-

二维二硫化钨(WS2)作为一种具有层依赖的电子和光电特性的半导体材料, 在光电器件领域展现出极具潜力的应用前景. 当前, 晶圆级单层WS2薄膜的制备是推动其在先进晶体管和集成电路中应用的关键挑战. 化学气相沉积(CVD)能够实现大尺寸、高质量的单层WS2薄膜合成, 但其生长过程的复杂性导致了WS2生长效率低, 质量参差不齐. 为指导实验上减少WS2晶界, 提高薄膜质量以增强其电子性能和机械稳定性, 本文基于第一性原理的理论计算, 深入探讨了WS2在CVD生长过程中的成核机制. 通过引入化学势这一变量, 分析了不同实验条件下WS2的生长能量曲线, 发现调整前驱体钨源和硫源的温度或压强能有效控制WS2的成核速率. 特别是当钨源温度为1250 K时, 成核速率达到最大, 而提高硫源温度或降低硫源压强则能降低成核速率, 从而提高单层WS2的结晶度和均匀性. 这些理论计算结果为实验中根据需求精确调整成核速率提供了坚实的理论依据, 并为如何通过优化实验参数来提高单层WS2薄膜的结晶度和均匀性提供了理论指导, 有望推动WS2材料在各类高性能电子器件中的应用发展, 对未来材料科学和工业应用具有重要意义.Two-dimensional tungsten disulfide (WS2), as a semiconductor material with unique layer-dependent electronic and optoelectronic characteristics, demonstrates a promising application prospect in the field of optoelectronic devices. The fabrication of wafer-scale monolayer WS2 films is currently a critical challenge that propels their application in advanced transistors and integrated circuits. Chemical vapor deposition (CVD) is a feasible technique for fabricating large-area, high-quality monolayer WS2 films, yet the complexity of its growth process results in low growth efficiency and inconsistent film quality of WS2. In order to guide experimental efforts to diminish grain boundaries in WS2, thereby improving film quality to enhance electronic performance and mechanical stability, this study investigates the nucleation mechanisms of WS2 during CVD growth through first-principles theoretical calculations. By considering chemical potential as a crucial variable, we analyze the growth energy curves of WS2 under diverse experimental conditions. Our findings demonstrate that modulating the temperature or pressure of the tungsten and sulfur precursors can decisively influence the nucleation rate of WS2. Notably, the nucleation rate reaches a peak at a tungsten source temperature of 1250 K, while an increase in sulfur source temperature or a decrease in pressure can suppress the nucleation rate, thereby enhancing the crystallinity and uniformity of monolayer WS2. These insights not only furnish a robust theoretical foundation for experimentally fine-tuning the nucleation rate as needed but also provide strategic guidance for optimizing experimental parameters to refine the crystallinity and uniformity of monolayer WS2 films. Such advancements are expected to accelerate the deployment of WS2 materials in a range of high-performance electronic devices, marking a significant stride in the field of materials science and industrial applications.

-

Keywords:

- first-principles calculation /

- growth mechanism /

- chemical vapor deposition /

- two-dimensional tungsten disulfide

[1] Zhao W J, Ghorannevis Z, Chu L Q, Toh M L, Kloc C, Tan P H, Eda G 2013 ACS Nano 7 791

Google Scholar

Google Scholar

[2] Ovchinnikov D, Allain A, Huang Y S, Dumcenco D, Kis A 2014 ACS Nano 8 8174

Google Scholar

Google Scholar

[3] Ding D G, Wang S, Xia Y P, Li P, He D L, Zhang J Q, Zhao S W, Yu G H, Zheng Y H, Cheng Y, Xie M H, Ding F, Jin C H 2022 ACS Nano 16 17356

Google Scholar

Google Scholar

[4] Falin A, Holwill M, Lü H F, Gan W, Cheng J, Zhang R, Qian D, Barnett M R, Santos E J G, Novoselov K S, Tao T, Wu X J, Lu H L 2021 ACS Nano 15 2600

Google Scholar

Google Scholar

[5] 陈蓉, 王远帆, 王熠欣, 梁前, 谢泉 2022 71 127301

Google Scholar

Google Scholar

Chen R, Wang Y F, Wang Y X, Liang Q, Xie Q 2022 Acta Phys. Sin. 71 127301

Google Scholar

Google Scholar

[6] Mahler B, Hoepfner V, Liao K, Ozin G A 2014 J. Am. Chem. Soc. 136 14121

Google Scholar

Google Scholar

[7] Kuc A, Zibouche N, Heine T 2011 Phy. Rev. B 83 245213

Google Scholar

Google Scholar

[8] Wu J M, Li L H, Zheng W H, Zheng B Y, Xu Z Y, Zhang X H, Zhu C G, Wu K, Zhang C, Jiang Y 2022 Chin. Phys. B 31 057803

Google Scholar

Google Scholar

[9] Huo N J, Yang S X, Wei Z M, Li S S, Xia J B, Li J B 2014 Sci. Rep. 4 5209

Google Scholar

Google Scholar

[10] Chernikov A, Ruppert C, Hill H M, Rigosi A F, Heinz T F 2015 Nat. Photonics 9 466

Google Scholar

Google Scholar

[11] Bin Rafiq M K S, Amin N, Alharbi H F, Luqman M, Ayob A, Alharthi Y S, Alharthi N H, Bais B, Akhtaruzzaman M 2020 Sci. Rep. 10 771

Google Scholar

Google Scholar

[12] Han L X, Yang M, Wen P T, Gao W, Huo N J, Li J B 2021 Nanoscale. Adv. 3 2657

Google Scholar

Google Scholar

[13] Pawbake A S, Waykar R G, Late D J, Jadkar S R 2016 ACS Appl. Mater. Interfaces 8 3359

Google Scholar

Google Scholar

[14] Wang H C, Lin Y H, Liu X, Deng X H, Ben J W, Yu W J, Zhu D L, Liu X K 2023 Chin. Phys. B 32 018504

Google Scholar

Google Scholar

[15] Chakraborty B, Gu J, Khatoniar M, Menon V M 2019 2019 Conference on Lasers and Electro-Optics IEEE Munich, Germany, June 23–27, 2019

[16] Xu Z Q, Zhang Y P, Lin S H, Zheng C X, Zhong Y L, Xia X, Li Z P, Sophia P J, Fuhrer M S, Cheng Y B, Bao Q L 2015 ACS Nano 9 6178

Google Scholar

Google Scholar

[17] Wan Y, Li E, Yu Z H, Huang J K, Li M Y, Chou A S, Lee Y T, Lee C J, Hsu H C, Zhan Q, Aljarb A, Fu J H, Chiu S P, Wang X R, Lin J J, Chiu S P, Chang W H, Wang H, Shi Y, Lin N, Cheng Y C, Tung V, Li L J 2022 Nat. Commun. 13 4149

Google Scholar

Google Scholar

[18] Zribi R, Crispi S, Giusi D, Zhukush M, Ampelli C, Shen C, Raza M H, Pinna N, Neri G 2024 ACS Appl. Nano Mater. 7 4998

Google Scholar

Google Scholar

[19] Georgiou T, Jalil R, Belle B D, Britnell L, Gorbachev R V, Morozov S V, Kim Y J, Gholinia A, Haigh S J, Makarovsky O, Eaves L, Ponomarenko L A, Geim A K, Novoselov K S, Mishchenko A 2012 Nat. Nanotechnol. 8 100

Google Scholar

Google Scholar

[20] Xu Z H, Lü Y F, Li J Z, Huang F, Nie P B, Zhang S W, Zhao S C, Zhao S X, Wei G D 2019 RSC Adv. 9 29628

Google Scholar

Google Scholar

[21] Chubarov M, Choudhury T H, Hickey D R, Bachu S, Zhang T, Sebastian A, Bansal A, Zhu H, Trainor N, Das S, Terrones M, Alem N, Redwing J M 2021 ACS Nano 15 2532

Google Scholar

Google Scholar

[22] Loh T A J, Chua D H C, Wee A T S 2015 Sci. Rep. 5 18116

Google Scholar

Google Scholar

[23] Zeng H L, Liu G B, Dai J F, Yan Y J, Zhu B R, He R C, Xie L, Xu S J, Chen X H, Yao W, Cui X D 2013 Sci. Rep. 3 1608

Google Scholar

Google Scholar

[24] 王铄, 王文辉, 吕俊鹏, 倪振华 2021 70 026802

Google Scholar

Google Scholar

Wang S, Wang W H, Lü J P, Ni Z H 2021 Acta Phys. Sin. 70 026802

Google Scholar

Google Scholar

[25] Meng L, Hu S, Yan W, Feng J, Li H, Yan X H 2020 Chem. Phys. Lett. 739 136945

Google Scholar

Google Scholar

[26] Rong Y M, Fan Y, Leen Koh A, Robertson A W, He K, Wang S S, Tan H J, Sinclair R, Warner J H 2014 Nanoscale 6 12096

Google Scholar

Google Scholar

[27] Richey N E, Haines C, Tami J L, McElwee-White L 2017 Chem. Commun. 53 7728

Google Scholar

Google Scholar

[28] Xie Y, Ma X H, Wang Z, Nan T, Wu R X, Zhang P, Wang H L, Wang Y B, Zhan Y J, Hao Y 2018 MRS Adv. 3 365

Google Scholar

Google Scholar

[29] Cong C X, Shang J Z, Wu X, Cao B C, Peimyoo N, Qiu C Y, Sun L T, Yu T 2013 Adv. Opt. Mater. 2 131

Google Scholar

Google Scholar

[30] Gao Y, Liu Z B, Sun D M, Huang L, Ma L P, Yin L C, Ma T, Zhang Z Y, Ma X L, Peng L M, Cheng H M, Ren W C 2015 Nat. Commun. 6 8569

Google Scholar

Google Scholar

[31] Zhang G X, Wang C X, Yan B, Ning B, Zhao Y, Zhou D H, Shi X, Chen S K, Shen J, Xiao Z Y, Zhao H Q 2022 J. Mater. Sci. Mater. Electron. 33 22560

Google Scholar

Google Scholar

[32] Liu P, Li X X, Ai H X, Shen Y, Deng J, Ding X L, Wang W J 2023 J. Phys. Chem. C 127 21204

Google Scholar

Google Scholar

[33] Huang L Y, Li M Y, Liew S L, Lin S C, Chou A S, Hsu M C, Hsu C H, Lin Y T, Mao P S, Hou D H, Liu W C, Wu C I, Chang W H, Wang H, Li L J, Wei K H 2023 ACS Mater. Lett. 5 1760

Google Scholar

Google Scholar

[34] Yang W H, Mu Y B, Chen X S, Jin N J, Song J H, Chen J J, Dong L X, Liu C R, Xuan W P, Zhou C J, Cong C X, Shang J S, He S L, Wang G F, Li J 2023 Discov. Nano 18 13

Google Scholar

Google Scholar

[35] Wang J H, Xu X Z, Cheng T, Gu L H, Qiao R X, Liang Z h, Ding D, Hong H, Zheng P M, Zhang Z B, Zhang Z H, Zhang S, Cui G L, Chang C, Huang C, Qi J, Liang J, Liu C, Zuo Y G, Xue G D, Fang X J, Tian J P, Wu M H, Guo Y, Yao Z X, Jiao Q Z, Liu L, Gao P, Li Q Y, Yang R, Zhang G Y, Tang Z X, Yu D P, Wang E, Lu J M, Zhao Y, Wu S W, Ding F, Liu K H 2022 Nat. Nanotechnol. 17 33

Google Scholar

Google Scholar

[36] Zhou W, Zou X, Najmaei S, Liu Z, Shi Y, Kong J, Lou J, Ajayan P M, Yakobson B I, Idrobo J C 2013 Nano Lett. 13 2615

Google Scholar

Google Scholar

[37] Qiu H, Xu T, Wang Z, Ren W, Nan H Y, Ni Z H, Chen Q, Yuan S J, Miao F, Song F Q, Long G, Shi Y, Sun L T, Wang J L, Wang X R 2013 Nat. Commun. 4 2642

Google Scholar

Google Scholar

[38] Su L Q, Yu Y F, Cao L Y, Zhang Y 2023 Sci. China Mater. 66 3949

Google Scholar

Google Scholar

[39] Thangaraja A, Shinde S M, Kalita G, Tanemura M 2015 Mater. Lett. 156 156

Google Scholar

Google Scholar

[40] Chen J, Shao K, Yang W H, Tang W Q, Zhou J P, He Q M, Wu Y P, Zhang C M, Li X, Yang X, Wu Z M, Kang J Y 2019 ACS Appl. Mater. Interfaces 11 19381

Google Scholar

Google Scholar

[41] Li C, Yamaguchi Y, Kaneko T, Kato T 2017 Appl. Phys. Express 10 075201

Google Scholar

Google Scholar

[42] Lan F F, Yang R X, Hao S, Zhou B Z, Sun K W, Cheng H J, Zhang S, Li L J, Jin L 2020 Appl. Surf. Sci. 504 144378

Google Scholar

Google Scholar

[43] Zhang Q H, Lu J F, Wang Z Y, Dai Z G, Zhang Y P, Huang F Z, Bao Q L, Duan W H, Fuhrer M S, Zheng C X 2018 Adv. Opt. Mater. 6 1701347

Google Scholar

Google Scholar

[44] Kang K N, Godin K, Yang E H 2015 Sci. Rep. 5 13205

Google Scholar

Google Scholar

[45] Shi B, Zhou D M, Qiu R S, Bahri M, Kong X D, Zhao H Q, Tlili C, Wang D Q 2020 Appl. Surf. Sci. 533 147479

Google Scholar

Google Scholar

[46] Yin H, Zhang X D, Lu J W, Geng X M, Wan Y F, Wu M Z, Yang P 2019 J. Mater. Sci 55 990

Google Scholar

Google Scholar

[47] Li K L, Wang W J 2020 J. Cryst. Growth 540 125645

Google Scholar

Google Scholar

[48] Dendzik M, Michiardi M, Sanders C, Bianchi M, Miwa J A, Grønborg S S, Lauritsen J V, Bruix A, Hammer B, Hofmann P 2015 Phy. Rev. B 92 245442

Google Scholar

Google Scholar

[49] Fuchtbauer H G, Tuxen A K, Moses P G, Topsoe H, Besenbacher F, Lauritsen J V 2013 Phys Chem. Chem. Phys. 15 15971

Google Scholar

Google Scholar

[50] Kresse G, Furthmuller J 1996 Comput. Mater. Sci 6 15

Google Scholar

Google Scholar

[51] Kresse G, Furthmuller J 1996 Phy. Rev. B 54 11169

Google Scholar

Google Scholar

[52] Perdew J P, Burke K, Ernzerhof M 1996 Phys. Rev. Lett. 77 3865

Google Scholar

Google Scholar

[53] Grimme S, Antony J, Ehrlich S, Krieg H 2010 J. Chem. Phys. 132 154104

Google Scholar

Google Scholar

[54] Blöchl P E 1994 Phy. Rev. B 50 17953

Google Scholar

Google Scholar

[55] Yue Y C, Chen J C, Zhang Y, Ding S, Zhao F L, Wang Y, Zhang D H, Li R J, Dong H L, Hu W P, Feng Y, Feng W 2018 ACS Appl. Mater. Interfaces 10 22435

Google Scholar

Google Scholar

[56] Gutiérrez H R, Perea-López N, Elías A L, Berkdemir A, Wang B, Lü R, López-Urías F, Crespi V H, Terrones H, Terrones M 2012 Nano Lett. 13 3447

Google Scholar

Google Scholar

[57] Misawa M, Tiwari S, Hong S, Krishnamoorthy A, Shimojo F, Kalia R K, Nakano A, Vashishta P 2017 J. Phys. Chem. Lett. 8 6206

Google Scholar

Google Scholar

[58] Gao J F, Yuan Q H, Hu H, Zhao J, Ding F 2011 J. Phys. Chem. C 115 17695

Google Scholar

Google Scholar

[59] Zhang W H, Wu P, Li Z Y, Yang J L 2011 J. Phys. Chem. C 115 17782

Google Scholar

Google Scholar

[60] Li X B, Zhang J B, Zhou N, Xu H, Yang R S 2021 ACS Appl. Electron. Mater. 3 5138

Google Scholar

Google Scholar

[61] Gao J F, Yip J, Zhao J, Yakobson B I, Ding F 2011 J. Am. Chem. Soc. 133 5009

Google Scholar

Google Scholar

[62] Regmi M, Chisholm M F, Eres G 2012 Carbon 50 134

Google Scholar

Google Scholar

[63] Lan S G, Zhang Z X, Hong Y K, She Y H, Pan B J, Xu Y, Wang P J 2023 Adv. Mater. Interfaces 10 2300713

Google Scholar

Google Scholar

[64] 刘兆肃, 刘国濠, 叶晓宜, 张仕源, 郑晓婷, 劳媚媚, 徐海涛 2021 材料研究与应用 15 486

Google Scholar

Google Scholar

Liu Z S, Liu G H, Ye X Y, Zhang S Y, Zheng X T, Lao M M, Xu H T 2021 Mater. Res. Appl. 15 486

Google Scholar

Google Scholar

[65] Babu Shinde N, Deul Ryu B, Hong C H, Francis B, Chandramohan S, Kumar Eswaran S 2021 Appl. Surf. Sci. 568 150908

Google Scholar

Google Scholar

-

图 1 (a)以W或S边终结的三角形WS2团簇的形成能(Ef)与其尺寸大小(N)的关系, $ {E_{\text{f}}} = {E_{{\text{tot}}}} - {N_{\text{W}}} \cdot {\mu _{{\text{W(ref)}}}} - {N_{\text{S}}} \cdot {\mu _{{\text{S(ref)}}}} $, 其中$ {E_{{\text{tot}}}} $为WS2整体能量, $ {N_{\text{W}}} $和$ {N_{\text{S}}} $分别为W, S原子数, $ {\mu _{{\text{W(ref)}}}} $, $ {\mu _{{\text{S(ref)}}}} $分别为W, S前驱体的参考化学势. (b), (c) Au(111)表面S边终结的WS2团簇的形成能及其线性拟合

Fig. 1. (a) Forming energy (Ef) versus size (N) of triangular WS2 clusters terminated with W or S edge, $ {E_{\text{f}}} = {E_{{\text{tot}}}} - {N_{\text{W}}} \cdot {\mu _{{\text{W(ref)}}}} - $$ {N_{\text{S}}} \cdot {\mu _{{\text{S(ref)}}}} $, where $ {E_{{\text{tot}}}} $ is the overall energy of WS2, $ {N_{\text{W}}} $ and $ {N_{\text{S}}} $ are the number of atoms W and S respectively, $ {\mu _{{\text{W(ref)}}}} $ and $ {\mu _{{\text{S(ref)}}}} $ are the reference chemical potential of W and S precursors respectively. (b), (c) Formation energy and linear fitting of WS2 clusters terminated with S edge on Au(111) surface.

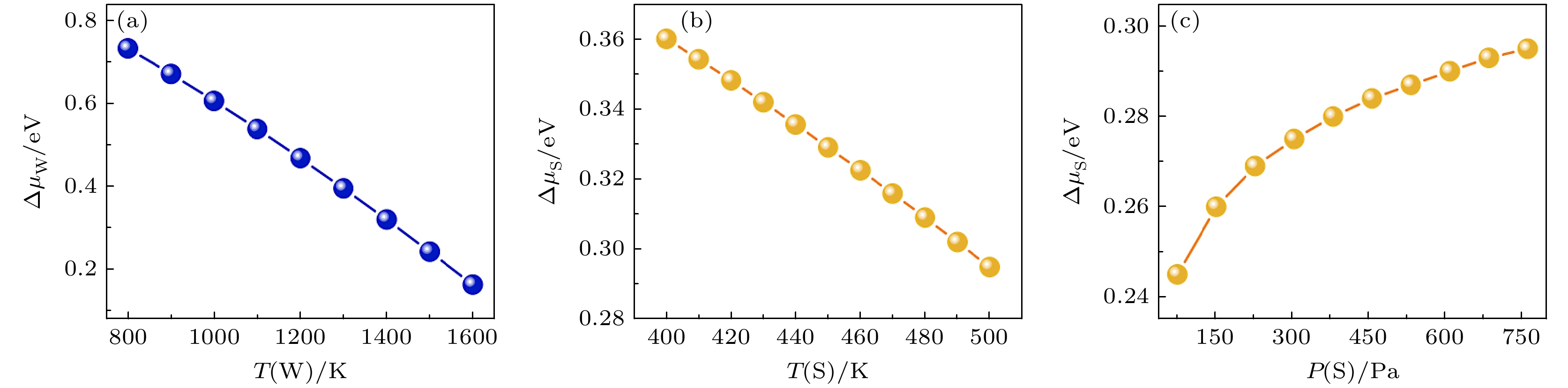

图 4 Au(111)表面 WS2团簇的成核速率与不同实验条件的关系 (a) T(W); (b) T(S); (c) P(S)/P0. 纵坐标为log10刻度类型, 红色虚线标注为T(W) = 1300 K, T(S) = 500 K, P(S) = 763.10 Pa实验条件下WS2团簇的成核速率

Fig. 4. Nucleation rates of WS2 clusters on Au(111) surface under different experimental conditions: (a) T(W); (b) T(S); (c) P(S)/P0. Scale of the vertical axis in the graph is non-linear and is of the log10 type, and the red dotted lines indicate the nucleation rates of WS2 clusters under experimental conditions of T(W) = 1300 K, T(S) = 500 K and P(S) = 763.10 Pa.

-

[1] Zhao W J, Ghorannevis Z, Chu L Q, Toh M L, Kloc C, Tan P H, Eda G 2013 ACS Nano 7 791

Google Scholar

Google Scholar

[2] Ovchinnikov D, Allain A, Huang Y S, Dumcenco D, Kis A 2014 ACS Nano 8 8174

Google Scholar

Google Scholar

[3] Ding D G, Wang S, Xia Y P, Li P, He D L, Zhang J Q, Zhao S W, Yu G H, Zheng Y H, Cheng Y, Xie M H, Ding F, Jin C H 2022 ACS Nano 16 17356

Google Scholar

Google Scholar

[4] Falin A, Holwill M, Lü H F, Gan W, Cheng J, Zhang R, Qian D, Barnett M R, Santos E J G, Novoselov K S, Tao T, Wu X J, Lu H L 2021 ACS Nano 15 2600

Google Scholar

Google Scholar

[5] 陈蓉, 王远帆, 王熠欣, 梁前, 谢泉 2022 71 127301

Google Scholar

Google Scholar

Chen R, Wang Y F, Wang Y X, Liang Q, Xie Q 2022 Acta Phys. Sin. 71 127301

Google Scholar

Google Scholar

[6] Mahler B, Hoepfner V, Liao K, Ozin G A 2014 J. Am. Chem. Soc. 136 14121

Google Scholar

Google Scholar

[7] Kuc A, Zibouche N, Heine T 2011 Phy. Rev. B 83 245213

Google Scholar

Google Scholar

[8] Wu J M, Li L H, Zheng W H, Zheng B Y, Xu Z Y, Zhang X H, Zhu C G, Wu K, Zhang C, Jiang Y 2022 Chin. Phys. B 31 057803

Google Scholar

Google Scholar

[9] Huo N J, Yang S X, Wei Z M, Li S S, Xia J B, Li J B 2014 Sci. Rep. 4 5209

Google Scholar

Google Scholar

[10] Chernikov A, Ruppert C, Hill H M, Rigosi A F, Heinz T F 2015 Nat. Photonics 9 466

Google Scholar

Google Scholar

[11] Bin Rafiq M K S, Amin N, Alharbi H F, Luqman M, Ayob A, Alharthi Y S, Alharthi N H, Bais B, Akhtaruzzaman M 2020 Sci. Rep. 10 771

Google Scholar

Google Scholar

[12] Han L X, Yang M, Wen P T, Gao W, Huo N J, Li J B 2021 Nanoscale. Adv. 3 2657

Google Scholar

Google Scholar

[13] Pawbake A S, Waykar R G, Late D J, Jadkar S R 2016 ACS Appl. Mater. Interfaces 8 3359

Google Scholar

Google Scholar

[14] Wang H C, Lin Y H, Liu X, Deng X H, Ben J W, Yu W J, Zhu D L, Liu X K 2023 Chin. Phys. B 32 018504

Google Scholar

Google Scholar

[15] Chakraborty B, Gu J, Khatoniar M, Menon V M 2019 2019 Conference on Lasers and Electro-Optics IEEE Munich, Germany, June 23–27, 2019

[16] Xu Z Q, Zhang Y P, Lin S H, Zheng C X, Zhong Y L, Xia X, Li Z P, Sophia P J, Fuhrer M S, Cheng Y B, Bao Q L 2015 ACS Nano 9 6178

Google Scholar

Google Scholar

[17] Wan Y, Li E, Yu Z H, Huang J K, Li M Y, Chou A S, Lee Y T, Lee C J, Hsu H C, Zhan Q, Aljarb A, Fu J H, Chiu S P, Wang X R, Lin J J, Chiu S P, Chang W H, Wang H, Shi Y, Lin N, Cheng Y C, Tung V, Li L J 2022 Nat. Commun. 13 4149

Google Scholar

Google Scholar

[18] Zribi R, Crispi S, Giusi D, Zhukush M, Ampelli C, Shen C, Raza M H, Pinna N, Neri G 2024 ACS Appl. Nano Mater. 7 4998

Google Scholar

Google Scholar

[19] Georgiou T, Jalil R, Belle B D, Britnell L, Gorbachev R V, Morozov S V, Kim Y J, Gholinia A, Haigh S J, Makarovsky O, Eaves L, Ponomarenko L A, Geim A K, Novoselov K S, Mishchenko A 2012 Nat. Nanotechnol. 8 100

Google Scholar

Google Scholar

[20] Xu Z H, Lü Y F, Li J Z, Huang F, Nie P B, Zhang S W, Zhao S C, Zhao S X, Wei G D 2019 RSC Adv. 9 29628

Google Scholar

Google Scholar

[21] Chubarov M, Choudhury T H, Hickey D R, Bachu S, Zhang T, Sebastian A, Bansal A, Zhu H, Trainor N, Das S, Terrones M, Alem N, Redwing J M 2021 ACS Nano 15 2532

Google Scholar

Google Scholar

[22] Loh T A J, Chua D H C, Wee A T S 2015 Sci. Rep. 5 18116

Google Scholar

Google Scholar

[23] Zeng H L, Liu G B, Dai J F, Yan Y J, Zhu B R, He R C, Xie L, Xu S J, Chen X H, Yao W, Cui X D 2013 Sci. Rep. 3 1608

Google Scholar

Google Scholar

[24] 王铄, 王文辉, 吕俊鹏, 倪振华 2021 70 026802

Google Scholar

Google Scholar

Wang S, Wang W H, Lü J P, Ni Z H 2021 Acta Phys. Sin. 70 026802

Google Scholar

Google Scholar

[25] Meng L, Hu S, Yan W, Feng J, Li H, Yan X H 2020 Chem. Phys. Lett. 739 136945

Google Scholar

Google Scholar

[26] Rong Y M, Fan Y, Leen Koh A, Robertson A W, He K, Wang S S, Tan H J, Sinclair R, Warner J H 2014 Nanoscale 6 12096

Google Scholar

Google Scholar

[27] Richey N E, Haines C, Tami J L, McElwee-White L 2017 Chem. Commun. 53 7728

Google Scholar

Google Scholar

[28] Xie Y, Ma X H, Wang Z, Nan T, Wu R X, Zhang P, Wang H L, Wang Y B, Zhan Y J, Hao Y 2018 MRS Adv. 3 365

Google Scholar

Google Scholar

[29] Cong C X, Shang J Z, Wu X, Cao B C, Peimyoo N, Qiu C Y, Sun L T, Yu T 2013 Adv. Opt. Mater. 2 131

Google Scholar

Google Scholar

[30] Gao Y, Liu Z B, Sun D M, Huang L, Ma L P, Yin L C, Ma T, Zhang Z Y, Ma X L, Peng L M, Cheng H M, Ren W C 2015 Nat. Commun. 6 8569

Google Scholar

Google Scholar

[31] Zhang G X, Wang C X, Yan B, Ning B, Zhao Y, Zhou D H, Shi X, Chen S K, Shen J, Xiao Z Y, Zhao H Q 2022 J. Mater. Sci. Mater. Electron. 33 22560

Google Scholar

Google Scholar

[32] Liu P, Li X X, Ai H X, Shen Y, Deng J, Ding X L, Wang W J 2023 J. Phys. Chem. C 127 21204

Google Scholar

Google Scholar

[33] Huang L Y, Li M Y, Liew S L, Lin S C, Chou A S, Hsu M C, Hsu C H, Lin Y T, Mao P S, Hou D H, Liu W C, Wu C I, Chang W H, Wang H, Li L J, Wei K H 2023 ACS Mater. Lett. 5 1760

Google Scholar

Google Scholar

[34] Yang W H, Mu Y B, Chen X S, Jin N J, Song J H, Chen J J, Dong L X, Liu C R, Xuan W P, Zhou C J, Cong C X, Shang J S, He S L, Wang G F, Li J 2023 Discov. Nano 18 13

Google Scholar

Google Scholar

[35] Wang J H, Xu X Z, Cheng T, Gu L H, Qiao R X, Liang Z h, Ding D, Hong H, Zheng P M, Zhang Z B, Zhang Z H, Zhang S, Cui G L, Chang C, Huang C, Qi J, Liang J, Liu C, Zuo Y G, Xue G D, Fang X J, Tian J P, Wu M H, Guo Y, Yao Z X, Jiao Q Z, Liu L, Gao P, Li Q Y, Yang R, Zhang G Y, Tang Z X, Yu D P, Wang E, Lu J M, Zhao Y, Wu S W, Ding F, Liu K H 2022 Nat. Nanotechnol. 17 33

Google Scholar

Google Scholar

[36] Zhou W, Zou X, Najmaei S, Liu Z, Shi Y, Kong J, Lou J, Ajayan P M, Yakobson B I, Idrobo J C 2013 Nano Lett. 13 2615

Google Scholar

Google Scholar

[37] Qiu H, Xu T, Wang Z, Ren W, Nan H Y, Ni Z H, Chen Q, Yuan S J, Miao F, Song F Q, Long G, Shi Y, Sun L T, Wang J L, Wang X R 2013 Nat. Commun. 4 2642

Google Scholar

Google Scholar

[38] Su L Q, Yu Y F, Cao L Y, Zhang Y 2023 Sci. China Mater. 66 3949

Google Scholar

Google Scholar

[39] Thangaraja A, Shinde S M, Kalita G, Tanemura M 2015 Mater. Lett. 156 156

Google Scholar

Google Scholar

[40] Chen J, Shao K, Yang W H, Tang W Q, Zhou J P, He Q M, Wu Y P, Zhang C M, Li X, Yang X, Wu Z M, Kang J Y 2019 ACS Appl. Mater. Interfaces 11 19381

Google Scholar

Google Scholar

[41] Li C, Yamaguchi Y, Kaneko T, Kato T 2017 Appl. Phys. Express 10 075201

Google Scholar

Google Scholar

[42] Lan F F, Yang R X, Hao S, Zhou B Z, Sun K W, Cheng H J, Zhang S, Li L J, Jin L 2020 Appl. Surf. Sci. 504 144378

Google Scholar

Google Scholar

[43] Zhang Q H, Lu J F, Wang Z Y, Dai Z G, Zhang Y P, Huang F Z, Bao Q L, Duan W H, Fuhrer M S, Zheng C X 2018 Adv. Opt. Mater. 6 1701347

Google Scholar

Google Scholar

[44] Kang K N, Godin K, Yang E H 2015 Sci. Rep. 5 13205

Google Scholar

Google Scholar

[45] Shi B, Zhou D M, Qiu R S, Bahri M, Kong X D, Zhao H Q, Tlili C, Wang D Q 2020 Appl. Surf. Sci. 533 147479

Google Scholar

Google Scholar

[46] Yin H, Zhang X D, Lu J W, Geng X M, Wan Y F, Wu M Z, Yang P 2019 J. Mater. Sci 55 990

Google Scholar

Google Scholar

[47] Li K L, Wang W J 2020 J. Cryst. Growth 540 125645

Google Scholar

Google Scholar

[48] Dendzik M, Michiardi M, Sanders C, Bianchi M, Miwa J A, Grønborg S S, Lauritsen J V, Bruix A, Hammer B, Hofmann P 2015 Phy. Rev. B 92 245442

Google Scholar

Google Scholar

[49] Fuchtbauer H G, Tuxen A K, Moses P G, Topsoe H, Besenbacher F, Lauritsen J V 2013 Phys Chem. Chem. Phys. 15 15971

Google Scholar

Google Scholar

[50] Kresse G, Furthmuller J 1996 Comput. Mater. Sci 6 15

Google Scholar

Google Scholar

[51] Kresse G, Furthmuller J 1996 Phy. Rev. B 54 11169

Google Scholar

Google Scholar

[52] Perdew J P, Burke K, Ernzerhof M 1996 Phys. Rev. Lett. 77 3865

Google Scholar

Google Scholar

[53] Grimme S, Antony J, Ehrlich S, Krieg H 2010 J. Chem. Phys. 132 154104

Google Scholar

Google Scholar

[54] Blöchl P E 1994 Phy. Rev. B 50 17953

Google Scholar

Google Scholar

[55] Yue Y C, Chen J C, Zhang Y, Ding S, Zhao F L, Wang Y, Zhang D H, Li R J, Dong H L, Hu W P, Feng Y, Feng W 2018 ACS Appl. Mater. Interfaces 10 22435

Google Scholar

Google Scholar

[56] Gutiérrez H R, Perea-López N, Elías A L, Berkdemir A, Wang B, Lü R, López-Urías F, Crespi V H, Terrones H, Terrones M 2012 Nano Lett. 13 3447

Google Scholar

Google Scholar

[57] Misawa M, Tiwari S, Hong S, Krishnamoorthy A, Shimojo F, Kalia R K, Nakano A, Vashishta P 2017 J. Phys. Chem. Lett. 8 6206

Google Scholar

Google Scholar

[58] Gao J F, Yuan Q H, Hu H, Zhao J, Ding F 2011 J. Phys. Chem. C 115 17695

Google Scholar

Google Scholar

[59] Zhang W H, Wu P, Li Z Y, Yang J L 2011 J. Phys. Chem. C 115 17782

Google Scholar

Google Scholar

[60] Li X B, Zhang J B, Zhou N, Xu H, Yang R S 2021 ACS Appl. Electron. Mater. 3 5138

Google Scholar

Google Scholar

[61] Gao J F, Yip J, Zhao J, Yakobson B I, Ding F 2011 J. Am. Chem. Soc. 133 5009

Google Scholar

Google Scholar

[62] Regmi M, Chisholm M F, Eres G 2012 Carbon 50 134

Google Scholar

Google Scholar

[63] Lan S G, Zhang Z X, Hong Y K, She Y H, Pan B J, Xu Y, Wang P J 2023 Adv. Mater. Interfaces 10 2300713

Google Scholar

Google Scholar

[64] 刘兆肃, 刘国濠, 叶晓宜, 张仕源, 郑晓婷, 劳媚媚, 徐海涛 2021 材料研究与应用 15 486

Google Scholar

Google Scholar

Liu Z S, Liu G H, Ye X Y, Zhang S Y, Zheng X T, Lao M M, Xu H T 2021 Mater. Res. Appl. 15 486

Google Scholar

Google Scholar

[65] Babu Shinde N, Deul Ryu B, Hong C H, Francis B, Chandramohan S, Kumar Eswaran S 2021 Appl. Surf. Sci. 568 150908

Google Scholar

Google Scholar

计量

- 文章访问数: 3660

- PDF下载量: 139

- 被引次数: 0

下载:

下载: