-

采用基于密度泛函理论和广义梯度近似的第一原理方法, 探究Ta元素和Re元素在Ni/Ni3Al相界面中的相互作用及其对界面强度的影响. 计算表明: 在绝大多数化学计量比范围内, Ta原子优先占据γ相中的顶点Ni位, Re原子优先占据γ'相中的Al位, Re原子和Ta原子共合金化时掺杂位置不发生改变. 通过格里菲斯断裂功、不稳定堆垛层错能及空位迁移能的计算, 得出Ta和Re合金化都可以增强界面的格里菲斯断裂能, 提高界面的结合强度, 两种合金化元素均提高了体系的不稳定堆垛层错能, 即提高了界面阻碍位错运动的能力和抵抗变形的能力, 其中Re的单独合金化效果更好. 两种元素的掺杂提高了界面上空位迁移的势垒, 阻碍了空位的发射和吸收, 进而提高了合金的蠕变能力.

-

关键词:

- 第一性原理计算 /

- Ni/Ni3Al相界面 /

- 合金化元素Ta和Re /

- 界面强度

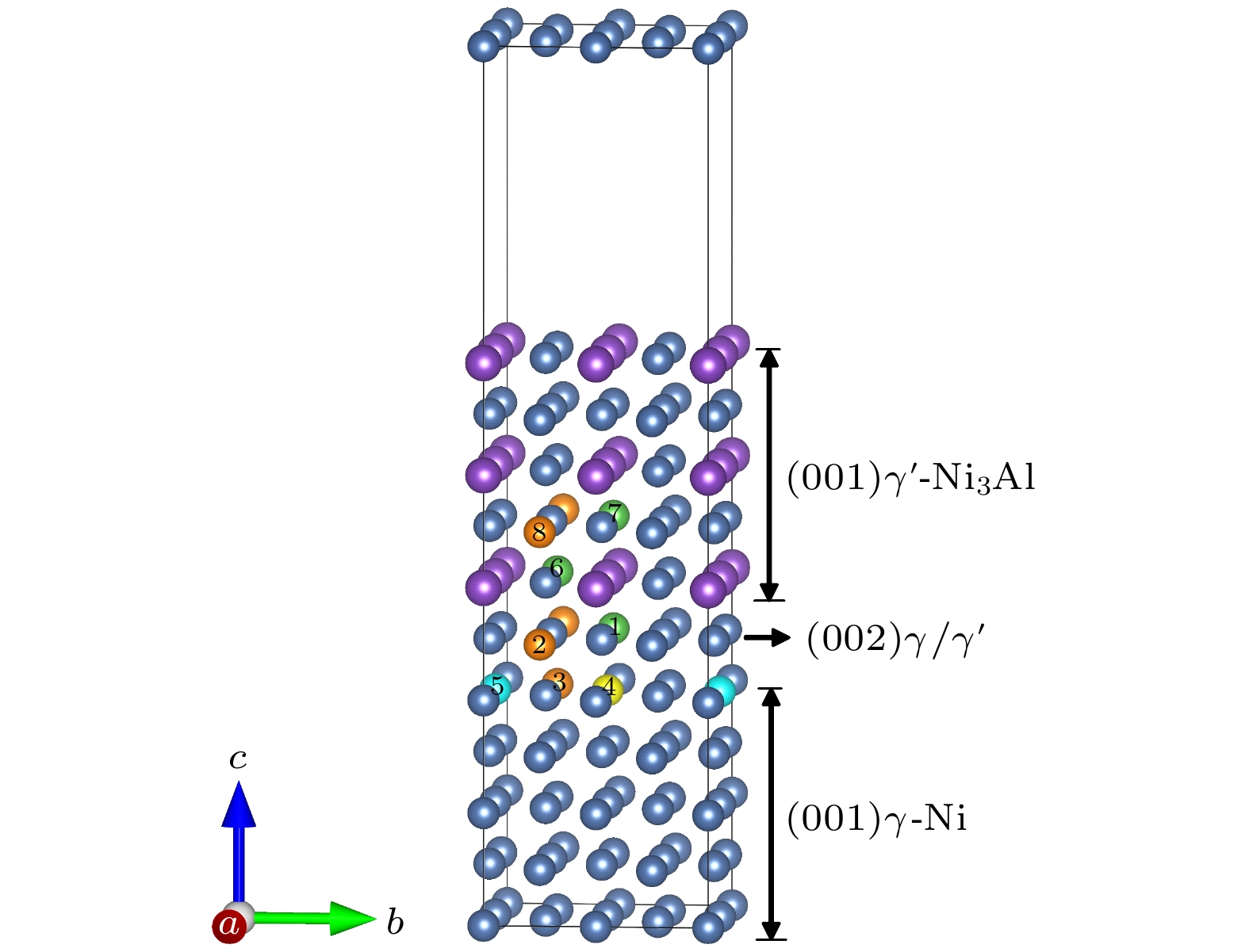

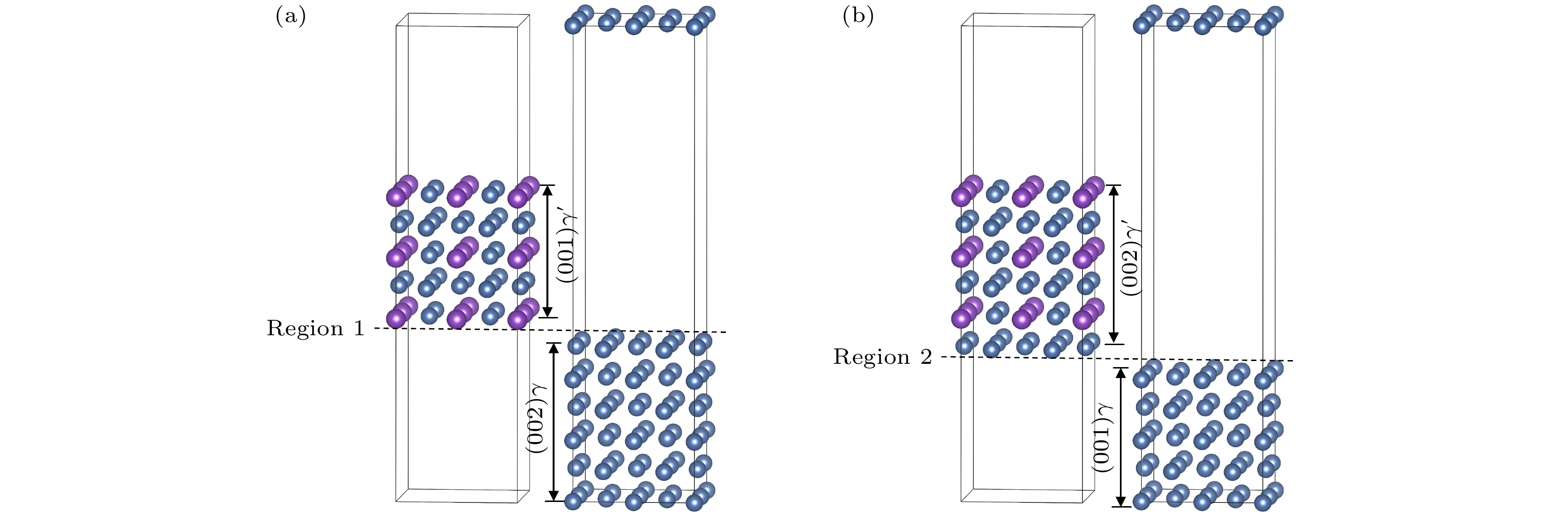

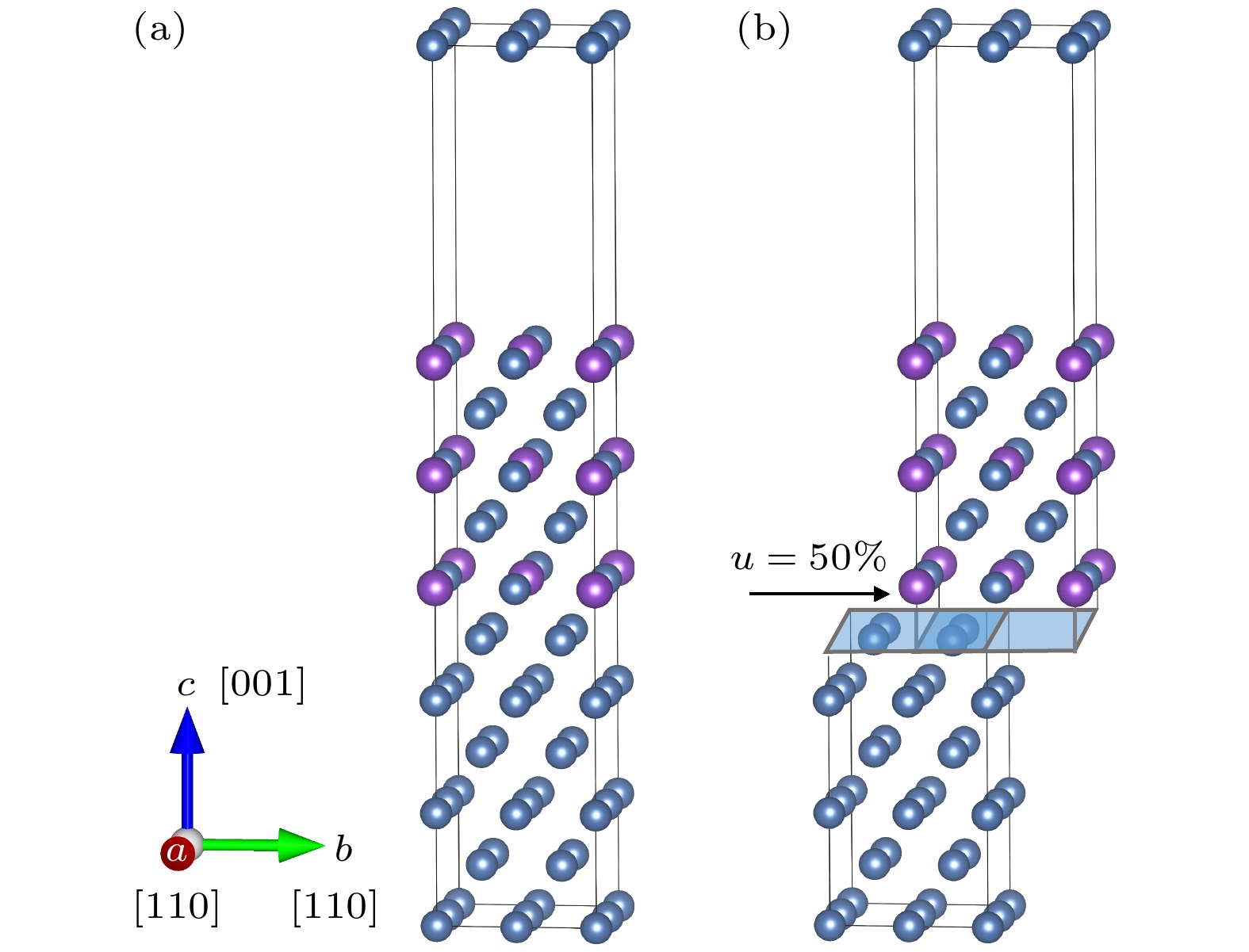

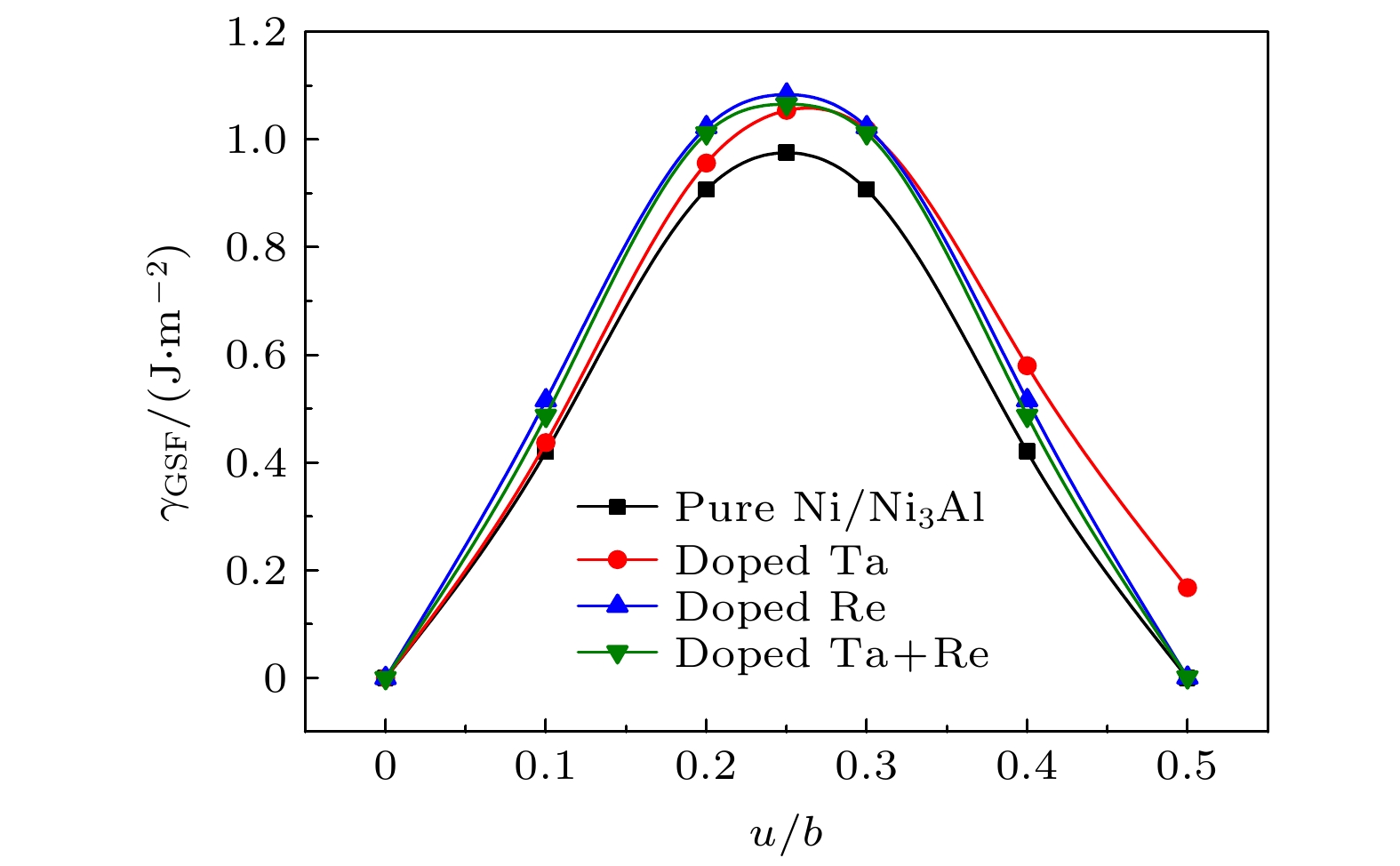

The first principle method based on density functional theory and generalized gradient approximation is used to investigate the interaction of Ta and Re elements at Ni/Ni3Al interface and their influence on the interface strength. According to the calculations of the dissolution energy of these two alloying elements at 7 different positions, it can be concluded that in most of the stoichiometric ranges, Ta atoms preferentially occupy Ni sites in the γ phase, while Re atoms occupy preferentially Al sites in γ' phase. The doping positions do not change when these two atoms are co-alloyed. The calculation of Griffith fracture work of Ni/Ni3Al interface system shows that the doping of Ta atoms can improve the interface fracture strength of the phase boundary region between the γ/γ' coherent atomic layer and γ atomic layer. The interface is easier to fracture in the phase boundary area between γ/γ' coherent atomic layer and γ' atomic layer after Ta atoms have been doped. The doping of Re atoms can improve the interface fracture strength of the phase boundary region between γ/γ' coherent atomic layer and γ' atomic layer. The interface is easier to break in the phase boundary area between γ/γ' coherent atomic layer and γ atomic layer. The calculation results of the unstable stacking fault energy under the interface slip system$ [110](001) $ before and after Ta and Re alloying show that the doping of these two types of atoms increases the value of the unstable stacking fault energy of the interface, and the slip system$ [110](001)$ becomes difficult to start, which enhances the ability of the interface to block the movement of dislocations, thus enhancing the creep strength of the nickel base superalloy. When doping Re atoms, the effect is greater, and the unstable stacking fault energy of the interface increases by 11.1%, which is better for improving the creep strength of the system. By studying the influence of alloying atoms on the path of vacancy migration and the energy barrier, it is concluded that the doping of Ta and Re atoms can increase the vacancy formation energy and the potential barrier of vacancy migration at the interface. The doping of Re atoms increases the migration energy barriers on both sides of the interface, and the doping of Ta atoms increases the migration energy barriers of γ phase. The increase of the migration barrier hinders the emission and absorption of vacancies, thereby improving the creep capability of the alloy.[1] 方昌德 2004 航空发动机 30 1

Fang C D 2004 Aeroengine 30 1

[2] Diranda L, Cormierb J, Jacquesa A, Jean-Philippe C, Schenka T, Ferrya O 2013 Mater. Charact. 77 32

Google Scholar

Google Scholar

[3] Yamabe-Mitarai Y, Ro Y, Harada H, T Maruko 1998 Metall. Mater. Trans. A 29 537

Google Scholar

Google Scholar

[4] Shang S L, Kim D E, Zacherl C L, Y Wang, Y Du, Z K Liu 2012 J. Appl. Phys 112 053515

Google Scholar

Google Scholar

[5] Huang M, Zhu J 2016 Rare Metals 35 1

Google Scholar

Google Scholar

[6] Chen K, Zhao L R, Tse J S 2004 Mater. Sci. Eng. A 365 80

Google Scholar

Google Scholar

[7] Chen K, Zhao L R, Tse J S 2003 Acta Mater. 51 1079

Google Scholar

Google Scholar

[8] Gong X F, Yang G X, Fu Y H, Xie Y Q, Zhuang J, Ning X J 2009 Comp. Mater. Sci. 47 320

Google Scholar

Google Scholar

[9] 彭黎, 刘云国, 杜付明, 文大东, 黄利群, 彭平 2012 中国有色金属学报 22 3356

Google Scholar

Google Scholar

Peng L, Liu Y G, Du F M, Wen D D, Huang L Q, Peng P 2012 Chin. J. Nonferrous Met. 22 3356

Google Scholar

Google Scholar

[10] 陈律, 彭平, 湛建平, 田泽安, 韩绍昌 2008 中国有色金属学报 18 890

Google Scholar

Google Scholar

Chen L, Peng P, Zhan J P, Tian Z A, Han S C 2008 Chin. J. Nonferrous Met. 18 890

Google Scholar

Google Scholar

[11] 彭平, 陈律, 周惦武, 田泽安, 韩绍昌, 金涛, 胡壮麒 2007 金属学报 43 137

Peng P, Chen L, Zhou D W, Tian Z A, Han S C, Jin T, Hu Z Q 2007 Acta Metall. Sin. 43 137

[12] Peng L, Peng P, Liu Y G, He S, Wei H, Jin T, Hu Z Q 2012 Comp. Mater. Sci. 63 292

Google Scholar

Google Scholar

[13] Wen Y F, Sun J, Huang J 2012 Trans. Nonferrous Met. Soc. China 22 661

Google Scholar

Google Scholar

[14] Zhu C, Yu T, Wang C, Wang D 2020 Comp. Mater. Sci. 175 109586

Google Scholar

Google Scholar

[15] Zhao W, Sun Z, Gong S 2017 Acta Mater. 135 25

Google Scholar

Google Scholar

[16] Sun M, Wang C Y 2016 Chin. Phys. B 25 067104

Google Scholar

Google Scholar

[17] 于松, 王崇愚, 于涛 2007 56 3212

Google Scholar

Google Scholar

Yu S, Wang C Y, Yu T 2007 Acta Phys. Sin. 56 3212

Google Scholar

Google Scholar

[18] 黄彦彦, 周青华, 刘青, 蔡聪德 2018 稀有金属材料与工程 47 261

Huang Y Y, Zhou Q H, Liu Q, Cai C D 2018 Rare Metal Mat. Eng. 47 261

[19] Tian S, Wu J, Shu D, Su Y, Yu H, Qian B 2014 Mater. Sci. Eng. A 616 260

Google Scholar

Google Scholar

[20] 孙跃军, 尚勇, 姜晓琳 2013 机械工程材料 37 6

Sun Y J, Shang Y, Jiang X L 2013 Mater. Mech. Eng. 37 6

[21] Tian S, Yu X, Yang J, Zhao N, Xu Y, Hu Z 2004 Mater. Sci. Eng. A 379 141

Google Scholar

Google Scholar

[22] Wang C, Wang C Y 2008 Surf. Sci. 602 2604

Google Scholar

Google Scholar

-

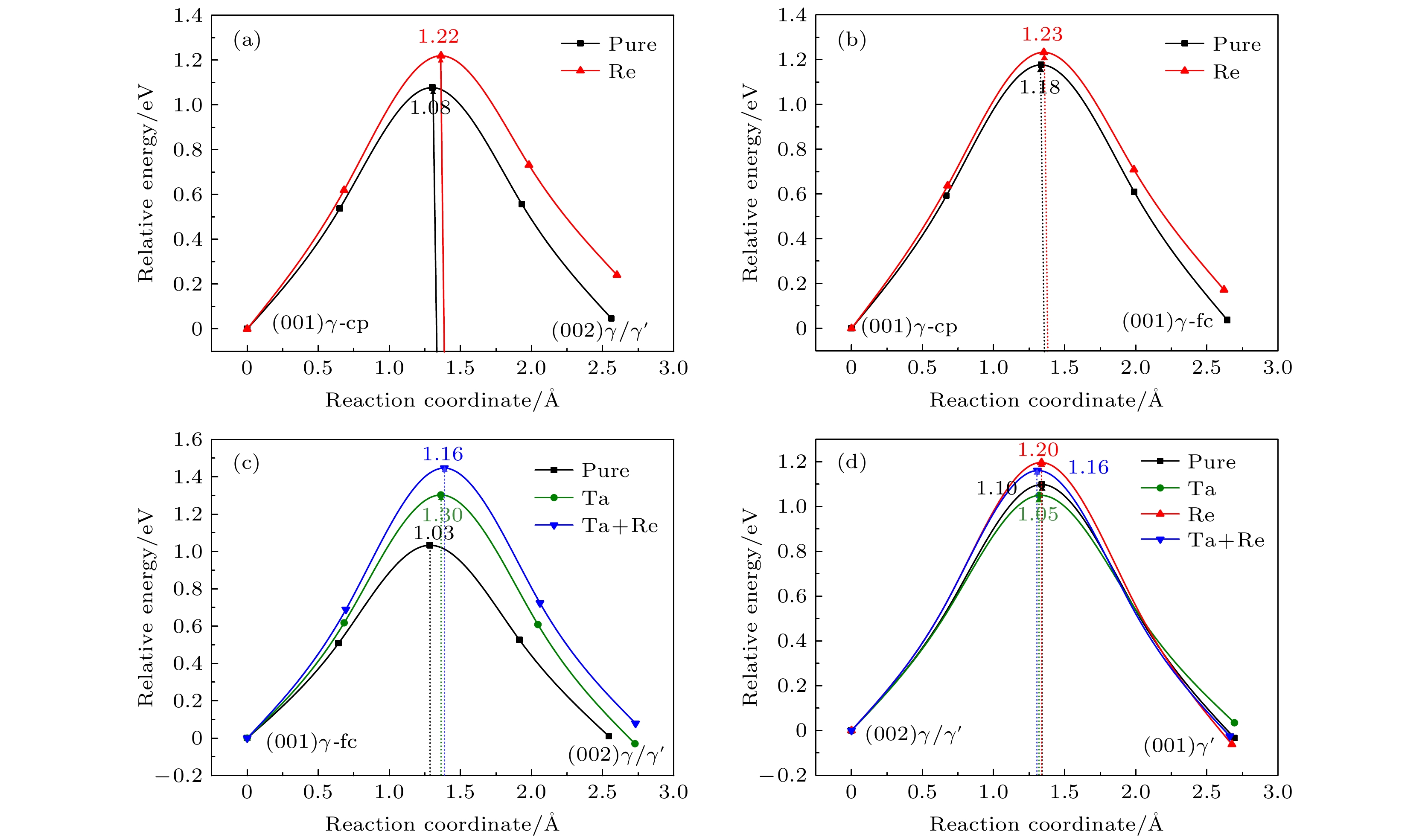

图 7 纯界面以及合金化界面的空位迁移能垒 (a) 纯界面和Re合金化界面γ-cpNi到γ/γ'空位迁移能垒; (b) 纯界面和Re合金化界面γ-cpNi到γ-fcNi空位迁移能垒; (c) Ta合金化和Ta, Re共同合金化界面γ-fcNi到γ/γ'-Ni的空位迁移能垒; (d) 4种界面γ/γ'-Ni到γ'-Ni相的空位迁移能垒

Fig. 7. Vacancy migration energy barriers at pure interface and alloying interface: (a) Vacancy migration barriers from γ-cpNi to γ/γ' at pure interface and Re alloying interface; (b) vacancy migration barriers from γ-cpNi to γ- fcNi at pure interface and Re alloying interface; (c) vacancy migration barrier from γ- fcNi to γ/γ'-Ni at Ta alloying interface and Ta, Re co-alloying interface; (d) vacancy migration barriers from γ/γ'-Ni to γ'-Ni at 4 interfaces

表 1 合金化Ni/Ni3Al-Ta界面和Ni/Ni3Al-Re界面的溶解能计算结果

Table 1. Calculation results of interface dissolution energy of the Ni/Ni3Al-Ta and Ni/Ni3Al-Re interface systems

位置序号 掺杂原

子占位Ni/Ni3Al-Ta

溶解能

/(meV·atom–1)Ni/Ni3Al-Re

溶解能

/(meV·atom–1)1 γ'-Ni –52.25 –66.52 2 γ'-Al –56.53 –66.65 3 γ/γ'-Ni –66.92 –54.03 4 γ-fcNi –74.27 –47.82 5 γ-cpNi –76.44 –46.00 6 γ-fcNi –76.53 — 7 γ-cpNi –76.55 — 表 2 Re原子和Ta原子共同合金化后界面溶解能计算结果

Table 2. Calculation results of interface dissolution energy after co-alloying of Re atom and Ta atom

Ta原子

所在位置序号 相对距离/Å 溶解能/(meV·atom–1) γ/γ'-Ni 1 2.48 55.89 2 4.30 53.68 γ-Ni 3 4.30 47.17 4 3.53 45.47 5 4.98 46.94 γ'-Ni 6 2.48 67.89 7 2.48 67.64 8 4.30 66.15 表 3 两种取向关系下Ni/Ni3Al相界面合金化前后的格里菲斯断裂功

Table 3. Griffith work before and after Ni/Ni3Al interface alloying under two orientations

界面体系 格里菲斯断裂功/(J·m–2) Region 1 Region 2 Ni/Ni3Al 4.145 4.403 Ni/Ni3Al-Ta 4.099 4.571 Ni/Ni3Al-Re 4.574 4.323 Ni/Ni3Al-Re-Ta 4.557 4.518 表 4 纯界面和合金化界面不同Ni空位位置的空位形成能

Table 4. Vacancy formation energy of different Ni positions at pure interface and alloying interface

界面体系 Ni空位位置 γ'-Ni γ/γ'-Ni γ-fcNi γ-cpNi Ni/Ni3Al 1.288 1.376 1.360 1.321 Ni/Ni3Al-Ta 1.322 1.342 1.355 1.467 Ni/Ni3Al-Re 1.375 1.475 1.407 1.233 Ni/Ni3Al-Ta-Re 1.489 1.563 1.460 1.511 -

[1] 方昌德 2004 航空发动机 30 1

Fang C D 2004 Aeroengine 30 1

[2] Diranda L, Cormierb J, Jacquesa A, Jean-Philippe C, Schenka T, Ferrya O 2013 Mater. Charact. 77 32

Google Scholar

Google Scholar

[3] Yamabe-Mitarai Y, Ro Y, Harada H, T Maruko 1998 Metall. Mater. Trans. A 29 537

Google Scholar

Google Scholar

[4] Shang S L, Kim D E, Zacherl C L, Y Wang, Y Du, Z K Liu 2012 J. Appl. Phys 112 053515

Google Scholar

Google Scholar

[5] Huang M, Zhu J 2016 Rare Metals 35 1

Google Scholar

Google Scholar

[6] Chen K, Zhao L R, Tse J S 2004 Mater. Sci. Eng. A 365 80

Google Scholar

Google Scholar

[7] Chen K, Zhao L R, Tse J S 2003 Acta Mater. 51 1079

Google Scholar

Google Scholar

[8] Gong X F, Yang G X, Fu Y H, Xie Y Q, Zhuang J, Ning X J 2009 Comp. Mater. Sci. 47 320

Google Scholar

Google Scholar

[9] 彭黎, 刘云国, 杜付明, 文大东, 黄利群, 彭平 2012 中国有色金属学报 22 3356

Google Scholar

Google Scholar

Peng L, Liu Y G, Du F M, Wen D D, Huang L Q, Peng P 2012 Chin. J. Nonferrous Met. 22 3356

Google Scholar

Google Scholar

[10] 陈律, 彭平, 湛建平, 田泽安, 韩绍昌 2008 中国有色金属学报 18 890

Google Scholar

Google Scholar

Chen L, Peng P, Zhan J P, Tian Z A, Han S C 2008 Chin. J. Nonferrous Met. 18 890

Google Scholar

Google Scholar

[11] 彭平, 陈律, 周惦武, 田泽安, 韩绍昌, 金涛, 胡壮麒 2007 金属学报 43 137

Peng P, Chen L, Zhou D W, Tian Z A, Han S C, Jin T, Hu Z Q 2007 Acta Metall. Sin. 43 137

[12] Peng L, Peng P, Liu Y G, He S, Wei H, Jin T, Hu Z Q 2012 Comp. Mater. Sci. 63 292

Google Scholar

Google Scholar

[13] Wen Y F, Sun J, Huang J 2012 Trans. Nonferrous Met. Soc. China 22 661

Google Scholar

Google Scholar

[14] Zhu C, Yu T, Wang C, Wang D 2020 Comp. Mater. Sci. 175 109586

Google Scholar

Google Scholar

[15] Zhao W, Sun Z, Gong S 2017 Acta Mater. 135 25

Google Scholar

Google Scholar

[16] Sun M, Wang C Y 2016 Chin. Phys. B 25 067104

Google Scholar

Google Scholar

[17] 于松, 王崇愚, 于涛 2007 56 3212

Google Scholar

Google Scholar

Yu S, Wang C Y, Yu T 2007 Acta Phys. Sin. 56 3212

Google Scholar

Google Scholar

[18] 黄彦彦, 周青华, 刘青, 蔡聪德 2018 稀有金属材料与工程 47 261

Huang Y Y, Zhou Q H, Liu Q, Cai C D 2018 Rare Metal Mat. Eng. 47 261

[19] Tian S, Wu J, Shu D, Su Y, Yu H, Qian B 2014 Mater. Sci. Eng. A 616 260

Google Scholar

Google Scholar

[20] 孙跃军, 尚勇, 姜晓琳 2013 机械工程材料 37 6

Sun Y J, Shang Y, Jiang X L 2013 Mater. Mech. Eng. 37 6

[21] Tian S, Yu X, Yang J, Zhao N, Xu Y, Hu Z 2004 Mater. Sci. Eng. A 379 141

Google Scholar

Google Scholar

[22] Wang C, Wang C Y 2008 Surf. Sci. 602 2604

Google Scholar

Google Scholar

计量

- 文章访问数: 4156

- PDF下载量: 78

- 被引次数: 0

下载:

下载: