-

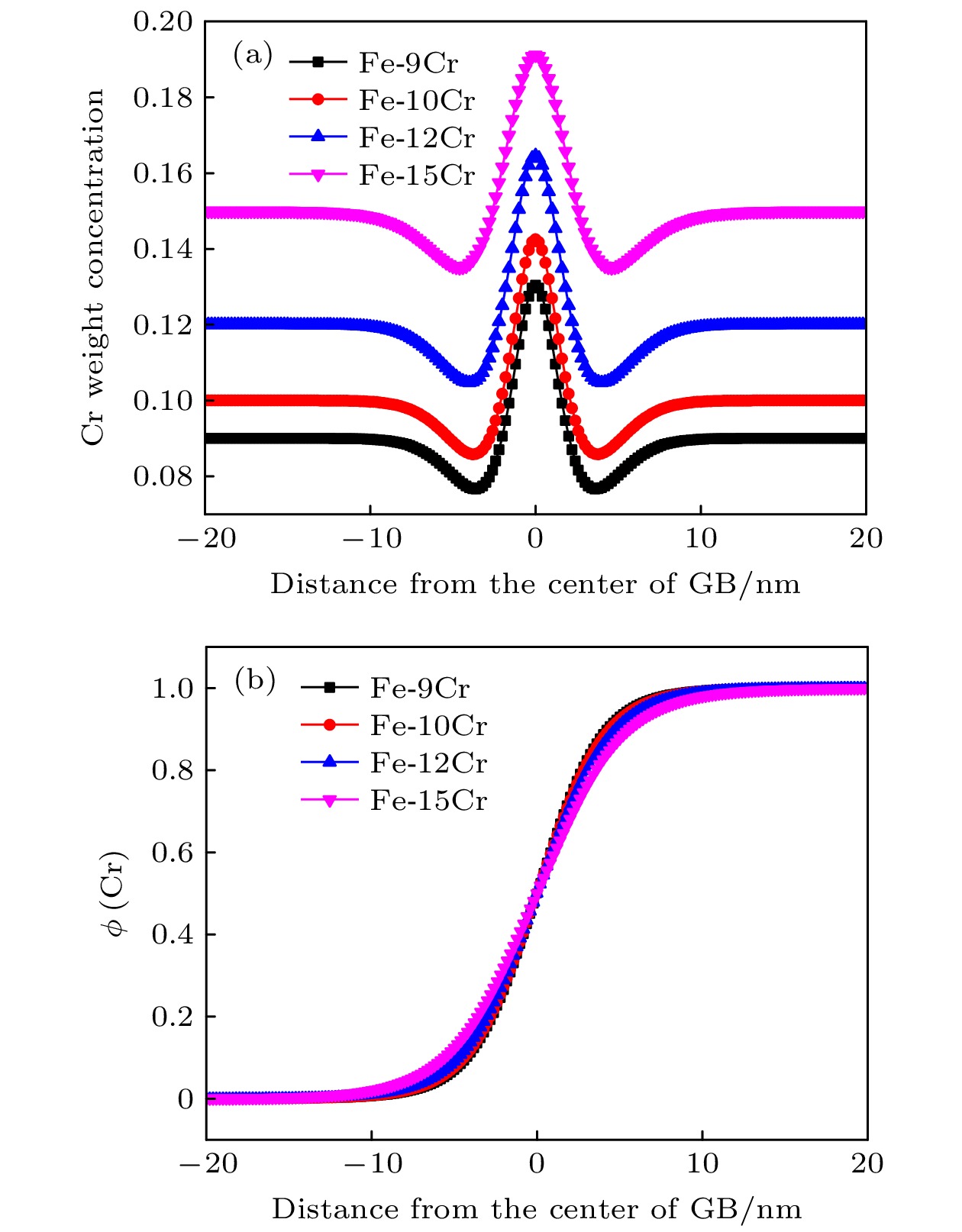

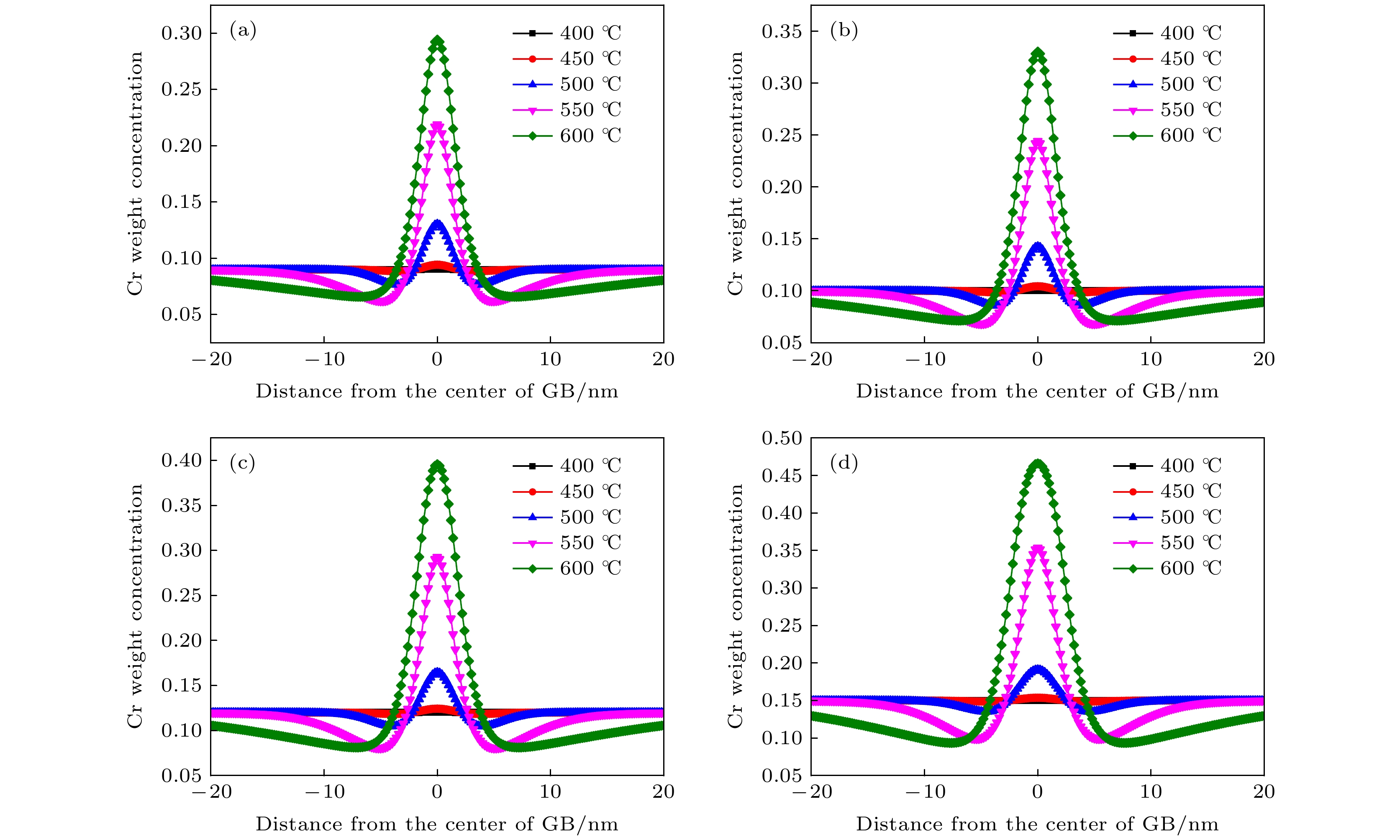

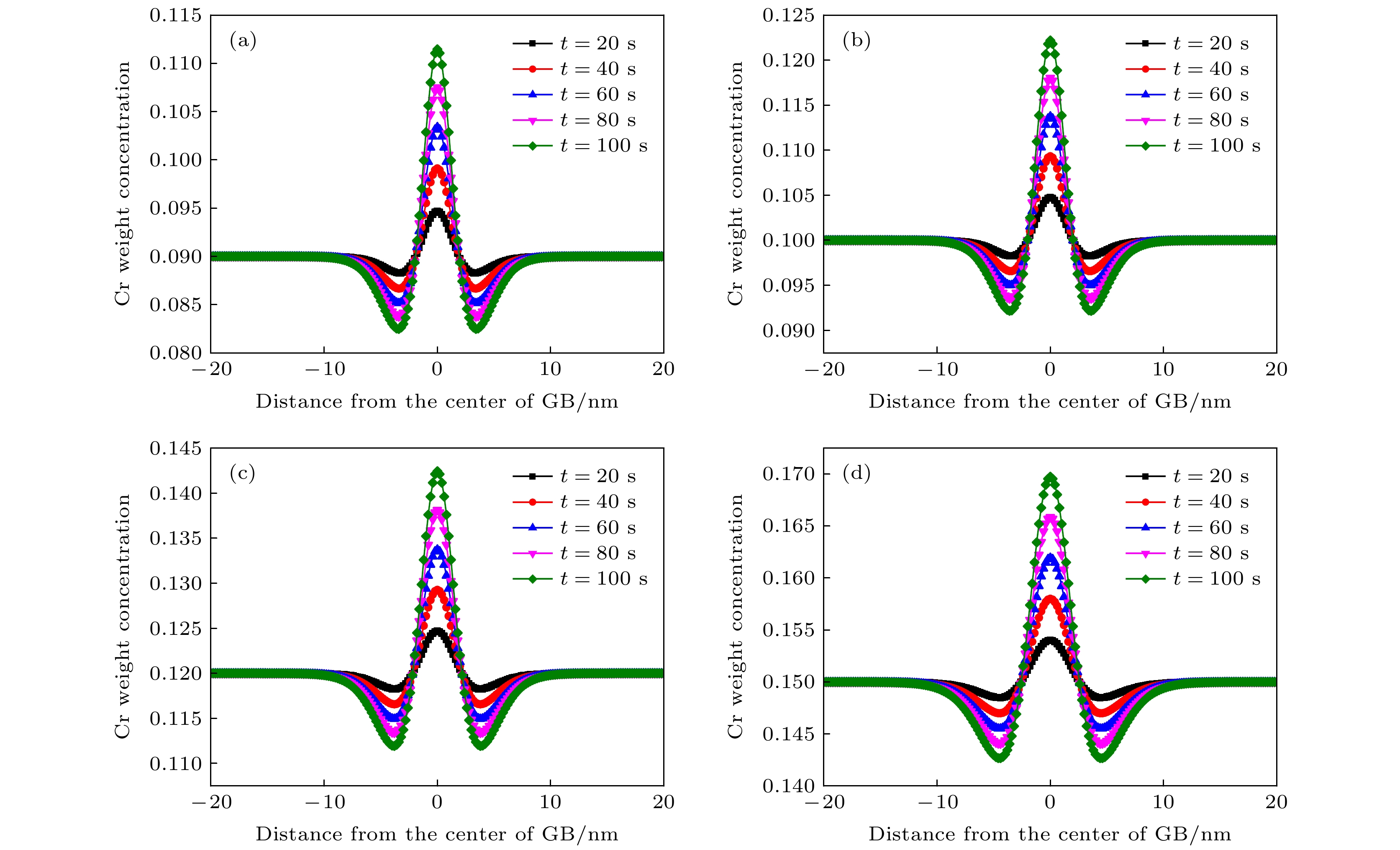

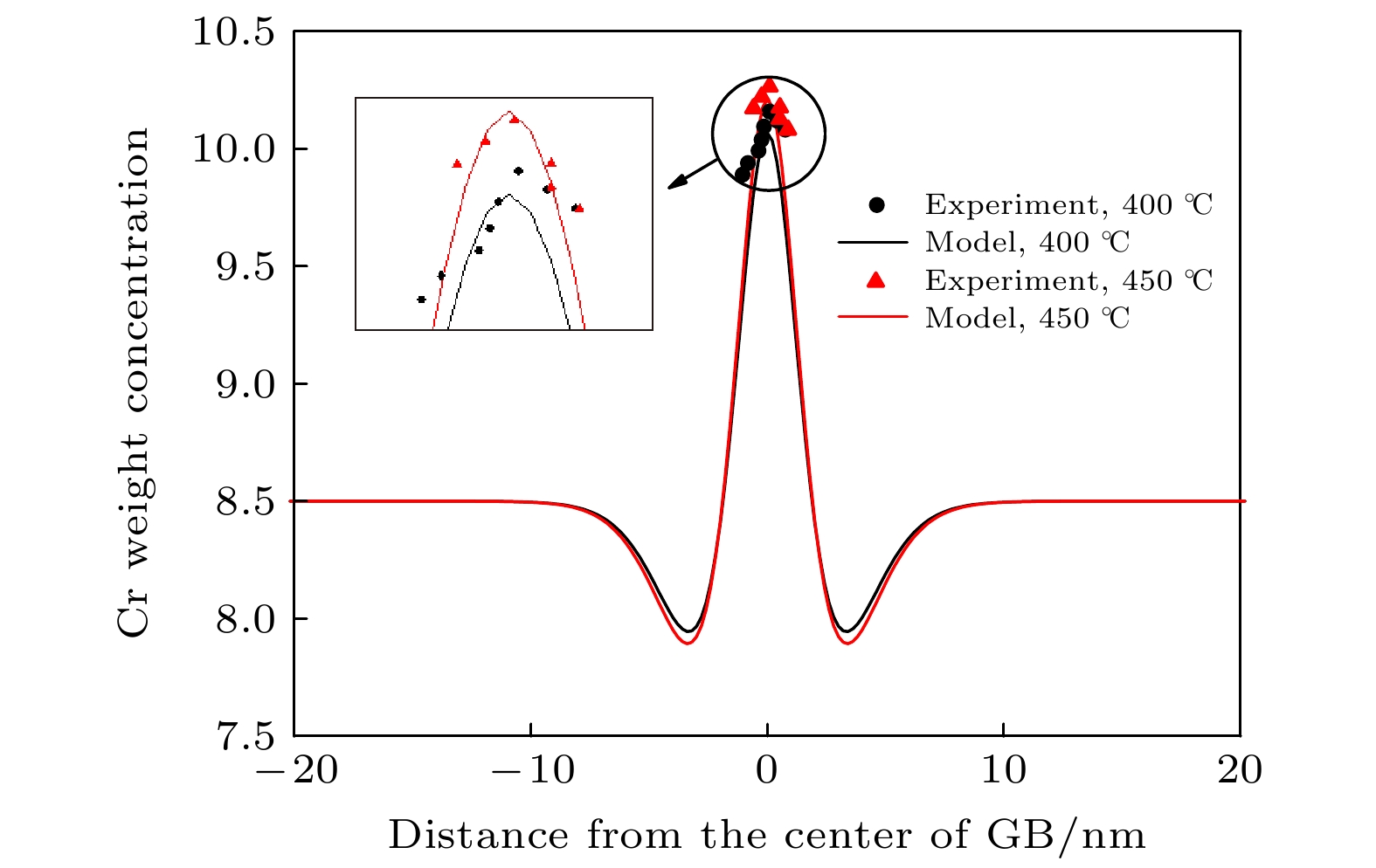

基于WBM相场模型对热力学条件和辐照条件下Fe-Cr合金晶界处Cr元素偏析行为进行了模拟. 模拟结果表明温度对Fe-Cr合金晶界处Cr元素的偏析有很大影响: 当温度低于500 ℃时, 晶界处的偏析量很小; 而当温度高于500 ℃时晶界处的偏析量增加明显. 基体中Cr元素含量对晶界Cr元素的相对偏析量也有显著影响: 随着基体中Cr元素含量的增加, 相同模拟条件下晶界处Cr元素的相对浓度增量降低. 辐照条件下, 晶界处Cr元素的相对偏析量比热力学条件下的相对偏析量有明显增加; 随着辐照剂量率的提高, 晶界中心处Cr元素浓度增量变大; 相同辐照条件下, 随着Cr元素含量的增加, 晶界处Cr元素的相对浓度增量也降低.Ferritic/martensitic steel, with Cr atomic content in a range of 7%–15%, is a promising candidate for advanced nuclear power systems, due to its swelling resistance and creep fracture resistance under irradiation. Under thermodynamic conditions, Cr segregation usually occurs at grain boundary (GB) in Fe-Cr alloys. However, irradiation can greatly accelerate this process. The enrichment of Cr at GB will enhance precipitation, resulting in embrittlement; while the depletion of Cr at GB may greatly weaken the corrosion resistance properties. In the present work, thermodynamic segregation and radiation-enhanced segregation of Cr element at GB in Fe-Cr alloy is investigated by using the Wheeler-Boettinger-McFadden (WBM) phase-field model. The simulation results show that temperature has a great influence during thermodynamic segregation of Cr at the GB without radiation: when the temperature is lower than 500 ℃ the segregation amount of Cr at the GB is relatively small; when the temperature is higher than 500 ℃ the Cr concentration at GB increases significantly. In addition, as the concentration of Cr in the matrix increases, the amount of relative increase of Cr concentration at GB decreases. However, the Cr concentration at GB under irradiation is significantly enhanced, compared with the counterpart without irradiation. With the increase of dose rate, the Cr concentration in the center of GB also increases. Moreover, with the increase of Cr concentration in the matrix, the relative increase of the Cr concentration at the GB weakens.

-

Keywords:

- phase-field simulation /

- Fe-Cr alloys /

- grain boundary segregation /

- radiation-enhanced diffusion

[1] Yvon P, Le F M, Cabet C, Seran J L 2015 Nucl. Eng. Des. 294 161

Google Scholar

Google Scholar

[2] Zinkle S J, Busby J T 2009 Mater. Today 385 217

Google Scholar

Google Scholar

[3] Yvon P, Carré F 2009 J. Nucl. Mater. 385 217

Google Scholar

Google Scholar

[4] Lucas G E 2002 J. Nucl. Mater. 302 232

Google Scholar

Google Scholar

[5] 刘涛, 杨梅, 王刚, 王璐, 徐东生 2020 稀有金属材料与工程 56 1114

Liu T, Yang M, Wang G, Wang L, Xu D S 2020 Rare Metal Mater. Eng. 56 1114

[6] Nastar M, Soisson F 2012 Compr. Nucl. Mater. 1 471

Google Scholar

Google Scholar

[7] Wharry J P, Was G S 2013 J. Nucl. Mater. 442 7

Google Scholar

Google Scholar

[8] Faulkner R G 1997 J. Nucl. Mater. 251 269

Google Scholar

Google Scholar

[9] Terentyev D, He X, Zhurkin E, Bakaev A 2011 J. Nucl. Mater. 408 161

Google Scholar

Google Scholar

[10] 朱陆陆 2014 硕士学位论文 (武汉: 华中师范大学)

Zhu L L 2014 M. S. Thesis (Wuhan: Central China Normal University) (in Chinese)

[11] Was G S, Wharry J P, Frisbie B, Wirth B D, Morgan D, Tucker J D, Allen T R 2011 J. Nucl. Mater. 411 41

Google Scholar

Google Scholar

[12] Xia L D, Ji Y Z, Liu W B, Chen H, Yang Z G, Zhang C, Chen L Q 2020 Nucl. Eng. Technol. 52 148

Google Scholar

Google Scholar

[13] 柯常波, 周敏波, 张新平 2014 金属学报 50 294

Google Scholar

Google Scholar

Ke C B, Zo H M, Zhang X P 2014 Acta Metall. Sin. 50 294

Google Scholar

Google Scholar

[14] Wheeler A A, Boettinger W J, McFadden G B 1992 Phys. Rev. A 45 7424

Google Scholar

Google Scholar

[15] Kim S G, Kim W T, Suzuki T 1999 Phys. Rev. E 60 7186

Google Scholar

Google Scholar

[16] Kim S G, Lee J S, Lee B J 2016 Acta Mater. 112 150

Google Scholar

Google Scholar

[17] Badillo A, Bellon P, Averback R S 2015 Model. Simul. Mater. Sci. Eng. 23 035008

Google Scholar

Google Scholar

[18] Piochaud J B, Nastar M, Soisson F, Thuinet L, Legris A 2016 Comput. Mater. Sci. 122 249

Google Scholar

Google Scholar

[19] Grönhagen K, Ågren J 2007 Acta Mater. 55 955

Google Scholar

Google Scholar

[20] Zhang C Y, Chen H, Zhu J N, Liu W B, Liu G, Zhang C, Yang Z G 2019 Scr. Mater. 162 44

Google Scholar

Google Scholar

[21] Allen S M, Cahn J W 1979 Acta Metall. 27 1085

Google Scholar

Google Scholar

[22] Cahn J W 1961 Acta Metall. 9 795

Google Scholar

Google Scholar

[23] Odette G R, Yamamoto T, Klingensmith D 2005 Philos. Mag. 85 779

Google Scholar

Google Scholar

[24] Ke H, Wells P, Edmondson P D, Almirall N, Barnard L, Odette G R, Morgan D 2017 Acta Mater. 138 10

Google Scholar

Google Scholar

[25] Gamsjäger E, Svoboda J, Fischer F D 2005 Comput. Mater. Sci. 32 360

[26] Ke J H, Reese E R, Marquis E A, Odette G R, Morgan D 2019 Acta Mater. 164 586

Google Scholar

Google Scholar

[27] Makin M J, Minter F J 1960 Acta Metall. 8 691

Google Scholar

Google Scholar

[28] Enomoto M, White C L, Aaronson H I 1988 Metall. Trans. A 19A 1807

[29] Chen H, Zwaag S V D 2014 Acta Mater. 72 1

Google Scholar

Google Scholar

[30] Zhu J N, Luo H W, Yang Z G, Zhang C, Zwaag S V D, Chen H 2017 Acta Mater. 133 258

Google Scholar

Google Scholar

[31] Malerba L 2006 J. Nucl. Mater. 351 28

Google Scholar

Google Scholar

[32] Martinez E, Senninger O, Fu C C 2012 Matter Mater. Phys. 86 1

Google Scholar

Google Scholar

[33] Lavrentiev M Y, Nguyen-Manh D, Dudarev S L 2018 J. Nucl. Mater. 499 613

Google Scholar

Google Scholar

[34] Moelans N, Blanpain B, Wollants P 2008 Calphad 32 268

Google Scholar

Google Scholar

[35] Li J, Wang J, Yang G 2009 Acta Mater. 57 2108

Google Scholar

Google Scholar

[36] 贾丽霞, 贺新福, 王东杰 2018 原子能科学技术 52 1040

Google Scholar

Google Scholar

Jia L X, He X F, Wang D J 2018 Atomic Energy Science and Technology 52 1040

Google Scholar

Google Scholar

[37] McLean D 1957 Grain Boundaries in Metals (London: Oxford at the Clarendon Press) p1

[38] Seah M P 1980 J. Phys. F: Met. Phys. 10 1063

-

表 1 Fe-Cr合金的物理参数

Table 1. Physical parameters of Fe-Cr alloys.

表 2 Fe-Cr合金辐照加速扩散模型的参数

Table 2. Parameters of radiation enhanced diffusion model of Fe-Cr alloys.

物理参数 数值 参考文献 d/m $ 2.49\times {10}^{-10} $ k/(J·K–1) $ 1.38\times {10}^{-23} $ $ {r}_{\rm{c}}/{\rm{m}} $ $ 3\times {10}^{-10} $ [26] ξ 0.33 [31] $ {V}_{{\rm{a}}} $/m3 $ 1.18\times {10}^{-29} $ $ {E}_{{\rm{m}}} $/eV 1.1 [32] $ {S}_{{\rm{d}}} $/m–2 $ 1.0\times {10}^{-13} $ $ {R}_{\rm{r}} $/m $ 5.7\times {10}^{-10} $ [23] $ {R}_{\rm{t}} $/m $ 5.7\times {10}^{-10} $ [23] $ {H}_{\rm{b}} $/eV 0.094 [33] $ {S}_{{\rm{s}}{\rm{a}}{\rm{t}}} $/m–2 $ 3.0\times {10}^{-15} $ -

[1] Yvon P, Le F M, Cabet C, Seran J L 2015 Nucl. Eng. Des. 294 161

Google Scholar

Google Scholar

[2] Zinkle S J, Busby J T 2009 Mater. Today 385 217

Google Scholar

Google Scholar

[3] Yvon P, Carré F 2009 J. Nucl. Mater. 385 217

Google Scholar

Google Scholar

[4] Lucas G E 2002 J. Nucl. Mater. 302 232

Google Scholar

Google Scholar

[5] 刘涛, 杨梅, 王刚, 王璐, 徐东生 2020 稀有金属材料与工程 56 1114

Liu T, Yang M, Wang G, Wang L, Xu D S 2020 Rare Metal Mater. Eng. 56 1114

[6] Nastar M, Soisson F 2012 Compr. Nucl. Mater. 1 471

Google Scholar

Google Scholar

[7] Wharry J P, Was G S 2013 J. Nucl. Mater. 442 7

Google Scholar

Google Scholar

[8] Faulkner R G 1997 J. Nucl. Mater. 251 269

Google Scholar

Google Scholar

[9] Terentyev D, He X, Zhurkin E, Bakaev A 2011 J. Nucl. Mater. 408 161

Google Scholar

Google Scholar

[10] 朱陆陆 2014 硕士学位论文 (武汉: 华中师范大学)

Zhu L L 2014 M. S. Thesis (Wuhan: Central China Normal University) (in Chinese)

[11] Was G S, Wharry J P, Frisbie B, Wirth B D, Morgan D, Tucker J D, Allen T R 2011 J. Nucl. Mater. 411 41

Google Scholar

Google Scholar

[12] Xia L D, Ji Y Z, Liu W B, Chen H, Yang Z G, Zhang C, Chen L Q 2020 Nucl. Eng. Technol. 52 148

Google Scholar

Google Scholar

[13] 柯常波, 周敏波, 张新平 2014 金属学报 50 294

Google Scholar

Google Scholar

Ke C B, Zo H M, Zhang X P 2014 Acta Metall. Sin. 50 294

Google Scholar

Google Scholar

[14] Wheeler A A, Boettinger W J, McFadden G B 1992 Phys. Rev. A 45 7424

Google Scholar

Google Scholar

[15] Kim S G, Kim W T, Suzuki T 1999 Phys. Rev. E 60 7186

Google Scholar

Google Scholar

[16] Kim S G, Lee J S, Lee B J 2016 Acta Mater. 112 150

Google Scholar

Google Scholar

[17] Badillo A, Bellon P, Averback R S 2015 Model. Simul. Mater. Sci. Eng. 23 035008

Google Scholar

Google Scholar

[18] Piochaud J B, Nastar M, Soisson F, Thuinet L, Legris A 2016 Comput. Mater. Sci. 122 249

Google Scholar

Google Scholar

[19] Grönhagen K, Ågren J 2007 Acta Mater. 55 955

Google Scholar

Google Scholar

[20] Zhang C Y, Chen H, Zhu J N, Liu W B, Liu G, Zhang C, Yang Z G 2019 Scr. Mater. 162 44

Google Scholar

Google Scholar

[21] Allen S M, Cahn J W 1979 Acta Metall. 27 1085

Google Scholar

Google Scholar

[22] Cahn J W 1961 Acta Metall. 9 795

Google Scholar

Google Scholar

[23] Odette G R, Yamamoto T, Klingensmith D 2005 Philos. Mag. 85 779

Google Scholar

Google Scholar

[24] Ke H, Wells P, Edmondson P D, Almirall N, Barnard L, Odette G R, Morgan D 2017 Acta Mater. 138 10

Google Scholar

Google Scholar

[25] Gamsjäger E, Svoboda J, Fischer F D 2005 Comput. Mater. Sci. 32 360

[26] Ke J H, Reese E R, Marquis E A, Odette G R, Morgan D 2019 Acta Mater. 164 586

Google Scholar

Google Scholar

[27] Makin M J, Minter F J 1960 Acta Metall. 8 691

Google Scholar

Google Scholar

[28] Enomoto M, White C L, Aaronson H I 1988 Metall. Trans. A 19A 1807

[29] Chen H, Zwaag S V D 2014 Acta Mater. 72 1

Google Scholar

Google Scholar

[30] Zhu J N, Luo H W, Yang Z G, Zhang C, Zwaag S V D, Chen H 2017 Acta Mater. 133 258

Google Scholar

Google Scholar

[31] Malerba L 2006 J. Nucl. Mater. 351 28

Google Scholar

Google Scholar

[32] Martinez E, Senninger O, Fu C C 2012 Matter Mater. Phys. 86 1

Google Scholar

Google Scholar

[33] Lavrentiev M Y, Nguyen-Manh D, Dudarev S L 2018 J. Nucl. Mater. 499 613

Google Scholar

Google Scholar

[34] Moelans N, Blanpain B, Wollants P 2008 Calphad 32 268

Google Scholar

Google Scholar

[35] Li J, Wang J, Yang G 2009 Acta Mater. 57 2108

Google Scholar

Google Scholar

[36] 贾丽霞, 贺新福, 王东杰 2018 原子能科学技术 52 1040

Google Scholar

Google Scholar

Jia L X, He X F, Wang D J 2018 Atomic Energy Science and Technology 52 1040

Google Scholar

Google Scholar

[37] McLean D 1957 Grain Boundaries in Metals (London: Oxford at the Clarendon Press) p1

[38] Seah M P 1980 J. Phys. F: Met. Phys. 10 1063

计量

- 文章访问数: 10169

- PDF下载量: 213

- 被引次数: 0

下载:

下载: