-

硒化锑(Sb2Se3)具有低毒、原材料丰富和光电性能优异等优点, 被认为是最具有发展潜力的薄膜太阳电池光吸收层材料之一. 但目前Sb2Se3薄膜太阳电池光电转换效率与碲化镉、铜铟镓硒和钙钛矿等太阳电池相比仍存在较大差距. 限制Sb2Se3薄膜太阳电池光电转换效率进一步提升的关键因素之一是, 太阳电池结构中Mo背电极和Sb2Se3薄膜构建的背接触界面处容易形成较高的势垒, 降低载流子的抽取效率. 本工作则对Mo背电极进行热处理生成缓冲层MoO2薄膜, 发现缓冲层MoO2的引入, 可有效地促进Sb2Se3薄膜的择优取向生长, 同时实现太阳电池Mo/MoO2/Sb2Se3背接触势垒降低, 相应的填充因子、开路电压和短路电流密度均获得显著提高, 构建的太阳电池光电转换效率从5.04%提升至7.05%.Antimony selenide (Sb2Se3) has advantages of low-toxicity, abundant and excellent photoelectric properties. It is widely considered as one of the most promising light-harvesting materials for thin-film solar cells. However, the power conversion efficiency of the Sb2Se3 thin-film solar cell is still far inferior to that of cadmium telluride, copper indium gallium selenium and perovskite solar cells. As is well known, the Sb2Se3 solar cell performance is closely related to the light absorber layer (crystallinity, composition, bulk defect density, etc.), PN heterojunction quality (charge carrier concertation, energy band alignment, interface defect density, etc.) and back-contact barrier formation, which determines the process of carrier generation, excitation, relaxation, transfer and recombination. The low fill factor is one of the core problems that limit further efficiency improvement of Sb2Se3 solar cells, which can be attributed to the high potential barrier at the back contact between the Mo electrode and Sb2Se3 absorption layer. In this work, a heat treatment is applied to the Mo electrode to generate a MoO2 buffer layer. It can be found that this buffer layer can inhibit MoSe2 film growth, exhibiting better Ohmic contact with Sb2Se3, and reducing the back contact barrier of the solar cell. The Sb2Se3 thin film is prepared by an effective combination reaction involving sputtered and selenized Sb precursor. After introducing the MoO2 buffer layer, it can also promote the formation of (hk1) (including (211), (221), (002), etc.) preferentially oriented Sb2Se3 thin films with average grain size over 1 μm. And the ratio of Sb to Se is optimized from 0.57 to 0.62, approaching to the stoichiometric ratio of Sb2Se3 thin film and inhibiting the formation of Vse and SbSe defects. Finally, it enhances the open-circuit voltage (VOC) of solar cells from 0.473 to 0.502 V, the short-circuit current density (JSC) from 22.71 to 24.98 mA/cm2, and the fill factor (FF) from 46.90% to 56.18%, thereby increasing the power conversion efficiency (PCE) from 5.04% to 7.05%. This work proposes a facile strategy for interfacial treatment and elucidates the related carrier transport enhancement mechanism, thus paving a bright avenue to breaking through the efficiency bottleneck of Sb2Se3 thin film solar cells.

-

Keywords:

- antimony selenide /

- thin-film solar cell /

- back contact /

- power conversion efficiency

[1] Duan Z T, Liang X Y, Feng Y, Ma H Y, Liang B L, Wang Y, Luo S P, Wang S F, Schropp R E I, Mai Y H, Li Z Q 2022 Adv. Mater. 34 2202969

Google Scholar

Google Scholar

[2] Chen S, Liu T X, Zheng Z H, Ishaq M, Liang G X, Fan P, Chen T, Tang J 2022 J Energy Chem. 67 508

Google Scholar

Google Scholar

[3] Zhou Y, Wang L, Chen S Y, Qin S K, Liu X S, Chen J, Xue D J, Luo M, Cao Y Z, Chen Y B, Sargent E H, Tang J 2015 Nat. Photonics 9 409

Google Scholar

Google Scholar

[4] Hadke S, Huang M L, Chen C, Tay Y F, Chen S Y, Tang J, Wong L 2022 Chem. Rev. 122 10170

Google Scholar

Google Scholar

[5] Rajpure K Y, Bhosale C H 2002 Mater. Chem. Phys. 73 6

Google Scholar

Google Scholar

[6] Choi Y C, Mandal T N, Yang W S, Lee Y H, Im S K, Noh J H, Seok S 2014 Angew. Chem. Int. Ed. 126 1353

Google Scholar

Google Scholar

[7] Zhou Y, Leng M Y, Xia Z, Zhong J, Song H B, Liu X S, Yang B, Zhang J P, Chen J, Zhou K H, Han J B, Cheng Y B, Tang J 2014 Adv. Energy Mater. 4 1301864

Google Scholar

Google Scholar

[8] Wang X, Tang R, Yin Y W, Ju H X, Li S A, Zhu C F, Chen T 2019 Sol. Energy Mater. Sol. Cells 189 5

Google Scholar

Google Scholar

[9] Wang L, Li D B, Li K H, Chen C, Deng H X, Gao L, Zhao Y, Jiang F, Li L Y, Huang F, He Y S, Song H S, Niu G D, Tang J 2017 Nat. Energy 2 17046

Google Scholar

Google Scholar

[10] Wen X X, Chen C, Lu S C, Li K H, Kondrotas R, Zhao Y, Chen W H, Gao L, Wang C, Zhang J, Niu G D, Tang J 2018 Nat. Commun. 9 2179

Google Scholar

Google Scholar

[11] Liang G X, Zheng Z H, Fan P, Luo J T, Hu J G, Zhang X H, Ma H L, Fan B, Luo Z K, Zhang D P 2018 Sol. Energy Mater. Sol. Cells 174 263

Google Scholar

Google Scholar

[12] Liang G X, Zhang X H, Ma H L, Hu J G, Fan B, Luo Z K, Zheng Z H, Luo J T, Fan P 2017 Sol. Energy Mater. Sol. Cells 160 257

Google Scholar

Google Scholar

[13] Tang R, Zheng Z H, Su Z H, Li X J, Wei Y D, Zhang X H, Fu Y Q, Luo J T, Fan P, Liang G X 2019 Nano Energy 64 103929

Google Scholar

Google Scholar

[14] Liang G X, Luo Y D, Chen S, Tang R, Zheng Z H, Li X J, Liu X S, Liu Y K, Li Y F, Chen X Y, Su Z H, Zhang X H, Ma H L, Fan P 2020 Nano Energy 73 104806

Google Scholar

Google Scholar

[15] Tang R, Chen S, Zheng Z H, Su Z H, Luo J T, Fan P, Zhang X H, Tan J, Liang G X 2022 Adv. Mater. 34 2109078

Google Scholar

Google Scholar

[16] Li J J, Zhang Y, Zhao W, Nam D, Cheong H, Wu L, Zhou Z Q, Sun Y 2015 Adv. Energy Mater. 5 1402178

Google Scholar

Google Scholar

[17] Neugebohrn N, Hammer M S, Sayed M H, Michalowski P, Stroth C, Parisi J, Richter M 2017 J. Alloys Compd. 725 69

Google Scholar

Google Scholar

[18] Li Z Q, Chen X, Zhu H B, Chen J W, Guo Y T, Zhang C, Zhang W, Niu X N, Mai Y H 2017 Sol. Energy Mater. Sol. Cells 161 190

Google Scholar

Google Scholar

[19] Zhang J Y, Guo H F, Jia X G, Ning H, Ma C H, Wang X Q, Yuan N Y, Ding J N 2021 Sol. Energy 214 231

Google Scholar

Google Scholar

[20] Wu H R, Zhou X C, Li J D, Li X M, Li B W, Fei W W, Zhou J X, Yin J, Guo W L 2018 Small 14 1802276

Google Scholar

Google Scholar

[21] Lopez S C, Lopez I O P, Lara M C, Garcia A E, Sanchez M C M, Hernandez J A R, Lopez M C 2018 Phys. Status Solidi A. 215 1800226

Google Scholar

Google Scholar

[22] 曹宇, 刘超颖, 赵耀, 那艳玲, 江崇旭, 王长刚, 周静, 于皓 2022 71 038802

Google Scholar

Google Scholar

Cao Y, Liu C Y, Zhao Y, Na Y L, Jiang C X, Wang C G, Zhou J, Yu H 2022 Acta Phys. Sin. 71 038802

Google Scholar

Google Scholar

[23] Luo Y D, Tang R, Chen S, Hu J G, Liu Y K, Li Y F, Liu X S, ZhengZ H, Su Z H, Ma X F, Fan P, Zhang X H, Ma H L, Chen Z G, Liang G X 2020 Chem. Eng. J. 393 124599

[24] 曹宇, 祝新运, 陈翰博, 王长刚, 张鑫童, 侯秉东, 申明仁, 周静 2018 67 247301

Google Scholar

Google Scholar

Cao Y, Zhu X Y, Chen H B, Wang C G, Zhang X T, Hou B D, Shen MR, Zhou J 2018 Acta Phys. Sin. 67 247301

Google Scholar

Google Scholar

[25] Luo M, Leng M Y, Liu X S, Chen J, Chen C, Qin S K, Tang J 2014 Appl. Phys. Lett. 104 173904

Google Scholar

Google Scholar

-

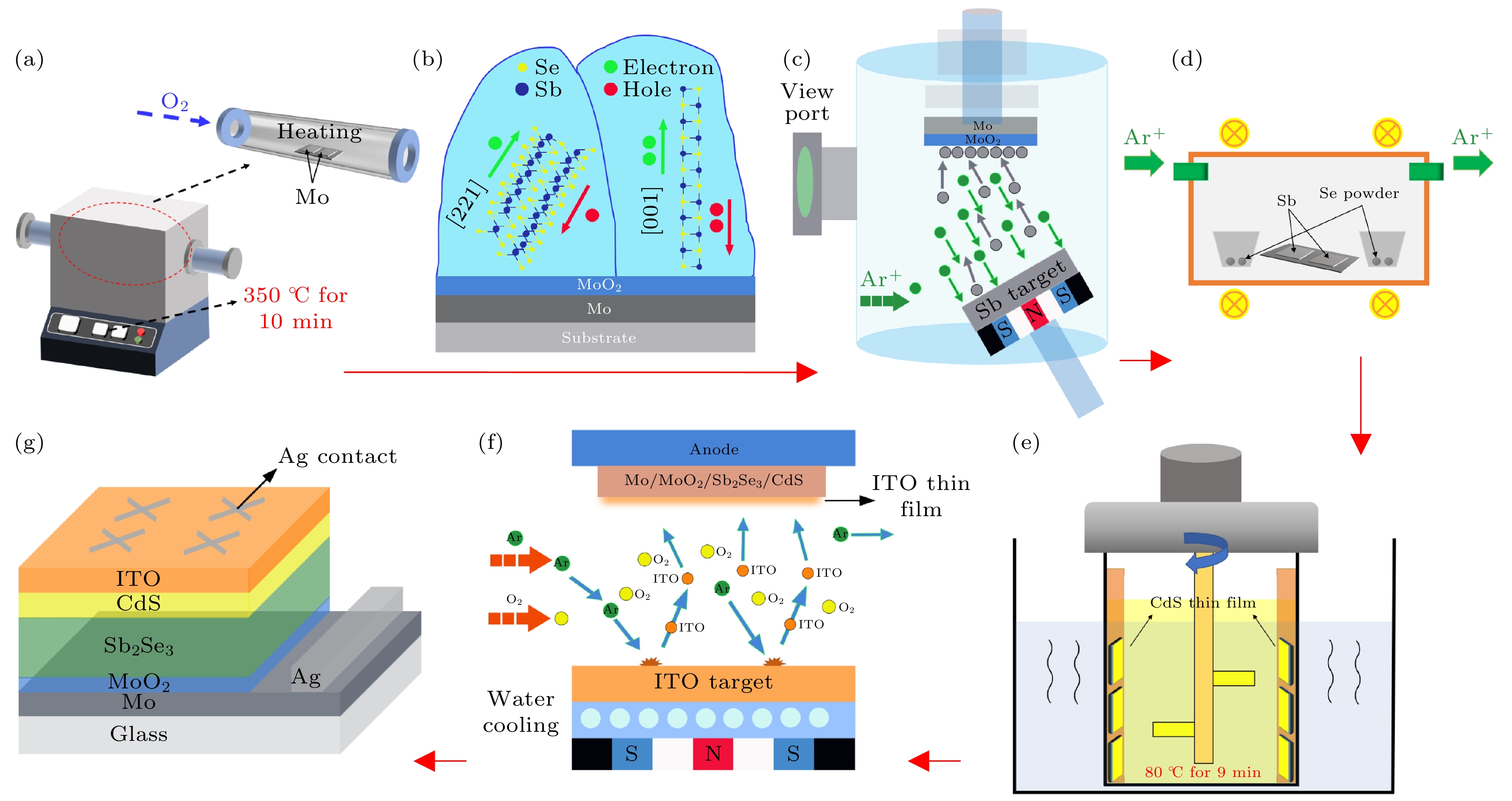

图 1 Sb2Se3薄膜太阳电池制备流程 (a) MoO2制备过程; (b) Mo/MoO2/Sb2Se3背接触结构图; (c) 磁控溅射制备Sb薄膜; (d) 采用后硒化工艺生长Sb2Se3薄膜; (e) 化学水浴法制备CdS薄膜; (f) 磁控溅射制备ITO薄膜; (g) Sb2Se3薄膜太阳电池结构图

Fig. 1. Fabrication process of Sb2Se3 solar cells: (a) MoO2 preparation; (b) back contact structure of Mo/MoO2/Sb2Se3; (c) sputtering Sb thin film; (d) post-selenation for Sb2Se3 thin film; (e) chemical bath deposition for CdS thin film; (f) sputtering ITO thin film; (g) Sb2Se3 solar cell sturcture.

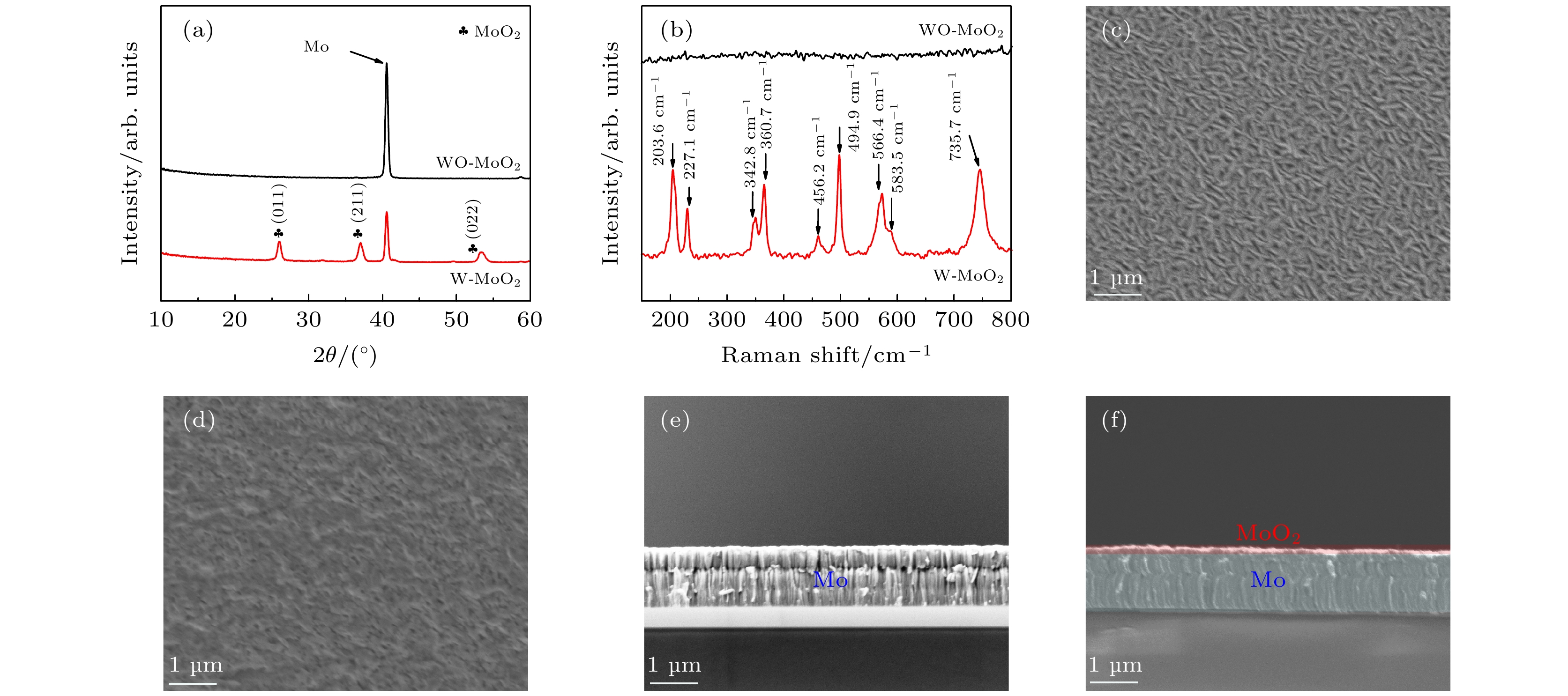

图 2 (a) W-MoO2和WO-MoO2样品的XRD图谱; (b) W-MoO2和WO-MoO2样品的拉曼图谱; (c) WO-MoO2样品的表面形貌; (d) W-MoO2样品的表面形貌; (e) WO-MoO2样品的剖面形貌图; (f) W-MoO2样品的剖面形貌图

Fig. 2. (a) XRD patterns of W-MoO2 and WO-MoO2 sample; (b) Raman patterns of W-MoO2 and WO-MoO2 sample; (c) surface morphology of WO-MoO2 sample; (d) surface morphology of W-MoO2 thin film; (e) cross sectional image of WO-MoO2 sample; (f) cross sectional image of W-MoO2 sample.

图 3 (a) W-MoO2和WO-MoO2样品上生长Sb2Se3薄膜的XRD图谱; (b) 关于(360), (211), (221)和(002)衍射峰的TC值; (c) WO-MoO2样品上生长Sb2Se3薄膜的表面形貌; (d) W-MoO2样品上生长Sb2Se3薄膜的表面形貌; (e) WO-MoO2样品上生长Sb2Se3薄膜太阳电池的剖面形貌图; (f) W-MoO2样品上生长Sb2Se3薄膜太阳电池的剖面形貌图

Fig. 3. (a) XRD patterns of Sb2Se3 thin film prepared on W-MoO2 and WO-MoO2 samples; (b) TC value comparation of the diffraction peaks (360), (211), (221) and (002); (c) morphology of Sb2Se3 thin film prepared on WO-MoO2 samples; (d) morphology of Sb2Se3 thin film prepared on W-MoO2 samples; (e) cross sectional image of Sb2Se3 solar cells based on WO-MoO2 sample; (f) cross sectional image of Sb2Se3 solar cells based on W-MoO2 sample.

图 4 (a) MoO2引入前后太阳电池的J - V曲线; (b) MoO2引入前后太阳电池的外量子效率EQE (左)和相应的积分电流(右); (c) MoO2引入前后Sb2Se3的禁带宽度; (d) MoO2引入前后乌尔巴赫能量(Eu)

Fig. 4. (a) J -V curve of solar cells before and after MoO2 introduction; (b) EQE curve (left) and integrating current (right) before and after MoO2 introduction; (c) Sb2Se3 bandgap calculated from EQE before and after MoO2 introduction; (d) Urbach energy (Eu) before and after MoO2 introduction.

表 1 Sb2Se3薄膜的化学成分

Table 1. Composition in Sb2Se3 thin films.

Samples Sb atomic percentage/% Se atomic percentage/% Sb/Se ratio WO- MoO2 36.35 63.65 0.57 W-MoO2 38.27 61.73 0.62 表 2 太阳电池性能参数对比

Table 2. Comparison of solar cell performance.

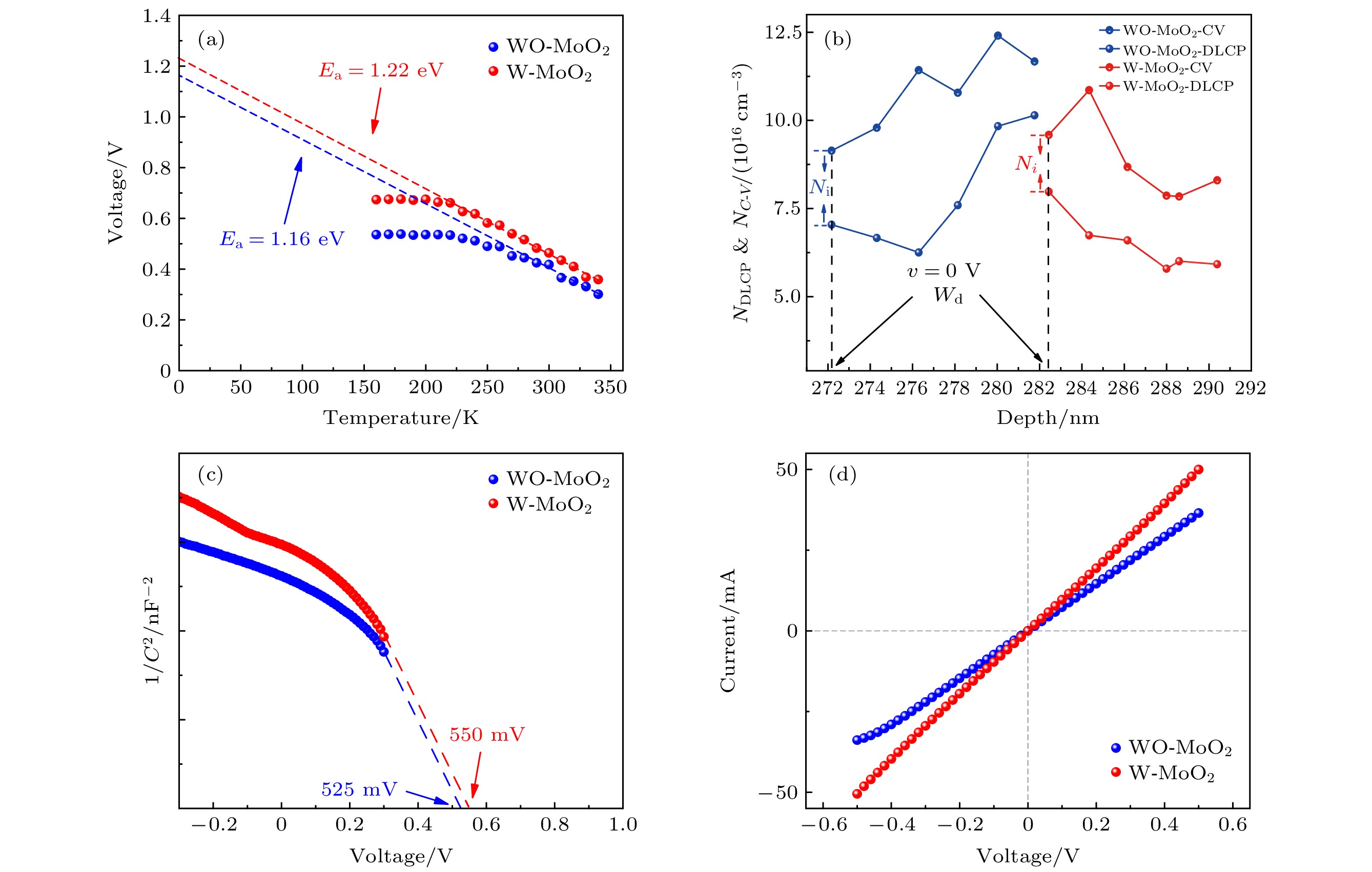

Devices VOC/V JSC/(mA·cm–2) FF/% PCE/% WO-MoO2 0.473 22.71 46.90 5.04 W-MoO2 0.502 24.98 56.18 7.05 表 3 太阳电池在暗态环境下测量的电学性能参数

Table 3. Solar cell performance in dark state.

Devices G/ (mS·cm–2) R/ (Ω·cm2) A J0/(mA·cm–2) WO-MoO2 3.49 10.02 2.15 2.65×10–2 W-MoO2 0.05 8.95 1.96 6.16×10–3 表 4 太阳电池的界面性能参数

Table 4. Solar cell interface performance.

Devices Ea/eV Ni/cm–3 x/nm Vbi/mV Slop/(A·V–1) Resistance/Ω WO-MoO2 1.16 2.10×1016 272.18 525 0.072 13.89 W-MoO2 1.22 1.61×1016 282.44 550 0.097 10.31 -

[1] Duan Z T, Liang X Y, Feng Y, Ma H Y, Liang B L, Wang Y, Luo S P, Wang S F, Schropp R E I, Mai Y H, Li Z Q 2022 Adv. Mater. 34 2202969

Google Scholar

Google Scholar

[2] Chen S, Liu T X, Zheng Z H, Ishaq M, Liang G X, Fan P, Chen T, Tang J 2022 J Energy Chem. 67 508

Google Scholar

Google Scholar

[3] Zhou Y, Wang L, Chen S Y, Qin S K, Liu X S, Chen J, Xue D J, Luo M, Cao Y Z, Chen Y B, Sargent E H, Tang J 2015 Nat. Photonics 9 409

Google Scholar

Google Scholar

[4] Hadke S, Huang M L, Chen C, Tay Y F, Chen S Y, Tang J, Wong L 2022 Chem. Rev. 122 10170

Google Scholar

Google Scholar

[5] Rajpure K Y, Bhosale C H 2002 Mater. Chem. Phys. 73 6

Google Scholar

Google Scholar

[6] Choi Y C, Mandal T N, Yang W S, Lee Y H, Im S K, Noh J H, Seok S 2014 Angew. Chem. Int. Ed. 126 1353

Google Scholar

Google Scholar

[7] Zhou Y, Leng M Y, Xia Z, Zhong J, Song H B, Liu X S, Yang B, Zhang J P, Chen J, Zhou K H, Han J B, Cheng Y B, Tang J 2014 Adv. Energy Mater. 4 1301864

Google Scholar

Google Scholar

[8] Wang X, Tang R, Yin Y W, Ju H X, Li S A, Zhu C F, Chen T 2019 Sol. Energy Mater. Sol. Cells 189 5

Google Scholar

Google Scholar

[9] Wang L, Li D B, Li K H, Chen C, Deng H X, Gao L, Zhao Y, Jiang F, Li L Y, Huang F, He Y S, Song H S, Niu G D, Tang J 2017 Nat. Energy 2 17046

Google Scholar

Google Scholar

[10] Wen X X, Chen C, Lu S C, Li K H, Kondrotas R, Zhao Y, Chen W H, Gao L, Wang C, Zhang J, Niu G D, Tang J 2018 Nat. Commun. 9 2179

Google Scholar

Google Scholar

[11] Liang G X, Zheng Z H, Fan P, Luo J T, Hu J G, Zhang X H, Ma H L, Fan B, Luo Z K, Zhang D P 2018 Sol. Energy Mater. Sol. Cells 174 263

Google Scholar

Google Scholar

[12] Liang G X, Zhang X H, Ma H L, Hu J G, Fan B, Luo Z K, Zheng Z H, Luo J T, Fan P 2017 Sol. Energy Mater. Sol. Cells 160 257

Google Scholar

Google Scholar

[13] Tang R, Zheng Z H, Su Z H, Li X J, Wei Y D, Zhang X H, Fu Y Q, Luo J T, Fan P, Liang G X 2019 Nano Energy 64 103929

Google Scholar

Google Scholar

[14] Liang G X, Luo Y D, Chen S, Tang R, Zheng Z H, Li X J, Liu X S, Liu Y K, Li Y F, Chen X Y, Su Z H, Zhang X H, Ma H L, Fan P 2020 Nano Energy 73 104806

Google Scholar

Google Scholar

[15] Tang R, Chen S, Zheng Z H, Su Z H, Luo J T, Fan P, Zhang X H, Tan J, Liang G X 2022 Adv. Mater. 34 2109078

Google Scholar

Google Scholar

[16] Li J J, Zhang Y, Zhao W, Nam D, Cheong H, Wu L, Zhou Z Q, Sun Y 2015 Adv. Energy Mater. 5 1402178

Google Scholar

Google Scholar

[17] Neugebohrn N, Hammer M S, Sayed M H, Michalowski P, Stroth C, Parisi J, Richter M 2017 J. Alloys Compd. 725 69

Google Scholar

Google Scholar

[18] Li Z Q, Chen X, Zhu H B, Chen J W, Guo Y T, Zhang C, Zhang W, Niu X N, Mai Y H 2017 Sol. Energy Mater. Sol. Cells 161 190

Google Scholar

Google Scholar

[19] Zhang J Y, Guo H F, Jia X G, Ning H, Ma C H, Wang X Q, Yuan N Y, Ding J N 2021 Sol. Energy 214 231

Google Scholar

Google Scholar

[20] Wu H R, Zhou X C, Li J D, Li X M, Li B W, Fei W W, Zhou J X, Yin J, Guo W L 2018 Small 14 1802276

Google Scholar

Google Scholar

[21] Lopez S C, Lopez I O P, Lara M C, Garcia A E, Sanchez M C M, Hernandez J A R, Lopez M C 2018 Phys. Status Solidi A. 215 1800226

Google Scholar

Google Scholar

[22] 曹宇, 刘超颖, 赵耀, 那艳玲, 江崇旭, 王长刚, 周静, 于皓 2022 71 038802

Google Scholar

Google Scholar

Cao Y, Liu C Y, Zhao Y, Na Y L, Jiang C X, Wang C G, Zhou J, Yu H 2022 Acta Phys. Sin. 71 038802

Google Scholar

Google Scholar

[23] Luo Y D, Tang R, Chen S, Hu J G, Liu Y K, Li Y F, Liu X S, ZhengZ H, Su Z H, Ma X F, Fan P, Zhang X H, Ma H L, Chen Z G, Liang G X 2020 Chem. Eng. J. 393 124599

[24] 曹宇, 祝新运, 陈翰博, 王长刚, 张鑫童, 侯秉东, 申明仁, 周静 2018 67 247301

Google Scholar

Google Scholar

Cao Y, Zhu X Y, Chen H B, Wang C G, Zhang X T, Hou B D, Shen MR, Zhou J 2018 Acta Phys. Sin. 67 247301

Google Scholar

Google Scholar

[25] Luo M, Leng M Y, Liu X S, Chen J, Chen C, Qin S K, Tang J 2014 Appl. Phys. Lett. 104 173904

Google Scholar

Google Scholar

计量

- 文章访问数: 9620

- PDF下载量: 149

- 被引次数: 0

下载:

下载: