-

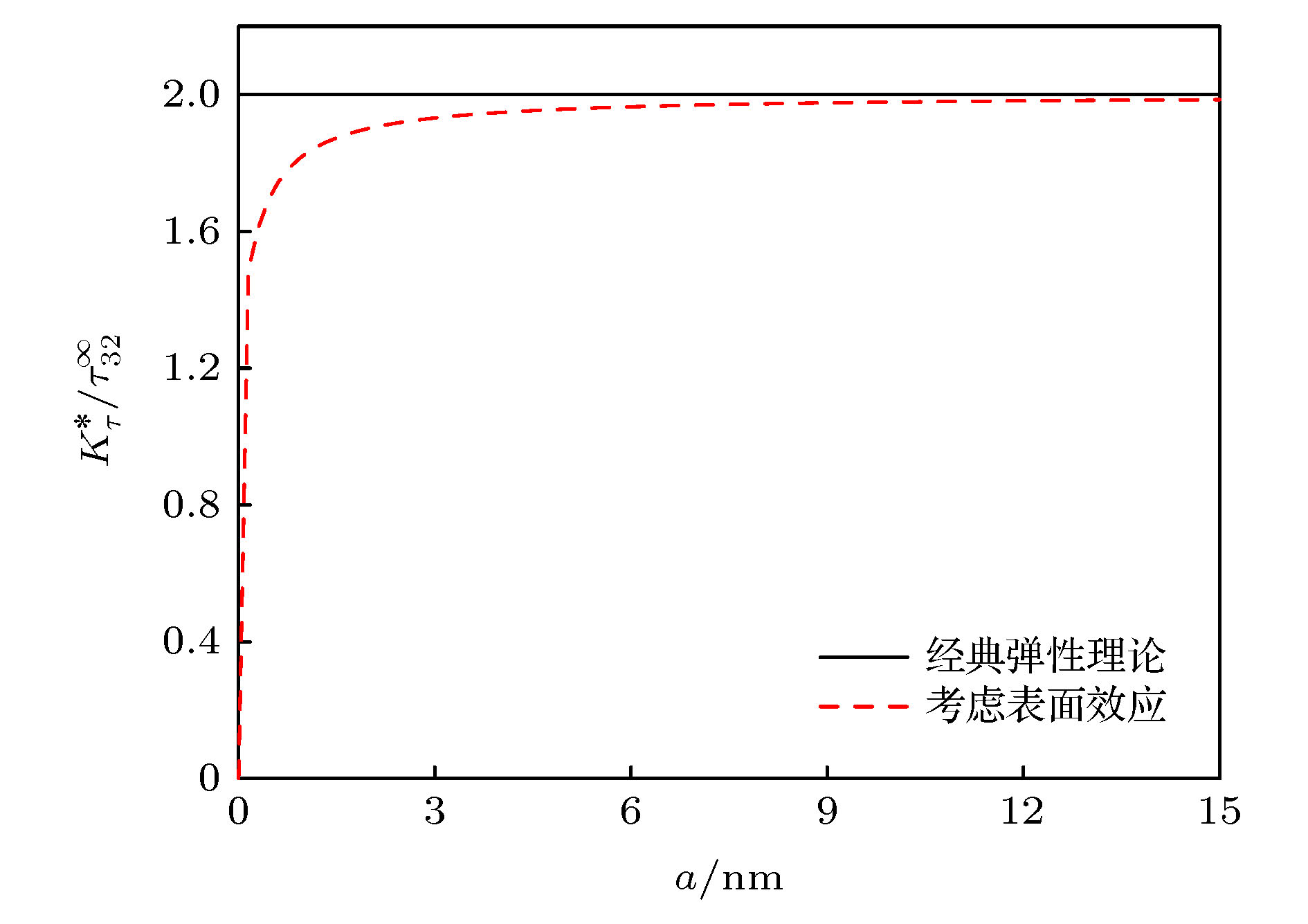

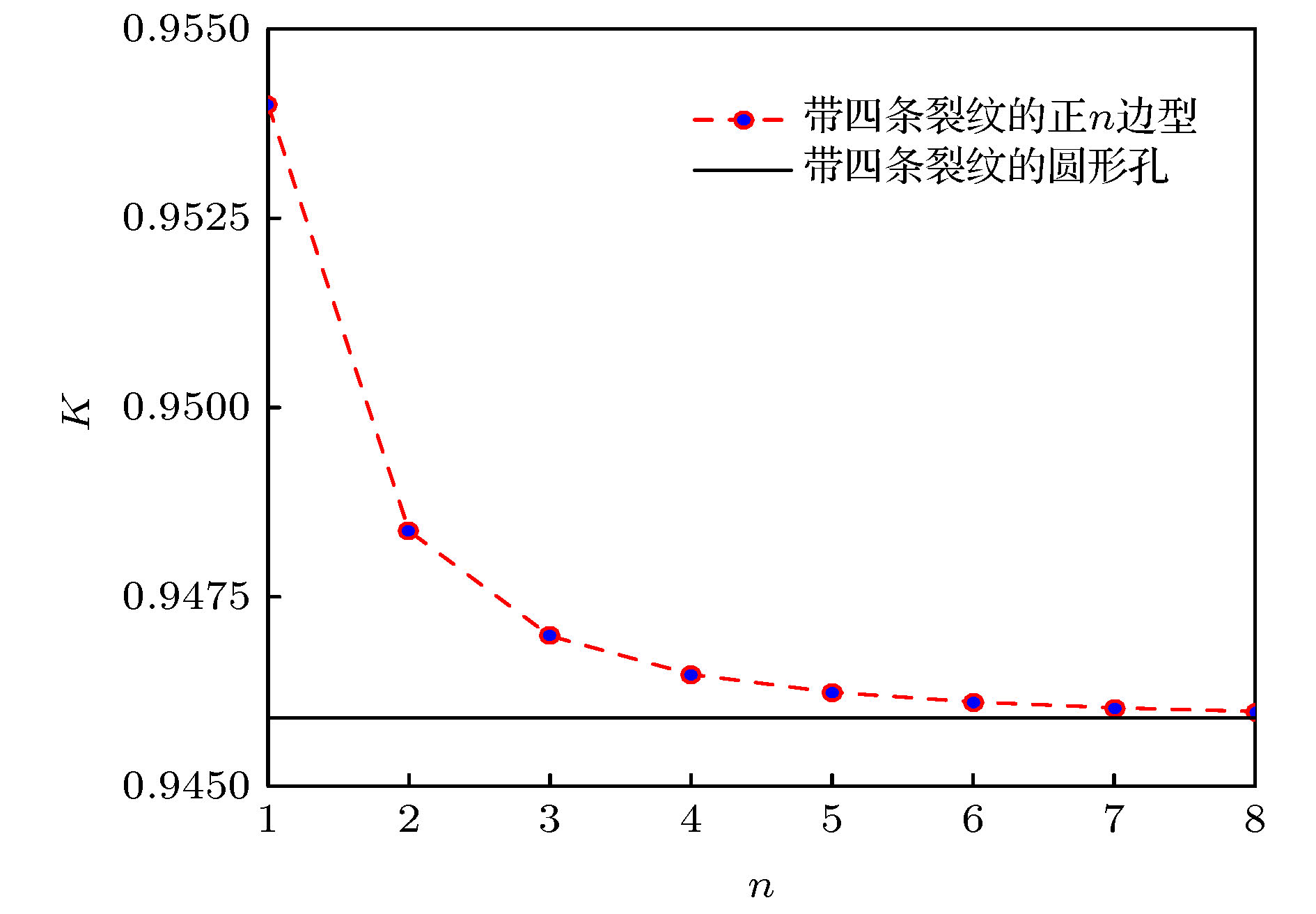

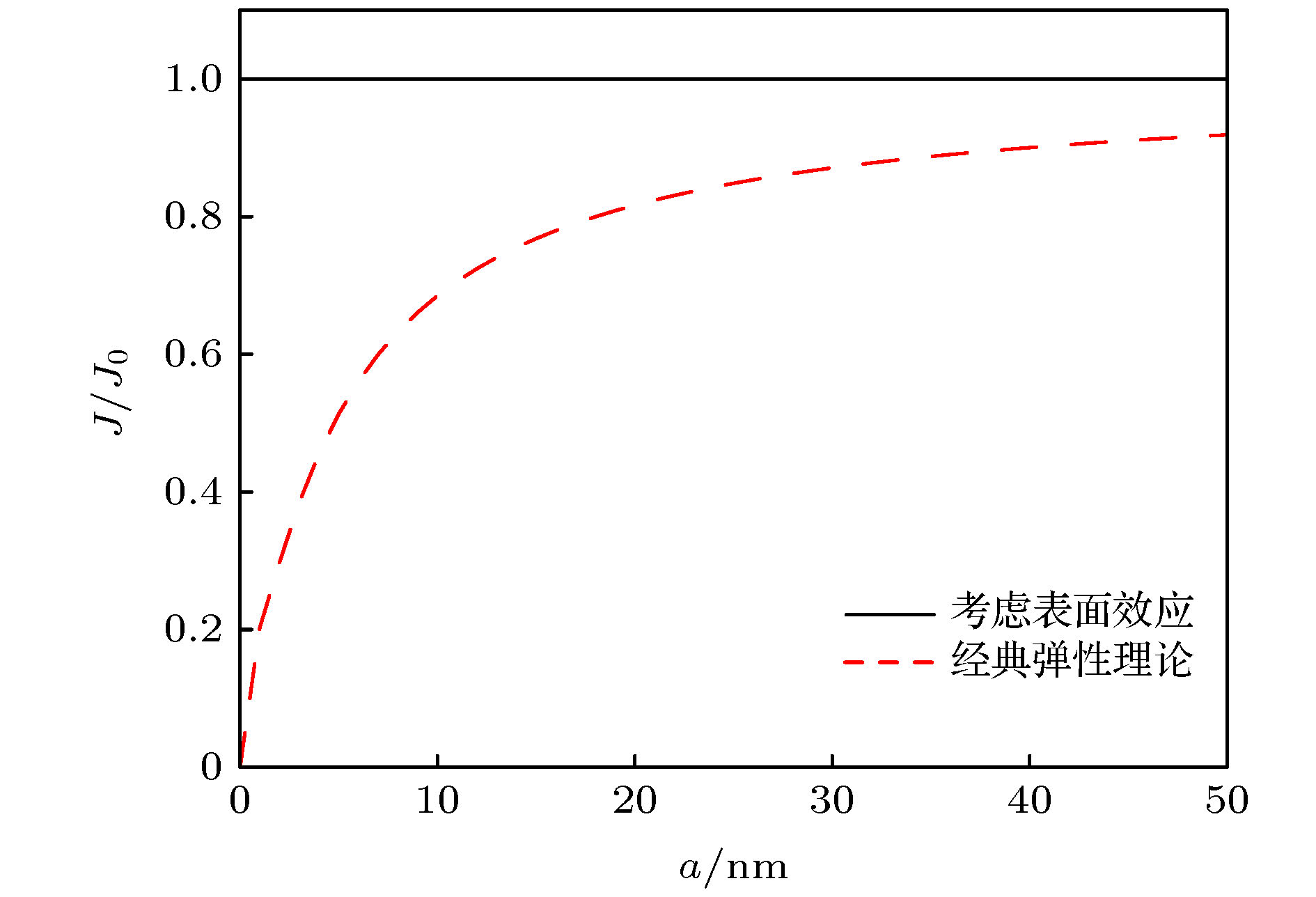

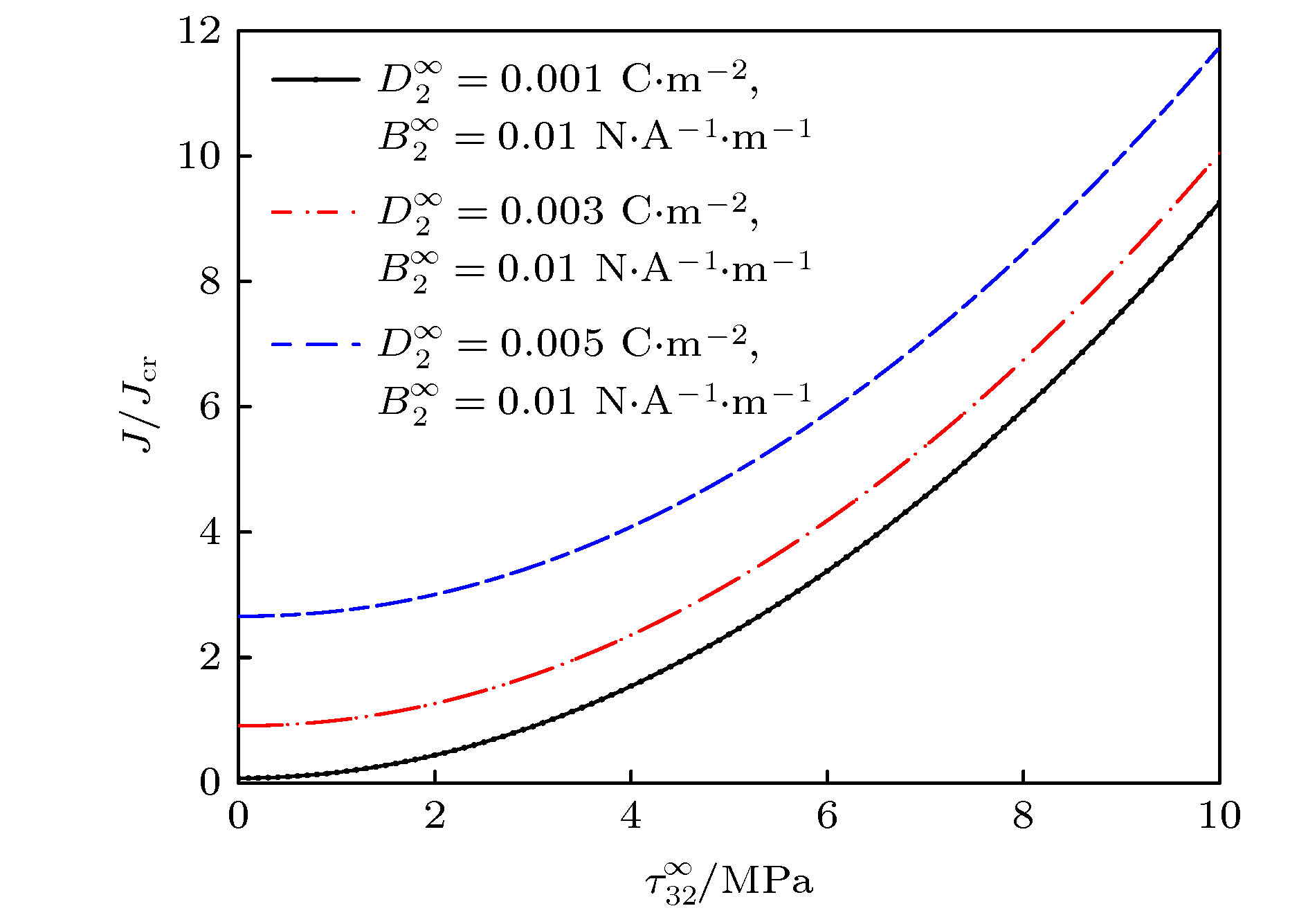

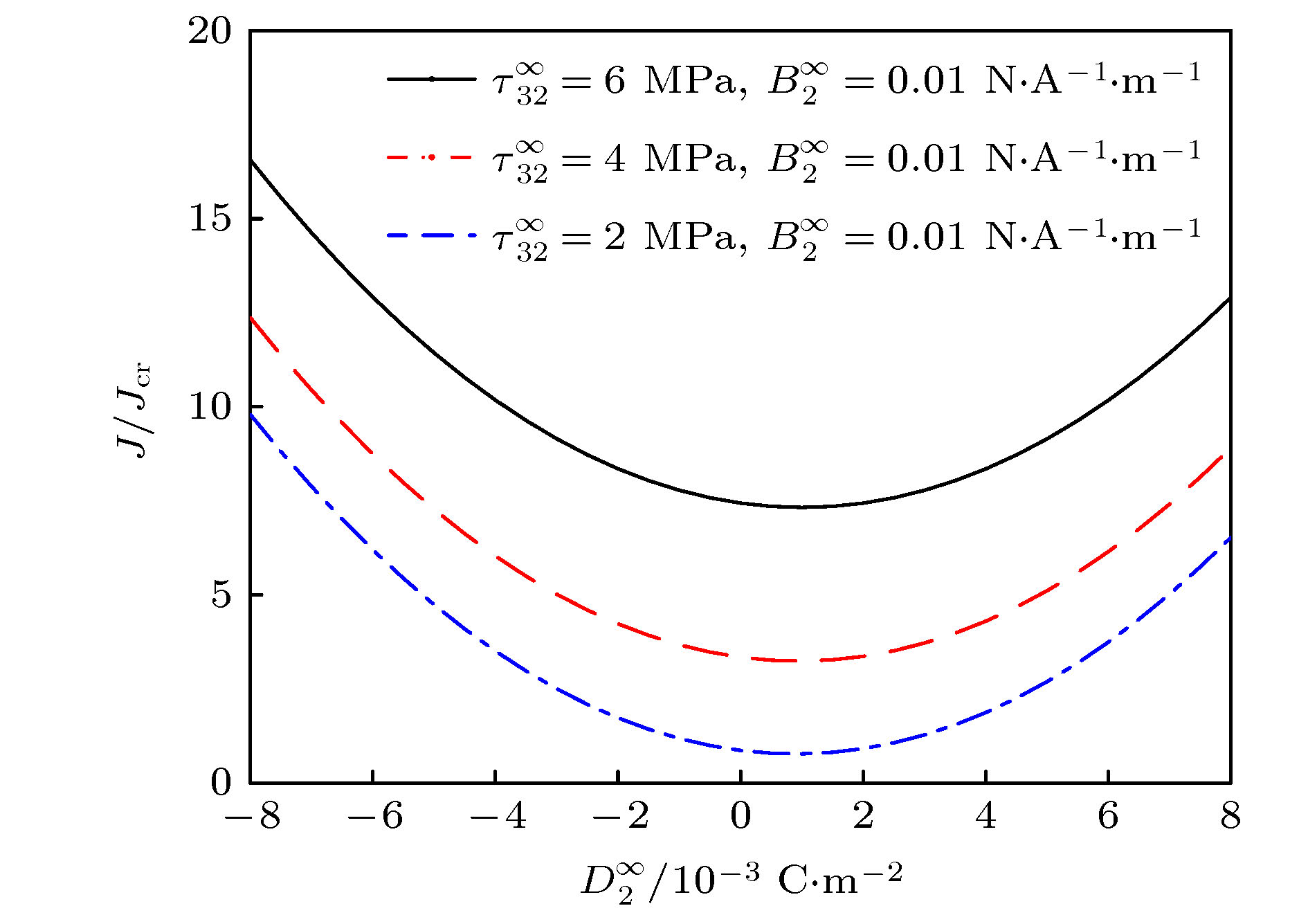

According to the conformal mapping from the exterior region of the regular n-polygon hole to the exterior region of a unit circle and from the exterior region of four cracks emanating from a circle to the interior region of a unit circle, a new conformal mapping is constructed to map the exterior region of four cracks emanating from a regular 4n-polygon hole to the interior of a unit circle. Then, based on the Gurtin-Murdoch surface/interface model and complex method, the anti-plane fracture of four nano-cracks emanating from a regular 4n-polygon nano-hole in magnetoelectroelastic material is studied. The exact solutions of stress intensity factor, electric displacement intensity factor, magnetic induction intensity factor, and energy release rate are obtained under the boundary condition of magnetoelectrically impermeable with considering the surface effect. Without considering the effect of the surface effect, the exact solution of four cracks emanating from a regular 4n-polygon hole in a magnetoelectroelastic material can be obtained. The numerical results show the influences of surface effect and the size of defect on the stress intensity factor, electric displacement intensity factor, magnetic induction intensity factor and energy release rate under the magnetoelectrically impermeable boundary condition. It can be seen that the stress intensity factor, electric displacement intensity factor, and magnetic induction intensity factor are significantly size-dependent when considering the surface effects of the nanoscale defects. And when the size of defect increases to a certain extent, the influence of surface effect begins to decrease and finally tends to follow the classical elasticity theory. When the distance between the center and the vertex of the regular 4n-polygon nano-hole is constant, the dimensionless field intensity factor decreases gradually with the increase of the number of edges, and approaches to the conclusion of a circular hole with four cracks. With the increase of the relative size of the crack, the dimensionless field intensity factor increases gradually. The dimensionless energy release rate of the nanoscale cracked hole has a significant size effect. The increase of mechanical load will increase the normalized energy release rate. The normalized energy release rate first decreases and then increases with electrical load increasing. The normalized energy release rate decreases with magnetic load increasing.

-

Keywords:

- magnetoelectroelastic materials /

- surface effect /

- nanoscale

[1] Nan C W 1994 Phys. Rev. B 50 6082

Google Scholar

Google Scholar

[2] Guo J H, Lu Z X 2010 Int. J. solids Struct. 47 1847

Google Scholar

Google Scholar

[3] Rogowski B 2011 Arch. Appl. Mech. 81 1607

Google Scholar

Google Scholar

[4] 刘鑫, 郭俊宏, 于静 2016 内蒙古大学学报(自然科学版) 41 37

Google Scholar

Google Scholar

Liu X, Guo J H, Yu J 2016 J. Inner Monglia Univ. (Natural Science Edition) 41 37

Google Scholar

Google Scholar

[5] Gao C F, Kessler H, Balke H 2003 Int. J. Eng. Sci. 41 969

Google Scholar

Google Scholar

[6] Gao C F, Kessler H, Balke H 2003 Int. J. Eng. Sci. 41 983

Google Scholar

Google Scholar

[7] Liu X, Guo J H 2016 Theor. Appl. Fract. Mech. 86 225

Google Scholar

Google Scholar

[8] 齐敏 2005 硕士学位论文 (石家庄: 石家庄铁道大学)

Qi M 2005 M. S. Thesis (Shijiazhuang: Shijiazhuang Tiedao University) (in Chinese)

[9] Lv X, Liu G T 2018 Chin. Phys. B 27 074601

Google Scholar

Google Scholar

[10] Zhong X C, Li C F 2008 Arch. Appl. Mech. 78 117

Google Scholar

Google Scholar

[11] Gurtin M E, Murdoch A I 1975 Arch. Ration. Mech. Anal. 57 291

Google Scholar

Google Scholar

[12] Gurtin M E, Murdoch A I 1978 Int. J. Solids Struct. 14 431

Google Scholar

Google Scholar

[13] Gurtin M E, Weissmuller J, Larche F 1998 Philos. Mag. A 78 1093

Google Scholar

Google Scholar

[14] Xiao J H, XU Y L, Zhang F C 2018 Acta. Mech. 229 4915

Google Scholar

Google Scholar

[15] 肖俊华, 崔友强, 徐耀玲, 张福成 2018 中国机械工程 29 2347

Google Scholar

Google Scholar

Xiao J H, Cui Y Q, Xu Y L, Zhang F C 2018 China Mech. Eng. 29 2347

Google Scholar

Google Scholar

[16] Xiao J H, Cui Y Q, Xu Y L, Zhang F C 2018 Theor. Appl. Fract. Mech. 96 476

Google Scholar

Google Scholar

[17] Guo J H, Li X F 2018 Acta Mech. 229 4251

Google Scholar

Google Scholar

[18] Liu Y Z, Guo J H, Zhang X Y 2019 Z. Angew. Math. Mech. 99 e201900043

[19] Guo J H, He L T, Liu Y Z, Li L H 2020 Theor. Appl. Fract. Mech. 107 102553

Google Scholar

Google Scholar

[20] Guo J H, Lu Z X 2011 Appl. Math. Comput. 217 9397

Google Scholar

Google Scholar

[21] 王永健 2012 博士学位论文 (南京: 南京航空航天大学)

Wang Y J 2012 Ph. D. Dissertation (Nanjing: Nanjing University of Aeronautics and Astronautics) (in Chinese)

[22] Fan S W, Guo J H, Yu J 2017 Chin. J. Aeronaut. 30 461

Google Scholar

Google Scholar

[23] Dharmendra S, Sharma 2014 Int. J. Mech. Sci. 78 177

Google Scholar

Google Scholar

[24] Wang Y B, Guo J H 2018 Appl. Math. Mech. -Engl. 39 797

Google Scholar

Google Scholar

[25] Fang X Q, Gupta V, Liu J X 2013 Philos. Mag. Lett. 93 58

Google Scholar

Google Scholar

[26] 穆斯海里什维里 著(赵惠元 译) 1958 数学弹性力学的几个基本问题 (北京: 科学出版社) 第233页

Muskhelishvili N I (translated by Zhao H Y) 1958 Some Basic Problems of the Mathematical Theory of Elasticity (Beijing: Science Press) p233 (in Chinese)

-

-

[1] Nan C W 1994 Phys. Rev. B 50 6082

Google Scholar

Google Scholar

[2] Guo J H, Lu Z X 2010 Int. J. solids Struct. 47 1847

Google Scholar

Google Scholar

[3] Rogowski B 2011 Arch. Appl. Mech. 81 1607

Google Scholar

Google Scholar

[4] 刘鑫, 郭俊宏, 于静 2016 内蒙古大学学报(自然科学版) 41 37

Google Scholar

Google Scholar

Liu X, Guo J H, Yu J 2016 J. Inner Monglia Univ. (Natural Science Edition) 41 37

Google Scholar

Google Scholar

[5] Gao C F, Kessler H, Balke H 2003 Int. J. Eng. Sci. 41 969

Google Scholar

Google Scholar

[6] Gao C F, Kessler H, Balke H 2003 Int. J. Eng. Sci. 41 983

Google Scholar

Google Scholar

[7] Liu X, Guo J H 2016 Theor. Appl. Fract. Mech. 86 225

Google Scholar

Google Scholar

[8] 齐敏 2005 硕士学位论文 (石家庄: 石家庄铁道大学)

Qi M 2005 M. S. Thesis (Shijiazhuang: Shijiazhuang Tiedao University) (in Chinese)

[9] Lv X, Liu G T 2018 Chin. Phys. B 27 074601

Google Scholar

Google Scholar

[10] Zhong X C, Li C F 2008 Arch. Appl. Mech. 78 117

Google Scholar

Google Scholar

[11] Gurtin M E, Murdoch A I 1975 Arch. Ration. Mech. Anal. 57 291

Google Scholar

Google Scholar

[12] Gurtin M E, Murdoch A I 1978 Int. J. Solids Struct. 14 431

Google Scholar

Google Scholar

[13] Gurtin M E, Weissmuller J, Larche F 1998 Philos. Mag. A 78 1093

Google Scholar

Google Scholar

[14] Xiao J H, XU Y L, Zhang F C 2018 Acta. Mech. 229 4915

Google Scholar

Google Scholar

[15] 肖俊华, 崔友强, 徐耀玲, 张福成 2018 中国机械工程 29 2347

Google Scholar

Google Scholar

Xiao J H, Cui Y Q, Xu Y L, Zhang F C 2018 China Mech. Eng. 29 2347

Google Scholar

Google Scholar

[16] Xiao J H, Cui Y Q, Xu Y L, Zhang F C 2018 Theor. Appl. Fract. Mech. 96 476

Google Scholar

Google Scholar

[17] Guo J H, Li X F 2018 Acta Mech. 229 4251

Google Scholar

Google Scholar

[18] Liu Y Z, Guo J H, Zhang X Y 2019 Z. Angew. Math. Mech. 99 e201900043

[19] Guo J H, He L T, Liu Y Z, Li L H 2020 Theor. Appl. Fract. Mech. 107 102553

Google Scholar

Google Scholar

[20] Guo J H, Lu Z X 2011 Appl. Math. Comput. 217 9397

Google Scholar

Google Scholar

[21] 王永健 2012 博士学位论文 (南京: 南京航空航天大学)

Wang Y J 2012 Ph. D. Dissertation (Nanjing: Nanjing University of Aeronautics and Astronautics) (in Chinese)

[22] Fan S W, Guo J H, Yu J 2017 Chin. J. Aeronaut. 30 461

Google Scholar

Google Scholar

[23] Dharmendra S, Sharma 2014 Int. J. Mech. Sci. 78 177

Google Scholar

Google Scholar

[24] Wang Y B, Guo J H 2018 Appl. Math. Mech. -Engl. 39 797

Google Scholar

Google Scholar

[25] Fang X Q, Gupta V, Liu J X 2013 Philos. Mag. Lett. 93 58

Google Scholar

Google Scholar

[26] 穆斯海里什维里 著(赵惠元 译) 1958 数学弹性力学的几个基本问题 (北京: 科学出版社) 第233页

Muskhelishvili N I (translated by Zhao H Y) 1958 Some Basic Problems of the Mathematical Theory of Elasticity (Beijing: Science Press) p233 (in Chinese)

计量

- 文章访问数: 5789

- PDF下载量: 67

- 被引次数: 0

下载:

下载: