-

结合扫描电子显微镜视频模块和原位纳米力学测试系统, 采用纳米压痕法研究了二维材料范德瓦耳斯异质结构的剥离撕裂行为. 利用湿法转移将化学气相沉积法制备的二维MoS2纳米片, 在SiO2/Si基底上组装成MoS2/SiO2异质结构, 然后采用原位力学杆探针对其实施压入实验. 钨探针压入MoS2纳米片形成W/MoS2/SiO2新的异质结构. 探针回撤过程, 黏附作用使二维MoS2纳米片从SiO2/Si基底剥离形成鼓包, 达到一定高度后沿针尖接触圆弧线发生不完全穿透断裂. 未断裂部分开始发生沿两个长条形裂纹面解理同时MoS2/SiO2界面分离, 随后MoS2纳米片发生大面积撕裂现象. 通过密度泛函理论计算范德瓦耳斯异质界面结合能密度, 结果表明MoS2/W的界面结合能密度比MoS2/SiO2更大, 解释了MoS2纳米片在异质界面范德瓦耳斯力引起的黏附剥离现象. 基于薄膜撕裂模型, 利用扫描电子显微镜实时记录的MoS2纳米片剥离高度和撕裂长度, 可确定MoS2断裂强度为27.055 GPa和应力-应变关系. 密度泛函理论计算结果表明, MoS2断裂强度为21.7—32.5 GPa, 应力-应变关系与薄膜撕裂模型实验测量结果基本一致. 该工作有望在探究二维材料断裂强度、二维材料及其范德瓦耳斯异质结构器件的组装、拆卸的操控与可靠性设计方面发挥重要的指导作用.Combining with in situ nanomechanical testing system and video module of scanning electron microscope, the nanoindentation testing is performed to study the peeling-tearing behavior of two-dimensional material van der Waals heterostructures. After two-dimensional MoS2 nanosheets prepared by chemical vapor deposition are assembled into MoS2/SiO2 heterostructures by wet transfer, the nanoindentation is carried out by manipulating the tungsten probe in the in situ nanomechanical testing system. When the tungsten probe is tightly indenting into MoS2 nanosheets, a new W/MoS2/SiO2 heterostructure is assembled. With the tungsten probe retracting, the adhesive effect makes the two-dimensional MoS2 nanosheet peel off from SiO2/Si substrate to form a bulge. After reaching a certain height, under the van der Waals adhesion interaction, an incomplete penetration fracture occurs along the arc line contacting the needle. Then cleavage appears and produces two strip cracks and MoS2/SiO2 interface separation takes place simultaneously, before a large area of MoS2 nanosheet is teared. Based on the density functional theory calculation of interface binding energy density of van der Waals heterogeneous interface, the interface binding energy density of MoS2/W is verified to be larger than that of MoS2/SiO2, which explains the adhesion peeling behavior of MoS2 induced by van der Waals force between heterogeneous interfaces, perfectly. By using the peeling height and tearing length of MoS2 recorded by video module, the fracture strength of MoS2 is obtained to be 27.055 GPa and stress-strain relation can be achieved according to the film tearing model. The density functional theory simulation results show that the fracture strength of MoS2 is in a range of 21.7–32.5 GPa, and the stress-strain relation is consistent with the experimental result measured based on film tearing model. The present work is expected to play an important role in measuring the fracture strengths of two-dimensional materials, the assembly, disassembly manipulation and reliability design of two-dimensional materials and van der Waals heterostructures devices.

-

Keywords:

- van der Waals heterostructures /

- tear /

- interface binding energy density /

- facture strength

[1] Liu Y, Weiss N O, Duan X, Cheng H-C, Huang Y, Duan X 2016 Nat. Rev. Mater 1 1

Google Scholar

Google Scholar

[2] 顾品超, 张楷亮, 冯玉林, 王芳, 苗银萍, 韩叶梅, 张韩霞 2016 65 018102

Google Scholar

Google Scholar

Gu P C, Zhang K L, Feng Y L, Wang F, Miao Y P, Han Y M, Zhang H X 2016 Acta Phys. Sin. 65 018102

Google Scholar

Google Scholar

[3] Li T, Galli G 2007 J. Phys. Chem. C 111 16192

Google Scholar

Google Scholar

[4] Castellanos‐Gomez A, Poot M, Steele G A, van Der Zant H S, Agraït N, Rubio-Bollinger G 2012 Adv. Mater 24 772

Google Scholar

Google Scholar

[5] Chhowalla M, Shin H S, Eda G, Li L J, Loh K P, Zhang H 2013 Nat. Chem 5 263

Google Scholar

Google Scholar

[6] Yim C, O'Brien M, McEvoy N, Winters S, Mirza I, Lunney J G, Duesberg G S 2014 Appl. Phys. Lett 104 103114

Google Scholar

Google Scholar

[7] Sahoo S, Gaur A P, Ahmadi M, Guinel M J-F, Katiyar R S 2013 J. Phys. Chem. C 117 9042

Google Scholar

Google Scholar

[8] Bertolazzi S, Krasnozhon D, Kis A 2013 ACS Nano 7 3246

Google Scholar

Google Scholar

[9] Radisavljevic B, Radenovic A, Brivio J, Giacometti V, Kis A 2011 Nat. Nanotechnol 6 147

Google Scholar

Google Scholar

[10] Chang K, Chen W 2011 ACS Nano 5 4720

Google Scholar

Google Scholar

[11] Lopez-Sanchez O, Lembke D, Kayci M, Radenovic A, Kis A 2013 Nat. Nanotechnol 8 497

Google Scholar

Google Scholar

[12] Bertolazzi S, Brivio J, Kis A 2011 ACS Nano 5 9703

Google Scholar

Google Scholar

[13] Wang Q H, Kalantar-Zadeh K, Kis A, Coleman J N, Strano M S 2012 Nat. Nanotechnol 7 699

Google Scholar

Google Scholar

[14] Han Y, Zhou J, Wang H, Gao L, Feng S, Cao K, Xu Z, Lu Y 2021 Appl. Nanosci 11 1075

Google Scholar

Google Scholar

[15] Liu K, Yan Q, Chen M, Fan W, Sun Y, Suh J, Fu D, Lee S, Zhou J, Tongay S 2014 Nano. Lett 14 5097

Google Scholar

Google Scholar

[16] Li B, Yin J, Liu X, Wu H, Li J, Li X, Guo W 2019 Nat. Nanotechnol 14 567

Google Scholar

Google Scholar

[17] Li B, Liu X, Guo W 2021 Nano. Res 14 692

Google Scholar

Google Scholar

[18] Tao Q, Wu R, Li Q, Kong L, Chen Y, Jiang J, Lu Z, Li B, Li W, Li Z 2021 Nat. Commun 12 1

Google Scholar

Google Scholar

[19] Zhang P, Ma L, Fan F, Zeng Z, Peng C, Loya P E, Liu Z, Gong Y, Zhang J, Zhang X 2014 Nat. Commun 5 1

[20] Yang Y, Li X, Wen M, Hacopian E, Chen W, Gong Y, Zhang J, Li B, Zhou W, Ajayan P M 2017 Adv. Mater 29 1604201

Google Scholar

Google Scholar

[21] Cao K, Feng S, Han Y, Gao L, Hue Ly T, Xu Z, Lu Y 2020 Nat. Commun 11 1

Google Scholar

Google Scholar

[22] Fang Z, Li X, Shi W, Li Z, Guo Y, Chen Q, Peng L, Wei X 2020 J. Phys. Chem. C 124 23419

Google Scholar

Google Scholar

[23] Reina A, Son H, Jiao L, Fan B, Dresselhaus M S, Liu Z, Kong J 2008 J. Phys. Chem. C 112 17741

Google Scholar

Google Scholar

[24] Yang X, Li X, Deng Y, Wang Y, Liu G, Wei C, Li H, Wu Z, Zheng Q, Chen Z 2019 Adv. Funct. Mater 29 1902427

Google Scholar

Google Scholar

[25] Nair R R, Blake P, Grigorenko A N, Novoselov K S, Booth T J, Stauber T, Peres N M, Geim A K 2008 Science 320 1308

Google Scholar

Google Scholar

[26] Kovalchick C, Molinari A, Ravichandran G 2014 J. Appl. Mech 81 4

Google Scholar

Google Scholar

[27] Rivlin R S 1997 Collected Papers of RS Rivlin (New York: Springer Science & Business Media) p2611

[28] Van Der Zande A M, Huang P Y, Chenet D A, Berkelbach T C, You Y, Lee G-H, Heinz T F, Reichman D R, Muller D A, Hone J C 2013 Nat. Mater 12 554

Google Scholar

Google Scholar

[29] Li H, Zhang Q, Yap C C R, Tay B K, Edwin T H T, Olivier A, Baillargeat D 2012 Adv. Funct. Mater 22 1385

Google Scholar

Google Scholar

[30] Li S-L, Miyazaki H, Song H, Kuramochi H, Nakaharai S, Tsukagoshi K 2012 ACS Nano 6 7381

Google Scholar

Google Scholar

[31] Xu D, Liechti K M, Ravi-Chandar K 2007 J. Colloid Interface Sci 315 772

Google Scholar

Google Scholar

[32] Perdew J P, Burke K, Ernzerhof M 1996 Phys. Rev. Lett 77 3865

Google Scholar

Google Scholar

[33] Grimme S, Antony J, Ehrlich S, Krieg H 2010 J. Chem. Phys 132 154104

Google Scholar

Google Scholar

[34] Liu J, Zhang J 2020 Chem. Rev 120 2123

Google Scholar

Google Scholar

[35] Li Y, Ching W 1985 Phys. Rev. B 31 2172

Google Scholar

Google Scholar

[36] Shemella P, Nayak S K 2009 Appl. Phys. Lett 94 032101

Google Scholar

Google Scholar

[37] Fan X, Zheng W, Chihaia V, Shen Z, Kuo J-L 2012 J. Phys.: Condens. Matter 24 305004

Google Scholar

Google Scholar

[38] Nguyen T C, Otani M, Okada S 2011 Phys. Rev. Lett 106 106801

Google Scholar

Google Scholar

[39] Gan Y, Zhao H 2014 Phys. Lett. A 378 2910

Google Scholar

Google Scholar

[40] Gan Y, Zhao H 2016 Phys. Lett. A 380 745

Google Scholar

Google Scholar

[41] Guo Y, Liu C, Yin Q, Wei C, Lin S, Hoffman T B, Zhao Y, Edgar J, Chen Q, Lau S P 2016 ACS Nano 10 8980

Google Scholar

Google Scholar

-

图 1 (a) MoS2光学显微镜图像; (b) MoS2 纳米片AFM二维形貌图及横截面轮廓线; (c) MoS2纳米片拉曼光谱; (d) MoS2转移到叉指电极上的SEM图像

Fig. 1. (a) Optical diagram of MoS2; (b) AFM morphology image and cross-section profile of MoS2 nanosheet; (c) Raman spectra of MoS2 nanosheet; (d) SEM image of MoS2 transferred onto the interdigitated electrodes.

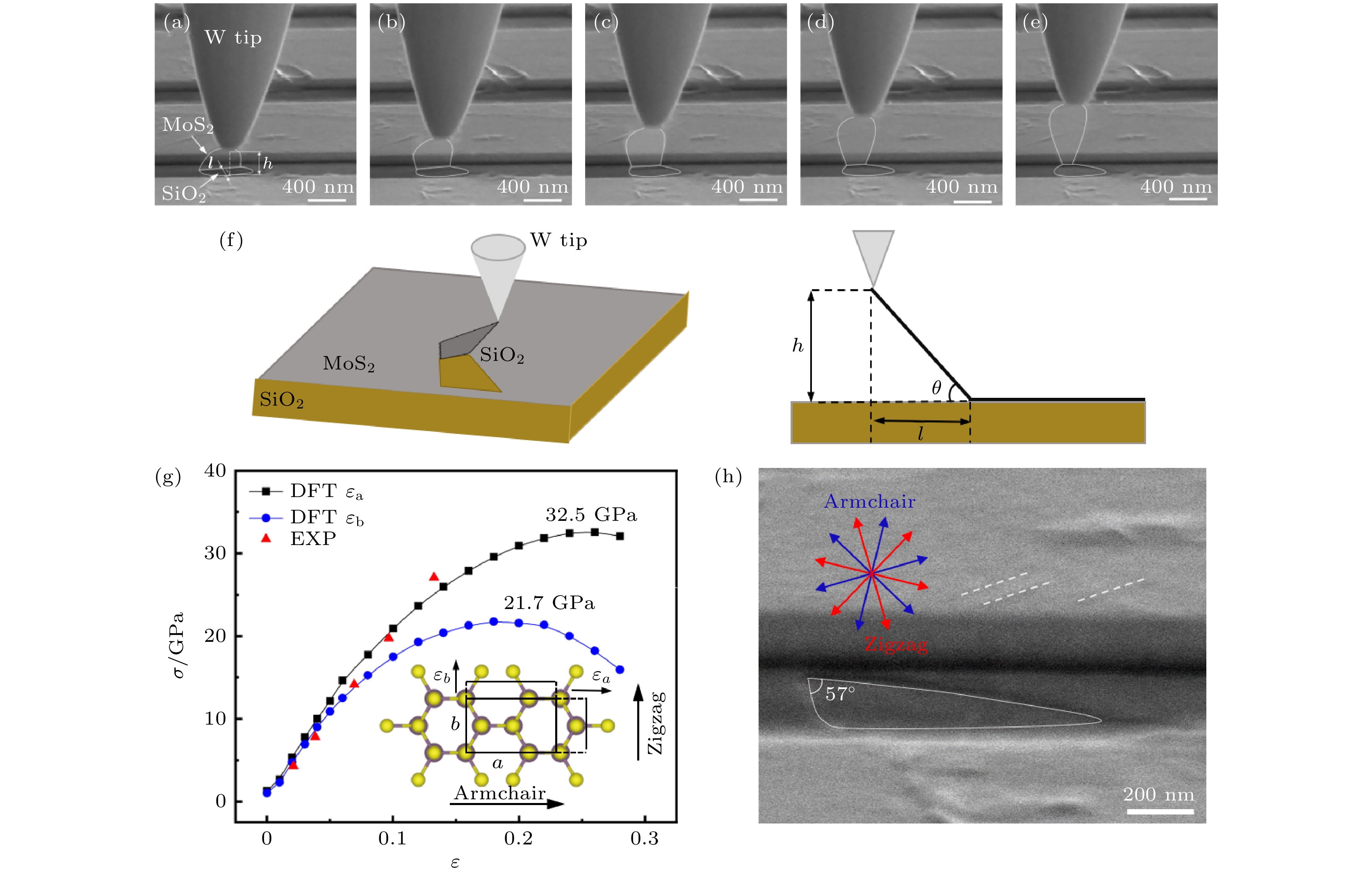

图 3 MoS2/SiO2 vdWHs纳米压痕过程典型的SEM图 (a) W探针压入形成W/MoS2/SiO2 vdWHs; (b) MoS2纳米片被W探针黏附从SiO2/Si基底剥离形成鼓包; (c) MoS2纳米片发生不完全穿透断裂; (d) MoS2纳米片解理撕裂后, 最终与SiO2/Si完全分离

Fig. 3. Typical SEM images of MoS2/SiO2 vdWHs nanoindentation processes: (a) W probe indentation to assemble W/MoS2/SiO2 vdWHs; (b) MoS2 peeled by W probe from SiO2/Si substrate to form bulge; (c) MoS2 incomplete penetration fracture; (d) MoS2 nanosheet teared along cleavage cracks and completely separated from SiO2/Si substrate.

图 4 (a), (b) MoS2/SiO2和MoS2/W异质结构的原子结构示意图; (c) MoS2/SiO2和MoS2/W vdWHs界面结合能密度Eb与层间位移关系曲线, 插图是范德瓦耳斯相互作用导致MoS2/SiO2界面分离示意图

Fig. 4. (a), (b) The original atomic structure schematics of MoS2/SiO2 and MoS2/W vdWHs; (c) the binding energy density Eb-interlayer displacement curves of MoS2/SiO2 and MoS2/W vdWHs, the inset is schematic for MoS2/SiO2 interface separation induced by vdW interaction.

图 5 (a)—(e) 剥离撕裂至断裂的SEM图像; (f) 薄膜撕裂模型示意图; (g) MoS2理论分析和DFT模拟的应力应变曲线, 插图表明DFT计算中MoS2原子结构沿a和b晶轴方向施加应变; (h) MoS2纳米片沿解理裂纹撕裂后的SEM图像, 插图是识别解理边缘判断MoS2纳米片的晶格方向

Fig. 5. (a)–(e) SEM images of the peeling, tear and fracture processes; (f) the film tear model diagram; (g) the experimental and DFT simulation stress-strains curve of MoS2, the inset represents basic unit of the atomic structure applied strains with a and b crystal axis directions. (h) SEM image of MoS2 nanosheet after teared along cleavage cracks, the inset is the lattice direction of MoS2 nanosheet is determined by identifying the cleavage edge.

-

[1] Liu Y, Weiss N O, Duan X, Cheng H-C, Huang Y, Duan X 2016 Nat. Rev. Mater 1 1

Google Scholar

Google Scholar

[2] 顾品超, 张楷亮, 冯玉林, 王芳, 苗银萍, 韩叶梅, 张韩霞 2016 65 018102

Google Scholar

Google Scholar

Gu P C, Zhang K L, Feng Y L, Wang F, Miao Y P, Han Y M, Zhang H X 2016 Acta Phys. Sin. 65 018102

Google Scholar

Google Scholar

[3] Li T, Galli G 2007 J. Phys. Chem. C 111 16192

Google Scholar

Google Scholar

[4] Castellanos‐Gomez A, Poot M, Steele G A, van Der Zant H S, Agraït N, Rubio-Bollinger G 2012 Adv. Mater 24 772

Google Scholar

Google Scholar

[5] Chhowalla M, Shin H S, Eda G, Li L J, Loh K P, Zhang H 2013 Nat. Chem 5 263

Google Scholar

Google Scholar

[6] Yim C, O'Brien M, McEvoy N, Winters S, Mirza I, Lunney J G, Duesberg G S 2014 Appl. Phys. Lett 104 103114

Google Scholar

Google Scholar

[7] Sahoo S, Gaur A P, Ahmadi M, Guinel M J-F, Katiyar R S 2013 J. Phys. Chem. C 117 9042

Google Scholar

Google Scholar

[8] Bertolazzi S, Krasnozhon D, Kis A 2013 ACS Nano 7 3246

Google Scholar

Google Scholar

[9] Radisavljevic B, Radenovic A, Brivio J, Giacometti V, Kis A 2011 Nat. Nanotechnol 6 147

Google Scholar

Google Scholar

[10] Chang K, Chen W 2011 ACS Nano 5 4720

Google Scholar

Google Scholar

[11] Lopez-Sanchez O, Lembke D, Kayci M, Radenovic A, Kis A 2013 Nat. Nanotechnol 8 497

Google Scholar

Google Scholar

[12] Bertolazzi S, Brivio J, Kis A 2011 ACS Nano 5 9703

Google Scholar

Google Scholar

[13] Wang Q H, Kalantar-Zadeh K, Kis A, Coleman J N, Strano M S 2012 Nat. Nanotechnol 7 699

Google Scholar

Google Scholar

[14] Han Y, Zhou J, Wang H, Gao L, Feng S, Cao K, Xu Z, Lu Y 2021 Appl. Nanosci 11 1075

Google Scholar

Google Scholar

[15] Liu K, Yan Q, Chen M, Fan W, Sun Y, Suh J, Fu D, Lee S, Zhou J, Tongay S 2014 Nano. Lett 14 5097

Google Scholar

Google Scholar

[16] Li B, Yin J, Liu X, Wu H, Li J, Li X, Guo W 2019 Nat. Nanotechnol 14 567

Google Scholar

Google Scholar

[17] Li B, Liu X, Guo W 2021 Nano. Res 14 692

Google Scholar

Google Scholar

[18] Tao Q, Wu R, Li Q, Kong L, Chen Y, Jiang J, Lu Z, Li B, Li W, Li Z 2021 Nat. Commun 12 1

Google Scholar

Google Scholar

[19] Zhang P, Ma L, Fan F, Zeng Z, Peng C, Loya P E, Liu Z, Gong Y, Zhang J, Zhang X 2014 Nat. Commun 5 1

[20] Yang Y, Li X, Wen M, Hacopian E, Chen W, Gong Y, Zhang J, Li B, Zhou W, Ajayan P M 2017 Adv. Mater 29 1604201

Google Scholar

Google Scholar

[21] Cao K, Feng S, Han Y, Gao L, Hue Ly T, Xu Z, Lu Y 2020 Nat. Commun 11 1

Google Scholar

Google Scholar

[22] Fang Z, Li X, Shi W, Li Z, Guo Y, Chen Q, Peng L, Wei X 2020 J. Phys. Chem. C 124 23419

Google Scholar

Google Scholar

[23] Reina A, Son H, Jiao L, Fan B, Dresselhaus M S, Liu Z, Kong J 2008 J. Phys. Chem. C 112 17741

Google Scholar

Google Scholar

[24] Yang X, Li X, Deng Y, Wang Y, Liu G, Wei C, Li H, Wu Z, Zheng Q, Chen Z 2019 Adv. Funct. Mater 29 1902427

Google Scholar

Google Scholar

[25] Nair R R, Blake P, Grigorenko A N, Novoselov K S, Booth T J, Stauber T, Peres N M, Geim A K 2008 Science 320 1308

Google Scholar

Google Scholar

[26] Kovalchick C, Molinari A, Ravichandran G 2014 J. Appl. Mech 81 4

Google Scholar

Google Scholar

[27] Rivlin R S 1997 Collected Papers of RS Rivlin (New York: Springer Science & Business Media) p2611

[28] Van Der Zande A M, Huang P Y, Chenet D A, Berkelbach T C, You Y, Lee G-H, Heinz T F, Reichman D R, Muller D A, Hone J C 2013 Nat. Mater 12 554

Google Scholar

Google Scholar

[29] Li H, Zhang Q, Yap C C R, Tay B K, Edwin T H T, Olivier A, Baillargeat D 2012 Adv. Funct. Mater 22 1385

Google Scholar

Google Scholar

[30] Li S-L, Miyazaki H, Song H, Kuramochi H, Nakaharai S, Tsukagoshi K 2012 ACS Nano 6 7381

Google Scholar

Google Scholar

[31] Xu D, Liechti K M, Ravi-Chandar K 2007 J. Colloid Interface Sci 315 772

Google Scholar

Google Scholar

[32] Perdew J P, Burke K, Ernzerhof M 1996 Phys. Rev. Lett 77 3865

Google Scholar

Google Scholar

[33] Grimme S, Antony J, Ehrlich S, Krieg H 2010 J. Chem. Phys 132 154104

Google Scholar

Google Scholar

[34] Liu J, Zhang J 2020 Chem. Rev 120 2123

Google Scholar

Google Scholar

[35] Li Y, Ching W 1985 Phys. Rev. B 31 2172

Google Scholar

Google Scholar

[36] Shemella P, Nayak S K 2009 Appl. Phys. Lett 94 032101

Google Scholar

Google Scholar

[37] Fan X, Zheng W, Chihaia V, Shen Z, Kuo J-L 2012 J. Phys.: Condens. Matter 24 305004

Google Scholar

Google Scholar

[38] Nguyen T C, Otani M, Okada S 2011 Phys. Rev. Lett 106 106801

Google Scholar

Google Scholar

[39] Gan Y, Zhao H 2014 Phys. Lett. A 378 2910

Google Scholar

Google Scholar

[40] Gan Y, Zhao H 2016 Phys. Lett. A 380 745

Google Scholar

Google Scholar

[41] Guo Y, Liu C, Yin Q, Wei C, Lin S, Hoffman T B, Zhao Y, Edgar J, Chen Q, Lau S P 2016 ACS Nano 10 8980

Google Scholar

Google Scholar

计量

- 文章访问数: 7330

- PDF下载量: 85

- 被引次数: 0

下载:

下载: