-

高熵合金(HEAs)作为多主元合金的重要分支, 因其优异的力学性能与功能特性受到广泛关注. 本文聚焦含硅高熵合金中的有序-无序相变机制, 系统综述其热力学与动力学调控规律及其对材料性能的影响. 研究表明, 硅的引入通过优化原子尺寸匹配与混合焓, 实现高熵合金中有序相和无序相的匹配, 显著提升合金的机械以及物理化学性能. 同时, 制备工艺与温度/压力调控可通过影响相形成实现多相结构的协同强化. 通过成分设计与工艺优化, 含硅高熵材料在航空航天、能源及电子器件等领域展现出广阔应用潜力. 未来研究需进一步结合多尺度表征与理论模型, 揭示相变动态机制, 推动其工程化应用.

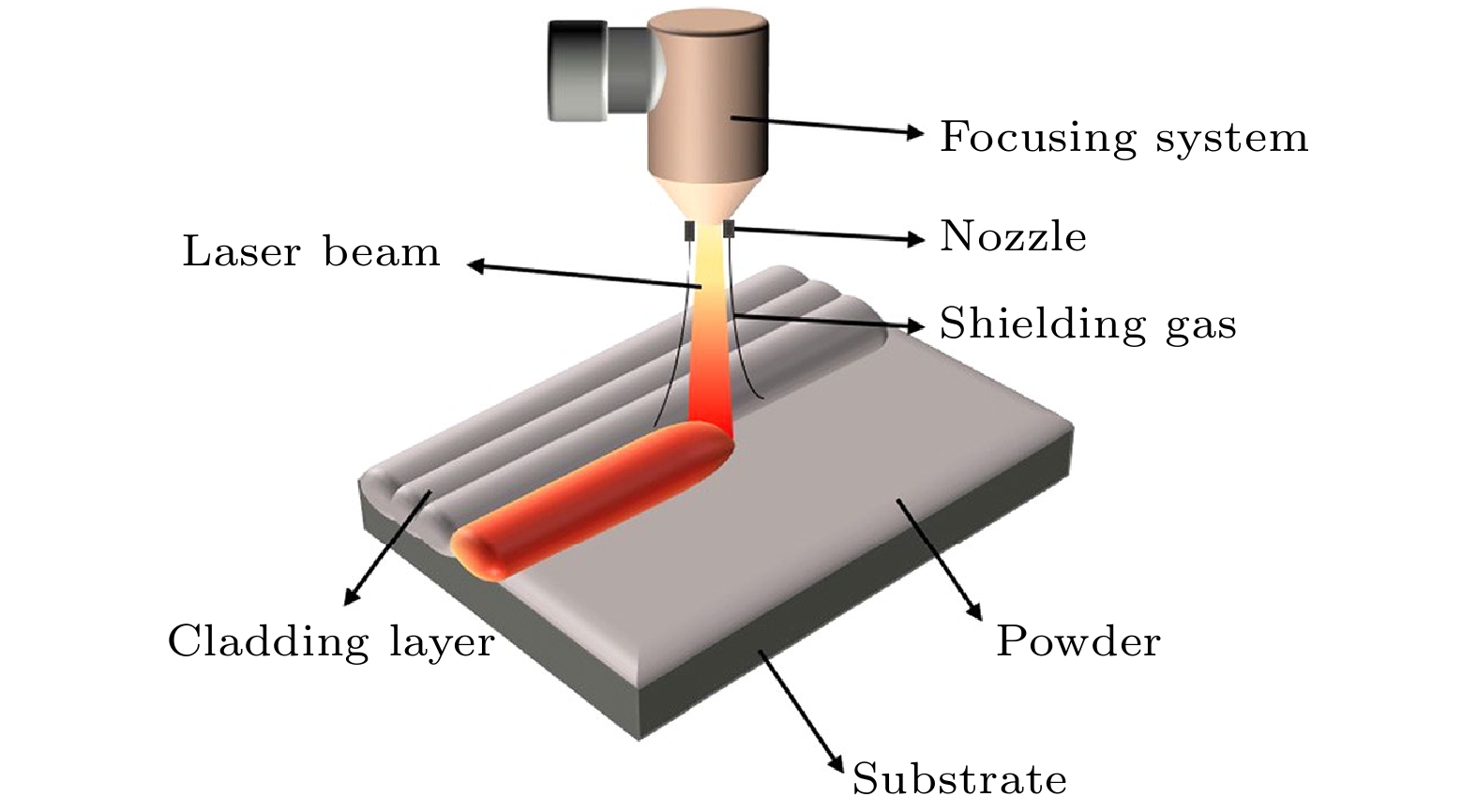

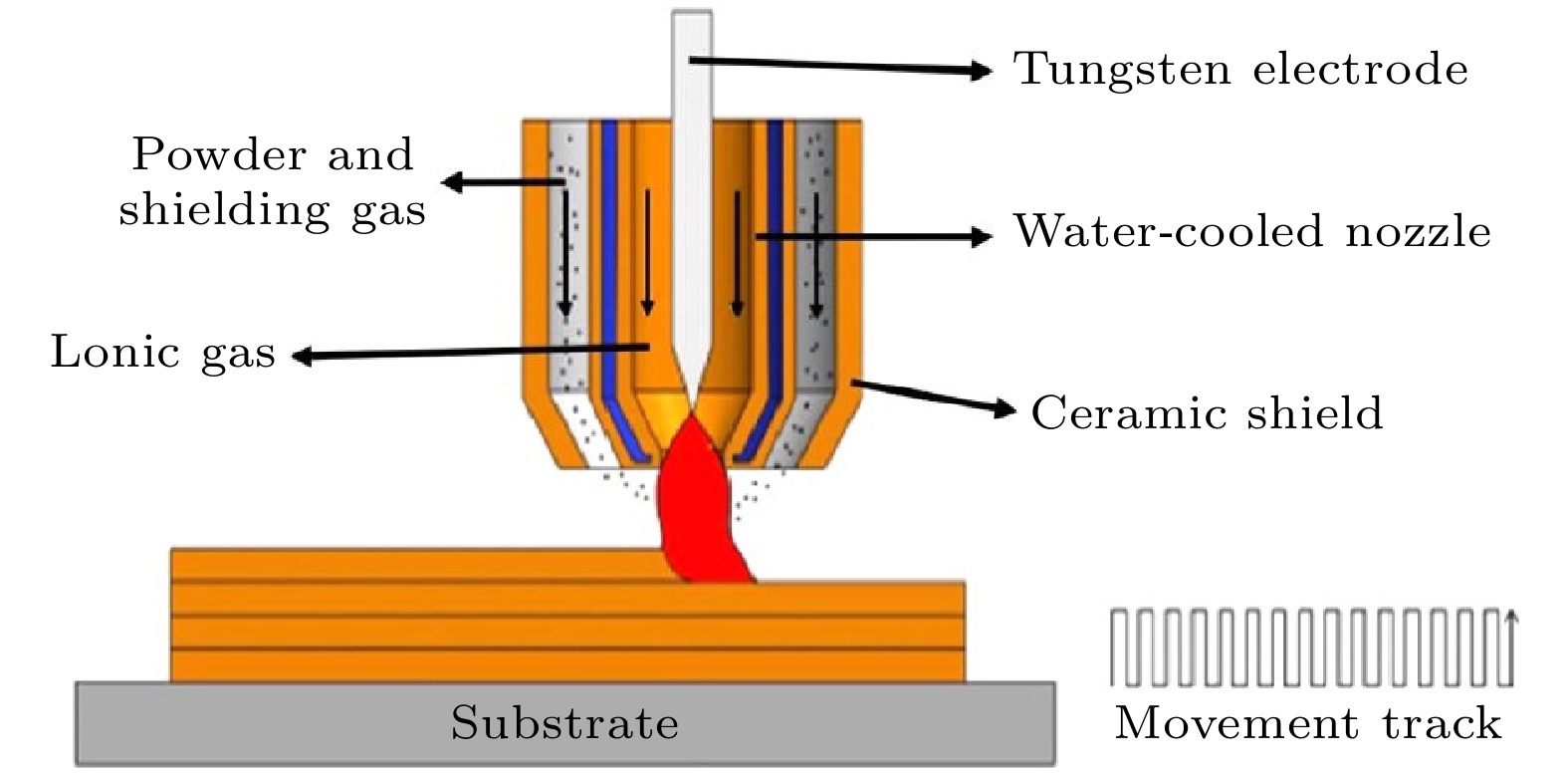

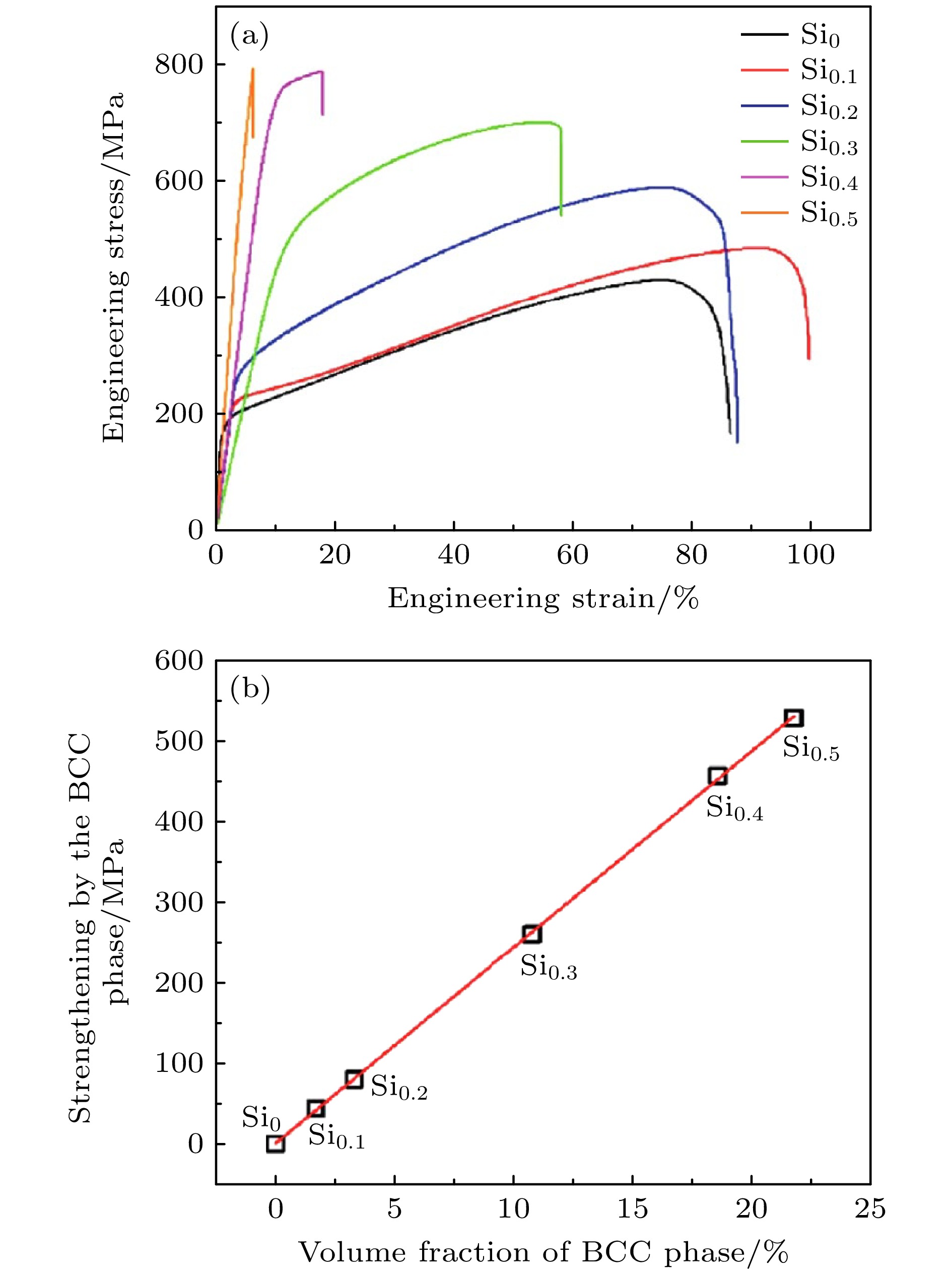

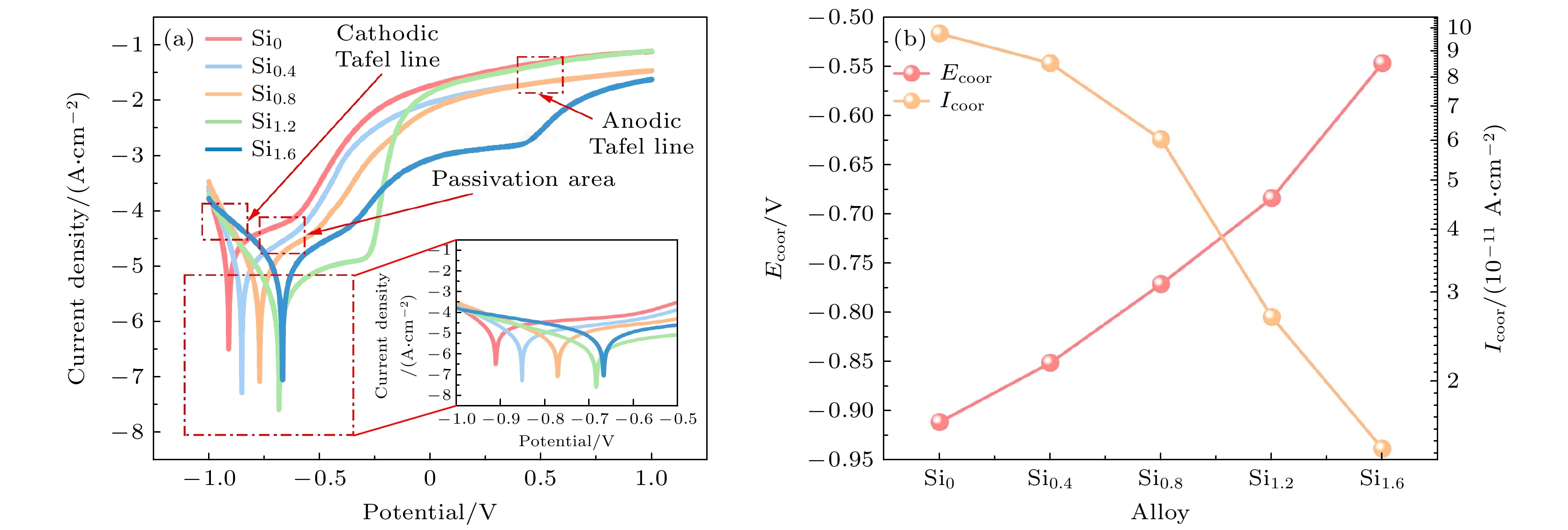

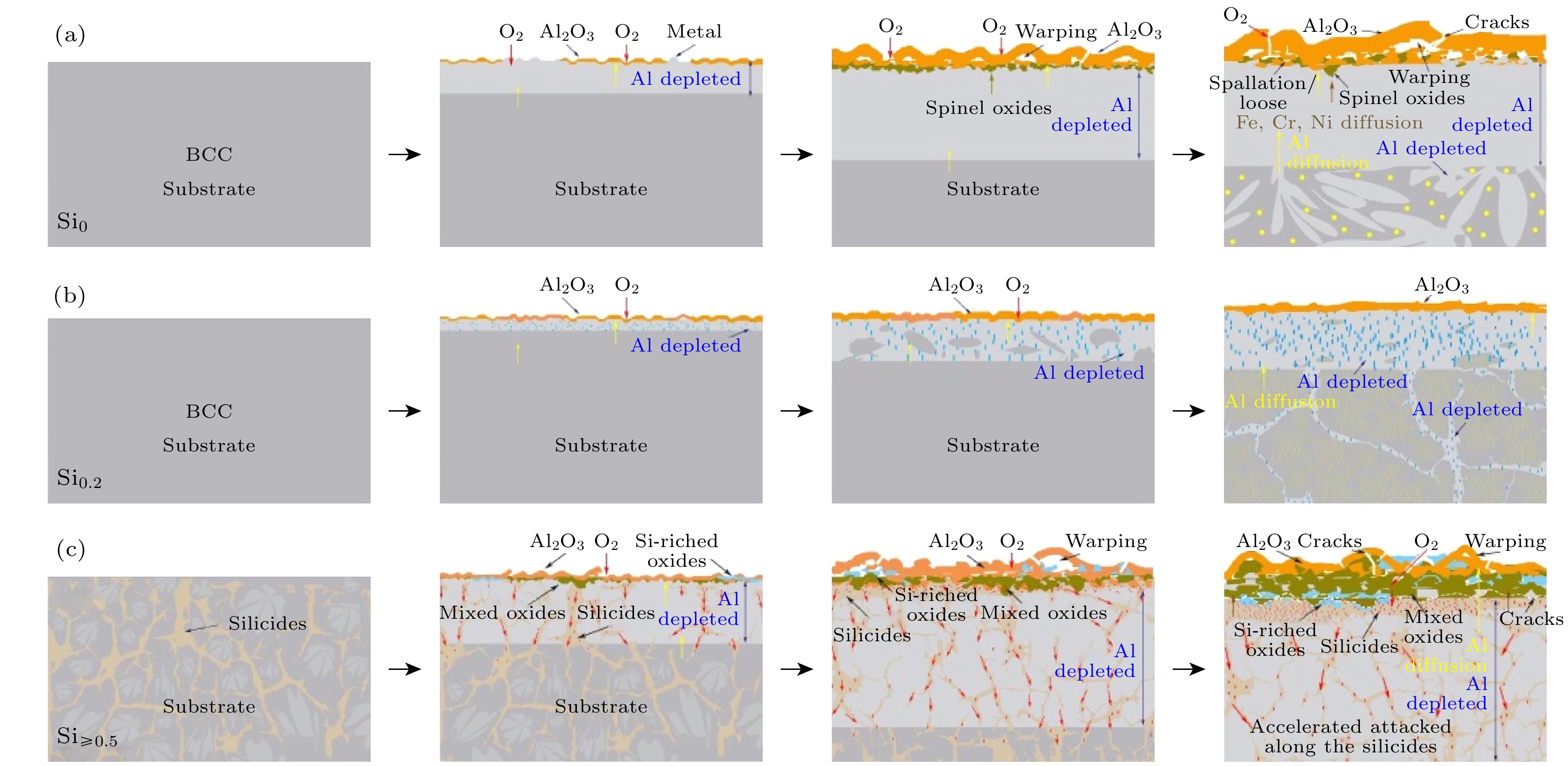

High-entropy alloys (HEAs), representing a significant category of multi-component alloys, have attracted significant attention due to their outstanding mechanical and functional properties. This review focuses on the order-disorder phase transition mechanisms in silicon-based HEAs, systematically addressing the thermodynamic and kinetic regulation principles and their effects on material performance. The research has shown that adding silicon improves atomic size matching and mixing enthalpy, allowing high-entropy alloys to have both ordered and disordered phases, thereby significantly enhancing their mechanical and physicochemical properties. The evolution of ordered and disordered phases is strictly controlled by fabrication processes. Advanced fabrication techniques, such as laser cladding and powder metallurgy, as well as temperature/pressure modulation, can precisely control phase formation and layered structure, achieving synergistic strengthening through multiphase structures. Rapid cooling techniques such as laser cladding suppress the nucleation and growth of brittle intermetallic compounds, which is beneficial for single-phase FCC structures. On the contrary, controlled annealing treatments can induce phase transitions towards ordered BCC/B2 structures, enhancing high-temperature stability. Advanced techniques such as powder plasma arc additive manufacturing (PPA-AM) utilize rapid solidification to refine grain size and effectively disperse second phases. Thermodynamic drivers, particularly the competition between entropy and enthalpy quantified by the parameter Ω, as well as external stimuli such as pressure, provide precise control over the phase transition pathways and final microstructures. Furthermore, the incorporation of sillicon enhances functional performance, including increasing electrical resistivity, customizing magnetic responses, and improved high-temperature oxidation resistance through the formation of Al2O3/SiO2 layers. Despite these advancements, there are still challenges in understanding atomic-scale dynamics of phase transitions and expanding cost-effective manufacturing processes. Future efforts should integrate multiscale characterization, computational modeling, and performance validation under extreme conditions to accelerate the engineering applications of silicon-based HEAs in aerospace, energy storage, and electronic devices. [1] Yeh J W, Chen S K, Lin S J, Gan J Y, Chin T S, Shun T T, Tsau C H, Chang S Y 2004 Adv. Eng. Mater. 6 299

Google Scholar

Google Scholar

[2] Cantor B, Chang I T H, Knight P, Vincent A J B 2004 Mater. Sci. Eng. A 375–377 213

Google Scholar

Google Scholar

[3] Huang E W, Lee W J, Singh S S, Kumar P, Lee C Y, Lam T N, Chin H H, Lin B H, Liaw P K 2022 Mater. Sci. Eng. : R: Rep. 147 100645

Google Scholar

Google Scholar

[4] Tsai M H, Yeh J W 2014 Mater. Res. Lett. 2 107

Google Scholar

Google Scholar

[5] Chandrakar R, Chandraker S, Kumar A, Jaiswal A 2024 Mater. Res. Express 11 116512

Google Scholar

Google Scholar

[6] Sohrabi M J, Kalhor A, Mirzadeh H, Rodak K, Kim H S 2024 Prog. Mater Sci. 144 101295

Google Scholar

Google Scholar

[7] Wu Y, Li Z, Feng H, He S 2022 Materials 15 3992

Google Scholar

Google Scholar

[8] Liu F F, Liaw P, Zhang Y 2022 Metals 12 501

Google Scholar

Google Scholar

[9] Luan H W, Shao Y, Li J F, Mao W L, Han Z D, Shao C, Yao K F 2020 Scr. Mater. 179 40

Google Scholar

Google Scholar

[10] 叶喜葱, 徐张洋, 王童, 徐东, 张文, 方东 2020 特种铸造及有色合金 40 1323

Google Scholar

Google Scholar

Ye X C, Xu Z Y, Wang T, Xu D, Zhang W, Fang D 2020 Spec. Cast. Nonferrous Alloys 40 1323

Google Scholar

Google Scholar

[11] Li Y T, Zhang P, Zhang J Y, Chen Z, Shen B L 2021 Corros. Sci. 190 109633

Google Scholar

Google Scholar

[12] Kumar A, Chandrakar R, Chandraker S, Rao K R, Chopkar M 2021 J. Alloys Compd. 856 158193

Google Scholar

Google Scholar

[13] Zhang Y T, Zhang M, Li D, Zuo T, Zhou K, Gao M C, Sun B, Shen T 2019 Metals 9 382

Google Scholar

Google Scholar

[14] Lee H, Sharma A, Ahn B 2023 J. Alloys Compd. 947 169545

Google Scholar

Google Scholar

[15] Gearhart C A 1990 Am. J. Phys. 58 468

Google Scholar

Google Scholar

[16] Li Z Z, Zhao S T, Ritchie R O, Meyers M A 2019 Prog. Mater Sci. 102 296

Google Scholar

Google Scholar

[17] Zhang Y, Zhou Y J, Lin J P, Chen G L, Liaw P K 2008 Adv. Eng. Mater. 10 534

Google Scholar

Google Scholar

[18] Yang X H, Zhang Y 2012 Mater. Chem. Phys. 132 233

Google Scholar

Google Scholar

[19] Yan X H, Liaw P K, Zhang Y 2021 Metall. Mater. Trans. A 52 2111

Google Scholar

Google Scholar

[20] Wu G, Liu C, Yan Y Q, Liu S D, Ma X Y, Yue S Y, Shan Z W 2024 Nat. Commun. 15 1223

Google Scholar

Google Scholar

[21] Wu G, Liu S D, Wang Q, Rao J, Xia W Z, Yan Y Q, Eckert J, Liu C, Ma E, Shan Z W 2023 Nat. Commun. 14 3670

Google Scholar

Google Scholar

[22] Miracle D B, Senkov O N 2017 Acta Mater. 122 448

Google Scholar

Google Scholar

[23] Lei Z F, Liu X J, Wu Y, Wang H, Jiang S H, Wang S D, Hui X D, Wu Y D, Gault B, Kontis P, Raabe D, Gu L, Zhang Q H, Chen H W, Wang H T, Liu J B, An K, Zeng Q S, Nieh T G, Lu Z P 2018 Nature 563 546

Google Scholar

Google Scholar

[24] Soni V, Gwalani B, Senkov O N, Viswanathan B, Alam T, Miracle D B, Banerjee R 2018 J. Mater. Res. 33 3235

Google Scholar

Google Scholar

[25] Soni V, Senkov O N, Gwalani B, Miracle D B, Banerjee R 2018 Sci. Rep. 8 8816

Google Scholar

Google Scholar

[26] Soni V, Gwalani B, Alam T, Dasari S, Zheng Y, Senkov O N, Miracle D, Banerjee R 2020 Acta Mater. 185 89

Google Scholar

Google Scholar

[27] Huang X J, Miao J S, Luo A A 2018 J. Mater. Sci. 54 2271

Google Scholar

Google Scholar

[28] Huang X J, Miao J S, Luo A A 2022 Scr. Mater. 210 114462

Google Scholar

Google Scholar

[29] Sundman B, Chen Q, Du Y 2018 J. Phase Equilib. Diffus. 39 678

Google Scholar

Google Scholar

[30] Singh P, Johnson D D 2021 J. Mater. Res. 37 136

Google Scholar

Google Scholar

[31] Zhang Y, Zuo T T, Tang Z, Gao M C, Dahmen K A, Liaw P K, Lu Z P 2014 Prog. Mater Sci. 61 1

Google Scholar

Google Scholar

[32] Gu X Y, Zhuang Y X, Jia P 2022 Mater. Sci. Eng. A 840 142983

Google Scholar

Google Scholar

[33] Cheng P, Zhao Y H, Xu X T, Wang S, Sun Y Y, Hou H 2020 Mater. Sci. Eng. A 772 138681

Google Scholar

Google Scholar

[34] Zhu J M, Fu H M, Zhang H F, Wang A M, Li H, Hu Z Q 2010 Mater. Sci. Eng. A 527 7210

Google Scholar

Google Scholar

[35] 林应征, 杨洪宇, 陈芳, 颜建辉 2023 材料热处理学报 44 69

Google Scholar

Google Scholar

Lin Y Z, Yang H Y, Chen F, Yan J H 2023 Trans. Mater. Heat Treat. 44 69

Google Scholar

Google Scholar

[36] Babilas R, Łoński W, Boryło P, Kądziołka Gaweł M, Gębara P, Radoń A 2020 J. Magn. Magn. Mater. 502 166492

Google Scholar

Google Scholar

[37] Zhang H, Pan Y, He Y Z 2011 J. Therm. Spray Technol. 20 1049

Google Scholar

Google Scholar

[38] Zhang S Y, Han B, Li M Y, Zhang Q, Hu C Y, Jia C X, Li Y, Wang Y 2021 Surf. Coat. Technol. 417 127218

Google Scholar

Google Scholar

[39] Santodonato L J, Liaw P K, Unocic R R, Bei H, Morris J R 2018 Nat. Commun. 9 4520

Google Scholar

Google Scholar

[40] Torralba J M, Alvaredo P, García Junceda A 2020 Powder Metall. 63 227

Google Scholar

Google Scholar

[41] Brif Y, Thomas M, Todd I 2015 Scr. Mater. 99 93

Google Scholar

Google Scholar

[42] Han C J, Fang Q H, Shi Y S, Tor S B, Chua C K, Zhou K 2020 Adv. Mater. 32 1903855

Google Scholar

Google Scholar

[43] Luo J, Wang J, Su C, Geng Y, Chen X 2024 J. Mater. Eng. Perform. 33 12413

Google Scholar

Google Scholar

[44] Shun T T, Hung C H, Lee C F 2010 J. Alloys Compd. 493 105

Google Scholar

Google Scholar

[45] Hazen R M, Navrotsky A 1996 Am. Mineral. 81 1021

Google Scholar

Google Scholar

[46] Starenchenko S V 2012 Russ. Phys. J. 54 965

Google Scholar

Google Scholar

[47] Ma Y M, Fan J T, Zhang L J, Zhang M D, Cui P, Dong W Q, Yu P F, Li Y C, Liaw P K, Li G 2018 Intermetallics 103 63

Google Scholar

Google Scholar

[48] Ma L L, Wang L, Nie Z H, Wang F C, Xue Y F, Zhou J L, Cao T Q, Wang Y D, Ren Y 2017 Acta Mater. 128 12

Google Scholar

Google Scholar

[49] Ji C W, Ma A, Jiang J H 2022 J. Alloys Compd. 900 163508

Google Scholar

Google Scholar

[50] Kumar A, Dhekne P, Swarnakar A K, Chopkar M 2018 Mater. Res. Express 6 026532

Google Scholar

Google Scholar

[51] Lin T X, Feng M Y, Lian G F, Lu H, Chen C R, Huang X 2024 Mater. Charact. 216 114246

Google Scholar

Google Scholar

[52] Li Z, Taheri M, Torkamany P, Heidarpour I, Torkamany M J 2024 Vacuum 219 112749

Google Scholar

Google Scholar

[53] Shang X L, Wang Z J, He F, Wang J C, Li J J, Yu J K 2017 Sci. China Technol. Sci. 61 189

Google Scholar

Google Scholar

[54] Wang S, Wu Y, Gesmundo F, Niu Y 2008 Oxid. Met. 69 299

Google Scholar

Google Scholar

[55] Jiang S M, Xu C Z, Li H Q, Liu S C, Gong J, Sun C 2010 Corros. Sci. 52 435

Google Scholar

Google Scholar

[56] Zuo T T, Li R B, Ren X J, Zhang Y 2014 J. Magn. Magn. Mater. 371 60

Google Scholar

Google Scholar

[57] Wen J J, Liu X, Li Z H, Li W W 2023 J. Alloys Compd. 934 167622

Google Scholar

Google Scholar

[58] Su Y, Lei X C, Chen W J, Su Y P, Liu H W, Ren S Y, Tong R Y, Lin Y T, Jiang W J, Liu X Z, Su D, Zhang Y G 2024 Chem. Eng. J. 500 157197

Google Scholar

Google Scholar

[59] Lei X C, Wang Y Y, Wang J Y, Su Y, Ji P X, Liu X Z, Guo S N, Wang X F, Hu Q M, Gu L, Zhang Y G, Yang R, Zhou G, Su D 2023 Small Methods 8 2300754

Google Scholar

Google Scholar

-

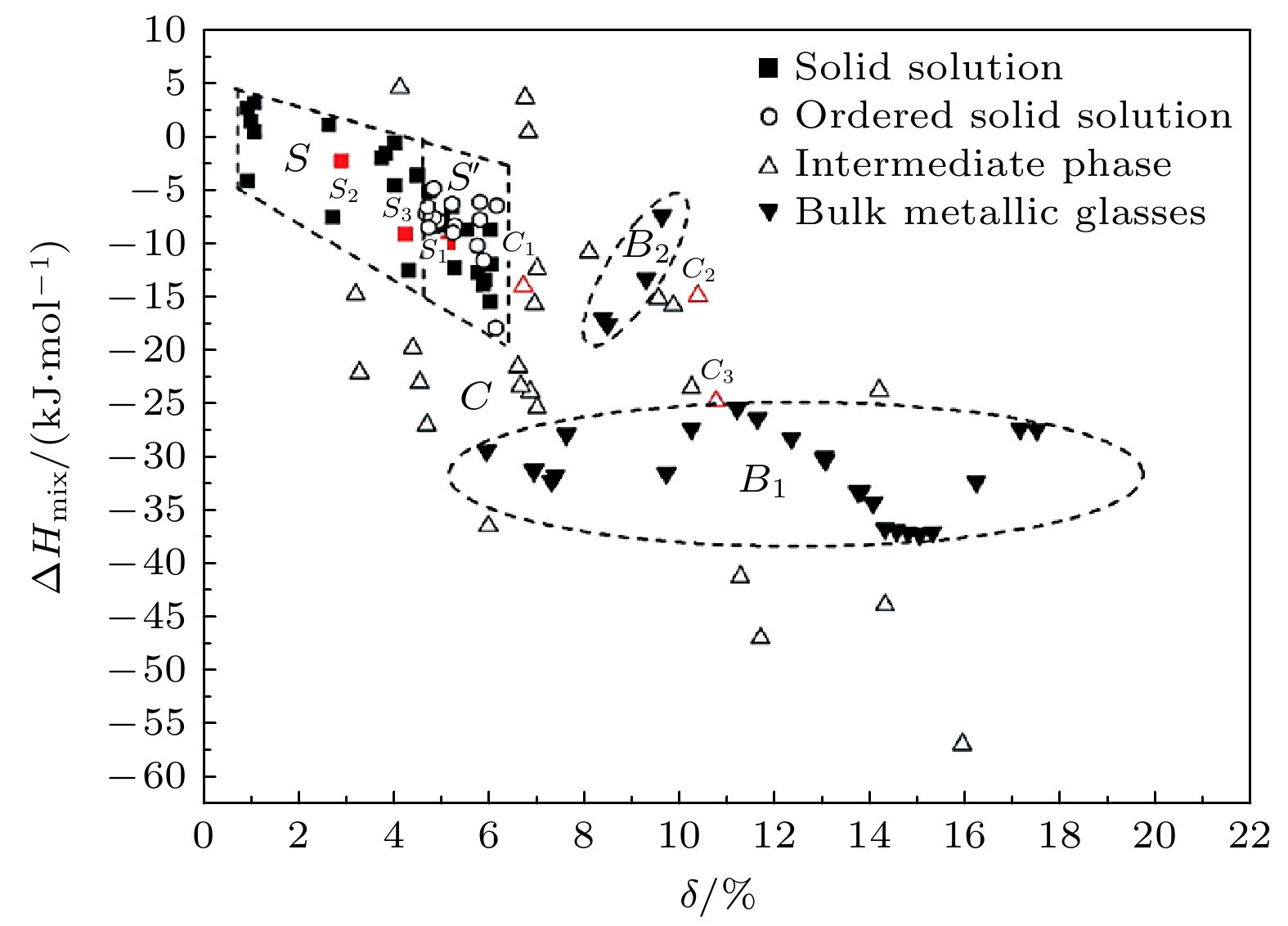

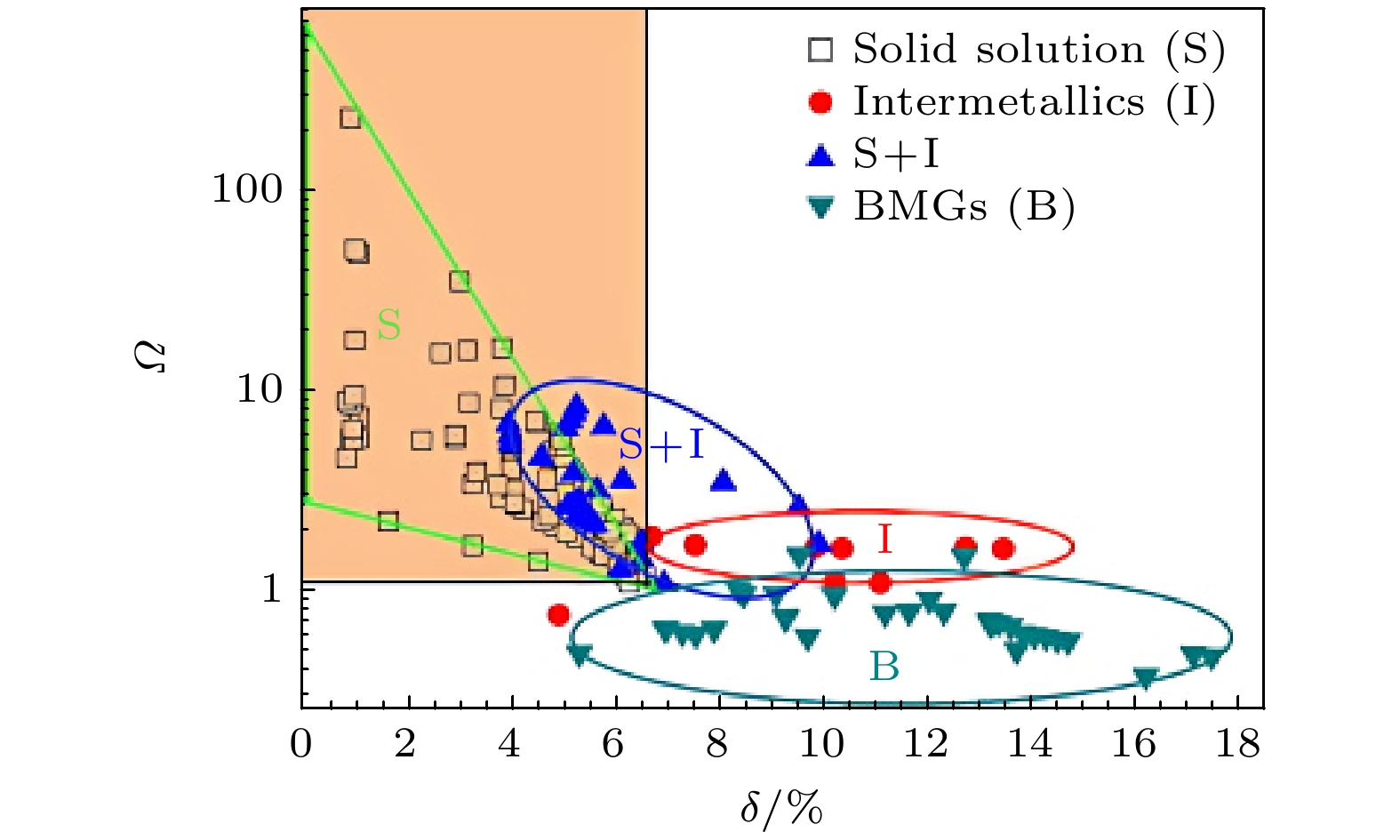

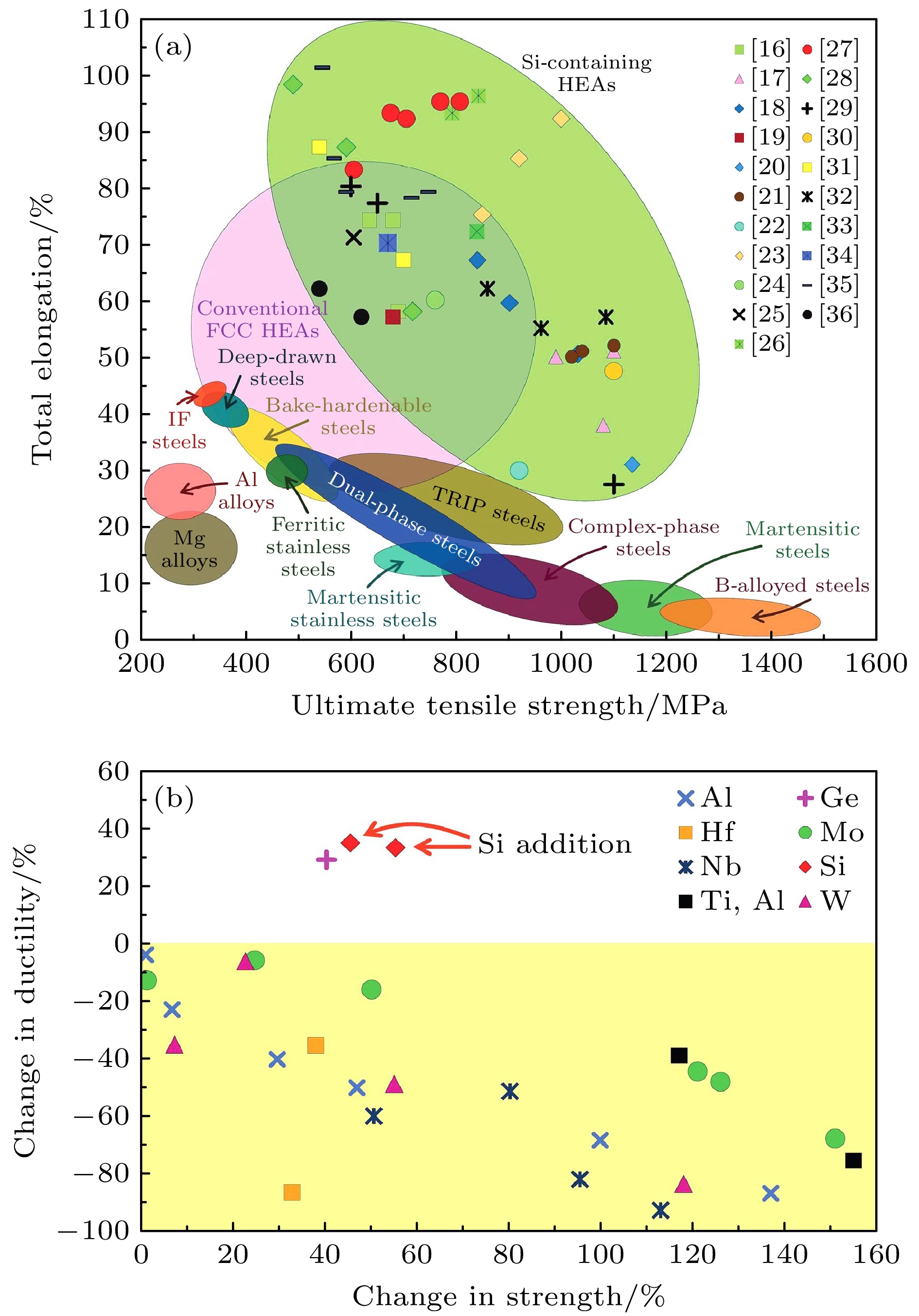

图 1 (a)各种合金和HEAs的强度-塑性图以及含Si HEAs的数据; (b)不同的合金元素对HEAs延展性和拉伸强度的影响[6]

Fig. 1. (a) Strength-ductility diagram of various alloys and HEAs with the addition of the data of the Si-containing HEAs; (b) changes in the ductility and tensile strength with the addition of the different alloying elements in HEAs[6].

-

[1] Yeh J W, Chen S K, Lin S J, Gan J Y, Chin T S, Shun T T, Tsau C H, Chang S Y 2004 Adv. Eng. Mater. 6 299

Google Scholar

Google Scholar

[2] Cantor B, Chang I T H, Knight P, Vincent A J B 2004 Mater. Sci. Eng. A 375–377 213

Google Scholar

Google Scholar

[3] Huang E W, Lee W J, Singh S S, Kumar P, Lee C Y, Lam T N, Chin H H, Lin B H, Liaw P K 2022 Mater. Sci. Eng. : R: Rep. 147 100645

Google Scholar

Google Scholar

[4] Tsai M H, Yeh J W 2014 Mater. Res. Lett. 2 107

Google Scholar

Google Scholar

[5] Chandrakar R, Chandraker S, Kumar A, Jaiswal A 2024 Mater. Res. Express 11 116512

Google Scholar

Google Scholar

[6] Sohrabi M J, Kalhor A, Mirzadeh H, Rodak K, Kim H S 2024 Prog. Mater Sci. 144 101295

Google Scholar

Google Scholar

[7] Wu Y, Li Z, Feng H, He S 2022 Materials 15 3992

Google Scholar

Google Scholar

[8] Liu F F, Liaw P, Zhang Y 2022 Metals 12 501

Google Scholar

Google Scholar

[9] Luan H W, Shao Y, Li J F, Mao W L, Han Z D, Shao C, Yao K F 2020 Scr. Mater. 179 40

Google Scholar

Google Scholar

[10] 叶喜葱, 徐张洋, 王童, 徐东, 张文, 方东 2020 特种铸造及有色合金 40 1323

Google Scholar

Google Scholar

Ye X C, Xu Z Y, Wang T, Xu D, Zhang W, Fang D 2020 Spec. Cast. Nonferrous Alloys 40 1323

Google Scholar

Google Scholar

[11] Li Y T, Zhang P, Zhang J Y, Chen Z, Shen B L 2021 Corros. Sci. 190 109633

Google Scholar

Google Scholar

[12] Kumar A, Chandrakar R, Chandraker S, Rao K R, Chopkar M 2021 J. Alloys Compd. 856 158193

Google Scholar

Google Scholar

[13] Zhang Y T, Zhang M, Li D, Zuo T, Zhou K, Gao M C, Sun B, Shen T 2019 Metals 9 382

Google Scholar

Google Scholar

[14] Lee H, Sharma A, Ahn B 2023 J. Alloys Compd. 947 169545

Google Scholar

Google Scholar

[15] Gearhart C A 1990 Am. J. Phys. 58 468

Google Scholar

Google Scholar

[16] Li Z Z, Zhao S T, Ritchie R O, Meyers M A 2019 Prog. Mater Sci. 102 296

Google Scholar

Google Scholar

[17] Zhang Y, Zhou Y J, Lin J P, Chen G L, Liaw P K 2008 Adv. Eng. Mater. 10 534

Google Scholar

Google Scholar

[18] Yang X H, Zhang Y 2012 Mater. Chem. Phys. 132 233

Google Scholar

Google Scholar

[19] Yan X H, Liaw P K, Zhang Y 2021 Metall. Mater. Trans. A 52 2111

Google Scholar

Google Scholar

[20] Wu G, Liu C, Yan Y Q, Liu S D, Ma X Y, Yue S Y, Shan Z W 2024 Nat. Commun. 15 1223

Google Scholar

Google Scholar

[21] Wu G, Liu S D, Wang Q, Rao J, Xia W Z, Yan Y Q, Eckert J, Liu C, Ma E, Shan Z W 2023 Nat. Commun. 14 3670

Google Scholar

Google Scholar

[22] Miracle D B, Senkov O N 2017 Acta Mater. 122 448

Google Scholar

Google Scholar

[23] Lei Z F, Liu X J, Wu Y, Wang H, Jiang S H, Wang S D, Hui X D, Wu Y D, Gault B, Kontis P, Raabe D, Gu L, Zhang Q H, Chen H W, Wang H T, Liu J B, An K, Zeng Q S, Nieh T G, Lu Z P 2018 Nature 563 546

Google Scholar

Google Scholar

[24] Soni V, Gwalani B, Senkov O N, Viswanathan B, Alam T, Miracle D B, Banerjee R 2018 J. Mater. Res. 33 3235

Google Scholar

Google Scholar

[25] Soni V, Senkov O N, Gwalani B, Miracle D B, Banerjee R 2018 Sci. Rep. 8 8816

Google Scholar

Google Scholar

[26] Soni V, Gwalani B, Alam T, Dasari S, Zheng Y, Senkov O N, Miracle D, Banerjee R 2020 Acta Mater. 185 89

Google Scholar

Google Scholar

[27] Huang X J, Miao J S, Luo A A 2018 J. Mater. Sci. 54 2271

Google Scholar

Google Scholar

[28] Huang X J, Miao J S, Luo A A 2022 Scr. Mater. 210 114462

Google Scholar

Google Scholar

[29] Sundman B, Chen Q, Du Y 2018 J. Phase Equilib. Diffus. 39 678

Google Scholar

Google Scholar

[30] Singh P, Johnson D D 2021 J. Mater. Res. 37 136

Google Scholar

Google Scholar

[31] Zhang Y, Zuo T T, Tang Z, Gao M C, Dahmen K A, Liaw P K, Lu Z P 2014 Prog. Mater Sci. 61 1

Google Scholar

Google Scholar

[32] Gu X Y, Zhuang Y X, Jia P 2022 Mater. Sci. Eng. A 840 142983

Google Scholar

Google Scholar

[33] Cheng P, Zhao Y H, Xu X T, Wang S, Sun Y Y, Hou H 2020 Mater. Sci. Eng. A 772 138681

Google Scholar

Google Scholar

[34] Zhu J M, Fu H M, Zhang H F, Wang A M, Li H, Hu Z Q 2010 Mater. Sci. Eng. A 527 7210

Google Scholar

Google Scholar

[35] 林应征, 杨洪宇, 陈芳, 颜建辉 2023 材料热处理学报 44 69

Google Scholar

Google Scholar

Lin Y Z, Yang H Y, Chen F, Yan J H 2023 Trans. Mater. Heat Treat. 44 69

Google Scholar

Google Scholar

[36] Babilas R, Łoński W, Boryło P, Kądziołka Gaweł M, Gębara P, Radoń A 2020 J. Magn. Magn. Mater. 502 166492

Google Scholar

Google Scholar

[37] Zhang H, Pan Y, He Y Z 2011 J. Therm. Spray Technol. 20 1049

Google Scholar

Google Scholar

[38] Zhang S Y, Han B, Li M Y, Zhang Q, Hu C Y, Jia C X, Li Y, Wang Y 2021 Surf. Coat. Technol. 417 127218

Google Scholar

Google Scholar

[39] Santodonato L J, Liaw P K, Unocic R R, Bei H, Morris J R 2018 Nat. Commun. 9 4520

Google Scholar

Google Scholar

[40] Torralba J M, Alvaredo P, García Junceda A 2020 Powder Metall. 63 227

Google Scholar

Google Scholar

[41] Brif Y, Thomas M, Todd I 2015 Scr. Mater. 99 93

Google Scholar

Google Scholar

[42] Han C J, Fang Q H, Shi Y S, Tor S B, Chua C K, Zhou K 2020 Adv. Mater. 32 1903855

Google Scholar

Google Scholar

[43] Luo J, Wang J, Su C, Geng Y, Chen X 2024 J. Mater. Eng. Perform. 33 12413

Google Scholar

Google Scholar

[44] Shun T T, Hung C H, Lee C F 2010 J. Alloys Compd. 493 105

Google Scholar

Google Scholar

[45] Hazen R M, Navrotsky A 1996 Am. Mineral. 81 1021

Google Scholar

Google Scholar

[46] Starenchenko S V 2012 Russ. Phys. J. 54 965

Google Scholar

Google Scholar

[47] Ma Y M, Fan J T, Zhang L J, Zhang M D, Cui P, Dong W Q, Yu P F, Li Y C, Liaw P K, Li G 2018 Intermetallics 103 63

Google Scholar

Google Scholar

[48] Ma L L, Wang L, Nie Z H, Wang F C, Xue Y F, Zhou J L, Cao T Q, Wang Y D, Ren Y 2017 Acta Mater. 128 12

Google Scholar

Google Scholar

[49] Ji C W, Ma A, Jiang J H 2022 J. Alloys Compd. 900 163508

Google Scholar

Google Scholar

[50] Kumar A, Dhekne P, Swarnakar A K, Chopkar M 2018 Mater. Res. Express 6 026532

Google Scholar

Google Scholar

[51] Lin T X, Feng M Y, Lian G F, Lu H, Chen C R, Huang X 2024 Mater. Charact. 216 114246

Google Scholar

Google Scholar

[52] Li Z, Taheri M, Torkamany P, Heidarpour I, Torkamany M J 2024 Vacuum 219 112749

Google Scholar

Google Scholar

[53] Shang X L, Wang Z J, He F, Wang J C, Li J J, Yu J K 2017 Sci. China Technol. Sci. 61 189

Google Scholar

Google Scholar

[54] Wang S, Wu Y, Gesmundo F, Niu Y 2008 Oxid. Met. 69 299

Google Scholar

Google Scholar

[55] Jiang S M, Xu C Z, Li H Q, Liu S C, Gong J, Sun C 2010 Corros. Sci. 52 435

Google Scholar

Google Scholar

[56] Zuo T T, Li R B, Ren X J, Zhang Y 2014 J. Magn. Magn. Mater. 371 60

Google Scholar

Google Scholar

[57] Wen J J, Liu X, Li Z H, Li W W 2023 J. Alloys Compd. 934 167622

Google Scholar

Google Scholar

[58] Su Y, Lei X C, Chen W J, Su Y P, Liu H W, Ren S Y, Tong R Y, Lin Y T, Jiang W J, Liu X Z, Su D, Zhang Y G 2024 Chem. Eng. J. 500 157197

Google Scholar

Google Scholar

[59] Lei X C, Wang Y Y, Wang J Y, Su Y, Ji P X, Liu X Z, Guo S N, Wang X F, Hu Q M, Gu L, Zhang Y G, Yang R, Zhou G, Su D 2023 Small Methods 8 2300754

Google Scholar

Google Scholar

计量

- 文章访问数: 258

- PDF下载量: 41

- 被引次数: 0

下载:

下载: