-

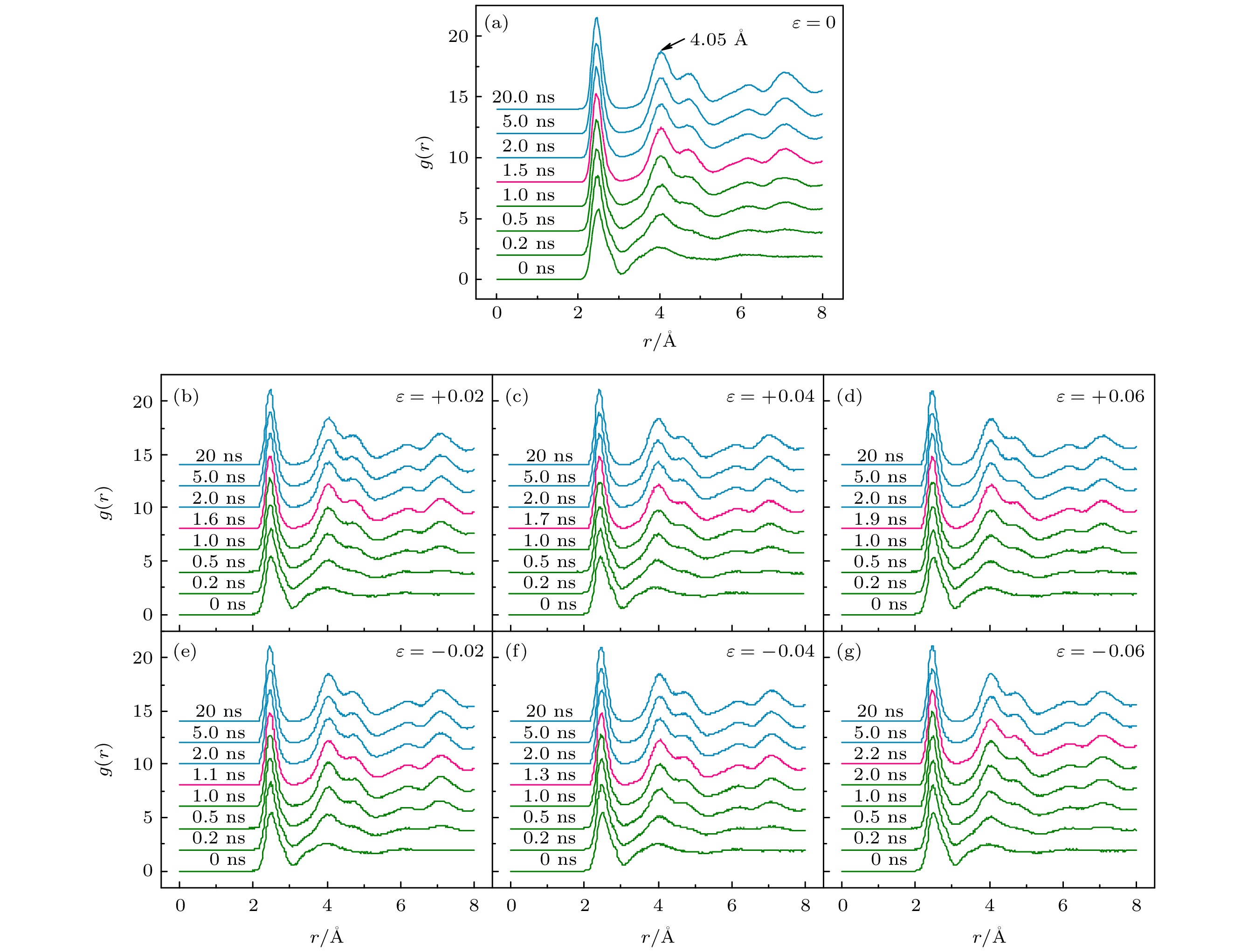

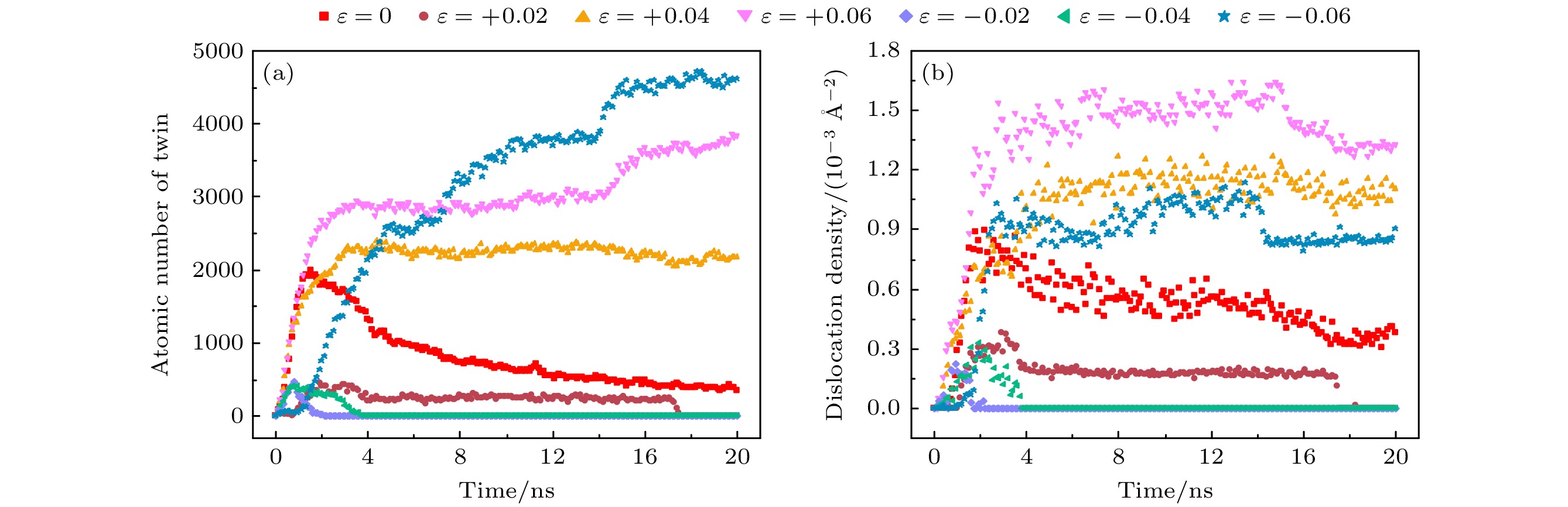

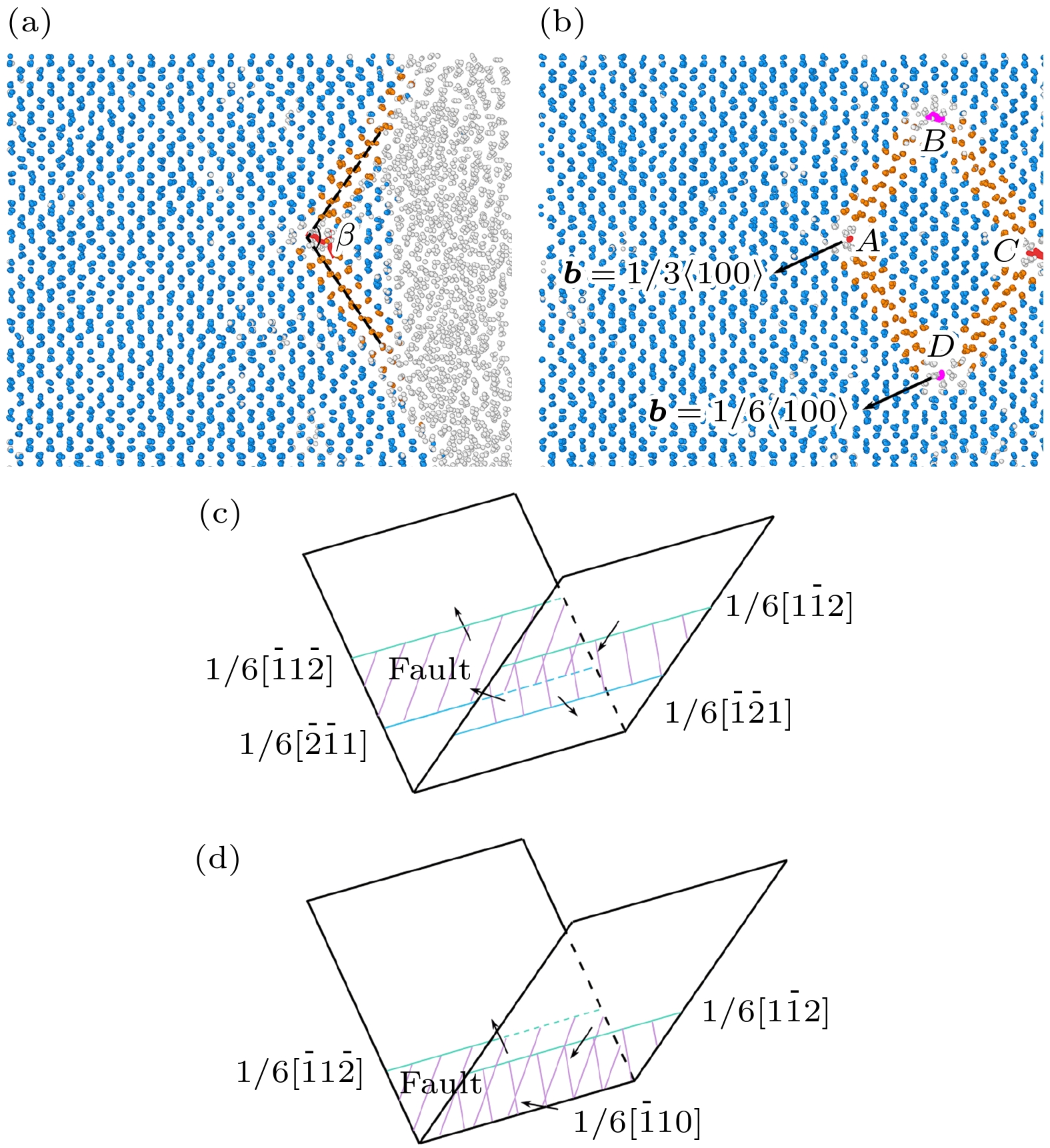

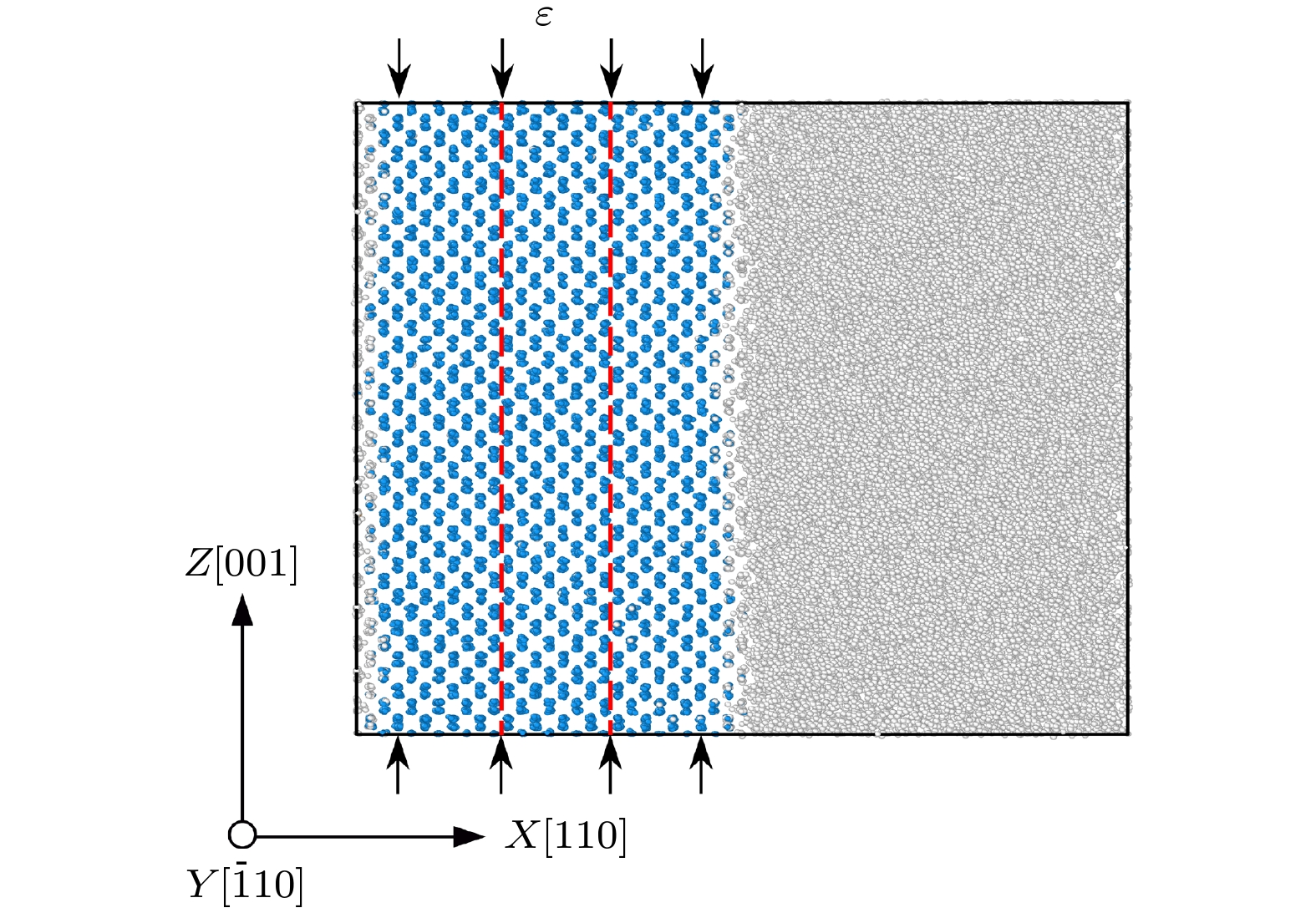

GaAs晶体的高质量生长对于制造高性能高频微波电子器件和发光器件具有重要意义. 本文通过分子动力学方法对GaAs晶体沿[110]晶向的诱导结晶进行模拟, 并采用最大标准团簇分析、双体分布函数和可视化等方法研究应变对生长过程和缺陷形成的影响. 结果表明, 不同应变条件下GaAs晶体的结晶过程发生显著变化. 在初始阶段, 施加一定拉应变和较大的压应变后, 体系的晶体生长速率发生降低, 且应变越大, 结晶速率越低. 此外, 随着晶体的生长, 体系形成以{111}小平面为边界的锯齿形界面, 生长平面与{111}小平面之间的夹角影响固液界面的形态, 进而影响孪晶的形成. 施加拉应变越大, 此夹角越小, 形成孪晶缺陷越多, 结构越不规则. 同时, 体系中极大部分的位错与孪晶存在伴生关系, 应变的施加可以抑制或促进位错的形核, 合适的应变甚至可以使晶体无位错生长. 本文从原子尺度上研究GaAs的微观结构演化, 可为晶体生长理论提供理论指导.The high-quality growth of GaAs crystals is extremely essential for the fabrication of high-performance high-frequency microwave electronic devices and light-emitting devices. In this work, the molecular dynamics (MD) simulation is used to simulate the induced crystallization of GaAs crystal along the [110] orientation. The effects of strain on the growth process and defect formation are analyzed by the largest standard cluster analysis, the pair distribution function, and visualization analysis. The results indicate that the crystallization process of GaAs crystal changes significantly under different strain conditions. At the initial stage, the crystal growth rate of the system decreases after a certain tensile strain and a large compressive strain have been applied, and the greater the strain, the lower the crystallization rate is. In addition, as the crystal grows, the system forms a zigzag interface bounded by the {111} facet, and the angle between the growth plane and the {111} facet affects the morphology of the solid-liquid interface and further affects the formation of twins. The larger the applied tensile strain and the smaller the angle, the more twin defects will form and the more irregular they will be. At the same time, a large proportion of the dislocations in the system is associated with twins. The application of strain can either inhibit or promote the nucleation of dislocations, and under an appropriate amount of strain size, crystals without dislocations can even grow. The study of the microstructural evolution of GaAs on an atomic scale provides a reference for crystal growth theory.

-

Keywords:

- molecular dynamics /

- GaAs /

- induced crystallization /

- strain

[1] Santos Gomes B, Masia F 2022 Journal of Colloid and Interface Science 625 743

Google Scholar

Google Scholar

[2] 王鹏华, 唐吉龙, 亢玉彬, 方铉, 房丹, 王登魁, 林逢源, 王晓华, 魏志鹏 2019 68 087803

Google Scholar

Google Scholar

Wang P H, Tang J L, Kang Y B, Fang X, Fang D, Wang D K, Lin F Y, Wang X H, Wei Z P 2019 Acta Phys. Sin. 68 087803

Google Scholar

Google Scholar

[3] Carter M A, Mottram A, Peaker A R, Sudlow P D, White T 1971 Nature 232 469

Google Scholar

Google Scholar

[4] Chuang L C, Sedgwick F G, Chen R, Ko W S, Moewe M, Ng K W, Tran T T D, Chang-Hasnain C 2011 Nano Lett. 11 385

Google Scholar

Google Scholar

[5] Currie M, Dianat P, Persano A, Martucci M C, Quaranta F, Cola A, Nabet B 2013 Sensors 13 2475

Google Scholar

Google Scholar

[6] Ukita H, Uenishi Y, Tanaka H 1993 Science 260 786

Google Scholar

Google Scholar

[7] Mangla O, Roy S 2020 Materials Letters 274 128036

Google Scholar

Google Scholar

[8] Papež N, Dallaev R, Ţălu Ş, Kaštyl J 2021 Materials 14 3075

Google Scholar

Google Scholar

[9] Ghalgaoui A, Reimann K, Woerner M, Elsaesser T, Flytzanis C, Biermann K 2018 Phys. Rev. Lett. 121 266602

Google Scholar

Google Scholar

[10] Whelan J M, Wheatley G H 1958 J. Phys. Chem. Solids 6 169

Google Scholar

Google Scholar

[11] Wu T, Wei J, Liu H, Ma S, Chen Y, Ren J 2021 Electronics 10 1482

Google Scholar

Google Scholar

[12] Murakami M 2002 Sci. Technol. Adv. Mater. 3 1

Google Scholar

Google Scholar

[13] Jiang P, Balram K C 2020 Opt. Express 28 12262

Google Scholar

Google Scholar

[14] Zhan L, Xia F, Xia Y, Xie B 2018 ACS Sustainable Chem. Eng. 6 1336

Google Scholar

Google Scholar

[15] Sosso G C, Chen J, Cox S J, Fitzner M, Pedevilla P, Zen A, Michaelides A 2016 Chem. Rev. 116 7078

Google Scholar

Google Scholar

[16] Shibuta Y, Sakane S, Miyoshi E, Okita S, Takaki T, Ohno M 2017 Nat. Communica. 8 10

Google Scholar

Google Scholar

[17] Jia T, Wang Z, Tang M, Xue Y, Huang G, Nie X, Lai S, Ma W, He B, Gou S 2022 Nanomaterials 12 611

Google Scholar

Google Scholar

[18] Thu H T T, Hoang V V 2010 Computa. Mater. Sci. 49 S221

Google Scholar

Google Scholar

[19] Luo J, Gao T, Ren L, Xie Q, Tian Z, Chen Q, Liang Y 2019 Mater. Sci. Semicon. Proc. 104 104680

Google Scholar

Google Scholar

[20] Gulluoglu A N, Zhu X, Tsai C T 2001 J. Mater. Sci. 36 3557

Google Scholar

Google Scholar

[21] Meduoye G O, Bacon D J, Evans K E 1988 J. Crystal Growth 88 397

Google Scholar

Google Scholar

[22] Subramanyam N, Tsai C T 1995 J. Mater. Proc. Technol. 55 278

Google Scholar

Google Scholar

[23] Zhu X A, Tsai C T 2004 Computa. Mater. Sci. 29 334

Google Scholar

Google Scholar

[24] Gulluoglu A N, Tsai C T, Hartley C S, Chait A 1994 Model. Simul. Mater. Sci. Eng. 2 67

Google Scholar

Google Scholar

[25] Pavia F, Curtin W A 2015 Model. Simul. Mater. Sci. Eng. 23 055002

Google Scholar

Google Scholar

[26] Plimpton S 1995 J. Computa. Phys. 117 1

Google Scholar

Google Scholar

[27] Albe K, Nordlund K, Nord J, Kuronen A 2002 Phys. Rev. B 66 035205

Google Scholar

Google Scholar

[28] Fichthorn K A, Tiwary Y, Hammerschmidt T, Kratzer P, Scheffler M 2011 Phys. Rev. B 83 195328

Google Scholar

Google Scholar

[29] 陈庆, 陈茜, 梁永超, 高廷红, 田泽安, 谢泉 2017 科学通报 62 1386

Google Scholar

Google Scholar

Chen Q, Chen Q, Liang Y C, Gao T H, Tian Z A, Xie Q 2017 Chin. Sci. Bulletin 62 1386

Google Scholar

Google Scholar

[30] Hoover W G 1985 Phys. Rev. A 31 1695

Google Scholar

Google Scholar

[31] Tian Z A, Liu R S, Dong K J, Yu A B 2011 EPL 96 36001

Google Scholar

Google Scholar

[32] Terban M W, Billinge S J L 2022 Chem. Rev. 122 1208

Google Scholar

Google Scholar

[33] Tian Z A, Dong K J, Yu A B 2013 AIP Confer. Proc. 1542 373

Google Scholar

Google Scholar

[34] 韦国翠, 田泽安 2021 70 246401

Google Scholar

Google Scholar

Wei G C, Tian Z A 2021 Acta Phys. Sin. 70 246401

Google Scholar

Google Scholar

[35] Hu L, Tian Z, Liang Y, Gao T, Chen Q, Zheng Q, Luo Y, Xie Q 2022 J. Alloys Compounds 897 162743

Google Scholar

Google Scholar

[36] Richert R, Angell C A 1998 J. Chem. Phys. 108 9016

Google Scholar

Google Scholar

[37] Capaccioli S, Prevosto D, Lucchesi M, Amirkhani M, Rolla P 2009 J. Non-Crystalline Solids 355 753

Google Scholar

Google Scholar

[38] Scott G D, Mader D L 1964 Nature 201 382

Google Scholar

Google Scholar

[39] Finney J L, Bernal J D 1997 Proc. Royal Society of London. A. Mathemat. Phys. Sci. 319 479

Google Scholar

Google Scholar

[40] Sheng H W, Luo W K, Alamgir F M, Bai J M, Ma E 2006 Nature 439 419

Google Scholar

Google Scholar

[41] Stukowski A, Bulatov V V, Arsenlis A 2012 Model. Simul. Mater. Sci. Eng. 20 085007

Google Scholar

Google Scholar

[42] Liu C S, Xia J, Zhu Z G, Sun D Y 2001 J. Chem. Phys. 114 7506

Google Scholar

Google Scholar

[43] Stukowski A 2009 Model. Simul. Mater. Sci. Eng. 18 015012

Google Scholar

Google Scholar

[44] Li D H, Moore R A, Wang S 1988 J. Chem. Phys. 89 4309

Google Scholar

Google Scholar

[45] Mitchell T E, Unal O 1991 J. Electro. Mater. 20 723

Google Scholar

Google Scholar

-

图 6 不同应变下GaAs诱导式结晶体系的微观结构演变过程 (蓝色原子代表闪锌矿结构原子; 黄色原子代表纤锌矿结构原子; 白色原子代表其他类型的无序原子)

Fig. 6. Microstructural evolution of GaAs-induced crystallization systems at different strains (Blue atoms represent zinc-blende structure atoms; yellow atoms represent wurtzite structure atoms; white atoms are other types of disordered atoms).

参数 Ga—Ga As—As Ga—As γ 0.007874 0.455 0.0166 S 1.11 1.86 1.1417 d 0.75 0.1612 0.56 β/Å–1 1.08 1.435 1.5228 D0/eV 1.40 3.96 2.10 R0/Å 2.3235 2.10 2.35 c 1.918 0.1186 1.29 h = cosθ0 0.3013 0.07748 0.237 α/Å–1 1.846 3.161 0 Rc/Å 2.95 3.40 3.10 D/Å 0.15 0.20 0.20 -

[1] Santos Gomes B, Masia F 2022 Journal of Colloid and Interface Science 625 743

Google Scholar

Google Scholar

[2] 王鹏华, 唐吉龙, 亢玉彬, 方铉, 房丹, 王登魁, 林逢源, 王晓华, 魏志鹏 2019 68 087803

Google Scholar

Google Scholar

Wang P H, Tang J L, Kang Y B, Fang X, Fang D, Wang D K, Lin F Y, Wang X H, Wei Z P 2019 Acta Phys. Sin. 68 087803

Google Scholar

Google Scholar

[3] Carter M A, Mottram A, Peaker A R, Sudlow P D, White T 1971 Nature 232 469

Google Scholar

Google Scholar

[4] Chuang L C, Sedgwick F G, Chen R, Ko W S, Moewe M, Ng K W, Tran T T D, Chang-Hasnain C 2011 Nano Lett. 11 385

Google Scholar

Google Scholar

[5] Currie M, Dianat P, Persano A, Martucci M C, Quaranta F, Cola A, Nabet B 2013 Sensors 13 2475

Google Scholar

Google Scholar

[6] Ukita H, Uenishi Y, Tanaka H 1993 Science 260 786

Google Scholar

Google Scholar

[7] Mangla O, Roy S 2020 Materials Letters 274 128036

Google Scholar

Google Scholar

[8] Papež N, Dallaev R, Ţălu Ş, Kaštyl J 2021 Materials 14 3075

Google Scholar

Google Scholar

[9] Ghalgaoui A, Reimann K, Woerner M, Elsaesser T, Flytzanis C, Biermann K 2018 Phys. Rev. Lett. 121 266602

Google Scholar

Google Scholar

[10] Whelan J M, Wheatley G H 1958 J. Phys. Chem. Solids 6 169

Google Scholar

Google Scholar

[11] Wu T, Wei J, Liu H, Ma S, Chen Y, Ren J 2021 Electronics 10 1482

Google Scholar

Google Scholar

[12] Murakami M 2002 Sci. Technol. Adv. Mater. 3 1

Google Scholar

Google Scholar

[13] Jiang P, Balram K C 2020 Opt. Express 28 12262

Google Scholar

Google Scholar

[14] Zhan L, Xia F, Xia Y, Xie B 2018 ACS Sustainable Chem. Eng. 6 1336

Google Scholar

Google Scholar

[15] Sosso G C, Chen J, Cox S J, Fitzner M, Pedevilla P, Zen A, Michaelides A 2016 Chem. Rev. 116 7078

Google Scholar

Google Scholar

[16] Shibuta Y, Sakane S, Miyoshi E, Okita S, Takaki T, Ohno M 2017 Nat. Communica. 8 10

Google Scholar

Google Scholar

[17] Jia T, Wang Z, Tang M, Xue Y, Huang G, Nie X, Lai S, Ma W, He B, Gou S 2022 Nanomaterials 12 611

Google Scholar

Google Scholar

[18] Thu H T T, Hoang V V 2010 Computa. Mater. Sci. 49 S221

Google Scholar

Google Scholar

[19] Luo J, Gao T, Ren L, Xie Q, Tian Z, Chen Q, Liang Y 2019 Mater. Sci. Semicon. Proc. 104 104680

Google Scholar

Google Scholar

[20] Gulluoglu A N, Zhu X, Tsai C T 2001 J. Mater. Sci. 36 3557

Google Scholar

Google Scholar

[21] Meduoye G O, Bacon D J, Evans K E 1988 J. Crystal Growth 88 397

Google Scholar

Google Scholar

[22] Subramanyam N, Tsai C T 1995 J. Mater. Proc. Technol. 55 278

Google Scholar

Google Scholar

[23] Zhu X A, Tsai C T 2004 Computa. Mater. Sci. 29 334

Google Scholar

Google Scholar

[24] Gulluoglu A N, Tsai C T, Hartley C S, Chait A 1994 Model. Simul. Mater. Sci. Eng. 2 67

Google Scholar

Google Scholar

[25] Pavia F, Curtin W A 2015 Model. Simul. Mater. Sci. Eng. 23 055002

Google Scholar

Google Scholar

[26] Plimpton S 1995 J. Computa. Phys. 117 1

Google Scholar

Google Scholar

[27] Albe K, Nordlund K, Nord J, Kuronen A 2002 Phys. Rev. B 66 035205

Google Scholar

Google Scholar

[28] Fichthorn K A, Tiwary Y, Hammerschmidt T, Kratzer P, Scheffler M 2011 Phys. Rev. B 83 195328

Google Scholar

Google Scholar

[29] 陈庆, 陈茜, 梁永超, 高廷红, 田泽安, 谢泉 2017 科学通报 62 1386

Google Scholar

Google Scholar

Chen Q, Chen Q, Liang Y C, Gao T H, Tian Z A, Xie Q 2017 Chin. Sci. Bulletin 62 1386

Google Scholar

Google Scholar

[30] Hoover W G 1985 Phys. Rev. A 31 1695

Google Scholar

Google Scholar

[31] Tian Z A, Liu R S, Dong K J, Yu A B 2011 EPL 96 36001

Google Scholar

Google Scholar

[32] Terban M W, Billinge S J L 2022 Chem. Rev. 122 1208

Google Scholar

Google Scholar

[33] Tian Z A, Dong K J, Yu A B 2013 AIP Confer. Proc. 1542 373

Google Scholar

Google Scholar

[34] 韦国翠, 田泽安 2021 70 246401

Google Scholar

Google Scholar

Wei G C, Tian Z A 2021 Acta Phys. Sin. 70 246401

Google Scholar

Google Scholar

[35] Hu L, Tian Z, Liang Y, Gao T, Chen Q, Zheng Q, Luo Y, Xie Q 2022 J. Alloys Compounds 897 162743

Google Scholar

Google Scholar

[36] Richert R, Angell C A 1998 J. Chem. Phys. 108 9016

Google Scholar

Google Scholar

[37] Capaccioli S, Prevosto D, Lucchesi M, Amirkhani M, Rolla P 2009 J. Non-Crystalline Solids 355 753

Google Scholar

Google Scholar

[38] Scott G D, Mader D L 1964 Nature 201 382

Google Scholar

Google Scholar

[39] Finney J L, Bernal J D 1997 Proc. Royal Society of London. A. Mathemat. Phys. Sci. 319 479

Google Scholar

Google Scholar

[40] Sheng H W, Luo W K, Alamgir F M, Bai J M, Ma E 2006 Nature 439 419

Google Scholar

Google Scholar

[41] Stukowski A, Bulatov V V, Arsenlis A 2012 Model. Simul. Mater. Sci. Eng. 20 085007

Google Scholar

Google Scholar

[42] Liu C S, Xia J, Zhu Z G, Sun D Y 2001 J. Chem. Phys. 114 7506

Google Scholar

Google Scholar

[43] Stukowski A 2009 Model. Simul. Mater. Sci. Eng. 18 015012

Google Scholar

Google Scholar

[44] Li D H, Moore R A, Wang S 1988 J. Chem. Phys. 89 4309

Google Scholar

Google Scholar

[45] Mitchell T E, Unal O 1991 J. Electro. Mater. 20 723

Google Scholar

Google Scholar

计量

- 文章访问数: 7742

- PDF下载量: 139

- 被引次数: 0

下载:

下载: