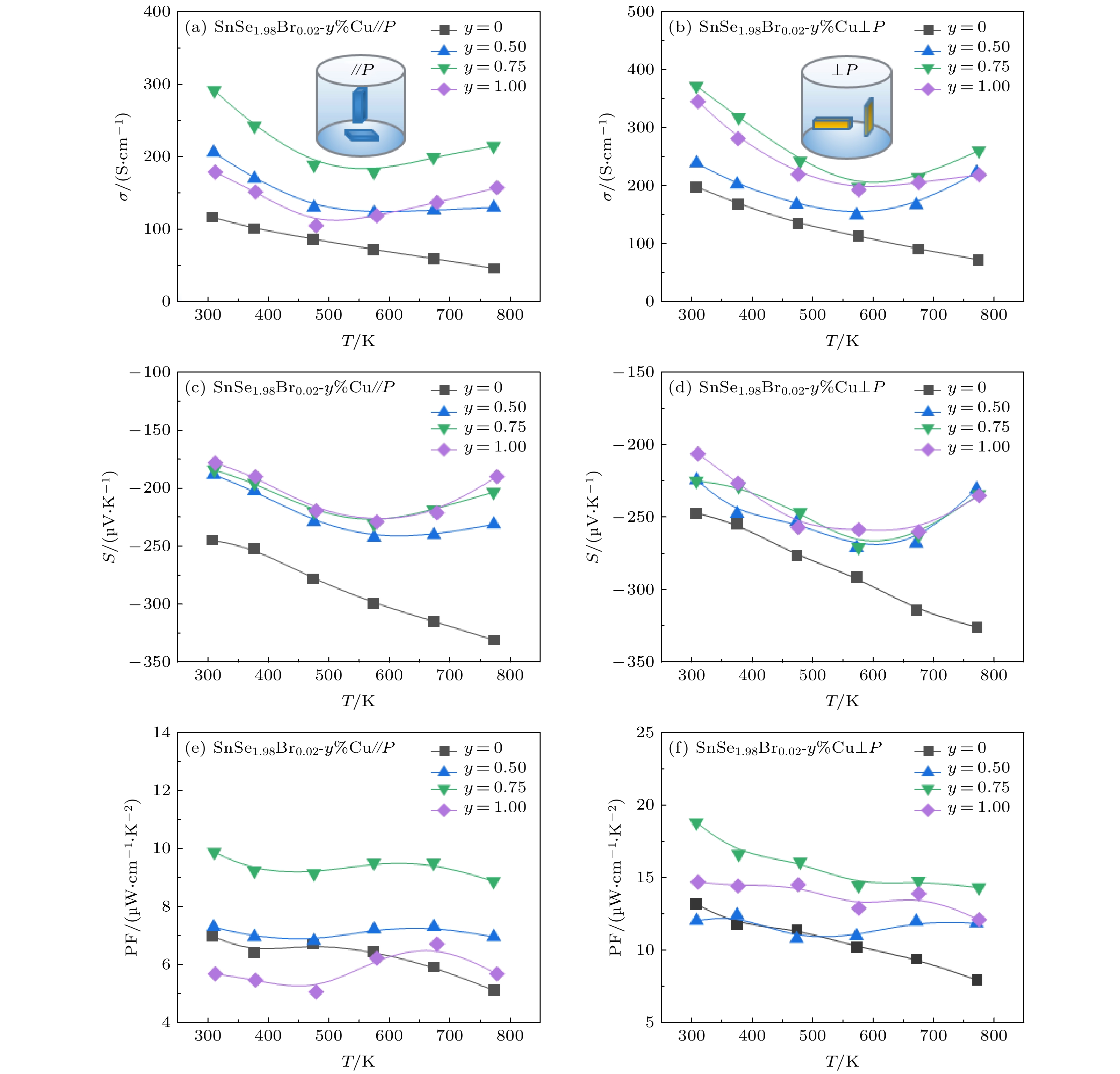

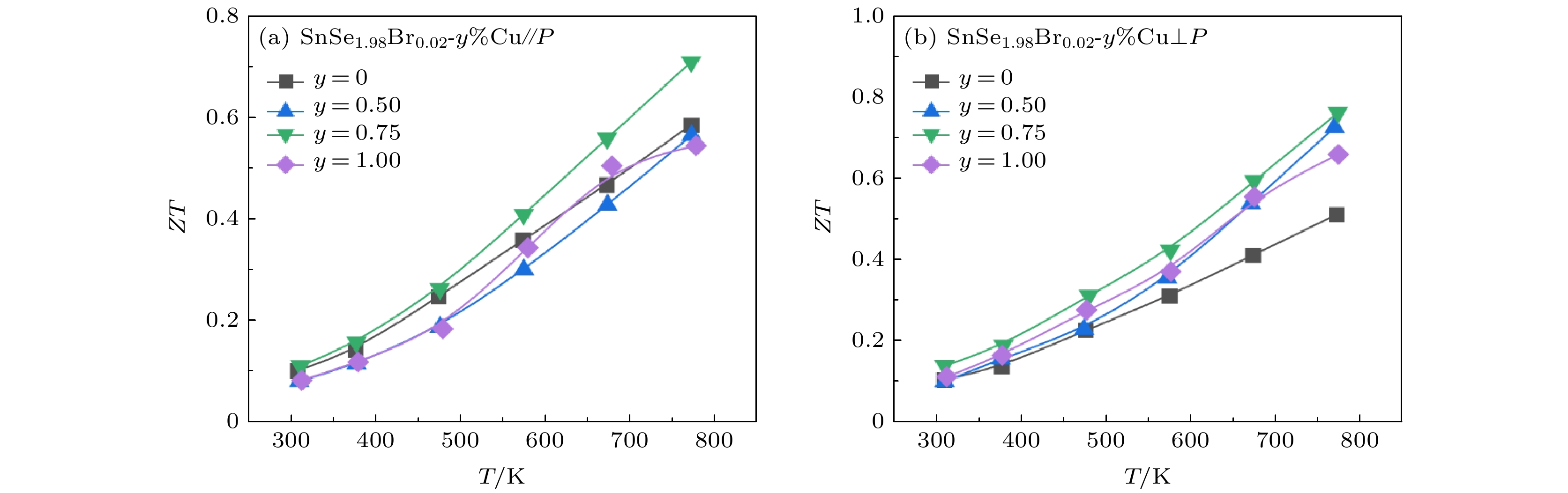

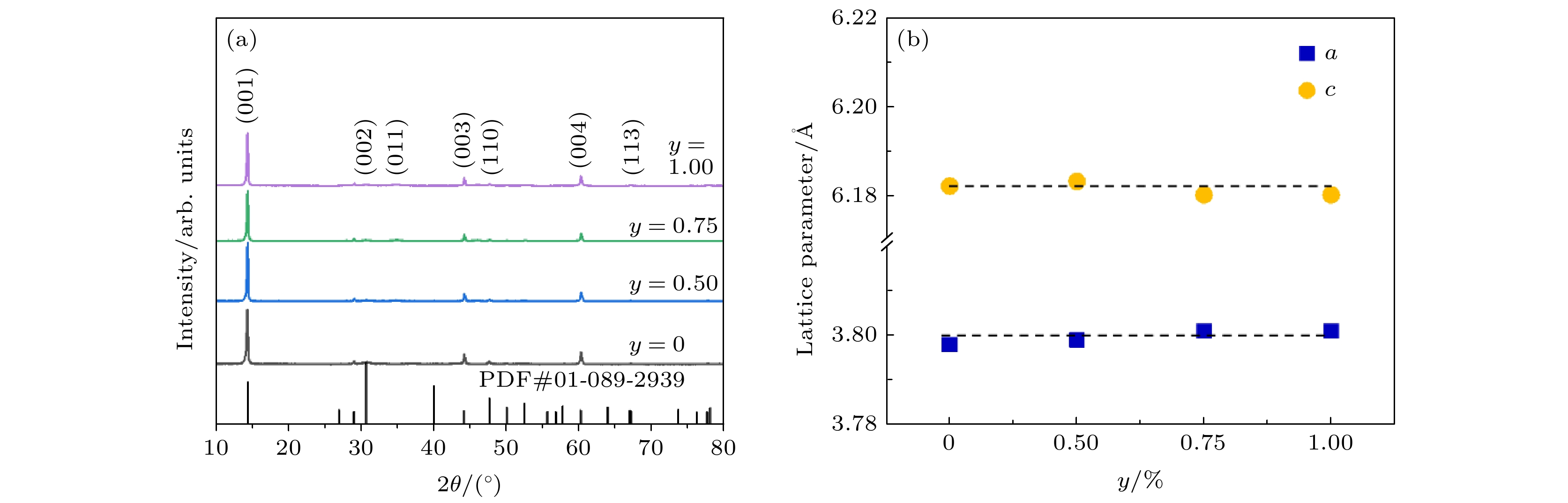

具有层状结构的SnSe展现出非常优异的热电性能. SnSe2与其具有相似结构, 但较低的电传输性能导致SnSe2热电性能表现不佳, 本征SnSe2在773 K下最大ZT值仅约 0.09. 本文在Br掺杂提升SnSe2载流子浓度的基础上, 通过熔融法结合放电等离子烧结(SPS)技术合成了一系列成分为SnSe1.98Br0.02–y%Cu (y = 0, 0.50, 0.75, 1.00)的块体材料, 研究了在具有层间范德瓦耳斯力结合的SnSe2材料中引入额外的Cu对其电传输性能的协同优化作用: 一方面, 引入的Cu不仅能提供额外的电子, 而且能稳定存在于范德瓦耳斯层间隙并形成插层结构, 促进层间和层内的电荷传输, 从而实现载流子浓度和迁移率的协同优化; 另一方面, Cu的动态掺杂特性, 使得高温下载流子浓度的增加弥补了因散射作用导致的迁移率的降低, 促使样品在高温下仍然保持高电传输特性. 研究结果表明, 在300 K下, SnSe2沿平行和垂直于SPS烧结方向(//P, ⊥P)的功率因子(PF)分别从本征的约0.65和0.98 µW·cm–1·K–2提高到SnSe1.98Br0.02–0.75%Cu的约10 和19 µW·cm–1·K–2. 最终, 在773 K下, 沿⊥P方向的最大ZT值达到约 0.8. 此研究表明SnSe2是一种很具发展潜力的热电材料.SnSe, a layered material with intrinsic low thermal conductivity, is reported to have excellent thermoelectric properties. SnSe2 has a similar structure to SnSe, but the SnSe2 has a low electrical transport, resulting in a poor thermoelectric performance, and the intrinsic SnSe2 has a maximum ZT value of only ~ 0.09 at 773 K. In this work, SnSe1.98Br0.02-y%Cu (y = 0, 0.50, 0.75, 1.0) bulk materials are synthesized by the melting method combined with spark plasma sintering (SPS) based on the carrier concentration improved through Br doping. In the SnSe2 materials with van der Waals chemical bonding between layers, the synergistic effects of intercalating Cu on the thermoelectric properties are investigated. On the one hand, the extra Cu not only provides additional electrons but also can be embedded stably in the van der Waals gap and form an intercalated structure, which is beneficial to the charge transfer in or out of the layers, and thus synergistically improving the carrier concentration and carrier mobility. On the other hand, owing to the dynamic Cu doping, the increase of carrier concentration compensates for the decrease of carrier mobility caused by carrier-carrier scattering, which maintains the high electrical transport properties at high temperature. The present results show that at room temperature, the power factors along the parallel and perpendicular to the SPS (//P and ⊥P) sintering directions increase from ~0.65 and ~0.98 µW·cm–1·K–2 for intrinsic SnSe2 to ~10 and ~19 μW·cm–1·K–2 for SnSe1.98Br0.02-0.75%Cu samples, respectively. Finally, at 773 K, the maximum ZT value of ~0.8 is achieved along the ⊥P direction. This study proves that the SnSe2 greatly promises to become an excellent thermoelectric material.

-

Keywords:

- SnSe2 /

- thermoelectric properties /

- Cu intercalation /

- anisotropic structure

[1] Zhang X, Zhao L D 2015 J. Materiomics 1 92

Google Scholar

Google Scholar

[2] Li J F, Liu W S, Zhao L D, Zhou M 2010 NPG Asia Mater. 2 152

Google Scholar

Google Scholar

[3] 赵立东, 张德培, 赵勇 2015 西华大学学报 (自然科学版) 34 1

Google Scholar

Google Scholar

Zhao L D, Zhang D P, Zhao Y 2015 J. Xihua Univ. (Nat. Sci. Ed. ) 34 1

Google Scholar

Google Scholar

[4] Xiao Y, Zhao L D 2020 Science 367 1196

Google Scholar

Google Scholar

[5] 蒋俊, 许高杰, 崔平, 陈立东 2005 55 4849

Google Scholar

Google Scholar

Jiang J, Xu G J, Cui P, Chen L D 2005 Acta Phys. Sin. 55 4849

Google Scholar

Google Scholar

[6] 郑丽仙, 胡剑峰, 骆军 2020 69 247102

Google Scholar

Google Scholar

Zheng L X, Hu J F, Luo J 2020 Acta Phys. Sin. 69 247102

Google Scholar

Google Scholar

[7] 赵英浩, 张瑞, 张波萍, 尹阳, 王明军, 梁豆豆 2021 70 128401

Google Scholar

Google Scholar

Zhao Y H, Zhang R, Zhang B P, Yin Y, Wang M J, Liang D D 2021 Acta Phys. Sin. 70 128401

Google Scholar

Google Scholar

[8] Xiao Y, Wang D Y, Zhang Y, Chen C G, Zhang S X, Wang K D, Wang G T, Pennycook S J, Snyder G J, Wu H J, Zhao L D 2020 J. Am. Chem. Soc 142 4051

Google Scholar

Google Scholar

[9] He W K, Wang D Y, Jun W H, et al. 2019 Science 365 1418

Google Scholar

Google Scholar

[10] Zhao L D, Chang C, Tan G J, Kanatzidis M G 2016 Energy Environ. Sci. 9 3044

Google Scholar

Google Scholar

[11] Tan G J, Zhao L D, Kanatzidis M G 2016 Chem. Rev. 116 12123

Google Scholar

Google Scholar

[12] Zhao L D, Lo S H, Zhang Y, Sun H, Tan G, Uher C, Wolverton C, Dravid V P, Kanatzidis M G 2014 Nature 508 373

Google Scholar

Google Scholar

[13] Chang C, Wu M H, He D S, Pei Y L, Wu C F, Wu X F, Yu H L, Zhu F Y, Wang K D, Chen Y, Huang L, Li J F, He J Q, Zhao L D 2018 Science 360(SI) 778

[14] Qin B C, Wang D Y, Liu X X, Qin Y X, Dong J F, Luo J F, Li J W, Liu W, Tan G J, Tang X F, Li J F, He J, Zhao L D 2021 Science 373 556

Google Scholar

Google Scholar

[15] Sun J, Liu S, Wang C, Bai Y, Chen G, Luo Q, Ma F 2020 Appl. Surf. Sci. 510 145478

Google Scholar

Google Scholar

[16] Wang H F, Gao Y, Liu G 2017 RSC Adv. 7 8098

Google Scholar

Google Scholar

[17] Pham A T, Vu T H, Chang C, Trinh T L, Lee J E, Ryu H, Hwang C, Mo S K, Kim J, Zhao L D, Duong A T, Cho S 2020 ACS Appl. Energy Mater. 3 10787

Google Scholar

Google Scholar

[18] Shu Y J, Su X L, Xie H Y, Zheng G, Liu W, Yan Y G, Luo T T, Yang X, Wang D Y, Uher C, Tang X F 2018 ACS Appl. Mater. Interfaces 10 15793

Google Scholar

Google Scholar

[19] Liu C Y, Huang Z W, Wang D H, Wang X X, Miao L, Wang X Y, Wu S H, Toyama N, Asaka T, Chen J L, Nishibori E, Zhao L D 2019 J. Mater. Chem. A 7 9761

Google Scholar

Google Scholar

[20] Xu P P, Fu T Z, Xin J Z, Liu Y T, Ying P T, Zhao X B, Pan H G, Zhu T J 2017 Sci. Bull. 62 1663

Google Scholar

Google Scholar

[21] Luo Y B, Zheng Y, Luo Z Z, Hao S Q, Du C F, Liang Q H, Li Z, Khor K A, Hippalgaonkar K, Xu J W, Yan Q Y, Wolverton C, Kanatzidis M G 2018 Adv. Energy Mater. 8 1702167

Google Scholar

Google Scholar

[22] 施先珍 2014 硕士学位论文 (武汉: 武汉理工大学)

Shi X Z 2014 M. S. Thesis (Wuhan: Wuhan University of Technology) (in Chinese)

[23] Sun G L, Qin X Y, Li D, Zhang J, Ren B J, Zou T H, Xin H X, Paschen S B, Yan X L 2015 J. Alloys Compd. 639 9

Google Scholar

Google Scholar

[24] Xiao Y, Wu H J, Li W, Yin M J, Pei Y L, Zhang Y, Fu L W, Chen Y X, Pennycook S J, Huang L, He J Q, Zhao L D 2017 J. Am. Chem. Soc 139 18732

Google Scholar

Google Scholar

[25] Qin B C, Wang D Y, He W K, Zhang Y, Wu H J, Pennycook S J, Zhao L D 2018 J. Am. Chem. Soc 141 1141

Google Scholar

Google Scholar

[26] Blöchl P E 1994 Phys. Rev. B 50 17953

Google Scholar

Google Scholar

[27] Kresse G, Furthmüller J 1996 Phys. Rev. B 54 11169

Google Scholar

Google Scholar

[28] John P P, Kieron B, Ernzerhof M 1996 Phys. Rev. Lett. 77 3865

Google Scholar

Google Scholar

[29] Zhou C, Yu Y, Zhang X, Cheng Y, Xu J, Lee Y K, Yoo B, Cojocaru‐Mirédin O, Liu G, Cho S P, Wuttig M, Hyeon T, Chung In 2019 Adv. Funct. Mater. 30 1908405

Google Scholar

Google Scholar

[30] Savin A, Jepsen O, Flad J, Andersen O K, Preuss H, von Schnering H G 1992 Angew. Chem. Int. Ed. 31 187

Google Scholar

Google Scholar

[31] Sun B Z, Ma Z J, He C, Wu K C 2015 Phys. Chem. Chem. Phys. 17 29844

Google Scholar

Google Scholar

[32] Qian X, Wang D Y, Zhang Y, Wu H J, Pennycook S J, Zheng L, Poudeu P F P, Zhao L D 2020 J. Mater. Chem. A 8 5699

Google Scholar

Google Scholar

[33] Li C Y, He W K, Wang D Y, Zhao L D 2021 Chin. Phys. B 30 067101

Google Scholar

Google Scholar

[34] Yamamoto M, Ohta H, Koumoto K 2007 Appl. Phys. Lett. 90 072101

Google Scholar

Google Scholar

[35] Zhao L D, Zhang B P, Liu W S, Zhang H L, Li J F 2008 J. Solid State Chem. 181 3278

Google Scholar

Google Scholar

[36] Pei Y L, He J Q, Li J F, Li F, Liu Q J, Pan W, Barreteau C, Berardan D, Dragoe N, Zhao L D 2013 NPG Asia Mater. 5 e47

Google Scholar

Google Scholar

[37] Ge Z H, Song D, Chong X, Zheng F, Jin L, Qian X, Zheng L, Dunin-Borkowski R E, Qin P, Feng J, Zhao L D 2017 J. Am. Chem. Soc 139 9714

Google Scholar

Google Scholar

-

图 3 (a) SnSe1.98Br0.02-y%Cu样品沿//P和⊥P方向的载流子浓度和载流子迁移率; (b) SnSe2–xBrx和SnSe1.98Br0.02-y%Cu的Seebeck系数随载流子浓度的变化; SnSe1.98Br0.02 [29]和SnSe1.98Br0.02-0.75%Cu样品的(c)载流子浓度和(d)载流子迁移率随温度的变化

Fig. 3. (a) Carrier concentration and carrier mobility at room temperature for the samples of SnSe1.98Br0.02-y%Cu along the //P and ⊥P directions; (b) Seebeck coefficient as function of carrier concentration; (c) carrier concentration and (d) carrier mobility as function of temperature for SnSe1.98Br0.02[29] and SnSe1.98Br0.02-0.75%Cu samples.

-

[1] Zhang X, Zhao L D 2015 J. Materiomics 1 92

Google Scholar

Google Scholar

[2] Li J F, Liu W S, Zhao L D, Zhou M 2010 NPG Asia Mater. 2 152

Google Scholar

Google Scholar

[3] 赵立东, 张德培, 赵勇 2015 西华大学学报 (自然科学版) 34 1

Google Scholar

Google Scholar

Zhao L D, Zhang D P, Zhao Y 2015 J. Xihua Univ. (Nat. Sci. Ed. ) 34 1

Google Scholar

Google Scholar

[4] Xiao Y, Zhao L D 2020 Science 367 1196

Google Scholar

Google Scholar

[5] 蒋俊, 许高杰, 崔平, 陈立东 2005 55 4849

Google Scholar

Google Scholar

Jiang J, Xu G J, Cui P, Chen L D 2005 Acta Phys. Sin. 55 4849

Google Scholar

Google Scholar

[6] 郑丽仙, 胡剑峰, 骆军 2020 69 247102

Google Scholar

Google Scholar

Zheng L X, Hu J F, Luo J 2020 Acta Phys. Sin. 69 247102

Google Scholar

Google Scholar

[7] 赵英浩, 张瑞, 张波萍, 尹阳, 王明军, 梁豆豆 2021 70 128401

Google Scholar

Google Scholar

Zhao Y H, Zhang R, Zhang B P, Yin Y, Wang M J, Liang D D 2021 Acta Phys. Sin. 70 128401

Google Scholar

Google Scholar

[8] Xiao Y, Wang D Y, Zhang Y, Chen C G, Zhang S X, Wang K D, Wang G T, Pennycook S J, Snyder G J, Wu H J, Zhao L D 2020 J. Am. Chem. Soc 142 4051

Google Scholar

Google Scholar

[9] He W K, Wang D Y, Jun W H, et al. 2019 Science 365 1418

Google Scholar

Google Scholar

[10] Zhao L D, Chang C, Tan G J, Kanatzidis M G 2016 Energy Environ. Sci. 9 3044

Google Scholar

Google Scholar

[11] Tan G J, Zhao L D, Kanatzidis M G 2016 Chem. Rev. 116 12123

Google Scholar

Google Scholar

[12] Zhao L D, Lo S H, Zhang Y, Sun H, Tan G, Uher C, Wolverton C, Dravid V P, Kanatzidis M G 2014 Nature 508 373

Google Scholar

Google Scholar

[13] Chang C, Wu M H, He D S, Pei Y L, Wu C F, Wu X F, Yu H L, Zhu F Y, Wang K D, Chen Y, Huang L, Li J F, He J Q, Zhao L D 2018 Science 360(SI) 778

[14] Qin B C, Wang D Y, Liu X X, Qin Y X, Dong J F, Luo J F, Li J W, Liu W, Tan G J, Tang X F, Li J F, He J, Zhao L D 2021 Science 373 556

Google Scholar

Google Scholar

[15] Sun J, Liu S, Wang C, Bai Y, Chen G, Luo Q, Ma F 2020 Appl. Surf. Sci. 510 145478

Google Scholar

Google Scholar

[16] Wang H F, Gao Y, Liu G 2017 RSC Adv. 7 8098

Google Scholar

Google Scholar

[17] Pham A T, Vu T H, Chang C, Trinh T L, Lee J E, Ryu H, Hwang C, Mo S K, Kim J, Zhao L D, Duong A T, Cho S 2020 ACS Appl. Energy Mater. 3 10787

Google Scholar

Google Scholar

[18] Shu Y J, Su X L, Xie H Y, Zheng G, Liu W, Yan Y G, Luo T T, Yang X, Wang D Y, Uher C, Tang X F 2018 ACS Appl. Mater. Interfaces 10 15793

Google Scholar

Google Scholar

[19] Liu C Y, Huang Z W, Wang D H, Wang X X, Miao L, Wang X Y, Wu S H, Toyama N, Asaka T, Chen J L, Nishibori E, Zhao L D 2019 J. Mater. Chem. A 7 9761

Google Scholar

Google Scholar

[20] Xu P P, Fu T Z, Xin J Z, Liu Y T, Ying P T, Zhao X B, Pan H G, Zhu T J 2017 Sci. Bull. 62 1663

Google Scholar

Google Scholar

[21] Luo Y B, Zheng Y, Luo Z Z, Hao S Q, Du C F, Liang Q H, Li Z, Khor K A, Hippalgaonkar K, Xu J W, Yan Q Y, Wolverton C, Kanatzidis M G 2018 Adv. Energy Mater. 8 1702167

Google Scholar

Google Scholar

[22] 施先珍 2014 硕士学位论文 (武汉: 武汉理工大学)

Shi X Z 2014 M. S. Thesis (Wuhan: Wuhan University of Technology) (in Chinese)

[23] Sun G L, Qin X Y, Li D, Zhang J, Ren B J, Zou T H, Xin H X, Paschen S B, Yan X L 2015 J. Alloys Compd. 639 9

Google Scholar

Google Scholar

[24] Xiao Y, Wu H J, Li W, Yin M J, Pei Y L, Zhang Y, Fu L W, Chen Y X, Pennycook S J, Huang L, He J Q, Zhao L D 2017 J. Am. Chem. Soc 139 18732

Google Scholar

Google Scholar

[25] Qin B C, Wang D Y, He W K, Zhang Y, Wu H J, Pennycook S J, Zhao L D 2018 J. Am. Chem. Soc 141 1141

Google Scholar

Google Scholar

[26] Blöchl P E 1994 Phys. Rev. B 50 17953

Google Scholar

Google Scholar

[27] Kresse G, Furthmüller J 1996 Phys. Rev. B 54 11169

Google Scholar

Google Scholar

[28] John P P, Kieron B, Ernzerhof M 1996 Phys. Rev. Lett. 77 3865

Google Scholar

Google Scholar

[29] Zhou C, Yu Y, Zhang X, Cheng Y, Xu J, Lee Y K, Yoo B, Cojocaru‐Mirédin O, Liu G, Cho S P, Wuttig M, Hyeon T, Chung In 2019 Adv. Funct. Mater. 30 1908405

Google Scholar

Google Scholar

[30] Savin A, Jepsen O, Flad J, Andersen O K, Preuss H, von Schnering H G 1992 Angew. Chem. Int. Ed. 31 187

Google Scholar

Google Scholar

[31] Sun B Z, Ma Z J, He C, Wu K C 2015 Phys. Chem. Chem. Phys. 17 29844

Google Scholar

Google Scholar

[32] Qian X, Wang D Y, Zhang Y, Wu H J, Pennycook S J, Zheng L, Poudeu P F P, Zhao L D 2020 J. Mater. Chem. A 8 5699

Google Scholar

Google Scholar

[33] Li C Y, He W K, Wang D Y, Zhao L D 2021 Chin. Phys. B 30 067101

Google Scholar

Google Scholar

[34] Yamamoto M, Ohta H, Koumoto K 2007 Appl. Phys. Lett. 90 072101

Google Scholar

Google Scholar

[35] Zhao L D, Zhang B P, Liu W S, Zhang H L, Li J F 2008 J. Solid State Chem. 181 3278

Google Scholar

Google Scholar

[36] Pei Y L, He J Q, Li J F, Li F, Liu Q J, Pan W, Barreteau C, Berardan D, Dragoe N, Zhao L D 2013 NPG Asia Mater. 5 e47

Google Scholar

Google Scholar

[37] Ge Z H, Song D, Chong X, Zheng F, Jin L, Qian X, Zheng L, Dunin-Borkowski R E, Qin P, Feng J, Zhao L D 2017 J. Am. Chem. Soc 139 9714

Google Scholar

Google Scholar

计量

- 文章访问数: 9140

- PDF下载量: 306

- 被引次数: 0

下载:

下载: