-

采用第一性原理计算方法, 研究了二维单层硒化锗(GeSe)的5种同分异构体结构的稳定性和在应力调控下的电子性质变化规律. 计算结果表明: 5种同分异构体结构都具有热力学稳定性; α-GeSe是直接带隙半导体, β-GeSe, γ-GeSe, δ-GeSe和ε-GeSe都是间接带隙半导体. α-GeSe在应力调控下出现了直接到间接带隙的转变和半导体到金属性质的转变. β-GeSe和γ-GeSe在应力的作用下具有可调节的间接带隙范围. 当沿δ-GeSe双轴方向施加压缩应力为1%和4%时, δ-GeSe的能带从间接带隙转变成直接带隙. 通过沿ε-GeSe的扶手椅形方向施加10%的拉伸应变, 出现了从间接带隙到直接带隙的转变; 继续增加拉伸应变到20%, 能带结构一直保持直接带隙的特征, 其可调范围为1.21—1.44 eV. 沿δ-GeSe双轴方向施加10%拉伸应变时, 也出现了从间接带隙到直接带隙的转变; 该直接带隙在双轴拉伸应变增加到19%前一直保持, 可调范围为0.61—1.19 eV.Using first-principles calculations, we investigate the stability and electronic properties of five isomers of two-dimensional (2D) GeSe monolayer under in-plane strain. Our calculated results show that the five isomers of GeSe monolayer are all stable. It is found that the α-GeSe has a direct band gap, while each of the β-GeSe, γ-GeSe, δ-GeSe and ε-GeSe possesses an indirect band gap. By applying compressive or tensile uniaxial and biaxial strain to the five GeSe isomers, the indirect-to-direct transition in band gap is found. In the α-GeSe, the changes from indirect-to-direct and semiconducting-to-metallic are both found under an applied strain. In the 2D β-GeSe and γ-GeSe, an adjustable range of indirect band gap under strain is found. Moreover, a direct band gap in the δ-GeSe is found separately under the biaxial compression strain of σxy = –2% and σxy = –4%. By applying a tensile strain of 10% along the armchair direction in ε-GeSe, a transition from an indirect to direct band gap occurs. When the tensile strain is continuously increased to 20%, the band structure of ε-GeSe maintains direct character. This direct band gap can be tuned from 1.21 eV to 1.44 eV. When 10% tensile strain is applied along the biaxial direction, the transition in band gap from indirect-to-direct also occurs. Our results indicate that the direct band gap can be tuned from 0.61 eV to 1.19 eV when the tensile strain is increased from 10% to 19% in ε-GeSe.

-

Keywords:

- first-principles /

- monolayer GeSe /

- strain /

- electronic property

[1] Zhao Y, Chen Y, Zhang Y H, Liu S F 2017 Mater. Chem. Phys. 189 215

Google Scholar

Google Scholar

[2] Fiori G, Bonaccorso F, Iannaccone G, Palacios T, Neumaier D, Seabaugh A, Colombo L 2014 Nat. Nanotech. 9 768

Google Scholar

Google Scholar

[3] Wang Q H, Kalantar-Zadeh K, Kis A, Coleman J N, Strano M S 2012 Nat. Nanotech. 7 699

Google Scholar

Google Scholar

[4] Ando T, Fowler A B, Stern F 1982 Rev. Mod. Phys. 54 437

Google Scholar

Google Scholar

[5] Schedin F, Geim A K, Morozov S V, Hill E W, Blake P, Katsnelson M I, Novoselov K S 2007 Nat. Mater. 6 652

Google Scholar

Google Scholar

[6] Wang T H, Zhu Y F, Jiang Q 2013 J. Phys. Chem. C 117 12873

Google Scholar

Google Scholar

[7] Liu L, Feng Y P, Shen Z X 2003 Phys. Rev. B 68 104102

Google Scholar

Google Scholar

[8] Balandin A A, Ghosh S, Bao W, Calizo I, Teweldebrhan D, Miao F, Lau C N 2008 Nano Lett. 8 902

Google Scholar

Google Scholar

[9] Mak K F, Lee C, Hone J, Shan J, Heinz T F 2010 Phys. Rev. Lett. 105 136805

Google Scholar

Google Scholar

[10] Splendiani A, Sun L, Zhang Y B, Li T S, Kim J, Chim C Y, Galli G, Wang F 2010 Nano Lett. 10 1271

Google Scholar

Google Scholar

[11] Peng X H, Wei Q, Copple A 2014 Phys. Rev. B 90 085402

Google Scholar

Google Scholar

[12] Liu H, Neal A T, Zhu Z, Luo Z, Xu X F, Tománek D, Ye P D 2014 ACS Nano. 8 4033

Google Scholar

Google Scholar

[13] Jain A, McGaughey A J 2015 Sci. Rep 5 8501

Google Scholar

Google Scholar

[14] Liang L B, Wang J, Lin W Z, Sumpter B G, Meunier V, Pan M 2014 Nano Lett. 14 6400

Google Scholar

Google Scholar

[15] Kou L Z, Chen C F, Smith S C 2015 Phys. Chem. Lett. 6 2794

Google Scholar

Google Scholar

[16] Reich E S 2014 Nature 506 19

Google Scholar

Google Scholar

[17] Singh A K, Hennig R G 2014 Appl. Phys. Lett. 105 042103

Google Scholar

Google Scholar

[18] Huang L, Wu F G, Li J B 2016 J. Chem. Phys. 144 114708

Google Scholar

Google Scholar

[19] Zhang S L, Wang N, Liu S G, Huang S P, Zhou W H, Cai B, Xie M Q, Yang Q, Chen X P, Zeng H B 2016 Nanotechnology 27 274001

Google Scholar

Google Scholar

[20] Wiedemeier H, Georg H, von Schnering G 1978 Z. Krist-Cryst. Mater. 148 295

[21] Vaughn II D D, Patel R J, Hickner M A, Schaak R E 2010 J. Am. Chem. Soc. 132 15170

Google Scholar

Google Scholar

[22] de Oliveira I S S, Longuinhos R 2016 Phys. Rev. B 94 035440

Google Scholar

Google Scholar

[23] Bosse J L, Grishin I, Gyu Choi Y, Cheong B K, Lee S, Kolosov O V, Huey B D 2014 Appl. Phys. Lett. 104 053109

Google Scholar

Google Scholar

[24] Zhang X Y, Shen J W, Lin S Q, Li J, Chen Z W, Li W, Pei Y Z 2016 J. Materiomics 2 331

Google Scholar

Google Scholar

[25] Xue D J, Liu S C, Dai C M, Chen S Y, He C, Zhao L, Hu J S, Wan L J 2017 J. Am. Chem. Soc. 139 958

Google Scholar

Google Scholar

[26] Liu S C, Mi Y, Xue D J, Chen Y X, He C, Liu X F, Hu J S, Wan L J 2017 Adv. Electron. Mater. 3 1700141

Google Scholar

Google Scholar

[27] Sannyal A, Zhang Z Q, Gao X F, Jang J 2018 Comp. Mater. Sci. 154 204

Google Scholar

Google Scholar

[28] Gomes L C, Carvalho A 2015 Physics 9 2

[29] Fei R X, Li W B, Li J, Y L 2015 Appl. Phys. Lett. 107 237

[30] Zhang S L, Liu S G, Huang S P, Cai B, Xie M Q, Qu L H, Zou Y S, Hu Z Y, Xu X C, Zeng H 2015 Sci. China: Mater. 58 929

[31] Zhao H Q, Mao Y L, Mao X, Shi X, Xu C S, Wang C X, Zhang S M, Zhou D H 2018 Adv. Funct. Mater. 28 1704855

Google Scholar

Google Scholar

[32] von Rohr F O, Ji H, Cevallos F A, Gao T, Ong N P, Cava R J 2017 J. Am. Chem. Soc. 139 2771

Google Scholar

Google Scholar

[33] Gomes L C, Trevisanutto P E, Carvalho A, Rodin A S, Neto A C 2016 Phys. Rev. B 94 155428

Google Scholar

Google Scholar

[34] Mao Y L, Xu C S, Yuan J M, Zhao H Q 2018 Phys. Chem. Chem. Phys. 20 6929

Google Scholar

Google Scholar

[35] Mao Y L, Long L B, Yuan J M, Zhong J X, Zhao H Q 2018 Chem. Phys. Lett. 706 501

Google Scholar

Google Scholar

[36] Ersan F, Arkin H, Aktürk E 2017 RSC Adv. 7 37815

Google Scholar

Google Scholar

[37] Xu Y F, Zhang H, Shao H Z, Ni G, Li J, Lu H L, Zhang R J, Peng B, Zhu Y Y, Zhu H Y, Soukoulis C M 2017 Phys. Rev. B 96 245421

Google Scholar

Google Scholar

[38] Hu Y H, Zhang S L, Sun S F, Xie M Q, Cai B, Zeng H B 2015 Appl. Phys. Lett. 107 122107

Google Scholar

Google Scholar

[39] Ong Z Y, Cai Y Q, Zhang G, Zhang Y W 2014 J. Phys. Chem. C 118 25272

Google Scholar

Google Scholar

[40] Ni Z H, Yu T, Lu Y H, Wang Y Y, Feng Y P, Shen Z X 2008 ACS Nano 2 2301

Google Scholar

Google Scholar

[41] Kresse G, Furthmüller J 1996 Phys. Rev. B 54 11169

Google Scholar

Google Scholar

[42] Hafner J 2008 J. Comp. Chem. 29 2044

Google Scholar

Google Scholar

[43] Segall M D, Lindan P J, Probert M A, Pickard C J, Hasnip P J, Clark S J, Payne M C 2002 J. Phys.: Condensed Mat. 14 2717

Google Scholar

Google Scholar

[44] Clark S J, Segall M D, Pickard C J, Hasnip P J, Probert M I, Refson K, Payne M C 2005 Z. Krist-Cryst Mater. 220 567

[45] Perdew J P, Burke K, Ernzerhof M 1996 Phys. Rev. Lett. 77 3865

Google Scholar

Google Scholar

[46] White J A, Bird D M 1994 Phys. Rev. B 50 4954

Google Scholar

Google Scholar

[47] Heyd J, Scuseria G E, Ernzerhof M 2003 J. Chem. Phys. 118 8207

Google Scholar

Google Scholar

[48] Monkhorst H J, Pack J D 1976 Phys. Rev. B 13 5188

Google Scholar

Google Scholar

[49] Mao Y L, Ben J, Yuan J M,Zhong J X 2018 Chem. Phys. Lett. 705 12

Google Scholar

Google Scholar

[50] 鲁源坤 2010 硕士学位论文 (山西: 太原科技大学)

Lu Y K 2010 M. S. Thesis (Taiyuan: University of Science & Technology) (in Chinese)

-

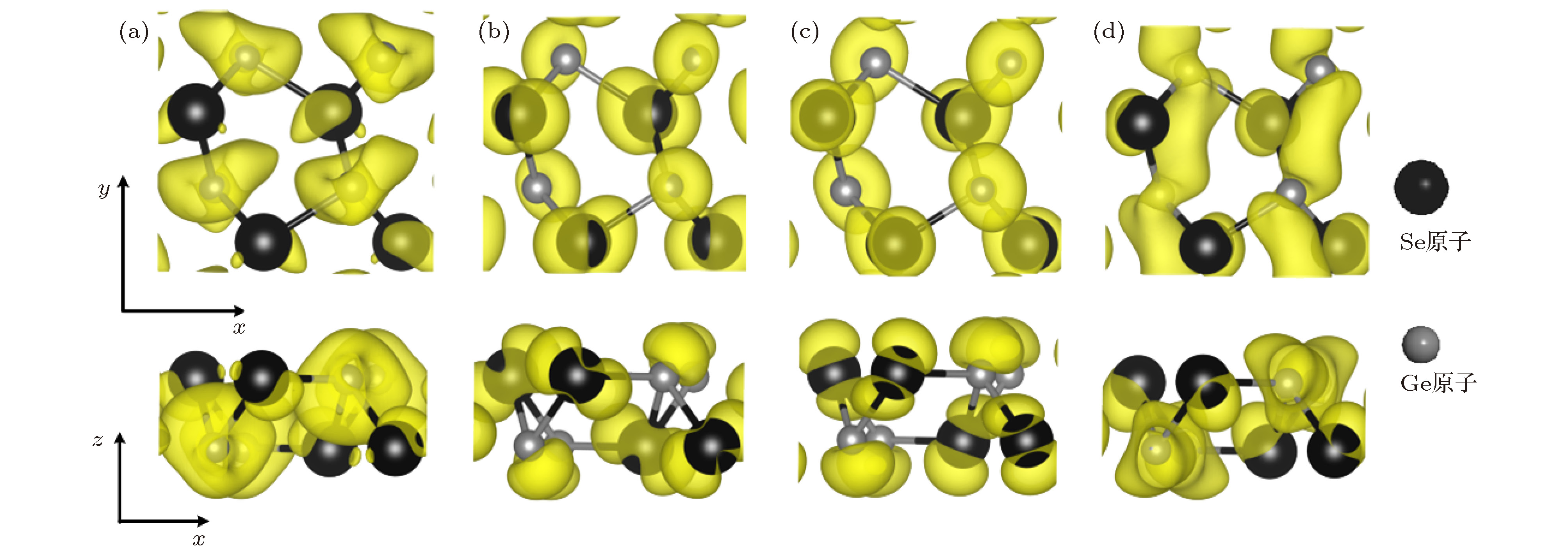

图 1 单层GeSe的5种同分异构弛豫后结构的俯视图和侧视图(图中a和b表示晶格常数) (a) α-GeSe; (b) β-GeSe; (c) γ-GeSe; (d) δ-GeSe; (e) ε-GeSe

Fig. 1. Top view and side views of relaxed structures of five isomers of GeSe monolayer (in the figures, a and b denote the lattice constants, respectively): (a) α-GeSe; (b) β-GeSe; (c) γ-GeSe; (d) δ-GeSe; (e) ε-GeSe.

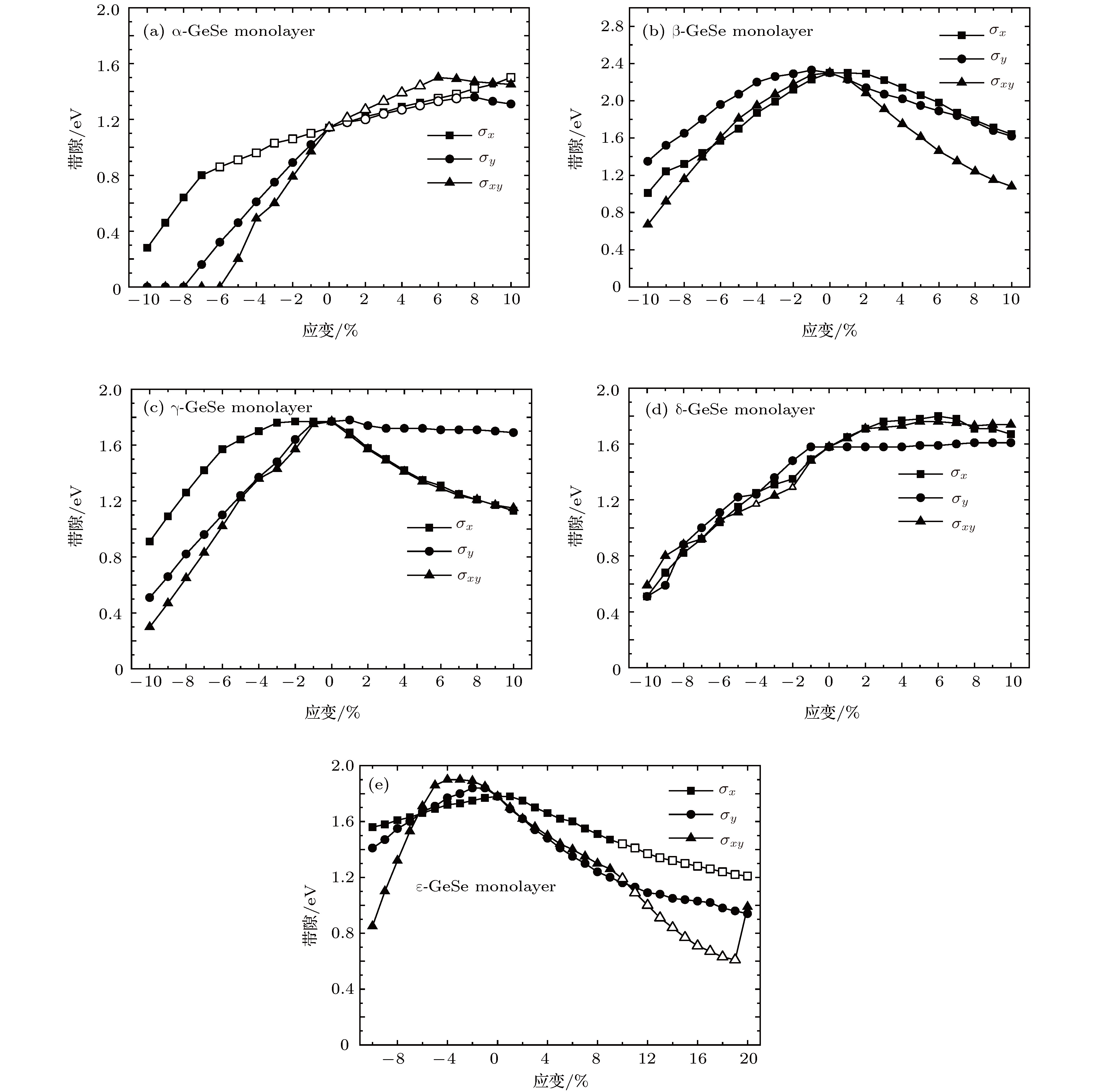

图 3 带隙随平面内应变的变化图(方块表示沿扶手椅(σx)方向的应变, 圆圈表示沿锯齿形(σy)方向的应变, 三角形代表双轴(σxy)应变, 实心和空心符号分别表示间接和直接带隙)

Fig. 3. Variation of band gap along with the applied in-plane strain (The square represents the strain along armchair (σx) direction, while the circle represents the strain along zigzag (σy) direction, the triangle represents the bi-axial (σxy) strain, the solid and hollow symbols denote the indirect and direct band gap, respectively)

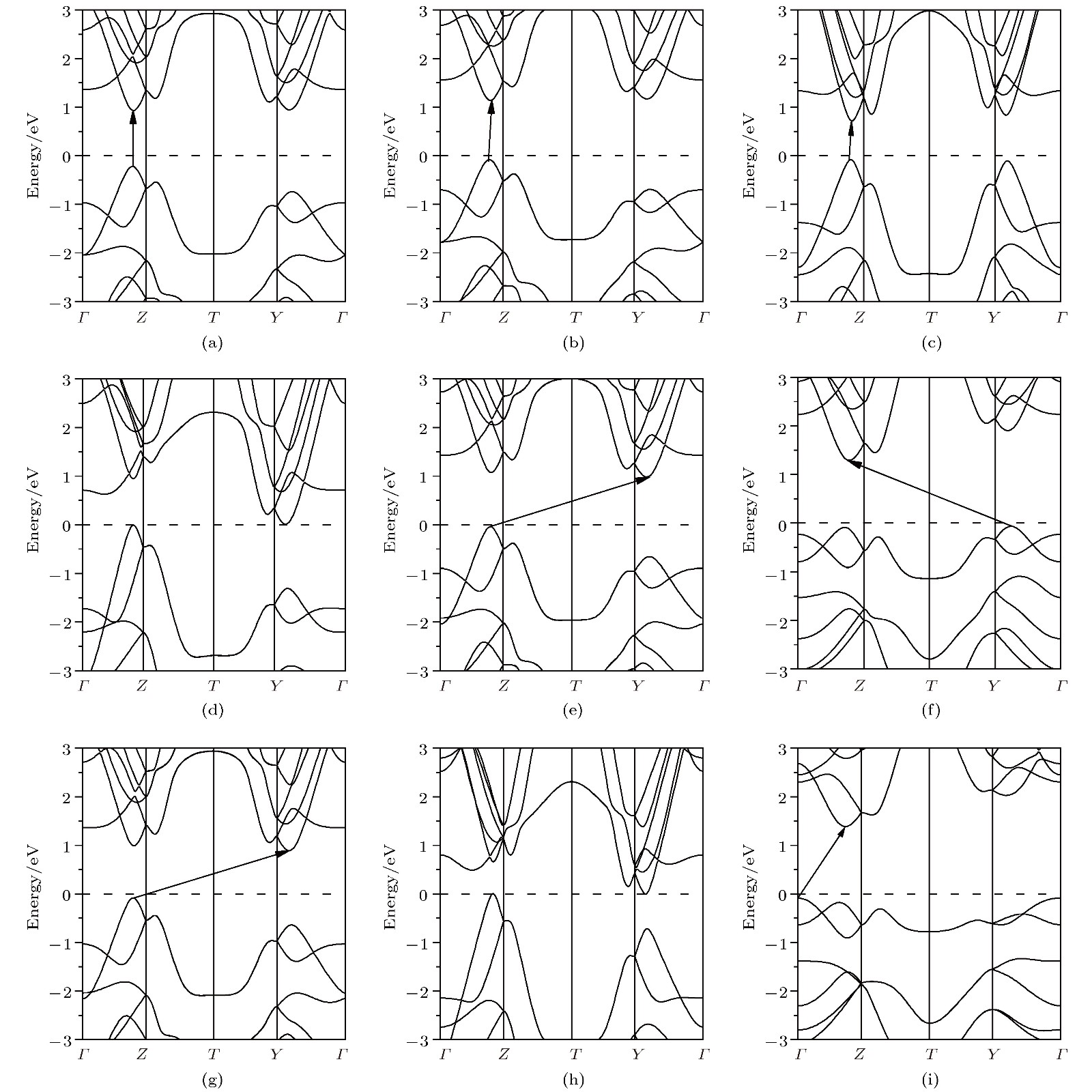

图 S1 单层α-GeSe在应变调控下能带结构 (a) σ = 0; (b) σx = 2%; (c) σx = 7%; (d) σy = –8%; (e) σy = –1%; (f) σy = 8%; (g) σxy = –1%; (h) σxy = –6%; (i) σxy = 8%

Fig. S1. Band structures of α-GeSe monolayer under applied strains: (a) σ = 0; (b) σx = 2%; (c) σx = 7%; (d) σy = –8%; (e) σy = –1%; (f) σy = 8%; (g) σxy = –1%; (h) σxy = –6%; (i) σxy = 8%.

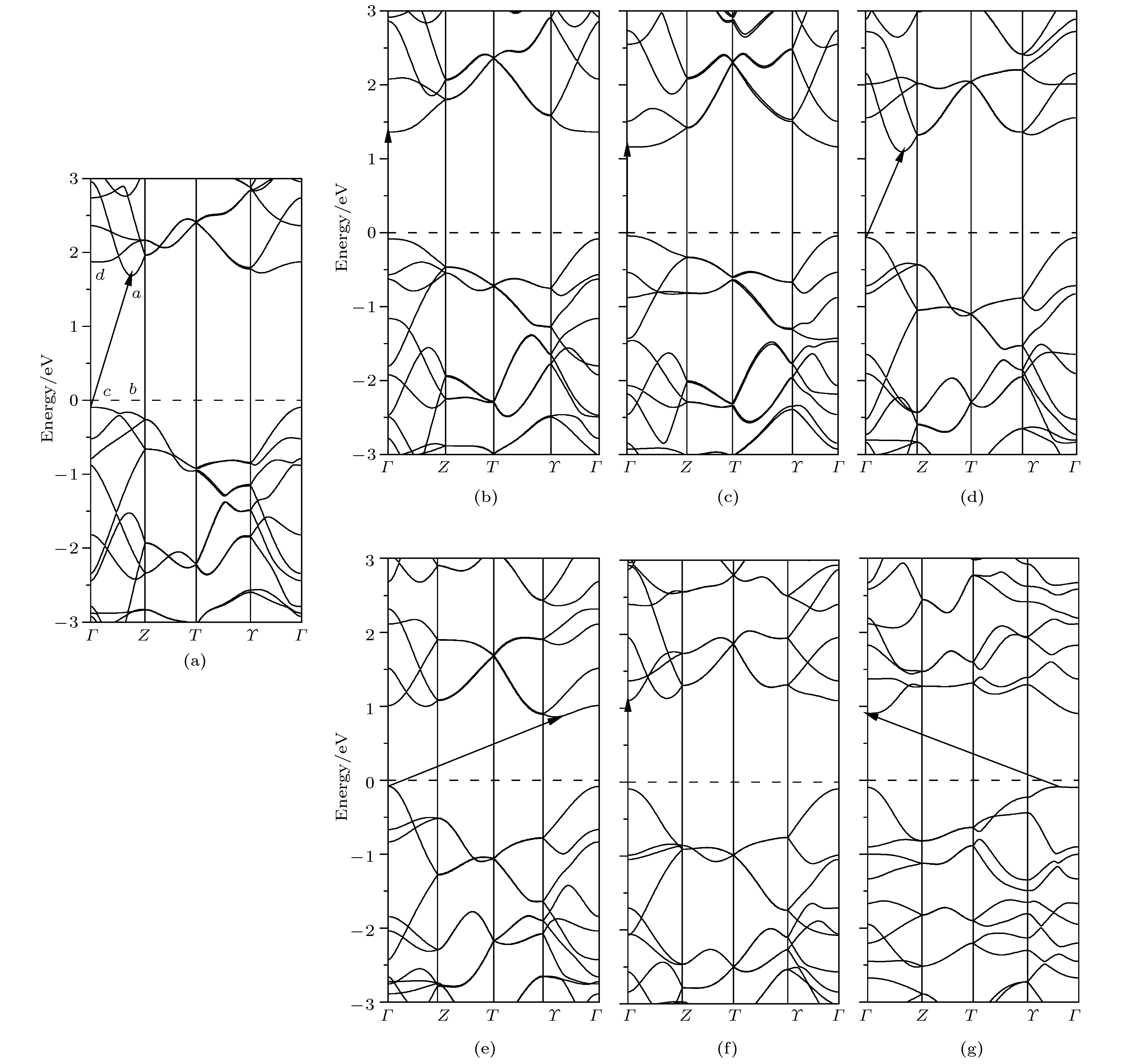

图 4 应变调控下ε-GeSe单层的能带结构 (σx, σy和σxy分别表示沿扶手椅形、锯齿形和双轴方向的应变箭头表示导带最小值 (CBM)指向价带最大值 (VBM)的方向) (a) σ = 0 (图中a表示ε-GeSe的导带最小值, b表示与a相同路径点的价带点, c是ε-GeSe的价带最大值, d是与c的相同路径点的导带点); (b) σx = 10%; (c) σx = 20%; (d) σy = 10%; (e) σy = 20%; (f) σxy = 10%; (g) σxy = 20%

Fig. 4. Band structures of ε-GeSe monolayer under applied strains (σx, σy, σxy represent the strains along the armchair, zigzag and biaxial directions, respectively. The arrow represents the direction from the conduction band minimum (CBM) to the valence band maximum (VBM)): (a) σ = 0 (in the figure, a represents the conduction band minimum of ε-GeSe, b represents the valence band point corresponding to the same path point of a, c is the valence band maximum of ε-GeSe, d is the conduction band point corresponding to the same path point of c); (b) σx = 10%; (c) σx = 20%; (d) σy = 10%; (e) σy = 20%; (f) σxy = 10%; (g) σxy = 20%.

表 2 5种GeSe同分异构体结构的振动频率计算结果 (E0代表零点能, Ef/i代表虚拟频率, Ef/i/E0为虚拟频率占据零点能的比例)

Table 2. Calculated results of vibration frequencies of five isomers of GeSe (E0 represents zero energy, Ef/i represents virtual frequency, Ef/i/E0 denotes virtual frequency occupies the proportion of zero energy).

α-GeSe β-GeSe γ-GeSe δ-GeSe ε-GeSe E0 73.88 39.55 77.92 151.22 179.68 Ef/i/meV 0.037 0.016 0.041 0.077 0.664 Ef/i/E0 0.05% 0.04% 0.05% 0.05% 0.03% 表 1 弛豫后单层GeSe 5种同分异构体的结构参数 ( a和b分别是晶格常数, h为GeSe的翘曲高度, Eb是相对于单个原子之间的结合能, Eg为基本带隙)

Table 1. Relaxed structural parameters of five isomers of GeSe monolayer (a and b are the lattice constants, respectively. h is the buckling height of GeSe; Eb is the bind energy per atom; Eg is the fundamental band gap).

α-GeSe β-GeSe γ-GeSe δ-GeSe ε-GeSe a/Å 4.27 3.68 3.67 5.80 6.85 b/Å 3.98 3.68 5.89 5.84 6.43 h/Å 2.52 1.45 1.76 2.52 1.72 |Eb|/eV·atom–1 4.14 4.12 4.11 4.13 4.08 Eg/eV 1.14 2.30 1.77 1.58 1.78 表 3 ε-GeSe沿扶手椅形(σx)、锯齿形(σy)和双轴(σxy)方向平面应变优化后的几何参数及能隙(负应变表示压缩应变, 正应变表示拉伸应变; d1, d2和d3 (如图1(e)所示)分别表示Ge和Se原子之间的距离, θ1表示θ (Ge-Se-Ge)的键角, θ2表示θ (Se-Ge-Se)的键角; Eg (eV)表示对应应变下的带隙, (ind.)表示间接带隙,(dir.)表示直接带隙)

Table 3. Summary of the optimized geometric structures and energy gaps for ε-GeSe under in-plane strains along the armchair (σx), zigzag (σy) and biaxial (σxy) directions (Negative values of strain denote compress strains, while positive values denote tensile strains. d1, d2 and d3 (as shown in Fig. 1(e)) represent the distance between Ge and Se atoms, respectively. θ1 represents the θ (Ge-Se-Ge) bond angle. θ2 represents the θ (Se-Ge-Se) bond angle. Eg (eV) is the band gap under the corresponding strain,(ind.)is the indirect band gap, (dir.) is the direct band gap)

Strain/% d1/Å d2/Å d3/Å θ1 θ2 Eg/eV σx 2.68 2.51 2.60 85.6 86.7 1.56 (ind.) –10 σy 2.60 2.58 2.56 98.2 85.1 1.41 (ind.) σxy 2.60 2.52 2.52 89.6 77.8 0.85 (ind.) σx 2.67 2.51 2.60 87.4 87.2 1.61 (ind.) –8 σy 2.61 2.57 2.57 97.1 85.8 1.55 (ind.) σxy 2.60 2.52 2.54 90.2 80.3 1.32 (ind.) σx 2.67 2.52 2.60 89.1 87.8 1.66 (ind.) –6 σy 2.61 2.56 2.58 96.3 86.6 1.67 (ind.) σxy 2.61 2.52 2.56 90.8 82.8 1.71 (ind.) σx 2.66 2.52 2.60 90.9 88.3 1.72 (ind.) –4 σy 2.62 2.55 2.59 95.5 87.5 1.77 (ind.) σxy 2.62 2.53 2.57 91.7 85.5 1.90 (ind.) σx 2.65 2.53 2.60 92.4 88.8 1.75 (ind.) –2 σy 2.63 2.55 2.59 94.8 88.4 1.84 (ind.) σxy 2.64 2.53 2.59 92.7 87.4 1.89 (ind.) 0 2.65 2.54 2.60 94.1 89.3 1.78 (ind.) σx 2.65 2.55 2.60 95.8 89.7 1.75 (ind.) 2 σy 2.67 2.54 2.60 93.3 90.5 1.62 (ind.) σxy 2.67 2.55 2.60 95.8 91.3 1.62 (ind.) σx 2.64 2.56 2.60 97.2 90.2 1.66 (ind.) 4 σy 2.69 2.54 2.60 93.2 91.6 1.48 (ind.) σxy 2.68 2.56 2.60 98.0 92.6 1.50 (ind.) σx 2.63 2.57 2.61 99.0 90.2 1.60 (ind.) 6 σy 2.71 2.54 2.60 92.8 92.8 1.35 (ind.) σxy 2.70 2.57 2.60 100.2 93.7 1.40 (ind.) σx 2.63 2.59 2.61 100.8 90.4 1.51 (ind.) 8 σy 2.74 2.54 2.60 92.8 94.1 1.24 (ind.) σxy 2.71 2.59 2.60 102.6 94.9 1.30 (ind.) σx 2.62 2.60 2.61 103.5 89.9 1.44 (dir.) 10 σy 2.77 2.54 2.59 93.0 95.5 1.16 (ind.) σxy 2.73 2.60 2.60 105.1 96.1 1.19 (dir.) σx 2.62 2.61 2.62 105.5 90.0 1.37 (dir.) 12 σy 2.80 2.54 2.59 92.9 96.8 1.09 (ind.) σxy 2.75 2.61 2.59 107.7 97.6 1.00 (dir.) σx 2.61 2.62 2.62 108.2 89.4 1.32 (dir.) 14 σy 2.84 2.53 2.58 93.2 98.3 1.05 (ind.) σxy 2.77 2.62 2.58 110.3 99.4 0.84 (dir.) σx 2.60 2.63 2.63 110.8 89.0 1.28 (dir.) 16 σy 2.87 2.53 2.57 93.4 100.0 1.03 (ind.) σxy 2.78 2.64 2.57 112.6 101.7 0.67 (dir.) σx 2.60 2.63 2.63 113.1 88.8 1.24 (dir.) 18 σy 2.92 2.52 2.56 93.5 102.0 0.98 (ind.) σxy 2.79 2.65 2.55 115.2 103.7 0.63 (dir.) σx 2.59 2.64 2.64 115.6 88.3 1.21 (dir.) 20 σy 2.96 2.51 2.54 94.1 103.8 0.94 (ind.) σxy 2.72 2.70 2.54 123.7 108.1 0.99 (ind.) 表 A1 单层ε-GeSe在施加20%拉伸应变下优化后的结构的振动频率的计算结果

Table A1. Calculated optimized results of vibration frequencies of ε-GeSe monolayer under application of 20% tensile strain.

σx = 20% σy = 20% σxy = 20% E0/meV 165.49 156.07 132.56 Ef/i/meV 2.650 0.030 0.005 Ef/i/E0 1.60% 0.02% 0.03% -

[1] Zhao Y, Chen Y, Zhang Y H, Liu S F 2017 Mater. Chem. Phys. 189 215

Google Scholar

Google Scholar

[2] Fiori G, Bonaccorso F, Iannaccone G, Palacios T, Neumaier D, Seabaugh A, Colombo L 2014 Nat. Nanotech. 9 768

Google Scholar

Google Scholar

[3] Wang Q H, Kalantar-Zadeh K, Kis A, Coleman J N, Strano M S 2012 Nat. Nanotech. 7 699

Google Scholar

Google Scholar

[4] Ando T, Fowler A B, Stern F 1982 Rev. Mod. Phys. 54 437

Google Scholar

Google Scholar

[5] Schedin F, Geim A K, Morozov S V, Hill E W, Blake P, Katsnelson M I, Novoselov K S 2007 Nat. Mater. 6 652

Google Scholar

Google Scholar

[6] Wang T H, Zhu Y F, Jiang Q 2013 J. Phys. Chem. C 117 12873

Google Scholar

Google Scholar

[7] Liu L, Feng Y P, Shen Z X 2003 Phys. Rev. B 68 104102

Google Scholar

Google Scholar

[8] Balandin A A, Ghosh S, Bao W, Calizo I, Teweldebrhan D, Miao F, Lau C N 2008 Nano Lett. 8 902

Google Scholar

Google Scholar

[9] Mak K F, Lee C, Hone J, Shan J, Heinz T F 2010 Phys. Rev. Lett. 105 136805

Google Scholar

Google Scholar

[10] Splendiani A, Sun L, Zhang Y B, Li T S, Kim J, Chim C Y, Galli G, Wang F 2010 Nano Lett. 10 1271

Google Scholar

Google Scholar

[11] Peng X H, Wei Q, Copple A 2014 Phys. Rev. B 90 085402

Google Scholar

Google Scholar

[12] Liu H, Neal A T, Zhu Z, Luo Z, Xu X F, Tománek D, Ye P D 2014 ACS Nano. 8 4033

Google Scholar

Google Scholar

[13] Jain A, McGaughey A J 2015 Sci. Rep 5 8501

Google Scholar

Google Scholar

[14] Liang L B, Wang J, Lin W Z, Sumpter B G, Meunier V, Pan M 2014 Nano Lett. 14 6400

Google Scholar

Google Scholar

[15] Kou L Z, Chen C F, Smith S C 2015 Phys. Chem. Lett. 6 2794

Google Scholar

Google Scholar

[16] Reich E S 2014 Nature 506 19

Google Scholar

Google Scholar

[17] Singh A K, Hennig R G 2014 Appl. Phys. Lett. 105 042103

Google Scholar

Google Scholar

[18] Huang L, Wu F G, Li J B 2016 J. Chem. Phys. 144 114708

Google Scholar

Google Scholar

[19] Zhang S L, Wang N, Liu S G, Huang S P, Zhou W H, Cai B, Xie M Q, Yang Q, Chen X P, Zeng H B 2016 Nanotechnology 27 274001

Google Scholar

Google Scholar

[20] Wiedemeier H, Georg H, von Schnering G 1978 Z. Krist-Cryst. Mater. 148 295

[21] Vaughn II D D, Patel R J, Hickner M A, Schaak R E 2010 J. Am. Chem. Soc. 132 15170

Google Scholar

Google Scholar

[22] de Oliveira I S S, Longuinhos R 2016 Phys. Rev. B 94 035440

Google Scholar

Google Scholar

[23] Bosse J L, Grishin I, Gyu Choi Y, Cheong B K, Lee S, Kolosov O V, Huey B D 2014 Appl. Phys. Lett. 104 053109

Google Scholar

Google Scholar

[24] Zhang X Y, Shen J W, Lin S Q, Li J, Chen Z W, Li W, Pei Y Z 2016 J. Materiomics 2 331

Google Scholar

Google Scholar

[25] Xue D J, Liu S C, Dai C M, Chen S Y, He C, Zhao L, Hu J S, Wan L J 2017 J. Am. Chem. Soc. 139 958

Google Scholar

Google Scholar

[26] Liu S C, Mi Y, Xue D J, Chen Y X, He C, Liu X F, Hu J S, Wan L J 2017 Adv. Electron. Mater. 3 1700141

Google Scholar

Google Scholar

[27] Sannyal A, Zhang Z Q, Gao X F, Jang J 2018 Comp. Mater. Sci. 154 204

Google Scholar

Google Scholar

[28] Gomes L C, Carvalho A 2015 Physics 9 2

[29] Fei R X, Li W B, Li J, Y L 2015 Appl. Phys. Lett. 107 237

[30] Zhang S L, Liu S G, Huang S P, Cai B, Xie M Q, Qu L H, Zou Y S, Hu Z Y, Xu X C, Zeng H 2015 Sci. China: Mater. 58 929

[31] Zhao H Q, Mao Y L, Mao X, Shi X, Xu C S, Wang C X, Zhang S M, Zhou D H 2018 Adv. Funct. Mater. 28 1704855

Google Scholar

Google Scholar

[32] von Rohr F O, Ji H, Cevallos F A, Gao T, Ong N P, Cava R J 2017 J. Am. Chem. Soc. 139 2771

Google Scholar

Google Scholar

[33] Gomes L C, Trevisanutto P E, Carvalho A, Rodin A S, Neto A C 2016 Phys. Rev. B 94 155428

Google Scholar

Google Scholar

[34] Mao Y L, Xu C S, Yuan J M, Zhao H Q 2018 Phys. Chem. Chem. Phys. 20 6929

Google Scholar

Google Scholar

[35] Mao Y L, Long L B, Yuan J M, Zhong J X, Zhao H Q 2018 Chem. Phys. Lett. 706 501

Google Scholar

Google Scholar

[36] Ersan F, Arkin H, Aktürk E 2017 RSC Adv. 7 37815

Google Scholar

Google Scholar

[37] Xu Y F, Zhang H, Shao H Z, Ni G, Li J, Lu H L, Zhang R J, Peng B, Zhu Y Y, Zhu H Y, Soukoulis C M 2017 Phys. Rev. B 96 245421

Google Scholar

Google Scholar

[38] Hu Y H, Zhang S L, Sun S F, Xie M Q, Cai B, Zeng H B 2015 Appl. Phys. Lett. 107 122107

Google Scholar

Google Scholar

[39] Ong Z Y, Cai Y Q, Zhang G, Zhang Y W 2014 J. Phys. Chem. C 118 25272

Google Scholar

Google Scholar

[40] Ni Z H, Yu T, Lu Y H, Wang Y Y, Feng Y P, Shen Z X 2008 ACS Nano 2 2301

Google Scholar

Google Scholar

[41] Kresse G, Furthmüller J 1996 Phys. Rev. B 54 11169

Google Scholar

Google Scholar

[42] Hafner J 2008 J. Comp. Chem. 29 2044

Google Scholar

Google Scholar

[43] Segall M D, Lindan P J, Probert M A, Pickard C J, Hasnip P J, Clark S J, Payne M C 2002 J. Phys.: Condensed Mat. 14 2717

Google Scholar

Google Scholar

[44] Clark S J, Segall M D, Pickard C J, Hasnip P J, Probert M I, Refson K, Payne M C 2005 Z. Krist-Cryst Mater. 220 567

[45] Perdew J P, Burke K, Ernzerhof M 1996 Phys. Rev. Lett. 77 3865

Google Scholar

Google Scholar

[46] White J A, Bird D M 1994 Phys. Rev. B 50 4954

Google Scholar

Google Scholar

[47] Heyd J, Scuseria G E, Ernzerhof M 2003 J. Chem. Phys. 118 8207

Google Scholar

Google Scholar

[48] Monkhorst H J, Pack J D 1976 Phys. Rev. B 13 5188

Google Scholar

Google Scholar

[49] Mao Y L, Ben J, Yuan J M,Zhong J X 2018 Chem. Phys. Lett. 705 12

Google Scholar

Google Scholar

[50] 鲁源坤 2010 硕士学位论文 (山西: 太原科技大学)

Lu Y K 2010 M. S. Thesis (Taiyuan: University of Science & Technology) (in Chinese)

计量

- 文章访问数: 14639

- PDF下载量: 210

- 被引次数: 0

下载:

下载: