-

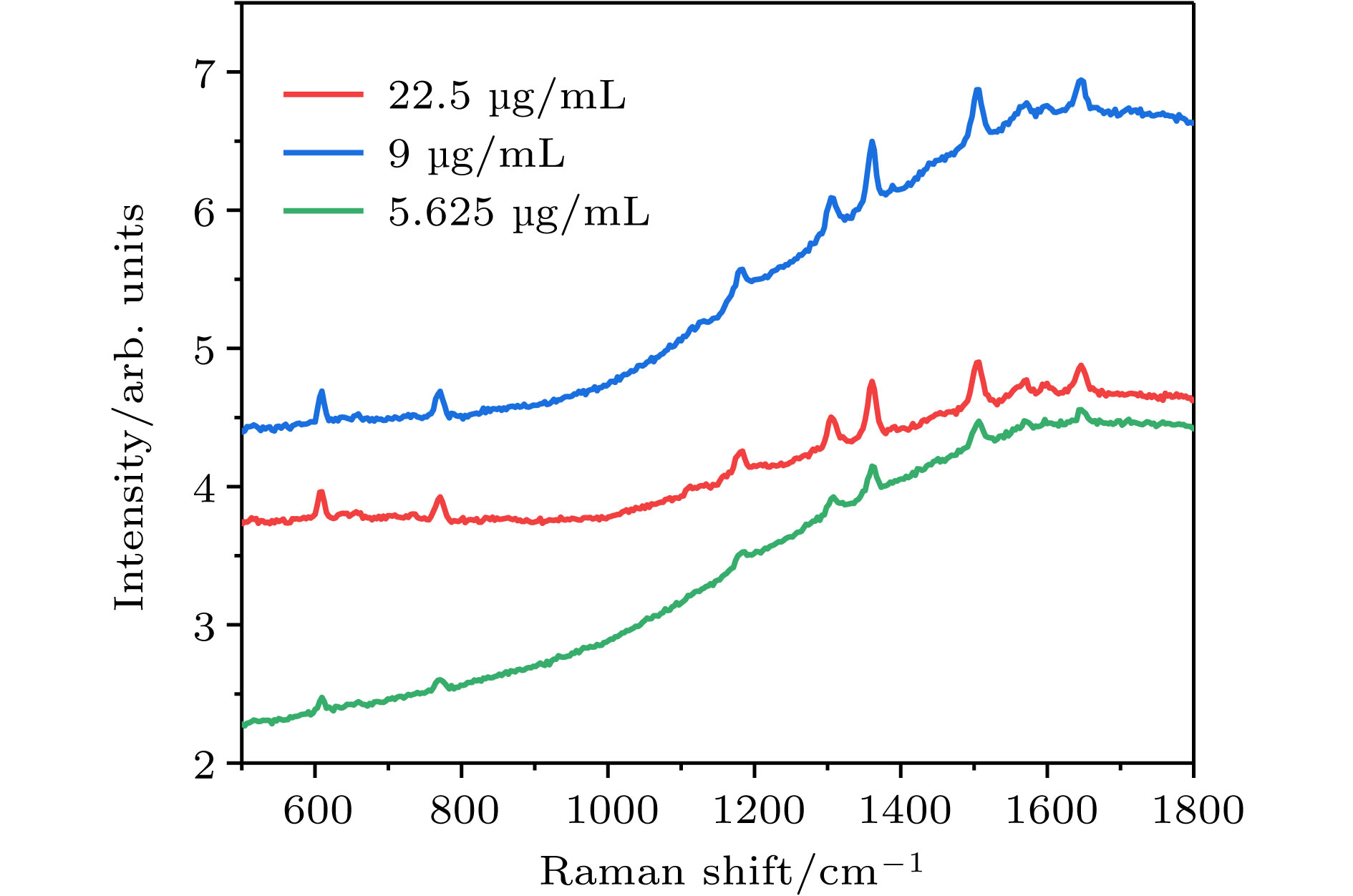

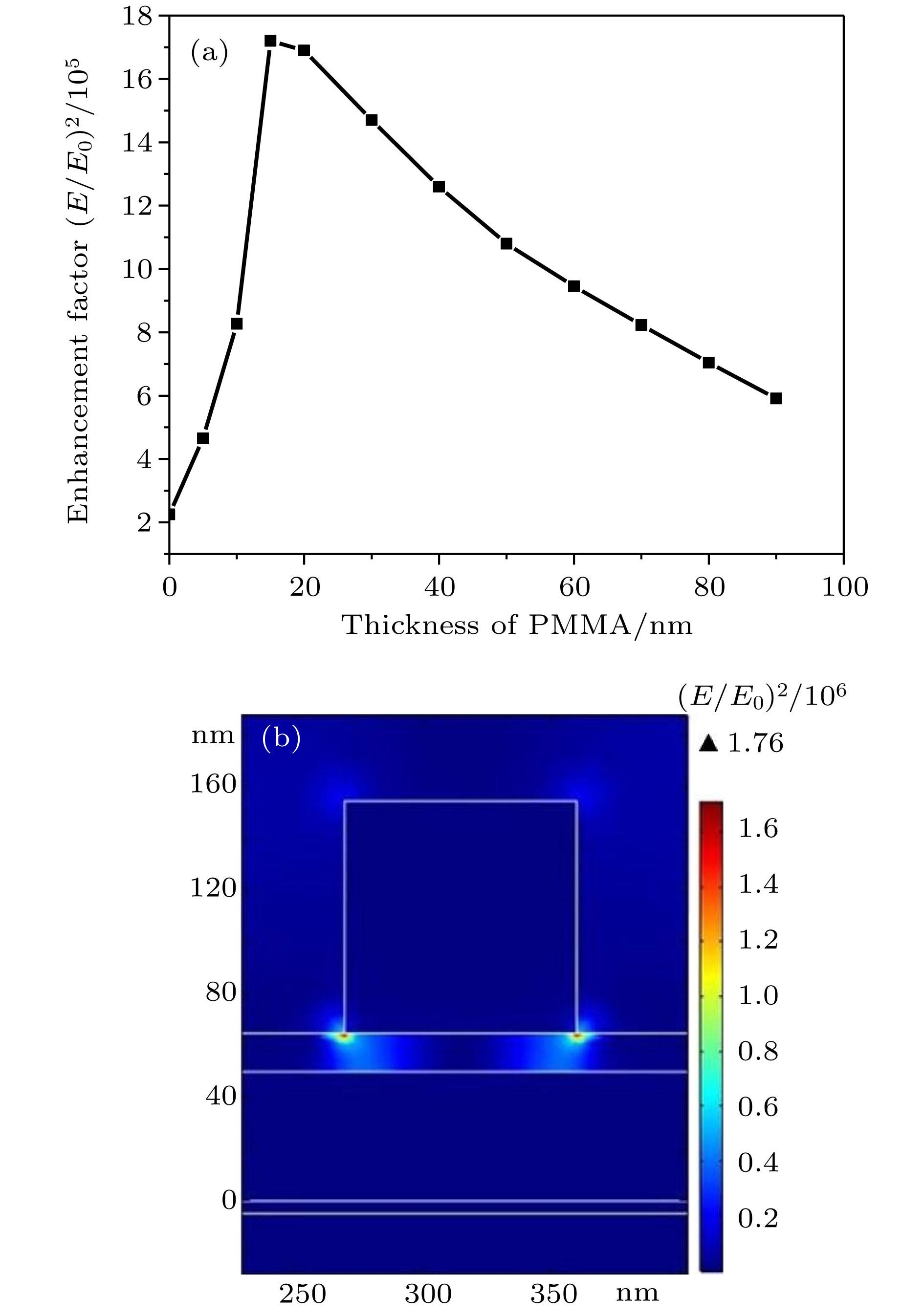

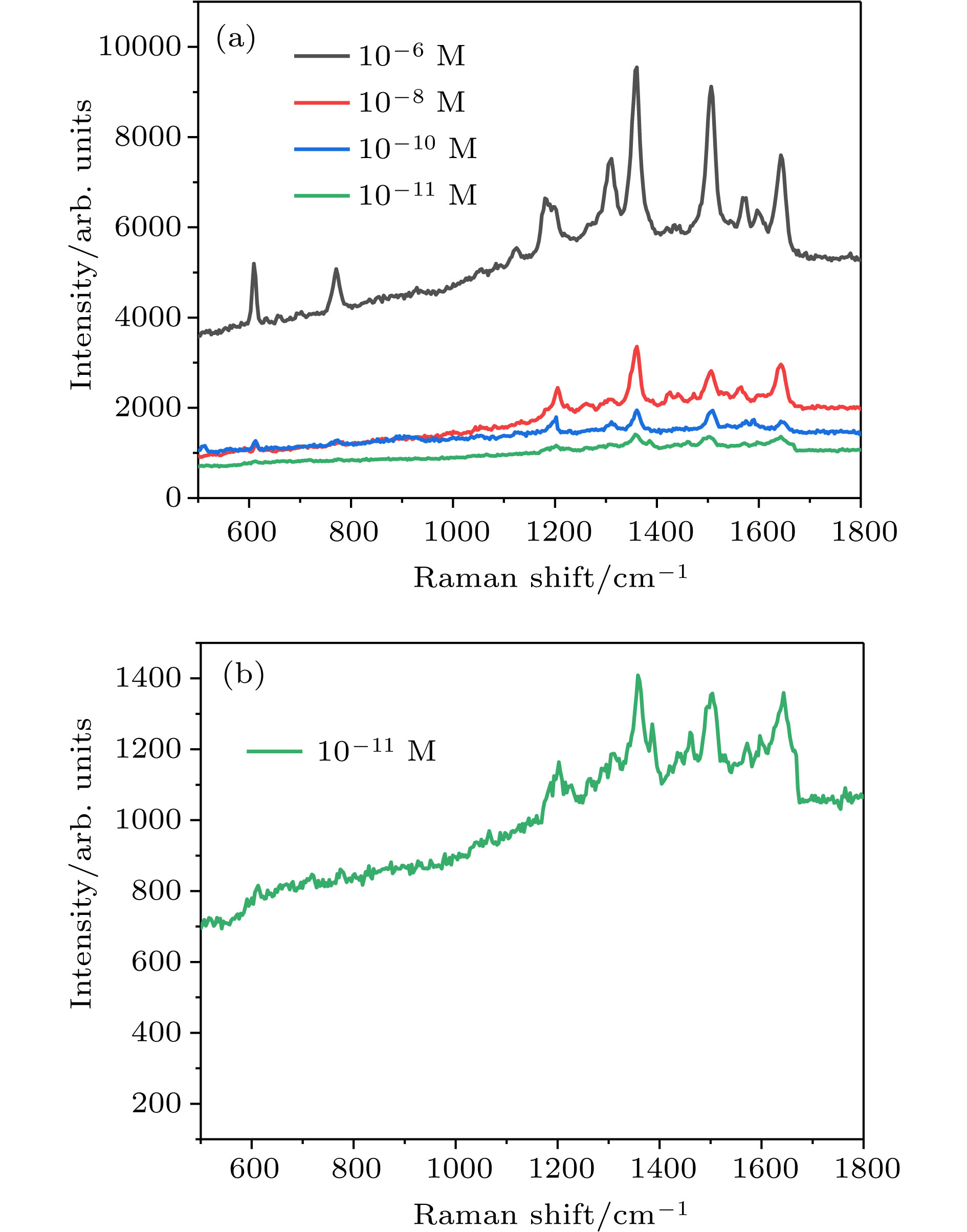

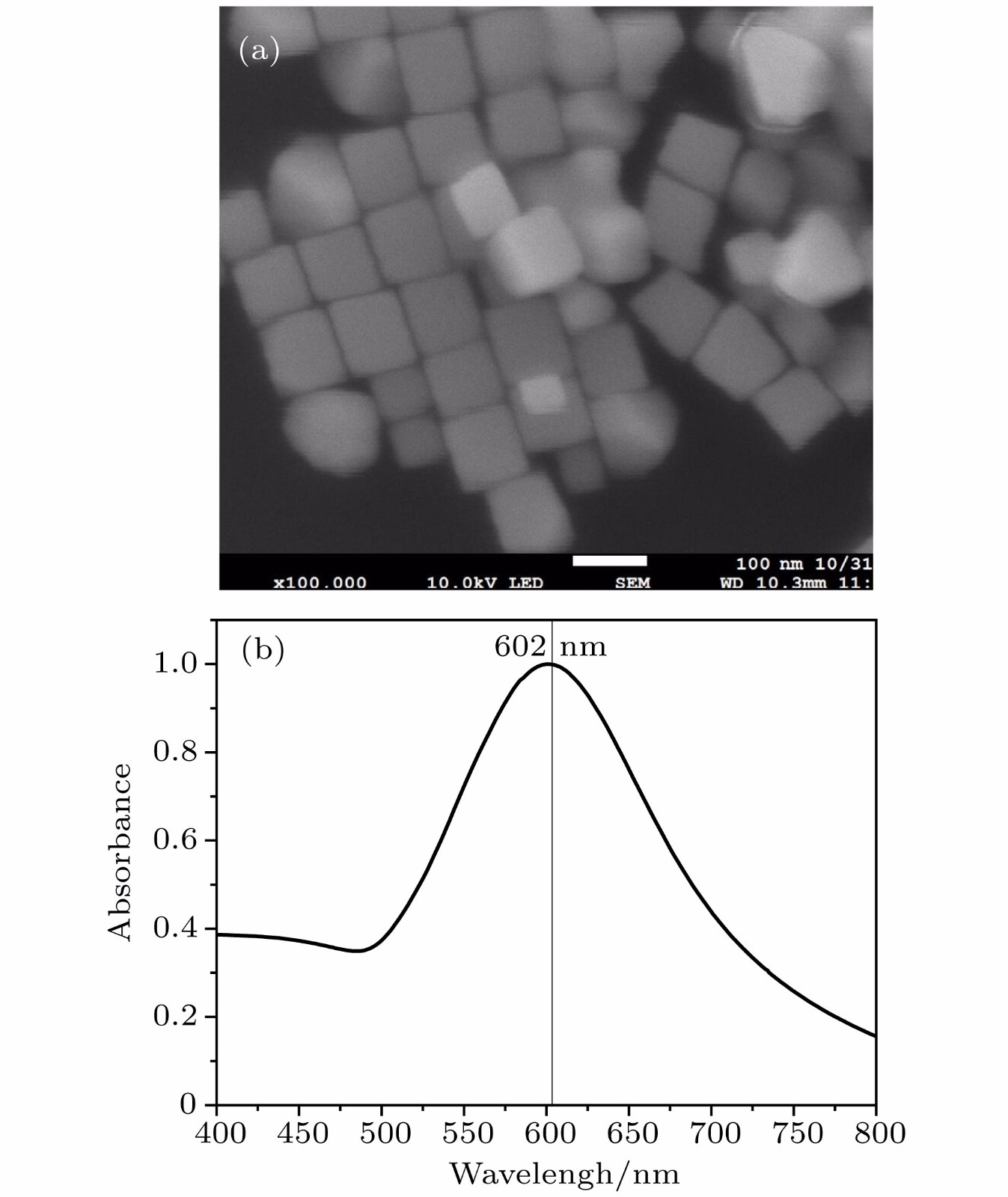

金属纳米颗粒与金属薄膜的复合结构由于其局域表面等离子体和传播表面等离子体间的强共振耦合作用, 可作为表面增强拉曼散射(SERS)基底, 显著增强吸附分子的拉曼信号. 本文提出了一种聚甲基丙烯酸甲酯(PMMA)间隔的90 nm金纳米立方体与50 nm金膜复合结构的SERS基底, 通过有限元方法数值模拟, 得到PMMA的最优化厚度为15 nm. 实验制备了PMMA间隔层厚度为14 nm的复合结构, 利用罗丹明6G (R6G)为拉曼探针分子, 633 nm的氦氖激光器作为激发光源, 研究了复合结构和单一金纳米立方体的SERS效应, 发现复合结构可以使探针分子产生比单一结构更强的拉曼信号. 在此基础上, 研究了不同浓度金纳米立方体水溶液条件下复合结构中R6G的拉曼光谱. 结果表明, 当金纳米立方体水溶液浓度为5.625

${\text μ}{\rm g/mL}$ 的条件下复合结构中R6G的拉曼信号最强, 且可测量R6G的最低浓度达10–11 mol/L.The composite structure of metal nanoparticle and metal film can be used as a surface-enhanced Raman scattering (SERS) substrate to significantly enhance the Raman signal of adsorbed molecules due to the strong coupling between local surface plasmons and propagating surface plasmons. An SERS substrate of the composite structure with gold nano-cubes and gold film separated by polymethylmethacrylate (PMMA) film is proposed. The optimum thickness of PMMA is 15 nm obtained by numerical simulation through using finite element method. The composite structure of PMMA spacer with a thickness of 14 nm is prepared experimentally. Using R6G as the Raman probe molecules and He-Ne laser with a wavelength of 633 nm as an excitation source, the SERS effect of the composite structure and single gold nano-cubes are studied. It is found that the composite structure can make the probe molecules produce a stronger Raman signal than the single structure. Furthermore, the SERS spectra of R6G molecules on the composite structure under the condition of aqueous solution of gold nano-cubes with different concentrations are studied. The results show that when the concentration of gold nano-cubes’ aqueous solution is 5.625${\text{μ}}{\rm g/mL}$ , the SERS signal of the R6G molecules on the composite structure is strongest. The lowest concentration of R6G molecules which can be detected is about 10–11 mol/L.-

Keywords:

- surface plasmon /

- surface-enhanced Raman scattering /

- gold nano-cube /

- gold film

[1] Liang C P, Niu G, Chen X F, Zhou Z G, Yi Z, Ye X, Duan T, Yi Y, Xiao S Y 2019 Opt. Commun. 436 57

Google Scholar

Google Scholar

[2] Cen C L, Lin H, Huang J, Liang C P, Chen X F, Tang Y J, Yi Z, Ye X, Liu J W, Yi Y G, Xiao S Y 2018 Sensors 18 4489

Google Scholar

Google Scholar

[3] Liu C, Su W Q, Liu Q, Lu X L, Wang F M, Sun T, Paul K C 2018 Opt. Express 26 9039

Google Scholar

Google Scholar

[4] Liu Z, Yu M, Huang S, Liu X, Wang Y, Liu M, Pan P, Liu G 2015 J. Mater. Chem. C 3 4222

Google Scholar

Google Scholar

[5] Wang X X, Wu X X, Chen Y Z, Bai X L, Pang Z Y, Yang H, Qi Y P, Wen X L 2018 AIP Adv. 8 105029

Google Scholar

Google Scholar

[6] Yan Y X, Hua Y, Zhao X X, Li R S, Wang X X 2018 Mater. Res. Bull. 105 286

Google Scholar

Google Scholar

[7] Zheng C X, Yang H 2018 J. Mater. Sci.: Mater. Electron. 29 9291

Google Scholar

Google Scholar

[8] Zhao X X, Hua Y, Li S H, Cui Z M, Zhang C R 2018 Mater. Res. Bull. 107 180

Google Scholar

Google Scholar

[9] Di L J, Yang H, Xian T, Chen X J 2018 Micromachines 9 613

Google Scholar

Google Scholar

[10] Cen C L, Chen J J, Liang C P, Huang J, Chen X F, Tang Y J, Yi Z, Xu X B, Yi Y G, Xiao S Y 2018 Physica E 103 93

Google Scholar

Google Scholar

[11] Liu Z, Liu X, Huang S, Pan P, Chen J, Liu G, Gu G 2015 ACS Appl. Mater. Inter. 7 4962

Google Scholar

Google Scholar

[12] Yang L, Wang J C, Yang L Z, Hu Z D, Wu X J, Zheng G G 2018 Sci. Rep. 8 2560

Google Scholar

Google Scholar

[13] Wang J C, Song C, Hang J, Hu Z D, Zhang F 2017 Opt. Express 25 23880

Google Scholar

Google Scholar

[14] Zhang X W, Qi Y P, Zhou P Y, Gong H H, Hu B B, Yan C M 2018 Photon. Sens. 8 367

Google Scholar

Google Scholar

[15] Chen J, Zhang T, Tang C J, Mao P, Liu Y J, Yu Y, Liu Z Q 2016 IEEE Photon. Tech. Lett. 28 1529

Google Scholar

Google Scholar

[16] Chen J, Tang C J, Mao P, Peng C, Gao D P, Yu Y, Wang Q G, Zhang L B 2016 IEEE Photon. J. 8 4800107

Google Scholar

Google Scholar

[17] Yang Z J, Zhao Q, He J 2017 Opt. Express 25 15927

Google Scholar

Google Scholar

[18] Wang X X, Pang Z Y , Tong H , Wu X X, Bai X L, Yang H, Wen X L, Qi Y P 2019 Results Phys. 12 732

Google Scholar

Google Scholar

[19] Pang Z Y, Tong H, Wu X X, Zhu J K, Wang X X, Yang H, Qi Y P 2018 Opt. Quant. Electron 50 335

Google Scholar

Google Scholar

[20] Wang X X, Zhang D G, Chen Y K, Zhu L F, Yu W H, Wang P, Yao P J, Ming H, Wu W X, Zhang Q J 2013 Appl. Phys. Lett. 102 031103

Google Scholar

Google Scholar

[21] Du H M, Zhang L P, Li D A 2018 Plasma Sci. Technol. 20 115001

Google Scholar

Google Scholar

[22] Li D A, Zhang L P, Du H M 2018 Plasma Sci. Technol.

Google Scholar

Google Scholar

[23] Shao H Y, Chen C, Wang J C, Pan L, Sang T 2017 J. Phys. D 50 384001

Google Scholar

Google Scholar

[24] Liu G Q, Yu M D, Liu Z Q, Liu X S, Huang S, Pan P P, Wang Y, Liu M L, Gu G 2015 Nanotechnology 26 185702

Google Scholar

Google Scholar

[25] Yu M D, Huang Z P, Liu Z Q, Chen J, Liu Y, Tang L, Liu G Q 2018 Sensor. Actuat. B: Chem. 262 845

Google Scholar

Google Scholar

[26] 李志远, 李家方 2011 科学通报 56 2631

Google Scholar

Google Scholar

Li Z Y, Li J F 2011 Chin. Sci. Bull. 56 2631

Google Scholar

Google Scholar

[27] Yi M F, Zhang D G, Wang P, Jiao X J, Blair S, Wen X L, Fu Q, Lu Y H, Ming H 2011 Plasmonics 6 515

Google Scholar

Google Scholar

[28] Gonçalves R M 2014 J. Phys. D: Appl. Phys. 47 213001

Google Scholar

Google Scholar

[29] Yan Z D, Du W, Tu L L, Gu P, Huang Z, Zhan P, Liuc F X, Wang Z L 2015 J. Raman Spectrosc. 46 795

Google Scholar

Google Scholar

[30] Su X D, Ma X B, Wang J, Tu Z Z, Han Y J, Teng Z G 2018 J. Mol. Struct. 1171 202

Google Scholar

Google Scholar

[31] Li R F, Shi G C, Wang Y H, Wang M L, Zhu Y Y, Sun X, Xu H J, Chang C X 2018 Optik 172 49

Google Scholar

Google Scholar

[32] Kume T, Hayashiba S, Yamamotobo K 1996 Jpn. J. Appl. Phys. 35 171

Google Scholar

Google Scholar

[33] Leveque G, Martin O J F 2006 Opt. Lett. 31 2750

Google Scholar

Google Scholar

[34] Zhou L, Li M Y, Tang L H, He J J 2016 J. Phys.: Conference Series 680 012003

Google Scholar

Google Scholar

[35] 祁云平, 张雪伟, 周培阳, 胡兵兵, 王向贤 2018 67 197301

Google Scholar

Google Scholar

Qi Y P, Zhang X W, Zhou P Y, Hu B B, Wang X X 2018 Acta Phys. Sin. 67 197301

Google Scholar

Google Scholar

[36] 马婧, 刘冬冬, 王继成, 冯延 2018 67 094102

Google Scholar

Google Scholar

Ma J, Liu D D, Wang J C, Feng Y 2018 Acta Phys. Sin. 67 094102

Google Scholar

Google Scholar

[37] Wang X X, Tong H, Pang Z Y, Zhu J K, Wu X X, Yang H, Qi Y P 2019 Opt. Quant. Electron. 51 38

Google Scholar

Google Scholar

[38] 程自强, 石海泉, 余萍, 刘志敏 2018 67 197302

Google Scholar

Google Scholar

Cheng Z Q, Shi H Q, Yu P, Liu Z M 2018 Acta Phys. Sin. 67 197302

Google Scholar

Google Scholar

-

图 5 10−4 mol/L的R6G, 5.625

${\text {\rm μg/mL}}$ 的金纳米立方体混合水溶液条件下玻璃基片和复合结构的SERS光谱Fig. 5. SERS spectra of R6G molecules on the glass substrate and composite structure in the condition of the mixed aqueous solution of gold nano-cubes with the concentration of 5.625

${\text {\rm μg/mL}}$ and R6G with the concentration of 10−4 mol/L.图 6 5.625

${\text {\rm μg/mL}}$ 的金纳米立方体混合水溶液条件下, 复合结构的SERS光谱 (a)不同R6G浓度; (b) 10−11 mol/L的R6G浓度(1 M = 1 mol/L)Fig. 6. SERS spectra of R6G molecules on the composite structure in the conditions of the mixed aqueous solution of gold nano-cubes with the concentration of 5.625

${\text{\rm μg/mL}} \!\! :$ (a) R6G with different concentrations of 10–6, 10−8, 10−10, 10–11 mol/L; (b) R6G with the concentration of 10−11 mol/L. -

[1] Liang C P, Niu G, Chen X F, Zhou Z G, Yi Z, Ye X, Duan T, Yi Y, Xiao S Y 2019 Opt. Commun. 436 57

Google Scholar

Google Scholar

[2] Cen C L, Lin H, Huang J, Liang C P, Chen X F, Tang Y J, Yi Z, Ye X, Liu J W, Yi Y G, Xiao S Y 2018 Sensors 18 4489

Google Scholar

Google Scholar

[3] Liu C, Su W Q, Liu Q, Lu X L, Wang F M, Sun T, Paul K C 2018 Opt. Express 26 9039

Google Scholar

Google Scholar

[4] Liu Z, Yu M, Huang S, Liu X, Wang Y, Liu M, Pan P, Liu G 2015 J. Mater. Chem. C 3 4222

Google Scholar

Google Scholar

[5] Wang X X, Wu X X, Chen Y Z, Bai X L, Pang Z Y, Yang H, Qi Y P, Wen X L 2018 AIP Adv. 8 105029

Google Scholar

Google Scholar

[6] Yan Y X, Hua Y, Zhao X X, Li R S, Wang X X 2018 Mater. Res. Bull. 105 286

Google Scholar

Google Scholar

[7] Zheng C X, Yang H 2018 J. Mater. Sci.: Mater. Electron. 29 9291

Google Scholar

Google Scholar

[8] Zhao X X, Hua Y, Li S H, Cui Z M, Zhang C R 2018 Mater. Res. Bull. 107 180

Google Scholar

Google Scholar

[9] Di L J, Yang H, Xian T, Chen X J 2018 Micromachines 9 613

Google Scholar

Google Scholar

[10] Cen C L, Chen J J, Liang C P, Huang J, Chen X F, Tang Y J, Yi Z, Xu X B, Yi Y G, Xiao S Y 2018 Physica E 103 93

Google Scholar

Google Scholar

[11] Liu Z, Liu X, Huang S, Pan P, Chen J, Liu G, Gu G 2015 ACS Appl. Mater. Inter. 7 4962

Google Scholar

Google Scholar

[12] Yang L, Wang J C, Yang L Z, Hu Z D, Wu X J, Zheng G G 2018 Sci. Rep. 8 2560

Google Scholar

Google Scholar

[13] Wang J C, Song C, Hang J, Hu Z D, Zhang F 2017 Opt. Express 25 23880

Google Scholar

Google Scholar

[14] Zhang X W, Qi Y P, Zhou P Y, Gong H H, Hu B B, Yan C M 2018 Photon. Sens. 8 367

Google Scholar

Google Scholar

[15] Chen J, Zhang T, Tang C J, Mao P, Liu Y J, Yu Y, Liu Z Q 2016 IEEE Photon. Tech. Lett. 28 1529

Google Scholar

Google Scholar

[16] Chen J, Tang C J, Mao P, Peng C, Gao D P, Yu Y, Wang Q G, Zhang L B 2016 IEEE Photon. J. 8 4800107

Google Scholar

Google Scholar

[17] Yang Z J, Zhao Q, He J 2017 Opt. Express 25 15927

Google Scholar

Google Scholar

[18] Wang X X, Pang Z Y , Tong H , Wu X X, Bai X L, Yang H, Wen X L, Qi Y P 2019 Results Phys. 12 732

Google Scholar

Google Scholar

[19] Pang Z Y, Tong H, Wu X X, Zhu J K, Wang X X, Yang H, Qi Y P 2018 Opt. Quant. Electron 50 335

Google Scholar

Google Scholar

[20] Wang X X, Zhang D G, Chen Y K, Zhu L F, Yu W H, Wang P, Yao P J, Ming H, Wu W X, Zhang Q J 2013 Appl. Phys. Lett. 102 031103

Google Scholar

Google Scholar

[21] Du H M, Zhang L P, Li D A 2018 Plasma Sci. Technol. 20 115001

Google Scholar

Google Scholar

[22] Li D A, Zhang L P, Du H M 2018 Plasma Sci. Technol.

Google Scholar

Google Scholar

[23] Shao H Y, Chen C, Wang J C, Pan L, Sang T 2017 J. Phys. D 50 384001

Google Scholar

Google Scholar

[24] Liu G Q, Yu M D, Liu Z Q, Liu X S, Huang S, Pan P P, Wang Y, Liu M L, Gu G 2015 Nanotechnology 26 185702

Google Scholar

Google Scholar

[25] Yu M D, Huang Z P, Liu Z Q, Chen J, Liu Y, Tang L, Liu G Q 2018 Sensor. Actuat. B: Chem. 262 845

Google Scholar

Google Scholar

[26] 李志远, 李家方 2011 科学通报 56 2631

Google Scholar

Google Scholar

Li Z Y, Li J F 2011 Chin. Sci. Bull. 56 2631

Google Scholar

Google Scholar

[27] Yi M F, Zhang D G, Wang P, Jiao X J, Blair S, Wen X L, Fu Q, Lu Y H, Ming H 2011 Plasmonics 6 515

Google Scholar

Google Scholar

[28] Gonçalves R M 2014 J. Phys. D: Appl. Phys. 47 213001

Google Scholar

Google Scholar

[29] Yan Z D, Du W, Tu L L, Gu P, Huang Z, Zhan P, Liuc F X, Wang Z L 2015 J. Raman Spectrosc. 46 795

Google Scholar

Google Scholar

[30] Su X D, Ma X B, Wang J, Tu Z Z, Han Y J, Teng Z G 2018 J. Mol. Struct. 1171 202

Google Scholar

Google Scholar

[31] Li R F, Shi G C, Wang Y H, Wang M L, Zhu Y Y, Sun X, Xu H J, Chang C X 2018 Optik 172 49

Google Scholar

Google Scholar

[32] Kume T, Hayashiba S, Yamamotobo K 1996 Jpn. J. Appl. Phys. 35 171

Google Scholar

Google Scholar

[33] Leveque G, Martin O J F 2006 Opt. Lett. 31 2750

Google Scholar

Google Scholar

[34] Zhou L, Li M Y, Tang L H, He J J 2016 J. Phys.: Conference Series 680 012003

Google Scholar

Google Scholar

[35] 祁云平, 张雪伟, 周培阳, 胡兵兵, 王向贤 2018 67 197301

Google Scholar

Google Scholar

Qi Y P, Zhang X W, Zhou P Y, Hu B B, Wang X X 2018 Acta Phys. Sin. 67 197301

Google Scholar

Google Scholar

[36] 马婧, 刘冬冬, 王继成, 冯延 2018 67 094102

Google Scholar

Google Scholar

Ma J, Liu D D, Wang J C, Feng Y 2018 Acta Phys. Sin. 67 094102

Google Scholar

Google Scholar

[37] Wang X X, Tong H, Pang Z Y, Zhu J K, Wu X X, Yang H, Qi Y P 2019 Opt. Quant. Electron. 51 38

Google Scholar

Google Scholar

[38] 程自强, 石海泉, 余萍, 刘志敏 2018 67 197302

Google Scholar

Google Scholar

Cheng Z Q, Shi H Q, Yu P, Liu Z M 2018 Acta Phys. Sin. 67 197302

Google Scholar

Google Scholar

计量

- 文章访问数: 15039

- PDF下载量: 0

- 被引次数: 0

下载:

下载: